lights JAGUAR XJ6 1997 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 108 of 227

model but the designations are the same.

Refer to the wiring diagrams at the end of

Chapter 12.

f) Start the engine and check the alternator

for abnormal noises (a shrieking or

squealing sound indicates a bad bushing).

g) Check the specific gravity of the battery

electrolyte. If it’s low, charge the battery

(doesn’t apply to maintenance free

batteries).

h) Make sure that the battery is fully charged

(one bad cell in a battery can cause

overcharging by the alternator).

i) Disconnect the battery cables (negative

first, then positive). Caution:If the stereo

in your vehicle is equipped with an anti-

theft system, make sure you have the

correct activation code before

disconnecting the battery. Inspect the

battery posts and the cable clamps for

corrosion. Clean them thoroughly if

necessary (see Chapter 1). Reconnect the

positive cable, then the negative cable.

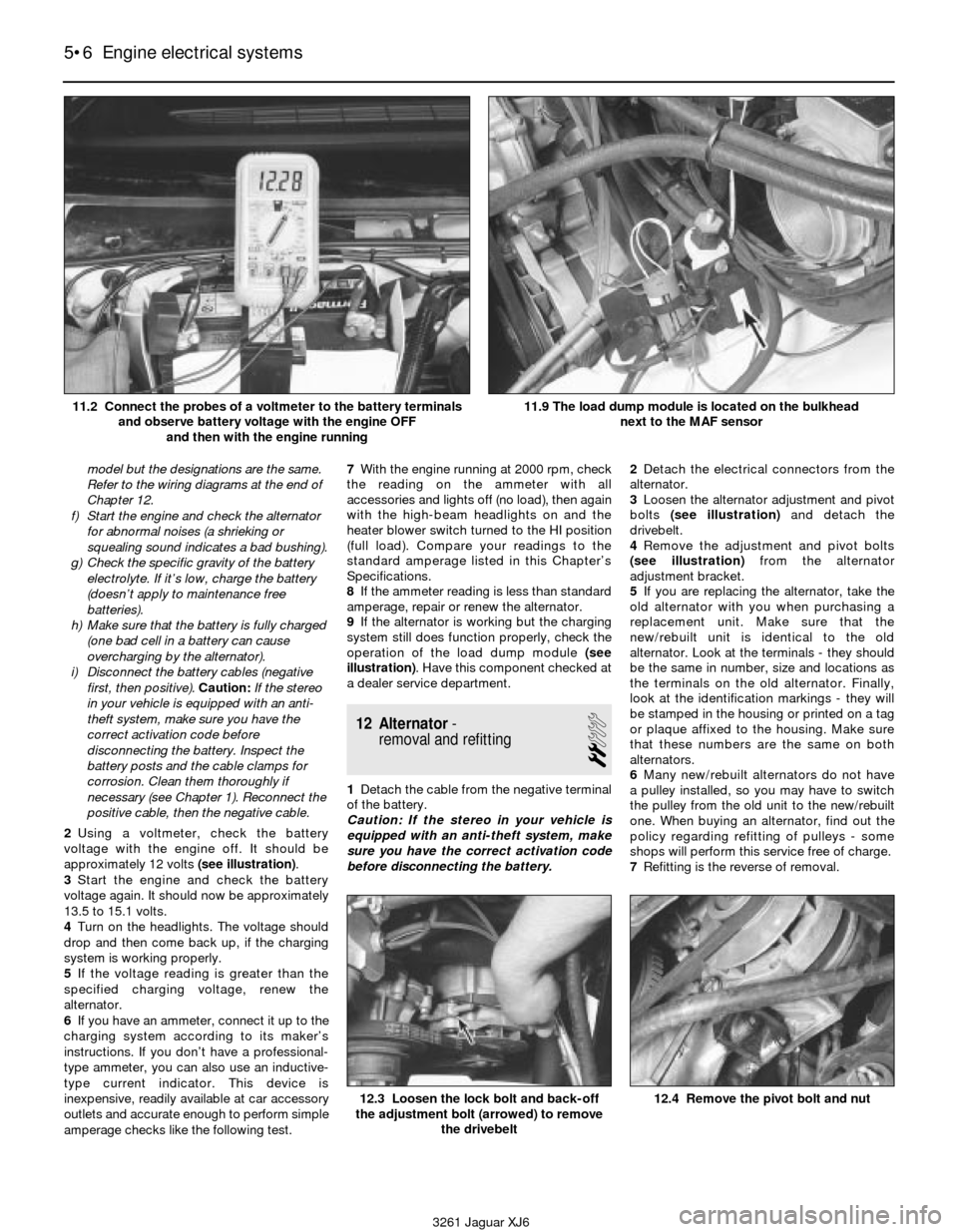

2Using a voltmeter, check the battery

voltage with the engine off. It should be

approximately 12 volts (see illustration).

3Start the engine and check the battery

voltage again. It should now be approximately

13.5 to 15.1 volts.

4Turn on the headlights. The voltage should

drop and then come back up, if the charging

system is working properly.

5If the voltage reading is greater than the

specified charging voltage, renew the

alternator.

6If you have an ammeter, connect it up to the

charging system according to its maker’s

instructions. If you don’t have a professional-

type ammeter, you can also use an inductive-

type current indicator. This device is

inexpensive, readily available at car accessory

outlets and accurate enough to perform simple

amperage checks like the following test.7With the engine running at 2000 rpm, check

the reading on the ammeter with all

accessories and lights off (no load), then again

with the high-beam headlights on and the

heater blower switch turned to the HI position

(full load). Compare your readings to the

standard amperage listed in this Chapter’s

Specifications.

8If the ammeter reading is less than standard

amperage, repair or renew the alternator.

9If the alternator is working but the charging

system still does function properly, check the

operation of the load dump module (see

illustration). Have this component checked at

a dealer service department.

12 Alternator-

removal and refitting

2

1Detach the cable from the negative terminal

of the battery.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.2Detach the electrical connectors from the

alternator.

3Loosen the alternator adjustment and pivot

bolts (see illustration) and detach the

drivebelt.

4Remove the adjustment and pivot bolts

(see illustration)from the alternator

adjustment bracket.

5If you are replacing the alternator, take the

old alternator with you when purchasing a

replacement unit. Make sure that the

new/rebuilt unit is identical to the old

alternator. Look at the terminals - they should

be the same in number, size and locations as

the terminals on the old alternator. Finally,

look at the identification markings - they will

be stamped in the housing or printed on a tag

or plaque affixed to the housing. Make sure

that these numbers are the same on both

alternators.

6Many new/rebuilt alternators do not have

a pulley installed, so you may have to switch

the pulley from the old unit to the new/rebuilt

one. When buying an alternator, find out the

policy regarding refitting of pulleys - some

shops will perform this service free of charge.

7Refitting is the reverse of removal.

