clock JAGUAR XJ6 1994 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 43 of 521

Engine (AJ16)

3.1.2 ENGlNE/ TRANSMlSSlON UN/& RENEW

SRO 12.41.02/20

The engine/transmission unit on the AJ 16 normally aspirated and supercharged engined vehicles are fitted ontothree

engine mounting/bracket assemblies. The two front engine mountings for the 3.2/4.0 liter normally aspirated and the

4.0 liter supercharged engined vehicles are identical. They are fitted to the front crossmember on either side of the

engine bay. Rubber to metal

engine/transmission rear mounts used for both engine types, are secured to a support

bracket which traverses the two body underframe longitudinal members. For access to remove the engine carry out the following procedures:

WARNING: WHEN WORKING WlTHlN THE ENGINE COMPARTMENT, KEEP CLEAR OF THE RADIATOR COOLING

FANS AS THEY COULD START WITHOUT WARNING EVEN IF THE ENGINE IS NOT RUNNING.

. Remove the hood, see SRO 76.16.01, section 13

. Remove the air cleaner assembly.

. Depressurize the fuel system, see SRO 19.50.02, section 5.1.

Disconnect the battery.

. In line with the relevant SRO's and sections, remove all appropriate obstructing parts, including their fixing and

. Disconnect all mechanical and isolate all electrical linkages leading to and from the engine.

. De-gas the airconditioning system, see section 14, Charge Recovery (System depressurization).

mounting

arrangements.

CAUTION : Do not vent refrigerant directly to the atmosphere and always use Jaguar approved recovery/recycle/re- charge equipment.

. Drain the engine oil, see 3.1.3 this section.

. Drain the coolant, see SRO 26.10.01, section 4.1.

WARNING: DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI- CLOCKWISE UNTILTHE EXCESS PRESSURE CAN ESCAPE. LEAVETHE CAP IN THIS POSITION UNTIL ALL

STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

Before lifting the complete engine/transmission unit with an engine hoist from the engine bay, ensure that two engine

lifting brackets (tool 18G. 1465) are secured equally spaced to the inlet manifold studs. The engine lifting brackets

should be positioned towards the front and the rear of the assembly. Ensure the front of the vehicle is jacked

up secure- ly on stands when removing the assembly.

e

0

0

X300 VSM Issue 1 August 1994 2

Page 49 of 521

3.2.2 ENGINE - GEARBOX/ TRANSMISSION

ASSEMBLY, RENEW

SRO 12.37.01/90

The engine /transmission unit on the V12 6.0 liter model is mounted on three engine mounting / bracket assemblies

fitted to the front crossmember on either side of the engine bay. The engine/ transmission rear mount is a mounting

bracket and spring assembly fitted and secured to body underframe longitudinal members. For access to remove the

engine carry

out the following procedures:

WARNING: WHEN WORKING WITHIN THE ENGINE COMPARTMENT, KEEP CLEAR OF THE RADIATOR COOLING

FANS AS THEY COULD START WITHOUT WARNING, EVEN IF THE ENGINE IS NOT RUNNING.

. Remove the hood, see SRO 76.16.01, section 13.

. Remove the two air cleaner assemblies, see SRO’s 19.10.01 & 19.10.02.

. Remove the engine cover, see SRO 12.29.93 (V12 Engine Service Manual).

Depressurize the fuel system, see SRO 19.50.02, section 5.1.

In line with the relevant SRO’s and sections, remove all appropriate obstructing parts, including their fixing and

. Disconnect all mechanical and isolate all electrical linkages leading to and from the engine.

. De-gas the air conditioning system, see section 14, Charge Recovery (System depressurization).

Disconnect

the battery.

mounting arrangements.

CAUTION: Do

not vent refrigerant directly to the atmosphere and always use Jaguar approved recovery/recycle/ra charge equipment.

Drain the engine oil, see 3.2.3 this section.

Drain the coolant, see SRO 26.10.01, section 4.1.

WARNING: DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL ALL

STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

Before

lifting the complete engine/transmission unit with an engine hoist from the engine bay, ensure that two engine

lifting brackets (tool 18G. 1465) are secured equallyspaced to the inlet manifold studs. The four engine lifting brackets

should be positioned towards the front and the rear of the assembly. Ensure the front of thevehicle is jacked

up secure- ly on stands when removing the assembly.

X300 VSM Issue 1 August 1994 2

Page 58 of 521

area washed to remove all traces of coolant.

