light JAGUAR XJ6 1994 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 376 of 521

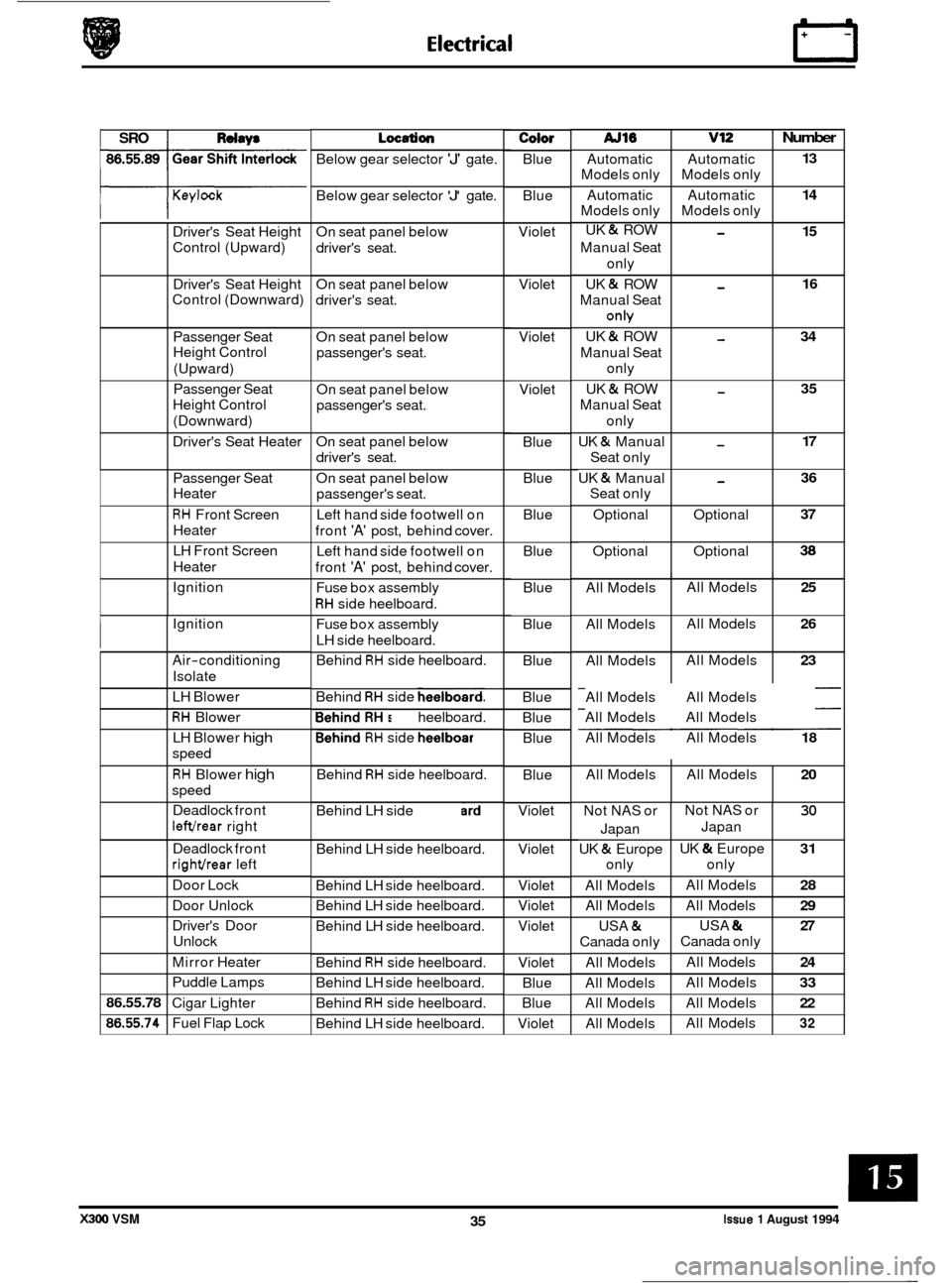

I SRO I Rdw* AJ16 v12

Automatic Automatic

Models only Models only

Automatic Automatic

Models only Models only

UK

& ROW -

Manual Seat

only

UK

& ROW -

Manual Seat

onh/

UK & ROW -

Manual Seat

only

Manual Seat

only

UK

& Manual -

Seat only

UK

& Manual -

Seat only

UK

& ROW -

Optional

Optional

Optional Optional

Keylock

Number

13

14

15

16

34

35

17

36

37

38

Driver's Seat Height

Control (Upward)

Driver's Seat Height

Control (Downward)

Passenger Seat

Height Control (Upward)

Passenger Seat

Height Control

(Downward)

Driver's Seat Heater

All Models

All Models

All Models

Passenger Seat

Heater

RH Front

Screen

Heater

LH Front Screen

Heater

Ignition All Models

25

All Models 26

All Models 23

Ignition

Air

-conditioning

Isolate

LH Blower

RH Blower

LH Blower

high

speed

RH Blower high

speed

Deadlock front

lefthear right All

Models All Models

20

Below gear selector 'J' gate.

Not NAS or

Japan

UK

& Europe

only

All Models

All Models

USA

&

Canada only

All Models

All Models

All Models

All Models

Below

gear selector

'J' gate.

Not NAS or

30

UK & Europe 31

All Models 28

All Models 29

USA & 27

All Models 24

All Models 33

All Models 22

All Models 32

Japan

only

Canada only

On

seat panel below

driver's seat.

86.55.78

86.55.74

On seat panel below

driver's seat.

Deadlock front

righthear left

Door Lock

Door Unlock

Driver's Door

Unlock

Mirror Heater

Puddle Lamps

Cigar Lighter

Fuel Flap Lock On

seat panel below

passenger's seat.

