check engine JAGUAR XJ6 1997 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 64 of 227

4Beginning at one end of the cylinder head,

lubricate and refit the first valve. Apply moly-

base grease or clean engine oil to the valve

stem.

5Place the spring seat or shim(s) over the

valve guide and set the valve spring and

retainer in place.

6Compress the springs with a valve spring

compressor and carefully refit the keepers in

the upper groove, then slowly release the

compressor and make sure the keepers seat

properly. Apply a small dab of grease to each

keeper to hold it in place if necessary (see

Haynes Hint).

7Repeat the procedure for the remaining

valves. Be sure to return the components to

their original locations - don’t mix them up!

13 Pistons/connecting rods-

removal

4

Note :Prior to removing the piston/connecting

rod assemblies, remove the cylinder head(s),

the sump and the oil pump transfer tubes by

referring to Chapter 2A.

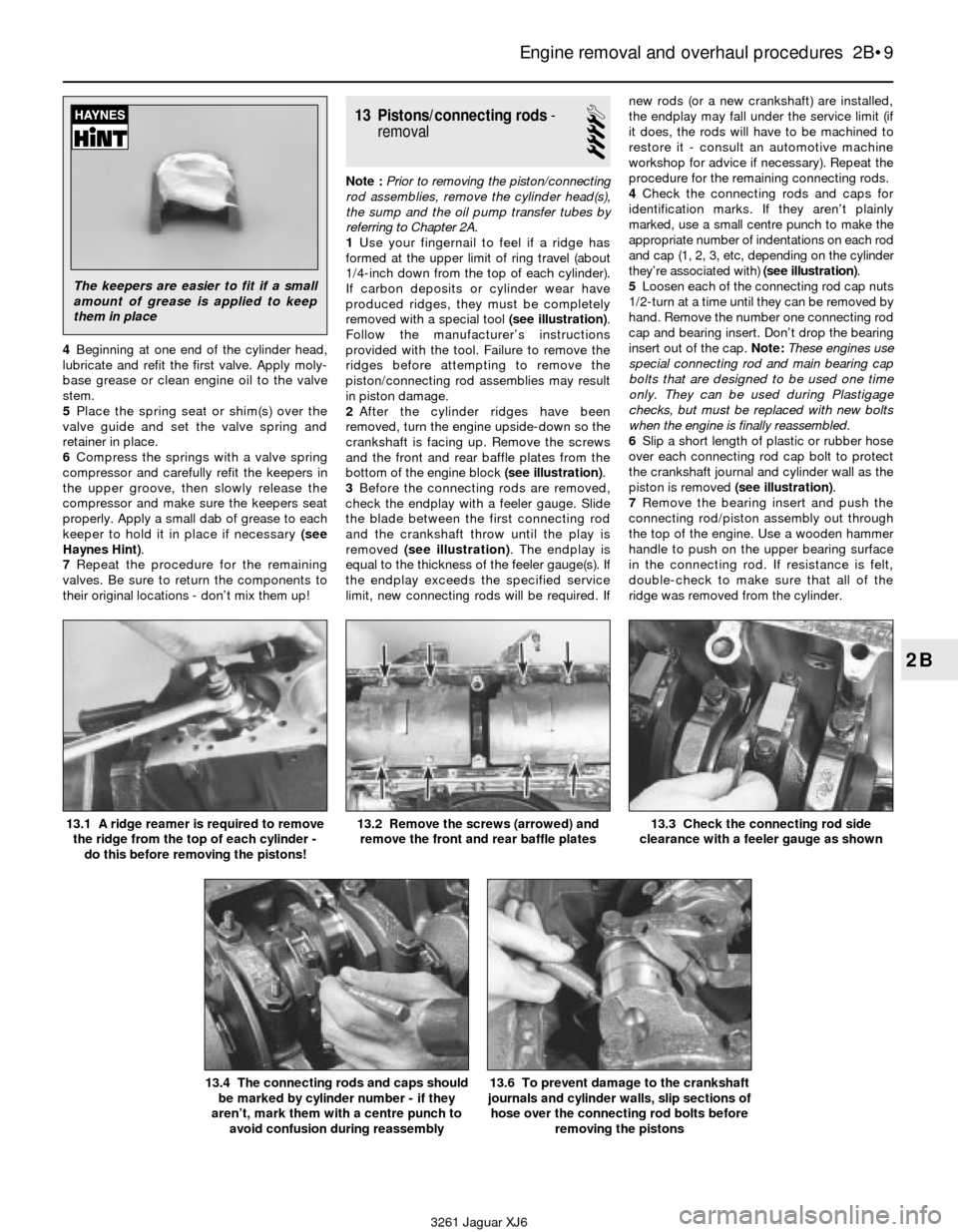

1Use your fingernail to feel if a ridge has

formed at the upper limit of ring travel (about

1/4-inch down from the top of each cylinder).

If carbon deposits or cylinder wear have

produced ridges, they must be completely

removed with a special tool (see illustration).

Follow the manufacturer’s instructions

provided with the tool. Failure to remove the

ridges before attempting to remove the

piston/connecting rod assemblies may result

in piston damage.

