battery JAGUAR XJ6 1994 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 192 of 521

Driveshafts & Final Drive

. Remove upper link assembly from differential and wide mounting bracket / 'A' frame.

. Release fixings, 'A' frame to differential, 'A' frame to wishbone tie and wide mounting bracket to 'A' frame.

. Remove wishbone tie assembly, rear mounting bracket and pendulum assembly.

. Release fixings differential nose to wide mounting bracket.

. Assembly and fitting is the reversal of this procedure, taking note of the following:

Drive shaft must be aligned in accordance with Sub

-Section 9.2.

Renew all self locking nuts.

Renew all bolts that were originally fitted with thread locking adhesive.

Replace all locking wire and split pins (cotter pins).

Tighten all fixings to the specified torque.

Correct the final drive oil level

if required.

Check and adjust rear wheel camber setting as required.

9.9 AXLE SHAFT ASSEMBLY, RENEW

SRO

47.10.01

Disconnect vehicle battery ground lead.

. Slacken appropriate axle shaft hub nut.

. Support the vehicle at the rear and remove rear road

. Remove brake caliper in accordance with 70.55.03. Sec-

wheel.

tion 12, but do not disconnect hydraulics.

Slacken hub carrier fulcrum and remove ABS sensor from

hub carrier.

. Remove axle shaft hub nut and collar.

. Remove fixings axle shaft to differential output shaft

flange, note camber shim.

