Ref 1 JAGUAR XJ6 1997 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 52 of 227

Refitting

5Remove all traces of old gasket material

and sealant from the engine block and sump.

Clean the mating surface with lacquer thinner

or acetone.

Caution: Do not use a sharp scraping tool.

Both the sump and the engine block are

aluminium and could be easily damaged.

6Make sure the threaded bolt holes in the

engine block and bellhousing are clean.

7Inspect the flange of the sump for any

cracks, pits or scratches that could cause an

oil leak.

8Remove the baffle plate at the rear of the

sump (see illustration). Clean the sump area

and the baffle, then refit the baffle.

9Inspect the oil pump pickup tube for

cracks, or foreign material blocking the screen

(see illustration).

10Apply a bead of RTV sealant to the sump

flange(see illustration). Note:The sump

must be installed within 5 minutes of sealer

application.

11Carefully position the sump on the engine

block and push it toward the transmission

adapter plate as you press it against the

engine block. Loosely refit four bolts, two on

each side of the sump. Tighten the four bolts

in a criss-cross pattern to the torque listed in

this Chapter’s Specifications, then loosen

each bolt 90°.

12Refit the two engine adapter-to-sump

bolts. Tighten the two bolts to the torque

listed in this Chapter’s Specifications, then

loosen each one 180°.

13Refit the remainder of the sump-to-engine

block bolts hand tight until all are installed,

then tighten them to the torque listed in this

Chapter’s Specifications. Lastly, tighten the

two adapter-to-sump bolts to the torque

listed in this Chapter’s Specifications.

Caution: Failure to follow this tightening

procedure could stress or possibly crack

the adapter plate.

14The remainder of refitting is the reverse of

removal. Be sure to add oil and refit a new oil

filter.

15Run the engine and check for oil pressure

and leaks.13 Oil pump- removal,

inspection and refitting

4

Removal

1Remove the sump (see Section 12).

2Unbolt the oil pickup tube and oil transfer

housing from the engine block (see

illustration). Note:Have a drain pan under the

transfer housing, as oil may drip out when the

housing is loosened from the engine block.

3Carefully pull the transfer housing and

transfer tubes to the rear to separate them

from the oil pump body.

4Bend back the locking tabs and remove thethree bolts retaining the oil pump drive

sprocket to the oil pump (see illustration).

Pull the chain and sprocket from the front of

the pump. Note:There are shims between the

sprocket and the pump. Collect them while

pulling off the sprocket.

5Remove the bolts and detach the oil pump

from the engine.

6Remove all traces of sealant and old gasket

material from the oil pump body and engine

block, then clean the mating surfaces with

lacquer thinner or acetone.

7Remove the screws and separate the front

and rear pump covers from the body. Lift out

the drive and driven rotors (see illustrations).

Note:Mark the front face of each rotor before

removing them.

Engine in-car repair procedures 2A•15

2A

12.8 Remove the bolts (arrowed) and the

sheetmetal baffle plate - clean the sump

area of the sump with the baffle removed12.9 Lubrication system components

A Oil pump

B Transfer tubesC Transfer housing

D Oil pump pickup12.10 Apply a bead of RTV sealant around

the perimeter of the sump mounting

flange, be sure to run the bead around the

outside all bolt the holes

13.7a Remove the bolts and separate the

front and rear pump covers13.7b Remove the outer rotor (A)

and inner rotor (B)

13.2 Unbolt the oil pump pickup (A) and

the bolts (B) retaining the transfer

assembly (C) to the engine block13.4 Pry back the locking tabs and remove

the three bolts retaining the oil pump drive

sprocket to the pump

3261 Jaguar XJ6

Page 53 of 227

Inspection

8Clean and dry the pump body and both

rotors. Measure the outside diameter of the

outer rotor and thickness of both rotors.

9Place the outer rotor into the pump body

and use feeler gauges to measure the

clearance between the outer rotor and the

body (see illustration).

10Place a straightedge across the pump

body and measure between the straightedge

and the rotors to check the over-the-rotor

clearance (see illustration). Compare your

measurements to this Chapter’s Specifications

and renew the oil pump if any are beyond the

maximum allowable.

11Remove the oil pressure relief valve cap.

Remove and clean the relief valve components

(see illustration).

12Clean all components with solvent and

inspect them for wear and damage. If

excessive wear, damage or if any clearance is

beyond the Specifications, renew the entire

pump as an assembly.

13Check the oil pressure relief valve piston

sliding surface and valve spring. If either the

spring or the valve is damaged, they must be

renewed as a set.

Refitting

14Lubricate the drive and driven rotors with

clean engine oil and place them in the casewith the marks facing out. Apply a thin coat

of anaerobic sealant (Loctite 510 or 518) to

the gasket flange and refit the cover (see

illustration).

15Lubricate the oil pressure relief valve

piston with clean engine oil and refit the valve

components into the oil pump body (see

illustration 13.11).

16Apply a thin coat of anaerobic sealant

(Loctite 510 or 518) to the oil pump-to-engine

block-mounting surface, position the oil pump

body against the engine block and refit the

mounting bolts, tightening the bolts to the

torque listed in this Chapter’s Specifications.

Follow a criss-cross pattern when tightening

the bolts to avoid warping the oil pump body.

17If using the original oil pump, refit the

original sprocket shim pack (see illustration).

If a new pump is installed, start off with a

0.38 mm (0.015-inch) thick shim pack, refit the

drive sprocket and align the sprocket as

follows.

18Use a straightedge to check the alignment

of the oil pump sprocket with the crankshaft

sprocket (see illustration). If they are not

aligned, increase or decrease the shim pack at

the oil pump sprocket until alignment is correct,

then secure the oil pump sprocket bolts by

bending up the sheetmetal tabs. Note:You

may be able to use all or part of the original

shim pack from the original oil pump (if a new

pump is being fitted). If required, shims areavailable in 0.127 mm (0.005 inch), 0.254 mm

(0.010 inch) and 0.508 mm (0.020 inch) sizes.

19Fit new O-rings to each end of the transfer

tubes and refit the tubes into the transfer

housing. Note:Use petroleum jelly to lubricate

the O-rings.

20Apply a thin coat of RTV sealant to the

engine block-mounting surface of the transfer

housing. Lift the transfer housing and tubes

into place and push the front of the tubes

in the back of the oil pump, until you can start

the transfer housing-to-engine block bolts.

Tighten the bolts to the torque listed in this

Chapter’s Specifications.

21Refit the remaining parts in the reverse

order of removal.

22Add oil, start the engine and check for oil

pressure and leaks.

23Recheck the engine oil level.

14 Driveplate-

removal and refitting

4

Removal

1Raise the car and support it securely on

axle stands, then refer to Chapter 7 and

remove the transmission. If it’s leaking, now

would be a very good time to renew the front

pump seal/O-ring.

2A•16 Engine in-car repair procedures

13.9 Measure the outer rotor-to-body

clearance with feeler gauges (arrowed)13.10 With a straightedge held tight to the

pump surface, measure the clearance over

the rotors with feeler gauges13.11 Oil pressure relief valve components

A Relief valve cap

B TubeC Spring

D Valve

13.14 Apply a thin coat anaerobic sealant

(Loctite 510 or 518) to the pump cover

sealing surface

13.17 Refit the original shim pack

(arrowed) if the original pump is being

used - if a new pump is being installed,

refit a 0.38 mm (0.015-inch) shim pack

3261 Jaguar XJ6

13.18 Check the oil pump and crankshaft

sprocket alignment with a straightedge -

add or subtract shims until the sprockets

are aligned for smooth chain operation

Page 54 of 227

2Use a centre punch or paint to make

alignment marks on the driveplate and

crankshaft to ensure correct alignment during

refitting(see illustration).

3Remove the bolts that secure the driveplate

to the crankshaft. If the crankshaft turns,

wedge a screwdriver through a hole in the

driveplate to keep it from turning (see

illustration).

4Remove the driveplate from the crankshaft.

A spacer is located behind the driveplate(see

illustration). Pry it off and store it with the

driveplate.

Warning: The ring-gear teeth

may be sharp, wear gloves to

protect your hands when

handling the driveplate.

