torque JAGUAR XJ6 1997 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 146 of 227

17 Steering gear-

removal and refitting

3

Warning: On models with an

airbag, do not apply excessive

force or severe shock to the

steering column shaft, or

accidental deployment of the airbag could

occur.

1Using a large syringe or hand pump, empty

the power steering fluid reservoir.

2Loosen the wheel nuts, raise the vehicle

and support it securely on axle stands.

Remove the wheels.

3Mark the relationship of the steering shaft

U-joint to the steering gear pinion shaft (see

illustration)to ensure proper alignment when

they’re reassembled. Remove the nut and bolt

that clamp the U-joint to the pinion shaft.

4Disconnect the power steering pressure

and return lines from the steering gear. Place

a container under the lines to catch spilledfluid. Plug the lines to prevent excessive fluid

loss and contamination. Discard the sealing

washers (new ones should be used when

reassembling).

5Disconnect the tie-rod ends from the

steering knuckle arms (see Section 17).

6Remove the nuts and bolts from the steering

gear mounting brackets (see illustration).

7Remove the steering gear assembly,

detaching the U-joint as you lower it. Don’t

damage the steering gear dust boots.

8Refitting is the reverse of removal. Ensure the

marks you made on the U-joint and the pinion

shaft are aligned before you tighten the U-joint

clamp bolt and nut. Tighten the mounting bolts,

the tie-rod end nuts and the U-joint shaft

clamping bolts to the specified torque.

9After lowering the vehicle, fill the reservoir

with the recommended fluid (see Chapter 1).

10Bleed the power steering system (see

Section 19).

11Have the front wheels aligned by a dealer

service department or alignment workshop

after reassembly.

18 Power steering pump-

removal and refitting

3

1Raise the vehicle and support it securely on

axle stands. Remove the engine under-cover.

2Loosen the hose clamp and disconnect the

fluid return hose from the top of the pump

(see illustration)and drain the power steering

fluid from the reservoir into a clean container.

Unscrew the pressure line fitting from the

back of the pump. Plug the return hose and

the pressure line to prevent fluid from leaking

and to protect the power steering system

from contamination.

3Remove the bolts (see illustration)that

attach the power steering pump adapter to

the auxiliary shaft housing.

4Remove the power steering pump and

adapter.

5Take the power steering pump and adapter

to a Jaguar dealer service department and

have the adapter removed from the old pump

10•10 Suspension and steering systems

18.2 Disconnect the steering fluid return hose from the upper

pipe (arrowed) and disconnect the pressure line

from the back of the pump18.3 To detach the pump adapter from the auxiliary shaft

housing, remove these bolts

3261 Jaguar XJ6 17.3 Mark the relationship of the steering shaft U-joint to the

steering gear pinion shaft, then unscrew the pressure and return

line fittings (arrowed) - plug the lines to prevent contamination

from entering the system

17.6 To detach the steering gear from the vehicle, remove these

nuts and bolts (arrowed) from the mounting brackets (right

bracket shown, left bracket similar)