2After the cylinder ridges have been

removed, turn the engine upside-down so the

crankshaft is facing up. Remove the screws

and the front and rear baffle plates from the

bottom of the engine block (see illustration).

3Before the connecting rods are removed,

check the endplay with a feeler gauge. Slide

the blade between the first connecting rod

and the crankshaft throw until the play is

removed (see illustration). The endplay is

equal to the thickness of the feeler gauge(s). If

the endplay exceeds the specified service

limit, new connecting rods will be required. Ifnew rods (or a new crankshaft) are installed,

the endplay may fall under the service limit (if

it does, the rods will have to be machined to

restore it - consult an automotive machine

workshop for advice if necessary). Repeat the

procedure for the remaining connecting rods.

4Check the connecting rods and caps for

identification marks. If they aren’t plainly

marked, use a small centre punch to make the

appropriate number of indentations on each rod

and cap (1, 2, 3, etc, depending on the cylinder

they’re associated with) (see illustration).

5Loosen each of the connecting rod cap nuts

1/2-turn at a time until they can be removed by

hand. Remove the number one connecting rod

cap and bearing insert. Don’t drop the bearing

insert out of the cap. Note:These engines use

special connecting rod and main bearing cap

bolts that are designed to be used one time

only. They can be used during Plastigage

checks, but must be replaced with new bolts

when the engine is finally reassembled.

6Slip a short length of plastic or rubber hose

over each connecting rod cap bolt to protect

the crankshaft journal and cylinder wall as the

piston is removed (see illustration).

7Remove the bearing insert and push the

connecting rod/piston assembly out through

the top of the engine. Use a wooden hammer

handle to push on the upper bearing surface

in the connecting rod. If resistance is felt,

double-check to make sure that all of the

ridge was removed from the cylinder.

Engine removal and overhaul procedures 2B•9

2B

13.2 Remove the screws (arrowed) and

remove the front and rear baffle plates13.3 Check the connecting rod side

clearance with a feeler gauge as shown

13.4 The connecting rods and caps should

be marked by cylinder number - if they

aren’t, mark them with a centre punch to

avoid confusion during reassembly13.6 To prevent damage to the crankshaft

journals and cylinder walls, slip sections of

hose over the connecting rod bolts before

removing the pistons

3261 Jaguar XJ6 13.1 A ridge reamer is required to remove

the ridge from the top of each cylinder -

do this before removing the pistons!

The keepers are easier to fit if a small

amount of grease is applied to keep

them in place

Page 65 of 227

8Repeat the procedure for the remaining

cylinders. Note:Turn the crankshaft as

needed to position the piston/connecting rod

assembly to be removed close to parallel with

the cylinder bore - i.e. don’t try to drive it out

while at a large angle to the bore.

9After removal, reassemble the connecting

rod caps and bearing inserts in their

respective connecting rods and refit the cap

nuts/bolts finger tight. Leaving the old bearing

inserts in place until reassembly will help

prevent the big-end bearing surfaces from

being accidentally nicked or gouged.

10Don’t separate the pistons from the

connecting rods (see Section 18 for additional

information).

14 Crankshaft- removal

3

Note:The rear main oil seal and retainer must

be removed from the engine block before

proceeding with crankshaft removal (see Part

A of this Chapter).

1Before the crankshaft is removed, check

the endplay. Mount a dial indicator to the front

of the engine with the stem in line with, and

just touching, the end of the crankshaft (see

illustration).2Push the crankshaft all the way to the rear

and zero the dial indicator. Next, pry the

crankshaft to the front as far as possible and

check the reading on the dial indicator. The

distance that it moves is the endplay. If it’s

greater than that specified in this Chapter’s

Specifications, check the crankshaft thrust

surfaces for wear. If no wear is evident, new

thrust washers should correct the endplay.

3If a dial indicator isn’t available, feeler

gauges can be used. Gently pry or push the

crankshaft all the way to the front of the

engine. Slip feeler gauges between the

crankshaft and the front face of the number 4

(thrust) main bearing to determine the

clearance (see illustration).

4Check the main bearing caps to see if

they’re marked to indicate their locations.

They should be numbered consecutively from

the front of the engine to the rear. If they

aren’t, mark them with number stamping dies

or a centre punch. Main bearing caps

generally have a cast-in arrow, which points

to the front of the engine. Loosen the main

bearing cap bolts 1/4-turn at a time each,

stating at the ends and working toward the

centre, until they can be removed by hand.

5The main bearing caps are numbered on

the right side with corresponding numbers

stamped into the sump rail on the same side

(see illustration). Gently tap the caps with asoft-face hammer, then separate them from

the engine block. If necessary, use the bolts

as levers to remove the main bearing caps.

Try not to drop the bearing inserts if they

come out with the caps. Note:The number

four main bearing is the thrust bearing and is

not numbered.

6Carefully lift the crankshaft out of the

engine. It may be a good idea to have an

assistant available, since the crankshaft is

quite heavy. With the bearing inserts in place

in the engine block and main bearing caps,

return the main bearing caps to their

respective locations on the engine block and

tighten the bolts finger tight.

