battery JAGUAR XJ6 1994 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 350 of 521

31

30

29

28 27

26

4 26 24 21 23 22 7 20 19 18 18 17 8

a

10

11

12

13

14

1s

1M-137

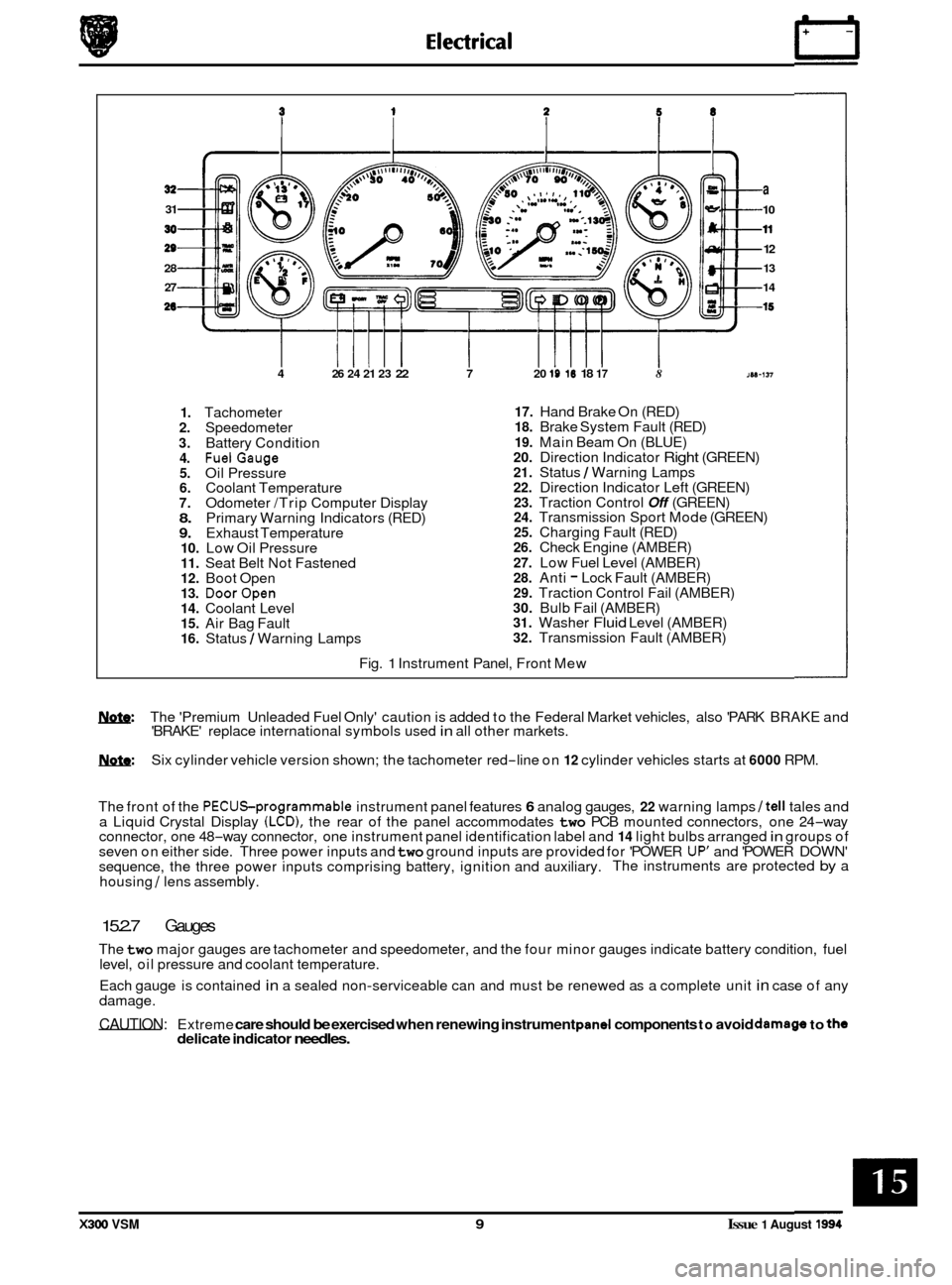

1. Tachometer 2. Speedometer

3. Battery Condition 4. FuelGauge 5. Oil Pressure 6. Coolant Temperature 7. Odometer /Trip Computer Display 8. Primary Warning Indicators (RED) 9. Exhaust Temperature 10. Low Oil Pressure 11. Seat Belt Not Fastened 12. Boot Open 13. DoorOpen 14. Coolant Level 15. Air Bag Fault 16. Status / Warning Lamps