On seat panel below

passenger's seat.

On seat panel below

driver's seat.

On seat panel below

passenger's seat.

Left hand side footwell on

front

'A' post, behind cover.

Left hand side footwell on

front

'A' post, behind cover.

Fuse box assembly

RH side heelboard.

Fuse box assembly

LH side heelboard.

Behind

RH side heelboard.

Behind

RH side heelboard.

Behind RH side heelboard.

Behind

RH side heelboard.

Behind

RH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind

RH side heelboard.

Behind LH side heelboard.

Behind

RH side heelboard.

Behind LH side heelboard.

Color

Blue

Blue

Violet

Violet

Violet Violet Blue Blue

Blue

Blue

Blue

Blue

Blue

Blue

Blue Blue

Blue

Violet

Violet

Violet

Violet

Violet

Violet Blue

Blue

Violet All

Models All Models

All Models All Models

All Models All Models

18

X300 VSM 35 Issue 1 August 1994

Page 389 of 521

Specificat ion

Electrical Equipment (continued)

Starter

Make and type ..................................................... Bosch DW 1,7K

Free spin speed .................................................... 3000 RPM

Free spin current ................................................... 90A maximum

Load

running current ............................................... 420A maximum

Stall

............................................................... 1050A

Make and type ..................................................... Magneti Marelli M80R

Free spin speed .................................................... 2650 RPM

Free spin current ................................................... 75A maximum

Load

running current ............................................... 375A maximum

Stall

............................................................... 1000A

lindshield Wiper Motor

Make ............................................................. Trico

Light running speed: (after 60 seconds from cold)

Slowspeed

....................................................... 40-48cycles

Fast speed ........................................................ 57 -67 cycles

Light

running current:

Fastspeed

......................................................... 5A max.

Slow speed ........................................................ 2.5A max.

Page 397 of 521

Specification

w IfrnrnJ

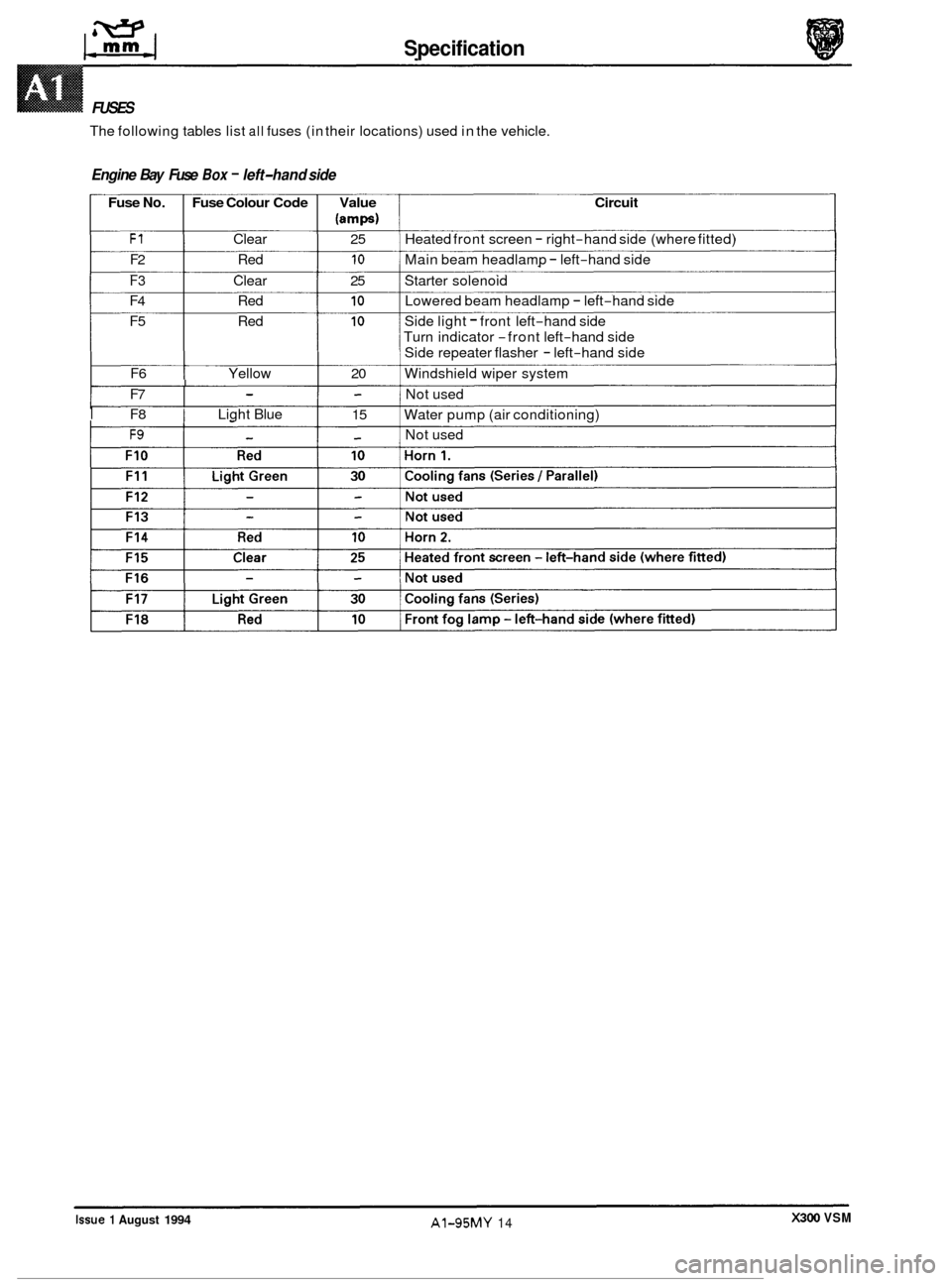

FUSES

The following tables list all fuses (in their locations) used in the vehicle.