CAUTION: To prevent the possibility of damage to the heater circuit pump and supercharger pump (where fitted),

the pumps should be electrically isolated if the ignition has to be turned ON while the cooling system is

drained.

WARNING: DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI

- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL

ALL THE STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT WITH THE ENGINE HOT, PROTECT THE HANDS AGAINST CONTACT

WITH HOT COOLANT.

WARNING: WHEN WORKING WITHIN THE ENGINE COMPARTMENT, KEEP CLEAR OF THE RADIATOR COOLING

FANS. THE FANS COULD START WITHOUT WARNING EVEN IF THE ENGINE IS NOT RUNNING.

4.1.3.2 Working Practices

Whenfilling thesystem with coolant,ensurethatthevehicle isstanding on a level surfaceandthatthecoolant is poured

in slowly so that airlocks are not introduced into the system. Airlocks can seriously affect the operation of the climate

control system and can cause damage to the heater circuit pump (and supercharger circuit pump if fitted).

Cooling System (AJ16)

4.1.3 SERVICE PROCEDURES

4.1.3.1 Safety Precautions

The anti-freeze specified in Appendix AI must be used wherever possible. It is designed to afford the maximum cor- rosion protection to all metals found in the engine cooling system, as well as having the frost protection properties

necessary during the winter months.

Should

it not be available, then anti-freeze conforming to Ford Motor Company specification ESLbM97B49-A may be

used. To provide optimum temperature and corrosion protection, the specified anti-freeze concentration must always

be used.

Once coolant has been drained from the system,

it must be discarded and not reused. Anti-freeze is harmful to the

environment. Used coolant must be disposed of safely and never poured down a drain connected to the public sewer.

CAUTION: Never fill or topup the system with water only.

CAUTION : Anti-freeze is harmful to paintwork. Coolant spillages must be wiped up immediately and the affected

Hose clips should always be positioned so that there is proper access for tightening and that the clip does not foul or

interfere with the operation of any components.

Drive belts must always be tensioned to the specified value and the tension checked

at the correct point on the belt.

This information is given in Subsection IV in the preliminary pages.

0

When tightening components, the torque figures given in Sukection II in the preliminary pages should always be

used for the fastenings listed.

4.1.3.3 Coolant Change

The coolant must be changed at intervals of four years. The system should be drained from the radiator drain plug,

flushed and filled with fresh coolant. Flushing should be carried out thoroughly to remove all the old coolant from the

engineand heater matrix. (The heatervalve isopen withthe ignition OFF). AfterfiIling,checkthecoolant concentration

with a hydrometer. For the specified anti-freeze and coolant concentration, see Appendix AI.

X300 VSM 3 Issue 1 August 1994

Page 59 of 521

€3 Cooling System (AJ16)