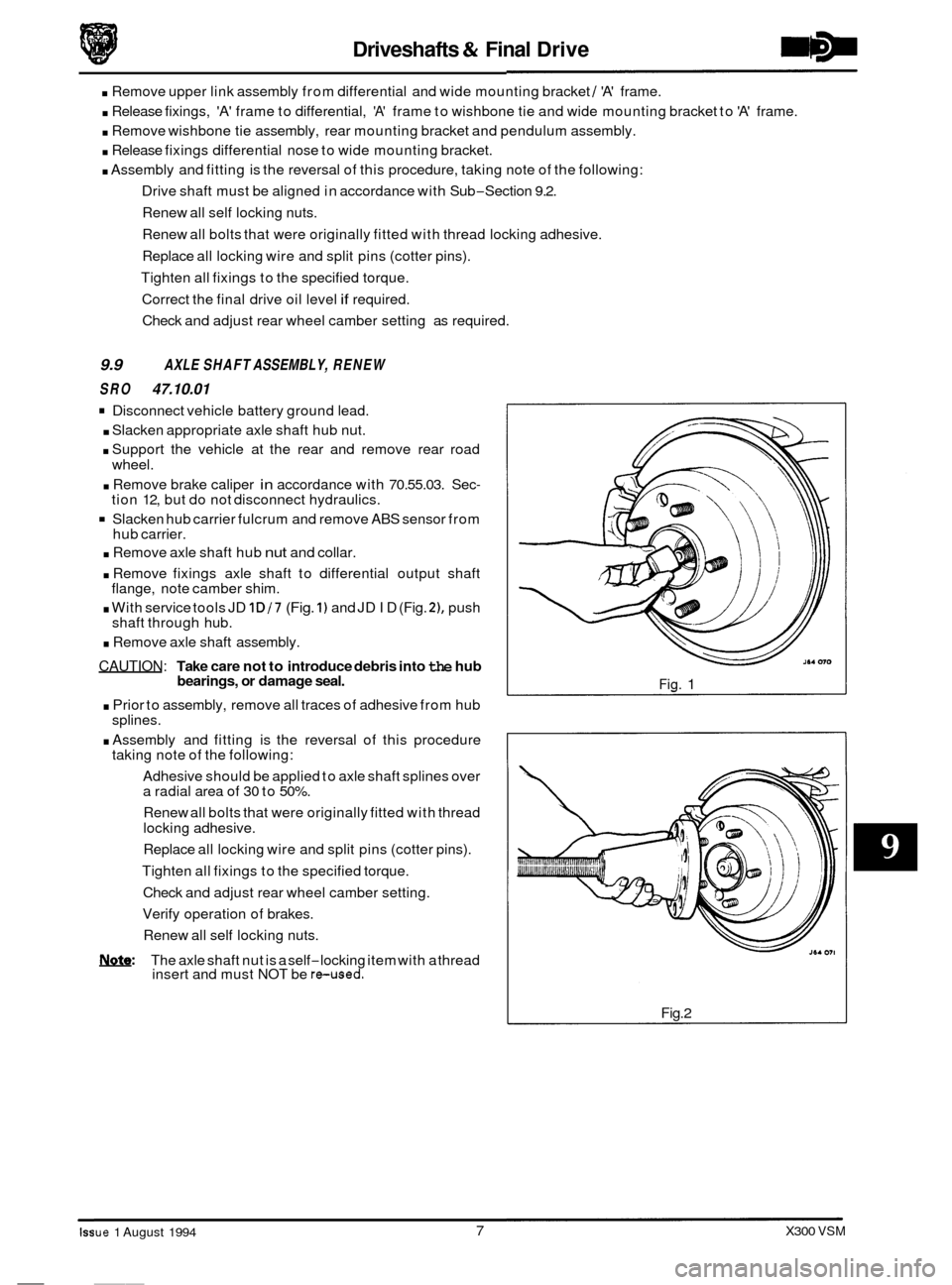

. With service tools JD 1D/7 (Fig. 1) and JD ID (Fig. 21, push

shaft through hub.

. Remove axle shaft assembly.

CAUTION: Take care not to introduce debris into the hub

bearings, or damage seal.

. Prior to assembly, remove all traces of adhesive from hub

. Assembly and fitting is the reversal of this procedure

Adhesive should be applied to axle shaft splines over

a radial area of

30 to 50%.

Renew all bolts that were originally fitted with thread

locking adhesive.

Replace all locking wire and split pins (cotter pins).

Tighten all fixings to the specified torque.

Check and adjust rear wheel camber setting.

Verify operation of brakes.

Renew all self locking nuts.

splines.

taking

note of the following:

0

NQ&: The axle shaft nut is a self-locking item with a thread

insert and must NOT be reused.

Fig. 1

Fig.2

- Iss ue 1 August 1994

__~

7 X300 VSM

Page 193 of 521

Driveshafts & Final Drive

9.10 REAR HUB BEARING, RENEW

SRO 64.15.14

9.11

SRO 64.15.15

REAR HUB OIL SEAL, RENEW

Removal

= Disconnect vehicle battery ground lead.

= Slacken appropriate axle shaft hub nut.

. Support the vehicle at the rear and remove rear road

m: To aid assembly, markthe position of the head of the

hub carrier fulcrum, relative to the wishbone slot.

. Disconnect handbrake cable inner and outer.

. Remove brake caliper in accordance with Section 12, but do not disconnect hydraulics.

. Slacken hub carrier fulcrum and remove ABS sensor from

hub carrier.

. Remove axle shaft hub nut (and discard), collar and hub

carrier fulcrum.