17. Hand Brake On (RED) 18. Brake System Fault (RED)

19. Main Beam On (BLUE) 20. Direction Indicator Right (GREEN) 21. Status / Warning Lamps 22. Direction Indicator Left (GREEN) 23. Traction Control Off (GREEN) 24. Transmission Sport Mode (GREEN) 25. Charging Fault (RED) 26. Check Engine (AMBER)

27. Low Fuel Level (AMBER) 28. Anti - Lock Fault (AMBER) 29. Traction Control Fail (AMBER) 30. Bulb Fail (AMBER) 31. Washer Fluid Level (AMBER) 32. Transmission Fault (AMBER)

Fig.

1 Instrument Panel, Front Mew

w: The 'Premium Unleaded Fuel Only' caution is added to the Federal Market vehicles, also 'PARK BRAKE and

'BRAKE' replace international symbols used in all other markets.

m: Six cylinder vehicle version shown; the tachometer red-line on 12 cylinder vehicles starts at 6000 RPM.

The front of the

PECUSprogrammable instrument panel features 6 analog gauges, 22 warning lamps /tell tales and

a Liquid Crystal Display (LCD), the rear of the panel accommodates two PCB mounted connectors, one 24-way

connector, one 48-way connector, one instrument panel identification label and 14 light bulbs arranged in groups of

seven on either side. Three power inputs and two ground inputs are provided for 'POWER UP' and 'POWER DOWN'

sequence, the three power inputs comprising battery, ignition and auxiliary. The instruments are protected by a

housing

/ lens assembly.

15.2.7 Gauges

The two major gauges are tachometer and speedometer, and the four minor gauges indicate battery condition, fuel

level, oil pressure and coolant temperature.

Each gauge is contained

in a sealed non-serviceable can and must be renewed as a complete unit in case of any

damage.

CAUTION: Extreme care should be exercised when renewing instrument pand components to avoid damago to the delicate indicator needles.

