battery JAGUAR XJ6 1997 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 25 of 227

5 Power hydraulic system

fluid level check

1

Caution: Use only Castrol or Jaguar

hydraulic system mineral oil (HSMO) in the

power hydraulic system (available at

Jaguar dealer service departments).

1The power hydraulic system controls the ride

levelling and the brake servo systems. The

fluid reservoir also supplies the power

steering system on some models. The level

of the fluid should be carefully maintained. Low

fluid levels can adversely affect the riding and

braking capabilities of your vehicle. The power

hydraulic system fluid reservoir is located on

the right inner wing of the engine compartment.

1988 and 1989 models

2The fluid level can easily be checked by

viewing the reservoir sight glass. A green

indicator in the sight glass indicates an OK

condition, while a red indicator in the sight glass

requires fluid to be added (see illustration).

3If additional fluid is required, pop open the

plastic tab located on top of the reservoir cap

(see illustration).

4Insert the mineral oil dispensing tube into

the reservoir filler hole. Push down and turn

until the dispensing tube is locked in place.

5Add fluid until the green indicator in the

sight glass appears, then release the

dispensing tube by pushing downward and

turning the opposite direction of refitting.

1990 to 1994 models

6The fluid level can be checked by removing

the cap and observing the level of fluid on the

dipstick.

7Wipe off the fluid with a clean rag, reinsert

it, then withdraw it and read the fluid level

(see illustration). The dipstick is marked so

the fluid can be checked either cold or hot.

The level should be at the HOT mark if the

fluid was hot to the touch. It should be at the

COLD mark if the fluid was cool to the touch.

At no time should the fluid level drop below

the add mark.8If additional fluid is required, pour the

specified type directly into the reservoir, using

a funnel to prevent spills.

6 Battery check

and general information

1

Warning: Certain precautions

must be followed when working

with the battery. Hydrogen gas,

which is highly flammable, is

always present in the battery cells, so don’t

smoke, and keep naked flames and sparks

away from the battery. The electrolyte in

the battery is actually dilute sulphuric acid,

which will cause injury if splashed on your

skin or in your eyes. It will also ruin clothes

and painted surfaces. When removing the

battery cables, always detach the negative

cable first and hook it up last!1A routine preventive maintenance program

for the battery in your vehicle is the only way

to ensure quick and reliable starts. But before

performing any battery maintenance, make

sure that you have the proper equipment

necessary to work safely around the battery

(see illustration).

2There are also several precautions that

should be taken whenever battery

maintenance is performed. Before servicing

the battery, always turn the engine and all

accessories off and disconnect the cable from

the negative terminal of the battery.

3The battery produces hydrogen gas, which

is both flammable and explosive. Never create

a spark, smoke or light a match around the

battery. Always charge the battery in a

ventilated area.

4Electrolyte contains poisonous and corrosive

sulphuric acid. Do not allow it to get in your

eyes, on your skin or on your clothes, and

Every 7500 miles or 6 months 1•9

1

5.2 The power hydraulic system reservoir

is located on the right-hand inner wing -

to check the fluid level on 1988 and 1989

models simply look through the sight glass

and note the colour of the indicator5.3 To add fluid, remove the filler hole

dust cap (arrowed)5.7 On 1990 and later models remove the

cap and check the fluid level on the dipstick

6.1 Tools and materials required for

battery maintenance

1 Face shield/safety goggles - When

removing corrosion with a brush, the

acidic particles can fly up into your eyes

2 Baking soda - A solution of baking soda

and water can be used to neutralise

corrosion

3 Petroleum jelly - A layer of this on the

battery posts will help prevent corrosion

4 Battery post/cable cleaner - This wire

brush cleaning tool will remove all traces

of corrosion from the battery posts and

cable clamps

5 Treated felt washers - Placing one of

these on each post, directly under the

cable clamps, will help prevent corrosion

6 Puller - Sometimes the cable clamps are

difficult to pull off the posts, even after the

nut/bolt has been completely loosened.

This tool pulls the clamp straight up and

off the post without damage

7 Battery post/cable cleaner - Here is

another cleaning tool which is a slightly

different version of number 4 above, but

it does the same thing

8 Rubber gloves - Another safety item to

consider when servicing the battery;

remember that’s acid inside the battery!

3261 Jaguar XJ6

Page 26 of 227

never ingest it. Wear protective safety glasses

when working near the battery. Keep children

away from the battery.

5Note the external condition of the battery. If

the positive terminal and cable clamp on your

vehicle’s battery is equipped with a rubber

protector, make sure it isn’t torn or damaged.

It should completely cover the terminal. Look

for any corroded or loose connections, cracks

in the case or cover or loose hold-down

clamps. Also check the entire length of each

cable for cracks and frayed conductors.

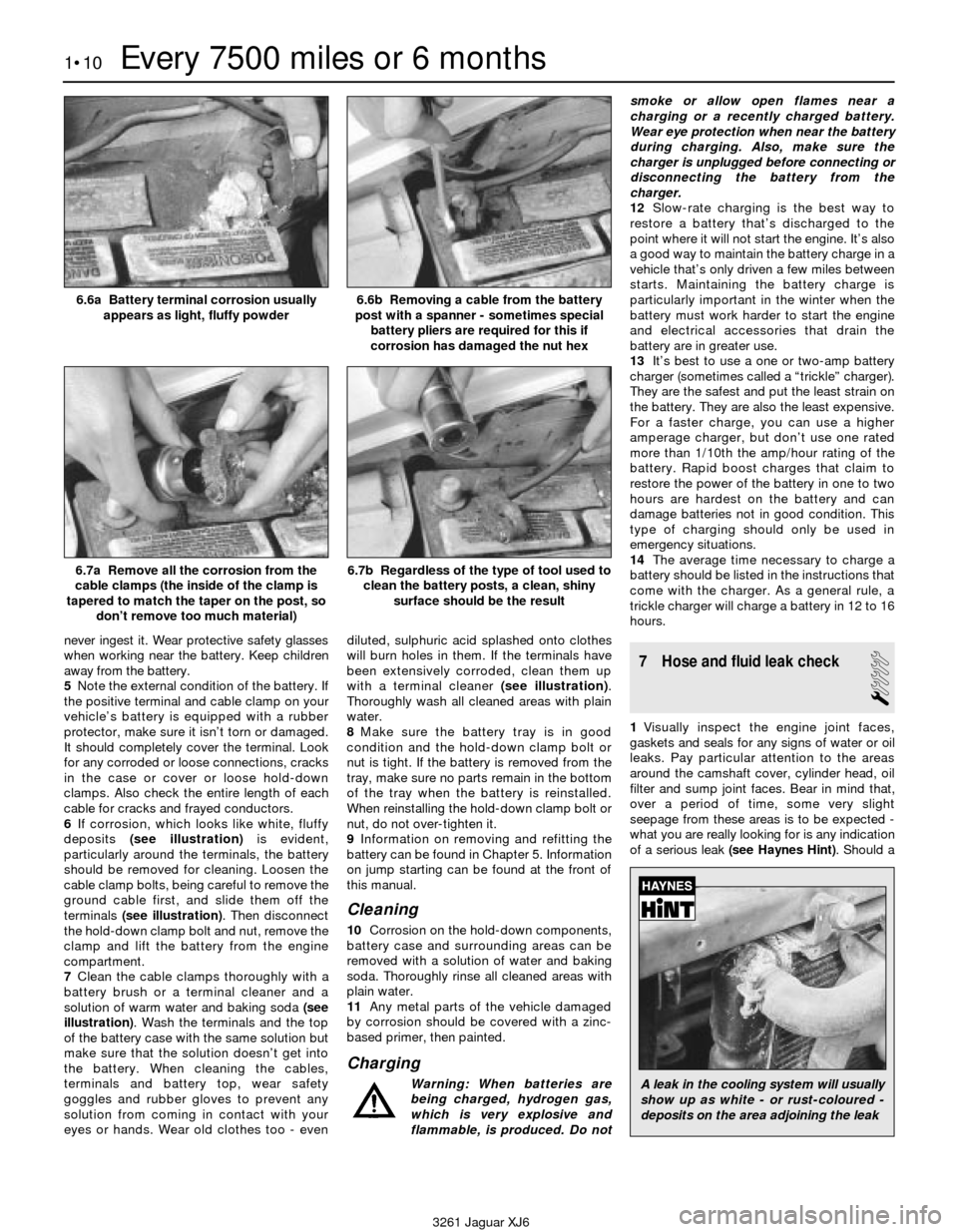

6If corrosion, which looks like white, fluffy

deposits (see illustration)is evident,

particularly around the terminals, the battery

should be removed for cleaning. Loosen the

cable clamp bolts, being careful to remove the

ground cable first, and slide them off the

terminals (see illustration). Then disconnect

the hold-down clamp bolt and nut, remove the

clamp and lift the battery from the engine

compartment.