Engine Bay Fuse Box - left-hand side

Fuse No. Fuse Colour Code Value Circuit

lamps)

F1 Clear 25 Heated front screen - right-hand side (where fitted)

F2 Red 10 Main beam headlamp - left-hand side

F3 Clear 25 Starter solenoid

F4 Red 10 Lowered beam headlamp - left-hand side

F5 Red 10 Side light - front left-hand side

Turn indicator

-front left-hand side

Side repeater flasher

- left-hand side

F6 Yellow 20 Windshield wiper system

I F8 I Light Blue

I Not used

F9 - - Not used

- - F7

15

Water pump (air conditioning) I - -

-l

X300 VSM Issue 1 August 1994 AI-95MY 14

Page 398 of 521

0

Engine Bay Fuse Box - right-hand side

Fuse No. Fuse Colour Code

- F1

F2 Red

F3

F4 Red

F5 Red

-

F6 Tan

F7 Clear

F8 Red

F9 -

FIO Tan

F12 Red

F13 Red

F14 Red F15

-

F16 Red

F17 Light Green

F18 Red

Value

(amps)

10

10

10

5

25

10

-

5

20

10

10

10

10

30

10

Circuit

Not used

Main beam headlamp

- right-hand side

Not used

Lowered beam

headlamD - riaht-hand side ."

Side light -front right-hand side

Turn indicator

-front right-hand side

Side repeater flasher

- right-hand side

Engine control module

(ECM)

Air pump (6 cyl. - where fitted)

Ignition coils

(VIZ)

Air conditioning clutch

Not used

Generator

Front lighting control module

- right-hand

Air conditioning clutch

Windshield wash

J headlamp power wash heaters and relays

Engine management system relay supply

Injectors

Engine management system

Starter relay Ignition coil sensing and air pump relay (6

cyl.)

Fuel injection relay

Engine management sensing

(VIZ)

Windshield washer pump

Lambda heaters

Idle speed control valve

Not used

Air pump control

Solenoid vacuum valve

(VIZ)

Water pump (supercharged)

Headlamp power wash pump

Front fog lamp

- right-hand side (where fitted)

0

0

Issue 1 August 1994 X300 VSM AI-95MY 15

Page 399 of 521

Specification

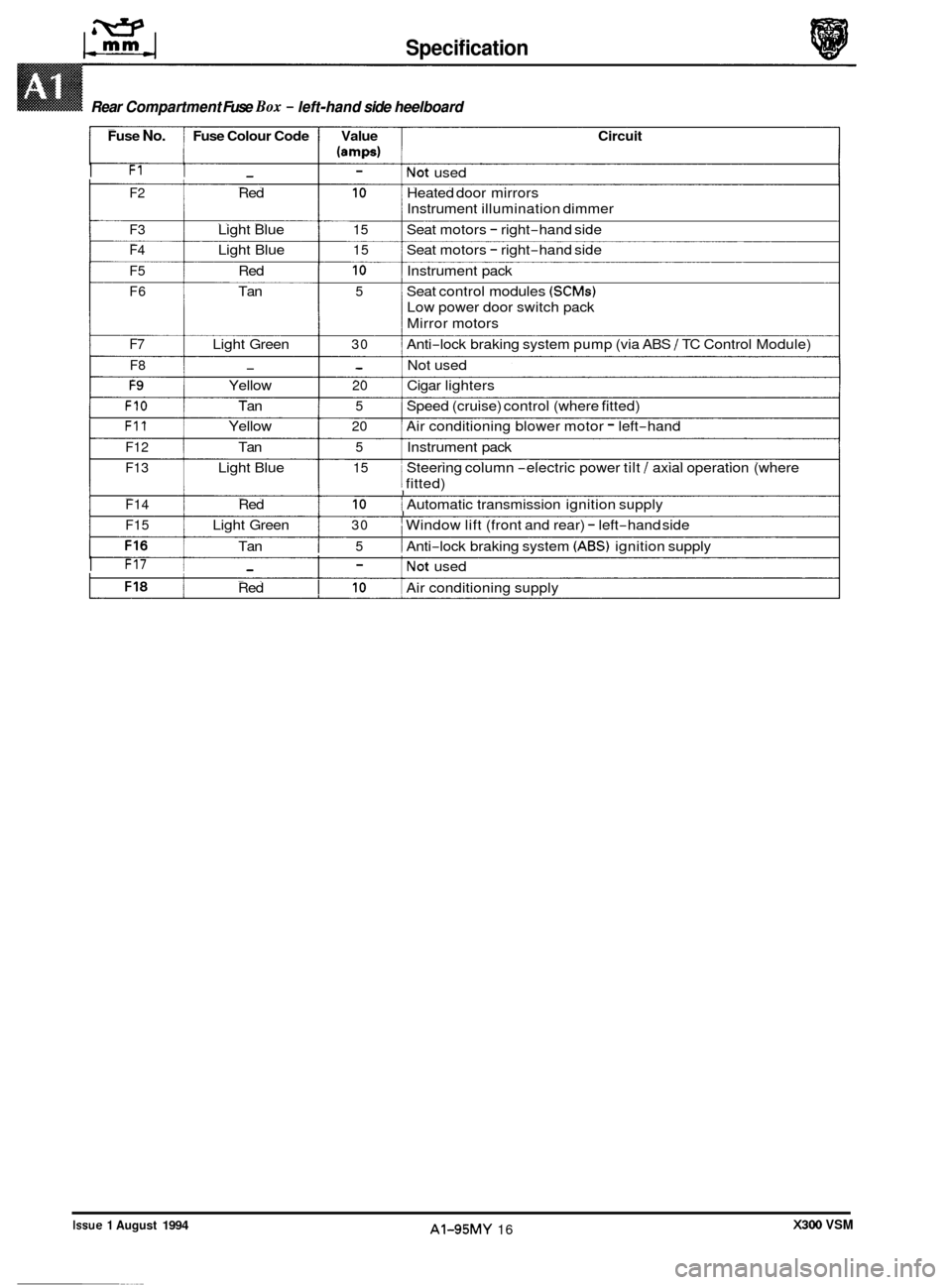

Rear Compartment Fuse Box - left-hand side heelboard

Fuse No. Fuse Colour Code Value Circuit

(amps)