X300 VSM 9 Issue 1 August 1994

Page 351 of 521

IT Electrical

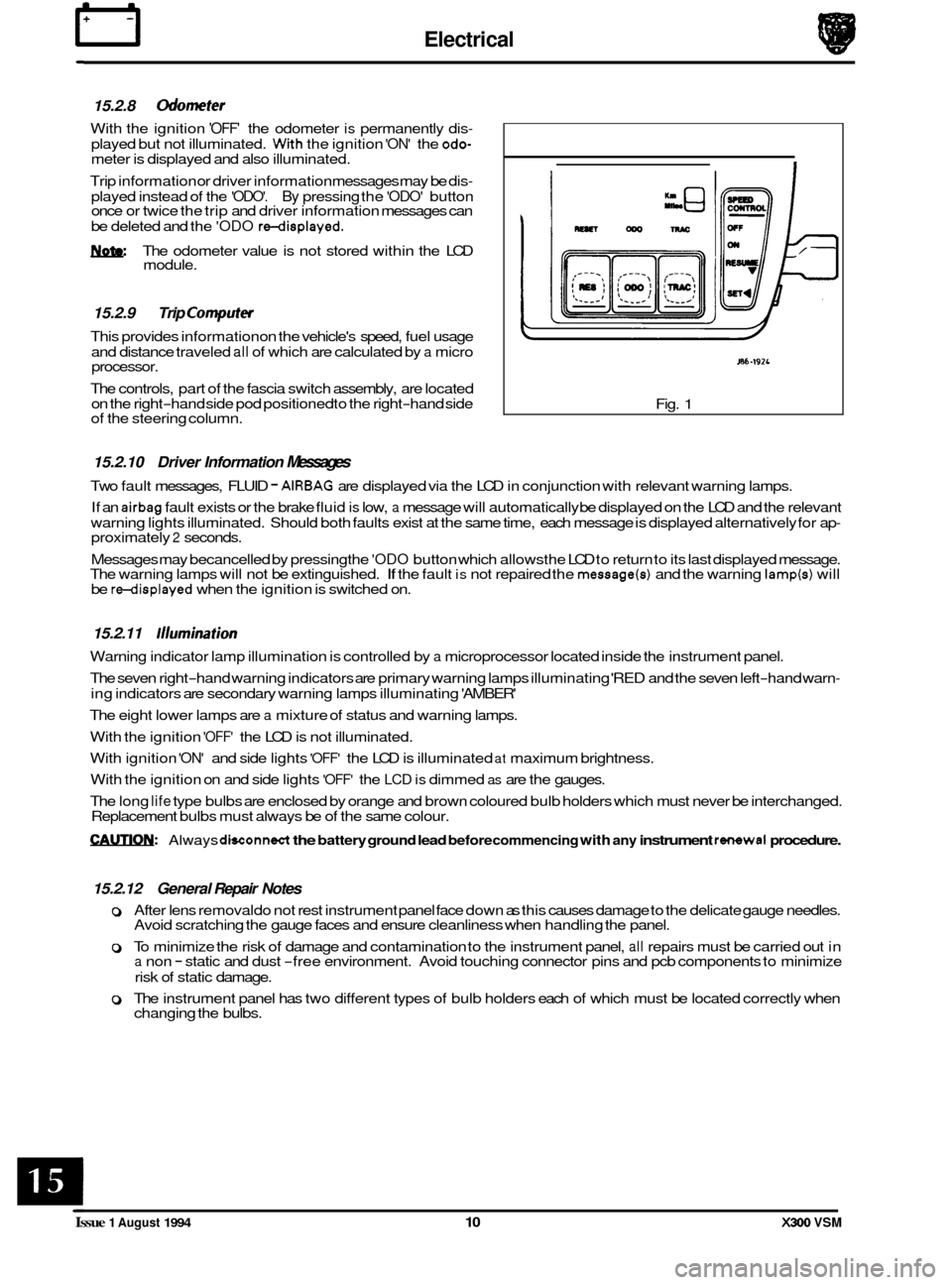

15.2.8 Odometer

With the ignition 'OFF' the odometer is permanently dis-

played but not illuminated. With the ignition 'ON' the odo- meter is displayed and also illuminated.

Trip information or driver information messages may be dis

-

played instead of the 'ODO'. By pressing the 'ODO' button

once or twice the trip and driver information messages can

be deleted and the

'ODO rdisplayed.

W. The odometer value is not stored within the LCD

module.

15.2.9 Trip Computev

This provides information on the vehicle's speed, fuel usage

and distance traveled

all of which are calculated by a micro

processor.

The controls, part of the fascia switch assembly, are located

on the right

-hand side pod positioned to the right-hand side

of the steering column.

I

/

J86-192L

Fig. 1

15.2.10 Driver Information Messages

Two fault messages, FLUID - AIRBAG are displayed via the LCD in conjunction with relevant warning lamps.

If an

airbag fault exists or the brake fluid is low, a message will automatically be displayed on the LCD and the relevant

warning lights illuminated. Should both faults exist at the same time, each message is displayed alternatively for ap

- proximately 2 seconds.

Messages may becancelled

by pressing the 'ODO button which allowsthe LCD to return to its last displayed message.

The warning lamps will not be extinguished. If the fault is not repaired the message(s) and the warning lamp(s) will

be redisplayed when the ignition is switched on.

15.2.11 /llumination

Warning indicator lamp illumination is controlled by a microprocessor located inside the instrument panel.

The seven right

-hand warning indicators are primary warning lamps illuminating 'RED and the seven left-hand warn-

ing indicators are secondary warning lamps illuminating 'AMBER'

The eight lower lamps are

a mixture of status and warning lamps.

With the ignition

'OFF' the LCD is not illuminated.

With ignition

'ON' and side lights 'OFF' the LCD is illuminated at maximum brightness.

With the ignition on and side lights

'OFF' the LCD is dimmed as are the gauges.

The long

life type bulbs are enclosed by orange and brown coloured bulb holders which must never be interchanged.

Replacement bulbs must always be of the same colour.

CAUTIQN: Always dwonnect the battery ground lead before commencing with any instrument rsimwal procedure.

15.2.12 General Repair Notes

0 After lens removal do not rest instrument panel face down as this causes damage to the delicate gauge needles.

Avoid scratching the gauge faces and ensure cleanliness when handling the panel.

0 To minimize the risk of damage and contamination to the instrument panel, all repairs must be carried out in a non - static and dust -free environment. Avoid touching connector pins and pcb components to minimize

risk of static damage.

0 The instrument panel has two different types of bulb holders each of which must be located correctly when

changing the bulbs.