Page 203 of 227

3261 Jaguar XJ6

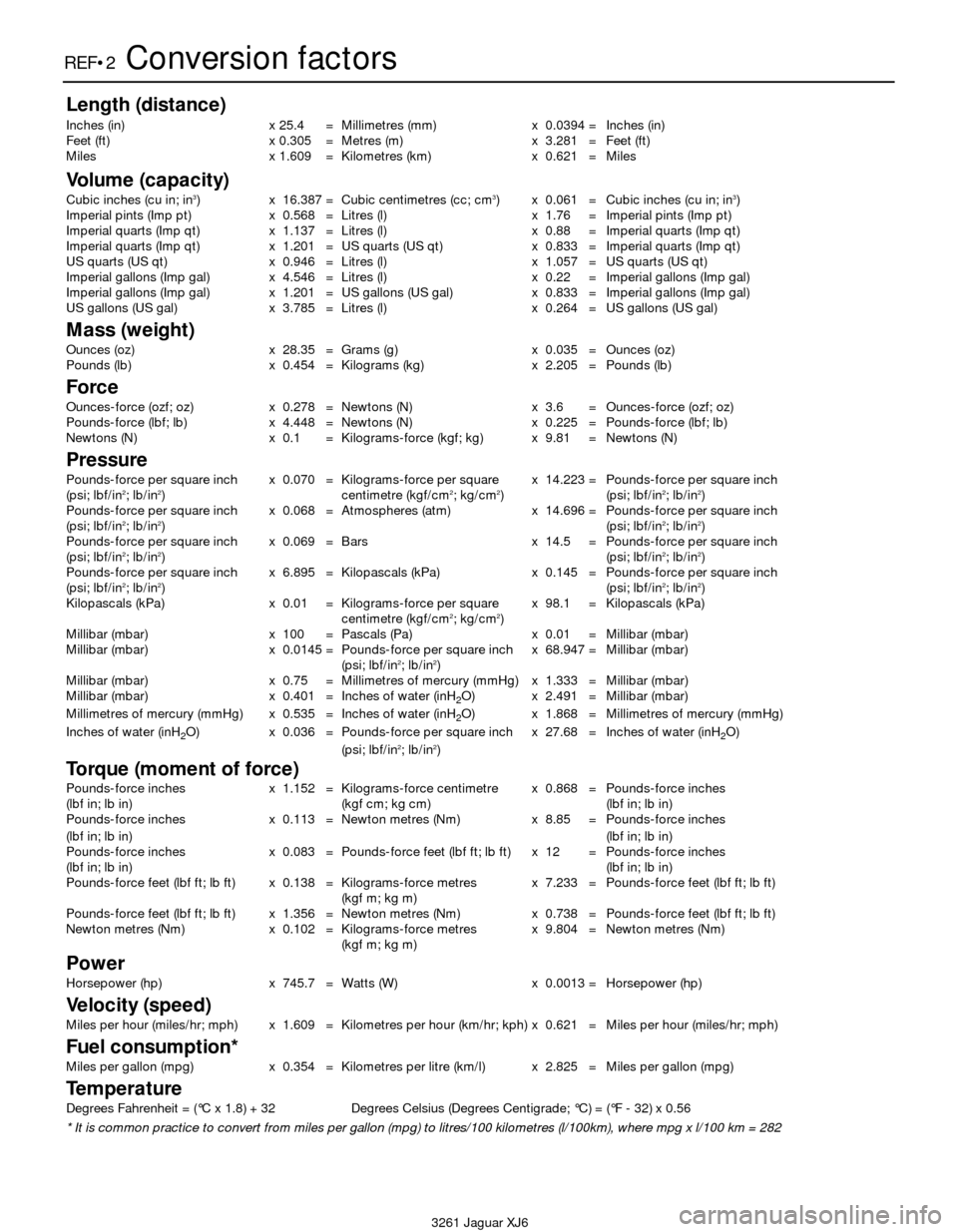

REF•2Conversion factors

Length (distance)

Inches (in) x 25.4 = Millimetres (mm) x 0.0394 = Inches (in)

Feet (ft) x 0.305 = Metres (m) x 3.281 = Feet (ft)

Miles x 1.609 = Kilometres (km) x 0.621 = Miles

Volume (capacity)

Cubic inches (cu in; in3) x 16.387 = Cubic centimetres (cc; cm3) x 0.061 = Cubic inches (cu in; in3)

Imperial pints (Imp pt) x 0.568 = Litres (l) x 1.76 = Imperial pints (Imp pt)

Imperial quarts (Imp qt) x 1.137 = Litres (l) x 0.88 = Imperial quarts (Imp qt)

Imperial quarts (Imp qt) x 1.201 = US quarts (US qt) x 0.833 = Imperial quarts (Imp qt)

US quarts (US qt) x 0.946 = Litres (l) x 1.057 = US quarts (US qt)

Imperial gallons (Imp gal) x 4.546 = Litres (l) x 0.22 = Imperial gallons (Imp gal)

Imperial gallons (Imp gal) x 1.201 = US gallons (US gal) x 0.833 = Imperial gallons (Imp gal)

US gallons (US gal) x 3.785 = Litres (l) x 0.264 = US gallons (US gal)

Mass (weight)

Ounces (oz) x 28.35 = Grams (g) x 0.035 = Ounces (oz)

Pounds (lb) x 0.454 = Kilograms (kg) x 2.205 = Pounds (lb)

Force

Ounces-force (ozf; oz) x 0.278 = Newtons (N) x 3.6 = Ounces-force (ozf; oz)

Pounds-force (lbf; lb) x 4.448 = Newtons (N) x 0.225 = Pounds-force (lbf; lb)