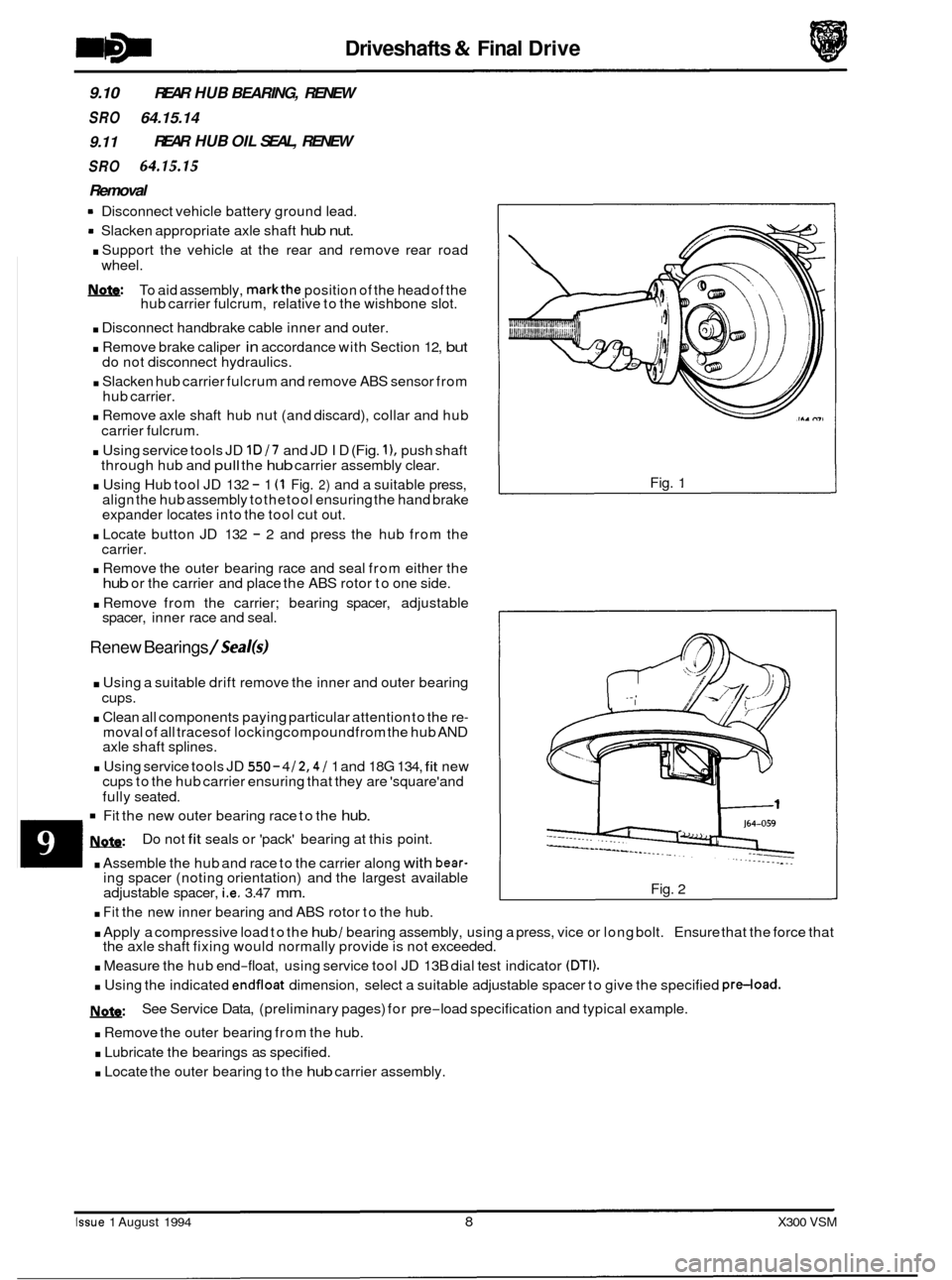

. Using service tools JD 1D/7 and JD ID (Fig. I), push shaft

through hub and pull the hub carrier assembly clear.

. Using Hub tool JD 132 - 1 (1 Fig. 2) and a suitable press,

align the hub assembly tothetool ensuring the hand brake

expander locates into the tool cut out.

. Locate button JD 132 - 2 and press the hub from the

carrier.

. Remove the outer bearing race and seal from either the hub or the carrier and place the ABS rotor to one side.

. Remove from the carrier; bearing spacer, adjustable

spacer, inner race and seal.

Renew Bearings /Sea/($

wheel.

. Using a suitable drift remove the inner and outer bearing

cups.

. Clean all components paying particular attention to the re- moval of all tracesof lockingcompoundfrom the hub AND

axle shaft splines.

. Using service tools JD 550 - 4 /2,4 / 1 and 18G 134, fit new

cups to the hub carrier ensuring that they are 'square'and

fully seated.

Fit the new outer bearing race to the hub.

&&Q:

. Assemble the hub and race to the carrier along with bear-

Do not fit seals or 'pack' bearing at this point.

ing spacer (noting orientation) and the largest available

adjustable spacer,

i.e. 3.47 mm.

. Fit the new inner bearing and ABS rotor to the hub. Fig.

1

Fig.

2

. Apply a compressive load to the hub / bearing assembly, using a press, vice or long bolt. Ensure that the force that

. Measure the hub end-float, using service tool JD 13B dial test indicator (DTI).

. Using the indicated endfloat dimension, select a suitable adjustable spacer to give the specified pre-load.

m:

. Remove the outer bearing from the hub.

. Lubricate the bearings as specified.

. Locate the outer bearing to the hub carrier assembly.

the axle shaft

fixing would normally provide is not exceeded.

See Service Data, (preliminary pages) for pre

-load specification and typical example.

Issue 1 August 1994 8 X300 VSM

Page 208 of 521

10.5 OUTER

TRACK ROD BALL JOINT, RENEW

sRo . Disconnect 57.55.02 vehicle battery ground lead.