I F1 I - I - lNot used

F2 Red 10 Heated door mirrors

F3 Light Blue 15 Seat motors - right-hand side

F4 Light Blue 15 Seat motors - right-hand side

F5 Red 10 Instrument pack

F6 Tan 5 Seat control modules (SCMs)

Low power door switch pack

Mirror motors

Instrument

illumination dimmer

F7 Light Green 30 Anti-lock braking system pump (via ABS / TC Control Module)

F8 - - Not used

F9 Yellow 20 Cigar lighters

FIO Tan 5 Speed (cruise) control (where fitted)

F11 Yellow 20 Air conditioning blower motor - left-hand

F12 Tan 5 Instrument pack

F13 Light Blue 15 Steering column -electric power tilt / axial operation (where

j fitted) 1 I I F14 Red 10 i Automatic transmission ignition supply I I I F15 Light Green 30 I Window lift (front and rear) - left-hand side

Tan

I 5 1 Anti-lock braking system (ABS) ignition supply

I F17 1 - I - lNot used

Red

I 10 I Air conditioning supply

Rear Compartment Fuse Box - left-hand side heelboard ~~

X300 VSM Issue 1 August 1994 AI-95MY 16

0

0

0

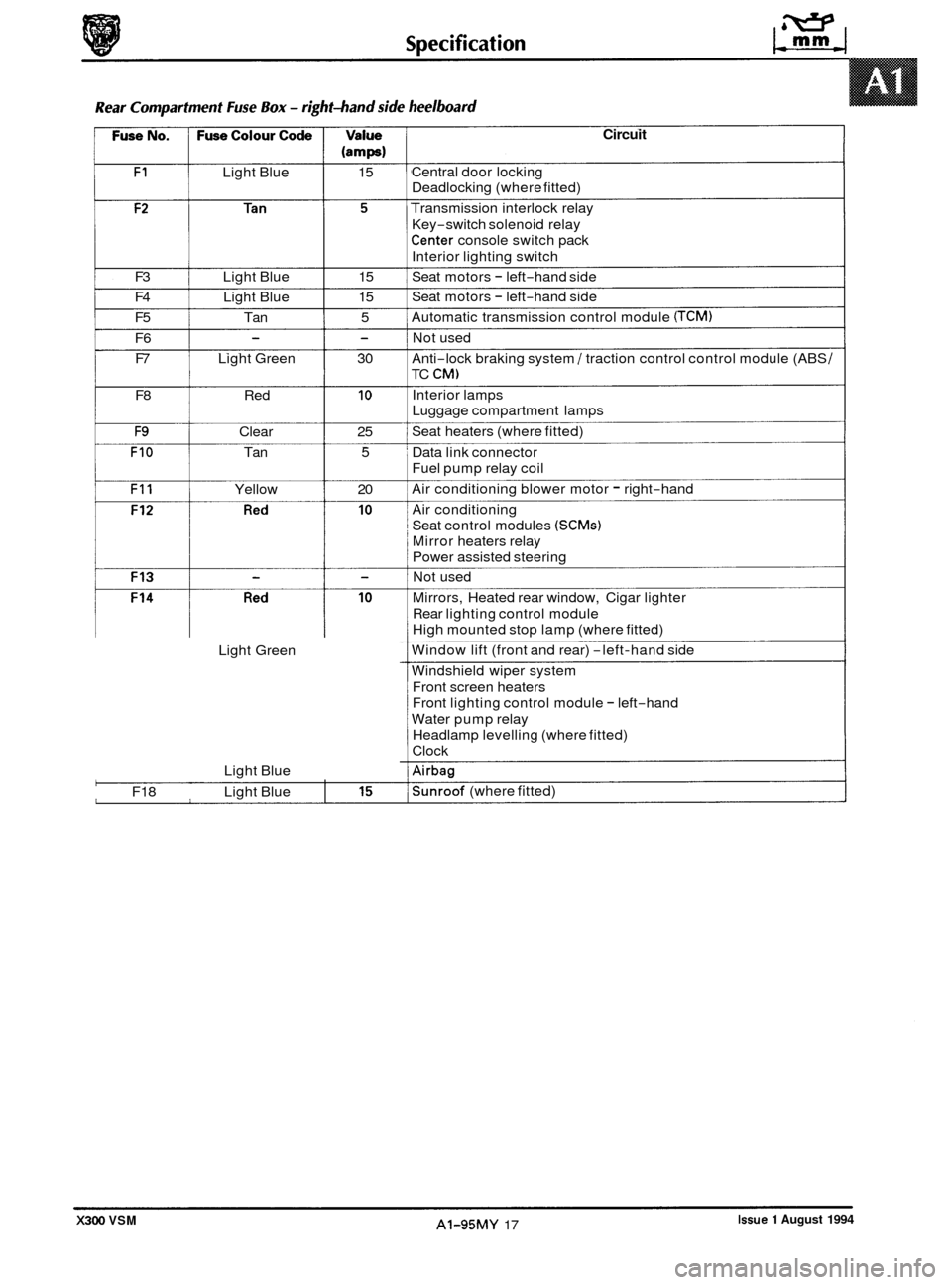

Page 400 of 521

(amps)

