check engine JAGUAR XJ6 1997 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 75 of 227

Heating system

The heating system consists of two blower

fans, one under the dash on the right and one

on the left, and a heater core located within

the heater/air conditioning assembly which is

under the dash and behind the console.

Hoses connect the heater core to the engine

cooling system. Heater function is controlled

by the heater/air conditioning control head on

the dashboard. Hot engine coolant is

circulated through the heater core. When the

heater mode is activated, a flap door opens to

expose the heater box to the passenger

compartment. A fan switch on the control

head activates the blower motor, which forces

air through the core, heating the air.

Air conditioning system

The air conditioning system consists of a

condenser mounted in front of the radiator, an

evaporator mounted in the heat/air

conditioning assembly behind the console and

under the centre of the dash, a compressor

mounted on the engine, a filter-drier which

contains a high pressure relief valve and the

plumbing connecting all of the above.

A blower fan forces the warmer air of the

passenger compartment through the

evaporator core (sort of a radiator-in-reverse),

transferring the heat from the air to the

refrigerant. The liquid refrigerant boils off into

low pressure vapour, taking the heat with it

when it leaves the evaporator. The

compressor keeps refrigerant circulating

through the system, pumping the warmed

coolant through the condenser where it is

cooled and then circulated back to the

evaporator.

2 Antifreeze/coolant-

general information

Warning: Do not allow antifreeze

to come in contact with your

skin or painted surfaces of the

vehicle. Rinse off spills immediately withplenty of water. Antifreeze is highly toxic if

ingested. Never leave antifreeze lying

around in an open container or in puddles

on the floor; children and pets are

attracted by it’s sweet smell and may drink

it. Check with local authorities about

disposing of used antifreeze. Many

communities have collection centres which

will see that antifreeze is disposed of

safely. Never dump used antifreeze on the

ground or into drains.

Note:Non-toxic antifreeze is now

manufactured and available at local car

accessory outlets, but even these types

should be disposed of properly.

The cooling system should be filled with a

water/ethylene-glycol based antifreeze

solution, which will prevent freezing down to

at least -20° F, or lower if local climate

requires it. It also provides protection against

corrosion and increases the coolant boiling

point.

The cooling system should be drained,

flushed and refilled every 24,000 miles or

every two years (see Chapter 1). The use of

antifreeze solutions for periods of longer than

two years is likely to cause damage and

encourage the formation of rust and scale in

the system. If your tap water is “hard”, i.e.

contains a lot of dissolved minerals, use

distilled water with the antifreeze.

Before adding antifreeze to the system,

check all hose connections, because

antifreeze tends to leak through very minute

openings. Engines do not normally consume

coolant. Therefore, if the level goes down, find

the cause and correct it.

The exact mixture of antifreeze-to-water

you should use depends on the relative

weather conditions. The mixture should

contain at least 50-percent antifreeze, but

should never contain more than 70-percent

antifreeze. Consult the mixture ratio chart on

the antifreeze container before adding

coolant. Hydrometers are available at most

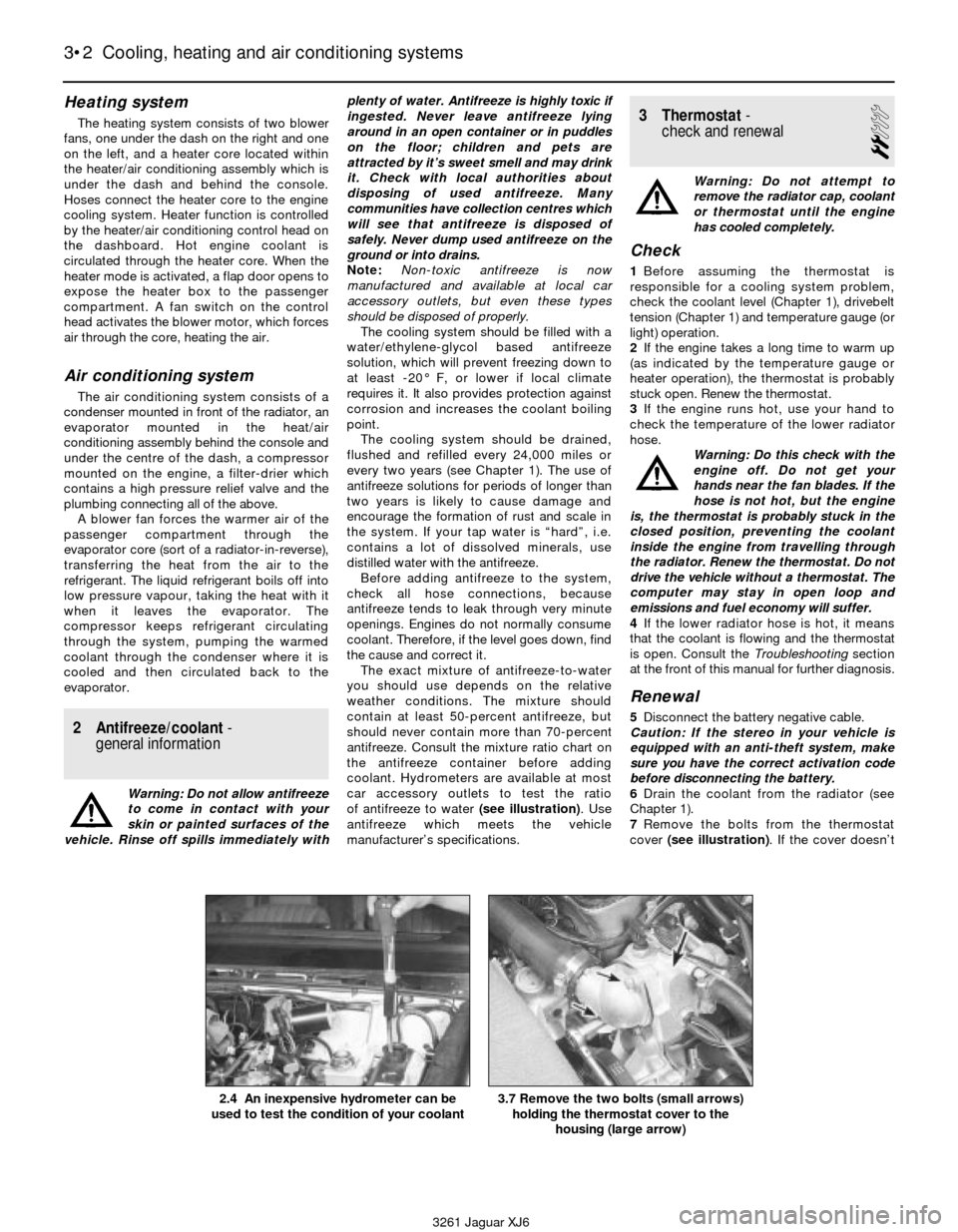

car accessory outlets to test the ratio

of antifreeze to water (see illustration). Use

antifreeze which meets the vehicle

manufacturer’s specifications.

3 Thermostat-

check and renewal

2

Warning: Do not attempt to

remove the radiator cap, coolant

or thermostat until the engine

has cooled completely.

Check

1Before assuming the thermostat is

responsible for a cooling system problem,

check the coolant level (Chapter 1), drivebelt

tension (Chapter 1) and temperature gauge (or

light) operation.

2If the engine takes a long time to warm up

(as indicated by the temperature gauge or

heater operation), the thermostat is probably

stuck open. Renew the thermostat.

3If the engine runs hot, use your hand to

check the temperature of the lower radiator

hose.

Warning: Do this check with the

engine off. Do not get your

hands near the fan blades. If the

hose is not hot, but the engine

is, the thermostat is probably stuck in the

closed position, preventing the coolant

inside the engine from travelling through

the radiator. Renew the thermostat. Do not

drive the vehicle without a thermostat. The

computer may stay in open loop and

emissions and fuel economy will suffer.

4If the lower radiator hose is hot, it means

that the coolant is flowing and the thermostat

is open. Consult the Troubleshootingsection

at the front of this manual for further diagnosis.

Renewal

5Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

6Drain the coolant from the radiator (see

Chapter 1).