. Raise the front of the vehicle and remove the appropriate

road wheel

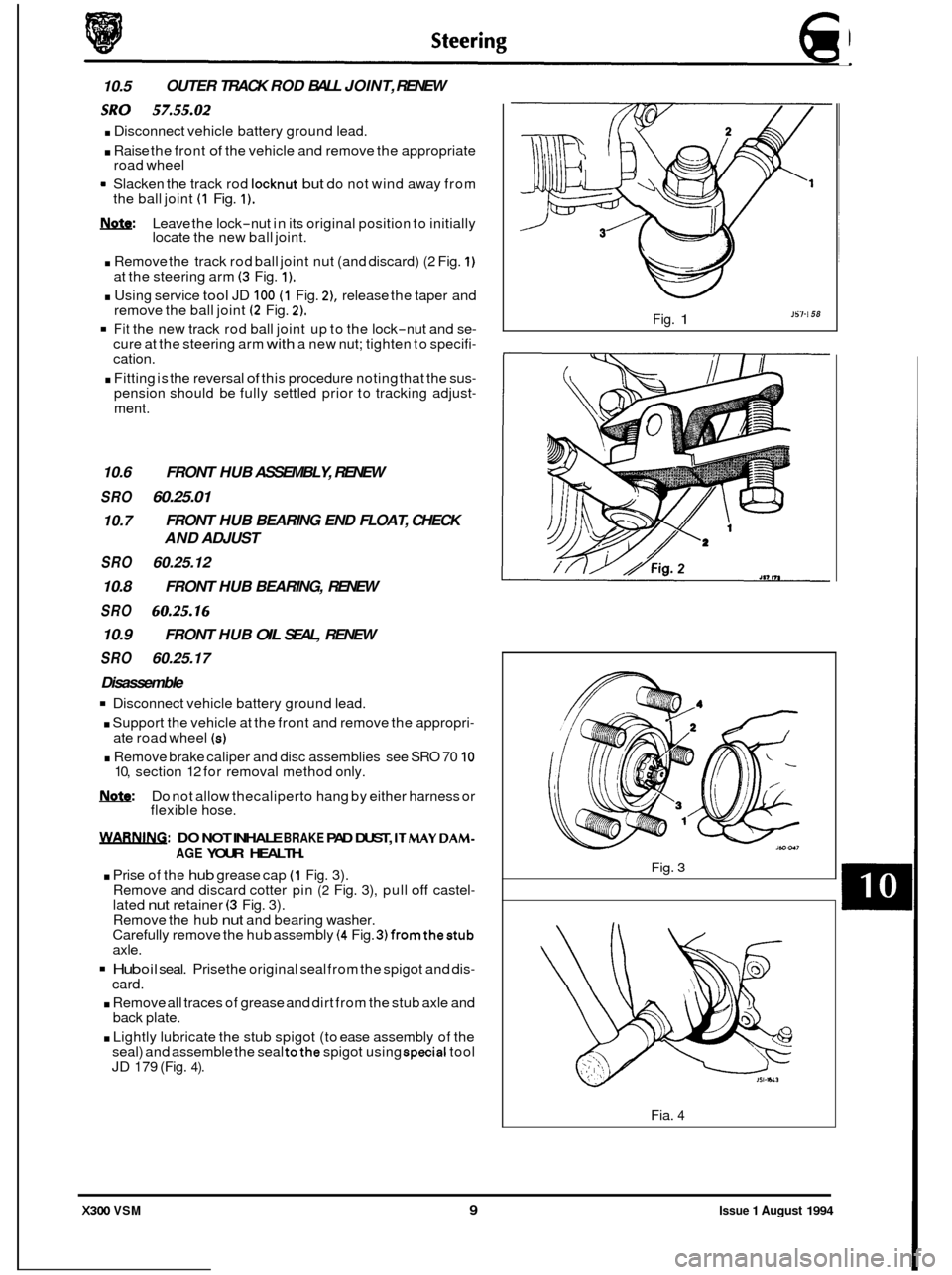

Slacken the track rod

locknut but do not wind away from

the ball joint (1 Fig. 1).

m: Leave the lock-nut in its original position to initially

locate the new ball joint.

. Remove the track rod ball joint nut (and discard) (2 Fig. 1)

at the steering arm (3 Fig. 1).

. Using service tool JD 100 (1 Fig. 2), release the taper and

remove the ball joint (2 Fig. 2).

Fit the new track rod ball joint up to the lock-nut and se- cure at the steering arm with a new nut; tighten to specifi- cation.

. Fitting is the reversal of this procedure noting that the sus- pension should be fully settled prior to tracking adjust-

ment.