Newtons (N) x 0.1 = Kilograms-force (kgf; kg) x 9.81 = Newtons (N)

Pressure

Pounds-force per square inch x 0.070 = Kilograms-force per square x 14.223 = Pounds-force per square inch

(psi; lbf/in2; lb/in2) centimetre (kgf/cm2; kg/cm2) (psi; lbf/in2; lb/in2)

Pounds-force per square inch x 0.068 = Atmospheres (atm) x 14.696 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Pounds-force per square inch x 0.069 = Bars x 14.5 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Pounds-force per square inch x 6.895 = Kilopascals (kPa) x 0.145 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2)(psi; lbf/in2; lb/in2)

Kilopascals (kPa) x 0.01 = Kilograms-force per square x 98.1 = Kilopascals (kPa)

centimetre (kgf/cm

2; kg/cm2)

Millibar (mbar) x 100 = Pascals (Pa) x 0.01 = Millibar (mbar)

Millibar (mbar) x 0.0145 = Pounds-force per square inch x 68.947 = Millibar (mbar)

(psi; lbf/in

2; lb/in2)

Millibar (mbar) x 0.75 = Millimetres of mercury (mmHg) x 1.333 = Millibar (mbar)

Millibar (mbar) x 0.401 = Inches of water (inH

2O) x 2.491 = Millibar (mbar)

Millimetres of mercury (mmHg) x 0.535 = Inches of water (inH

2O) x 1.868 = Millimetres of mercury (mmHg)

Inches of water (inH

2O) x 0.036 = Pounds-force per square inch x 27.68 = Inches of water (inH2O)

(psi; lbf/in2; lb/in2)

Torque (moment of force)

Pounds-force inches x 1.152 = Kilograms-force centimetre x 0.868 = Pounds-force inches

(lbf in; lb in) (kgf cm; kg cm) (lbf in; lb in)

Pounds-force inches x 0.113 = Newton metres (Nm) x 8.85 = Pounds-force inches

(lbf in; lb in)(lbf in; lb in)

Pounds-force inches x 0.083 = Pounds-force feet (lbf ft; lb ft) x 12 = Pounds-force inches

(lbf in; lb in)(lbf in; lb in)

Pounds-force feet (lbf ft; lb ft) x 0.138 = Kilograms-force metres x 7.233 = Pounds-force feet (lbf ft; lb ft)

(kgf m; kg m)

Pounds-force feet (lbf ft; lb ft) x 1.356 = Newton metres (Nm) x 0.738 = Pounds-force feet (lbf ft; lb ft)

Newton metres (Nm) x 0.102 = Kilograms-force metres x 9.804 = Newton metres (Nm)

(kgf m; kg m)

Power

Horsepower (hp) x 745.7 = Watts (W) x 0.0013 = Horsepower (hp)

Velocity (speed)

Miles per hour (miles/hr; mph) x 1.609 = Kilometres per hour (km/hr; kph) x 0.621 = Miles per hour (miles/hr; mph)

Fuel consumption*

Miles per gallon (mpg) x 0.354 = Kilometres per litre (km/l) x 2.825 = Miles per gallon (mpg)

Temperature

Degrees Fahrenheit = (°C x 1.8) + 32 Degrees Celsius (Degrees Centigrade; °C) = (°F - 32) x 0.56

* It is common practice to convert from miles per gallon (mpg) to litres/100 kilometres (l/100km), where mpg x l/100 km = 282

Page 206 of 227

3261 Jaguar XJ6

General repair proceduresREF•5

Whenever servicing, repair or overhaul work

is carried out on the car or its components, it

is necessary to observe the following

procedures and instructions. This will assist in

carrying out the operation efficiently and to a

professional standard of workmanship.

Joint mating faces and gaskets

When separating components at their

mating faces, never insert screwdrivers or

similar implements into the joint between the

faces in order to prise them apart. This can

cause severe damage which results in oil

leaks, coolant leaks, etc upon reassembly.

Separation is usually achieved by tapping

along the joint with a soft-faced hammer in

order to break the seal. However, note that

this method may not be suitable where

dowels are used for component location.

Where a gasket is used between the mating

faces of two components, ensure that it is

renewed on reassembly, and fit it dry unless

otherwise stated in the repair procedure. Make

sure that the mating faces are clean and dry,

with all traces of old gasket removed. When

cleaning a joint face, use a tool which is not

likely to score or damage the face, and remove

any burrs or nicks with an oilstone or fine file.

