light JAGUAR XJ6 1994 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 418 of 521

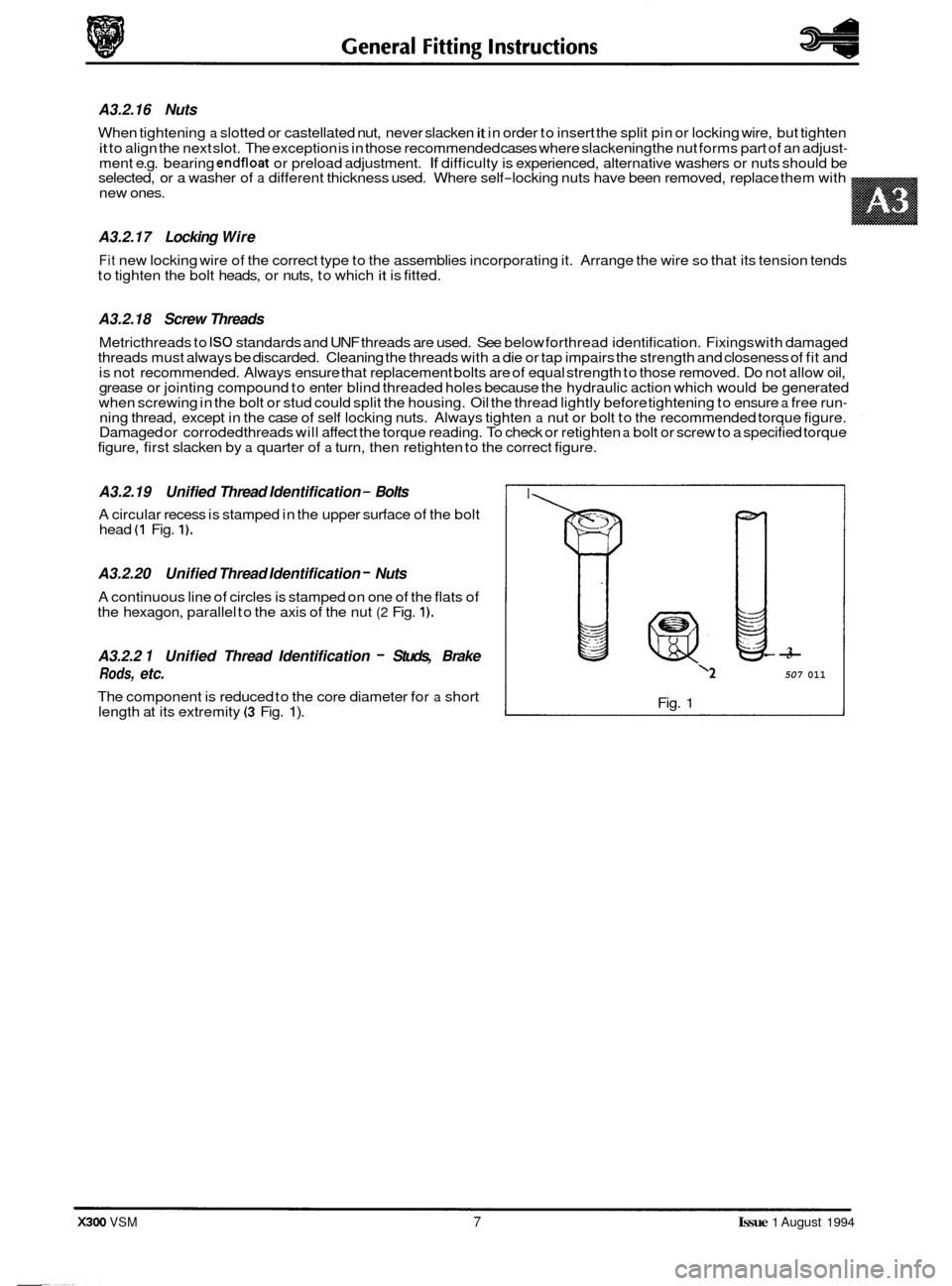

- A3.2.19 Unified Thread Identification - Bolts

A circular recess is stamped in the upper surface of the bolt

head (1 Fig. 1).

A3.2.20 Unified Thread Identification - Nuts

A continuous line of circles is stamped on one of the flats of

the hexagon, parallel to the axis of the nut (2 Fig. 1).

A3.2.2 1 Unified Thread Identification - Studs, Brake

Rods, etc.

The component is reduced to the core diameter for a short

length at its extremity (3 Fig. 1).

A3.2.16 Nuts

When tightening a slotted or castellated nut, never slacken it in order to insert the split pin or locking wire, but tighten

it to align the next slot. The exception is in those recommended cases where slackening the nut forms part of an adjust- ment e.g. bearing endfloat or preload adjustment. If difficulty is experienced, alternative washers or nuts should be

selected, or a washer of a different thickness used. Where self-locking nuts have been removed, replace them with

new ones.

A3.2.17 Locking Wire

Fit new locking wire of the correct type to the assemblies incorporating it. Arrange the wire so that its tension tends

to tighten the bolt heads, or nuts, to which it is fitted.

A3.2.18 Screw Threads

Metricthreads to IS0 standards and UNF threads are used. See below forthread identification. Fixings with damaged

threads must always be discarded. Cleaning the threads with a die or tap impairs the strength and closeness of fit and

is not recommended. Always ensure that replacement bolts are of equal strength to those removed. Do not allow oil,

grease or jointing compound to enter blind threaded holes because the hydraulic action which would be generated

when screwing in the bolt or stud could split the housing. Oil the thread lightly before tightening to ensure

a free run- ning thread, except in the case of self locking nuts. Always tighten a nut or bolt to the recommended torque figure.

Damaged or corroded threads will affect the torque reading. To check or retighten a bolt or screw to a specified torque

figure, first slacken by a quarter of a turn, then retighten to the correct figure.