5•6 Engine electrical systems

12.3 Loosen the lock bolt and back-off

the adjustment bolt (arrowed) to remove

the drivebelt12.4 Remove the pivot bolt and nut

3261 Jaguar XJ6 11.2 Connect the probes of a voltmeter to the battery terminals

and observe battery voltage with the engine OFF

and then with the engine running

11.9 The load dump module is located on the bulkhead

next to the MAF sensor

Page 135 of 227

at a time, so you can use the other side as a

reference during reassembly.

6Refitting is the reverse of removal.

7After refitting the brake disc, adjust the

handbrake shoes. Temporarily refit two nuts,

turn the adjuster (see illustration 5.7c)and

expand the shoes until the disc locks, then

back off the adjuster until you can spin the

disc without the shoes dragging.

8Adjust the handbrake cable (Section 10).

9Remove the axle stands and lower the

vehicle. Tighten the wheel nuts to the specified

torque (see Chapter 1 Specifications).

13 Brake light switch-

check and renewal

1

1The brake light switch activates the brake

lights when the brake pedal is depressed. It‘s

located at the top of the brake pedal, inside

the pedal box.

2If the brake lights don’t come on when the

brake pedal is depressed, check the fuses

(the fuse for the left brake light is in the left

fuse panel and the fuse for the right brake

light is in the right panel).

3If the fuses are okay, check the brake light

bulbs (see Chapter 12).

4If the fuses and bulbs are okay, either the

switch isn’t getting voltage (there’s an open-

circuit between the voltage source and the

switch), voltage isn’t reaching the brake light

Braking system 9•13

9

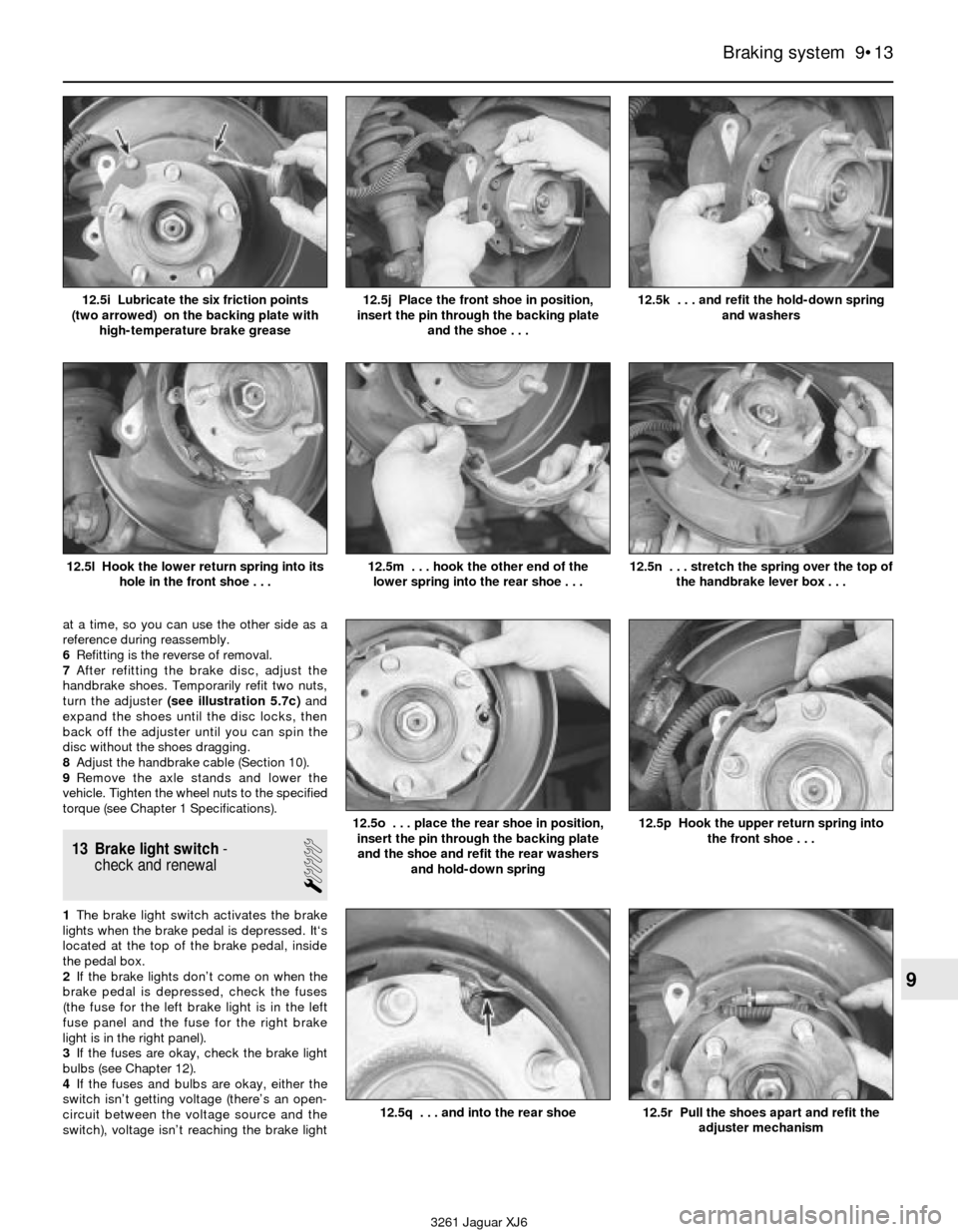

12.5j Place the front shoe in position,

insert the pin through the backing plate

and the shoe . . .12.5k . . . and refit the hold-down spring

and washers12.5i Lubricate the six friction points

(two arrowed) on the backing plate with

high-temperature brake grease

3261 Jaguar XJ6 12.5l Hook the lower return spring into its

hole in the front shoe . . .

12.5m . . . hook the other end of the

lower spring into the rear shoe . . .12.5n . . . stretch the spring over the top of

the handbrake lever box . . .

12.5o . . . place the rear shoe in position,

insert the pin through the backing plate

and the shoe and refit the rear washers

and hold-down spring12.5p Hook the upper return spring into

the front shoe . . .

12.5q . . . and into the rear shoe12.5r Pull the shoes apart and refit the

adjuster mechanism

Page 136 of 227

bulbs (open-circuit between the switch and

the bulbs), or the switch is defective.

5To remove the switch, reach up under the

dash and unplug the two electrical connectors

- one for the brake lights and one for the

cruise control system. Locate the two pairs of

leads coming down the pedal box and trace

them to their connectors on or near the

steering column.