15 Engine block- cleaning

2

Caution: The core plugs (also known as

freeze or soft plugs) may be difficult or

impossible to retrieve if they’re driven

completely into the engine block coolant

passages.

1Using the blunt end of a punch, tap in on

the outer edge of the core plug to turn the

plug sideways in the bore. Then using pliers,

pull the core plug from the engine block (see

illustrations).

2B•10 Engine removal and overhaul procedures

14.5 The right side of each main bearing

cap is stamped with a number (left arrow)

that corresponds to the stamped number

on the pan rail (right arrow)15.1a A hammer and a large punch can be

used to knock the core plugs sideways in

their bores15.1b Pull the core plugs from the engine

block with pliers

3261 Jaguar XJ6 14.1 Checking crankshaft endplay with a dial indicator

14.3 Checking crankshaft endplay with a feeler gauge

Page 66 of 227

2Using a gasket scraper, remove all traces of

gasket material from the engine block. Be very

careful not to nick or gouge the gasket sealing

surfaces.

3Remove the main bearing caps and

separate the bearing inserts from the caps

and the engine block. Tag the bearings,

indicating which cylinder they were removed

from and whether they were in the cap or the

engine block, then set them aside.

4Remove all of the threaded oil gallery plugs

from the engine block. The plugs are usually

very tight - they may have to be drilled out and

the holes retapped. Use new plugs when the

engine is reassembled.

5If the engine is extremely dirty, it should be

taken to an automotive machine workshop to

be steam cleaned or hot tanked.

6After the engine block is returned, clean all

oil holes and oil galleries one more time.

Brushes specifically designed for this purpose

are available at most car accessory outlets.

Flush the passages with warm water until the

water runs clear, dry the engine block

thoroughly and wipe all machined surfaces

with a light, rust preventive oil. If you have

access to compressed air, use it to speed the

drying process and to blow out all the oil

holes and galleries. Warning: Wear eye protection

when using compressed air!

7If the engine block isn’t extremely dirty or

sludged up, you can do an adequate cleaning

job with hot soapy water and a stiff brush.

Take plenty of time and do a thorough job.

Regardless of the cleaning method used, be

sure to clean all oil holes and galleries very

thoroughly, dry the engine block completely

and coat all machined surfaces with light oil.

8The threaded holes in the engine block

must be clean to ensure accurate torque

readings during reassembly. Run the proper

size tap into each of the holes to remove rust,

corrosion, thread sealant or sludge and

restore damaged threads (see illustration). If

possible, use compressed air to clear the

holes of debris produced by this operation.

9Refit the main bearing caps and tighten the

bolts finger tight.

10After coating the sealing surfaces of the

new core plugs with suitable sealant, refit

them in the engine block (see illustration).

Make sure they’re driven in straight and

seated properly or leakage could result.

Special tools are available for this purpose,

but a large socket, with an outside diameter

that will just slip into the core plug, a 1/2-inchdrive extension and a hammer will work just

as well.

11Apply non-hardening sealant (such as

Permatex no. 2 or Teflon pipe sealant) to the

new oil gallery plugs and thread them into the

holes in the engine block. Make sure they’re

tightened securely.

12If the engine isn’t going to be

reassembled right away, cover it with a large

plastic trash bag to keep it clean.

16 Engine block- inspection

2

1Before the engine block is inspected, it

should be cleaned as described in Section 15.

2Visually check the engine block for cracks,

rust and corrosion (see illustration 10.12).

Look for stripped threads in the threaded

holes. It’s also a good idea to have the engine

block checked for hidden cracks by an

automotive machine workshop that has the

special equipment to do this type of work,

especially if the vehicle had a history of

overheating or using coolant. If defects are

found, have the engine block repaired, if

possible, or renewed. If the top of the engine

block has been eroded by coolant leakage

and the erosion is near the cylinder bores, the

engine block must be renewed.

3Check the cylinder bores for scuffing and

scoring.

4Check the cylinders for taper and out-of-

round conditions as follows (see illustrations):

5Measure the diameter of each cylinder at

the top (just under the ridge area), centre and

bottom of the cylinder bore, parallel to the

crankshaft axis.

6Next, measure each cylinder’s diameter at

the same three locations perpendicular to the

crankshaft axis.

7The taper of each cylinder is the difference

between the bore diameter at the top of the

cylinder and the diameter at the bottom. The

out-of-round specification of the cylinder bore

Engine removal and overhaul procedures 2B•11

2B

16.4a Measure the diameter of each

cylinder at 90° to engine centreline (A), and

parallel to engine centreline (B) - out-of-

round is the difference between A and B;

taper is the difference between A and B at

the top of the cylinder and A and B at the

bottom of the cylinder16.4b The ability to “feel” when the

telescoping gauge is at the correct point

will be developed over time, so work

slowly and repeat the check until you’re

satisfied that the bore measurement is

accurate

3261 Jaguar XJ6

15.8 All bolt holes in the engine block -

particularly the main bearing cap and

cylinder head bolt holes - should be

cleaned and restored with a tap (remove

debris from holes after this is done)15.10 A large socket on an extension can

be used to drive the new core plugs into

the bores

16.4c The gauge is then measured with a

micrometer to determine the bore size

Page 67 of 227

is the difference between the parallel and

perpendicular readings. Compare your results

to this Chapter’s Specifications.