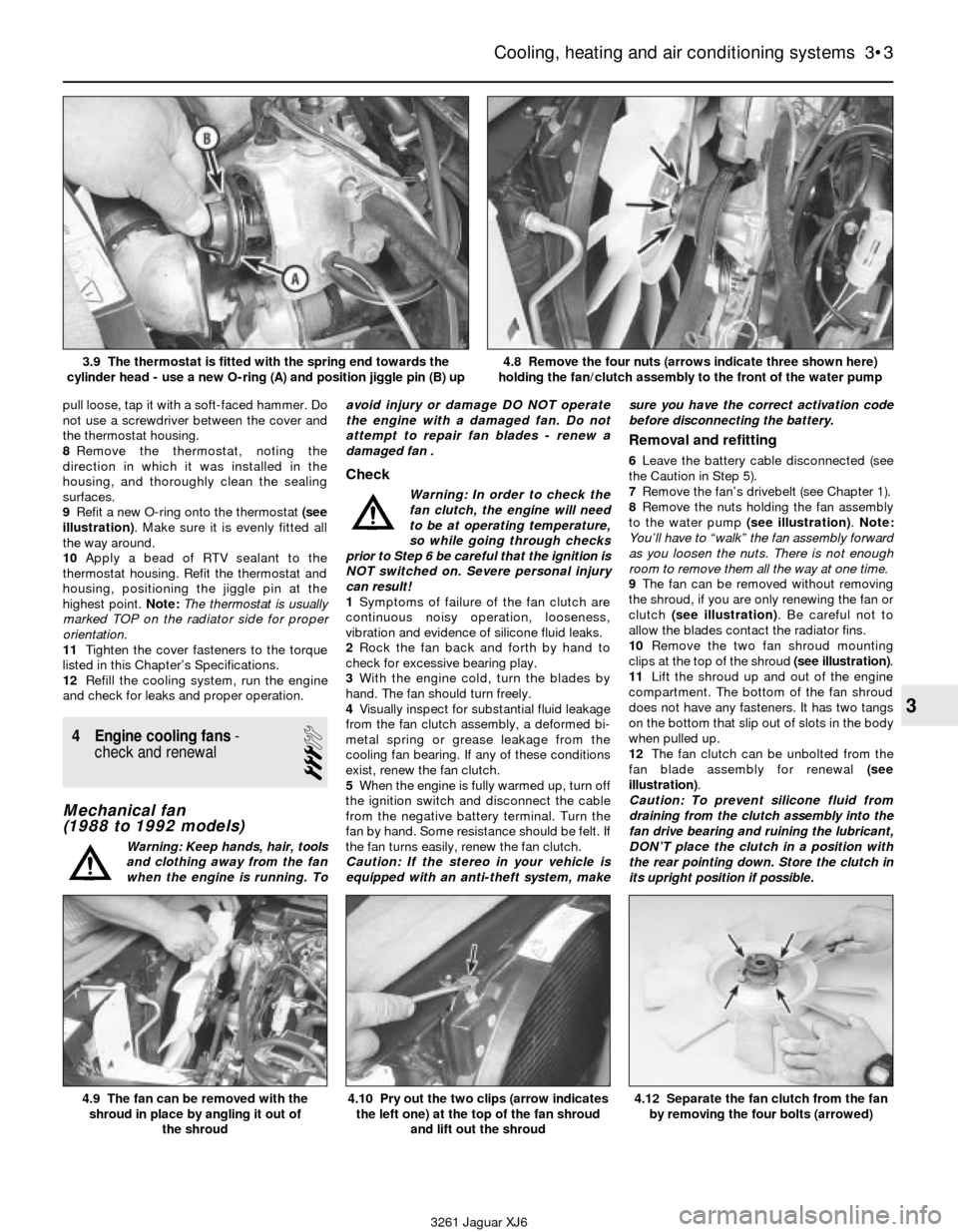

7Remove the bolts from the thermostat

cover (see illustration). If the cover doesn’t

3•2 Cooling, heating and air conditioning systems

3261 Jaguar XJ6 2.4 An inexpensive hydrometer can be

used to test the condition of your coolant

3.7 Remove the two bolts (small arrows)

holding the thermostat cover to the

housing (large arrow)

Page 76 of 227

pull loose, tap it with a soft-faced hammer. Do

not use a screwdriver between the cover and

the thermostat housing.

8Remove the thermostat, noting the

direction in which it was installed in the

housing, and thoroughly clean the sealing

surfaces.

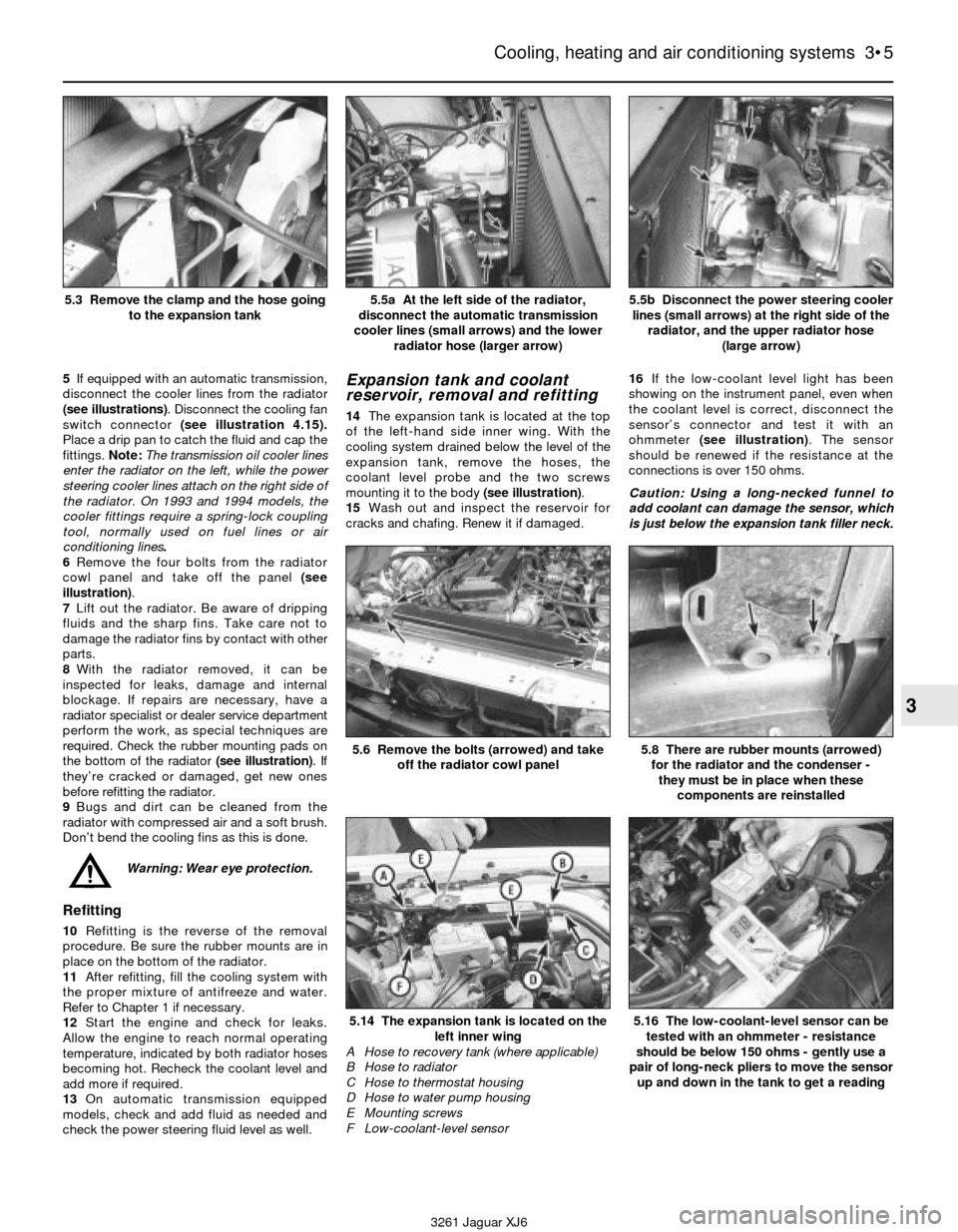

9Refit a new O-ring onto the thermostat (see

illustration). Make sure it is evenly fitted all

the way around.

10Apply a bead of RTV sealant to the

thermostat housing. Refit the thermostat and

housing, positioning the jiggle pin at the

highest point. Note:The thermostat is usually

marked TOP on the radiator side for proper

orientation.

11Tighten the cover fasteners to the torque

listed in this Chapter’s Specifications.

12Refill the cooling system, run the engine

and check for leaks and proper operation.

4 Engine cooling fans-

check and renewal

3

Mechanical fan

(1988 to 1992 models)

Warning: Keep hands, hair, tools

and clothing away from the fan

when the engine is running. Toavoid injury or damage DO NOT operate

the engine with a damaged fan. Do not

attempt to repair fan blades - renew a

damaged fan .