Issue 1 August 1994 10 X300 VSM

Page 354 of 521

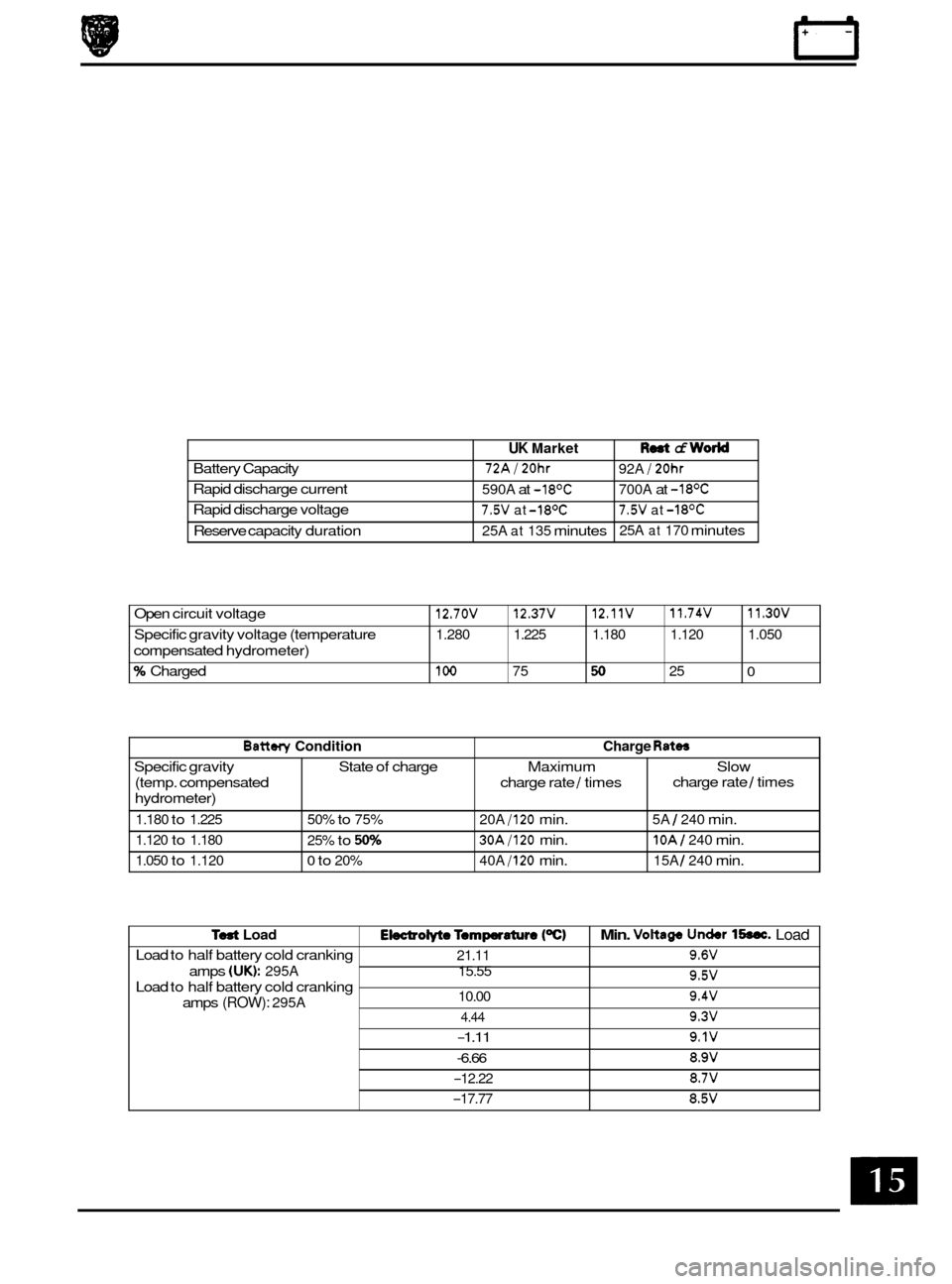

UK Market

Battery Capacity 7214 120hr

Rapid discharge voltage

Reserve capacity duration

Rapid

discharge current

590A at -18OC

7.5V at -18OC

25A at 135 minutes

Reat of World

92A 120hr

7.5V at -18OC

25A at 170 minutes

700A at -18OC

Open circuit voltage 12.70V 12.37V 12.11V 11.74V

Specific gravity voltage (temperature 1.280 1.225 1.180 1.120

compensated hydrometer)

% Charged 100 75 50 25

11.30V

1.050

0

Battmy Condition

Specific gravity State of charge

(temp. compensated

hydrometer)

1.180 to 1.225

1.120

to 1.180

1.050

to 1.120 50%

to 75%

25%

to 50%

0 to 20% Charge

Rates

Maximum Slow

charge rate

1 times charge

rate 1 times

20A 1120 min.

30A1120 min.

40A 1120 min.