8If the cylinder walls are badly scuffed or

scored, or if they’re out-of-round or tapered

beyond the limits given in this Chapter’s

Specifications, have the engine block rebored

and honed at an automotive machine

workshop. If a rebore is done, oversize

pistons and rings will be required.

9Using a precision straightedge and feeler

gauge, check the engine block deck (the

surface that mates with the cylinder head) for

distortion (see illustration 10.13). If it’s

distorted beyond the specified limit, it can be

resurfaced by an automotive machine

workshop.

10If the cylinders are in reasonably good

condition and not worn to the outside of the

limits, and if the piston-to-cylinder clearances

can be maintained properly, then they don’t

have to be rebored. Honing is all that’s

necessary (refer to Section 17).

17 Cylinder honing

3

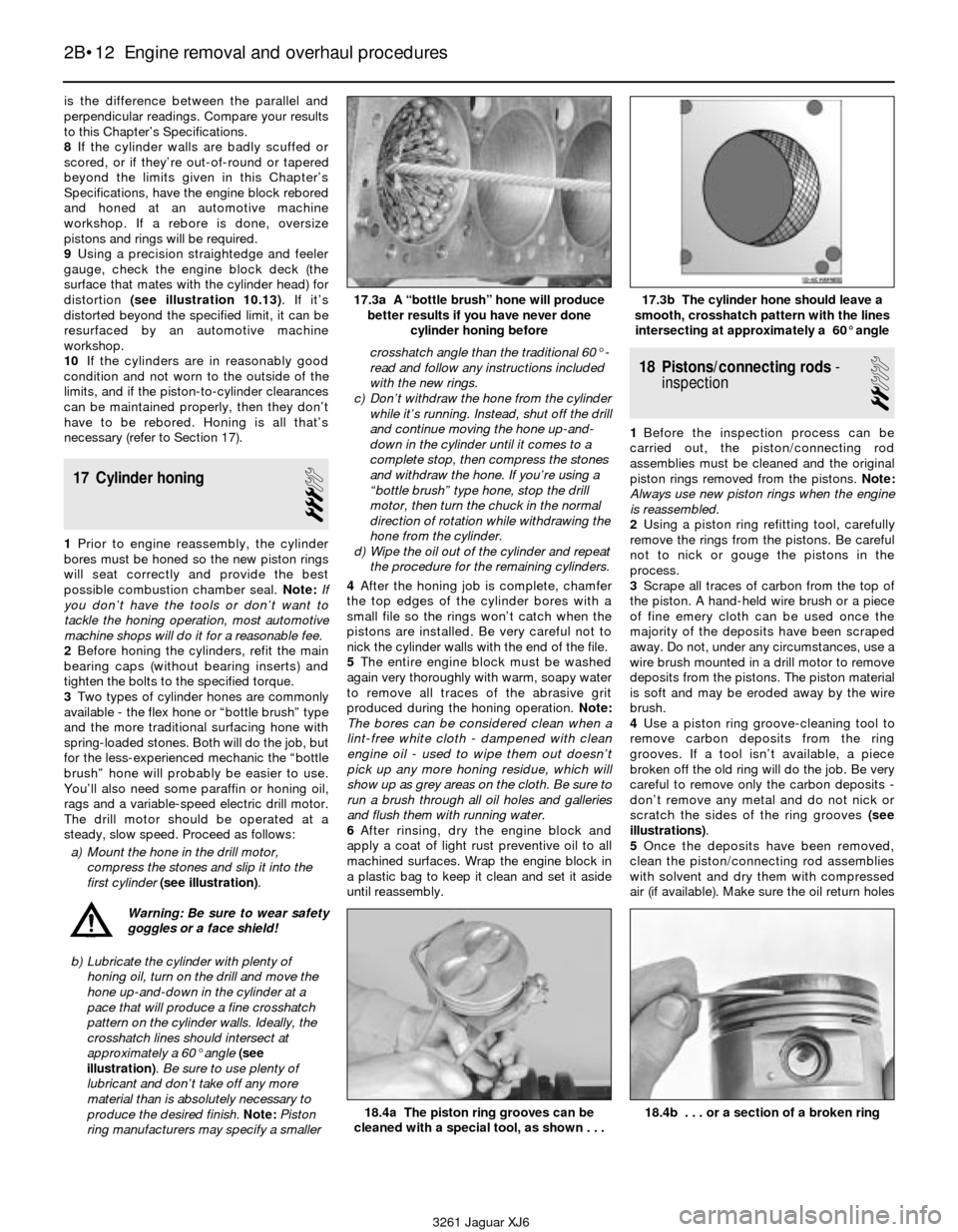

1Prior to engine reassembly, the cylinder

bores must be honed so the new piston rings

will seat correctly and provide the best

possible combustion chamber seal. Note:If

you don’t have the tools or don’t want to

tackle the honing operation, most automotive

machine shops will do it for a reasonable fee.