Check

Warning: In order to check the

fan clutch, the engine will need

to be at operating temperature,

so while going through checks

prior to Step 6 be careful that the ignition is

NOT switched on. Severe personal injury

can result!

1Symptoms of failure of the fan clutch are

continuous noisy operation, looseness,

vibration and evidence of silicone fluid leaks.

2Rock the fan back and forth by hand to

check for excessive bearing play.

3With the engine cold, turn the blades by

hand. The fan should turn freely.

4Visually inspect for substantial fluid leakage

from the fan clutch assembly, a deformed bi-

metal spring or grease leakage from the

cooling fan bearing. If any of these conditions

exist, renew the fan clutch.

5When the engine is fully warmed up, turn off

the ignition switch and disconnect the cable

from the negative battery terminal. Turn the

fan by hand. Some resistance should be felt. If

the fan turns easily, renew the fan clutch.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, makesure you have the correct activation code

before disconnecting the battery.

Removal and refitting

6Leave the battery cable disconnected (see

the Caution in Step 5).

7Remove the fan’s drivebelt (see Chapter 1).

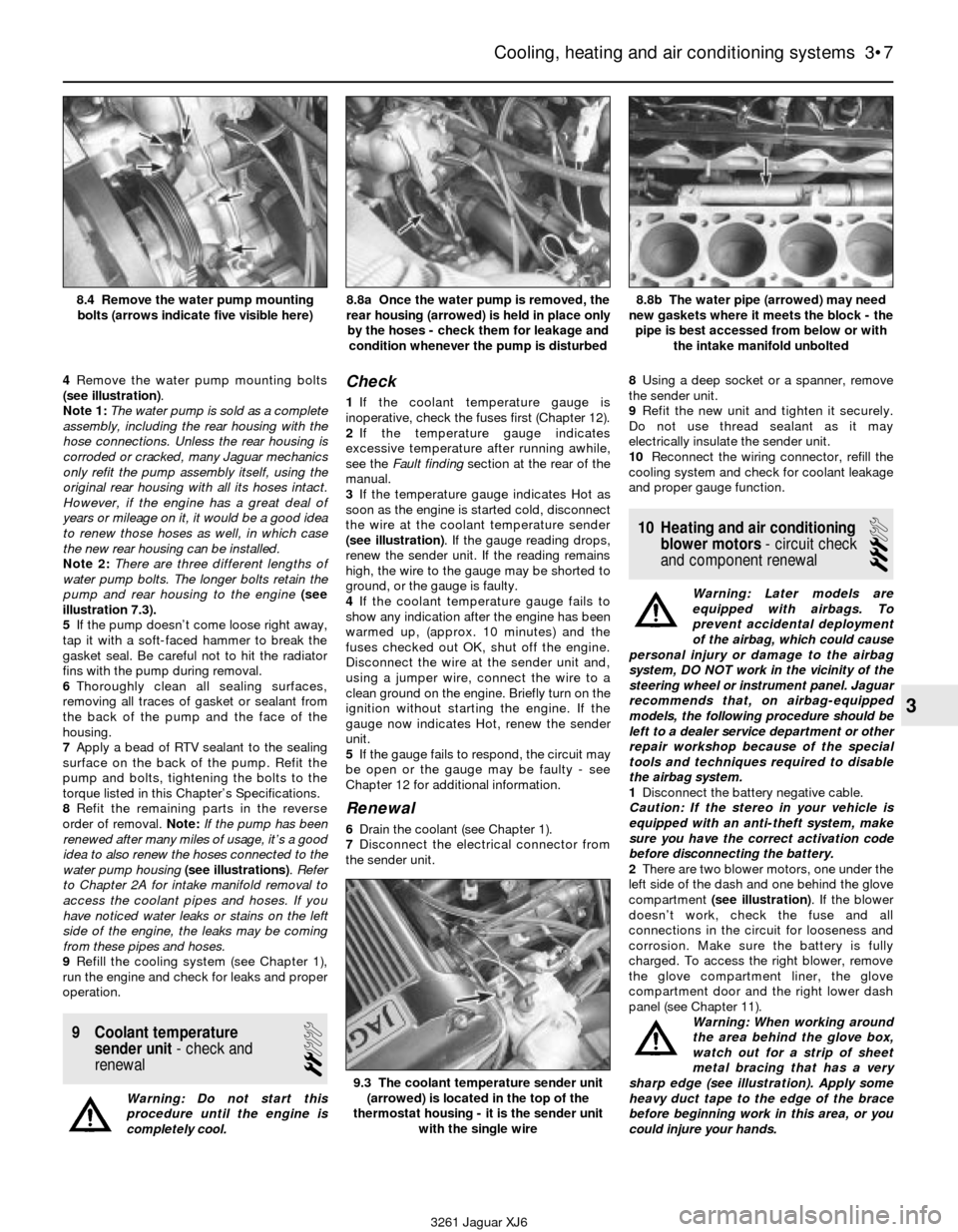

8Remove the nuts holding the fan assembly

to the water pump (see illustration). Note:

You’ll have to “walk” the fan assembly forward

as you loosen the nuts. There is not enough

room to remove them all the way at one time.

9The fan can be removed without removing

the shroud, if you are only renewing the fan or

clutch (see illustration). Be careful not to

allow the blades contact the radiator fins.

10Remove the two fan shroud mounting

clips at the top of the shroud (see illustration).

11Lift the shroud up and out of the engine

compartment. The bottom of the fan shroud

does not have any fasteners. It has two tangs

on the bottom that slip out of slots in the body

when pulled up.

12The fan clutch can be unbolted from the

fan blade assembly for renewal (see

illustration).

Caution: To prevent silicone fluid from

draining from the clutch assembly into the

fan drive bearing and ruining the lubricant,

DON’T place the clutch in a position with

the rear pointing down. Store the clutch in

its upright position if possible.

Cooling, heating and air conditioning systems 3•3

3

4.9 The fan can be removed with the

shroud in place by angling it out of

the shroud4.10 Pry out the two clips (arrow indicates

the left one) at the top of the fan shroud

and lift out the shroud

3261 Jaguar XJ6 3.9 The thermostat is fitted with the spring end towards the

cylinder head - use a new O-ring (A) and position jiggle pin (B) up

4.8 Remove the four nuts (arrows indicate three shown here)

holding the fan/clutch assembly to the front of the water pump

4.12 Separate the fan clutch from the fan

by removing the four bolts (arrowed)

Page 77 of 227

13Refitting is the reverse of removal. Tighten

the fan clutch-to-fan blade bolts and the fan

assembly-to-drive hub nut to the torque listed

in this Chapter’s Specifications.

Electric fans

Check

Warning: Keep your hands or

clothing away from the fan

blades at all times.

14On 1988 through 1992 models, a single

electric fan is mounted in front of the radiator,

controlled by a thermostatic switch. Access to

the fan is with the grille removed. The 1993

and 1994 models have a fan shroud assembly

that includes two electric fans, and a “twin”

thermostatic switch, with the assembly

mounted on the engine side of the radiator.

15If the electric fan does not come on at any

time, bypass the thermostatic switch by

disconnecting the electrical connector at the

switch and connecting the two pins with a

jumper wire (see illustration). If the fan now

operates, renew the thermostatic switch. If the

fan doesn’t operate, the problem is either the

fan relay or the fan motor. On 1993 and 1994

models with twin electric fans, jumpering one

set of connections in the plug from the switch

should make both fans operate at slow speed

(fans in series) and jumpering the other two

should run both fans at higher speed (fans in

parallel). In normal operation, the fans operate

at the higher-speed only when the air

conditioning is on, or when coolant

temperature exceeds 212° F. When the

coolant cools down to below 200° F, the fans

revert to the normal speed.

16To renew a defective thermostatic switch,

allow the vehicle to cool off and drain the

coolant (see Chapter 1). Remove the switch

from the radiator and refit the new switch.

Connect the electrical connector and test

again for proper fan operation.17To test an inoperative fan motor (one that

doesn’t come on when the engine gets hot or

when the air conditioner is on), first check the

fuses and/or fusible links (see Chapter 12).

Then disconnect the electrical connector at

the motor (refer to Chapter 11 for removal of

the grille for access on front-mounted-fan

models) and use fused jumper wires to

connect the fan directly to the battery and to

chassis ground (see illustration). If the fan

still does not work, renew the fan motor.

Warning: Do not allow the test

clips to contact each other or

any metallic part of the vehicle.

18If the motor tested OK in the previous test

but is still inoperative, then the fault lies in the

relay, fuse, or wiring. The fan relay can be

tested for continuity (see Chapter 12).