4.1.4 DRAIN AND FILL PROCEDURES

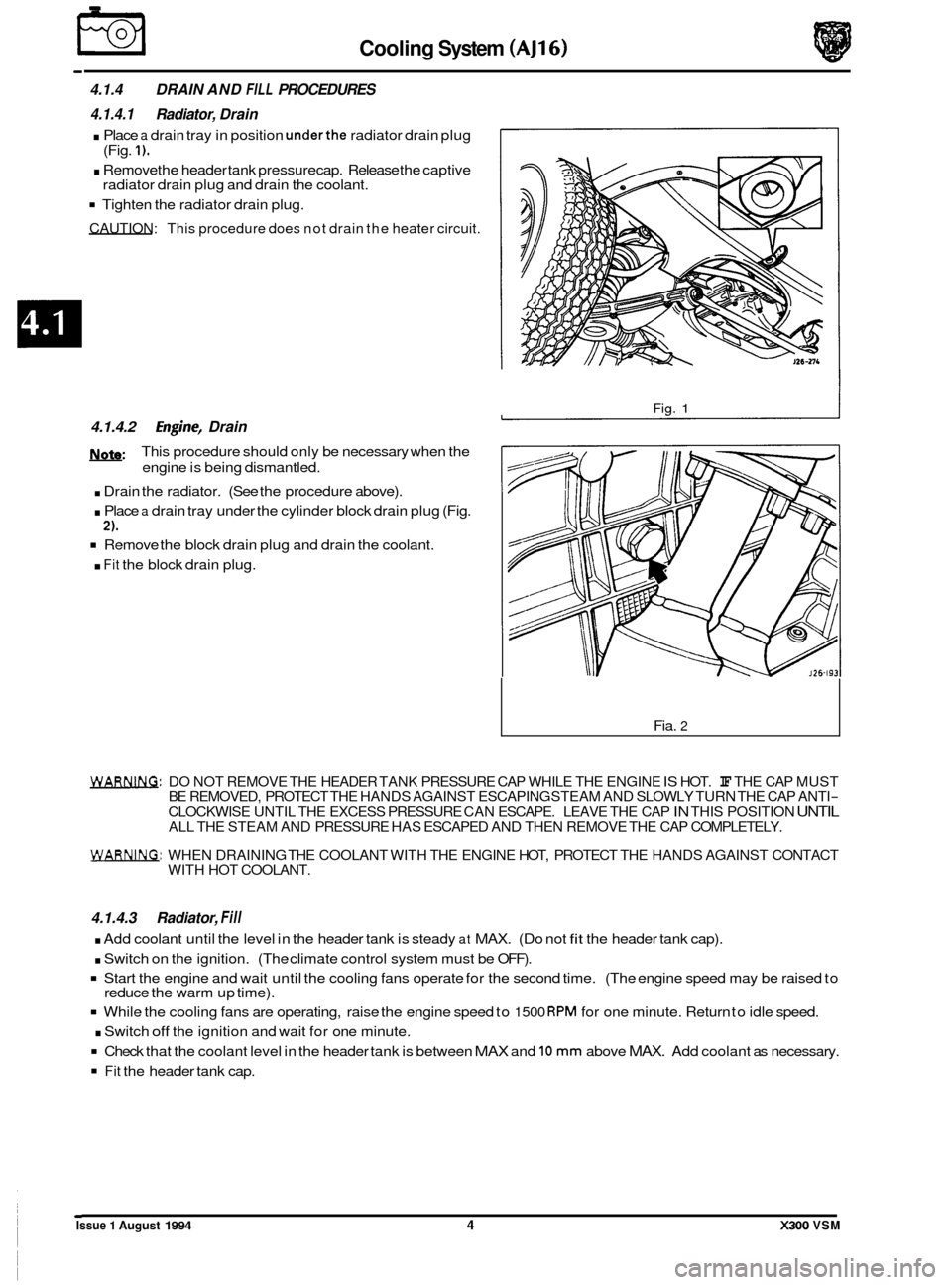

4.1.4.1 Radiator, Drain

. Place a drain tray in position underthe radiator drain plug

. Remove the header tank pressure cap. Release the captive

Tighten the radiator drain plug.

CAUTION: This procedure does not drain the heater circuit.

(Fig. 1).

radiator drain plug and drain the coolant.

4.1.4.2 Engh-, Drain

m:

. Drain the radiator. (See the procedure above).

. Place a drain tray under the cylinder block drain plug (Fig.

Remove the block drain plug and drain the coolant.

. Fit the block drain plug.

This procedure

should only be necessary when the

engine is being dismantled.

2).

Fig. 1

Fia. 2

WAm. DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL ALL THE STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT WITH THE ENGINE HOT, PROTECT THE HANDS AGAINST CONTACT

WITH HOT COOLANT.

4.1.4.3 Radiator, Fill

. Add coolant until the level in the header tank is steady at MAX. (Do not fit the header tank cap).

. Switch on the ignition. (The climate control system must be OFF).

Start the engine and wait until the cooling fans operate for the second time. (The engine speed may be raised to

While the cooling fans are operating, raise the engine speed to 1500 RPM for one minute. Return to idle speed.

. Switch off the ignition and wait for one minute.

Check that the coolant level in the header tank is between MAX and 10 mm above MAX. Add coolant as necessary.

Fit the header tank cap.

reduce

the warm up time).

Issue 1 August 1994 4 X300 VSM

Page 68 of 521

WARNING: DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL

ALL THE STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT WITH THE ENGINE HOT, PROTECT THE HANDS AGAINST CONTACT

WITH HOT COOLANT.

WARNING

: WHEN WORKING WITHIN THE ENGINE COMPARTMENT, KEEP CLEAR OF THE ENGINE DRIVEN RADI- ATOR COOLING FAN WHEN THE ENGINE IS RUNNING.

4.2.3.2 Working Practices

Whenfilling thesystem with coolant,ensurethatthevehicle isstanding on a level surfaceand thatthecoolant is poured

in slowly so that airlocks are not introduced into the system. Airlocks can seriously affect the operation of the climate

control system and can cause damage to the heater circuit pump.

Hose clips should always be positioned

so that there is proper access for tightening and that the clip does not foul or

interfere with the operation of any components.