2Before honing the cylinders, refit the main

bearing caps (without bearing inserts) and

tighten the bolts to the specified torque.

3Two types of cylinder hones are commonly

available - the flex hone or “bottle brush” type

and the more traditional surfacing hone with

spring-loaded stones. Both will do the job, but

for the less-experienced mechanic the “bottle

brush” hone will probably be easier to use.

You’ll also need some paraffin or honing oil,

rags and a variable-speed electric drill motor.

The drill motor should be operated at a

steady, slow speed. Proceed as follows:

a) Mount the hone in the drill motor,

compress the stones and slip it into the

first cylinder (see illustration).

Warning: Be sure to wear safety

goggles or a face shield!

b) Lubricate the cylinder with plenty of

honing oil, turn on the drill and move the

hone up-and-down in the cylinder at a

pace that will produce a fine crosshatch

pattern on the cylinder walls. Ideally, the

crosshatch lines should intersect at

approximately a 60° angle (see

illustration). Be sure to use plenty of

lubricant and don’t take off any more

material than is absolutely necessary to

produce the desired finish. Note:Piston

ring manufacturers may specify a smallercrosshatch angle than the traditional 60° -

read and follow any instructions included

with the new rings.

c) Don’t withdraw the hone from the cylinder

while it’s running. Instead, shut off the drill

and continue moving the hone up-and-

down in the cylinder until it comes to a

complete stop, then compress the stones

and withdraw the hone. If you’re using a

“bottle brush” type hone, stop the drill

motor, then turn the chuck in the normal

direction of rotation while withdrawing the

hone from the cylinder.

d) Wipe the oil out of the cylinder and repeat

the procedure for the remaining cylinders.

4After the honing job is complete, chamfer

the top edges of the cylinder bores with a

small file so the rings won’t catch when the

pistons are installed. Be very careful not to

nick the cylinder walls with the end of the file.

5The entire engine block must be washed

again very thoroughly with warm, soapy water

to remove all traces of the abrasive grit

produced during the honing operation. Note:

The bores can be considered clean when a

lint-free white cloth - dampened with clean

engine oil - used to wipe them out doesn’t

pick up any more honing residue, which will

show up as grey areas on the cloth. Be sure to

run a brush through all oil holes and galleries

and flush them with running water.

6After rinsing, dry the engine block and

apply a coat of light rust preventive oil to all

machined surfaces. Wrap the engine block in

a plastic bag to keep it clean and set it aside

until reassembly.

18 Pistons/connecting rods-

inspection

2

1Before the inspection process can be

carried out, the piston/connecting rod

assemblies must be cleaned and the original

piston rings removed from the pistons. Note:

Always use new piston rings when the engine

is reassembled.

2Using a piston ring refitting tool, carefully

remove the rings from the pistons. Be careful

not to nick or gouge the pistons in the

process.

3Scrape all traces of carbon from the top of

the piston. A hand-held wire brush or a piece

of fine emery cloth can be used once the

majority of the deposits have been scraped

away. Do not, under any circumstances, use a

wire brush mounted in a drill motor to remove

deposits from the pistons. The piston material

is soft and may be eroded away by the wire

brush.

4Use a piston ring groove-cleaning tool to

remove carbon deposits from the ring

grooves. If a tool isn’t available, a piece

broken off the old ring will do the job. Be very

careful to remove only the carbon deposits -

don’t remove any metal and do not nick or

scratch the sides of the ring grooves (see

illustrations).

5Once the deposits have been removed,

clean the piston/connecting rod assemblies

with solvent and dry them with compressed

air (if available). Make sure the oil return holes

2B•12 Engine removal and overhaul procedures

17.3a A “bottle brush” hone will produce

better results if you have never done

cylinder honing before17.3b The cylinder hone should leave a

smooth, crosshatch pattern with the lines

intersecting at approximately a 60° angle

18.4a The piston ring grooves can be

cleaned with a special tool, as shown . . .18.4b . . . or a section of a broken ring

3261 Jaguar XJ6

Page 68 of 227

in the back sides of the ring grooves and the

oil hole in the lower end of each rod are clear.

6If the pistons and cylinder walls aren’t

damaged or worn excessively, and if the

engine block is not rebored, new pistons

won’t be necessary. Normal piston wear

appears as even vertical wear on the piston

thrust surfaces and slight looseness of the top

ring in its groove. New piston rings, however,

should always be used when an engine is

rebuilt.

7Carefully inspect each piston for cracks

around the skirt, at the pin bosses and at the

ring lands.

Caution: Some early 1988 3.6 litre engines

(before engine no. 9D 121113) have

incorrectly-stamped pistons. On these, the

word FRONT is actually stamped on the rear

of the pistons. Correct pistons will have the

cast arrows on the inside of the skirt to your

left when facing the word FRONT.