Renewal

19Disconnect the negative battery cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.20Access the 1988 through 1992 single

electric fan with the grille removed (see

Chapter 11 for grille removal). Disconnect the

electrical connector and remove the bolts

holding the fan assembly to the body (see

illustration).

21On 1993 and 1994 models, remove the

two bolts holding the fan shroud to the top of

the radiator and lift the shroud/fans assembly

from the vehicle.

22If the fan on 1988 to 1992 models must be

renewed, renew the fan, motor and shroud as

a unit. The fan is separate from the shroud on

later models.

23Refitting is the reverse of removal. If the

thermostatic switch was renewed, refill the

cooling system.5 Radiator, expansion tank

and coolant reservoir-

removal and refitting

3

Warning: Do not start this

procedure until the engine is

completely cool.

Radiator

Removal

1Disconnect the negative battery cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Drain the coolant into a container (see

Chapter 1).

3Remove both the upper and lower radiator

hoses, and the small expansion tank hose from

the top left of the radiator (see illustration).

4Remove the cooling fan and shroud (see

Section 4).

3•4 Cooling, heating and air conditioning systems

4.20 Disconnect the fan’s electrical

connector (large arrow) and remove the

bolts (small arrows) on single-fan models -

grille is removed here

3261 Jaguar XJ6 4.15 Disconnect the electrical connector (A) from the

thermostatic switch (B) in the radiator and bypass it with a

jumper wire (C) - the fan should operate now with the ignition on

4.17 Disconnect the fan wiring connector and connect jumper

wires from there directly to the positive and negative terminals of

the battery - the purple wire’s terminal should receive the battery

power and the black wire’s terminal should be earthed

Page 78 of 227

5If equipped with an automatic transmission,

disconnect the cooler lines from the radiator

(see illustrations). Disconnect the cooling fan

switch connector (see illustration 4.15).

Place a drip pan to catch the fluid and cap the

fittings. Note:The transmission oil cooler lines

enter the radiator on the left, while the power

steering cooler lines attach on the right side of

the radiator. On 1993 and 1994 models, the

cooler fittings require a spring-lock coupling

tool, normally used on fuel lines or air

conditioning lines.

6Remove the four bolts from the radiator

cowl panel and take off the panel (see

illustration).

7Lift out the radiator. Be aware of dripping

fluids and the sharp fins. Take care not to

damage the radiator fins by contact with other

parts.

8With the radiator removed, it can be

inspected for leaks, damage and internal

blockage. If repairs are necessary, have a

radiator specialist or dealer service department

perform the work, as special techniques are

required. Check the rubber mounting pads on

the bottom of the radiator (see illustration). If

they’re cracked or damaged, get new ones

before refitting the radiator.

9Bugs and dirt can be cleaned from the

radiator with compressed air and a soft brush.

Don’t bend the cooling fins as this is done.

Warning: Wear eye protection.

Refitting

10Refitting is the reverse of the removal

procedure. Be sure the rubber mounts are in

place on the bottom of the radiator.

11After refitting, fill the cooling system with

the proper mixture of antifreeze and water.

Refer to Chapter 1 if necessary.

12Start the engine and check for leaks.

Allow the engine to reach normal operating

temperature, indicated by both radiator hoses

becoming hot. Recheck the coolant level and

add more if required.

13On automatic transmission equipped

models, check and add fluid as needed and

check the power steering fluid level as well.

Expansion tank and coolant

reservoir, removal and refitting

14The expansion tank is located at the top

of the left-hand side inner wing. With the

cooling system drained below the level of the

expansion tank, remove the hoses, the

coolant level probe and the two screws

mounting it to the body (see illustration).

15Wash out and inspect the reservoir for

cracks and chafing. Renew it if damaged.16If the low-coolant level light has been

showing on the instrument panel, even when

the coolant level is correct, disconnect the

sensor’s connector and test it with an

ohmmeter (see illustration). The sensor

should be renewed if the resistance at the

connections is over 150 ohms.

Caution: Using a long-necked funnel to

add coolant can damage the sensor, which

is just below the expansion tank filler neck.

Cooling, heating and air conditioning systems 3•5

3

5.5a At the left side of the radiator,

disconnect the automatic transmission

cooler lines (small arrows) and the lower

radiator hose (larger arrow)5.5b Disconnect the power steering cooler

lines (small arrows) at the right side of the

radiator, and the upper radiator hose

(large arrow)

3261 Jaguar XJ6 5.3 Remove the clamp and the hose going

to the expansion tank

5.6 Remove the bolts (arrowed) and take

off the radiator cowl panel

5.14 The expansion tank is located on the

left inner wing

A Hose to recovery tank (where applicable)

B Hose to radiator

C Hose to thermostat housing

D Hose to water pump housing

E Mounting screws

F Low-coolant-level sensor

5.8 There are rubber mounts (arrowed)

for the radiator and the condenser -

they must be in place when these

components are reinstalled

5.16 The low-coolant-level sensor can be

tested with an ohmmeter - resistance

should be below 150 ohms - gently use a

pair of long-neck pliers to move the sensor

up and down in the tank to get a reading

Page 79 of 227

17A coolant recovery bottle is used on 1988

and 1989 models, located in the passenger’s

inner wing. The plastic inner wing splash

shield must be removed for access to the

recovery bottle (see Chapter 11). Disconnect

the recovery hose and remove the mounting

screws to renew the recovery bottle (see

illustration). Models from 1990 on do not

have the recovery bottle, but do have a larger

expansion tank.

18Refitting of either expansion tank or

recovery bottle is the reverse of removal.

6 Engine oil cooler- renewal

2

1Models from 1988 through 1991 have a

engine oil cooler, mounted ahead of the

radiator. The engine’s mechanical fan draws

air through the oil cooler, cooling off hot

engine oil that is circulated from the engine by

steel tubes. Access to the cooler is with the

grille removed (refer to Chapter 11 for grille

removal).

2To renew the oil cooler, first disconnect thetwo fittings connecting the lines to the cooler

(see illustration).

Caution: The engine should be cool for this

procedure, and you should have a small

drain pan handy because the fittings are

on the bottom of the cooler and will

probably drip some oil on dismantling.

3Remove the mounting nuts to take the

cooler out of the vehicle (see illustration).

4The other ends of the oil cooler tubes

mount to a block just below the oil filter. With

a drain pan handy, remove the nut retaining

both pipes to the block.

5Refitting the oil cooler and oil lines is the

reverse of removal. When refitting the lines to

the block or the cooler, use new O-rings.7 Water pump- check

1

1A failure in the water pump can cause

serious engine damage due to overheating.

2With the engine running and warmed to

normal operating temperature, squeeze the

upper radiator hose. If the water pump is

working properly, a pressure surge should be

felt as the hose is released.

Warning: Keep hands away from

fan blades!

3Water pumps are equipped with weep or

vent holes (see illustration). If a failure occurs

in the pump seal, coolant will leak from this

hole. In most cases it will be necessary to use

a flashlight to find the hole on the water pump

by looking through the space behind the

pulley just below the water pump shaft.

4If the water pump shaft bearings fail there

may be a howling sound at the front of the

engine while it is running. Bearing wear can be

felt if the water pump pulley is rocked up anddown. Do not mistake drivebelt slippage,

which causes a squealing sound, for water

pump failure. Spray automotive drivebelt

dressing on the belts to eliminate the belt as a

possible cause of the noise.

8 Water pump and pipes-

renewal

3

Warning: Do not start this

procedure until the engine is

completely cool.

1Disconnect the negative battery cable and

drain the cooling system (see Chapter 1).

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Refer to Section 4 to remove the

mechanical fan and clutch (if applicable to

your model).

3Refer to Chapter 1 for removal of the

drivebelts.

3•6 Cooling, heating and air conditioning systems

6.3 Remove the mounting nuts (arrowed)

to take the oil cooler out

7.3 Check the weep hole (arrowed) for

signs of leakage (pump removed for

clarity) - grey discolouration is normal,

large brown stains indicates seal failure

3261 Jaguar XJ6 5.17 The recovery bottle (arrowed) on 1988 and 1989 models is

located in the footwell - disconnect the hoses and the two

mounting screws

6.2 Disconnect the two metal oil lines (arrowed) where they

mount to the bottom of the cooler - use two spanners

Page 80 of 227

4Remove the water pump mounting bolts

(see illustration).

Note 1:The water pump is sold as a complete

assembly, including the rear housing with the

hose connections. Unless the rear housing is

corroded or cracked, many Jaguar mechanics

only refit the pump assembly itself, using the

original rear housing with all its hoses intact.