Refitting

5Clean the driveplate to remove grease and

oil. Inspect the surface for cracks. Check for

cracked and broken ring gear teeth. Note:If

there is any damage to the driveplate, replace

the driveplate with a new driveplate, a new

spacer and new bolts. Improved parts are

available as a set from the dealer.

6Clean and inspect the mating surfaces of

the driveplate and the crankshaft. If the

crankshaft rear seal is leaking, renew it before

refitting the driveplate (see Section 15).

7Position the driveplate against the

crankshaft. Be sure to align the marks made

during removal. Some models may have an

alignment dowel or staggered bolt holes to

ensure correct refitting. Before refitting the

bolts, apply thread-locking compound to the

bolt threads.

8Wedge a screwdriver in the ring gear teeth

to keep the driveplate from turning and tighten

the bolts to the torque listed in this Chapter’s

Specifications. Follow a criss-cross pattern

and work up to the final torque in three or four

steps.

9The remainder of refitting is the reverse of

the removal procedure.

15 Crankshaft rear oil seal-

renewal

4

1The transmission adapter plate and

driveplate must be removed from the car for

this procedure (see Chapter 7).

2Remove the bolts, and detach the oil seal

retainer. Remove the gasket material from the

block and the seal retainer (see illustration).

3Position the oil seal and retainer assembly

between two wood blocks on a workbench

and drive the old seal out from the backside

(see illustration).

4The new seal must be driven into the

retainer plate from the engine side. Drive thenew seal into the retainer with a wood block

or a section of pipe slightly smaller in diameter

than the outside diameter of the seal (see

illustration). The seal should be driven in only

until it is flush with the transmission side of

the retainer.

Caution: The new seal comes with a

special plastic refitting sleeve inserted in

the seal. It is designed to allow the seal to

slide over the end of the crankshaft

without displacing the seal lip. Do NOT

remove this plastic sleeve until the retainer

and seal have been installed on the engine.

5Lubricate the seal area of the crankshaft

with engine oil. Apply a bead of RTV sealant

to the sealing surface of the retainer (see

illustration).

Engine in-car repair procedures 2A•17

2A

14.2 Mark the driveplate and the

crankshaft so they can be reassembled in

the same relative position14.3 Use a screwdriver to secure the

flywheel while the bolts are removed14.4 Pry off the driveplate spacer - if a

driveplate is replaced, the spacer should

be replaced also

15.2 Remove the bolts (arrowed) and the

crankshaft rear oil seal retainer from the

back of the engine block15.3 After removing the retainer assembly

from the engine block, support it between

two wood blocks and drive out the old seal

with a drift punch and hammer

15.4 Drive the new seal into the retainer

with a wood block

3261 Jaguar XJ6

15.5 Apply RTV sealant

to the sealing surface

Page 55 of 227

6Slowly and carefully press the seal and

retainer squarely onto the crankshaft (see

illustration). The plastic sleeve may be

pushed out as the retainer seats on the engine

block. Remove the plastic sleeve.

7Refit and tighten the retainer bolts to the

torque listed in this Chapter’s Specifications.

8The remaining steps are the reverse of

removal.

16 Engine mounts-

check and renewal

3

1Engine mounts seldom require attention,

but broken or deteriorated mounts should be

renewed immediately or the added strain

placed on the driveline components may

cause damage or wear.

Check

2During the check, the engine must be

raised to remove the weight from the mounts.3Raise the car and support it securely on

axle stands, then position a jack under the

engine sump. Place a large wood block

between the jack head and the sump, then

carefully raise the engine just enough to take

the weight off the mounts. Do not position the

wood block under the drain plug.

Warning: DO NOT place any part

of your body under the engine

when it’s supported by a jack!

4Check the front mounts to see if the rubber

is cracked, hardened or separated from the

metal plates. Sometimes the rubber will split

down the centre.

5Check for relative movement between the

mount plates and the engine or frame (use a

large screwdriver or pry bar to attempt to

move the mounts). If movement is noted,

lower the engine and tighten the mount

fasteners.

6Rubber preservative should be applied to

the mounts to slow deterioration.

Renewal

7Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

8Raise the car and support it securely on

axle stands. Support the engine as described

in paragraph 3.

Caution: Ensure the cooling fan doesn’t hit

the shroud as the engine is raised.

9To remove either engine mount, remove the

nut from the engine bracket, then raise the

engine (see illustration).

10From underneath the car, lower the

steering gear (see Chapter 10) for access to

the nut retaining the insulator to the chassis

bracket.

11Refitting is the reverse of removal. Use

thread-locking compound on the mount

bolts/nuts and be sure to tighten them

securely.

12See Chapter 7 for transmission mount

renewal.

2A•18 Engine in-car repair procedures

3261 Jaguar XJ6 15.6 Refit the retainer and oil seal onto the crankshaft

16.9 Front engine mount (A)

and retaining nut to engine bracket (B)

Page 56 of 227

3261 Jaguar XJ6

2B

Chapter 2 Part B

Engine removal and overhaul procedures

General

Cylinder compression pressure @ 300 rpm, warm

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.6 to 11.3 bar (150 to 160 psi)

High compression models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.3 to 12.1 bar (160 to 170 psi)

Maximum variation between cylinders . . . . . . . . . . . . . . . . . . . . . . . . 0.8 bar (10 psi)

Oil pressure (engine warm)

At idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bar (30 psi) minimum

At 4000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.9 bar (70 psi) minimum

Cylinder head

Resurfacing limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 mm (0.010 inch) maximum

Minimum thickness (see text)

3.6 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129.6 mm (5.101 inches)

3.2 and 4.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129.7 mm (5.108 inches)

Valves and related components

Valve stem-to-guide clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.038 to 0.076 mm (0.0015 to 0.0030 inch)

Valve springs, free length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.13 mm (1.580 inches)

Valve lifter

Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33.34 to 33.35 mm (1.3126 to 1.3130 inches)

Lifter-to-bore clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.05 mm (0.0008 to 0.0020 inch)

Crankshaft and connecting rods

Connecting rod journal

Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52.97 to 52.99 mm (2.0856 to 2.0861 inches)

Taper and out-of-round limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.008 mm (0.0003 inch) maximum

Bearing oil clearance

3.6 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.040 to 0.083 mm (0.0016 to 0.0033 inch)

3.2 and 4.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 to 0.0068 mm (0.0010 to 0.0027 inch)

Connecting rod side clearance (endplay) . . . . . . . . . . . . . . . . . . . . . . . . 0.127 to 0.228 mm (0.005 to 0.009 inch)

Main bearing journal

Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76.217 to 76.233 mm (3.0007 to 3.0012 inches)

Taper and out-of-round limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.008 mm (0.0003 inch) maximum

Bearing oil clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.040 to 0.083 mm (0.0016 to 0.0033 inch)

Crankshaft endplay (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.101 to 0.254 mm (0.004 to 0.010 inch) CHECK ENGINE light . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 6

Crankshaft - inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Crankshaft - refitting and main bearing oil clearance check . . . . . . . 23

Crankshaft - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cylinder head - cleaning and inspection . . . . . . . . . . . . . . . . . . . . . . 10

Cylinder head - dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cylinder head - reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cylinder compression check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cylinder honing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Engine block - cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Engine block - inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Engine overhaul - dismantling sequence . . . . . . . . . . . . . . . . . . . . . . 8

Engine overhaul - general information . . . . . . . . . . . . . . . . . . . . . . . . 2

Engine overhaul - reassembly sequence . . . . . . . . . . . . . . . . . . . . . . 21Engine rebuilding alternatives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Engine - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Engine removal - methods and precautions . . . . . . . . . . . . . . . . . . . 5

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Initial start-up and running-in after overhaul . . . . . . . . . . . . . . . . . . . 26

Main and connecting big-end bearings - inspection and selection . 20

Pistons/connecting rods - inspection . . . . . . . . . . . . . . . . . . . . . . . . 18

Pistons/connecting rods - refitting and big-end bearing

oil clearance check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pistons/connecting rods - removal . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Piston rings - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Rear main oil seal refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Vacuum gauge diagnostic checks . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Valves - servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2B•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 57 of 227