4.2.3 SERVICE PROCEDURES

4.2.3.1 Safety Precautions

The anti-freeze specified in Appendix A1 must be used wherever possible. It is designed to afford the maximum cor- rosion protection to all metals found in the engine cooling system, as well as having the frost protection properties

necessary during the winter months. Should it not be available, then anti-freeze conforming to Ford Motor Company

specification

ESBM97B49-A may be used. To provide optimum temperature and corrosion protection, the specified

anti-freeze concentration must always be used. Once coolant has been drained from the system, it must be discarded

and not reused. Anti-freeze is harmful to the environment. Always dispose of used coolant safely and never pour it down a drain connected to the public sewer.

CAUTION: Never fill or topup the system with water only.

CAUTION

: Anti-freeze is harmful to paintwork. Coolant spillages must be wiped up immediately and the affected

area washed to remove all traces of coolant.

CAUTION: To prevent the possibility of damage to the heater circuit

pump, the pump should be electrically isolated if the ignition has to be turned ON while the cooling system is drained.

The drive belt must always be tensioned to the specified value and the tension checked at the correct point on the belt.

This information is given in Sub-section IV in the preliminary pages.

When tightening components, the torque figures given in Sub

-section II in the preliminary pages should always be

used for the fastenings listed.

When fitting a replacement thermostat, ensure that the jiggle-pin is to the top of the thermostat housing.

4.2.3.3 Coolant Change

The coolant must be changed at intervals of four years. The system should be drained from the radiator drain plug,

flushed and filled with fresh coolant. Flushing should be carried out thoroughly to remove all the old coolant from the

engine and heater matrix. (The heatervalve isopen with the ignition OFF). AfterfilIing,checkthecoolant concentration

with a hydrometer. For specified anti-freeze and coolant concentration, see in Appendix Al.

X300 VSM 3 Issue 1 August 1994

Page 69 of 521

€3 Cooling System (V12)