I

7

-3

‘2 507 011

Fig. 1

X300 VSM 7 Issue 1 August 1994

Page 421 of 521

General Fitting Instructions

I

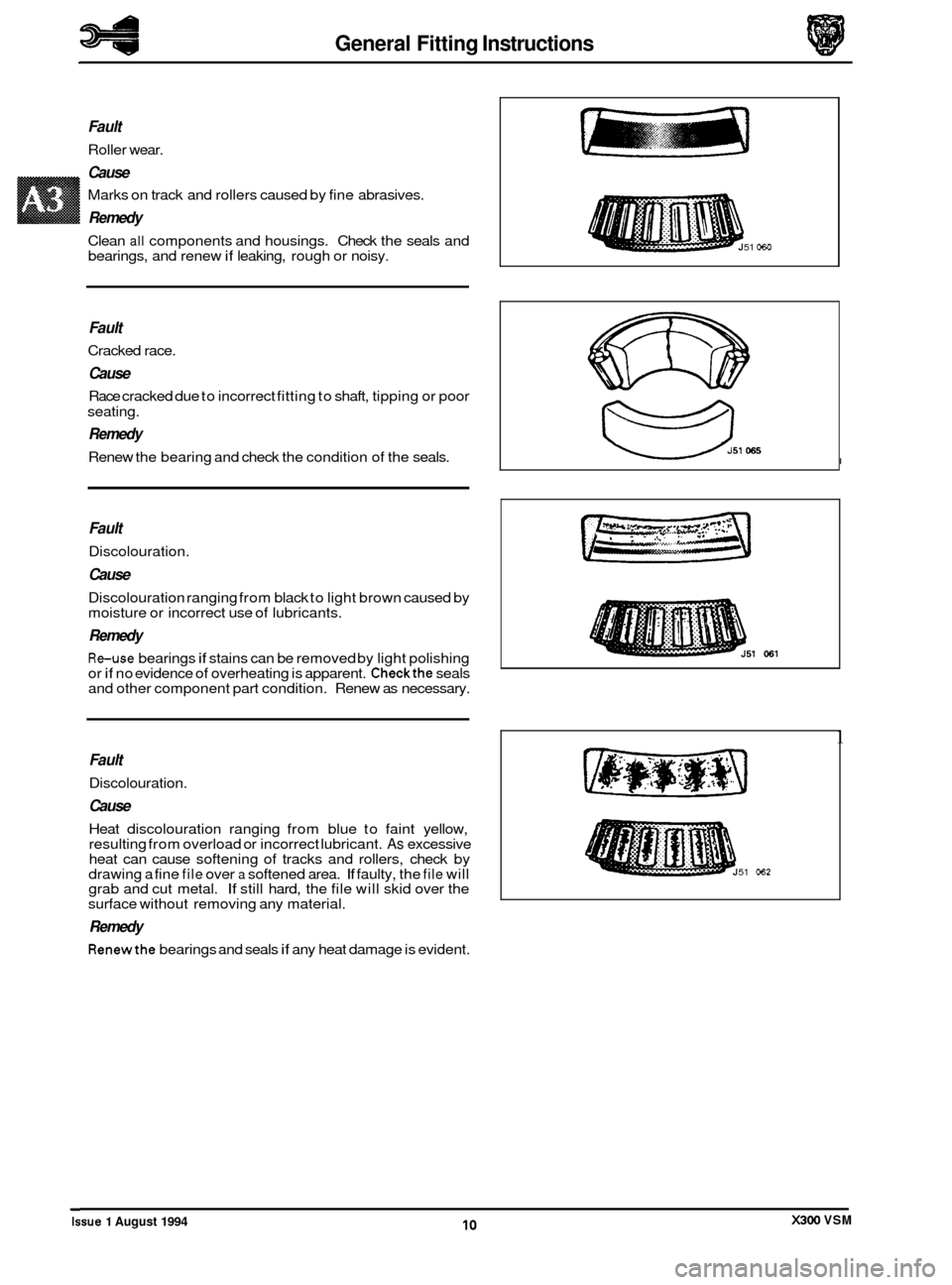

Fault

Roller wear.

Cause

Marks on track and rollers caused by fine abrasives.

Remedy

Clean all components and housings. Check the seals and

bearings, and renew if leaking, rough or noisy.

Fault

Cracked race.

Cause

Race cracked due to incorrect fitting to shaft, tipping or poor

seating.

Remedy

Renew the bearing and check the condition of the seals.

Fault

Discolouration.

Cause

Discolouration ranging from black to light brown caused by

moisture or incorrect use of lubricants.

Remedy

Reuse bearings if stains can be removed by light polishing

or if no evidence of overheating is apparent. Checkthe seals

and other component part condition. Renew as necessary.

51 060

[pzq-j - ..., .... *au

....... ........ e L. U

1

Fault

Discolouration.

Cause

Heat discolouration ranging from blue to faint yellow,

resulting from overload or incorrect lubricant. As excessive

heat can cause softening of tracks and rollers, check by

drawing a fine

file over a softened area. If faulty, the file will

grab and cut metal. If still hard, the file will skid over the

surface without removing any material.

Remedy

Renewthe bearings and seals if any heat damage is evident.

51 062

Issue 1 August 1994 X300 VSM 10

Page 441 of 521

Body Systems & Body Repair

A4.2.3 ZINC COATED PANELS

A4.2.3.1

Description

Approximately 65% of the 'body in white' (BIW) mass is made up of zinc coated panels.

All exterior skin panels, with the exception of the roof, are double side zinc plated and this coating (nominally

7,5 mi- crons) provides corrosion protection in two ways.

1. Should the outer layer of paint become chipped but the zinc coating remain intact, the zinc will oxidize on contact

with air. This coat of oxidation is impermeable and will prevent corrosion damage to the base metal.