Engine block

Deck warpage limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.076 mm (0.003 inch)

Cylinder bore diameter

Standard

Size group A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.990 to 91.003 mm (3.5823 to 3.5828 inches)

Size group B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91.005 to 91.018 mm (3.5829 to 3.5834 inches)

Oversize

0.25 mm (0.010 inch) OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91.259 to 91.272 mm (3.5929 to 3.5934 inches)

0.50 mm (0.020 inch) OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91.513 to 91.526 mm (3.6029 to 3.6034 inches)

Pistons and rings

Piston-to-bore clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.017 to 0.043 mm (0.0007 to 0.0017 inch)

Piston ring end gap

No.1 (top) compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 to 0.66 mm (0.016 to 0.026 inch)

No.2 (middle) compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.40 to 0.66 mm (0.016 to 0.026 inch)

Oil ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 to 0.55 mm (0.012 to 0.022 inch)

Piston ring groove clearance

No. 1 (top) compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.040 to 0.076 mm (0.0016 to 0.0030 inch)

No. 2 (middle) compression ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.040 to 0.076 mm (0.0016 to 0.0030 inch)

Torque wrench settingsNm lbf ft

Main bearing cap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136 to 142 100 to 105

Connecting rod cap nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 to 60 37 to 44

* Note:Refer to Part A for additional torque specifications.

2B•2 Engine removal and overhaul procedures

3261 Jaguar XJ6

1 General information

Included in this portion of Chapter 2 are the

general overhaul procedures for the cylinder

head and internal engine components.

The information ranges from advice

concerning preparation for an overhaul and

the purchase of replacement parts to detailed,

step-by-step procedures covering removal

and refitting of internal engine components

and the inspection of parts.

The following Sections have been written

based on the assumption that the engine has

been removed from the vehicle. For

information concerning in-vehicle engine

repair, as well as removal and refitting of the

external components necessary for the

overhaul, see Part A of this Chapter.

The Specifications included in this Part are

only those necessary for the inspection and

overhaul procedures which follow. Refer to

Part A for additional Specifications.

2 Engine overhaul-

general information

It’s not always easy to determine when, or if,

an engine should be completely overhauled,

as a number of factors must be considered.

High mileage is not necessarily an indication

that an overhaul is needed, while low mileage

doesn’t preclude the need for an overhaul.

Frequency of servicing is probably the most

important consideration. An engine that’s had

regular and frequent oil and filter changes, as

well as other required maintenance, will most

likely give many thousands of miles of reliableservice. Conversely, a neglected engine may

require an overhaul very early in its life.

Excessive oil consumption is an indication

that piston rings, valve seals and/or valve

guides are in need of attention. Make sure that

oil leaks aren’t responsible before deciding

that the rings and/or guides are bad. Perform a

cylinder compression check to determine the

extent of the work required (see Section 4).

Also check the vacuum readings under various

conditions (see Section 3).

Check the oil pressure with a gauge

installed in place of the oil pressure sender

unit (see illustrations)and compare it to this

Chapter’s Specifications. If it’s extremely low,

the bearings and/or oil pump are probably

worn out.

Loss of power, rough running, knocking or

metallic engine noises, excessive valve train

noise and high fuel consumption rates may

also point to the need for an overhaul,

especially if they’re all present at the same

time. If a complete tune-up doesn’t remedy

the situation, major mechanical work is the

only solution.An engine overhaul involves restoring the

internal parts to the specifications of a new

engine. During an overhaul, the piston rings

are replaced and the cylinder walls are

reconditioned (rebored and/or honed). If a

rebore is done by an automotive machine

workshop, new oversize pistons will also be

installed. The main bearings, big-end bearings

and camshaft bearings are generally replaced

with new ones and, if necessary, the

crankshaft may be reground to restore the

journals. Generally, the valves are serviced as

well, since they’re usually in less-than-perfect

condition at this point. While the engine is

being overhauled, other components, such as

the distributor, starter and alternator, can be

rebuilt as well. The end result should be a like

new engine that will give many trouble free

miles. Note:Critical cooling system

components such as the hoses, drivebelts,

thermostat and water pump should be

replaced with new parts when an engine is

overhauled. The radiator should be checked

carefully to ensure that it isn’t clogged or

leaking (see Chapter 3).If you purchase a

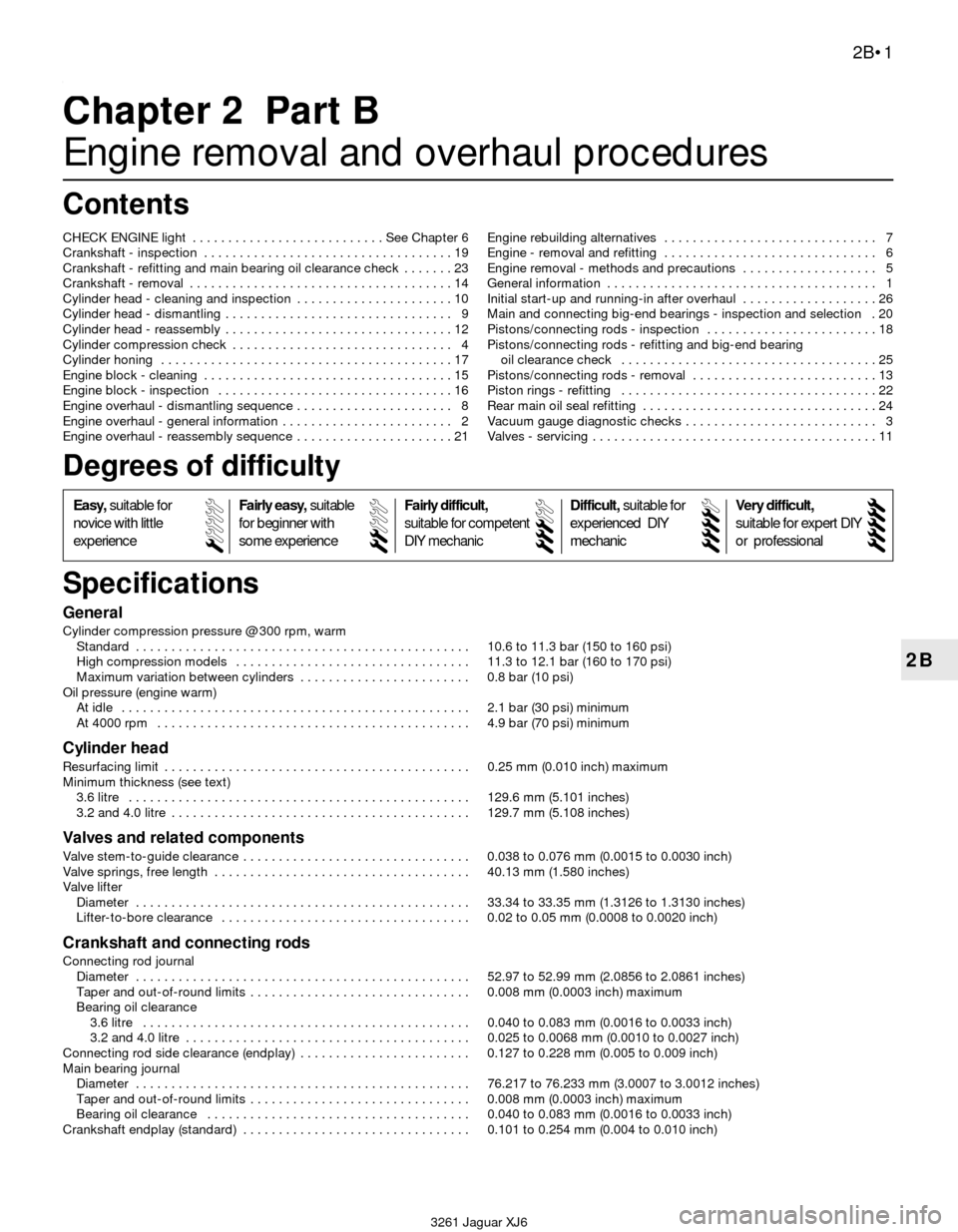

2.4a The oil pressure sender unit (arrowed)

is located in the right front corner of the

engine block, near the oil filter2.4b The oil pressure can be checked by

removing the sender unit and refitting a

pressure gauge in its place

Page 58 of 227

rebuilt engine or short block, some rebuilders

will not warranty their engines unless the

radiator has been professionally flushed. Also,

we don’t recommend overhauling the oil

pump - always refit a new one when an engine

is rebuilt.