7Clean the cable clamps thoroughly with a

battery brush or a terminal cleaner and a

solution of warm water and baking soda (see

illustration). Wash the terminals and the top

of the battery case with the same solution but

make sure that the solution doesn’t get into

the battery. When cleaning the cables,

terminals and battery top, wear safety

goggles and rubber gloves to prevent any

solution from coming in contact with your

eyes or hands. Wear old clothes too - evendiluted, sulphuric acid splashed onto clothes

will burn holes in them. If the terminals have

been extensively corroded, clean them up

with a terminal cleaner (see illustration).

Thoroughly wash all cleaned areas with plain

water.

8Make sure the battery tray is in good

condition and the hold-down clamp bolt or

nut is tight. If the battery is removed from the

tray, make sure no parts remain in the bottom

of the tray when the battery is reinstalled.

When reinstalling the hold-down clamp bolt or

nut, do not over-tighten it.

9Information on removing and refitting the

battery can be found in Chapter 5. Information

on jump starting can be found at the front of

this manual.

Cleaning

10Corrosion on the hold-down components,

battery case and surrounding areas can be

removed with a solution of water and baking

soda. Thoroughly rinse all cleaned areas with

plain water.

11Any metal parts of the vehicle damaged

by corrosion should be covered with a zinc-

based primer, then painted.

Charging

Warning: When batteries are

being charged, hydrogen gas,

which is very explosive and

flammable, is produced. Do notsmoke or allow open flames near a

charging or a recently charged battery.

Wear eye protection when near the battery

during charging. Also, make sure the

charger is unplugged before connecting or

disconnecting the battery from the

charger.

12Slow-rate charging is the best way to

restore a battery that’s discharged to the

point where it will not start the engine. It’s also

a good way to maintain the battery charge in a

vehicle that’s only driven a few miles between

starts. Maintaining the battery charge is

particularly important in the winter when the

battery must work harder to start the engine

and electrical accessories that drain the

battery are in greater use.

13It’s best to use a one or two-amp battery

charger (sometimes called a “trickle” charger).

They are the safest and put the least strain on

the battery. They are also the least expensive.

For a faster charge, you can use a higher

amperage charger, but don’t use one rated

more than 1/10th the amp/hour rating of the

battery. Rapid boost charges that claim to

restore the power of the battery in one to two

hours are hardest on the battery and can

damage batteries not in good condition. This

type of charging should only be used in

emergency situations.

14The average time necessary to charge a

battery should be listed in the instructions that

come with the charger. As a general rule, a

trickle charger will charge a battery in 12 to 16

hours.

7 Hose and fluid leak check

1

1Visually inspect the engine joint faces,

gaskets and seals for any signs of water or oil

leaks. Pay particular attention to the areas

around the camshaft cover, cylinder head, oil

filter and sump joint faces. Bear in mind that,

over a period of time, some very slight

seepage from these areas is to be expected -

what you are really looking for is any indication

of a serious leak (see Haynes Hint). Should a

1•10Every 7500 miles or 6 months

6.6a Battery terminal corrosion usually

appears as light, fluffy powder6.6b Removing a cable from the battery

post with a spanner - sometimes special

battery pliers are required for this if

corrosion has damaged the nut hex

6.7a Remove all the corrosion from the

cable clamps (the inside of the clamp is

tapered to match the taper on the post, so

don’t remove too much material)6.7b Regardless of the type of tool used to

clean the battery posts, a clean, shiny

surface should be the result

3261 Jaguar XJ6

A leak in the cooling system will usually

show up as white - or rust-coloured -

deposits on the area adjoining the leak

Page 30 of 227

16 Spark plug renewal

2

Refer to Section 4, renewing the plugs

regardless of their apparent condition.

17 Air cleaner element renewal

1

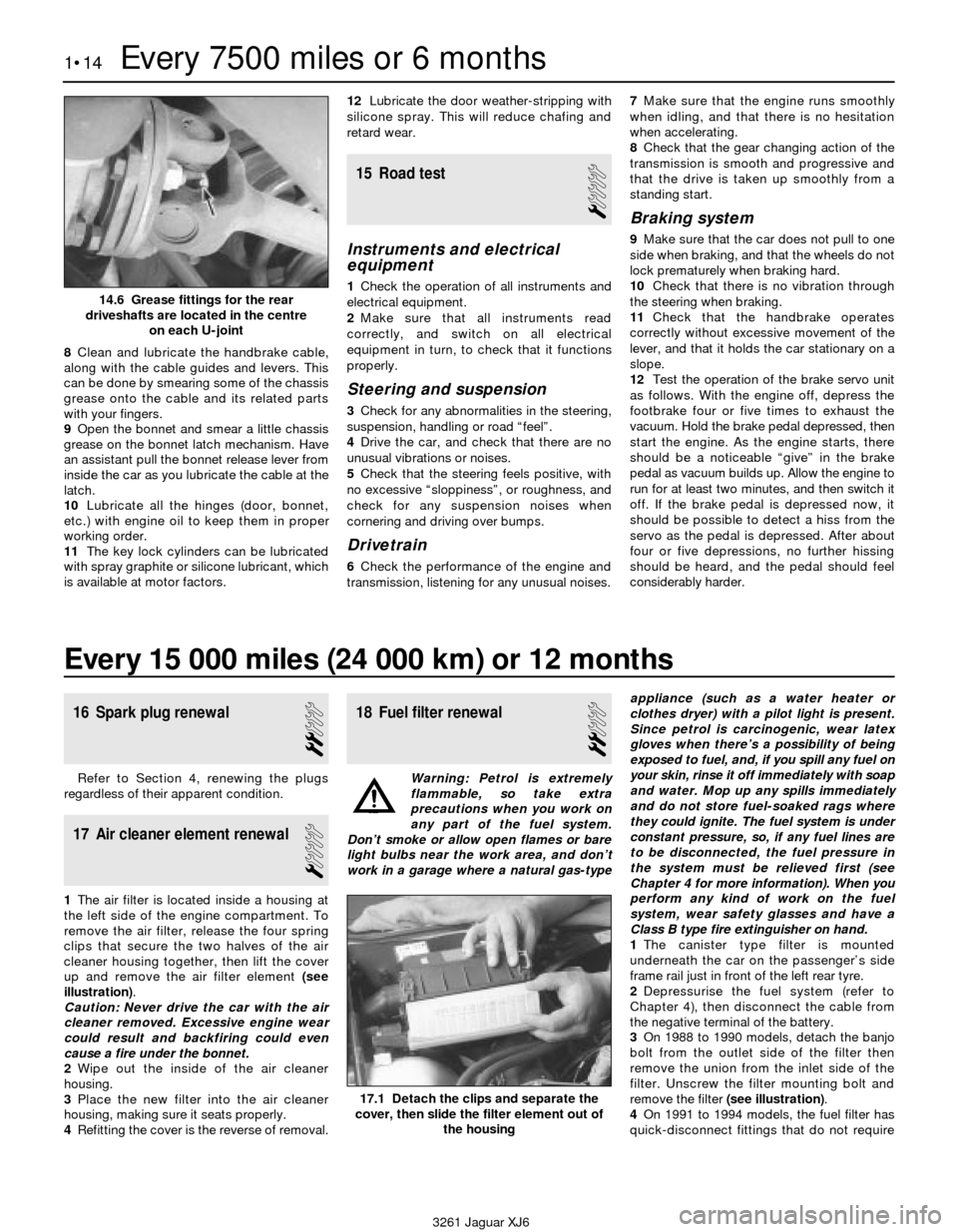

1The air filter is located inside a housing at

the left side of the engine compartment. To

remove the air filter, release the four spring

clips that secure the two halves of the air

cleaner housing together, then lift the cover

up and remove the air filter element (see

illustration).

Caution: Never drive the car with the air

cleaner removed. Excessive engine wear

could result and backfiring could even

cause a fire under the bonnet.

2Wipe out the inside of the air cleaner

housing.

3Place the new filter into the air cleaner

housing, making sure it seats properly.

4Refitting the cover is the reverse of removal.

18 Fuel filter renewal

2

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system.

Don’t smoke or allow open flames or bare

light bulbs near the work area, and don’t

work in a garage where a natural gas-typeappliance (such as a water heater or

clothes dryer) with a pilot light is present.