2. If both the outer layer of paint and the zinc coating become damaged, the zinc will react with the air and 'sacrifice'

itself to corrosion, rather than the base metal. In this process the zinc is known as a 'sacrificial anode'.

Iynpp: To maintain the protective qualities of the zinc treatment, repairs to any damaged coated area MUST be made as soon as possible after the damage has occurred.

A4.2.3.2 Wdding Preparation

Where 'resistance spot welding' is employed, the zinc coating should be lightly abraded away on the mating surfaces

and those in contact with the electrode tips. Do not remove more of the zinc coating than is absolutely necessary.

Before welding,

a weld-through primer or inter-weld sealer should be applied, as detailed in the Body Sealing and

Preservation man ua I.

Contamination of the weld will occur ifthe plating is not removed, thus making the joint less strong; another side effect

of this will be a greater need for electrode tip dressing and increased tool down time.

In exceptional cases where the plating must remain intact, increase the tip pressure and welding current by 10 to

20%.

Where MIG welding is used as an alternative to resistance spot welding for plug, butt welds, or limited access, the prob- lems caused by the presence of zinc coating are much the same as those previously mentioned. There may also be

the added problems of increased weld spatter and nozzle contamination.

0

A4.2.3.3 Body Fillers

Conventional polyester fillers do not adhere satisfactorily to zinc plated panels. Therefore, it is important to use only

those products specifically designed for this application and follow the manufacturers recommendations.

A4.2.3.4 Refinishing

Use only those products approved by Jaguar Cars Ltd and take special care with zinc coated panels.

Replacement panels are supplied ready primed

so there should be no need for bare metal to be exposed, other than

those areas prepared for welding etc (see 'Welding Preparation' sub section 4.2.3.2).

Where any part of a panel is dressed backto a bare surface, it should be treated with a zinc rich primer compatible with

the chosen paint application system, please refer to section A4.4.1.1.

X300 VSM Issue 1 August 1994 14

Page 443 of 521

Body Systems & Body Repair

A4.2.5 SURFACES (OLD), PREPARE

SRO

77.10.03

Observe all appropriate safety procedures.

WARNINO: DO NOT BURN UNDERSEAL OFF. USE A 'HOT KNIFE' OR SUITABLE SOLVENT

Remove the weld nuggets with a sander and 36 grit disc.

Clean all flanges to a bright smooth finish. (A Fig. 1).

Straighten existing panel joint edges as required.

A4.2.5.1 SURFACES (NEW), PREPARE

SRO 77.10.04

Observe all appropriate safety procedures.

Mark off the area of new panel and cut to size leaving approximately two inches overlap on the existing panel.

Offer up new panel or section, and align with associated parts, i.e. new rear fender aligned with door / luggage com- partment lid / backlight aperture.

Clamp the panel into position.

Where necessary, cut the new and original panels to form a butt joint.

Remove all clamps and the new panel.

rn If required, apply inner panel protection and or sound insulation.

Prepare the new panel joint edges for welding by cleaning to bright metal (A Fig. 1); this includes all interior and

Apply weld-through primer or interweld sealer (6 Fig. 1) to all surfaces to be resistance spot welded.

Where appropriate, apply metal-to-metal adhesive or sealer (C Fig 1) in accordance with the manufacturer's instruc

exterior edges.

tions.

6

C

,,,A'

Fig. 1

0

0

0

X300 VSM Issue 1 August 1994 16

Page 480 of 521

I 03 I Door lock actuators (4 off) 1 part of door assemblv I I

Issue 1 August 1994 X300 VSM 3 I

1 04 I Door lock switches (2 off) I part of door latch assembly I I

1 05 IHoodswitch 1 located above siren I I

1 06 IHorn 1 located on front RH side of en(

1 07 I Inclination sensor I behind luggage compartment LH liner I I

I 08 I Intrusion sensor (LH) I located above LH door behind roof lining I

I 09 I intrusion sensor (RH) 1 located above LH door behind roof lining I

I

1 1 part of door latch assembly I 10 I Key barrel switches (2 off)

1 11 I Key fob transmitter 1 part of key fob I I

I 12 I Key transponder 1 part of key I I

I 13 I Reader exciter coil 1 part of ignition switch I I

I 14 I Reader exciter module 1 part of steering column assembly I I

1 15 I Relays (deadlock) I I I

1 18 I Security active indicator part of central locking switch I I

I 19 I Securitv and lockina control module (SLCM) located in luaaaae compartment behind LH liner I I