0 10.6 FRONT HUB ASSEMBLY, RENEW

SRO 60.25.01

10.7

SRO 60.25.12

10.8 FRONT HUB BEARING, RENEW

SRO 60.25.16

10.9

SRO 60.25.17

Disassemble

Disconnect vehicle battery ground lead.

. Support the vehicle at the front and remove the appropri-

. Remove brake caliper and disc assemblies see SRO 70 10

IWQ: Do not allow thecaliperto hang by either harness or

flexible hose.

FRONT HUB BEARING END FLOAT, CHECK

AND ADJUST

FRONT HUB

OIL SEAL, RENEW

ate road wheel (s)

10, section 12 for removal method only.

WARNIM: DO NOT INHALE BRAKE PAD DUST, ITMAY DAM-

0

AGE YOUR HEALTH.

. Prise of the hub grease cap (1 Fig. 3).

Remove and discard cotter pin (2 Fig. 3), pull off castel- lated nut retainer (3 Fig. 3).

Remove the hub nut and bearing washer.

Carefully remove the hub assembly (4 Fig. 3)fromthestub axle.

Hub oil seal. Prise the original seal from the spigot and dis-

card.

. Remove all traces of grease and dirt from the stub axle and

back plate.

. Lightly lubricate the stub spigot (to ease assembly of the

seal) and assemble the seal tothe spigot using special tool JD 179 (Fig. 4).

JS7-i 58 Fig. 1

Fig. 3

Fia.