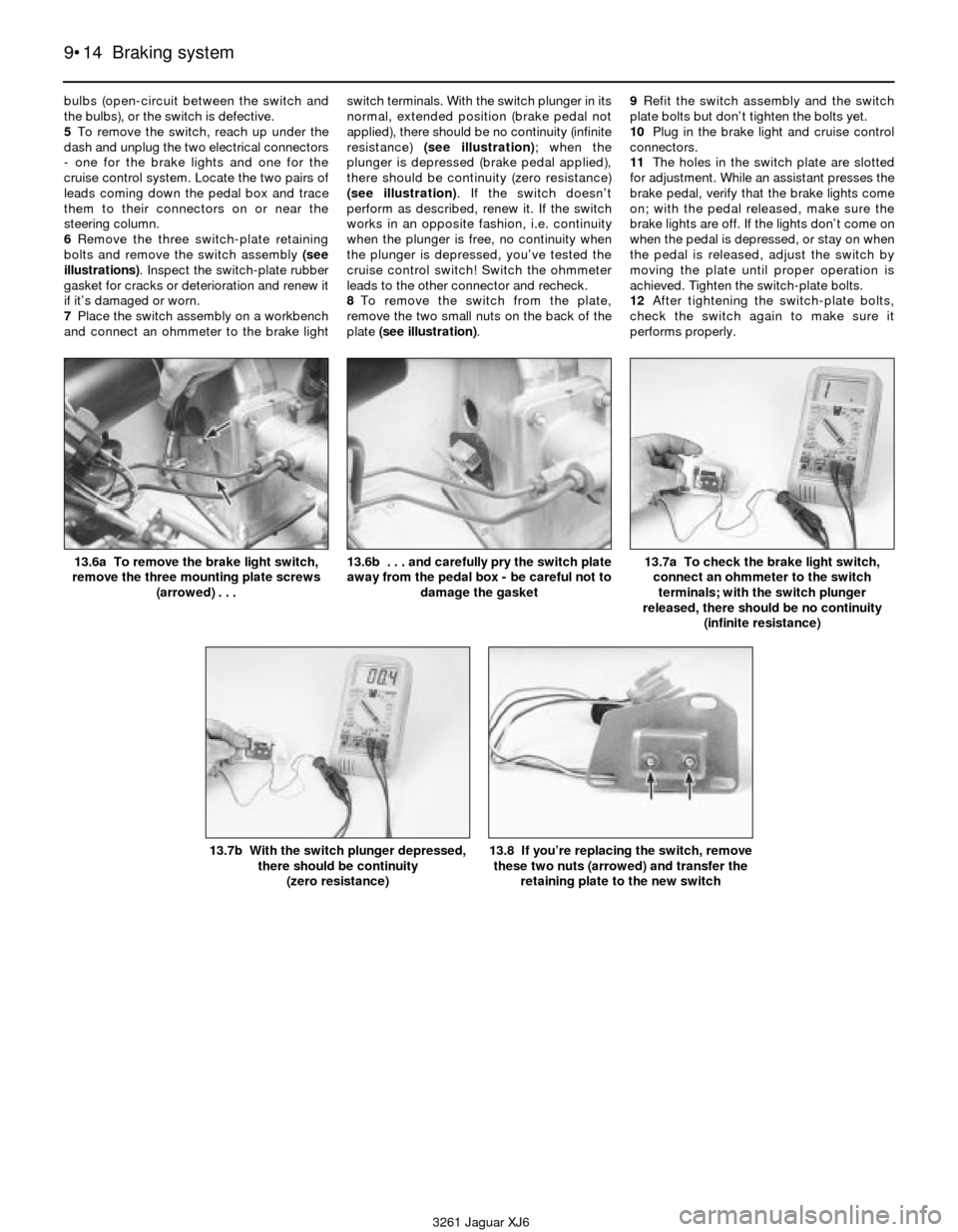

6Remove the three switch-plate retaining

bolts and remove the switch assembly (see

illustrations). Inspect the switch-plate rubber

gasket for cracks or deterioration and renew it

if it’s damaged or worn.

7Place the switch assembly on a workbench

and connect an ohmmeter to the brake lightswitch terminals. With the switch plunger in its

normal, extended position (brake pedal not

applied), there should be no continuity (infinite

resistance) (see illustration); when the

plunger is depressed (brake pedal applied),

there should be continuity (zero resistance)

(see illustration). If the switch doesn’t

perform as described, renew it. If the switch

works in an opposite fashion, i.e. continuity

when the plunger is free, no continuity when

the plunger is depressed, you’ve tested the

cruise control switch! Switch the ohmmeter

leads to the other connector and recheck.

8To remove the switch from the plate,

remove the two small nuts on the back of the

plate (see illustration).9Refit the switch assembly and the switch

plate bolts but don’t tighten the bolts yet.

10Plug in the brake light and cruise control

connectors.

11The holes in the switch plate are slotted

for adjustment. While an assistant presses the

brake pedal, verify that the brake lights come

on; with the pedal released, make sure the

brake lights are off. If the lights don’t come on

when the pedal is depressed, or stay on when

the pedal is released, adjust the switch by

moving the plate until proper operation is

achieved. Tighten the switch-plate bolts.

12After tightening the switch-plate bolts,

check the switch again to make sure it

performs properly.

9•14 Braking system

13.6a To remove the brake light switch,

remove the three mounting plate screws

(arrowed) . . .13.6b . . . and carefully pry the switch plate

away from the pedal box - be careful not to

damage the gasket13.7a To check the brake light switch,

connect an ohmmeter to the switch

terminals; with the switch plunger

released, there should be no continuity

(infinite resistance)

13.7b With the switch plunger depressed,

there should be continuity

(zero resistance)13.8 If you’re replacing the switch, remove

these two nuts (arrowed) and transfer the

retaining plate to the new switch

3261 Jaguar XJ6

Page 154 of 227

3Remove two bumper retaining bolts located

on the bottom side of the bumper (see

illustration). Pull the bumper assembly out

and away from the vehicle to remove it.

4Refitting is the reverse of removal.

15 Front wing-

removal and refitting

3

1Loosen the front wheel nuts. Raise the

vehicle, support it securely on axle stands and

remove the front wheel.

2Remove the front bumper assembly (see

Section 14).

3Remove the front spoiler (see Section 13).4Detach the inner wing splash shield (see

illustration).

5On 1988 and 1989 models, remove the

coolant overflow reservoir located behind the

splash shield (see Chapter 3).

6On models with round headlights, remove

the headlight bezel. On models with

composite headlights (1992 Vanden Plas, all

1993 and later models), remove the headlight

(see Chapter 12).

7Remove the wing mounting bolts and nuts

(see illustrations).

8Detach the wing. It’s a good idea to have an

assistant support the wing while it’s being

moved away from the vehicle to prevent

damage to the surrounding body panels.

9Refitting is the reverse of removal.

16 Boot lid- removal,

refitting and adjustment

2

Note:The boot lid is heavy and somewhat

awkward to remove and refit - at least two

people should perform this procedure.

Removal and refitting

1Open the boot lid and cover the edges of

the boot compartment with pads or cloths to

protect the painted surfaces when the lid is

removed.