Make sure that tapped holes are cleaned

with a pipe cleaner, and keep them free of

jointing compound, if this is being used,

unless specifically instructed otherwise.

Ensure that all orifices, channels or pipes

are clear, and blow through them, preferably

using compressed air.

Oil seals

Oil seals can be removed by levering them

out with a wide flat-bladed screwdriver or

similar tool. Alternatively, a number of self-

tapping screws may be screwed into the seal,

and these used as a purchase for pliers or

similar in order to pull the seal free.

Whenever an oil seal is removed from its

working location, either individually or as part

of an assembly, it should be renewed.

The very fine sealing lip of the seal is easily

damaged, and will not seal if the surface it

contacts is not completely clean and free from

scratches, nicks or grooves. If the original

sealing surface of the component cannot be

restored, and the manufacturer has not made

provision for slight relocation of the seal

relative to the sealing surface, the component

should be renewed.

Protect the lips of the seal from any surface

which may damage them in the course of

fitting. Use tape or a conical sleeve where

possible. Lubricate the seal lips with oil before

fitting and, on dual-lipped seals, fill the space

between the lips with grease.

Unless otherwise stated, oil seals must be

fitted with their sealing lips toward the

lubricant to be sealed.

Use a tubular drift or block of wood of the

appropriate size to install the seal and, if the

seal housing is shouldered, drive the seal

down to the shoulder. If the seal housing isunshouldered, the seal should be fitted with

its face flush with the housing top face (unless

otherwise instructed).

Screw threads and fastenings

Seized nuts, bolts and screws are quite a

common occurrence where corrosion has set

in, and the use of penetrating oil or releasing

fluid will often overcome this problem if the

offending item is soaked for a while before

attempting to release it. The use of an impact

driver may also provide a means of releasing

such stubborn fastening devices, when used

in conjunction with the appropriate

screwdriver bit or socket. If none of these

methods works, it may be necessary to resort

to the careful application of heat, or the use of

a hacksaw or nut splitter device.

Studs are usually removed by locking two

nuts together on the threaded part, and then

using a spanner on the lower nut to unscrew

the stud. Studs or bolts which have broken off

below the surface of the component in which

they are mounted can sometimes be removed

using a stud extractor. Always ensure that a

blind tapped hole is completely free from oil,

grease, water or other fluid before installing

the bolt or stud. Failure to do this could cause

the housing to crack due to the hydraulic

action of the bolt or stud as it is screwed in.

When tightening a castellated nut to accept

a split pin, tighten the nut to the specified

torque, where applicable, and then tighten

further to the next split pin hole. Never

slacken the nut to align the split pin hole,

unless stated in the repair procedure.

When checking or retightening a nut or bolt

to a specified torque setting, slacken the nut

or bolt by a quarter of a turn, and then

retighten to the specified setting. However,

this should not be attempted where angular

tightening has been used.

For some screw fastenings, notably

cylinder head bolts or nuts, torque wrench

settings are no longer specified for the latter

stages of tightening, “angle-tightening” being

called up instead. Typically, a fairly low torque

wrench setting will be applied to the

bolts/nuts in the correct sequence, followed

by one or more stages of tightening through

specified angles.

Locknuts, locktabs and washers

Any fastening which will rotate against a

component or housing during tightening

should always have a washer between it and

the relevant component or housing.

Spring or split washers should always be

renewed when they are used to lock a critical

component such as a big-end bearing

retaining bolt or nut. Locktabs which are

folded over to retain a nut or bolt should

always be renewed.

Self-locking nuts can be re-used in non-

critical areas, providing resistance can be felt

when the locking portion passes over the bolt

or stud thread. However, it should be noted

that self-locking stiffnuts tend to lose theireffectiveness after long periods of use, and

should be renewed as a matter of course.

Split pins must always be replaced with

new ones of the correct size for the hole.

When thread-locking compound is found

on the threads of a fastener which is to be re-

used, it should be cleaned off with a wire

brush and solvent, and fresh compound

applied on reassembly.

Special tools

Some repair procedures in this manual

entail the use of special tools such as a press,

two or three-legged pullers, spring

compressors, etc. Wherever possible, suitable

readily-available alternatives to the

manufacturer’s special tools are described,

and are shown in use. In some instances,

where no alternative is possible, it has been

necessary to resort to the use of a

manufacturer’s tool, and this has been done

for reasons of safety as well as the efficient

completion of the repair operation. Unless you

are highly-skilled and have a thorough

understanding of the procedures described,

never attempt to bypass the use of any

special tool when the procedure described

specifies its use. Not only is there a very great

risk of personal injury, but expensive damage

could be caused to the components involved.