4

X300 VSM 9 Issue 1 August 1994

Page 254 of 521

Body Components & Trim -

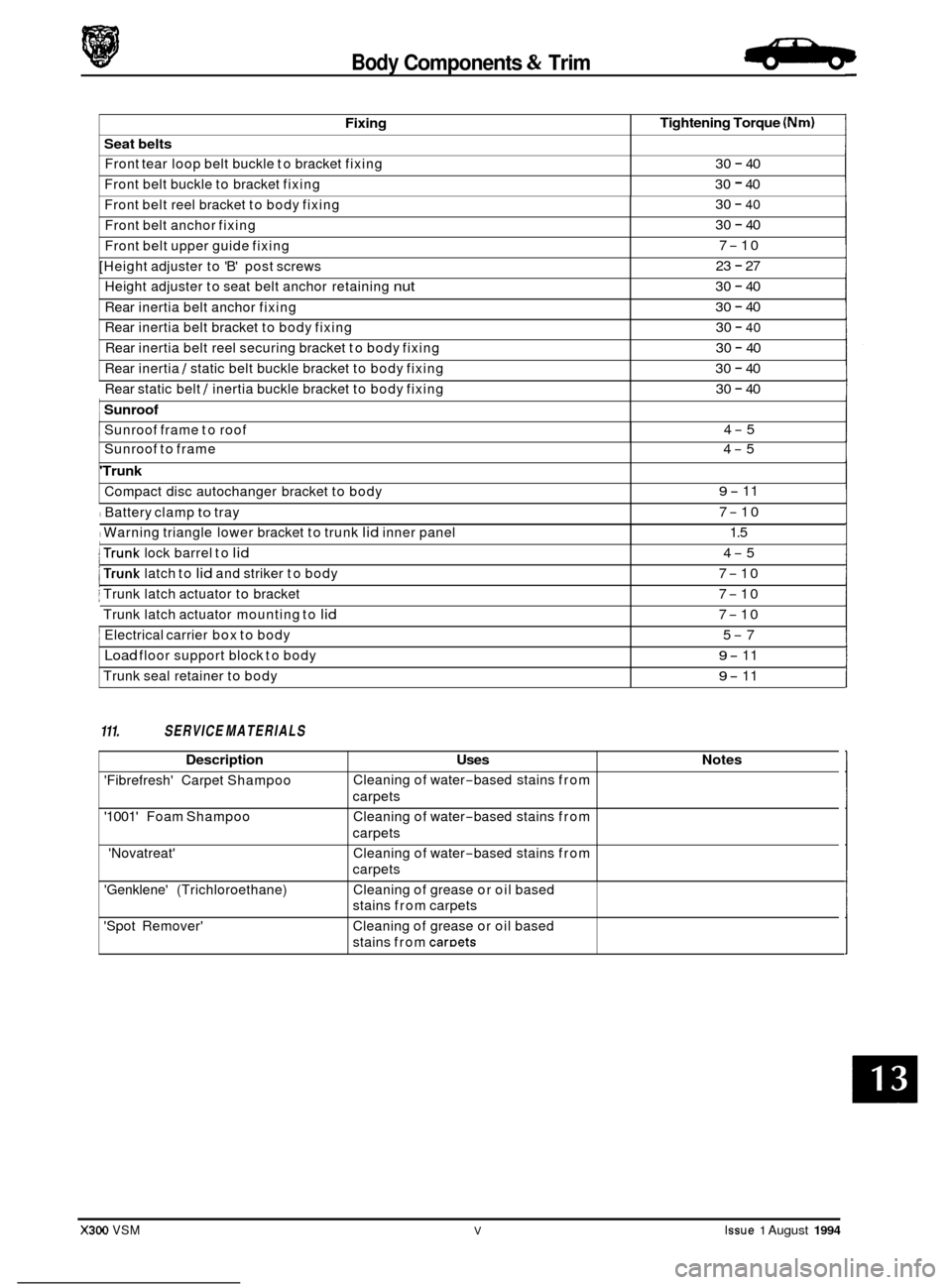

Fixing

Seat belts

Front tear loop belt buckle to bracket fixing

Front belt buckle to bracket fixing

Tightening Torque (Nm)

30 - 40

30

- 40

Front belt reel bracket to body fixing

Front belt anchor fixing 30 - 40

30 - 40

7

-10

23

- 27

30

- 40

30 - 40

30

- 40

30 - 40

30

- 40

Front belt upper guide fixing

[Height adjuster to 'B' post screws

Height adjuster to seat belt anchor retaining

nut

Rear inertia belt anchor fixing

Rear inertia belt bracket to body fixing

Rear inertia belt reel securing bracket to body fixing

Rear inertia

/ static belt buckle bracket to body fixing ~

Rear

static belt / inertia buckle bracket to body fixing

: Sunroof ~

Sunroof frame

to roof

30 - 40

4

-5

111. SERVICE MATERIALS

Sunroof to frame 4-5

'Trunk

Compact disc autochanger bracket to body

I Battery clamp to tray

I Warning triangle lower bracket to trunk lid inner panel

9- 11

7

-10

1.5

X300 VSM V Issue 1 August 1994

I trunk lock barrel to lid

j Trunk latch actuator to bracket

Trunk latch actuator mounting to

lid

j Electrical carrier box to body

Load floor support block to body

Trunk seal retainer to body

trunk latch to lid and striker to body

4-5

7

-10

7

-10

7

-10

5

-7

9- 11

9- 11

Description Uses

'Fibrefresh' Carpet Shampoo

'1001' Foam Shampoo

'Novatreat' Cleaning

of water

-based stains from

carpets

Cleaning of water

-based stains from

carpets

Cleaning of water

-based stains from

carpets

Notes

'Genklene' (Trichloroethane)

'Spot Remover' Cleaning

of grease or oil based

stains from carpets

Cleaning of grease or oil based

stains from

caroets

Page 256 of 521

Body Components & Trim

13.1 GENERAL DESCRIPTION

This section covers the following areas of the vehicle body:

0 Battery cover

0 Carpets - passenger compartment, trunk

0 Console - including radio, glovebox

0 Doors -frames, sealing, locks, trim, glazing

0 Fascia

0 Fuel filler flap assembly

0 Footrest

0 Hood - liners, gas strut, locking,

0 Illuminated sunvisor - inc mirror

0 Interior trim - trim pads, finishers, veneers

0 Mirrors - internal, external

0 Rear parcel tray

0 Roof console

0 Roof lining (headlining)

o Seats -front, rear -

0 Seat belts - front, rear

0 Sliding roof

0 Steering column cowl

0 Underscuttle pad

Refer to Appendix

A4 - Body Systems & Body Repair for information relating to crash-damage repairs and to the fol- lowing external components: exterior trim, bumpers, windscreen and rear screen, closures and sealing.

Refer to Section 15, Electrical for details of the following motors and solenoids: driver's and interior mirrors, window

lift, sunroof, seat / headrest and locking mechanisms (doors, trunk and filler cap).

Refer to Section 15, Electrical and Electrical Diagnostic Manual (EDM) for details of the passenger and driver airbags.

X300 VSM 1 Issue 1 August 1994

Page 261 of 521

Body Components & Trim -

13.2.10 Front Door Upper Trim Pad, Renew

. Disconnect vehicle battery ground lead.

. Remove the front door veneer panel.