5A 1 240 min.

10A 1 240 min.

15A 1 240 min.

Test Load Electrolyte lemper8ture (OC)

Load to half battery cold cranking

Load to half battery cold cranking

amps

(ROW): 295A 21.11

amps (UK): 295A

15.55

10.00

4.44

-1.11

-6.66

-12.22

-17.77

Min. Voltage Under 1Ssec. Load

9.6V

9.5v

9.4v

9.3v

9.1v

8.9V

8.7V

8.5V

Page 355 of 521

15.5.8 wific Gravity Test

The specific gravity of the electrolyte determines the level of the float in the liquid. With the float in a high position

the specific gravity is high and when the specific gravity is low the float sinks to the lower position.

Using

a hydrometer the specific gravity readings are taken when the liquid level crosses the scale on float. This should

give a accurate indication of the state charge of the battery.

The volume and the specific gravity of the electrolyte varies with the change in temperature.

15.5.9 Electrolyte Temperature Correctkm

For every 10- below 15% subtract 0.007 from the hydrometer reading, and for every 10°C above 15OC add 0.007 to

the hydrometer reading.

Note: Use only distilled water for topping up electrolyte. The electrolyte must not exceed 51.66OC during charging.

If after 30 minutes charging the battery current is not equal or greater than 3A, dispose of the battery.

15.5.10 Heahh and Sakty Precautions

As batteries contain sulphuric acid and explosive mixtures of hydrogen and oxygen gases, it is strongly recommended

that protective clothing is worn.

Avoid spilling acid to prevent damage to clothing and skin bums.

If accidentalty spilled or splashed on clothing or skin, rinse with cold water. As a neutralizer, a solution of baking soda

or ammonia and water may be used.

In the event of skin or eye contact rinse the affected areas with water and should this not

be sufficient seek medical

attention.

Any trace of acid spilled or splashed on the vehicle should be rinsed with clean water.

BEFORE AND WHILST WORKING WITH THE BATTERY BE AWARE OF THE FOLLOWING SAFETY PRECAUTIONS

o particularly during charging, highly explosive hydrogen is emitted.

0 do not smoke when working near the battery.

o avoid sparks, short circuits or other sources of ignition.

o switch off current before connecting or disconnecting any electrical terminals.

o always disconnect battery ground lead first and reconnect last.

o ensure battery is charged in a well ventilated area.

o switch off the charger before disconnecting.

WARNING: WHEN PREPARING ELECTROLYTE OF A DESIRED SPECIFIC GRAVITY, ALWAYS POUR THE

CONCENTRATED ACID SLOWLY INTO THE WATER AND NOT WATER INTO THE ACID.

HEAT IS GENERATED WHEN MIXING ACID WITH WATER, HENCE ADD SMALL AMOUNTS OF ACID AND

STIR SLOWLY INTO THE WATER. ALLOW TO COOL IF NOTICEABLE HEAT DEVELOPS. EXCEPT FOR LEAD

DO NOT STORE ACID

IN EXCESSIVELY WARM LOCATIONS OR DIRECT SUN LIGHT.FUEL VAPOUR IS EXTREMELY FLAMMABLE, HENCE GREAT CARE MUST BE TAKEN WHILST WORKING ON THE FUEL

SYSTEM. LINED

CONTAINERS, ALWAYS USE NON

- METALLIC CONTAINERS AND / OR FUNNELS.

Issue 1 August 1994 14 X300 VSM

Page 356 of 521

15.5.11 6atteq5 Remove & Refit

0 SRO 86.15.01

Remove

m Open the trunk lid.

Remove the battery cover.

Disconnect and insulate the battery negative lead (1 Fig. 1).

Disconnect and insulate the positive lead (2 Fig. 1).

Remove the battery (3 Fig. 1).

Rea

Refitting is a reversal of the removal procedure.