However, if the engine has a great deal of

years or mileage on it, it would be a good idea

to renew those hoses as well, in which case

the new rear housing can be installed.

Note 2:There are three different lengths of

water pump bolts. The longer bolts retain the

pump and rear housing to the engine(see

illustration 7.3).

5If the pump doesn’t come loose right away,

tap it with a soft-faced hammer to break the

gasket seal. Be careful not to hit the radiator

fins with the pump during removal.

6Thoroughly clean all sealing surfaces,

removing all traces of gasket or sealant from

the back of the pump and the face of the

housing.

7Apply a bead of RTV sealant to the sealing

surface on the back of the pump. Refit the

pump and bolts, tightening the bolts to the

torque listed in this Chapter’s Specifications.

8Refit the remaining parts in the reverse

order of removal. Note:If the pump has been

renewed after many miles of usage, it’s a good

idea to also renew the hoses connected to the

water pump housing(see illustrations). Refer

to Chapter 2A for intake manifold removal to

access the coolant pipes and hoses. If you

have noticed water leaks or stains on the left

side of the engine, the leaks may be coming

from these pipes and hoses.

9Refill the cooling system (see Chapter 1),

run the engine and check for leaks and proper

operation.

9 Coolant temperature

sender unit- check and

renewal

2

Warning: Do not start this

procedure until the engine is

completely cool.

Check

1If the coolant temperature gauge is

inoperative, check the fuses first (Chapter 12).

2If the temperature gauge indicates

excessive temperature after running awhile,

see the Fault finding section at the rear of the

manual.

3If the temperature gauge indicates Hot as

soon as the engine is started cold, disconnect

the wire at the coolant temperature sender

(see illustration). If the gauge reading drops,

renew the sender unit. If the reading remains

high, the wire to the gauge may be shorted to

ground, or the gauge is faulty.

4If the coolant temperature gauge fails to

show any indication after the engine has been

warmed up, (approx. 10 minutes) and the

fuses checked out OK, shut off the engine.

Disconnect the wire at the sender unit and,

using a jumper wire, connect the wire to a

clean ground on the engine. Briefly turn on the

ignition without starting the engine. If the

gauge now indicates Hot, renew the sender

unit.

5If the gauge fails to respond, the circuit may

be open or the gauge may be faulty - see

Chapter 12 for additional information.

Renewal

6Drain the coolant (see Chapter 1).

7Disconnect the electrical connector from

the sender unit.8Using a deep socket or a spanner, remove

the sender unit.

9Refit the new unit and tighten it securely.

Do not use thread sealant as it may

electrically insulate the sender unit.

10Reconnect the wiring connector, refill the

cooling system and check for coolant leakage

and proper gauge function.

10 Heating and air conditioning

blower motors- circuit check

and component renewal

3

Warning: Later models are

equipped with airbags. To

prevent accidental deployment

of the airbag, which could cause

personal injury or damage to the airbag

system, DO NOT work in the vicinity of the

steering wheel or instrument panel. Jaguar

recommends that, on airbag-equipped

models, the following procedure should be

left to a dealer service department or other

repair workshop because of the special

tools and techniques required to disable

the airbag system.

1Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2There are two blower motors, one under the

left side of the dash and one behind the glove

compartment (see illustration). If the blower

doesn’t work, check the fuse and all

connections in the circuit for looseness and

corrosion. Make sure the battery is fully

charged. To access the right blower, remove

the glove compartment liner, the glove

compartment door and the right lower dash

panel (see Chapter 11).

Warning: When working around

the area behind the glove box,

watch out for a strip of sheet

metal bracing that has a very

sharp edge (see illustration). Apply some

heavy duct tape to the edge of the brace

before beginning work in this area, or you

could injure your hands.

Cooling, heating and air conditioning systems 3•7

3

8.4 Remove the water pump mounting

bolts (arrows indicate five visible here)8.8a Once the water pump is removed, the

rear housing (arrowed) is held in place only

by the hoses - check them for leakage and

condition whenever the pump is disturbed8.8b The water pipe (arrowed) may need

new gaskets where it meets the block - the

pipe is best accessed from below or with

the intake manifold unbolted

9.3 The coolant temperature sender unit

(arrowed) is located in the top of the

thermostat housing - it is the sender unit

with the single wire

3261 Jaguar XJ6

Page 83 of 227

metal bracing that has a very sharp edge

(see illustration 10.2b). Apply some heavy

duct tape to the edge of the brace before

beginning work in this area, or you could

injure your hands.

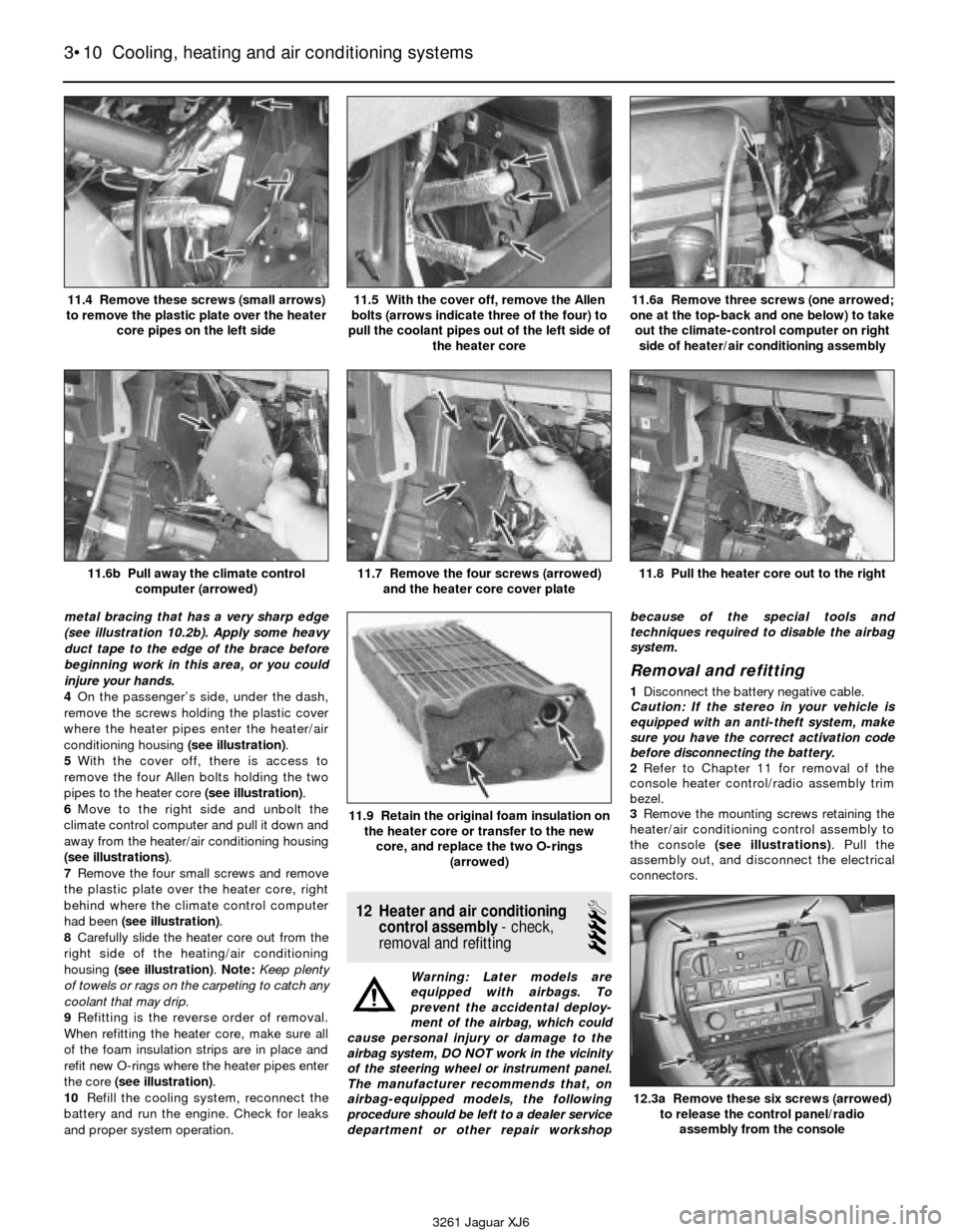

4On the passenger’s side, under the dash,

remove the screws holding the plastic cover

where the heater pipes enter the heater/air

conditioning housing (see illustration).