Since petrol is carcinogenic, wear latex

gloves when there’s a possibility of being

exposed to fuel, and, if you spill any fuel on

your skin, rinse it off immediately with soap

and water. Mop up any spills immediately

and do not store fuel-soaked rags where

they could ignite. The fuel system is under

constant pressure, so, if any fuel lines are

to be disconnected, the fuel pressure in

the system must be relieved first (see

Chapter 4 for more information). When you

perform any kind of work on the fuel

system, wear safety glasses and have a

Class B type fire extinguisher on hand.

1The canister type filter is mounted

underneath the car on the passenger’s side

frame rail just in front of the left rear tyre.

2Depressurise the fuel system (refer to

Chapter 4), then disconnect the cable from

the negative terminal of the battery.

3On 1988 to 1990 models, detach the banjo

bolt from the outlet side of the filter then

remove the union from the inlet side of the

filter. Unscrew the filter mounting bolt and

remove the filter (see illustration).

4On 1991 to 1994 models, the fuel filter has

quick-disconnect fittings that do not require 8Clean and lubricate the handbrake cable,

along with the cable guides and levers. This

can be done by smearing some of the chassis

grease onto the cable and its related parts

with your fingers.

9Open the bonnet and smear a little chassis

grease on the bonnet latch mechanism. Have

an assistant pull the bonnet release lever from

inside the car as you lubricate the cable at the

latch.

10Lubricate all the hinges (door, bonnet,

etc.) with engine oil to keep them in proper

working order.

11The key lock cylinders can be lubricated

with spray graphite or silicone lubricant, which

is available at motor factors.12Lubricate the door weather-stripping with

silicone spray. This will reduce chafing and

retard wear.

15 Road test

1

Instruments and electrical

equipment

1Check the operation of all instruments and

electrical equipment.

2Make sure that all instruments read

correctly, and switch on all electrical

equipment in turn, to check that it functions

properly.

Steering and suspension

3Check for any abnormalities in the steering,

suspension, handling or road “feel”.

4Drive the car, and check that there are no

unusual vibrations or noises.

5Check that the steering feels positive, with

no excessive “sloppiness”, or roughness, and

check for any suspension noises when

cornering and driving over bumps.

Drivetrain

6Check the performance of the engine and

transmission, listening for any unusual noises.7Make sure that the engine runs smoothly

when idling, and that there is no hesitation

when accelerating.

8Check that the gear changing action of the

transmission is smooth and progressive and

that the drive is taken up smoothly from a

standing start.

Braking system

9Make sure that the car does not pull to one

side when braking, and that the wheels do not

lock prematurely when braking hard.

10Check that there is no vibration through

the steering when braking.

11Check that the handbrake operates

correctly without excessive movement of the

lever, and that it holds the car stationary on a

slope.

12Test the operation of the brake servo unit

as follows. With the engine off, depress the

footbrake four or five times to exhaust the

vacuum. Hold the brake pedal depressed, then

start the engine. As the engine starts, there

should be a noticeable “give” in the brake

pedal as vacuum builds up. Allow the engine to

run for at least two minutes, and then switch it

off. If the brake pedal is depressed now, it

should be possible to detect a hiss from the

servo as the pedal is depressed. After about

four or five depressions, no further hissing

should be heard, and the pedal should feel

considerably harder.

1•14Every 7500 miles or 6 months

17.1 Detach the clips and separate the

cover, then slide the filter element out of

the housing

3261 Jaguar XJ6

14.6 Grease fittings for the rear

driveshafts are located in the centre

on each U-joint

Every 15 000 miles (24 000 km) or 12 months

Page 31 of 227

hand tools to remove. Simply slide back the

locking collars and remove the inlet and outlet

fuel lines (see illustration). Detach the filter

mounting bracket and discard the old filter in

a proper container.

5Note the direction of the arrow on the

outside of the filter; it should be pointed

towards the front of the car. Make sure the

new filter is installed so that it’s facing the

proper direction. Note:Always refit new

copper washers where equipped.

6Refit the inlet and outlet fittings then tighten

the filter mounting bracket. Reconnect the

battery cable, start the engine and check for

leaks.

19 Ignition system check

2

1The spark plug leads should be checked

whenever new spark plugs are installed.

2Begin this procedure by making a visual

check of the spark plug leads while the engine

is running. In a darkened garage (make sure

there is adequate ventilation) start the engine

and observe each plug lead. Be careful not to

come into contact with any moving engine

parts. If there is a break in the lead, you will

see arcing or a small spark at the damaged

area. If arcing is noticed, make a note to

obtain new leads, then allow the engine to

cool and check the distributor cap and rotor.

3The spark plug leads should be inspected

one at a time to prevent mixing up the order,

which is essential for proper engine operation.

Each original plug lead should be numbered

to help identify its location. If the number is

illegible, a piece of tape can be marked with

the correct number and wrapped around the

plug lead.

4Disconnect the plug lead from the spark

plug. A removal tool can be used for this

purpose or you can grasp the rubber boot,

twist the boot half a turn and pull the boot

free. Do not pull on the lead itself.

5Check inside the boot for corrosion, which

will look like a white crusty powder.6Push the lead and boot back onto the end

of the spark plug. It should fit tightly onto the

end of the plug. If it doesn’t, remove the lead

and use pliers to carefully crimp the metal

connector inside the lead boot until the fit is

snug.

7Using a clean rag, wipe the entire length of

the lead to remove built-up dirt and grease.

Once the lead is clean, check for burns,

cracks and other damage. Do not bend the

lead sharply, because the conductor might

break.

8Disconnect the spark plug lead from the

distributor cap. Again, pull only on the rubber

boot. Check for corrosion and a tight fit.

Reinsert the lead in the distributor cap.

9Inspect the remaining spark plug leads,

making sure that each one is securely

fastened at the distributor and spark plug

when the check is complete.10If new spark plug leads are required,

purchase a set for your specific engine model.

Remove and replace the leads one at a time

to avoid mix-ups in the firing order.