. Remove the upper trim pad securing clip and screws.

. Lift the trim pad to release it from the door and remove the

To refit, carry out reversal of the above procedure.

inner

waist rail seal.

13.2.1 1 Front Door lower Trim Pad, Renew

. Disconnect vehicle battery ground lead.

Remove armrest.

. From inside door pocket, release guard retainer, discon-

. Carefully prise the trim pad away from the door and re-

With the trim pad moved for access, disconnect loud-

. Feed guard lamp harness through aperture and place trim

. Remove front door pocket and trim pad retainers.

. To refit, carry out reversal of the above procedure. Check

the trim pad retainers for damage before refitting.

nect

multi

-plug and remove lamp.

lease from the upper retainer.

speaker and window

lift switch multi-plugs.

pad on a clean workbench.

13.2.12 Door lock Barrel, Renew

. Disconnect vehicle battery ground lead.

. Remove the door trim veneer, door upper trim pad, door

. Remove the handle assembly to a clean workbench.

. Remove the lock barrel from its bayonet type mounting.

. Carefully remove the barrel components noting the order

. To refit, carry out reversal of the above procedure, ensur-

lower trim pad and door handle.

and position if reassembly is required.

ing that the components are lightly greased.

13.2.13 Front or Rear Door Lock Striker, Renew

. Note position of striker before removal.

. Remove two screws attaching striker to pillar.

Remove striker from pillar.

. To refit, carry out reversal of the above procedure, ensur- ing that the striker is correctly aligned with the door lock

before final torque tightening.

13.2.14 Front or Rear Door Outer Handle Operating

Rod, Renew

. Disconnect vehicle battery ground lead.

. Remove the door trim veneer, door upper trim pad, door

lower trim pad.

. Disengage the handle operating rod retaining clip and free

the rod from the operating pivot.

. Allowthe latch levertocontact the release mechanism, re- position the operating rod and replace the retaining clip.

. Check that the setting is correct by operating the door

mechanism.

To refit, carry out reversal of the above procedure.

/ 2 176 -1053

1. Water shedder 2. Multi connector 3. Armrest support

Fig. 1 Door Interior Components

Issue 1 August 1994 6 X300 VSM

Page 262 of 521

Body Components & Trim -

0 13.2.15 Front Armrest, Renew

. Disconnect vehicle battery ground lead.

. Remove access covers to armrest fixings.

. Remove screws securing armrest to support bracket.

. Remove armrest and remove fixing screw inserts from

. To refit, carry out reversal of the above procedure.

armrest.

13.2.16

Front or Rear Armrest Support, Renew

. Disconnect vehicle battery ground lead.

Remove door armrest.

. Remove lower trim pad from door.

. Drill out rivets and remove retaining screwsfromfront and

rear armrest support brackets.

. Remove drilling debris and swarf.

. Make good any damage to body finish caused by drilling;

use zinc primer and body colour.

. To refit, carry out reversal of the above procedure.

13.2.17 Front Door Pocket, Renew e

. Disconnect vehicle battery ground lead.

. Remove armrest.

Remove lower trim pad and place on a clean workbench.

. Remove fixings and remove door pocket.

. Remove veneer panel, switch assembly, loudspeaker and

To refit, carry out reversal of the above procedure.

loudspeaker

grille.

J76-'552

1. Primary seal 5. Uppertrim

2. Secondary seal 6. Lower trim 3. Armrest

4. Door pocket

7. Coin box

Fig.

1 Door With Full Trim

0

Issue 1 August 1994 x300 VSM 7

Page 263 of 521

13.2.18 Fuel Filler Flap, Description

The fuel filler flap comprises a hinged flap attached to the body decking panel by two M5 nuts; the flap incorporates

a rubber buffer, snap

-in striker, hinge spring and the fuel cap stowage magnet. The rubber fuel bowl moulding is at- tached via a steel armature to the body reinforcement panel by five M5 nuts and is retained at the filler neck by a clip.

The mating drain tube is fitted with an internal filter.

The fuel filler flap latch mechanism attached

tothe fuel bowl armature bytwo M5 nuts, includes a locking pin and actua- tor which are both serviceable items. The latch actuator operates independently from the central locking system; it is

driven directly

by the security and locking control module. Locking of the fuel filler flap is achieved only by operation

of the key or by the remote rf transmitter.

13.2.19 Filler Flap and Hinge, Renew

. Disconnect vehicle battery ground lead.