1 20 ISounder , located on front RH side of engine bay I I

1 25 IValet switch 1 in centre console compartment I I

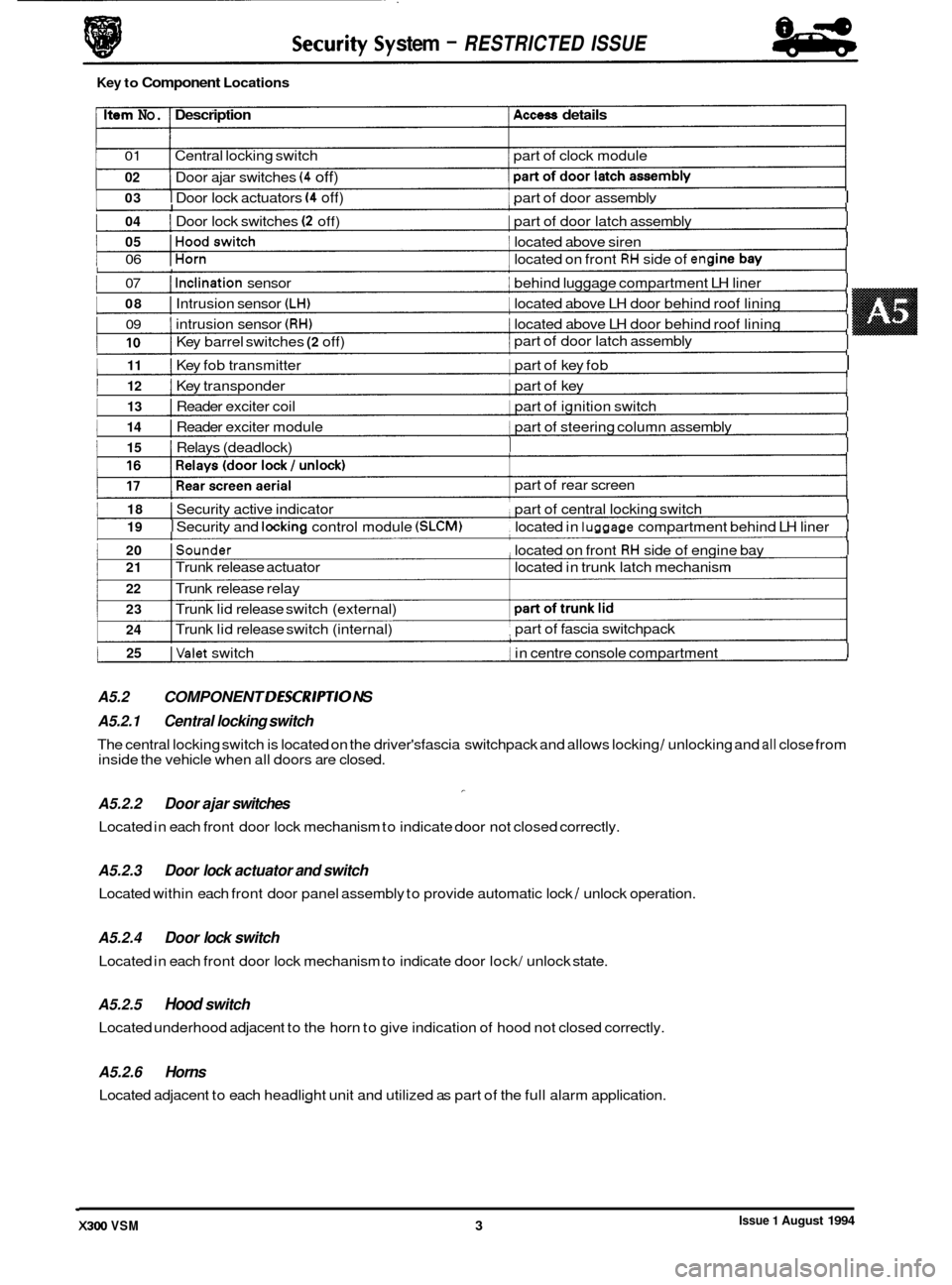

A5.2 COMPONENT DESCR/PT/O NS I

stem - RESTRICTED ISSUE

Key to Component Locations

Item No. Description Access details

01 Central locking switch part of clock module

02

1 I

Door ajar switches (4 off)

I I

part of rear screen

I 21 I Trunk release actuator located in trunk latch mechanism

22 I Trunk release relay

23

24 I Trunk lid release switch (external)

I Trunk lid release switch (internal) part of

fascia switchpack ,

A5.2.1 Central locking switch

A5.2.2 Door ajar switches

Located in each front door lock mechanism to indicate door not closed correctly.

-

The central locking switch is located on the driver'sfascia switchpack and allows locking / unlocking and all close from

inside the vehicle when all doors are closed.

A5.2.3

Located within each front door panel assembly to provide automatic lock / unlock operation.

Door lock actuator and switch

A5.2.4 Door lock switch

Located in each front door lock mechanism to indicate door lock/ unlock state.

A5.2.5 Hood switch

Located underhood adjacent to the horn to give indication of hood not closed correctly.

A5.2.6 Horns

Located adjacent to each headlight unit and utilized as part of the full alarm application.