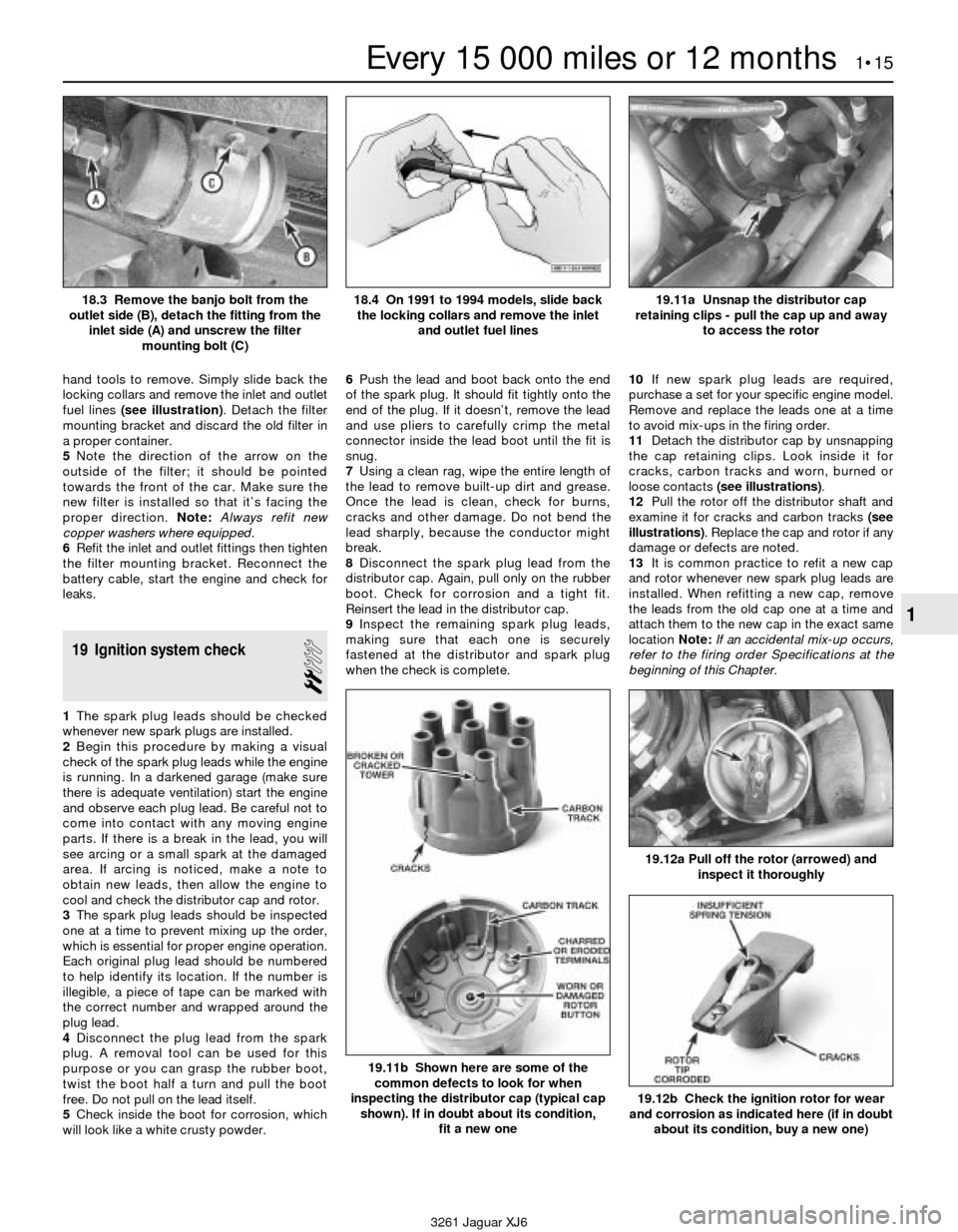

11Detach the distributor cap by unsnapping

the cap retaining clips. Look inside it for

cracks, carbon tracks and worn, burned or

loose contacts (see illustrations).

12Pull the rotor off the distributor shaft and

examine it for cracks and carbon tracks (see

illustrations). Replace the cap and rotor if any

damage or defects are noted.

13It is common practice to refit a new cap

and rotor whenever new spark plug leads are

installed. When refitting a new cap, remove

the leads from the old cap one at a time and

attach them to the new cap in the exact same

location Note:If an accidental mix-up occurs,

refer to the firing order Specifications at the

beginning of this Chapter.

Every 15 000 miles or 12 months 1•15

1

19.11a Unsnap the distributor cap

retaining clips - pull the cap up and away

to access the rotor

19.11b Shown here are some of the

common defects to look for when

inspecting the distributor cap (typical cap

shown). If in doubt about its condition,

fit a new one

19.12a Pull off the rotor (arrowed) and

inspect it thoroughly

19.12b Check the ignition rotor for wear

and corrosion as indicated here (if in doubt

about its condition, buy a new one)

3261 Jaguar XJ6 18.3 Remove the banjo bolt from the

outlet side (B), detach the fitting from the

inlet side (A) and unscrew the filter

mounting bolt (C)

18.4 On 1991 to 1994 models, slide back

the locking collars and remove the inlet

and outlet fuel lines

Page 40 of 227

attached to the bolt threaded into the

front of the crankshaft. Apply pressure on

the bolt in a clockwise direction only.

Never turn the bolt anti-clockwise.

b) A remote starter switch, which may save

some time, can also be used. Follow the

instructions included with the switch.

Once the piston is close to TDC, use a

socket and ratchet as described in the

previous paragraph.

c) If an assistant is available to turn the

ignition switch to the Start position in

short bursts, you can get the piston close

to TDC without a remote starter switch.

Make sure your assistant is out of the car,

away from the ignition switch, then use a

socket and ratchet as described in

Paragraph a) to complete the procedure.

5Note the position of the terminal for the

number one spark plug lead on the distributor

cap. If the terminal isn’t marked, follow the

plug lead from the number one cylinder spark

plug to the cap.

6Use a felt-tip pen or chalk to make a mark

on the distributor body directly under the

number one terminal (see Chapter 5).

7Detach the cap from the distributor and set

it aside (see Chapter 1 if necessary).

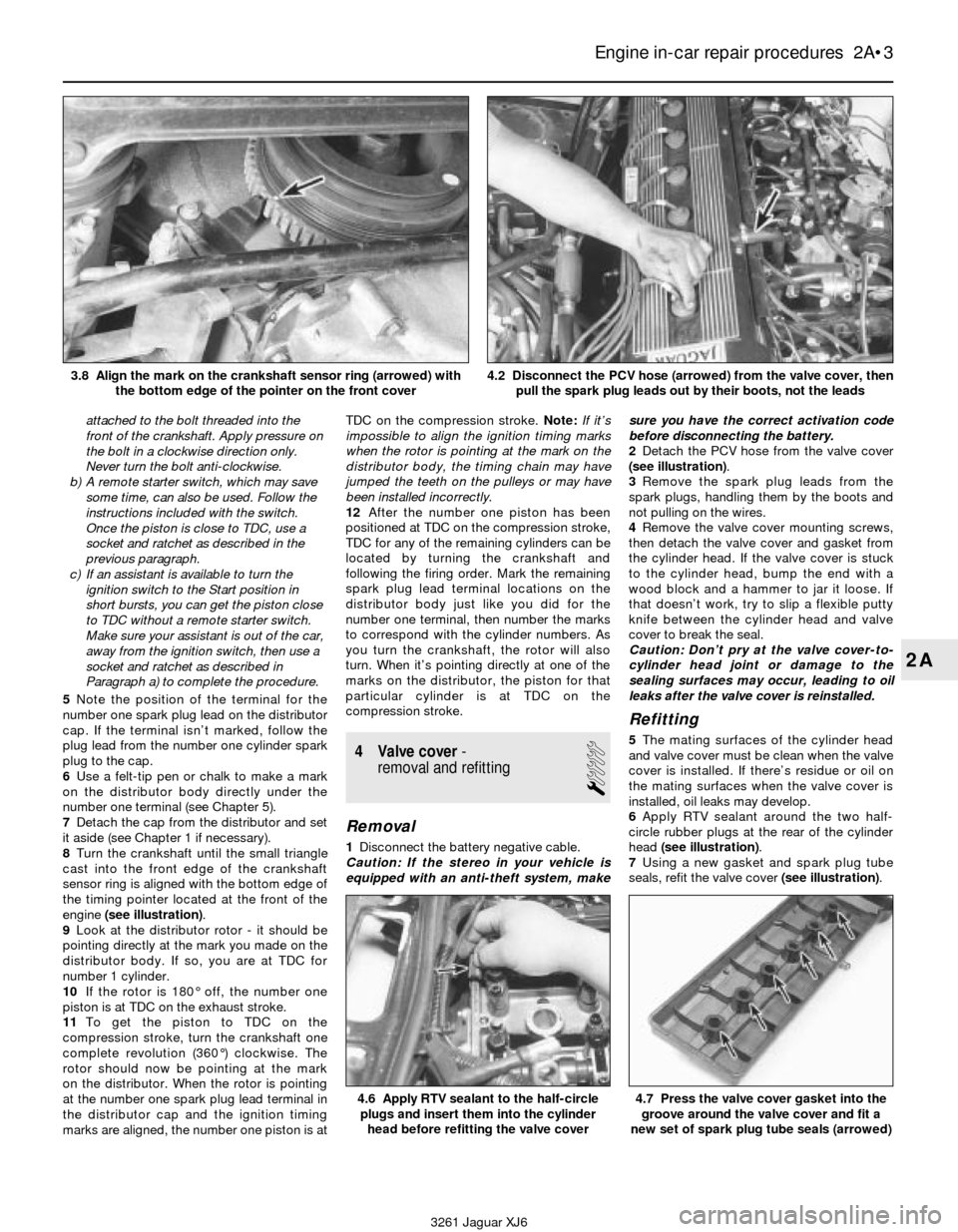

8Turn the crankshaft until the small triangle

cast into the front edge of the crankshaft

sensor ring is aligned with the bottom edge of

the timing pointer located at the front of the

engine(see illustration).

9Look at the distributor rotor - it should be

pointing directly at the mark you made on the

distributor body. If so, you are at TDC for

number 1 cylinder.

10If the rotor is 180° off, the number one

piston is at TDC on the exhaust stroke.

11To get the piston to TDC on the

compression stroke, turn the crankshaft one

complete revolution (360°) clockwise. The

rotor should now be pointing at the mark

on the distributor. When the rotor is pointing

at the number one spark plug lead terminal in

the distributor cap and the ignition timing

marks are aligned, the number one piston is atTDC on the compression stroke. Note:If it’s

impossible to align the ignition timing marks

when the rotor is pointing at the mark on the

distributor body, the timing chain may have

jumped the teeth on the pulleys or may have

been installed incorrectly.

12After the number one piston has been

positioned at TDC on the compression stroke,

TDC for any of the remaining cylinders can be

located by turning the crankshaft and

following the firing order. Mark the remaining

spark plug lead terminal locations on the

distributor body just like you did for the

number one terminal, then number the marks

to correspond with the cylinder numbers. As

you turn the crankshaft, the rotor will also

turn. When it’s pointing directly at one of the

marks on the distributor, the piston for that

particular cylinder is at TDC on the

compression stroke.