4.2.4 DRAIN AND FILL PROCEDURES

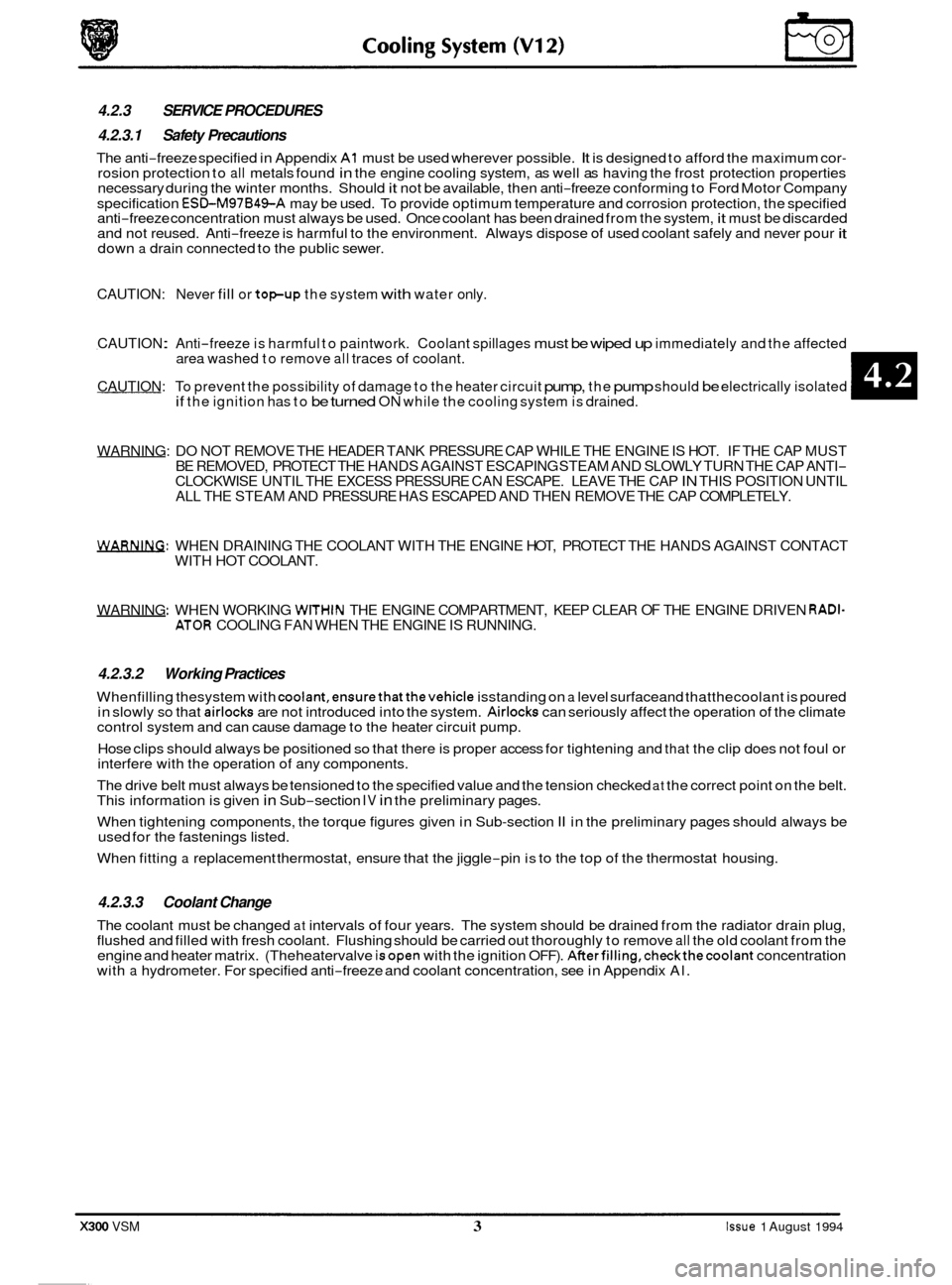

4.2.4.1 Radiator, Drain

. Place a drain tray in position under the radiator drain plug

. Remove the headertank pressure cap. Release thecaptive

Tighten the radiator drain plug.

(Fig.

1).

radiator drain

plug and drain the coolant.

CAUTION: This procedure does not drain the heater cir- cuit.

m: DO NOT REMOVE THE HEADER TANK PRES- SURE CAP WHILE THE ENGINE IS HOT. IF THE

CAP MUST BE REMOVED, PROTECT THE

HANDS AGAINST ESCAPING STEAM AND

SLOWLY TURN THE CAP

ANTI-CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE.

LEAVE THE CAP IN THIS POSITION UNTIL ALL

THE STEAM AND PRESSURE HAS ESCAPED

AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT

WITH THE

ENGINE HOT, PROTECT ME HANDS AGAINST

CONTACT WITH HOT COOLANT.

Fig. 1

4.2.4.2 Radiator, Fill

. Add coolant until the level in the header tank is steady at MAX. (Do not fit the header tank cap).

. Switch on the ignition. (The climate control system must be OFF).

. Start the engine and add coolant to the header tank if required to ensure that it does not empty.

. Run the engine until thetemperature gauge reads normal. (The enginespeed may be raised to reduce warm uptime).

. Switch off the ignition and wait for one minute.

Check that the coolant level in the header tank is between MAX and

10 mm above MAX. Add coolant as necessary.

. Fit the header tank cap.

4.2.4.3 Complete System, Fill

. Add coolant until the level in the header tank is steady at MAX. (Do not fit the header tank cap).

= Switch on the ignition. (The climate control system must be OFF).

. Start the engine and add coolant to the header tank if required to ensure that it does not empty.

. Run the engine until the temperature gauge reads normal, (The engine speed may be raised to reduce the warm up

. Turn the climate control system ON. Set the temperature to HI. Manually select a fan speed of approximately 50%.

. Run the engine for four minutes. Ensure that the climate control system outlet air temperature is hot to very hot and

that there is no noise from the heater coolant circulating pump. (The engine speed may be raised to assist with heat- ing).

time).

8 Switch

off the ignition and wait for one minute.

. Check that the coolant level in the header tank is between MAX and 10 mm above MAX. Add coolant as necessary.

. Fit the header tank cap.

4.2.4.4 System, Air Bleeding

After filling the system with coolant, any air present must be purged before effective cooling is possible. Provided the

correct fill procedure has been followed, purging of the system takes place automatically as follows:

The air entrained by the coolant, rises to the top of the radiator and to the highest point on each side of the engine (the

thermostat housings). While the thermostats are closed, the radiator is under reduced pressure due to the pump suc

- tion and air is bled through the jiggle-pins in each thermostat. Purged air is returnedvia the bleed system to the header

tank. When normal operating temperature is reached, the thermostats open and the system operates normally. ~~