2Disconnect any cables or wire harness

connectors attached to the boot lid that would

interfere with removal.

3Make alignment marks around the hinge

mounting bolts with a marking pen.

4While an assistant supports the boot lid,

remove the lid-to-hinge bolts on both sides

and lift it off(see illustration).

5Refitting is the reverse of removal. Note:

When refitting the boot lid, align the lid-to-

hinge bolts with the marks made during

removal.

Adjustment

6Fore-and-aft and side-to-side adjustment

of the boot lid is done by moving the bonnet in

relation to the hinge plate after loosening the

bolts or nuts.

7Scribe a line around the entire hinge plate

as described earlier in this section so you can

judge the amount of movement.

11•6 Bodywork and fittings

14.3 Remove the two retaining bolts from

the bottom of the bumper, then remove the

bumper from the vehicle15.4 Remove the bolts (arrowed) securing

the inner wing splash shield15.7a Detach the wing retaining bolts

(arrowed) at the front of the wing

15.7c Working in the wheel opening,

remove the wing-to-rocker panel bolt

(arrowed)

15.7d Remove the wing-to-door pillar bolt

(arrow; lower bolt not visible)15.7e Detach the bolts along the

top of the wing

3261 Jaguar XJ6

15.7b Remove the wing-to-radiator

support bolt (arrowed)

16.4 With the help of an assistant to hold

the boot lid, remove the retaining bolts and

lift off the boot lid

Page 160 of 227

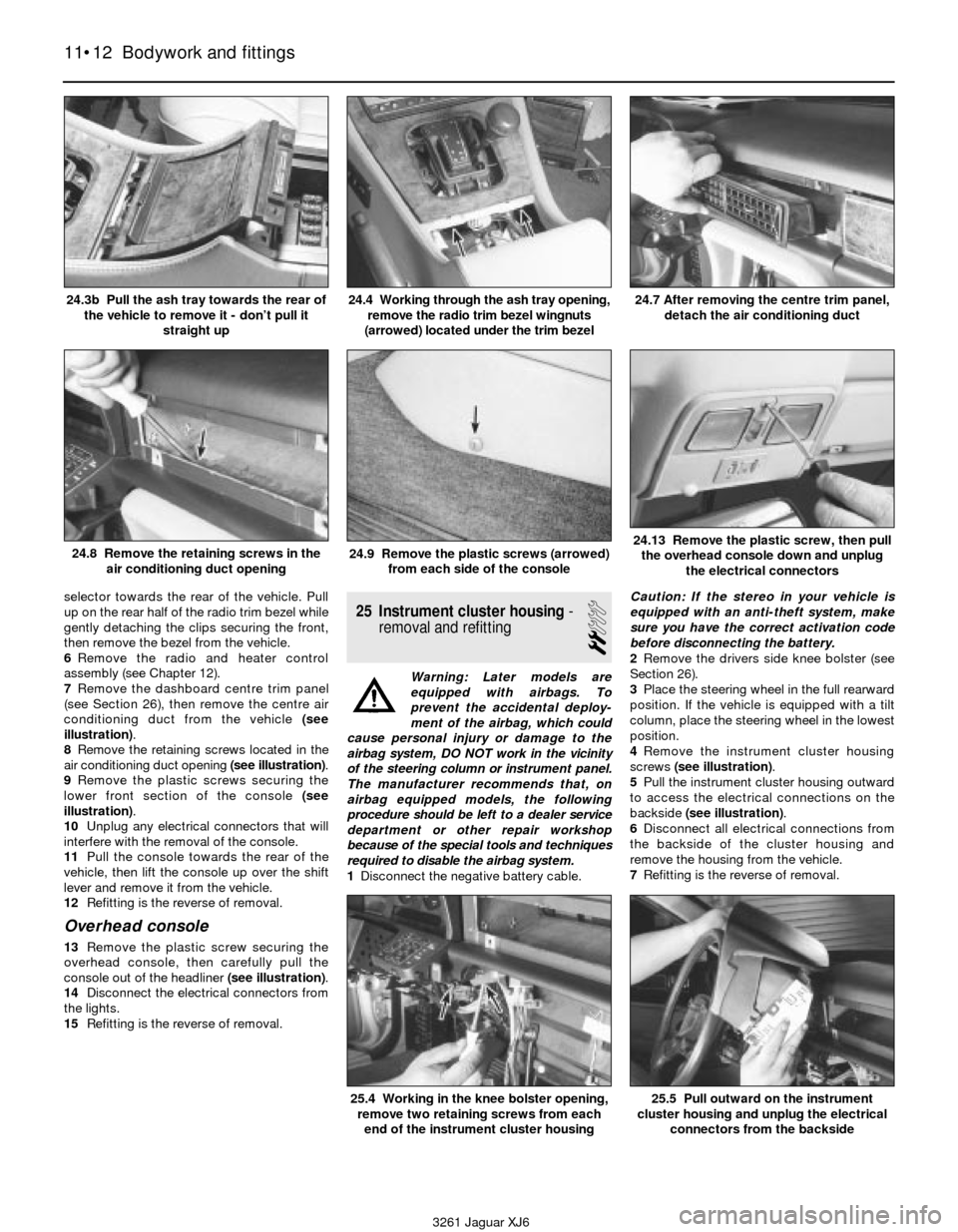

selector towards the rear of the vehicle. Pull

up on the rear half of the radio trim bezel while

gently detaching the clips securing the front,

then remove the bezel from the vehicle.

6Remove the radio and heater control

assembly (see Chapter 12).

7Remove the dashboard centre trim panel

(see Section 26), then remove the centre air

conditioning duct from the vehicle (see

illustration).

8Remove the retaining screws located in the

air conditioning duct opening (see illustration).

9Remove the plastic screws securing the

lower front section of the console (see

illustration).

10Unplug any electrical connectors that will

interfere with the removal of the console.

11Pull the console towards the rear of the

vehicle, then lift the console up over the shift

lever and remove it from the vehicle.

12Refitting is the reverse of removal.

Overhead console

13Remove the plastic screw securing the

overhead console, then carefully pull the

console out of the headliner (see illustration).

14Disconnect the electrical connectors from

the lights.

15Refitting is the reverse of removal.

25 Instrument cluster housing-

removal and refitting

2

Warning: Later models are

equipped with airbags. To

prevent the accidental deploy-

ment of the airbag, which could

cause personal injury or damage to the

airbag system, DO NOT work in the vicinity

of the steering column or instrument panel.

The manufacturer recommends that, on

airbag equipped models, the following

procedure should be left to a dealer service

department or other repair workshop

because of the special tools and techniques

required to disable the airbag system.

1Disconnect the negative battery cable. Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Remove the drivers side knee bolster (see

Section 26).

3Place the steering wheel in the full rearward

position. If the vehicle is equipped with a tilt

column, place the steering wheel in the lowest

position.