F1 Light Blue 15

F3 Light Blue 15

F4 Light Blue 15

F5 Tan 5

F6 F7 Light Green 30

- -

F8 Red 10

F9 Clear 25

FIO Tan 5

F11 Yellow 20 0

Light Green

Light Blue

F18 Light Blue

0'

I

Circuit

Central door locking

Deadlocking (where fitted)

Transmission interlock relay

Key

-switch solenoid relay

Center console switch pack

Interior lighting switch

Seat motors

- left-hand side

Seat motors

- left-hand side

Automatic transmission control module

(TCM)

Not used

Anti

-lock braking system / traction control control module (ABS /

TC CM)

Interior lamps

Luggage compartment lamps

Seat heaters (where fitted)

Data link connector

Fuel pump relay coil

Air conditioning blower motor

- right-hand

Air conditioning

Seat control modules

(SCMs)

Mirror heaters relay

Power assisted steering

Not used

Mirrors, Heated rear window, Cigar lighter

Rear lighting control module

High mounted stop lamp (where fitted)

Window lift (front and rear)

-left-hand side

Windshield wiper system Front screen heaters

Front lighting control module

- left-hand

Water pump relay

Headlamp levelling (where fitted)

Clock

Airbag

Sunroof (where fitted)

Issue 1 August 1994 AI-95MY 17 X300 VSM

Page 401 of 521

Clear

(amps) 1

Circuit

I

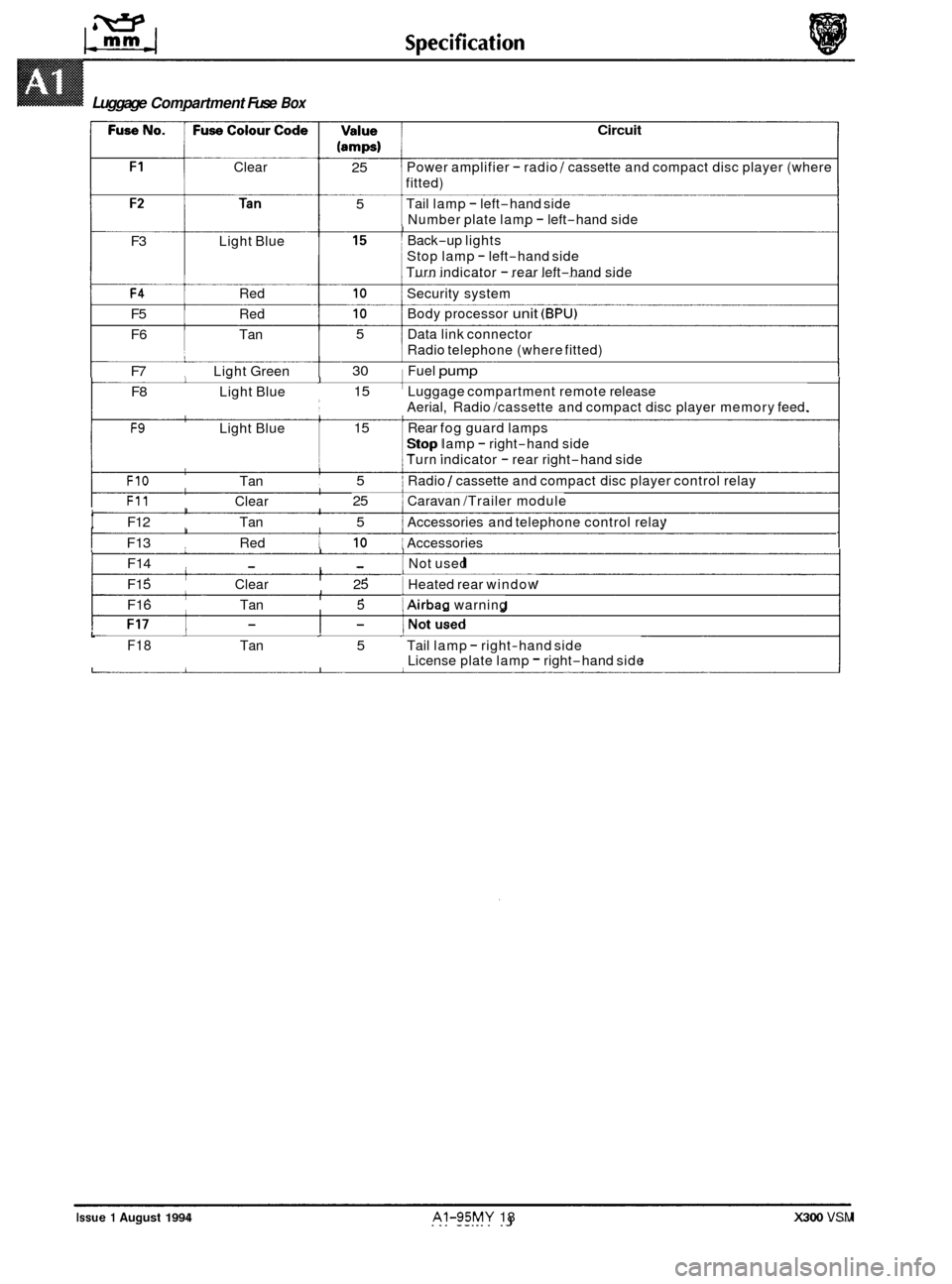

25 5 Power amplifier - radio / cassette and compact disc player (where

fitted)

Tail lamp

- left-hand side

Number plate lamp

- left-hand side I Back-up lights

Stop lamp

- left-hand side

Turn indicator

- rear left-hand side

F3 Light Blue

F4 Red 10 Security system

F5 Red 10 Body processor unit (BPU)

F6 Tan 5 Data link connector

F7 Light Green 30 Fuel pump

F8 Light Blue 15 Luggage compartment remote release

F9 Light Blue 15 i Rear fog guard lamps

Radio

telephone (where fitted)

1

Aerial, Radio /cassette and compact disc player memory feed.