Before beginning the engine overhaul, read

through the entire procedure to familiarise

yourself with the scope and requirements of

the job. Overhauling an engine isn’t difficult,

but it is time-consuming. Plan on the vehicle

being tied up for a minimum of two weeks,

especially if parts must be taken to an

automotive machine workshop for repair or

reconditioning. Check on availability of parts

and make sure that any necessary special

tools and equipment are obtained in advance.

Most work can be done with typical hand

tools, although a number of precision

measuring tools are required for inspecting

parts to determine if they must be renewed.

Often an automotive machine workshop will

handle the inspection of parts and offer

advice concerning reconditioning and

renewal. Note:Always wait until the engine

has been completely dismantled and all

components, especially the engine block,

have been inspected before deciding what

service and repair operations must be

performed by an automotive machine

workshop. Since the engine block’s condition

will be the major factor to consider when

determining whether to overhaul the original

engine or buy a rebuilt one, never purchase

parts or have machine work done on other

components until the engine block has been

thoroughly inspected. As a general rule, time

is the primary cost of an overhaul, so it

doesn’t pay to refit worn or substandard

parts.

If it turns out that a number of major

components are beyond reconditioning, it

may be cost effective to buy a factory-rebuilt

engine from a Jaguar dealership.

As a final note, to ensure maximum life and

minimum trouble from a rebuilt engine,

everything must be assembled with care in a

spotlessly-clean environment.

3 Vacuum gauge

diagnostic checks

2

A vacuum gauge provides valuable

information about what is going on in the

engine at a low cost. You can check for worn

rings or cylinder walls, leaking cylinder head or

intake manifold gaskets, incorrect carburettor

adjustments, restricted exhaust, stuck or

burned valves, weak valve springs, improper

ignition or valve timing and ignition problems.

Unfortunately, vacuum gauge readings are

easy to misinterpret, so they should be used

with other tests to confirm the diagnosis.

Both the absolute readings and the rate of

needle movement are important for accurate

interpretation. Most gauges measure vacuumin inches of mercury (in-Hg). As vacuum

increases (or atmospheric pressure decreases),

the reading will decrease. Also, for every

1000 foot increase in elevation above sea level;

the gauge readings will decrease about one

inch of mercury.

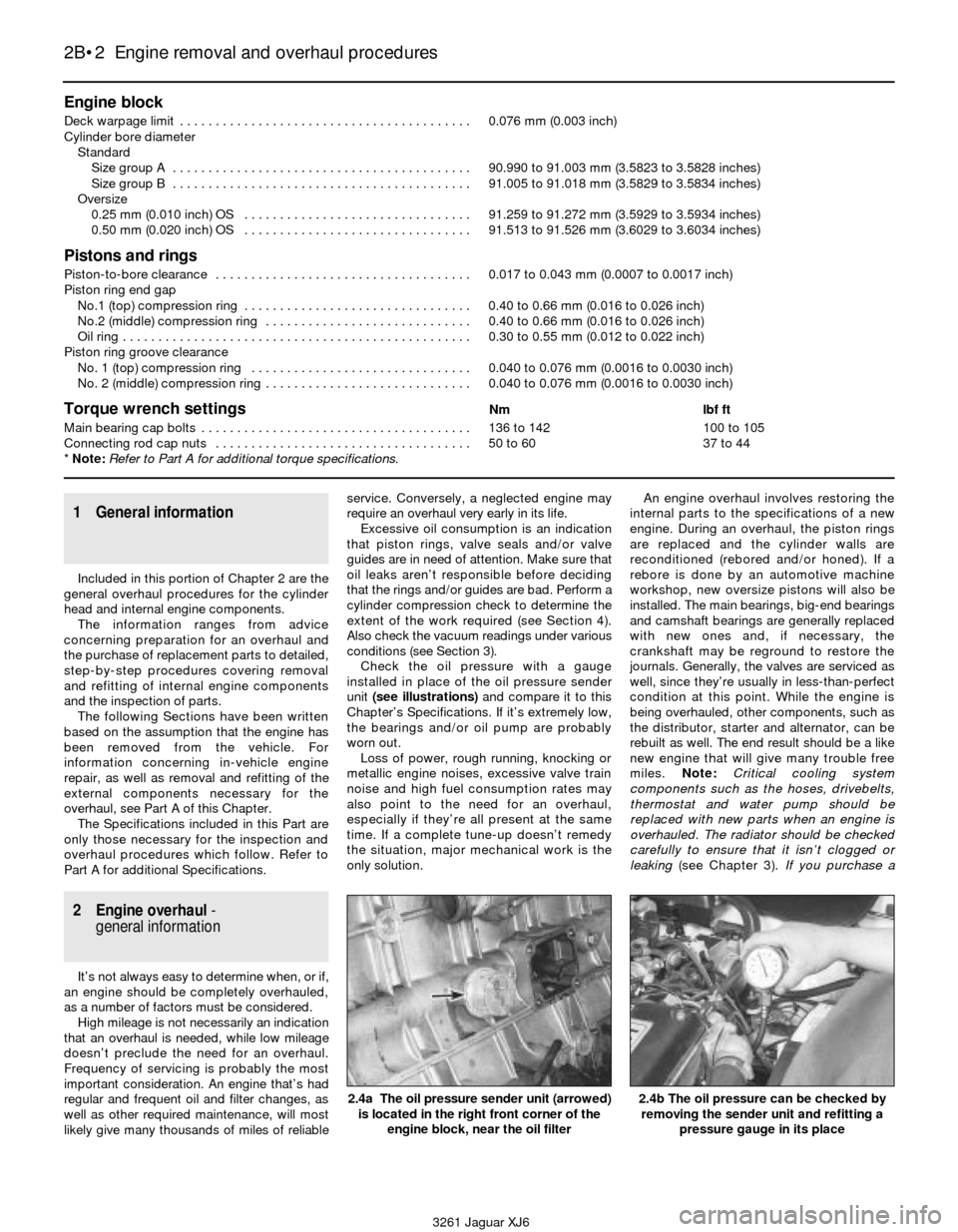

Connect the vacuum gauge directly to

intake manifold vacuum, not to ported (above

the throttle plate) vacuum (see illustration).

Be sure no hoses are left disconnected during

the test or false readings will result.

Before you begin the test, allow the engine

to warm up completely. Block the wheels and

set the handbrake. With the transmission in

Park, start the engine and allow it to run at

normal idle speed.

Warning: Carefully inspect the

fan blades for cracks or damage

before starting the engine. Keep

your hands and the vacuum

tester clear of the fan and do not stand in

front of the vehicle or in line with the fan

when the engine is running.

Read the vacuum gauge; an average,

healthy engine should normally produce

between 17 and 22 inches of vacuum with a

fairly steady needle.

Refer to the following vacuum gauge

readings and what they indicate about the

engines condition:

1A low steady reading usually indicates a

leaking gasket between the intake manifold

and carburettor or throttle body, a leaky

vacuum hose, late ignition timing or incorrect

camshaft timing. Check ignition timing with a

timing light and eliminate all other possible

causes, utilising the tests provided in this

Chapter before you remove the timing belt

cover to check the timing marks.

2If the reading is three to eight inches below

normal and it fluctuates at that low reading,

suspect an intake manifold gasket leak at an

intake port or a faulty injector.

3If the needle has regular drops of about two

to four inches at a steady rate the valves are

probably leaking. Perform a compression or

leak-down test to confirm this.

4An irregular drop or down-flick of the

needle can be caused by a sticking valve or

an ignition misfire. Perform a compression or

leak-down test and read the spark plugs.5A rapid vibration of about four in-Hg

vibration at idle combined with exhaust

smoke indicates worn valve guides. Perform a

leak-down test to confirm this. If the rapid

vibration occurs with an increase in engine

speed, check for a leaking intake manifold

gasket or cylinder head gasket, weak valve

springs, burned valves or ignition misfire.