4 Valve cover-

removal and refitting

1

Removal

1Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, makesure you have the correct activation code

before disconnecting the battery.

2Detach the PCV hose from the valve cover

(see illustration).

3Remove the spark plug leads from the

spark plugs, handling them by the boots and

not pulling on the wires.

4Remove the valve cover mounting screws,

then detach the valve cover and gasket from

the cylinder head. If the valve cover is stuck

to the cylinder head, bump the end with a

wood block and a hammer to jar it loose. If

that doesn’t work, try to slip a flexible putty

knife between the cylinder head and valve

cover to break the seal.

Caution: Don’t pry at the valve cover-to-

cylinder head joint or damage to the

sealing surfaces may occur, leading to oil

leaks after the valve cover is reinstalled.

Refitting

5The mating surfaces of the cylinder head

and valve cover must be clean when the valve

cover is installed. If there’s residue or oil on

the mating surfaces when the valve cover is

installed, oil leaks may develop.

6Apply RTV sealant around the two half-

circle rubber plugs at the rear of the cylinder

head (see illustration).

7Using a new gasket and spark plug tube

seals, refit the valve cover (see illustration).

Engine in-car repair procedures 2A•3

2A

4.6 Apply RTV sealant to the half-circle

plugs and insert them into the cylinder

head before refitting the valve cover4.7 Press the valve cover gasket into the

groove around the valve cover and fit a

new set of spark plug tube seals (arrowed)

3261 Jaguar XJ6 3.8 Align the mark on the crankshaft sensor ring (arrowed) with

the bottom edge of the pointer on the front cover

4.2 Disconnect the PCV hose (arrowed) from the valve cover, then

pull the spark plug leads out by their boots, not the leads

Page 41 of 227

8Tighten the screws to the torque listed in

this Chapter’s Specifications in three or four

equal steps.

9Refit the remaining components, start the

engine and check for oil leaks.

5 Intake manifold-

removal and refitting

2

Removal

1Disconnect the negative cable from the

battery.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Refer to Chapter 4 to remove the

accelerator and cruise-control linkage, safely

relieve the fuel system pressure, and

disconnect the fuel supply lines.

3Label or mark and detach the PCV and

vacuum hoses connected to the intake

manifold, (see illustration).

4The intake manifold can be removed with

the injectors and fuel rail still in place.

Disconnect the electrical connectors at

each injector (label them first for reassembly).

If the injectors are to be removed from the

intake manifold, refer to Chapter 4.

5Refer to Chapter 4 and remove the throttle

body.6Remove the three nuts retaining the oil filler

tube bracket, then pull the tube up as far as

possible (see illustrations).

7Remove the ground strap and intake

manifold mounting nuts/bolts, then detach the

intake manifold from the engine (see

illustrations).

Refitting

8Clean the mating surfaces of the intake

manifold and the cylinder head mounting

surface with lacquer thinner or acetone. If the

gasket shows signs of leaking, have the

manifold checked for warpage at an

automotive machine workshop and

resurfaced if necessary.

9Refit a new gasket, then position the intake

manifold on the cylinder head and refit the

nuts/bolts (see illustration).

10Tighten the nuts/bolts in three or four

equal steps to the torque listed in this

Chapter’s Specifications. Work from the

centre out towards the ends to avoid warping

the manifold.

11Refit the remaining parts in the reverse

order of removal.

12Before starting the engine, check the

throttle linkage for smooth operation.

13Run the engine and check for coolant and

vacuum leaks.

14Road test the car and check for proper

operation of all accessories, including the

cruise control system.

6 Exhaust manifolds-

removal and refitting

2

Warning: The engine must be

completely cool before beginning

this procedure.

Removal

1Disconnect the negative cable from the

battery.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2On 1990 and later models, disconnect the

EGR pipe and remove the EGR valve from the

top of the exhaust manifold (see Chapter 6).

3Apply penetrating oil to the exhaust

manifold mounting nuts/bolts, and the nuts

retaining the exhaust pipes to the manifolds.

After the nuts have soaked, remove the nuts

retaining the exhaust pipes to the manifolds

and the lower bolt from the heat shield (see

illustration).

4Remove the heat shield from the exhaust

manifolds(see illustration).

5Disconnect the electrical connector to the

oxygen sensor. Unless the oxygen sensor is

being renewed, leave the sensor in place.

6Remove the nuts/bolts and detach the

manifolds and gaskets (see illustration).

2A•4 Engine in-car repair procedures

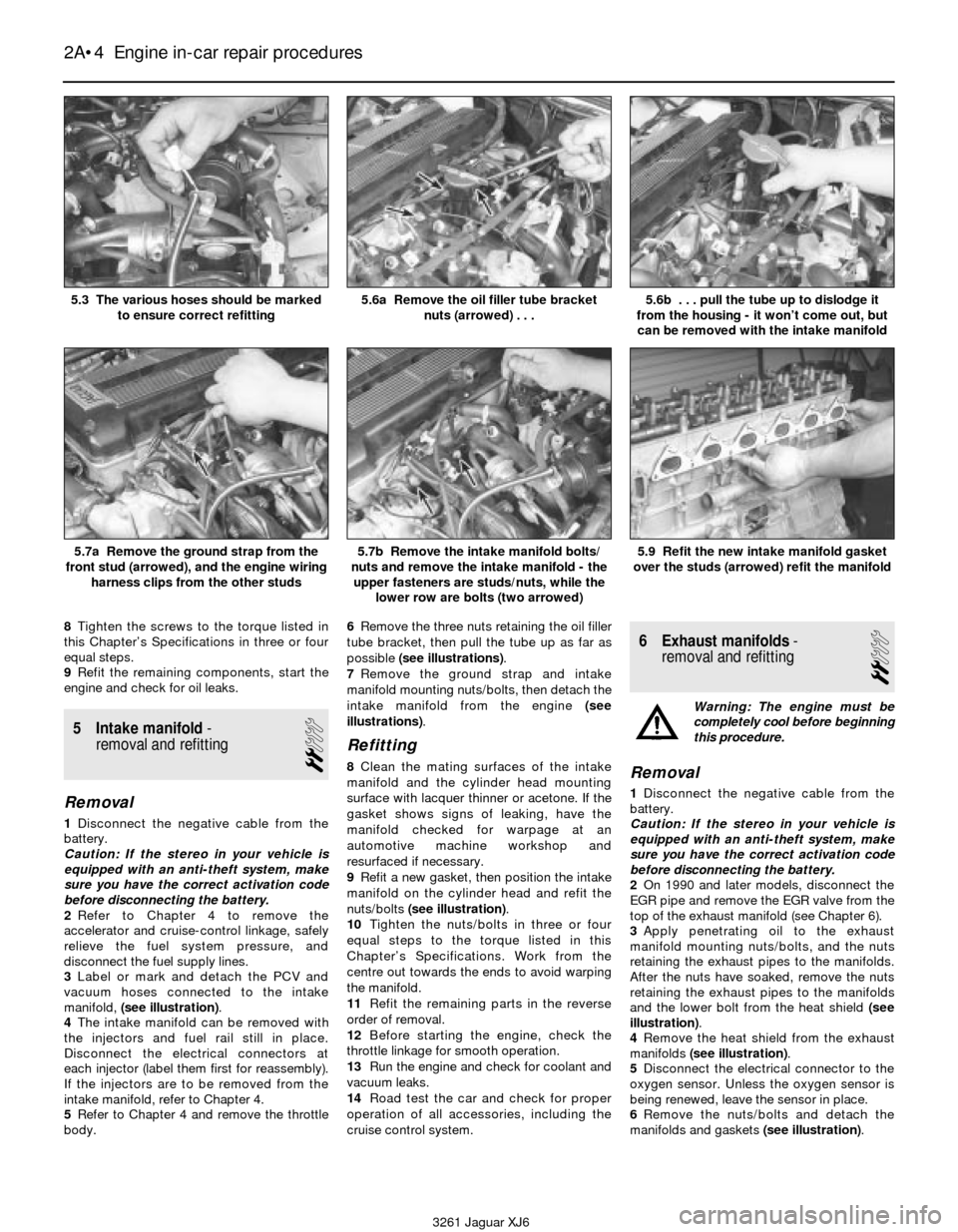

5.3 The various hoses should be marked

to ensure correct refitting5.6a Remove the oil filler tube bracket

nuts (arrowed) . . .5.6b . . . pull the tube up to dislodge it

from the housing - it won’t come out, but

can be removed with the intake manifold

5.7a Remove the ground strap from the

front stud (arrowed), and the engine wiring

harness clips from the other studs5.7b Remove the intake manifold bolts/

nuts and remove the intake manifold - the

upper fasteners are studs/nuts, while the

lower row are bolts (two arrowed)5.9 Refit the new intake manifold gasket

over the studs (arrowed) refit the manifold

3261 Jaguar XJ6

Page 42 of 227

Refitting

7Use a scraper to remove all traces of old

gasket material and carbon deposits from the

manifold and cylinder head mating surfaces. If

the gasket was leaking, have the manifold

checked for warpage at an automotive

machine workshop and resurfaced if

necessary.