Stop lamp

- right-hand side

1 Turn indicator - rear right-hand side I.

I FIO Tan 5 i Radio / cassette and compact disc player control relay

F11 Clear 25 1 Caravan /Trailer module I

t F12 Tan 5 ~ Accessories

and telephone control relay I I

I I I F13 Red 10 ~ Accessories 1 1 I I F14 - - I Not used 1 I I F15 Clear 25 1 Heated

rear window I I I F16 Tan 5 1 Airbag warning

Luggage Compartment Fuse Box

Issue 1 August 1994 AI-95MY 18 X300 VSM

L F18 Tan 5 Tail lamp - right-hand side

License plate lamp - right-hand side

Page 413 of 521

General Fitting Instructions

A3.2 GENERAL FITTING INSTRUCTIONS

A3.2.1

Always fit covers to protect the wings before commencing work in the engine compartment. Cover the seats and

carpets, wear clean overalls and wash hands or wear gloves before working inside the car. Avoid spilling hydraulic

fluid, anti

-freeze or battery acid on the paintwork. In the event of spillage, wash off with water immediately. Use poly- thene sheets in the boot to protect carpets. Always use the recommended service tool, or a satisfactory equivalent,

where specified. Protect temporarily exposed screw threads by replacing nuts or fitting caps.

Precautions Against Damage To The Vehicle

A3.2.2 Preparation

Before disassembly, clean the surrounding area as thoroughly as possible. When components have been removed,

blank off any exposed openings using greaseproof paper and masking tape. Immediately seal fuel, oil and hydraulic

lines when separated, using plastic caps or plugs, to prevent loss of fluid and the entry of dirt. Close the open ends

of oilways, exposed by component removal, with tapered hardwood plugs or readily visible plastic plugs. Immediately

a component is removed, place

it in a suitable container; use a separate container for each component and its asso- ciated parts. Before dismantling a component, clean it thoroughly with a recommended cleaning agent: check that the

agent will not damage any of the materials within the component. Clean the bench and obtain marking materials, la-

bels, containers and locking wire before dismantling a component.

A3.2.3 Dismantling

Observe scrupulous cleanliness when dismantling components, particularly when parts of the brake, fuel or hydraulic

system are being worked on. A particle of dirt or a fragment of cloth could cause a dangerous malfunction if trapped in these systems. Clean all tapped holes, crevices, oilways and fluid passages with compressed air.

WRNIFLG: DO NOT PERMIT COMPRESSED AIR TO ENTER AN OPEN WOUND. ALWAYS USE EVE PROTECTION

WHEN USING COMPRESSED AIR.

Ensure that any 'O'-rings used for sealing are correctly refitted or renewed if disturbed. Mark mating parts to ensure

that they are replaced as dismantled. Whenever possible use marking materials which avoid the possibilities of caus- ing distortion or the initiation of cracks, which could occur if a center punch or scriber were used. Wire together mating

parts where necessary to prevent accidental interchange (e.g roller bearing components). Tie labels on to all parts to

be renewed and to parts requiring further inspection before being passed for reassembly.

Place labelled parts and other parts for rebuild

in separate containers.

Do not discard a part which is due for renewal until it has been compared with the new part, to ensure that the correct

part has been obtained.

A3.2.4 Inspection

Before inspecting a component for wear or performing a dimensional check, ensure that it is absolutely clean; a slight

smear of grease can conceal an incipient failure. When a component is to be checked dimensionally against figures

quoted for

it, use the correct equipment (surface plates, micrometers, dial gauges etc.) in serviceable condition. The

use of makeshift equipment can be dangerous. Reject a component if its dimensions are outside the limits quoted,

or if damage is apparent. A part may be refitted if its critical dimension is exactly to the limit size and it is otherwise

satisfactory. Use Plastigauge 12 Type PG-1 for checking bearing surface clearance e.g. big end bearing shell to crank

journal. Instructions for the use of Plastigauge and a scale giving bearing clearances in steps of

0,0025 mm (0.0001

in) are supplied with the package.