5With the cover off, there is access to

remove the four Allen bolts holding the two

pipes to the heater core (see illustration).

6Move to the right side and unbolt the

climate control computer and pull it down and

away from the heater/air conditioning housing

(see illustrations).

7Remove the four small screws and remove

the plastic plate over the heater core, right

behind where the climate control computer

had been (see illustration).

8Carefully slide the heater core out from the

right side of the heating/air conditioning

housing (see illustration). Note:Keep plenty

of towels or rags on the carpeting to catch any

coolant that may drip.

9Refitting is the reverse order of removal.

When refitting the heater core, make sure all

of the foam insulation strips are in place and

refit new O-rings where the heater pipes enter

the core (see illustration).

10Refill the cooling system, reconnect the

battery and run the engine. Check for leaks

and proper system operation.

12 Heater and air conditioning

control assembly- check,

removal and refitting

4

Warning: Later models are

equipped with airbags. To

prevent the accidental deploy-

ment of the airbag, which could

cause personal injury or damage to the

airbag system, DO NOT work in the vicinity

of the steering wheel or instrument panel.

The manufacturer recommends that, on

airbag-equipped models, the following

procedure should be left to a dealer service

department or other repair workshopbecause of the special tools and

techniques required to disable the airbag

system.

Removal and refitting

1Disconnect the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Refer to Chapter 11 for removal of the

console heater control/radio assembly trim

bezel.

3Remove the mounting screws retaining the

heater/air conditioning control assembly to

the console (see illustrations). Pull the

assembly out, and disconnect the electrical

connectors.

3•10 Cooling, heating and air conditioning systems

11.4 Remove these screws (small arrows)

to remove the plastic plate over the heater

core pipes on the left side11.5 With the cover off, remove the Allen

bolts (arrows indicate three of the four) to

pull the coolant pipes out of the left side of

the heater core11.6a Remove three screws (one arrowed;

one at the top-back and one below) to take

out the climate-control computer on right

side of heater/air conditioning assembly

11.6b Pull away the climate control

computer (arrowed)11.7 Remove the four screws (arrowed)

and the heater core cover plate11.8 Pull the heater core out to the right

3261 Jaguar XJ6

11.9 Retain the original foam insulation on

the heater core or transfer to the new

core, and replace the two O-rings

(arrowed)

12.3a Remove these six screws (arrowed)

to release the control panel/radio

assembly from the console

Page 84 of 227

4Refitting is the reverse of the removal

procedure.

5Run the engine and check for proper

functioning of the heater (and air conditioning,

if equipped).

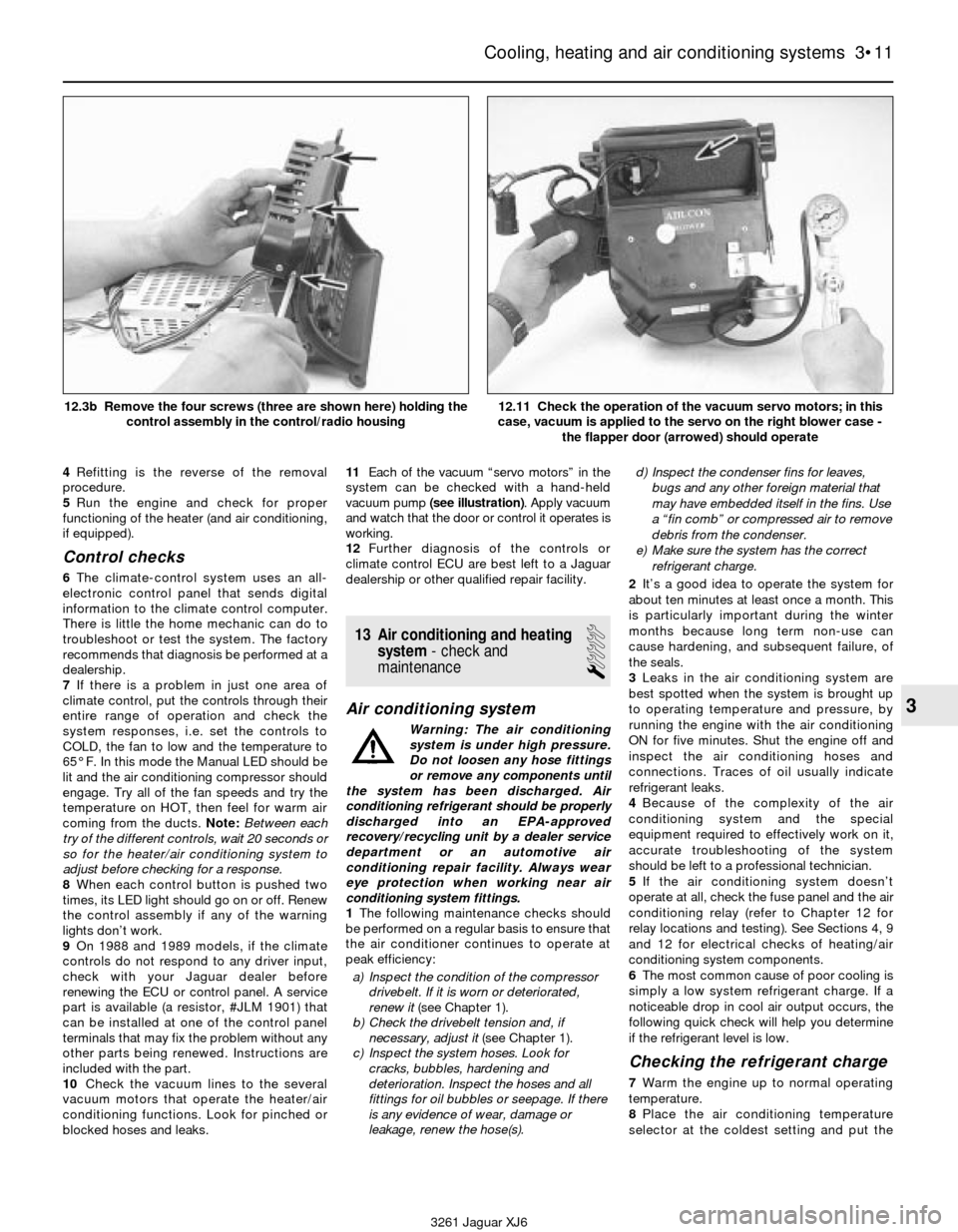

Control checks

6The climate-control system uses an all-

electronic control panel that sends digital

information to the climate control computer.

There is little the home mechanic can do to

troubleshoot or test the system. The factory

recommends that diagnosis be performed at a

dealership.

7If there is a problem in just one area of

climate control, put the controls through their

entire range of operation and check the

system responses, i.e. set the controls to

COLD, the fan to low and the temperature to

65° F. In this mode the Manual LED should be

lit and the air conditioning compressor should

engage. Try all of the fan speeds and try the

temperature on HOT, then feel for warm air

coming from the ducts. Note:Between each

try of the different controls, wait 20 seconds or

so for the heater/air conditioning system to

adjust before checking for a response.

8When each control button is pushed two

times, its LED light should go on or off. Renew

the control assembly if any of the warning

lights don’t work.

9On 1988 and 1989 models, if the climate

controls do not respond to any driver input,

check with your Jaguar dealer before

renewing the ECU or control panel. A service

part is available (a resistor, #JLM 1901) that

can be installed at one of the control panel

terminals that may fix the problem without any

other parts being renewed. Instructions are

included with the part.

10Check the vacuum lines to the several

vacuum motors that operate the heater/air

conditioning functions. Look for pinched or

blocked hoses and leaks.11Each of the vacuum “servo motors” in the

system can be checked with a hand-held

vacuum pump (see illustration). Apply vacuum

and watch that the door or control it operates is

working.

12Further diagnosis of the controls or

climate control ECU are best left to a Jaguar

dealership or other qualified repair facility.

13 Air conditioning and heating

system- check and

maintenance

1

Air conditioning system

Warning: The air conditioning

system is under high pressure.

Do not loosen any hose fittings

or remove any components until

the system has been discharged. Air

conditioning refrigerant should be properly

discharged into an EPA-approved

recovery/recycling unit by a dealer service

department or an automotive air

conditioning repair facility. Always wear

eye protection when working near air

conditioning system fittings.