Page 482 of 521

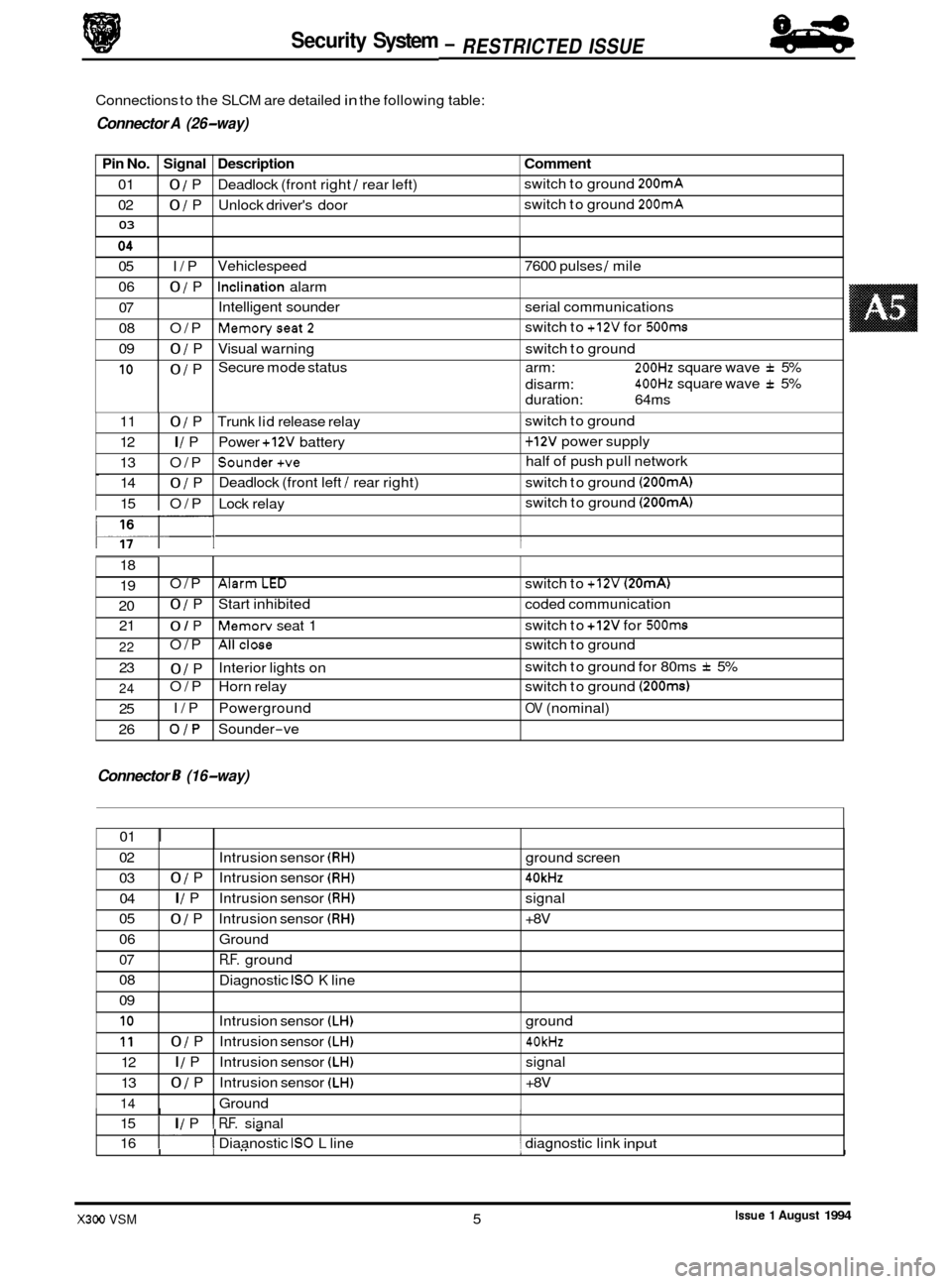

Security System

Pin No. Signal Description

01 0 / P Deadlock (front right / rear left)

02

0 / P Unlock driver's door

03

Connections to the SLCM are detailed in the following table:

9 Connector A (26-way)

Comment

switch to ground 200mA

switch to ground 200mA

05 I/P

06

0 / P

07

08 O/P

09

0 / P

10 0 / P Vehiclespeed

7600 pulses

/ mile

Inclination alarm

Intelligent sounder serial communications

Memoryseat2

Visual warning switch to ground

Secure mode status arm:

200Hz square wave f 5%

400Hz square wave f 5%

switch

to

+12V for 500ms

disarm:

duration: 64ms

0

117- I I

11 0 / P Trunk lid release relay 1 switch to ground

12

I / P Power +12V battery 1 + 12V power supply

13 O/P

Sounder+ve half of push pull network

14

0 / P Deadlock

(front left / rear right) switch to ground (200mA)

15 O/P Lock relay switch

to ground (200mA)

18

19

20 21 O/P

AlarmLED switch

to +12V (20mA)

0 / P Start inhibited coded communication

0 / P Memorv seat 1 switch

to +12V for 500ms

Connector 8 (16-way)

22

23

24

25

26 O/P

Allclose switch

to ground

0 / P

O/P Horn relay switch to ground

(200ms)

I/P Powerground OV (nominal)