8Look for scoring and scuffing on the thrust

faces of the skirt, holes in the piston crown

and burned areas at the edge of the crown. If

the skirt is scored or scuffed, the engine may

have been suffering from overheating and/or

abnormal combustion, which caused

excessively high operating temperatures. The

cooling and lubrication systems should be

checked thoroughly. A hole in the piston

crown is an indication that abnormal

combustion (pre-ignition) was occurring.

Burned areas at the edge of the piston crown

are usually evidence of spark knock

(detonation). If any of the above problems

exist, the causes must be corrected or the

damage will occur again. The causes may

include intake air leaks, incorrect air/fuel

mixture, incorrect ignition timing and EGR

system malfunctions.

9Corrosion of the piston, in the form of small

pits, indicates that coolant is leaking into the

combustion chamber and/or the crankcase.

Again, the cause must be corrected or the

problem may persist in the rebuilt engine.

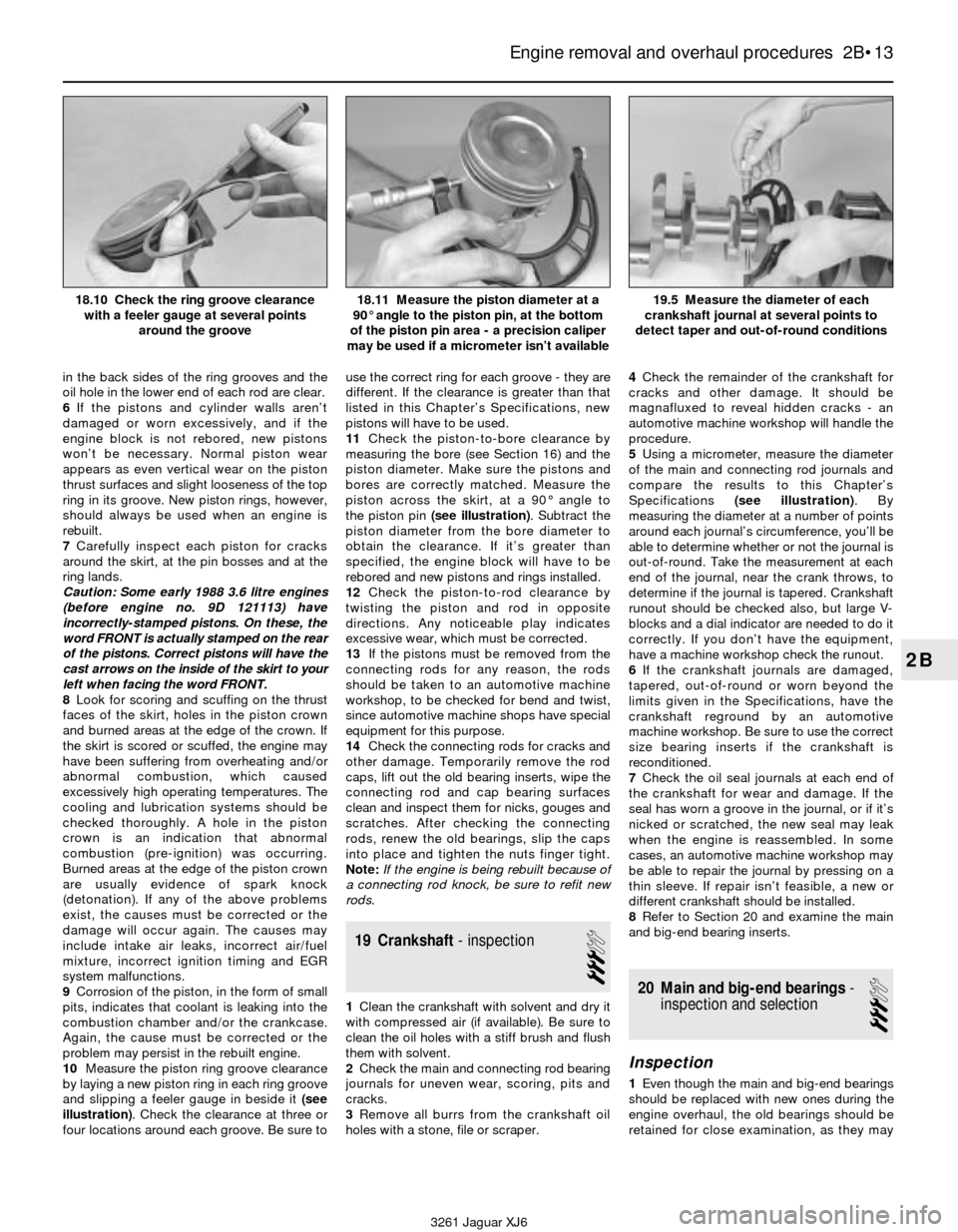

10Measure the piston ring groove clearance

by laying a new piston ring in each ring groove

and slipping a feeler gauge in beside it (see

illustration). Check the clearance at three or

four locations around each groove. Be sure touse the correct ring for each groove - they are

different. If the clearance is greater than that

listed in this Chapter’s Specifications, new

pistons will have to be used.