8Position new gaskets over the cylinder

head studs (see illustration). Note:The

marks on the gasket should face out (away

from the cylinder head) and the arrow should

point toward the rear of the engine.

9Refit the manifolds and thread the mounting

nuts/bolts into place.

10Working from the centre out, tighten the

nuts/bolts to the torque listed in this Chapter’s

Specifications in three or four equal steps.

11Refit the remaining parts in the reverse

order of removal.

12Run the engine and check for exhaust

leaks.

7 Crankshaft front oil seal-

renewal

3

1Disconnect the negative cable from the

battery.

Caution: If the stereo in your vehicle isequipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Refer to Chapter 1 and remove the

accessory drive belts.

3Refer to Chapter 3 and remove the fan

shroud and fan clutch assembly.

4Remove the crankshaft damper bolt with a

socket and large breaker bar (see illustration).

To hold the crankshaft stationary, remove the

flywheel inspection cover (see Chapter 8) and

wedge a large screwdriver into the flywheel

ring gear teeth. Warning: The damper bolt is

under considerable torque, so

be sure the socket is firmly in

place and that your hands are

not in danger of hitting anything sharp.

5Use a bolt-type damper puller (available at

most car accessory outlets) to remove the

crankshaft damper (see illustration).

7Remove the Woodruff key from the

crankshaft keyway (see illustration).

8Carefully pry the seal out of the front cover

with a screwdriver or seal-removal tool(see

illustration). Don’t scratch the bore or

Engine in-car repair procedures 2A•5

2A

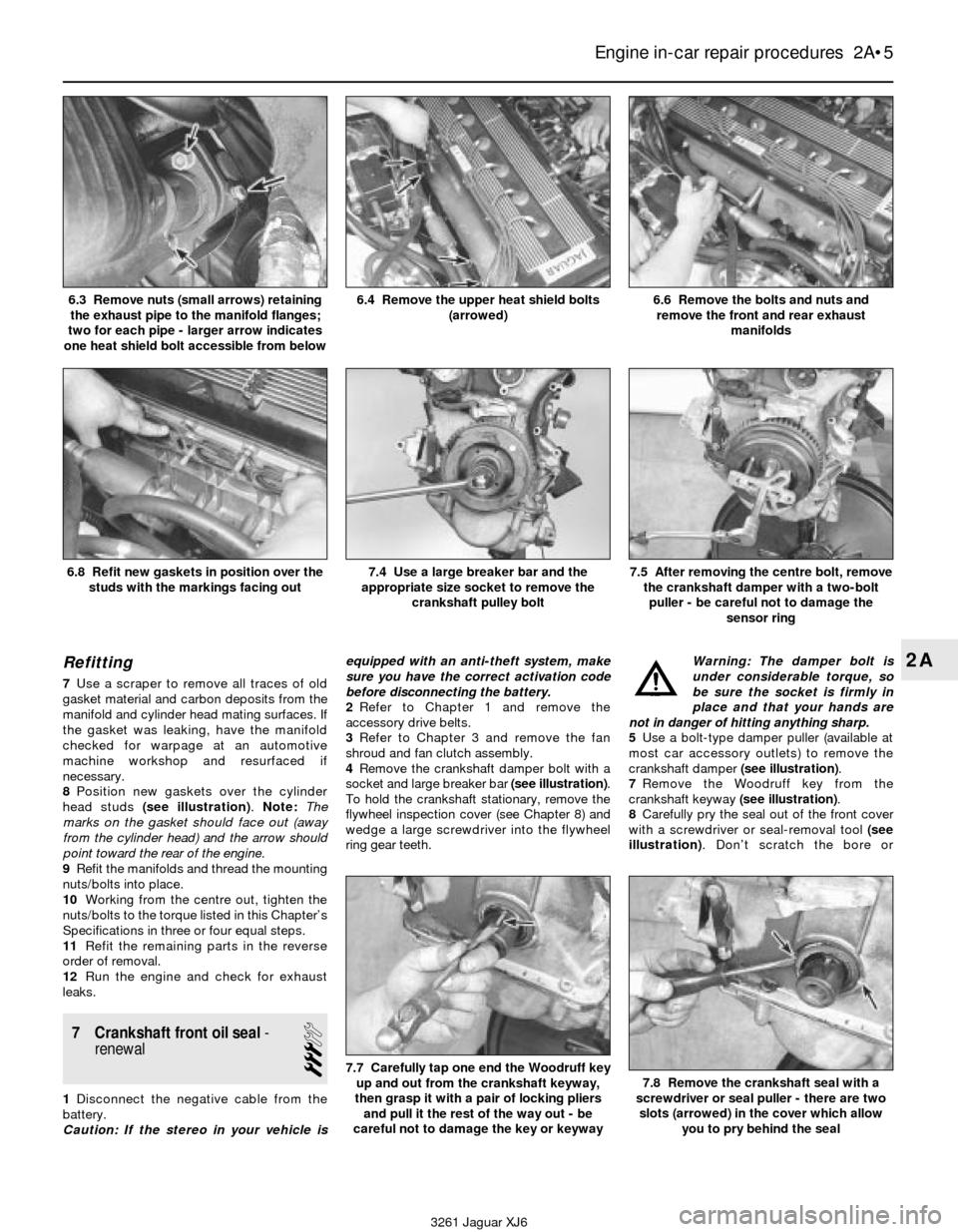

6.3 Remove nuts (small arrows) retaining

the exhaust pipe to the manifold flanges;

two for each pipe - larger arrow indicates

one heat shield bolt accessible from below6.4 Remove the upper heat shield bolts

(arrowed)6.6 Remove the bolts and nuts and

remove the front and rear exhaust

manifolds

6.8 Refit new gaskets in position over the

studs with the markings facing out

7.7 Carefully tap one end the Woodruff key

up and out from the crankshaft keyway,

then grasp it with a pair of locking pliers

and pull it the rest of the way out - be

careful not to damage the key or keyway7.8 Remove the crankshaft seal with a

screwdriver or seal puller - there are two

slots (arrowed) in the cover which allow

you to pry behind the seal

7.4 Use a large breaker bar and the

appropriate size socket to remove the

crankshaft pulley bolt7.5 After removing the centre bolt, remove

the crankshaft damper with a two-bolt

puller - be careful not to damage the

sensor ring

3261 Jaguar XJ6

Page 43 of 227

damage the crankshaft in the process (if the

crankshaft is damaged, the new seal will end

up leaking).