Issue 1 August 1994 4 X300 VSM

Page 202 of 521

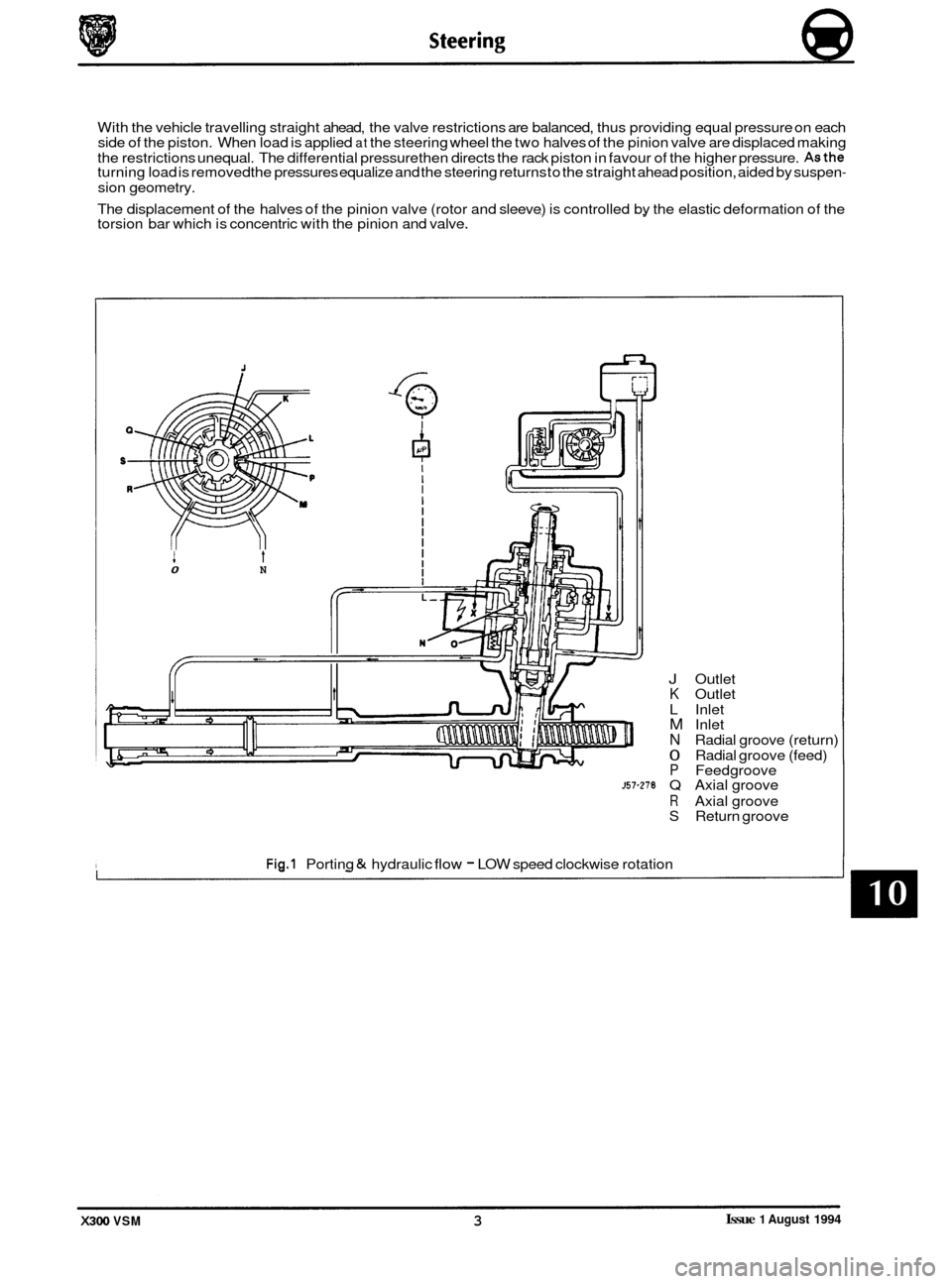

With the vehicle travelling straight ahead, the valve restrictions are balanced, thus providing equal pressure on each

side of the piston. When load is applied at the steering wheel the two halves of the pinion valve are displaced making

the restrictions unequal. The differential pressure then directs the rack piston in favour of the higher pressure.

Asthe turning load is removed the pressures equalize and the steering returns to the straight ahead position, aided by suspen-

sion geometry.

The displacement

of the halves of the pinion valve (rotor and sleeve) is controlled by the elastic deformation of the

torsion bar which is concentric with the pinion and valve.