0

0

0

X300 VSM Issue 1 August 1994 2

Page 416 of 521

General Fitting Instructions

Issue 1 August 1994 5 X300 VSM I

0

0

0

0

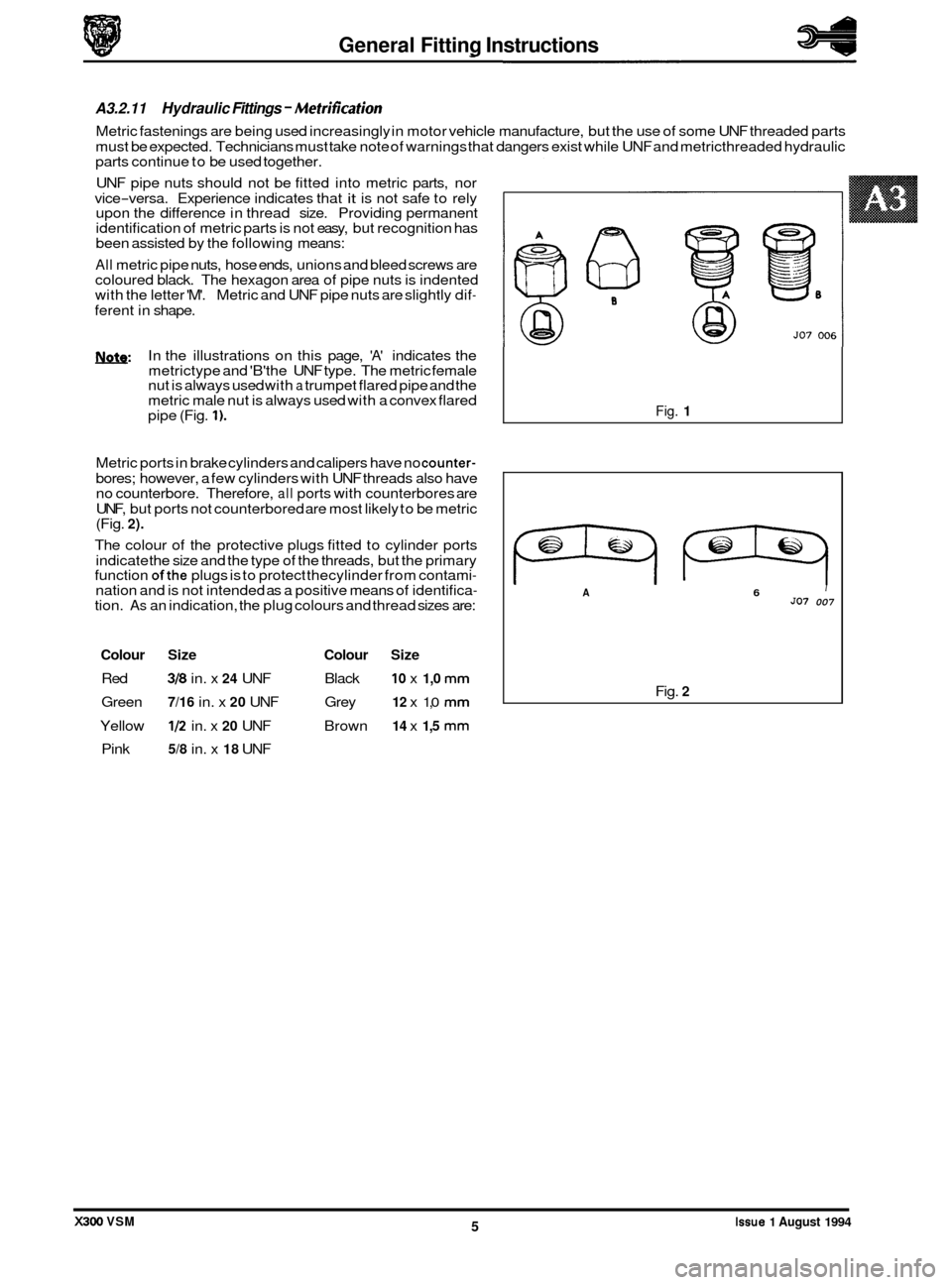

A3.2.11 Hydraulic Fittings - Metrification

Metric fastenings are being used increasingly in motor vehicle manufacture, but the use of some UNF threaded parts

must be expected. Technicians must take note of warnings that dangers exist while UNF and metricthreaded hydraulic

parts continue to be used together.

UNF pipe nuts should not be fitted into metric parts, nor

vice

-versa. Experience indicates that it is not safe to rely

upon the difference in thread size. Providing permanent

identification of metric parts is not easy, but recognition has

been assisted by the following means:

All metric pipe nuts, hose ends, unions and bleed screws are

coloured black. The hexagon area of pipe nuts is indented

with the letter 'M'. Metric and UNF pipe nuts are slightly dif

-

ferent in shape.

hlnfe: In the illustrations on this page, 'A' indicates the

metrictype and 'B'the UNF type. The metric female

nut is always used with

a trumpet flared pipe and the

metric male nut is always used with a convex flared

pipe (Fig.

1).

Metric ports in brake cylinders and calipers have no counter-

bores; however, a few cylinders with UNF threads also have

no counterbore. Therefore, all ports with counterbores are

UNF, but ports not counterbored are most likely to be metric

(Fig.

2).

The colour of the protective plugs fitted to cylinder ports

indicate the size and the type of the threads, but the primary

function

ofthe plugs is to protect thecylinder from contami- nation and is not intended as a positive means of identifica- tion. As an indication, the plug colours and thread sizes are:

Colour Size Colour Size

Red 318 in. x 24 UNF Black 10 x 1,0 mm

Green 7/16 in. x 20 UNF Grey 12 x 1,0 mm

Yellow 112 in. x 20 UNF Brown 14 x 1,5 mm

Pink 5/8 in. x 18 UNF

Fig. 1

A 6 I 507 007

Fig. 2

Page 417 of 521

General Fitting Instructions

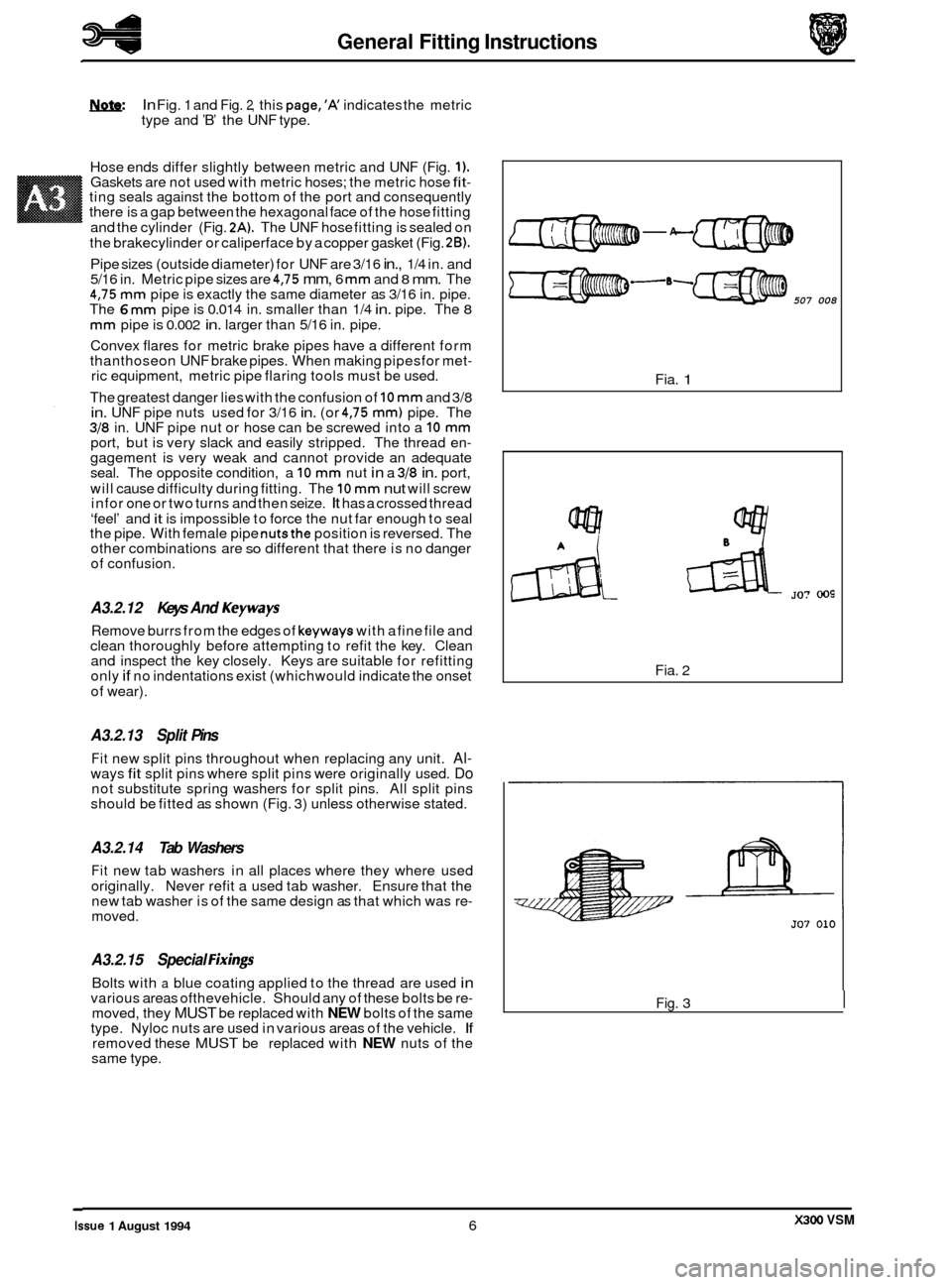

In Fig. 1 and Fig. 2, this page,’K indicates the metric

type and ’B’ the UNF type.

Hose ends differ slightly between metric and UNF (Fig.

1). Gaskets are not used with metric hoses; the metric hose fit- ting seals against the bottom of the port and consequently

there is a gap between the hexagonal face of the hose fitting

and the cylinder (Fig.

2A). The UNF hose fitting is sealed on

the brakecylinder or caliperface by a copper gasket (Fig.

2B).

Pipe sizes (outside diameter) for UNF are 3/16 in., 1/4 in. and

5/16 in. Metric pipe sizes are 4,75 mm, 6 mm and 8 mm. The 4,75 mm pipe is exactly the same diameter as 3/16 in. pipe.

The 6 mm pipe is 0.014 in. smaller than 1/4 in. pipe. The 8

mm pipe is 0.002 in. larger than 5/16 in. pipe.

Convex flares for metric brake pipes have a different form

thanthoseon UNF brake pipes. When making pipesfor met

- ric equipment, metric pipe flaring tools must be used.

The greatest danger lies with the confusion of

10 mm and 3/8 in. UNF pipe nuts used for 3/16 in. (or 4,75 mm) pipe. The 318 in. UNF pipe nut or hose can be screwed into a 10 mm port, but is very slack and easily stripped. The thread en- gagement is very weak and cannot provide an adequate

seal. The opposite condition, a 10 mm nut in a 318 in. port,

will cause difficulty during fitting. The

10 mm nut will screw

in for one or two turns and then seize. It has a crossed thread

‘feel’ and

it is impossible to force the nut far enough to seal

the pipe. With female pipe nutsthe position is reversed. The

other combinations are so different that there is no danger

of confusion.

A3.2.12 Keys And Keyways

Remove burrs from the edges of keyways with a fine file and

clean thoroughly before attempting to refit the key. Clean

and inspect the key closely. Keys are suitable for refitting

only

if no indentations exist (which would indicate the onset

of wear).

A3.2.13 Split Pins

Fit new split pins throughout when replacing any unit. Al- ways fit split pins where split pins were originally used. Do not substitute spring washers for split pins. All split pins

should be fitted as shown (Fig. 3) unless otherwise stated.

A3.2.14 Tab Washers

Fit new tab washers in all places where they where used

originally. Never refit a used tab washer. Ensure that the

new tab washer is of the same design as that which was re

- moved.

A3.2.15 Special Fixing

Bolts with a blue coating applied to the thread are used in various areas ofthevehicle. Should any of these bolts be re- moved, they MUST be replaced with NEW bolts of the same

type. Nyloc nuts are used in various areas of the vehicle. If removed these MUST be replaced with NEW nuts of the

same type.

-A

507 008

Fia. 1

Fia. 2

Fig. 3 I

X300 VSM Issue 1 August 1994 6