Issue 1 August 1994 X300 VSM 15

Page 363 of 521

Electrical

0

15.10 HARNESSES & CABLES

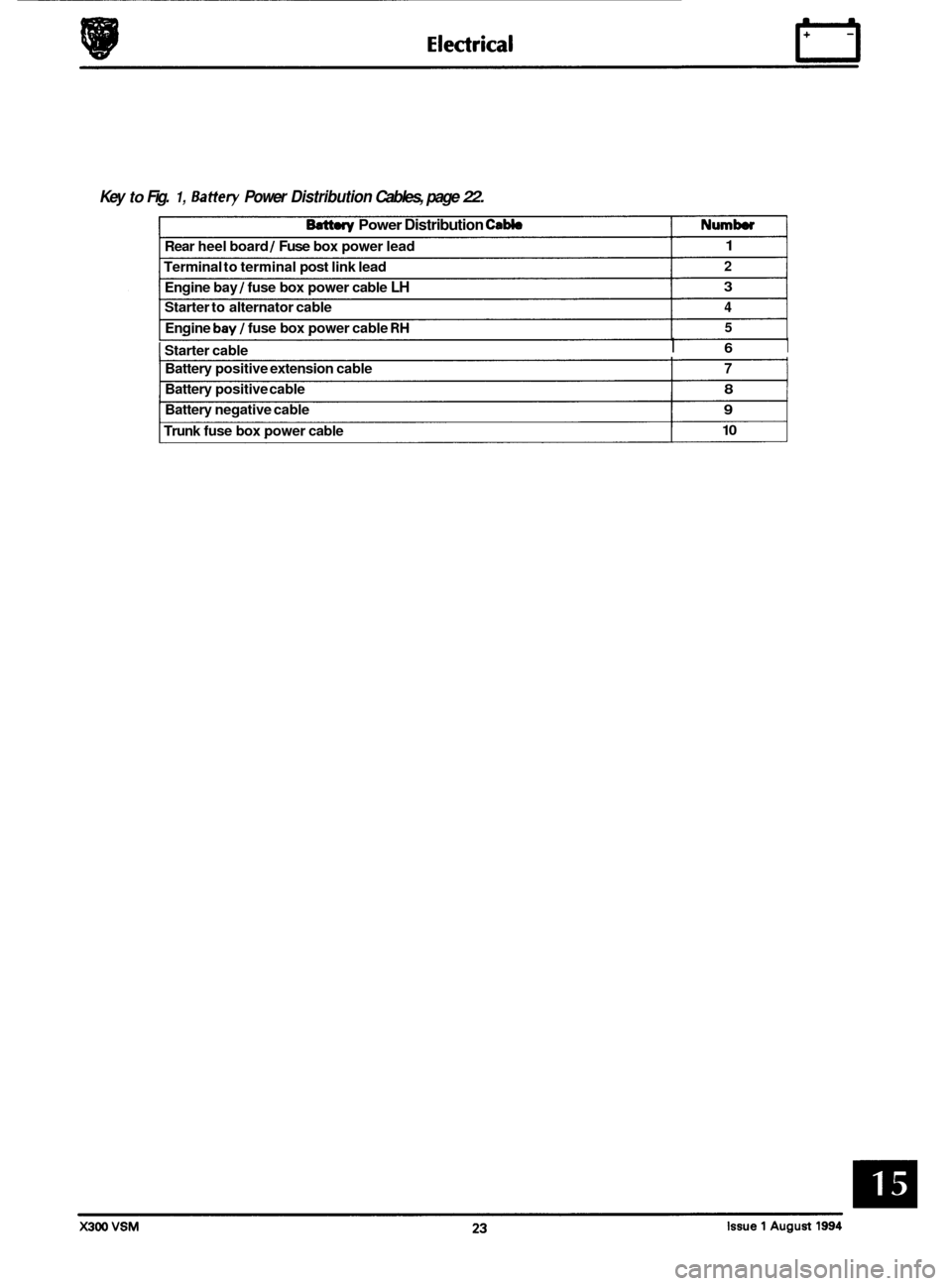

15.10.1 Battery Power Distribution Cabk, General Description

1 2 8

10-

Fig.1 Battery Power Distribution Cables

Figure 1 shows

a plan view of the battery power distribution cables and their distribution points. This illustration is

to be read in conjunction with the following table. To avoid any accidents such as electric shocks, always disconnect

the battery negative lead from the battery negative terminal before disconnecting any of the listed cables.

Page 364 of 521

Key to Fig. 1, Battery Power Distribution Cables, page 22.