4Remove the instrument cluster housing

screws (see illustration).

5Pull the instrument cluster housing outward

to access the electrical connections on the

backside (see illustration).

6Disconnect all electrical connections from

the backside of the cluster housing and

remove the housing from the vehicle.

7Refitting is the reverse of removal.

11•12 Bodywork and fittings

24.3b Pull the ash tray towards the rear of

the vehicle to remove it - don’t pull it

straight up24.4 Working through the ash tray opening,

remove the radio trim bezel wingnuts

(arrowed) located under the trim bezel24.7 After removing the centre trim panel,

detach the air conditioning duct

24.8 Remove the retaining screws in the

air conditioning duct opening24.9 Remove the plastic screws (arrowed)

from each side of the console24.13 Remove the plastic screw, then pull

the overhead console down and unplug

the electrical connectors

3261 Jaguar XJ6

25.4 Working in the knee bolster opening,

remove two retaining screws from each

end of the instrument cluster housing25.5 Pull outward on the instrument

cluster housing and unplug the electrical

connectors from the backside

Page 162 of 227

personal injury or damage to the airbag

system, DO NOT work in the vicinity of the

steering column or instrument panel. The

manufacturer recommends that, on airbag

equipped models, the following procedure

should be left to a dealer service

department or other repair workshop

because of the special tools and techniques

required to disable the airbag system.

1Remove the steering wheel (Chapter 10)

2Remove the knob from the rheostat

(dimmer) for the instrument panel lights (see

illustration).

3Remove the lower steering column cover

screws (see illustration), then detach the

lower cover.

4Working through the lower cover opening,

remove the four screws securing the upper

half of the cover, then pull the cover forward

and out to remove it (see illustration).

5Refitting is the reverse of removal.

28 Cowl cover-

removal and refitting

2

1Remove the windscreen wiper arms (see

Chapter 12).2Remove the retaining screws located along

the top of the cowl cover (see illustration).

3Lift the cowl cover up slightly, then detach

the electrical connectors and the spray nozzle

hoses from the backside of the cowl cover.

4Detach the cowl cover from the vehicle.

5Refitting is the reverse of removal.

29 Seats- removal and refitting

2

Front seat

1Position the seat all the way forward or all

the way to the rear to access the front seat

retaining bolts.

2Detach any bolt trim covers and remove the

retaining bolts (see illustration).

3Tilt the seat upward to access the

underneath, then unplug any electrical

connectors and lift the seat from the vehicle.

4Refitting is the reverse of removal.

Rear seat

5Remove retaining screws at the lower edge

of the seat cushion (see illustration). Then lift

up on the front edge and remove the cushion

from the vehicle.

6Detach the retaining bolts at the lower edge

of the seat back.

7Lift up on the lower edge of the seat back to

release the clips securing the top. Then

remove it from the vehicle.

8Refitting is the reverse of removal.

11•14 Bodywork and fittings

27.4 Remove the four screws securing the

upper half of the steering column cover

28.2 Remove the screws (arrowed)

located along the top of the cowl cover29.2 Use a Torx bit to remove the front

seat retaining bolts (arrowed)

3261 Jaguar XJ6 27.2 Pull off the knob from the instrument panel light rheostat

27.3 Remove the lower steering column cover screws

29.5 Detach the screws (arrowed) along

the lower edge of the seat cove

Page 163 of 227

3261 Jaguar XJ6

12

Chapter 12

Body electrical system

1 General information

The electrical system is a 12-volt, negative

earth type. Power for the lights and all

electrical accessories is supplied by a

lead/acid-type battery which is charged by

the alternator.

This Chapter covers repair and service

procedures for the various electrical

components not associated with the engine.

Information on the battery, alternator,

distributor and starter motor will be found in

Chapter 5.

It should be noted that when portions of the

electrical system are serviced, the cable

should be disconnected from the negative

battery terminal to prevent electrical shorts

and/or fires.

2 Electrical fault finding-

general information

A typical electrical circuit consists of an

electrical component, any switches, relays,

motors, fuses, fusible links, in-line fuses or

circuit breakers related to that component

and the wiring and electrical connectors that

link the component to both the battery andthe chassis. To help you pinpoint an electrical

circuit problem, wiring diagrams are included

at the end of this Chapter.

Before tackling any troublesome electrical

circuit, first study the appropriate wiring

diagrams to get a complete understanding of

what makes up that individual circuit. Trouble

spots, for instance, can often be narrowed

down by noting if other components related to

the circuit are operating properly. If several

components or circuits fail at one time,

chances are the problem is in a fuse or earth

connection, because several circuits are often

routed through the same fuse and earth

connections.

Electrical problems usually stem from

simple causes, such as loose or corroded

connections, a blown fuse, a melted fusible

link or a bad relay. Visually inspect the

condition of all fuses, wires and connections

in a problem circuit before diagnosing it.

If testing instruments are going to be

utilised, use the diagrams to plan ahead of

time where you will make the necessary

connections in order to accurately pinpoint

the trouble spot.

The basic tools needed for electrical fault

finding include a circuit tester or voltmeter (a

12-volt bulb with a set of test leads can also

be used), a continuity tester, which includes a

bulb, battery and set of test leads, and a

jumper wire, preferably with a circuit breaker

incorporated, which can be used to bypasselectrical components. Before attempting to

locate a problem with test instruments,

use the wiring diagram(s) to decide where to

make the connections.

Voltage checks

Voltage checks should be performed if a

circuit is not functioning properly. Connect

one lead of a circuit tester to either the

negative battery terminal or a known good

earth. Connect the other lead to a electrical

connector in the circuit being tested,

preferably nearest to the battery or fuse. If the

bulb of the tester lights, voltage is present,

which means that the part of the circuit

between the electrical connector and the

battery is problem free. Continue checking the

rest of the circuit in the same fashion. When

you reach a point at which no voltage is

present, the problem lies between that point

and the last test point with voltage. Most of

the time the problem can be traced to a loose

connection. Note:Keep in mind that some

circuits receive voltage only when the ignition

key is in the Accessory or Run position.