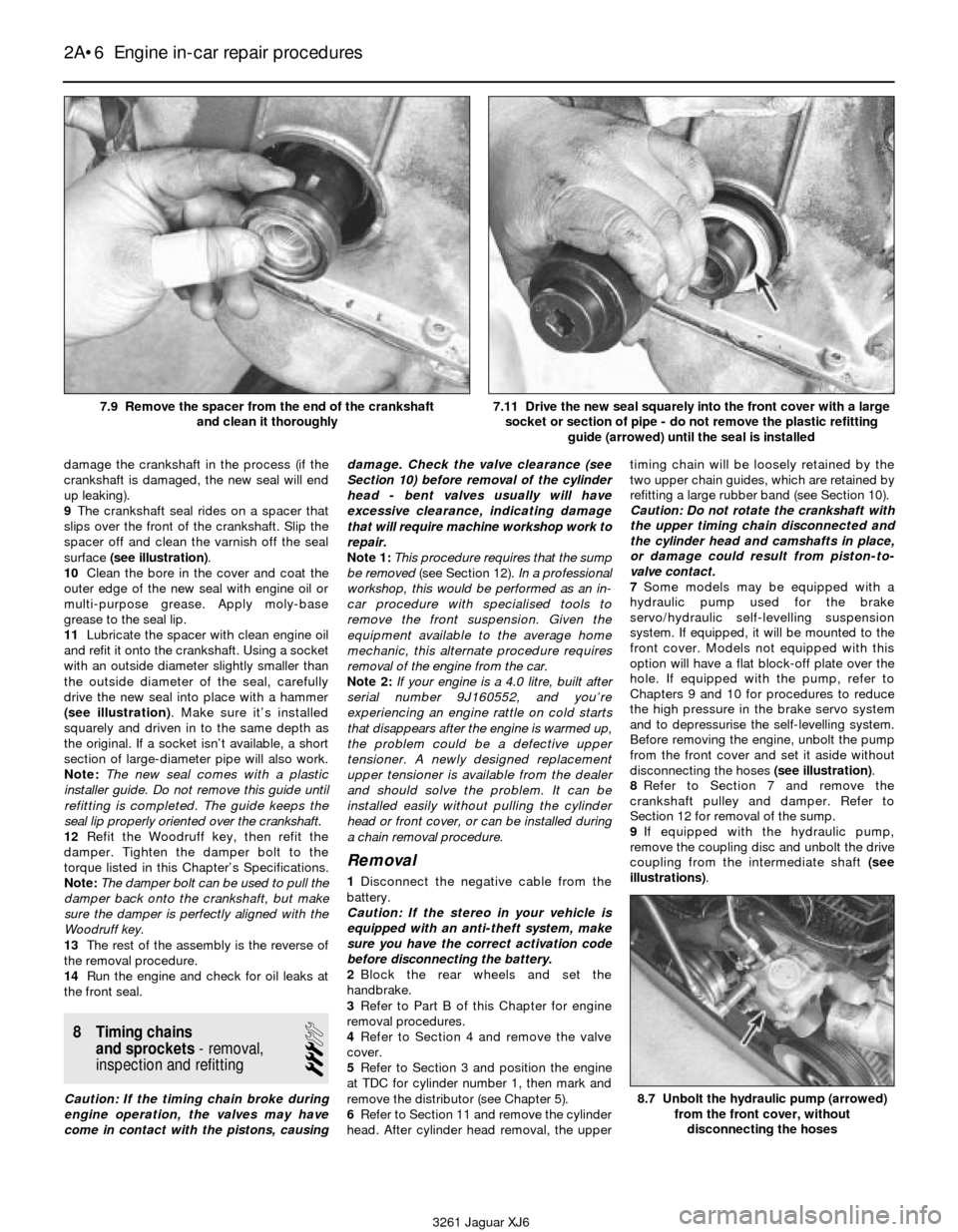

9The crankshaft seal rides on a spacer that

slips over the front of the crankshaft. Slip the

spacer off and clean the varnish off the seal

surface (see illustration).

10Clean the bore in the cover and coat the

outer edge of the new seal with engine oil or

multi-purpose grease. Apply moly-base

grease to the seal lip.

11Lubricate the spacer with clean engine oil

and refit it onto the crankshaft. Using a socket

with an outside diameter slightly smaller than

the outside diameter of the seal, carefully

drive the new seal into place with a hammer

(see illustration). Make sure it’s installed

squarely and driven in to the same depth as

the original. If a socket isn’t available, a short

section of large-diameter pipe will also work.

Note:The new seal comes with a plastic

installer guide. Do not remove this guide until

refitting is completed. The guide keeps the

seal lip properly oriented over the crankshaft.

12Refit the Woodruff key, then refit the

damper. Tighten the damper bolt to the

torque listed in this Chapter’s Specifications.

Note:The damper bolt can be used to pull the

damper back onto the crankshaft, but make

sure the damper is perfectly aligned with the

Woodruff key.

13The rest of the assembly is the reverse of

the removal procedure.

14Run the engine and check for oil leaks at

the front seal.

8 Timing chains

and sprockets- removal,

inspection and refitting

3

Caution: If the timing chain broke during

engine operation, the valves may have

come in contact with the pistons, causingdamage. Check the valve clearance (see

Section 10) before removal of the cylinder

head - bent valves usually will have

excessive clearance, indicating damage

that will require machine workshop work to

repair.

Note 1:This procedure requires that the sump

be removed (see Section 12).In a professional

workshop, this would be performed as an in-

car procedure with specialised tools to

remove the front suspension. Given the

equipment available to the average home

mechanic, this alternate procedure requires

removal of the engine from the car.

Note 2:If your engine is a 4.0 litre, built after

serial number 9J160552, and you’re

experiencing an engine rattle on cold starts

that disappears after the engine is warmed up,

the problem could be a defective upper

tensioner. A newly designed replacement

upper tensioner is available from the dealer

and should solve the problem. It can be

installed easily without pulling the cylinder

head or front cover, or can be installed during

a chain removal procedure.

Removal

1Disconnect the negative cable from the

battery.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Block the rear wheels and set the

handbrake.

3Refer to Part B of this Chapter for engine

removal procedures.

4Refer to Section 4 and remove the valve

cover.

5Refer to Section 3 and position the engine

at TDC for cylinder number 1, then mark and

remove the distributor (see Chapter 5).

6Refer to Section 11 and remove the cylinder

head. After cylinder head removal, the uppertiming chain will be loosely retained by the

two upper chain guides, which are retained by

refitting a large rubber band (see Section 10).

Caution: Do not rotate the crankshaft with

the upper timing chain disconnected and

the cylinder head and camshafts in place,

or damage could result from piston-to-

valve contact.

7Some models may be equipped with a

hydraulic pump used for the brake

servo/hydraulic self-levelling suspension

system. If equipped, it will be mounted to the

front cover. Models not equipped with this

option will have a flat block-off plate over the

hole. If equipped with the pump, refer to

Chapters 9 and 10 for procedures to reduce

the high pressure in the brake servo system

and to depressurise the self-levelling system.

Before removing the engine, unbolt the pump

from the front cover and set it aside without

disconnecting the hoses (see illustration).

8Refer to Section 7 and remove the

crankshaft pulley and damper. Refer to

Section 12 for removal of the sump.

9If equipped with the hydraulic pump,

remove the coupling disc and unbolt the drive

coupling from the intermediate shaft (see

illustrations).

2A•6 Engine in-car repair procedures

8.7 Unbolt the hydraulic pump (arrowed)

from the front cover, without

disconnecting the hoses

3261 Jaguar XJ6 7.9 Remove the spacer from the end of the crankshaft

and clean it thoroughly

7.11 Drive the new seal squarely into the front cover with a large

socket or section of pipe - do not remove the plastic refitting

guide (arrowed) until the seal is installed

Page 45 of 227

23Clean and lubricate the lower tensioner.

Fill the lower tensioner oil reservoir with engine

oil and refit it on the engine block, aligning the

notch in the tensioner with the lug on the back

of the guide (see illustrations). This should

remove all slack from the lower timing chain. If

not, push the lower tensioner guide back and

forth a few times to prime the tensioner.

24Refit the upper chain tensioner guide and

mounting bracket to the engine block.

Caution: Before fully tightening the

mounting bracket to the engine block,

make sure the mount and chain guide are

clear of the lower chain, auxiliary sprocket

and intermediate sprocket. If necessary,

position the mount for clearance before

tightening the mounting bolts.

25Refit the oil pump drive chain and

sprocket to the crankshaft (see Section 13).

26Refit the upper chain fixed guide to the

engine block and place the upper timing chain

over the intermediate sprocket and auxiliary

shaft sprocket, draping the excess chain over

the top of the fixed guide. Lubricate the chain

and sprockets with clean engine oil.27Gather the loose portion of the upper

timing chain and place it between the upper

guides. Use a large rubber band to hold the

two guides snugly around the chain (see

Section 11).

28If necessary, renew the intermediate shaft

seal (see illustrations).

29Apply a thin coat of RTV sealant to the

engine side of the front cover and RTV sealant

to the oil-pan mating surface (bottom of the

front cover), then refit the front cover. Note:

Make sure the top surface of the cover aligns

with the top surface of the engine block, by

checking with a straightedge(see illustration).

30Refer to Section 11 for refitting of the

cylinder head and Section 10 for refitting of

the camshafts and connection of the upper

timing chain to the two camshaft sprockets.

31The remainder of the refitting is the

reverse of the removal procedure. If your car

is equipped with the hydraulic/self-levelling

suspension, refit the drive coupling and

coupling disc to the intermediate shaft (see

illustrations 8.9a and 8.9b). Coat the

mounting surface of the pump with RTVsealant and make sure the tang on the pump

aligns with the slot in the intermediate shaft

before bolting the pump to the front cover.

Refer to Section 7 for refitting of the

crankshaft spacer, damper and puller.

Caution: DO NOT start the engine until

you’re absolutely certain that the timing

chains are installed correctly. Serious and

costly engine damage could occur if the

chains are installed wrong.

32Run the engine and check for proper

operation.