11Check the piston-to-bore clearance by

measuring the bore (see Section 16) and the

piston diameter. Make sure the pistons and

bores are correctly matched. Measure the

piston across the skirt, at a 90° angle to

the piston pin (see illustration). Subtract the

piston diameter from the bore diameter to

obtain the clearance. If it’s greater than

specified, the engine block will have to be

rebored and new pistons and rings installed.

12Check the piston-to-rod clearance by

twisting the piston and rod in opposite

directions. Any noticeable play indicates

excessive wear, which must be corrected.

13If the pistons must be removed from the

connecting rods for any reason, the rods

should be taken to an automotive machine

workshop, to be checked for bend and twist,

since automotive machine shops have special

equipment for this purpose.

14Check the connecting rods for cracks and

other damage. Temporarily remove the rod

caps, lift out the old bearing inserts, wipe the

connecting rod and cap bearing surfaces

clean and inspect them for nicks, gouges and

scratches. After checking the connecting

rods, renew the old bearings, slip the caps

into place and tighten the nuts finger tight.

Note:If the engine is being rebuilt because of

a connecting rod knock, be sure to refit new

rods.

19 Crankshaft- inspection

3

1Clean the crankshaft with solvent and dry it

with compressed air (if available). Be sure to

clean the oil holes with a stiff brush and flush

them with solvent.

2Check the main and connecting rod bearing

journals for uneven wear, scoring, pits and

cracks.

3Remove all burrs from the crankshaft oil

holes with a stone, file or scraper.4Check the remainder of the crankshaft for

cracks and other damage. It should be

magnafluxed to reveal hidden cracks - an

automotive machine workshop will handle the

procedure.

5Using a micrometer, measure the diameter

of the main and connecting rod journals and

compare the results to this Chapter’s

Specifications (see illustration). By

measuring the diameter at a number of points

around each journal’s circumference, you’ll be

able to determine whether or not the journal is

out-of-round. Take the measurement at each

end of the journal, near the crank throws, to

determine if the journal is tapered. Crankshaft

runout should be checked also, but large V-

blocks and a dial indicator are needed to do it

correctly. If you don’t have the equipment,

have a machine workshop check the runout.

6If the crankshaft journals are damaged,

tapered, out-of-round or worn beyond the

limits given in the Specifications, have the

crankshaft reground by an automotive

machine workshop. Be sure to use the correct

size bearing inserts if the crankshaft is

reconditioned.

7Check the oil seal journals at each end of

the crankshaft for wear and damage. If the

seal has worn a groove in the journal, or if it’s

nicked or scratched, the new seal may leak

when the engine is reassembled. In some

cases, an automotive machine workshop may

be able to repair the journal by pressing on a

thin sleeve. If repair isn’t feasible, a new or

different crankshaft should be installed.

8Refer to Section 20 and examine the main

and big-end bearing inserts.

20 Main and big-end bearings-

inspection and selection

3

Inspection

1Even though the main and big-end bearings

should be replaced with new ones during the

engine overhaul, the old bearings should be

retained for close examination, as they may

Engine removal and overhaul procedures 2B•13

2B

19.5 Measure the diameter of each

crankshaft journal at several points to

detect taper and out-of-round conditions

3261 Jaguar XJ6 18.10 Check the ring groove clearance

with a feeler gauge at several points

around the groove

18.11 Measure the piston diameter at a

90° angle to the piston pin, at the bottom

of the piston pin area - a precision caliper

may be used if a micrometer isn’t available

Page 70 of 227

21 Engine overhaul-

reassembly sequence

1Before beginning engine reassembly, make

sure you have all the necessary new parts,

gaskets and seals as well as the following

items on hand:

Common hand tools

A 1/2-inch drive torque wrench

Piston ring refitting tool

Piston ring compressor

Short lengths of rubber or plastic hose to

fit over connecting rod bolts

Plastigauge

Feeler gauges

A fine-tooth file

New engine oil

Engine assembly lube or moly-base

grease

Gasket sealer

Thread locking compound

Special Jaguar tools:

Engine lifting brackets (18G 1465)

Timing damper simulator (18E 1436)

Camshaft TDC tool (18G 1433)

2In order to save time and avoid problems,

engine reassembly must be done in the

following general order:

Piston rings (Part B)

Crankshaft and main bearings (Part B)

Piston/connecting rod assemblies (Part B)

Rear main (crankshaft) oil seal (Part B)

Auxiliary shaft (Part A)

Timing chains and sprockets (Part A)

Oil pump (Part A)

Timing chain cover (Part A)

Cylinder head and lifters (Part A)

Camshafts (Part A)

Oil pick-up (Part A)

Sump (Part A)

Intake and exhaust manifolds (Part A)

Valve cover (Part A)

Flywheel/driveplate (Part A)

22 Piston rings- refitting

3

1Before refitting the new piston rings, the ring

end gaps must be checked. It’s assumed that

the piston ring groove clearance has been

checked and verified correct (see Section 18).

2Lay out the piston/connecting rod

assemblies and the new ring sets so the ring

sets will be matched with the same piston and

cylinder during the end gap measurement and

engine assembly.