OJP Sounder-ve

Interior lights

on switch

to ground for 80ms

f 5%

01

I

02

03 04

05

06

07

08

09

I I I I 15 I I / P I R.F. sianal

Intrusion

sensor

(RH) ground screen

0 / P Intrusion sensor (RH) 40kHz

I / P Intrusion sensor (RH) signal

0 / P Intrusion sensor (RH) +8V

Ground

R.F. ground

Diagnostic

IS0 K line

I. I - I 16 I I Diaanostic IS0 L line 1 diagnostic link input

10

11

12

13

14

.I

I I" 1- I

Intrusion sensor (LH) ground

0 / P Intrusion sensor (LH) 40kHz

I / P Intrusion sensor (LH) signal

0 / P Intrusion sensor (LH) +8V

Ground

Issue 1 August 1994 X300 VSM 5

84

- RESTRICTED ISSUE -

Page 485 of 521

Security System - RESTRICTED ISSUE 8-8

-

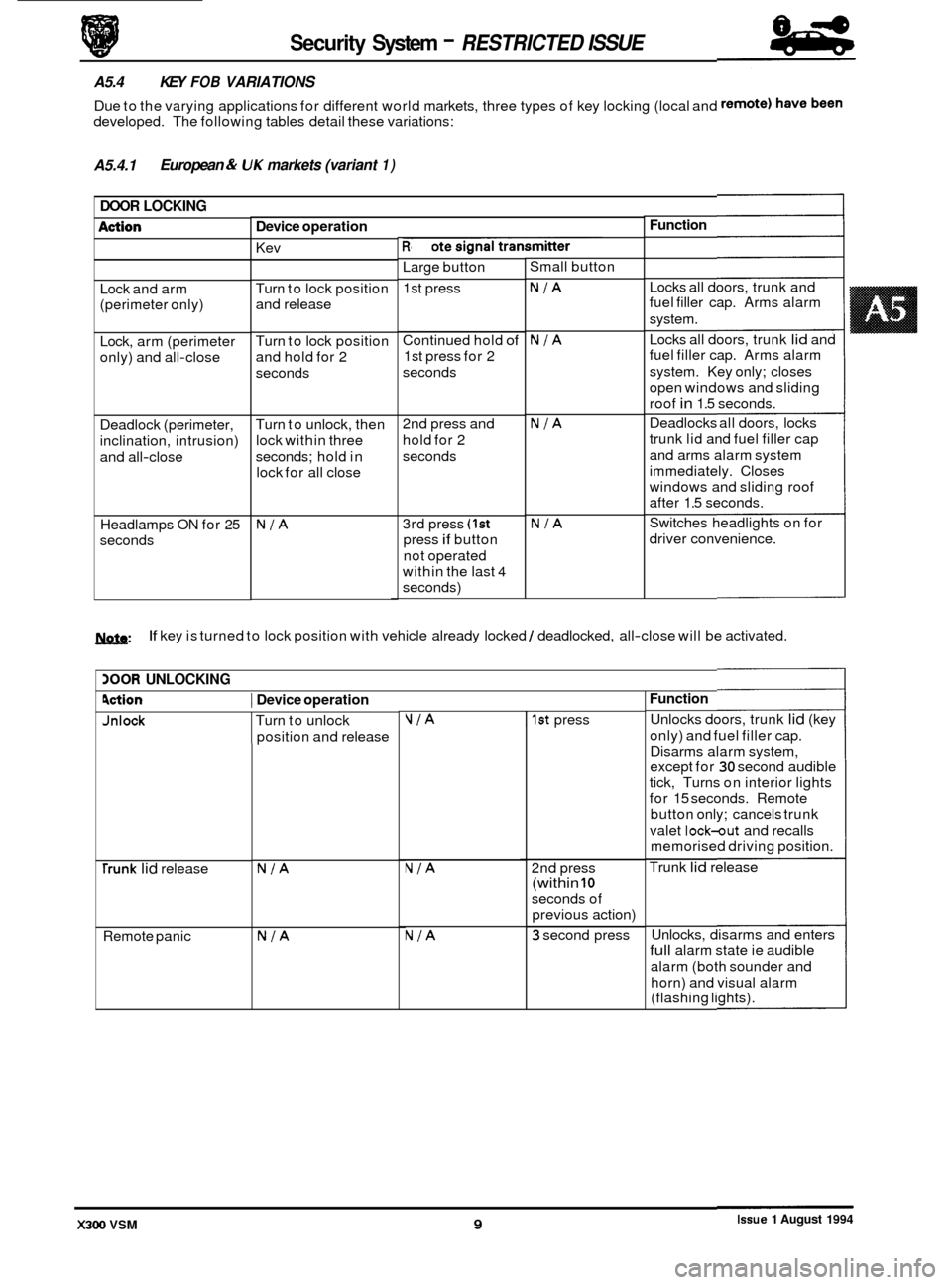

A5.3.2 Security system

Base system

Provides standard vehicle arming, ie door ajar, actuator lockstatus, trunk lid or hood ajar and passenger door unlock- ing, does not include inclination or

Intrusion sensing

Detection of intrusion into the passenger compartment by removal or breakage of any glazed area, entry via any pro- tected enclosure and unauthorized door opening detection.

Inclination (tilt) sensing

Detection of unauthorized jacking /towing.

Passive arming

Arming of the security system, excluding intrusion sensors, without audible confirmation.

Audible tones

Audible indication of driver error when attempting to arm the system, or on initiation of deadlocking.

Engine immobilization

Automatic immobilization of the engine crank facility whenever the ignition key is turned to position 0.

A5.3.3 Convenience

All close

Automatic closure of open windows and sliding roof by prolonged action of key, or remote fob transmitter after door

locking.

Headlamp convenience

Automatic illumination of headlamps for driver convenience on operation of key fob button after locking sequence

completed.

Remote trunk lid release

Automatic release of the trunk lid lock on operation of the smaller key fob button after door unlocking.

Trunk valet isolate

Independent locking of the trunk lid to eliminate unauthorized entry to the luggage compartment.

Driver seat memory select

Automatic recall of a memorized driving position on operation of the smaller key fob button.

Intrusion sensing override

Allows intrusion sensing to be disabled until the next disarm action.

A5.3.4 Alarms

There are eight possible alarm activation modes; driver's door, hood, ignition key in (ignition auxiliary position, ignition ON), inclination, inner door handle action (causing actuator status switches to operate), intrusion, passenger door and

trunk.

Any of the above conditions occurring after the vehicle is fully armed will cause full alarm state.

Any of the above conditions, except door opening, occurring

after the vehicle is fully armed and active disarming is

selected will cause full alarm state. Door opening after active disarming selection will give a 30 second audible tick

period before full alarm is entered.

Any of the above conditions occurring

after the vehicle has been passively armed will give a 30 second audible tick

period before full alarm is entered.

Activation of full alarm state causes sidelights, direction indicators, interior lights or headlamps to flash (dependant

upon market variations), the security sounder to operate and the vehicle horns to operate

(if programmed to do so).

An error tone is generated if active arming is selected with either hood or trunk open, or the transmitter is pressed with

ignition key in auxiliary position.

0

X300 VSM Issue 1 August 1994 8

Page 486 of 521

Jnlock Turn to unlock

position and release VIA I 1st press

Security System - RESTRICTED ISSUE

A5.4 KEY FOB VARIATIONS

Due to the varying applications for different world markets, three types of key locking (local and

developed. The following tables detail these variations:

A5.4.1 European & UK markets

(variant 1)

DOOR LOCKING

Function

Device operation

Remote signal transmitter

Kev -

Large button

1st press Small

button

Locks all doors, trunk and

fuel filler cap. Arms alarm

system.

Locks all doors, trunk

lid and

fuel filler cap. Arms alarm

system. Key only; closes

open windows and sliding

roof

in 1.5 seconds.

Deadlocks all doors, locks

trunk lid and fuel filler cap

and arms alarm system

immediately. Closes

windows and sliding roof

after 1.5 seconds.

Switches headlights on for

driver convenience.