Finding a short

One method of finding shorts in a circuit is

to remove the fuse and connect a test light or

voltmeter in its place. There should be no

voltage present in the circuit. Move the wiring

harness from side to side while watching the

test light. If the bulb goes on, there is a short Airbag system - general information . . . . . . . . . . . . . . . . . . . . . . . . . 28

Bulb renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Central locking system - description and check . . . . . . . . . . . . . . . . 25

Circuit breakers - general information . . . . . . . . . . . . . . . . . . . . . . . . 5

Cruise control system - description and check . . . . . . . . . . . . . . . . . 23

Direction indicators/hazard flashers - general information . . . . . . . . 7

Electric aerial - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electric side view mirrors - description and check . . . . . . . . . . . . . . 26

Electric sunroof - description and check . . . . . . . . . . . . . . . . . . . . . . 27

Electric window system - description and check . . . . . . . . . . . . . . . 24

Electrical fault finding - general information . . . . . . . . . . . . . . . . . . . 2

Fuel, oil and temperature gauges - check . . . . . . . . . . . . . . . . . . . . . 11

Fuses - general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Headlight housing (1992 to 1994 models) - removal and refitting . . . 19Headlights - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Headlights - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Heated rear window - check and repair . . . . . . . . . . . . . . . . . . . . . . 16

Horn - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ignition switch and key lock cylinder - removal and refitting . . . . . . 9

Inertia switch - description and check . . . . . . . . . . . . . . . . . . . . . . . . 22

In-line fuses - general information . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Instrument cluster - removal and refitting . . . . . . . . . . . . . . . . . . . . . 12

Instrument panel switches - removal and refitting . . . . . . . . . . . . . . 10

Radio and speakers - removal and refitting . . . . . . . . . . . . . . . . . . . 13

Relays - general information and testing . . . . . . . . . . . . . . . . . . . . . . 6

Steering column switches - removal and refitting . . . . . . . . . . . . . . . 8

Windscreen wiper motor - removal and refitting . . . . . . . . . . . . . . . . 15

Wiring diagrams - general information . . . . . . . . . . . . . . . . . . . . . . . 29

12•1

Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 165 of 227

wash system, radio memory and the ABS

main feed and pump circuits.

In-line fuses are located through out the

vehicle depending on the year, make and

model. Consult the wiring diagrams at the end

of this Chapter for further information.

In-line fuses also have a blade terminal

design, which allow fingertip removal and

renewal. If an electrical component fails,

always check the fuse first. A blown fuse is

easily identified through the clear plastic

body. Inspect the element for evidence of

damage (see illustration 3.3).

Be sure to renew blown fuses with the

correct type. Fuses are usually colour-coded

to indicate their rating. Fuses of different

ratings are physically interchangeable, but

only fuses of the proper rating should be

used. Replacing a fuse with one of a different

value than specified is not recommended.

Each electrical circuit needs a specific

amount of protection. The amperage value of

each fuse is moulded into the fuse body.If the renewal fuse immediately fails, don’t

renew it again until the cause of the problem

is isolated and corrected. Don’t substitute

anything else for the fuse. In most cases, this

will be a short circuit in the wiring caused by a

broken or deteriorated wire.

5 Circuit breakers-

general information

Circuit breakers generally protect

components such as electric windows, central

locking and headlights. On some models the

circuit breaker resets itself automatically, so

an electrical overload in the circuit will cause it

to fail momentarily, then come back on. If the

circuit doesn’t come back on, check it

immediately. Once the condition is corrected,

the circuit breaker will resume its normal

function. Some circuit breakers have a button

on top and must be reset manually.To test a circuit breaker, use an ohmmeter

to check continuity between the terminals. A

reading of zero to 1.0 ohms indicates a good

circuit breaker. An open circuit reading on the

meter indicates a bad circuit breaker.

6 Relays- general information

and testing

2

General information

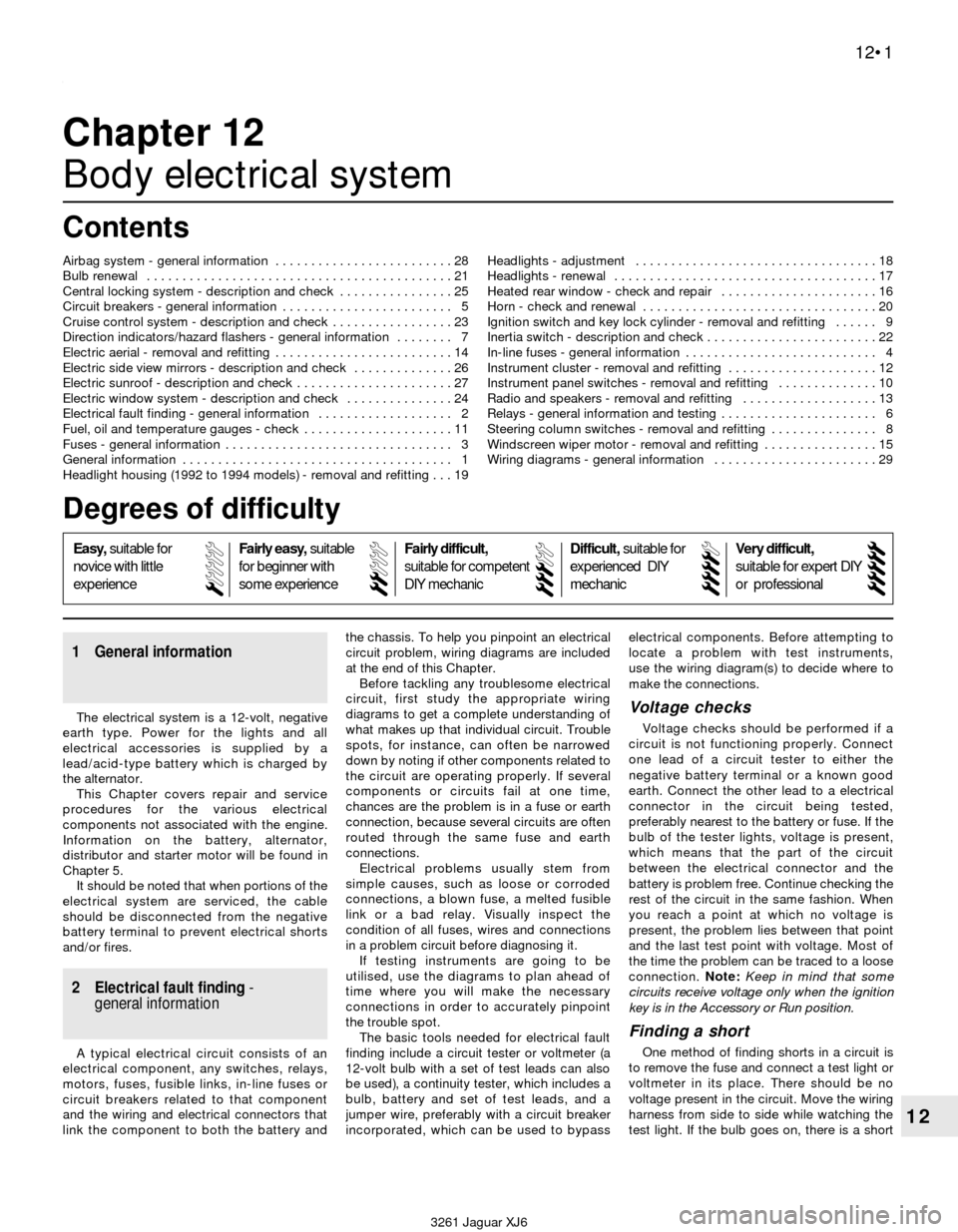

Several electrical accessories in the vehicle,

such as the fuel injection system, electric

windows, central locking, etc, use relays to

transmit the electrical signal to the component.