9 Auxiliary shaft- renewal

3

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

1Refer to Chapter 10 and remove the power

steering pump, without disconnecting the

hoses. Remove the plastic power steering

pump drive coupling disc.

2A•8 Engine in-car repair procedures

8.28a Drill a small hole in the intermediate

shaft seal, thread a sheet metal screw into

it and use a small slide-hammer pull the

seal out of the cover8.28b Drive the new seal in with a seal-

driver or socket, to the same depth as the

original seal8.29 Bolt the front cover on hand tight, use

a straightedge to make sure the cover’s

top surface is level with the top of the

engine block, then tighten the cover bolts

3261 Jaguar XJ6 8.23a Add oil to the reservoir in the lower tensioner . . .

8.23b . . . and refit the tensioner against the guide -

after it’s installed, push the tensioner guide back and forth

a few times to prime the tensioner

Page 50 of 227

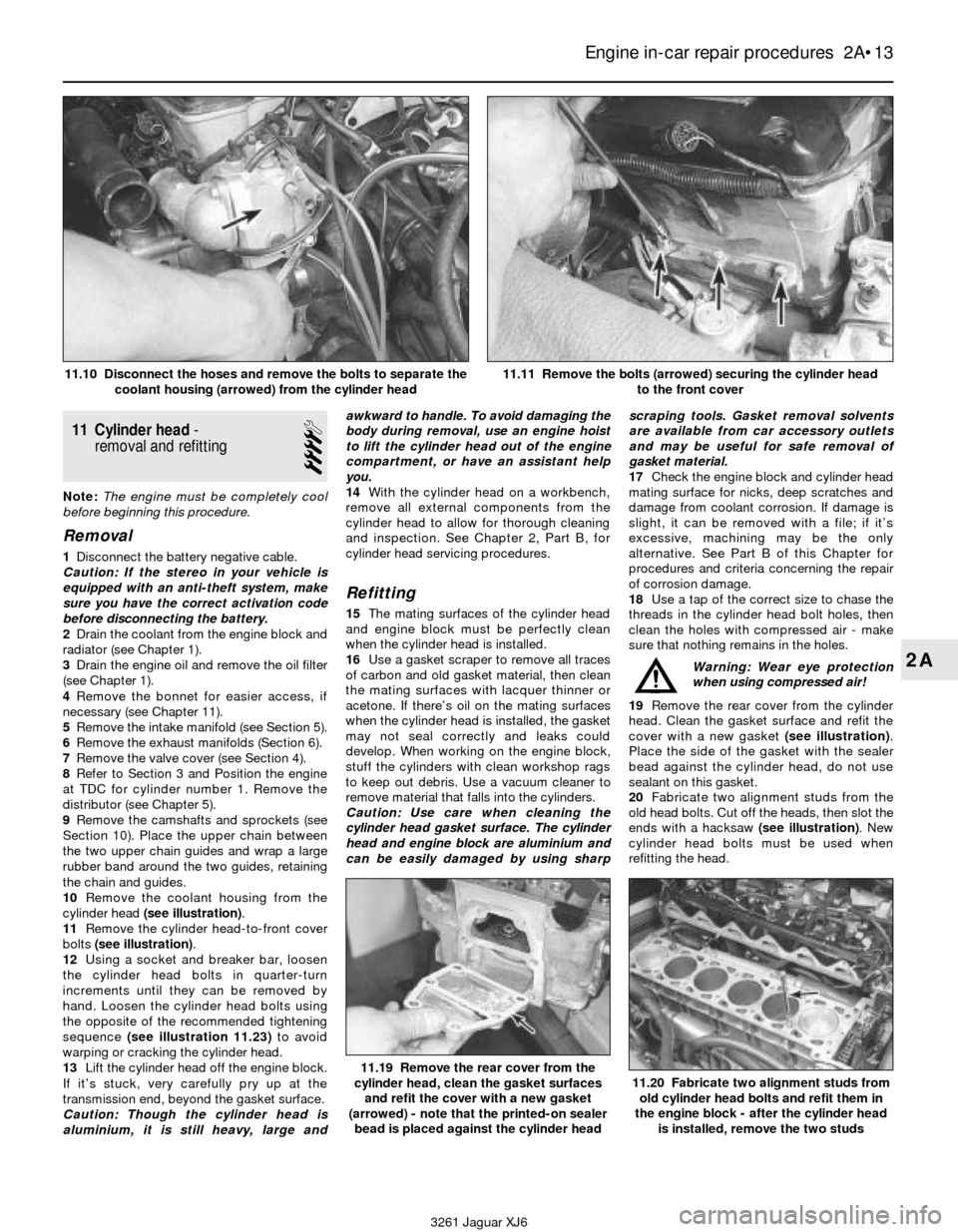

11 Cylinder head-

removal and refitting

4

Note:The engine must be completely cool

before beginning this procedure.

Removal

1Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Drain the coolant from the engine block and

radiator (see Chapter 1).

3Drain the engine oil and remove the oil filter

(see Chapter 1).

4Remove the bonnet for easier access, if

necessary (see Chapter 11).

5Remove the intake manifold (see Section 5).

6Remove the exhaust manifolds (Section 6).

7Remove the valve cover (see Section 4).

8Refer to Section 3 and Position the engine

at TDC for cylinder number 1. Remove the

distributor (see Chapter 5).

9Remove the camshafts and sprockets (see

Section 10). Place the upper chain between

the two upper chain guides and wrap a large

rubber band around the two guides, retaining

the chain and guides.

10Remove the coolant housing from the

cylinder head (see illustration).

11Remove the cylinder head-to-front cover

bolts (see illustration).

12Using a socket and breaker bar, loosen

the cylinder head bolts in quarter-turn

increments until they can be removed by

hand. Loosen the cylinder head bolts using

the opposite of the recommended tightening

sequence (see illustration 11.23)to avoid

warping or cracking the cylinder head.

13Lift the cylinder head off the engine block.

If it’s stuck, very carefully pry up at the

transmission end, beyond the gasket surface.

Caution: Though the cylinder head is

aluminium, it is still heavy, large andawkward to handle. To avoid damaging the

body during removal, use an engine hoist

to lift the cylinder head out of the engine

compartment, or have an assistant help

you.

14With the cylinder head on a workbench,

remove all external components from the

cylinder head to allow for thorough cleaning

and inspection. See Chapter 2, Part B, for

cylinder head servicing procedures.

Refitting

15The mating surfaces of the cylinder head

and engine block must be perfectly clean

when the cylinder head is installed.

16Use a gasket scraper to remove all traces

of carbon and old gasket material, then clean

the mating surfaces with lacquer thinner or

acetone. If there’s oil on the mating surfaces

when the cylinder head is installed, the gasket

may not seal correctly and leaks could

develop. When working on the engine block,

stuff the cylinders with clean workshop rags

to keep out debris. Use a vacuum cleaner to

remove material that falls into the cylinders.

Caution: Use care when cleaning the

cylinder head gasket surface. The cylinder

head and engine block are aluminium and

can be easily damaged by using sharpscraping tools. Gasket removal solvents

are available from car accessory outlets

and may be useful for safe removal of

gasket material.

17Check the engine block and cylinder head

mating surface for nicks, deep scratches and

damage from coolant corrosion. If damage is

slight, it can be removed with a file; if it’s

excessive, machining may be the only

alternative. See Part B of this Chapter for

procedures and criteria concerning the repair

of corrosion damage.

18Use a tap of the correct size to chase the

threads in the cylinder head bolt holes, then

clean the holes with compressed air - make

sure that nothing remains in the holes.

Warning: Wear eye protection

when using compressed air!

19Remove the rear cover from the cylinder

head. Clean the gasket surface and refit the

cover with a new gasket (see illustration).

Place the side of the gasket with the sealer

bead against the cylinder head, do not use

sealant on this gasket.

20Fabricate two alignment studs from the

old head bolts. Cut off the heads, then slot the

ends with a hacksaw (see illustration). New

cylinder head bolts must be used when

refitting the head.

Engine in-car repair procedures 2A•13

2A

11.19 Remove the rear cover from the

cylinder head, clean the gasket surfaces

and refit the cover with a new gasket

(arrowed) - note that the printed-on sealer

bead is placed against the cylinder head11.20 Fabricate two alignment studs from

old cylinder head bolts and refit them in

the engine block - after the cylinder head

is installed, remove the two studs

3261 Jaguar XJ6 11.10 Disconnect the hoses and remove the bolts to separate the

coolant housing (arrowed) from the cylinder head

11.11 Remove the bolts (arrowed) securing the cylinder head

to the front cover