Lock

and arm

(perimeter only)

NIA Turn to lock position

and release

Continued hold

of

1st press for 2

seconds NIA

NIA

Lock, arm (perimeter

only) and all

-close Turn

to lock position

and hold for 2

seconds

Deadlock (perimeter,

inclination, intrusion)

and all

-close Turn

to unlock, then

lock within three

seconds; hold in

lock for all close 2nd

press and

hold for 2

seconds

0

Headlamps ON for 25

seconds 3rd

press (1st

press if button

not operated

within the last

4

seconds)

NIA NIA

1ynfn: If key is turned to lock position with vehicle already locked / deadlocked, all-close will be activated.

BOOR UNLOCKING

Function

Unlocks doors, trunk lid (key

only) and fuel filler cap.

Disarms alarm system,

except for

30 second audible

tick, Turns on interior lights

for 15 seconds. Remote

button only; cancels trunk

valet

lock-out and recalls

memorised driving position.

Trunk

lid release

9ction I Device operation

0

0

NIA 2nd press

(within 10

seconds of

previous action)

NIA

NIA

rrunk lid release

Remote panic

NIA 3 second press Unlocks,

disarms and enters full alarm state ie audible

alarm (both sounder and

horn) and visual alarm

(flashing lights).

Issue 1 August 1994 X300 VSM 9

Page 487 of 521

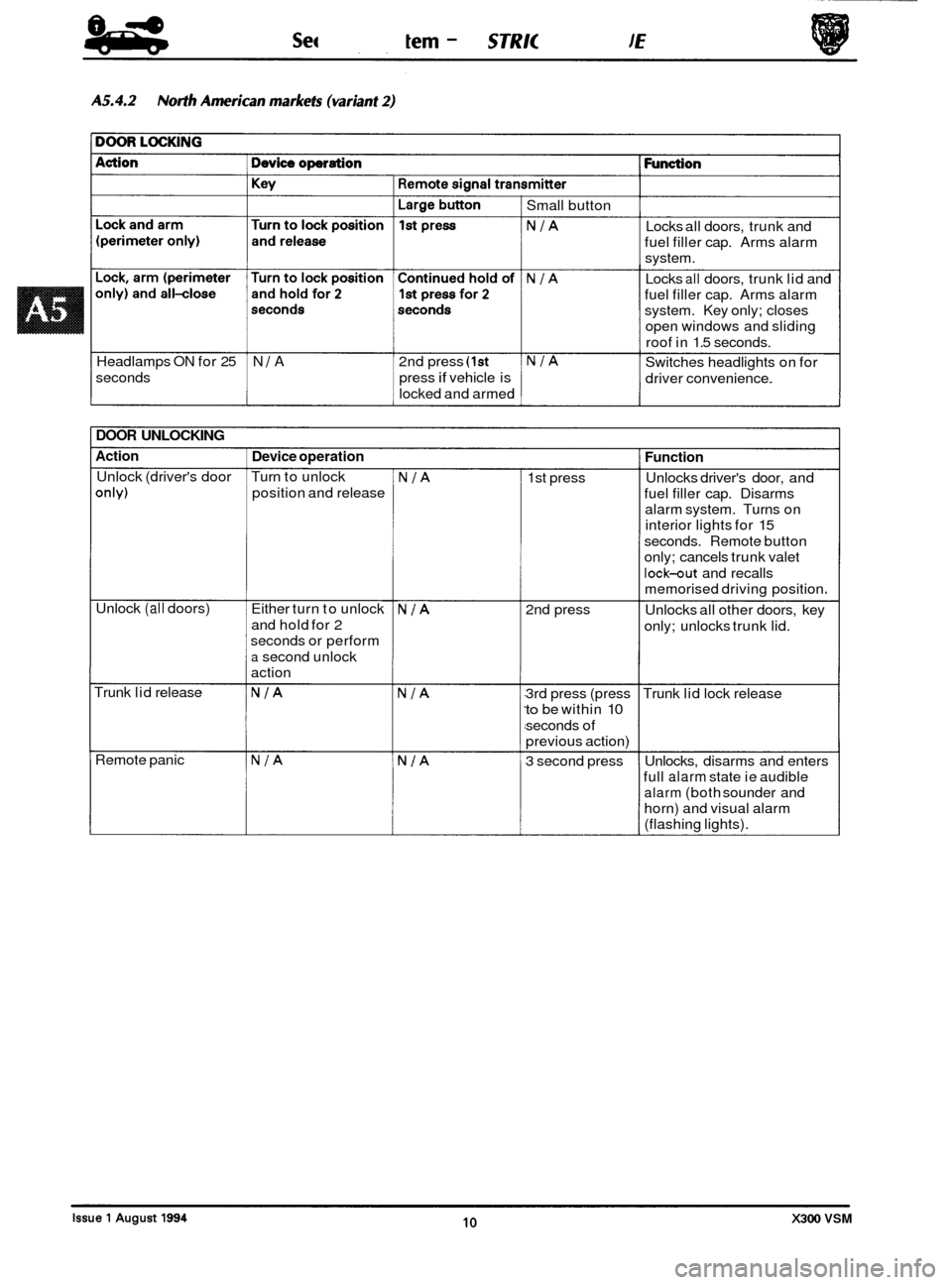

Security System - RESTRICTED ISSUE

Headlamps ON for 25 N 1 A 2nd press (1st

seconds press if vehicle is

locked and armed Small

button

NIA Locks all doors, trunk and

fuel filler cap. Arms alarm

system.

Locks

all doors, trunk lid and

fuel filler cap. Arms alarm

system. Key only; closes

open windows and sliding

roof in 1.5 seconds.

NIA Switches headlights on for

driver convenience.

NIA

DOOR UNLOCKING

Action

Unlock (driver's door

only)

Unlock (all doors)

Trunk lid release

Remote panic

Device operation

Turn to unlock

position and release

Either turn to unlock

and hold for 2

seconds or perform

a second unlock

action

NIA

NIA

NIA

NIA

NIA

NIA

1st press

2nd press

3rd press (press

to be within 10

seconds of

previous action)

3 second press

Function

Unlocks driver's door, and

fuel filler cap. Disarms

alarm system. Turns on

interior lights for 15

seconds. Remote button

only; cancels trunk valet

lock-out and recalls

memorised driving position.