6A slight fluctuation, say one inch up and

down, may mean ignition problems. Check all

the usual tune-up items and, if necessary, run

the engine on an ignition analyser.

7If there is a large fluctuation, perform a

compression or leak-down test to look for a

weak or dead cylinder or a blown cylinder

head gasket.

8If the needle moves slowly through a wide

range, check for a clogged PCV system,

incorrect idle fuel mixture, throttle body or

intake manifold gasket leaks.

9Check for a slow return after revving the

engine by quickly snapping the throttle open

until the engine reaches about 2,500 rpm and

let it shut. Normally the reading should drop to

near zero, rise above normal idle reading

(about 5 in.-Hg over) and then return to the

previous idle reading. If the vacuum returns

slowly and doesn’t peak when the throttle is

snapped shut, the rings may be worn. If there

is a long delay, look for a restricted exhaust

system (often the silencer or catalytic

converter). An easy way to check this is to

temporarily disconnect the exhaust ahead of

the suspected part and redo the test.

4 Cylinder compression check

2

1A compression check will tell you what

mechanical condition the upper end (pistons,

rings, valves, cylinder head gasket) of your

engine is in. Specifically, it can tell you if the

compression is down due to leakage caused

by worn piston rings, defective valves and

seats or a blown cylinder head gasket. Note:

The engine must be at normal operating

temperature and the battery must be fully

charged for this check.

2Begin by cleaning the area around the

spark plugs before you remove them

(compressed air should be used, if available,

otherwise a small brush or even a bicycle tyre

pump will work). The idea is to prevent dirt

from getting into the cylinders as the

compression check is being done.

3Remove all of the spark plugs from the

engine (see Chapter 1).

4Block the throttle wide open.

5Detach the coil wire from the centre of the

distributor cap and ground it on the engine

block. Use a jumper wire with alligator clips on

each end to ensure a good earth. Also,

remove the fuel pump relay (see Chapter 4) to

disable the fuel pump during the compression

test.

Engine removal and overhaul procedures 2B•3

2B

3.4 The vacuum gauge is easily attached

to a port on the intake manifold, and can

tell a lot about an engine’s state of tune

3261 Jaguar XJ6

Page 59 of 227

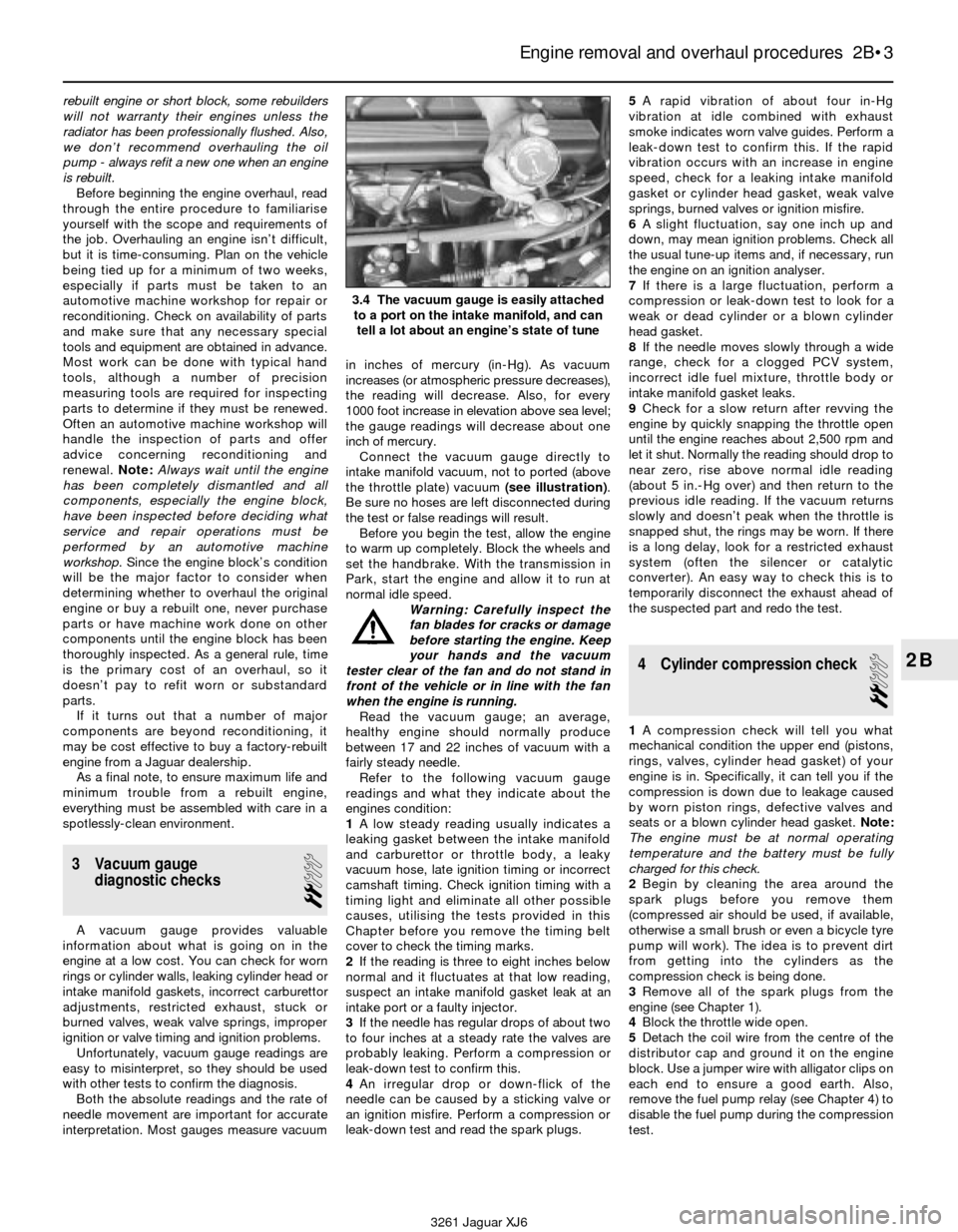

6Refit the compression gauge in the spark

plug hole (see illustration).

7Crank the engine over at least seven

compression strokes and watch the gauge.

The compression should build up quickly in a

healthy engine. Low compression on the first

stroke, followed by gradually increasing

pressure on successive strokes, indicates

worn piston rings. A low compression reading

on the first stroke, which doesn’t build up

during successive strokes, indicates leaking

valves or a blown cylinder head gasket (a

cracked cylinder head could also be the

cause). Deposits on the undersides of the

valve heads can also cause low compression.

Record the highest gauge reading obtained.

8Repeat the procedure for the remaining

cylinders and compare the results to this

Chapter’s Specifications.

9Add some engine oil (about three squirts

from a plunger-type oil can) to each cylinder,

through the spark plug hole, and repeat the

test.

10If the compression increases after the oil

is added, the piston rings are definitely worn.

If the compression doesn’t increase

significantly, the leakage is occurring at the

valves or cylinder head gasket. Leakage past

the valves may be caused by burned valve

seats and/or faces or warped, cracked or bent

valves.

11If two adjacent cylinders have equally low

compression, there’s a strong possibility that

the cylinder head gasket between them is

blown. The appearance of coolant in the

combustion chambers or the crankcase

would verify this condition.

12If one cylinder is 20 percent lower than the

others, and the engine has a slightly rough

idle, a worn exhaust lobe on the camshaft

could be the cause.

13If the compression is unusually high, the

combustion chambers are probably coated

with carbon deposits. If that’s the case, the

cylinder head(s) should be removed and

decarbonised.

14If compression is way down or varies

greatly between cylinders, it would be a goodidea to have a leak-down test performed by

an automotive repair workshop. This test will

pinpoint exactly where the leakage is

occurring and how severe it is.

5 Engine removal-

methods and precautions

If you’ve decided that an engine must be

removed for overhaul or major repair work,

several preliminary steps should be taken.

Locating a suitable place to work is

extremely important. Adequate work space,

along with storage space for the vehicle, will

be needed. If a workshop or garage isn’t

available, at the very least a flat, level, clean

work surface made of concrete or asphalt is

required.