Relays use a low-current circuit (the control

circuit) to open and close a high-current circuit

(the power circuit). If the relay is defective, that

component will not operate properly. The

relays are mounted throughout the vehicle (see

illustrations). If a faulty relay is suspected, it

Body electrical system 12•3

12

3261 Jaguar XJ6 1988 to 1989 relay location details

Page 171 of 227

6If the voltage is 6 volts, the element is okay

(there is no break). If the voltage is 12 volts,

the element is broken between the centre

of the element and the positive end. If the

voltage is 0 volts the element is broken

between the centre of the element and earth.

7To find the break, place the voltmeter

positive lead against the defogger positive

terminal. Place the voltmeter negative lead

with the foil strip against the heating element

at the positive terminal end and slide it toward

the negative terminal end. The point at which

the voltmeter deflects from zero to several

volts is the point at which the heating element

is broken (see illustration).

Repair

8Repair the break in the element using a

repair kit specifically recommended for this

purpose.

9Prior to repairing a break, turn off the system

and allow it to cool off for a few minutes.

10Lightly buff the element area with fine

steel wool, then clean it thoroughly with

rubbing alcohol.

11Use masking tape to mask off the area

being repaired.

12Thoroughly mix the epoxy, following the

instructions provided with the repair kit.

13Apply the epoxy material to the slit in the

masking tape, overlapping the undamaged

area about 3/4-inch on either end (see

illustration).

14Allow the repair to cure for 24 hours before

removing the tape and using the system.

17 Headlights- renewal

1

Warning: Later models are

equipped with halogen gas-filled

headlight bulbs which are underpressure and may shatter if the surface is

damaged or the bulb is dropped. Wear eye

protection and handle the bulbs carefully,

grasping only the base whenever possible.

Do not touch the surface of the bulb with

your fingers because the oil from your skin

could cause it to overheat and fail

prematurely. If you do touch the bulb

surface, clean it with rubbing alcohol.

Sealed beam units

1Remove the radiator grille (see Chapter 11).

2Detach the headlight bezel trim cover (see

illustration).

3Remove the headlight bezel (see

illustrations).

4Remove the screws which secure the

retaining ring and withdraw the ring. Support

the light as this is done (see illustration).

Body electrical system 12•9

12

16.13 Apply masking tape to the inside of

the window at the damaged area, then

brush on the special conductive coating17.2 Remove the screws (arrowed) and

detach the headlight bezel trim cover

17.3a Remove the two retaining screws

at the top and the one in the grille opening

(arrowed)17.3b The retaining screw at the

outside lower corner can be accessed

from under the bumper

3261 Jaguar XJ6 16.5 To determine if a heating element has broken, check the

voltage at the centre of each element. If the voltage is 6-volts, the

element is unbroken; if the voltage is 12-volts, the element is

broken between the centre and the positive end. If there is no

voltage, the element is broken between the centre and earth

16.7 To find the break, place the voltmeter positive lead against

the heated window positive terminal, place the voltmeter negative

lead with the foil strip against the heating element at the positive

terminal end and slide it toward the negative terminal end -

the point at which the voltmeter reading changes abruptly is the

point at which the element is broken

Page 172 of 227

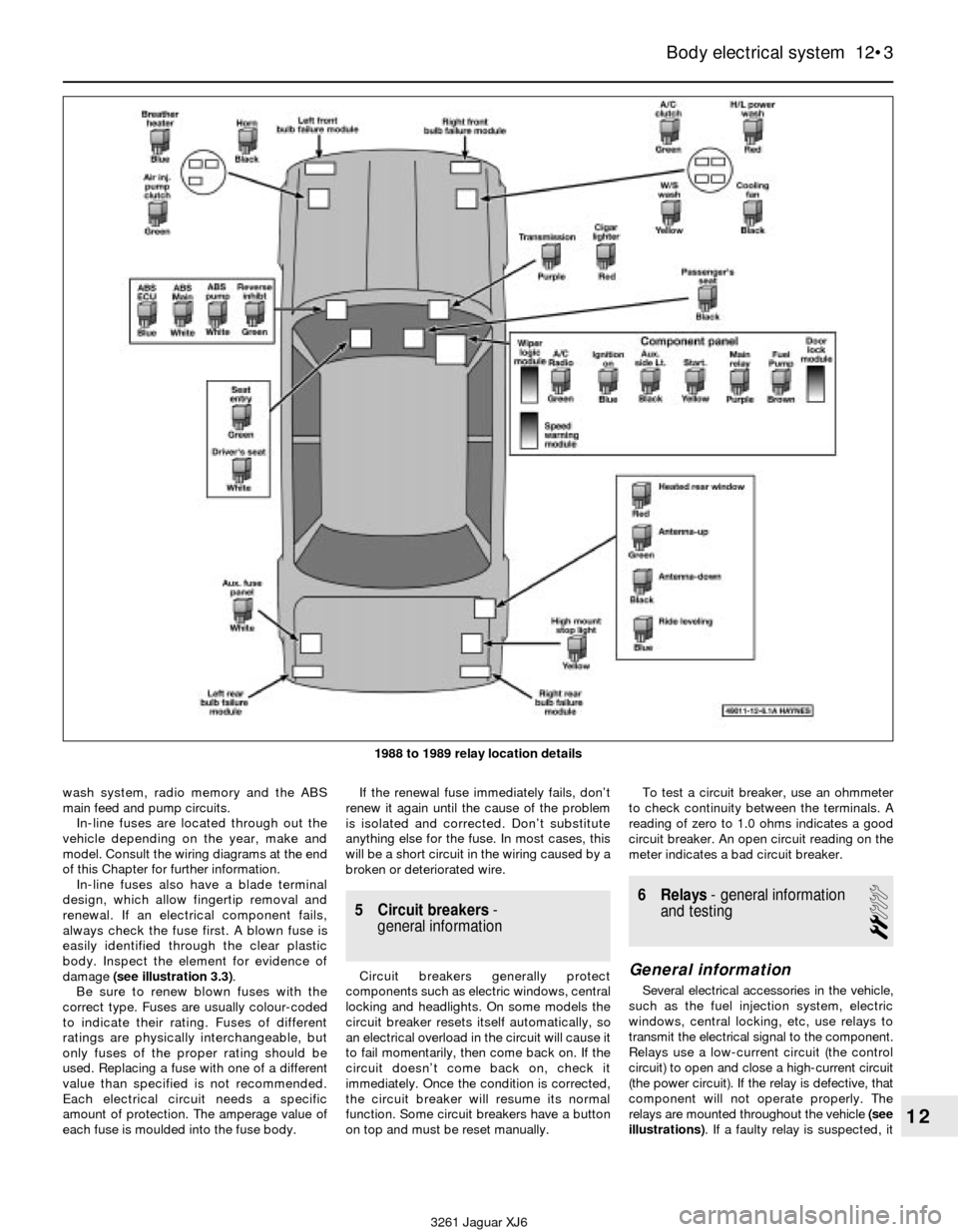

5Pull the headlight out slightly and

disconnect the electrical connector from the

rear of the light, then remove the light from the

vehicle.