0 N

J Outlet K Outlet

L Inlet

M Inlet

N Radial groove (return)

0 Radial groove (feed) P Feedgroove ~57-278 Q Axial groove

R Axial groove S Return groove

Fig.1 Porting & hydraulic flow - LOW speed clockwise rotation

Issue 1 August 1994 X300 VSM 3

Page 203 of 521

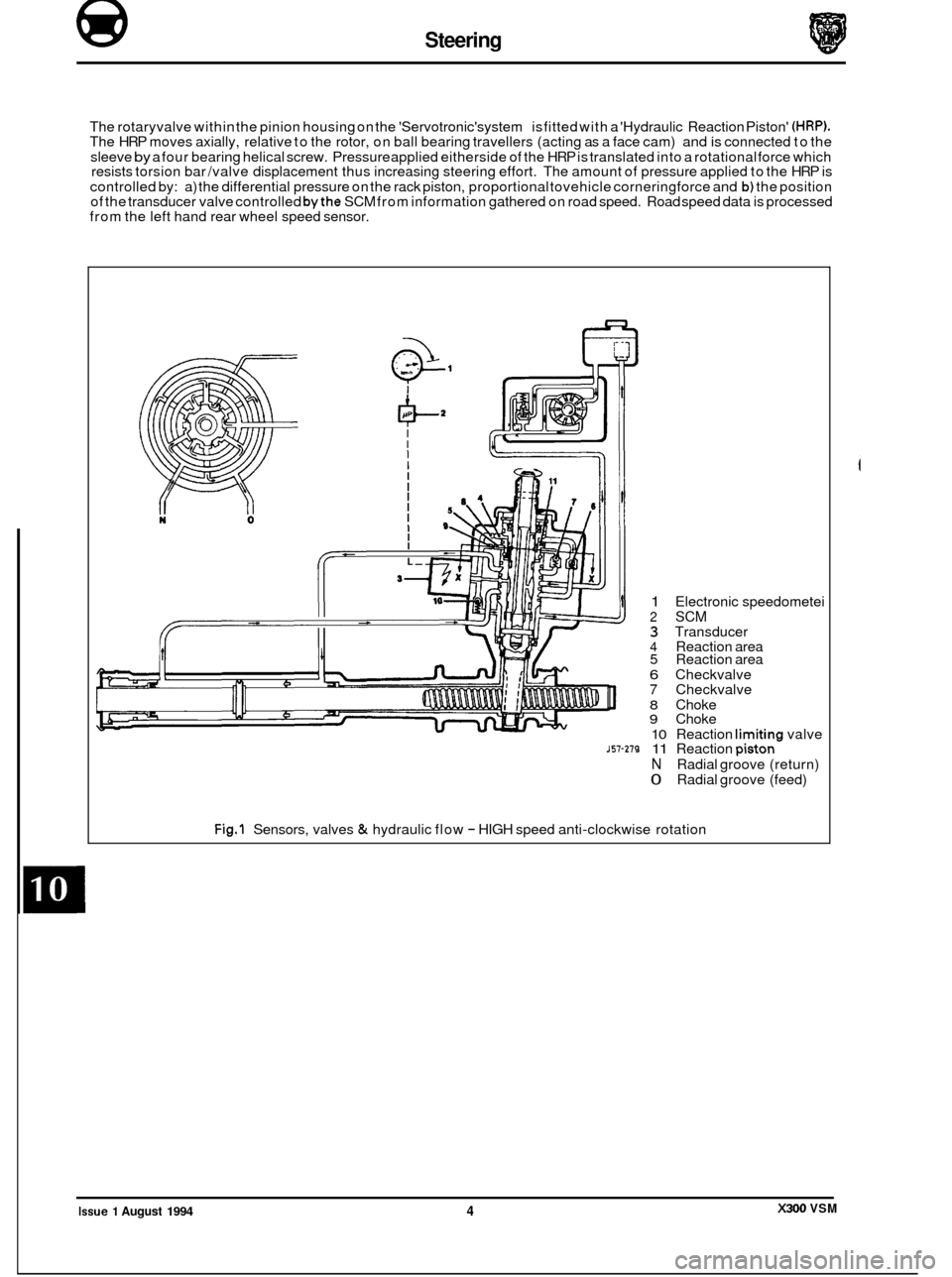

@ Steering

The rotaryvalve within the pinion housing on the 'Servotronic'system is fitted with a 'Hydraulic Reaction Piston' (HRP). The HRP moves axially, relative to the rotor, on ball bearing travellers (acting as a face cam) and is connected to the

sleeve

by a four bearing helical screw. Pressure applied eitherside of the HRP is translated into a rotational force which

resists torsion bar /valve displacement thus increasing steering effort. The amount of pressure applied to the HRP is

controlled by: a) the differential pressure on the rack piston, proportional tovehicle corneringforce and

b) the position

of the transducer valve controlled bythe SCM from information gathered on road speed. Road speed data is processed

from the left hand rear wheel speed sensor.