Cleaning the engine compartment and

engine before beginning the removal

procedure will help keep tools clean and

organised.

An engine hoist or A-frame will also be

necessary. Make sure the equipment is rated

in excess of the combined weight of the

engine and transmission. Safety is of primary

importance, considering the potential hazards

involved in lifting the engine out of the vehicle.

If the engine is being removed by a novice,

a helper should be available. Advice and aid

from someone more experienced would also

be helpful. There are many instances when

one person cannot simultaneously perform all

of the operations required when lifting the

engine out of the vehicle.

Plan the operation ahead of time. Arrange

for or obtain all of the tools and equipment

you’ll need prior to beginning the job. Some of

the equipment necessary to perform engine

removal and refitting safely and with relative

ease are (in addition to an engine hoist) a

heavy duty trolley jack, complete sets of

spanners and sockets as described in the

front of this manual, wooden blocks and

plenty of rags and cleaning solvent for

mopping up spilled oil, coolant and petrol. If

the hoist must be rented, make sure that you

arrange for it in advance and perform all of the

operations possible without it beforehand.

This will save you money and time.

Plan for the vehicle to be out of use for

quite a while. A machine workshop will be

required to perform some of the work which

the do-it-yourselfer can’t accomplish without

special equipment. These shops often have a

busy schedule, so it would be a good idea to

consult them before removing the engine in

order to accurately estimate the amount of

time required to rebuild or repair components

that may need work.

Always be extremely careful when removing

and refitting the engine. Serious injury can

result from careless actions. Plan ahead, take

your time and a job of this nature, although

major, can be accomplished successfully.

6 Engine- removal and refitting

3

Note:Read through the entire Section before

beginning this procedure. It is recommended

to remove the engine and transmission from

the top as a unit, then separate the engine

from the transmission on the workshop floor. If

the transmission is not being serviced, it is

possible to leave the transmission in the

vehicle and remove the engine from the top by

itself, by removing the crankshaft damper and

tilting up the front end of the engine for

clearance,but access to the upper

bellhousing bolts is only practical when the

rear transmission mount and driveshaft have

been removed and the transmission is angled

down with a trolley jack.

Removal

1Relieve the fuel system pressure (see

Chapter 4).

2Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

3Place protective covers on the wings and

cowl and remove the bonnet (see Chapter 11).

4Remove the battery and battery tray.

5Remove the air cleaner assembly (see

Chapter 4).

6Raise the vehicle and support it securely on

axle stands. Drain the cooling system and

engine oil and remove the drivebelts (see

Chapter 1).

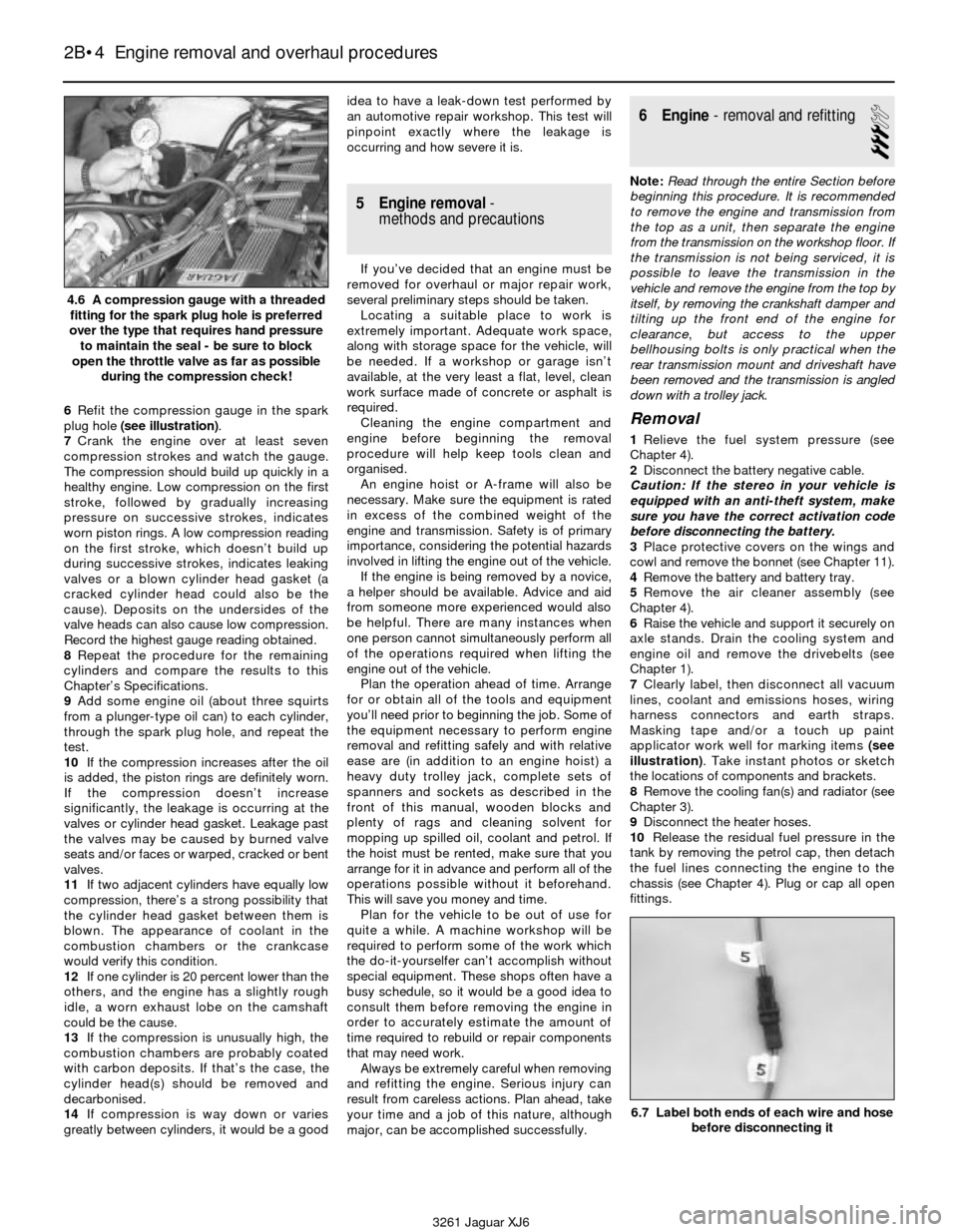

7Clearly label, then disconnect all vacuum

lines, coolant and emissions hoses, wiring

harness connectors and earth straps.

Masking tape and/or a touch up paint

applicator work well for marking items (see

illustration). Take instant photos or sketch

the locations of components and brackets.

8Remove the cooling fan(s) and radiator (see

Chapter 3).

9Disconnect the heater hoses.

10Release the residual fuel pressure in the

tank by removing the petrol cap, then detach

the fuel lines connecting the engine to the

chassis (see Chapter 4). Plug or cap all open

fittings.

2B•4 Engine removal and overhaul procedures

4.6 A compression gauge with a threaded

fitting for the spark plug hole is preferred

over the type that requires hand pressure

to maintain the seal - be sure to block

open the throttle valve as far as possible

during the compression check!

6.7 Label both ends of each wire and hose

before disconnecting it

3261 Jaguar XJ6

Page 60 of 227

11Disconnect the throttle linkage,

transmission linkage (and dipstick tube) and

speed control cable, if equipped, from the

engine (see Chapters 4 and 7).

12Refer to Part A of this Chapter and

remove the intake and exhaust manifolds.

13Unbolt the power steering pump (see

Chapter 10). Tie the pump aside without

disconnecting the hoses. Refer to Part A for

removal of the hydraulic pump (if equipped)

from the timing chain cover.

14On air-conditioned models, unbolt the

compressor and set it aside. Do not

disconnect the refrigerant hoses. Note:Wire

the compressor out of the way with a coat

hanger, don’t let the compressor hang on the

hoses.

15Refer to Part A of this Chapter and

remove the drivebelts, water pump pulley and

crankshaft pulley.

16Attach a lifting sling to the engine.

Position a hoist and connect the sling to it.

Take up the slack until there is slight tension

on the hoist.