Unlocks all other doors, key

only; unlocks trunk lid.

Trunk lid lock release

Unlocks, disarms and enters

full

alarm state ie audible

alarm (both sounder and

horn) and visual alarm

(flashing lights).

10 X300 VSM

Page 488 of 521

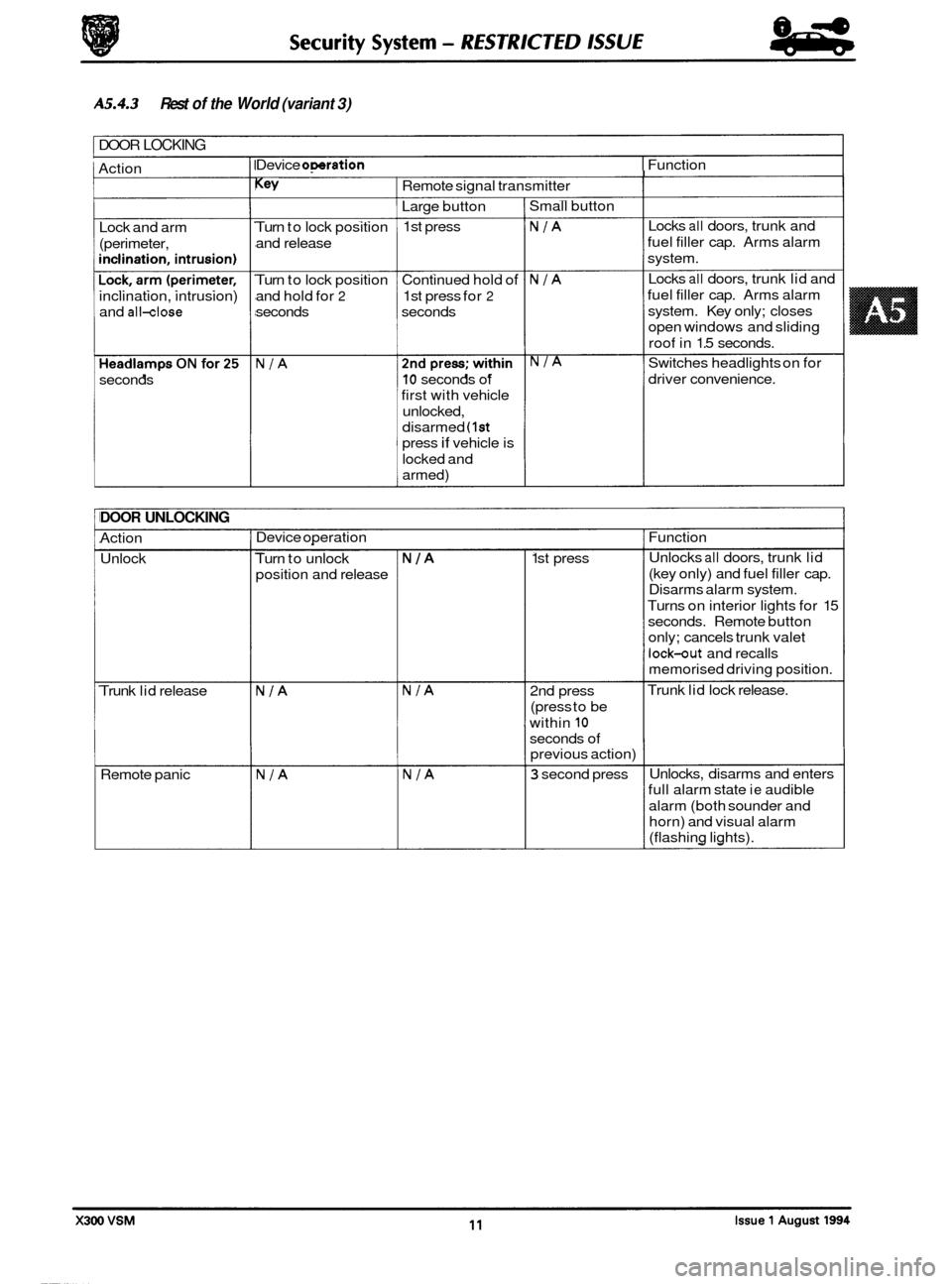

A5.4.3

I DOOR LOCKING

Rest of the World (variant 3)

-

1 Action Lock and arm

(perimeter,

inclination, intrusion)

and

all-close

seconds Device

omration I Function I Key I Remote

signal transmitter

Large button

1st press

Turn to lock position

and release

Turn to lock position Continued hold of

and hold for

2 1st press for 2

seconds seconds

NIA 10 seconds of

first with vehicle

unlocked,

disarmed

(1st

press if vehicle is

locked and

armed) Small

button

NIA Locks all doors, trunk and

fuel filler cap. Arms alarm

system.

Locks

all doors, trunk lid and

fuel filler cap. Arms alarm

system. Key only; closes

open windows and sliding

roof in 1.5 seconds.

NIA Switches headlights on for

driver convenience.

NIA

DOOR UNLOCKING

Action

Unlock

Trunk lid release

Remote panic Device

operation I Function

Turn to unlock

position and release

NIA

NIA

NIA

NIA

NIA

1 st press Unlocks all doors,

trunk lid

(key only) and fuel filler cap.

Disarms alarm system.

Turns on interior lights for 15

seconds. Remote button

only; cancels trunk valet

lock-out and recalls

memorised driving position.

Trunk lid lock release.

2nd press

(press to be

within

10

seconds of

previous action)

3 second press Unlocks,

disarms and enters

full alarm state

ie audible

alarm (both sounder and

horn) and visual alarm

(flashing lights).