6To refit, position the new unit close enough

to connect the electrical connector. Make

sure that the numbers moulded into the lens

are at the top.

7Refit and tighten the retaining ring. Test the

headlight operation.

8The remainder of the refitting is the reverse

of removal.

Halogen gas-filled bulbs

9Disconnect the electrical connector from

the bulb assembly. Rotate the headlight bulb

connector 1/4-turn anti-clockwise (viewed

from the rear) (see illustration).

10Withdraw the bulb assembly from the

headlight housing.

11Without touching the glass with your bare

fingers (see the Warningat the start of the

Section), insert the new bulb assembly into

the headlight housing and rotate the bulb

socket 1/4-turn clockwise to refit it.

12Plug in the electrical connector and test

headlight operation.

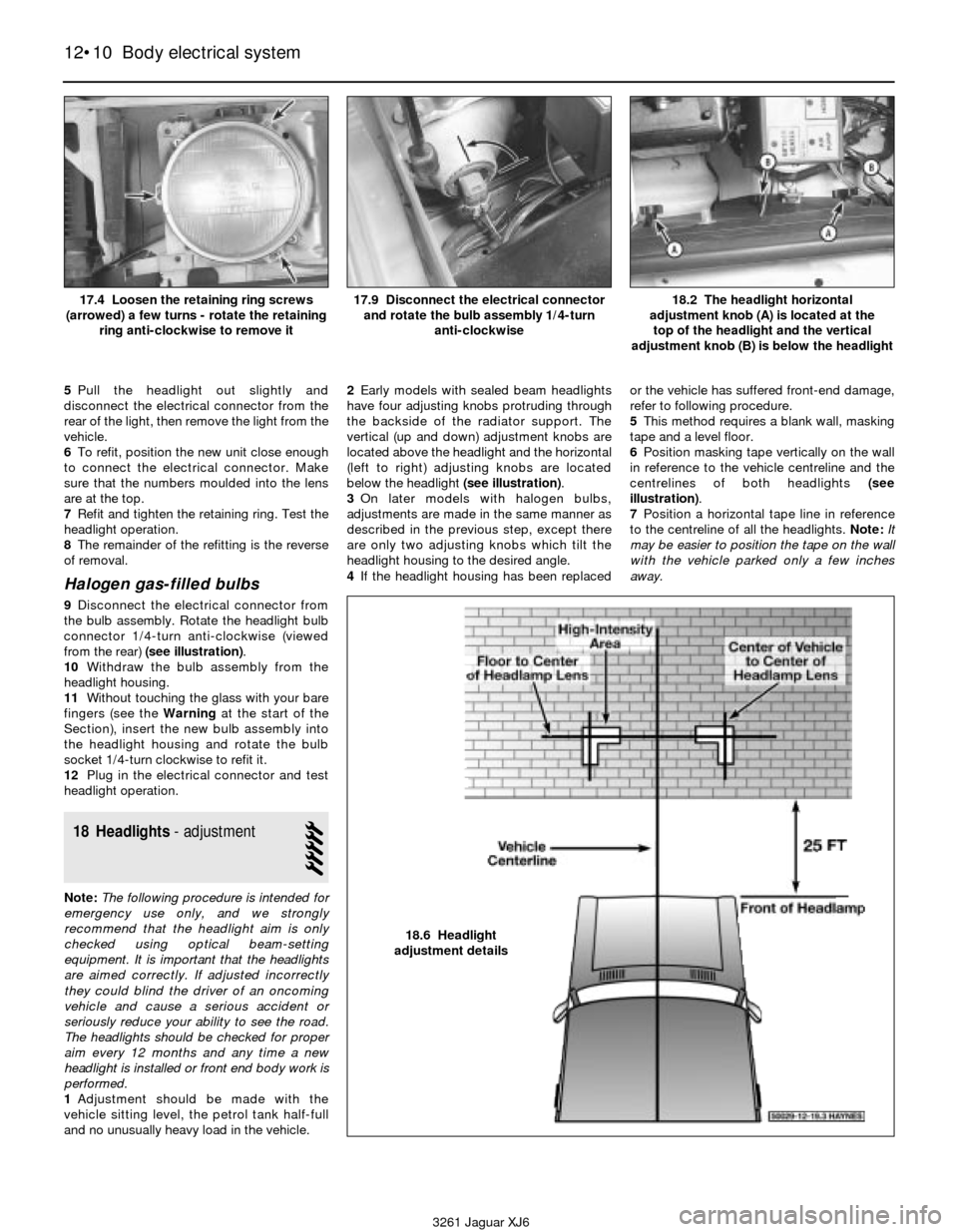

18 Headlights- adjustment

5

Note:The following procedure is intended for

emergency use only, and we strongly

recommend that the headlight aim is only

checked using optical beam-setting

equipment. It is important that the headlights

are aimed correctly. If adjusted incorrectly

they could blind the driver of an oncoming

vehicle and cause a serious accident or

seriously reduce your ability to see the road.

The headlights should be checked for proper

aim every 12 months and any time a new

headlight is installed or front end body work is

performed.

1Adjustment should be made with the

vehicle sitting level, the petrol tank half-full

and no unusually heavy load in the vehicle.2Early models with sealed beam headlights

have four adjusting knobs protruding through

the backside of the radiator support. The

vertical (up and down) adjustment knobs are

located above the headlight and the horizontal

(left to right) adjusting knobs are located

below the headlight (see illustration).

3On later models with halogen bulbs,

adjustments are made in the same manner as

described in the previous step, except there

are only two adjusting knobs which tilt the

headlight housing to the desired angle.

4If the headlight housing has been replacedor the vehicle has suffered front-end damage,

refer to following procedure.

5This method requires a blank wall, masking

tape and a level floor.

6Position masking tape vertically on the wall

in reference to the vehicle centreline and the

centrelines of both headlights (see

illustration).

7Position a horizontal tape line in reference

to the centreline of all the headlights. Note:It

may be easier to position the tape on the wall

with the vehicle parked only a few inches

away.

12•10 Body electrical system

3261 Jaguar XJ618.2 The headlight horizontal

adjustment knob (A) is located at the

top of the headlight and the vertical

adjustment knob (B) is below the headlight

17.4 Loosen the retaining ring screws

(arrowed) a few turns - rotate the retaining

ring anti-clockwise to remove it17.9 Disconnect the electrical connector

and rotate the bulb assembly 1/4-turn

anti-clockwise

18.6 Headlight

adjustment details