17With a trolley jack and piece of wood

supporting the bottom of the transmission

sump, refer to Chapter 8 and remove the

driveshaft and rear transmission mount.

Warning: Do not place any part

of your body under the

engine/transmission when it’s

supported only by a hoist or

other lifting device.

18With the hoist taking the weight of the

engine, unbolt the engine mounts (see Part A

of this Chapter).

19Recheck to be sure nothing is still

connecting the engine or transmission to the

vehicle. Disconnect and label anything still

remaining.

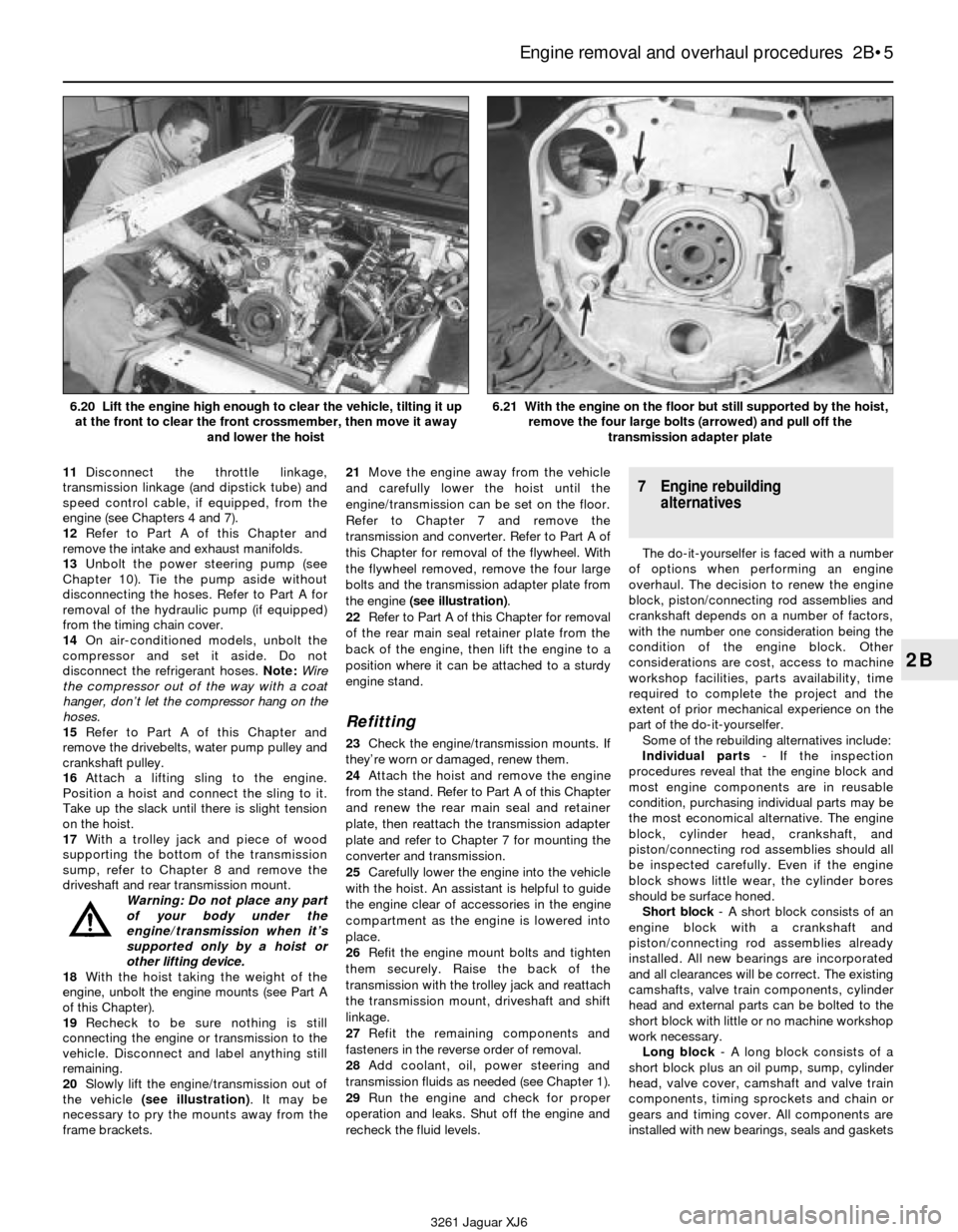

20Slowly lift the engine/transmission out of

the vehicle (see illustration). It may be

necessary to pry the mounts away from the

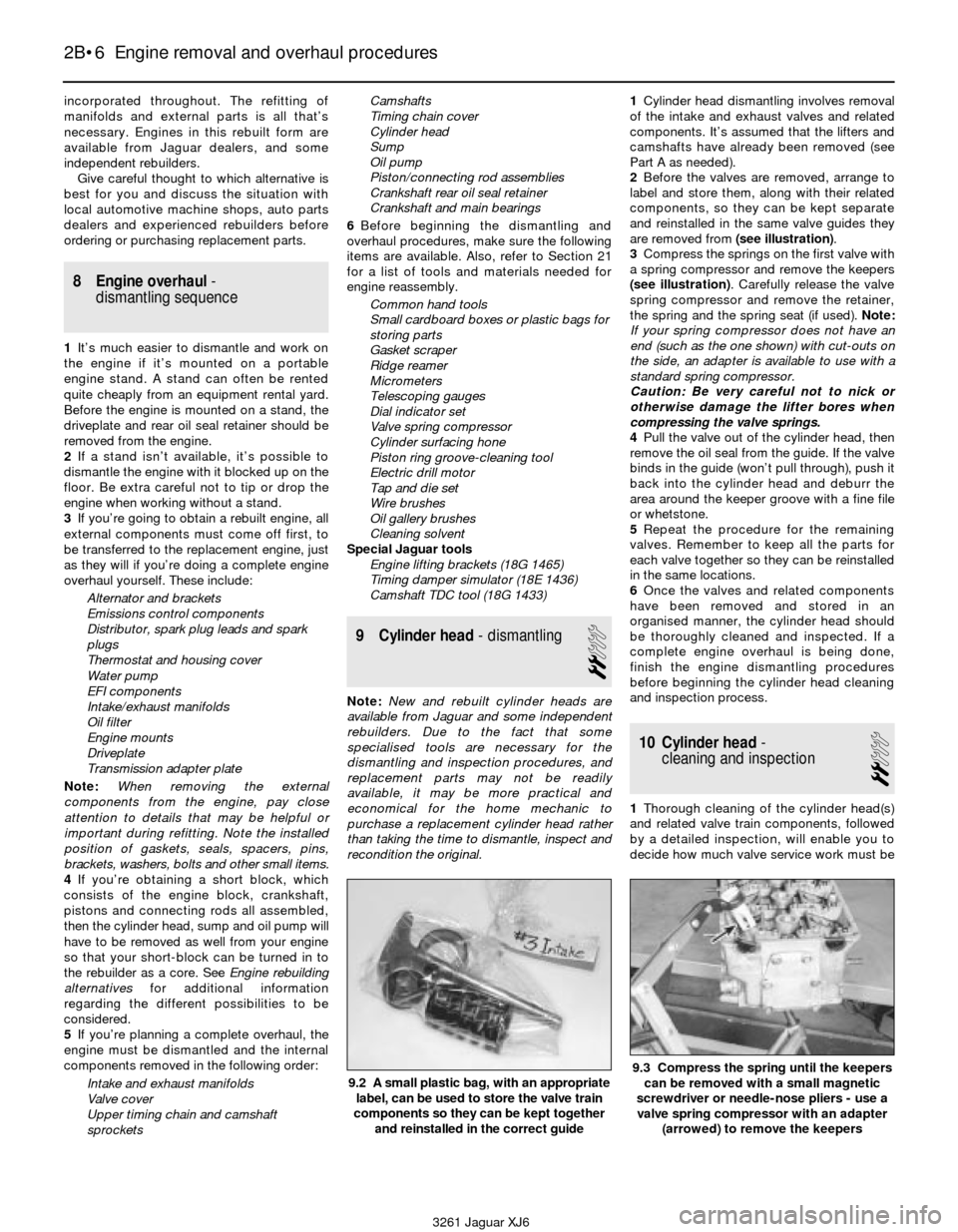

frame brackets.21Move the engine away from the vehicle

and carefully lower the hoist until the

engine/transmission can be set on the floor.