Environmental considerations

When disposing of used engine oil, brake

fluid, antifreeze, etc, give due consideration to

any detrimental environmental effects. Do not,

for instance, pour any of the above liquids

down drains into the general sewage system,

or onto the ground to soak away. Many local

council refuse tips provide a facility for waste

oil disposal, as do some garages. If none of

these facilities are available, consult your local

Environmental Health Department, or the

National Rivers Authority, for further advice.

With the universal tightening-up of

legislation regarding the emission of

environmentally-harmful substances from

motor vehicles, most current vehicles have

tamperproof devices fitted to the main

adjustment points of the fuel system. These

devices are primarily designed to prevent

unqualified persons from adjusting the fuel/air

mixture, with the chance of a consequent

increase in toxic emissions. If such devices

are encountered during servicing or overhaul,

they should, wherever possible, be renewed

or refitted in accordance with the vehicle

manufacturer’s requirements or current

legislation.

Note: It is

antisocial and

illegal to dump oil

down the drain.

To find the

location of your

local oil recycling

bank, call this

number free.

Page 207 of 227

3261 Jaguar XJ6

REF•6Tools and working facilities

Introduction

A selection of good tools is a fundamental

requirement for anyone contemplating the

maintenance and repair of a motor vehicle.

For the owner who does not possess any,

their purchase will prove a considerable

expense, offsetting some of the savings made

by doing-it-yourself. However, provided that

the tools purchased meet the relevant national

safety standards and are of good quality, they

will last for many years and prove an

extremely worthwhile investment.

To help the average owner to decide which

tools are needed to carry out the various tasks

detailed in this manual, we have compiled

three lists of tools under the following

headings: Maintenance and minor repair,

Repair and overhaul, and Special. Newcomers

to practical mechanics should start off with

the Maintenance and minor repairtool kit, and

confine themselves to the simpler jobs around

the vehicle. Then, as confidence and

experience grow, more difficult tasks can be

undertaken, with extra tools being purchased

as, and when, they are needed. In this way, a

Maintenance and minor repairtool kit can be

built up into a Repair and overhaultool kit over

a considerable period of time, without any

major cash outlays. The experienced do-it-

yourselfer will have a tool kit good enough for

most repair and overhaul procedures, and will

add tools from the Specialcategory when it is

felt that the expense is justified by the amount

of use to which these tools will be put.

Maintenance

and minor repair tool kit

The tools given in this list should be

considered as a minimum requirement if

routine maintenance, servicing and minor

repair operations are to be undertaken. We

recommend the purchase of combination

spanners (ring one end, open-ended the

other); although more expensive than open-

ended ones, they do give the advantages of

both types of spanner.

MCombination spanners:

Metric - 8 to 19 mm inclusive

MAdjustable spanner - 35 mm jaw (approx.)

MSpark plug spanner (with rubber insert) -

petrol models

MSpark plug gap adjustment tool - petrol

models

MSet of feeler blades

MBrake bleed nipple spanner

MScrewdrivers:

Flat blade - 100 mm long x 6 mm dia

Cross blade - 100 mm long x 6 mm dia

MCombination pliers

MHacksaw (junior)

MTyre pump

MTyre pressure gauge

MOil can

MOil filter removal tool

MFine emery cloth

MWire brush (small)

MFunnel (medium size)

Repair and overhaul tool kit

These tools are virtually essential for

anyone undertaking any major repairs to a

motor vehicle, and are additional to those

given in the Maintenance and minor repairlist.

Included in this list is a comprehensive set of

sockets. Although these are expensive, they

will be found invaluable as they are so

versatile - particularly if various drives are

included in the set. We recommend the half-

inch square-drive type, as this can be used

with most proprietary torque wrenches.