With filler cap open, remove hinge securing screws, fuel

. To refit, carry out reversal of the above procedure.

filler cap

and remove flap and hinge assembly.

13.2.20 Filler Cap Retention Magnet, Renew

. With filler flap open, use a blunt flat bladed implement and

CAUTION: Take care not to damage paintwork.

. To refit, carry out reversal of the above procedure.

Disconnect

vehicle battery ground lead.

remove the magnet assembly.

13.2.21 Filler Flap latching Assembly, Renew

. Disconnect vehicle battery ground lead.

. Depress the latching assembly retaining nut and remove

CAUTION: Take care not to damage paintwork.

. To refit, carry out reversal of the above procedure.

the

assembly.

1. Hingedflap 2. Striker 3. Hinge spring 4. Stowage magnet 5. Fuelbowl

Fig. 1 Fuel Filler Flap

X300 VSM Issue 1 August 1994 8

e

0

0

Page 264 of 521

Body Components & Trim

13.3 PASSENGER COMPARTMENT

13.3.1

SRO 76.25.01/90

9 Remove the battery cover. Disconnect the battery.

* Remove the drivers side underscuttle pad, see sub-sec- tion 13.3.19.

. Remove the passenger side underscuttle pad, see sub- section 13.3.20.

Remove the console ashtray, see sub-section 13.3.28.

. Remove the console finisher veneer panel, see sub-sec- tion 13.3.24.

. Remove the radio console, see sub-section 13.3.10.

. Remove the fascia center veneer panel, see sub-section

9 Undo and remove the console upper securing screws.

. Displace and reposition the rear air distribution outlet box.

. Disconnect the cigar lighter multi-plug (where fitted).

. Disconnect the security system valet switch harness

mult i-plug ,

9 Remove the rear air distribution outlet box.

. Undo and removethecenter console rear mounting secur- ing screw.

Displace and remove the console assembly and place on

the bench.

. Place the console in position in the vehicle.

. Fit and tighten the console front securing screws.

. Fit and tighten the console rear securing screw.

. Reconnect the security system valet switch multi-plug.

. Place the air distribution outlet in position.

. Connect the rear cigar lighter harness multi-plug (where

. Fit and fully seat the air distribution outlet.

. Refit the fascia center veneer panel.

Refit the radio console.

. Refit the console finisher veneer panel.

Console Assembly - Remove For Access And

Refit

13.3.23.

fitted).

Refit the console ashtray.

Refit the underscuttle pads.

. Reconnect the battery. Refit the battery cover.

X300 VSM 9 Issue 1 August 1994

Page 265 of 521

Body Components & Trim -

13.3.2

SRO 76.25.01/50

. Remove the console rear extension finisher, see sub-sec-

. Remove the console rear extension veneer panel, see sub-

. Remove the console rear extension, see sub-section

. Remove the drivers side underscuttle pad, see sub-sec-

. Remove the passenger side underscuttle pad, see sub-

. Remove the console ashtray, see sub-section 13.3.28.

. Remove the console finisher veneer panel, see sub-sec-

. Remove the radio console, see sub-section 13.3.10.

Remove the fascia center veneer panel, see sub-section

Undo and remove the console upper securing screws.

. Displace and reposition the rear air distribution outlet box.

. Disconnect the cigar lighter multi-plug (where fitted).

. Disconnect the security system valet switch harness

multi

-plug.

. Remove the air distribution outlet box.

9 Undo and remove the center console rear mounting secur- ing screw.

. Displace and remove the console assembly and place on

the bench.

. Displace and remove the spire clips from the console as- sembly.

. Open the glove box lid.

. Remove the glove box lid latch.

. Undo and remove the glove box lid rear securing screws.

. Displace and remove the glove box lid /glove box assem- bly.

. Place the console aside.

. Place the new console to the front.

. Fit and align the glove box lid /glove box assembly.

. Fit but do not fully tighten the glove box lid securing screw.

. Close the glove box lid and check the adjustment.

. Open and adjust the lid.

. Finally tighten the securing screws.

. Fit and align the glove box lid latch.

. Close the glove box lid.

. Fit and align the spire clips to the console.

Console Assembly - Renew (Daimler / VDP)

Remove the battery cover. Disconnect the battery.

tion 13.3.5.

section 13.3.27.

13.3.6.

tion 13.3.19.

section

13.3.20.

tion 13.3.24.

13.3.23.

Issue 1 August 1994 10 X300 VSM