Rear heel board 1 Fuse box power lead 1

Terminal to terminal post link lead 2

Engine bay 1 fuse box power cable LH 3

Starter to alternator cable 4

Engine bay 1 fuse box power cable RH 5

Batt.ry Power Distribution Cabb Numb

1 Starter cable I 6 I

Battery positive extension cable 7

Battery positive cable 8

Battery negative cable 9

Trunk fuse box power cable 10

Page 365 of 521

IT E I ectr ical

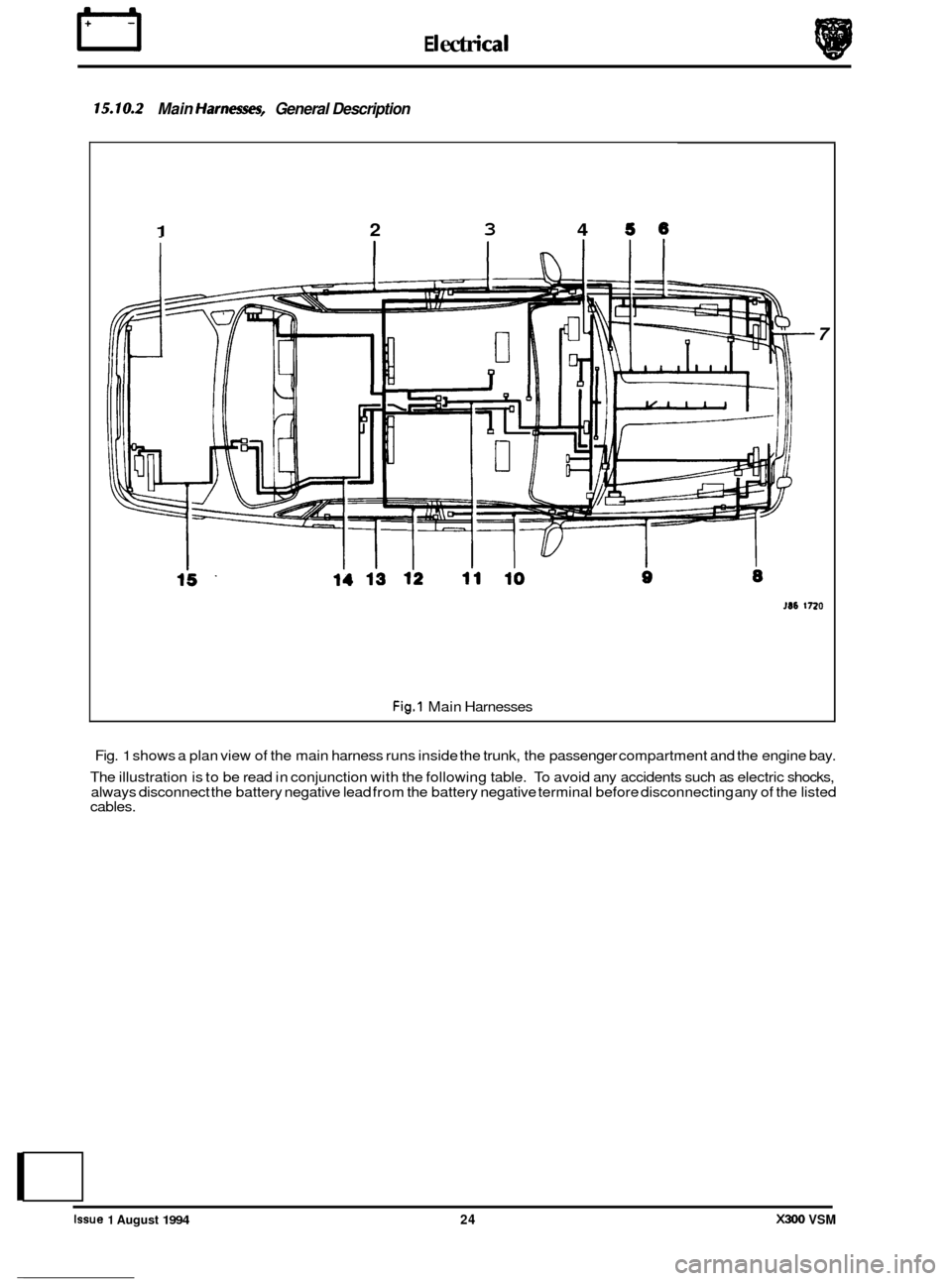

15.10.2 Main Harnm, General Description

1 2 3 4 56

7

M6 1720

Fig.1 Main Harnesses

Fig.

1 shows a plan view of the main harness runs inside the trunk, the passenger compartment and the engine bay.

The illustration is to be read in conjunction with the following table.