The tools in this list will sometimes need to

be supplemented by tools from the Speciallist:

MSockets (or box spanners) to cover range in

previous list (including Torx sockets)

MReversible ratchet drive (for use with

sockets)

MExtension piece, 250 mm (for use with

sockets)

MUniversal joint (for use with sockets)

MTorque wrench (for use with sockets)

MSelf-locking grips

MBall pein hammer

MSoft-faced mallet (plastic/aluminium or

rubber)

MScrewdrivers:

Flat blade - long & sturdy, short (chubby),

and narrow (electrician’s) types

Cross blade – Long & sturdy, and short

(chubby) types

MPliers:

Long-nosed

Side cutters (electrician’s)

Circlip (internal and external)

MCold chisel - 25 mm

MScriber

MScraper

MCentre-punch

MPin punch

MHacksaw

MBrake hose clamp

MBrake/clutch bleeding kit

MSelection of twist drills

MSteel rule/straight-edge

MAllen keys (inc. splined/Torx type)

MSelection of files

MWire brush

MAxle stands

MJack (strong trolley or hydraulic type)

MLight with extension lead

Sockets and reversible ratchet drive

Clutch plate alignment setPiston ring compressorSpline bit set

Valve spring compressor

Page 225 of 227

3261 Jaguar XJ6

NNeutral start switch -7•5

Notes for UK readers -0•4, REF•3

Number plate light - 12•12

OObtaining diagnostic code output -6•3

Oil cooler -3•6

Oil filter -1•6

Oil gauge - 12•7

Oil pump -2A•15

Oil seals -2A•5, 2A•17, 2B•17, 7•7, 8•4, 8•5, REF•5

Oil,differential -1•2, 1•11, 1•20

Oil,engine -0•11, 0•16, 1•2, 1•6

On Board Diagnosis (OBD) system -6•2

Open circuit check - 12•2

Output shaft -7•7

Oxygen sensor -6•4

PPads (brake) -9•1, 9•2

Painting - 11•2

Parking lights - 12•11

Piston rings -2B•15

Pistons -2B•9, 2B•12, 2B•17

Poisonous or irritant substances -0•5

Power hydraulic system -0•16

fluid - 1•9

Power steering - 10•10, 10•11

fluid - 0•13, 0•16

Propshaft -1•18, 8•1, 8•2, 8•3

Punctures- 0•8

RRadiator -3•4

grille - 11•5

Radio - 12•7, REF•1

Rear lights - 12•12

Receiver/drier -3•12

Regulator (window) - 11•10

Relays - 12•3

Repair procedures - REF•5

Reversing lights -7•5, 12•12

Road test -1•14

Roadside repairs-0•6et seq

Routine maintenance and servicing-1•1et seq

Rust holes - 11•2

SSafety first -0•5

Scalding -0•5

Scratches - 11•2Screw threads and fastenings - REF•5

Seat belts -1•13, REF•9

Seats - 11•14, REF•9

Self-levelling rear suspension system - 10•3

Servo -1•12, 9•1, 9•9

Shift cable -7•4

Shock absorber - 10•4, 10•6, REF•9, REF•10

Shoes (brake) -1•20, 9•11

Short circuit check - 12•1

Side marker lights - 12•11

Spare parts - REF•4

Spark plugs -1•7, 1•14

Speakers - 12•7

Speed sensor -6•7

Spoiler - 11•5

Springs - 10•5, 10•6, REF•10

Starter motor -5•7

Steering - See Suspension and steering systems

Steering wheel and column - 11•13, 12•5, REF•8

Sump -2A•14

Sunroof - 12•14

Supplementary air valve -4•13

Suspension and steering systems- 1•12, 10•1et seq, REF•9, REF•10

fault finding - REF•16, REF•17

Switches -4•1, 7•5, 9•13, 12•5, 12•6, 12•12

TTail lights - 12•12

Temperature gauge - 12•7

Temperature sender unit -3•7

Thermostat -3•2

Throttle body -4•10

Throttle potentiometer -6•5

Tie-rod ends - 10•9

Timing chains -2A•6

Tools - REF•5, REF•6, REF•7

Top Dead Centre (TDC) for number one piston -2A•2

Torque converter -7•7

Towing -0•6

Trim panels - 11•7, 11•13

Tyres - 0•14, 10•11, REF•11

UUK readers information -0•4, REF•3

Universal joint -8•1, 8•2, 8•5

Upholstery - 11•1

VVacuum gauge checks -2B•3

Valve cover -2A•3

Valve lifters -2A•9

Valves -2B•8

Vehicle identification - REF•4, REF•9

Vehicle support - REF•1

Vinyl trim - 11•1

Voltage checks - 12•1

REF•24Index