1 Electronic speedometei

2 SCM 3 Transducer 4 Reaction area 5 Reaction area

6 Checkvalve 7 Checkvalve

8 Choke 9 Choke

10 Reaction limitina valve 157-279 11 Reaction piston-

N Radial groove (return)

0 Radial groove (feed)

Fig.1 Sensors, valves & hydraulic flow - HIGH speed anti-clockwise rotation

X300 VSM Issue 1 August 1994 4

Page 271 of 521

Body Components & Trim e

Remove the battery cover. Disconnect the battery.

. Remove the console ashtray, see subsection 13.3.28.

. Remove console veneer panel, see subsection 13.3.24.

. Remove the gear selector ident plate securing screws.

. Carefully reposition the radio console assembly from the

mounted position.

. Disconnect the assembly harness multi-plugs.

. Disconnect the antenna co-axial connector.

Undo and remove the ground lead to radio securing nut.

. Reposition the ground lead from radio stud.

. Disconnect the radio harness multi-plugs.

. Reposition the radio harness from the center console.

. Displace the radio console assembly.

. Remove the radio assembly from the console.

. Remove the radio retaining plate.

Undo and remove the air conditioning control module se

-

curing screws.

. Displace and remove the module.

. Undo and remove switch/clock module securing screws.

. Displace and remove the module assembly.

. Place the radio console aside.

. Place the new radio console to the front.

. Fit and fully seat the switch /clock module to the console.

. Fit and tighten the module securing screws.

. Fit and fully seat air conditioning module to the console.

. Fit and tighten the securing screws.

. Fit and fully seat the radio mounting plate to the console.

. Place the radio console to the center console position.

. Place the radio to the center console position.

* Route the radio harness / multi-plugs through the radio

. Connect the radio harness multi-plugs.

8 Connect the radio console harness multi-plugs.

. Route the radio ground and antenna leads through the

. Fully seat the radio console in the mounted position.

Reposition the ground lead to radio securing stud.

Fit and tighten the securing nut.

Connect the antenna co-axial to the radio.

. Reposition the excess harness / leads into the radio

mounting hole, ensuring that the harnesses are posi- tioned to allow the radio to be pushed fully home.

console

into the center console position.

radio console.

Fit and tighten the securing screws.

. Fully seat the radio into the console.

. Reposition and fit the selector ident plate.

. Fit and tighten the ident plate securing screws.

. Refit the console veneer panel. I

13.3.10 Radio Console, Renew

SRO

76.25.15

Issue 1 August 1994 16 X300 VSM

Page 299 of 521

Body Components & Trim #ib

13.6 GLAZING (FIXED)

13.6.1 Glazing (Fixed), Description

The fixed glazing comprises internal and external driving mirrors, sunvisor mirror and rear quarter light glass; see Ap- pendix A4, Body Components and Trim for details of the windscreen and rear screen glazing.

13.6.2 Interior Mirror, Renew

. Disconnect vehicle battery ground lead.

. Rotate mirror stem approximately one quarter turn clock- wise to release stem from spring contact on windscreen

boss.

. Disconnect mirror harness.

To refit, locate mirror stem base on windscreen boss with

stem parallel to top of windscreen, ie one quarter turn dis- placed from normal position; apply firmly over boss and

turn anti-clockwise to lock stem on windscreen boss.

. Reconnect mirror harness.

13.6.3

. Disconnect vehicle battery ground lead.

. Lower the sunvisor.

. Raise the sunvisor cover and remove the lenses.

Remove the screws securing the mirror to the sunvisor

and remove the mirror.

. To refit, carry out reversal of the above procedure, taking

care to correctly locate switch and bulb holders priortose-

curing the mirror.

Sun Visor Mirror Assembly, Renew

13.6.4 Exterior Mirror, Renew

= Disconnect vehicle battery ground lead.

Remove door trim pad veneer panel and upper trim pad.

9 Remove the cheater by sliding off.

. Remove mirror fixings.

. Disconnect the mirror harness block connectors.

. Remove the mirror securing screws and remove the mir-

ror assembly.

. To refit, carry out reversal of the above procedure.

13.6.5 Exterior Mirror Glass, Renew

. Switch ignition on and position the mirrorto inboard posi-

. Disconnect vehicle battery ground lead.

. Slide assembly outboard and pull outwards.

. To refit, carry out reversal of the above procedure.

tion.

Issue 1 August 1994 44 X300 VSM