Refer to Chapter 7 and remove the

transmission and converter. Refer to Part A of

this Chapter for removal of the flywheel. With

the flywheel removed, remove the four large

bolts and the transmission adapter plate from

the engine (see illustration).

22Refer to Part A of this Chapter for removal

of the rear main seal retainer plate from the

back of the engine, then lift the engine to a

position where it can be attached to a sturdy

engine stand.

Refitting

23Check the engine/transmission mounts. If

they’re worn or damaged, renew them.

24Attach the hoist and remove the engine

from the stand. Refer to Part A of this Chapter

and renew the rear main seal and retainer

plate, then reattach the transmission adapter

plate and refer to Chapter 7 for mounting the

converter and transmission.

25Carefully lower the engine into the vehicle

with the hoist. An assistant is helpful to guide

the engine clear of accessories in the engine

compartment as the engine is lowered into

place.

26Refit the engine mount bolts and tighten

them securely. Raise the back of the

transmission with the trolley jack and reattach

the transmission mount, driveshaft and shift

linkage.

27Refit the remaining components and

fasteners in the reverse order of removal.

28Add coolant, oil, power steering and

transmission fluids as needed (see Chapter 1).

29Run the engine and check for proper

operation and leaks. Shut off the engine and

recheck the fluid levels.

7 Engine rebuilding

alternatives

The do-it-yourselfer is faced with a number

of options when performing an engine

overhaul. The decision to renew the engine

block, piston/connecting rod assemblies and

crankshaft depends on a number of factors,

with the number one consideration being the

condition of the engine block. Other

considerations are cost, access to machine

workshop facilities, parts availability, time

required to complete the project and the

extent of prior mechanical experience on the

part of the do-it-yourselfer.

Some of the rebuilding alternatives include:

Individual parts- If the inspection

procedures reveal that the engine block and

most engine components are in reusable

condition, purchasing individual parts may be

the most economical alternative. The engine

block, cylinder head, crankshaft, and

piston/connecting rod assemblies should all

be inspected carefully. Even if the engine

block shows little wear, the cylinder bores

should be surface honed.

Short block- A short block consists of an

engine block with a crankshaft and

piston/connecting rod assemblies already

installed. All new bearings are incorporated

and all clearances will be correct. The existing

camshafts, valve train components, cylinder

head and external parts can be bolted to the

short block with little or no machine workshop

work necessary.

Long block- A long block consists of a

short block plus an oil pump, sump, cylinder

head, valve cover, camshaft and valve train

components, timing sprockets and chain or

gears and timing cover. All components are

installed with new bearings, seals and gaskets

Engine removal and overhaul procedures 2B•5

2B

3261 Jaguar XJ6 6.20 Lift the engine high enough to clear the vehicle, tilting it up

at the front to clear the front crossmember, then move it away

and lower the hoist

6.21 With the engine on the floor but still supported by the hoist,

remove the four large bolts (arrowed) and pull off the

transmission adapter plate

Page 61 of 227

incorporated throughout. The refitting of

manifolds and external parts is all that’s

necessary. Engines in this rebuilt form are

available from Jaguar dealers, and some

independent rebuilders.

Give careful thought to which alternative is

best for you and discuss the situation with

local automotive machine shops, auto parts

dealers and experienced rebuilders before

ordering or purchasing replacement parts.

8 Engine overhaul-

dismantling sequence

1It’s much easier to dismantle and work on

the engine if it’s mounted on a portable

engine stand. A stand can often be rented

quite cheaply from an equipment rental yard.

Before the engine is mounted on a stand, the

driveplate and rear oil seal retainer should be

removed from the engine.

2If a stand isn’t available, it’s possible to

dismantle the engine with it blocked up on the

floor. Be extra careful not to tip or drop the

engine when working without a stand.

3If you’re going to obtain a rebuilt engine, all

external components must come off first, to

be transferred to the replacement engine, just

as they will if you’re doing a complete engine

overhaul yourself. These include:

Alternator and brackets

Emissions control components

Distributor, spark plug leads and spark

plugs

Thermostat and housing cover

Water pump

EFI components

Intake/exhaust manifolds

Oil filter

Engine mounts

Driveplate

Transmission adapter plate

Note:When removing the external

components from the engine, pay close

attention to details that may be helpful or

important during refitting. Note the installed

position of gaskets, seals, spacers, pins,

brackets, washers, bolts and other small items.

4If you’re obtaining a short block, which

consists of the engine block, crankshaft,

pistons and connecting rods all assembled,

then the cylinder head, sump and oil pump will

have to be removed as well from your engine

so that your short-block can be turned in to

the rebuilder as a core. See Engine rebuilding

alternativesfor additional information

regarding the different possibilities to be

considered.

5If you’re planning a complete overhaul, the

engine must be dismantled and the internal

components removed in the following order:

Intake and exhaust manifolds

Valve cover

Upper timing chain and camshaft

sprocketsCamshafts

Timing chain cover

Cylinder head

Sump

Oil pump

Piston/connecting rod assemblies

Crankshaft rear oil seal retainer

Crankshaft and main bearings

6Before beginning the dismantling and

overhaul procedures, make sure the following

items are available. Also, refer to Section 21

for a list of tools and materials needed for

engine reassembly.

Common hand tools

Small cardboard boxes or plastic bags for

storing parts

Gasket scraper

Ridge reamer

Micrometers

Telescoping gauges

Dial indicator set

Valve spring compressor

Cylinder surfacing hone

Piston ring groove-cleaning tool

Electric drill motor

Tap and die set

Wire brushes

Oil gallery brushes

Cleaning solvent

Special Jaguar tools

Engine lifting brackets (18G 1465)

Timing damper simulator (18E 1436)

Camshaft TDC tool (18G 1433)

9 Cylinder head- dismantling

2

Note: New and rebuilt cylinder heads are

available from Jaguar and some independent

rebuilders. Due to the fact that some

specialised tools are necessary for the

dismantling and inspection procedures, and

replacement parts may not be readily

available, it may be more practical and

economical for the home mechanic to

purchase a replacement cylinder head rather

than taking the time to dismantle, inspect and

recondition the original.1Cylinder head dismantling involves removal

of the intake and exhaust valves and related

components. It’s assumed that the lifters and

camshafts have already been removed (see

Part A as needed).

2Before the valves are removed, arrange to

label and store them, along with their related

components, so they can be kept separate

and reinstalled in the same valve guides they

are removed from (see illustration).

3Compress the springs on the first valve with

a spring compressor and remove the keepers

(see illustration). Carefully release the valve

spring compressor and remove the retainer,

the spring and the spring seat (if used). Note:

If your spring compressor does not have an

end (such as the one shown) with cut-outs on

the side, an adapter is available to use with a

standard spring compressor.

Caution: Be very careful not to nick or

otherwise damage the lifter bores when

compressing the valve springs.

4Pull the valve out of the cylinder head, then

remove the oil seal from the guide. If the valve

binds in the guide (won’t pull through), push it

back into the cylinder head and deburr the

area around the keeper groove with a fine file

or whetstone.

5Repeat the procedure for the remaining

valves. Remember to keep all the parts for

each valve together so they can be reinstalled

in the same locations.

6Once the valves and related components

have been removed and stored in an

organised manner, the cylinder head should

be thoroughly cleaned and inspected. If a

complete engine overhaul is being done,

finish the engine dismantling procedures

before beginning the cylinder head cleaning

and inspection process.

10 Cylinder head-

cleaning and inspection

2

1Thorough cleaning of the cylinder head(s)

and related valve train components, followed

by a detailed inspection, will enable you to

decide how much valve service work must be

2B•6 Engine removal and overhaul procedures

9.2 A small plastic bag, with an appropriate

label, can be used to store the valve train

components so they can be kept together

and reinstalled in the correct guide

3261 Jaguar XJ6

9.3 Compress the spring until the keepers

can be removed with a small magnetic

screwdriver or needle-nose pliers - use a

valve spring compressor with an adapter

(arrowed) to remove the keepers