1The following maintenance checks should

be performed on a regular basis to ensure that

the air conditioner continues to operate at

peak efficiency:

a) Inspect the condition of the compressor

drivebelt. If it is worn or deteriorated,

renew it (see Chapter 1).

b) Check the drivebelt tension and, if

necessary, adjust it (see Chapter 1).

c) Inspect the system hoses. Look for

cracks, bubbles, hardening and

deterioration. Inspect the hoses and all

fittings for oil bubbles or seepage. If there

is any evidence of wear, damage or

leakage, renew the hose(s).d) Inspect the condenser fins for leaves,

bugs and any other foreign material that

may have embedded itself in the fins. Use

a “fin comb” or compressed air to remove

debris from the condenser.

e) Make sure the system has the correct

refrigerant charge.

2It’s a good idea to operate the system for

about ten minutes at least once a month. This

is particularly important during the winter

months because long term non-use can

cause hardening, and subsequent failure, of

the seals.

3Leaks in the air conditioning system are

best spotted when the system is brought up

to operating temperature and pressure, by

running the engine with the air conditioning

ON for five minutes. Shut the engine off and

inspect the air conditioning hoses and

connections. Traces of oil usually indicate

refrigerant leaks.

4Because of the complexity of the air

conditioning system and the special

equipment required to effectively work on it,

accurate troubleshooting of the system

should be left to a professional technician.

5If the air conditioning system doesn’t

operate at all, check the fuse panel and the air

conditioning relay (refer to Chapter 12 for

relay locations and testing). See Sections 4, 9

and 12 for electrical checks of heating/air

conditioning system components.

6The most common cause of poor cooling is

simply a low system refrigerant charge. If a

noticeable drop in cool air output occurs, the

following quick check will help you determine

if the refrigerant level is low.

Checking the refrigerant charge

7Warm the engine up to normal operating

temperature.

8Place the air conditioning temperature

selector at the coldest setting and put the

Cooling, heating and air conditioning systems 3•11

3

3261 Jaguar XJ6 12.3b Remove the four screws (three are shown here) holding the

control assembly in the control/radio housing

12.11 Check the operation of the vacuum servo motors; in this

case, vacuum is applied to the servo on the right blower case -

the flapper door (arrowed) should operate

Page 89 of 227

3261 Jaguar XJ6

4

Chapter 4

Fuel and exhaust systems

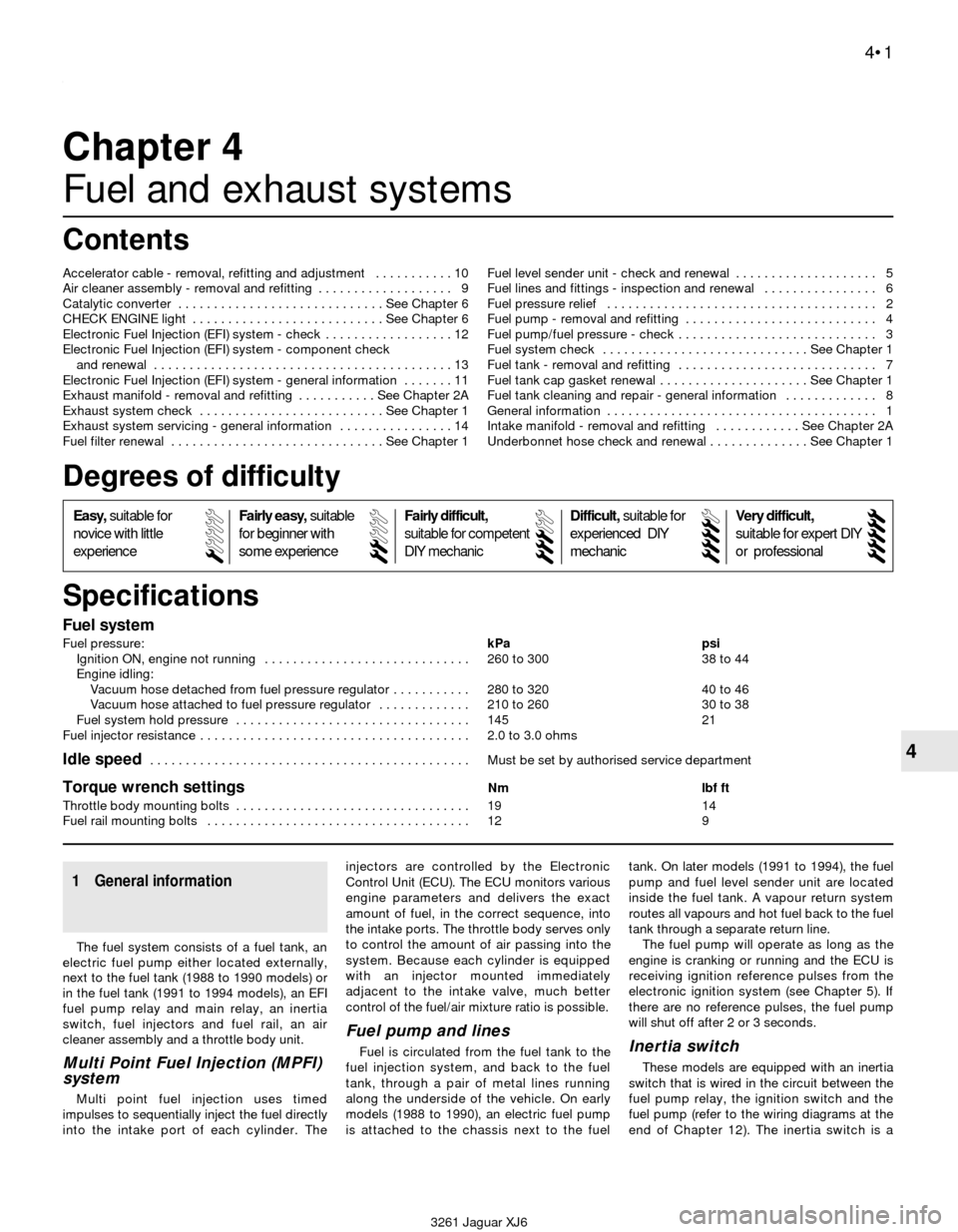

Fuel system

Fuel pressure:kPa psi

Ignition ON, engine not running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260 to 300 38 to 44

Engine idling:

Vacuum hose detached from fuel pressure regulator . . . . . . . . . . . 280 to 320 40 to 46

Vacuum hose attached to fuel pressure regulator . . . . . . . . . . . . . 210 to 260 30 to 38

Fuel system hold pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145 21

Fuel injector resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 to 3.0 ohms

Idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Must be set by authorised service department

Torque wrench settingsNm lbf ft

Throttle body mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 14

Fuel rail mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 9 Accelerator cable - removal, refitting and adjustment . . . . . . . . . . . 10

Air cleaner assembly - removal and refitting . . . . . . . . . . . . . . . . . . . 9

Catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 6

CHECK ENGINE light . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 6

Electronic Fuel Injection (EFI) system - check . . . . . . . . . . . . . . . . . . 12

Electronic Fuel Injection (EFI) system - component check

and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electronic Fuel Injection (EFI) system - general information . . . . . . . 11

Exhaust manifold - removal and refitting . . . . . . . . . . . See Chapter 2A

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Exhaust system servicing - general information . . . . . . . . . . . . . . . . 14

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1Fuel level sender unit - check and renewal . . . . . . . . . . . . . . . . . . . . 5

Fuel lines and fittings - inspection and renewal . . . . . . . . . . . . . . . . 6

Fuel pressure relief . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Fuel pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fuel pump/fuel pressure - check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fuel system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Fuel tank - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fuel tank cap gasket renewal . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Fuel tank cleaning and repair - general information . . . . . . . . . . . . . 8

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Intake manifold - removal and refitting . . . . . . . . . . . . See Chapter 2A

Underbonnet hose check and renewal . . . . . . . . . . . . . . See Chapter 1

4•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 General information

The fuel system consists of a fuel tank, an

electric fuel pump either located externally,

next to the fuel tank (1988 to 1990 models) or

in the fuel tank (1991 to 1994 models), an EFI

fuel pump relay and main relay, an inertia

switch, fuel injectors and fuel rail, an air

cleaner assembly and a throttle body unit.

Multi Point Fuel Injection (MPFI)

system

Multi point fuel injection uses timed

impulses to sequentially inject the fuel directly

into the intake port of each cylinder. Theinjectors are controlled by the Electronic

Control Unit (ECU). The ECU monitors various

engine parameters and delivers the exact

amount of fuel, in the correct sequence, into

the intake ports. The throttle body serves only

to control the amount of air passing into the

system. Because each cylinder is equipped

with an injector mounted immediately

adjacent to the intake valve, much better

control of the fuel/air mixture ratio is possible.