To avoid any accidents such as electric shocks,

always disconnect the battery negative lead from the battery negative terminal before disconnecting any of the listed

cables.

e

0

0

0

Issue 1 August 1994 24 X300 VSM

Page 367 of 521

rl Electrical

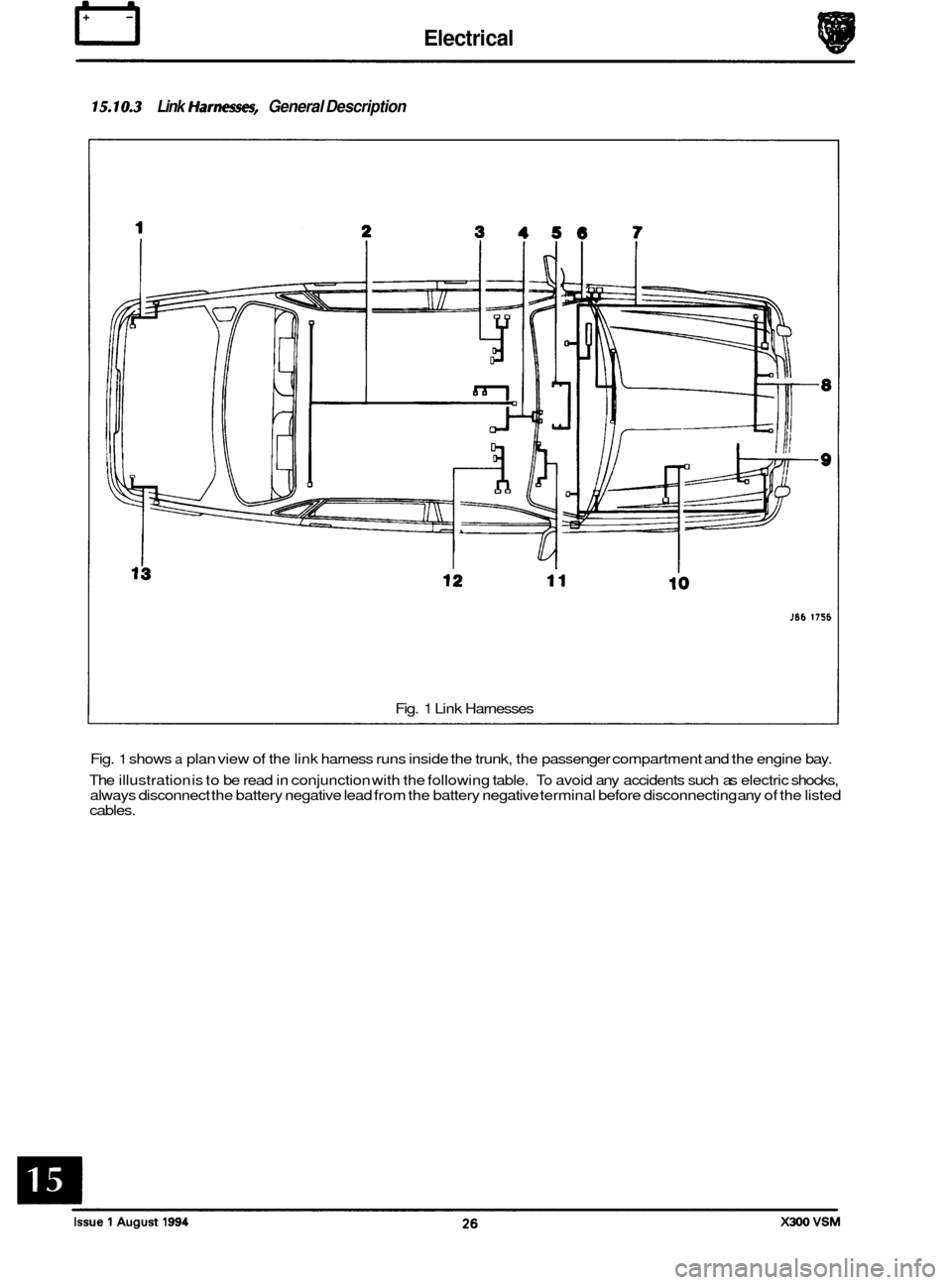

'5.10.3 Link /farnest?$, General Description

Fig. 1 Link Harnesses

Fig.

1 shows a plan view of the link harness runs inside the trunk, the passenger compartment and the engine bay.

The illustration is to be read in conjunction with the following table.

To avoid any accidents such as electric shocks,

always disconnect the battery negative lead from the battery negative terminal before disconnecting any of the listed

cables.

Page 369 of 521

I3 Electrical

'5.10.4 Hamess Connecton, General Descriptbn

21

1 23 4 7 09

10

Fig. 1 Harness Connectors

Fig.

1 shows a plan view of the harness connectors physically linking all the harnesses located in the trunk, the passen- ger compartment and the engine bay.

The illustration

is to be read in conjunction with the following table. To avoid any accidents such as electric shocks,

always disconnect the battery negative lead from the battery negative terminal before disconnecting any of the listed

cables.