Fuel pump and lines

Fuel is circulated from the fuel tank to the

fuel injection system, and back to the fuel

tank, through a pair of metal lines running

along the underside of the vehicle. On early

models (1988 to 1990), an electric fuel pump

is attached to the chassis next to the fueltank. On later models (1991 to 1994), the fuel

pump and fuel level sender unit are located

inside the fuel tank. A vapour return system

routes all vapours and hot fuel back to the fuel

tank through a separate return line.

The fuel pump will operate as long as the

engine is cranking or running and the ECU is

receiving ignition reference pulses from the

electronic ignition system (see Chapter 5). If

there are no reference pulses, the fuel pump

will shut off after 2 or 3 seconds.Inertia switch

These models are equipped with an inertia

switch that is wired in the circuit between the

fuel pump relay, the ignition switch and the

fuel pump (refer to the wiring diagrams at the

end of Chapter 12). The inertia switch is a

Page 90 of 227

special electrical device that provides circuit

protection by switching off the ignition and

fuel pump upon impact in the event of vehicle

collision. Later Jaguar models are equipped

with an additional specialised inertia switch.

This later device switches OFF all ignition fed

circuits, locks the fuel filler cap, locks the boot

(only if doors are locked) and unlocks the

doors if they are locked during the accident.

All these functions are directed by the inertia

switch. The inertia switch is located behind

the left kick panel. Refer to Chapter 12 for

more information.

Exhaust system

The exhaust system includes an exhaust

manifold equipped with an exhaust oxygen

sensor, a catalytic converter, an exhaust pipe,

and a silencer.

The catalytic converter is an emission

control device added to the exhaust system to

reduce pollutants. A single-bed converter is

used in combination with a three-way

(reduction) catalyst. See Chapter 6 for more

information regarding the catalytic converter.

2 Fuel pressure relief

1

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system.

Don’t smoke or allow open flames or bare

light bulbs near the work area, and don’t

work in a garage where a natural gas-type

appliance (such as a water heater or a

clothes dryer) with a pilot light is present.

Since petrol is carcinogenic, wear latex

gloves when there’s a possibility of being

exposed to fuel, and, if you spill any fuel on

your skin, rinse it off immediately with soap

and water. Mop up any spills immediately

and do not store fuel-soaked rags wherethey could ignite. The fuel system is under

constant pressure, so, if any fuel lines are

to be disconnected, the fuel pressure in

the system must be relieved first. When

you perform any kind of work on the fuel

system, wear safety glasses and have a

Class B type fire extinguisher on hand.

1Before servicing any fuel system

component, you must relieve the fuel pressure

to minimise the risk of fire or personal injury.

2Remove the fuel filler cap - this will relieve

any pressure built up in the tank.

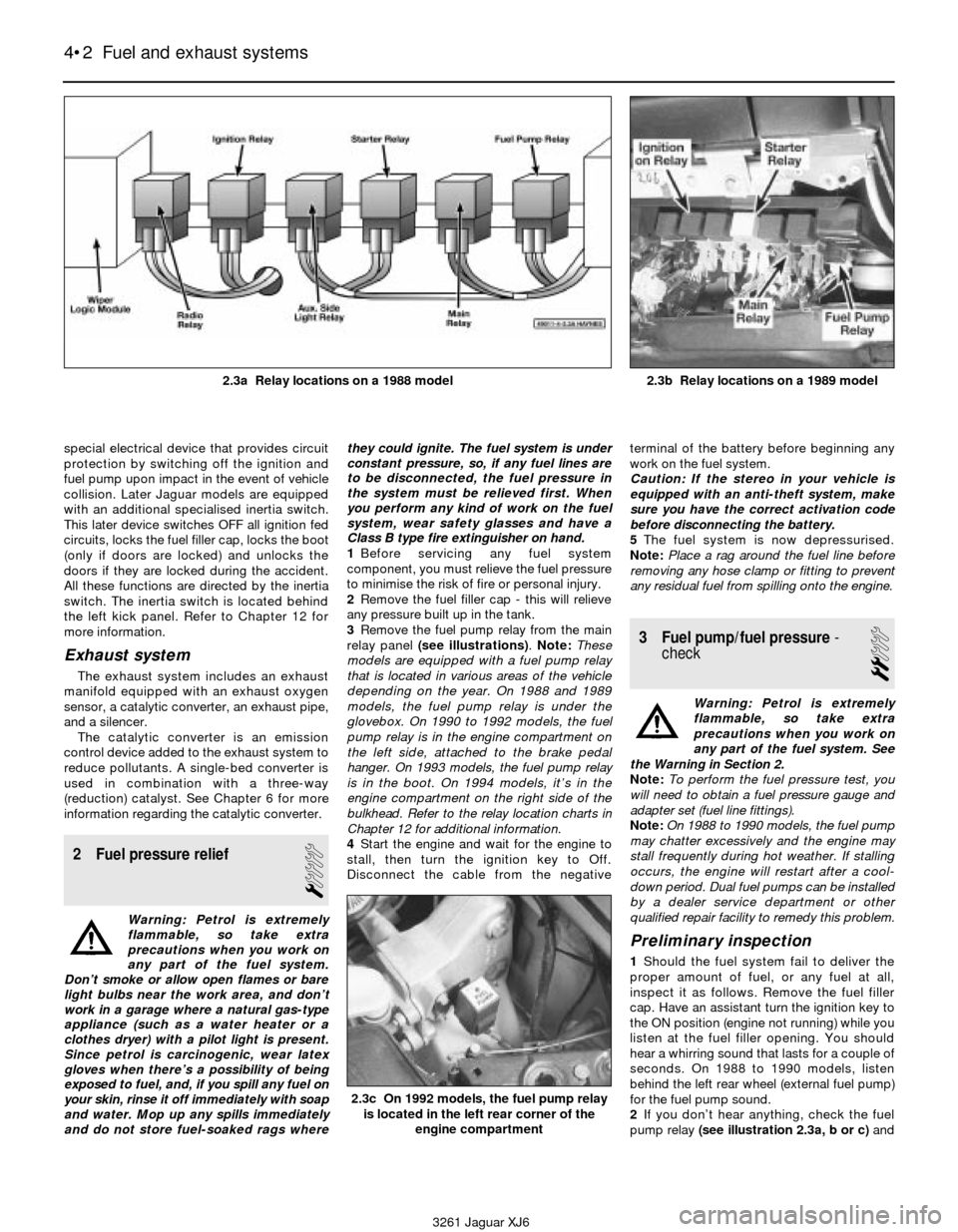

3Remove the fuel pump relay from the main

relay panel (see illustrations). Note:These

models are equipped with a fuel pump relay

that is located in various areas of the vehicle

depending on the year. On 1988 and 1989

models, the fuel pump relay is under the

glovebox. On 1990 to 1992 models, the fuel

pump relay is in the engine compartment on

the left side, attached to the brake pedal

hanger. On 1993 models, the fuel pump relay

is in the boot. On 1994 models, it’s in the

engine compartment on the right side of the

bulkhead. Refer to the relay location charts in

Chapter 12 for additional information.

4Start the engine and wait for the engine to

stall, then turn the ignition key to Off.

Disconnect the cable from the negativeterminal of the battery before beginning any

work on the fuel system.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

5The fuel system is now depressurised.

Note:Place a rag around the fuel line before

removing any hose clamp or fitting to prevent

any residual fuel from spilling onto the engine.

3 Fuel pump/fuel pressure-

check

2

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. See

the Warning in Section 2.

Note: To perform the fuel pressure test, you

will need to obtain a fuel pressure gauge and

adapter set (fuel line fittings).

Note: On 1988 to 1990 models, the fuel pump

may chatter excessively and the engine may

stall frequently during hot weather. If stalling

occurs, the engine will restart after a cool-

down period. Dual fuel pumps can be installed

by a dealer service department or other

qualified repair facility to remedy this problem.

Preliminary inspection

1Should the fuel system fail to deliver the

proper amount of fuel, or any fuel at all,

inspect it as follows. Remove the fuel filler

cap. Have an assistant turn the ignition key to

the ON position (engine not running) while you

listen at the fuel filler opening. You should

hear a whirring sound that lasts for a couple of

seconds. On 1988 to 1990 models, listen

behind the left rear wheel (external fuel pump)

for the fuel pump sound.

2If you don’t hear anything, check the fuel

pump relay (see illustration 2.3a, b or c)and

4•2 Fuel and exhaust systems

2.3c On 1992 models, the fuel pump relay

is located in the left rear corner of the

engine compartment

3261 Jaguar XJ6 2.3a Relay locations on a 1988 model

2.3b Relay locations on a 1989 model