3Insert the top (number one) ring into the first

cylinder and square it up with the cylinder

walls by pushing it in with the top of the piston

(see illustration). The ring should be near the

bottom of the cylinder, at the lower limit of

ring travel.

4To measure the end gap, slip feeler gauges

between the ends of the ring until a gauge

equal to the gap width is found (see

illustration). The feeler gauge should slide

between the ring ends with a slight amount of

drag. Compare the measurement to that

found in this Chapter’s Specifications. If the

gap is larger or smaller than specified,

double-check to make sure you have the

correct rings before proceeding.

5If the gap is too small, it must be enlarged

or the ring ends may come in contact with

each other during engine operation, which

can cause serious damage to the engine. The

end gap can be increased by filing the ring

ends very carefully with a fine file. Mount thefile in a vice equipped with soft jaws, slip the

ring over the file with the ends contacting the

file face and slowly move the ring to remove

material from the ends(see illustration).

Caution: When performing this operation,

file only from the outside in, and after the

correct gap is achieved, deburr the filed

ends of the rings with a fine whetstone.

6Excess end gap isn’t critical unless it’s

greater than Specifications. Again, double-

check to make sure you have the correct rings

for your engine.

7Repeat the procedure for each ring that will

be installed in the first cylinder and for each

ring in the remaining cylinders. Remember to

keep rings, pistons and cylinders matched.

8Once the ring end gaps have been

checked/corrected, the rings can be installed

on the pistons.

9The oil control ring (lowest one on the

piston) is usually installed first. It’s composed

of three separate components. Slip the

spacer/expander into the groove (see

illustration). If an anti-rotation tang is used,

make sure it’s inserted into the drilled hole in

the ring groove. Next, refit the lower side rail.

Don’t use a piston ring refitting tool on the oil

ring side rails, as they may be damaged.

Instead, place one end of the side rail into the

groove between the spacer/expander and the

ring land, hold it firmly in place and slide a

finger around the piston while pushing the rail

into the groove (see illustrations). Next, refit

the upper side rail in the same manner.

10After the three oil ring components have

been installed, check to make sure that both

Engine removal and overhaul procedures 2B•15

2B

22.3 When checking piston ring end gap,

the ring must be square in the cylinder

bore (this is done by pushing the ring down

with the top of a piston as shown)22.4 With the ring square in the cylinder,

measure the end gap with a feeler gauge22.5 If the end gap is too small, clamp a

file in a vice and file the ring ends (from the

outside in only) to enlarge the gap slightly

22.9a Refit the spacer/expander in the oil

control ring groove22.9b DO NOT use a piston ring refitting

tool when refitting the oil ring side rails

3261 Jaguar XJ6

Page 71 of 227

the upper and lower side rails can be turned

smoothly in the ring groove.

11The number two (middle) ring is installed

next. It’s usually stamped with a mark which

must face up, toward the top of the piston.

Note:Always follow the instructions on the

ring package or box - different manufacturers

may require different approaches. Do not mix

up the top and middle rings, as they have

different cross sections.

12Use a piston ring refitting tool and make

sure the ring’s identification mark is facing the

top of the piston, then slip the ring into the

middle groove on the piston (see illustration).

Don’t expand the ring any more than

necessary to slide it over the piston.

13Refit the number one (top) ring in the

same manner. Make sure the mark is facing

up. Be careful not to confuse the number one

and number two rings.

14Repeat the procedure for the remaining

pistons and rings.

23 Crankshaft- refitting and

main bearing oil clearance

check

3

1Crankshaft refitting is the first major step in

engine reassembly. It’s assumed at this point

that the engine block and crankshaft have

been cleaned, inspected and repaired or

reconditioned.

2Position the engine with the bottom facing

up.

3Remove the main bearing cap bolts and lift

out the caps. Lay the caps out in the proper

order.

4If they’re still in place, remove the old

bearing inserts from the engine block and the

main bearing caps. Wipe the main bearing

surfaces of the engine block and caps with a

clean, lint free cloth. They must be kept

spotlessly clean!

Main bearing

oil clearance check

5Clean the back sides of the new main

bearing inserts and lay the bearing half with

the oil groove in each main bearing saddle inthe engine block. Lay the other bearing half

from each bearing set in the corresponding

main bearing cap. Make sure the tab on each

bearing insert fits into the recess in the engine

block or cap. Also, the oil holes in the block

must line up with the oil holes in the bearing

insert.

Caution: Do not hammer the bearings into

place and don’t nick or gouge the bearing

faces. No lubrication should be used at this

time.

6The thrust bearings (washers) must be

installed in the number four main bearing cap

and saddle.

7Clean the faces of the bearings in the

engine block and the crankshaft main bearing

journals with a clean, lint free cloth. Check or

clean the oil holes in the crankshaft, as any

dirt here can go only one way - straight

through the new bearings.

8Once you’re certain the crankshaft is clean,

carefully lay it in position in the main bearings.

9Before the crankshaft can be permanently

installed, the main bearing oil clearance must

be checked.

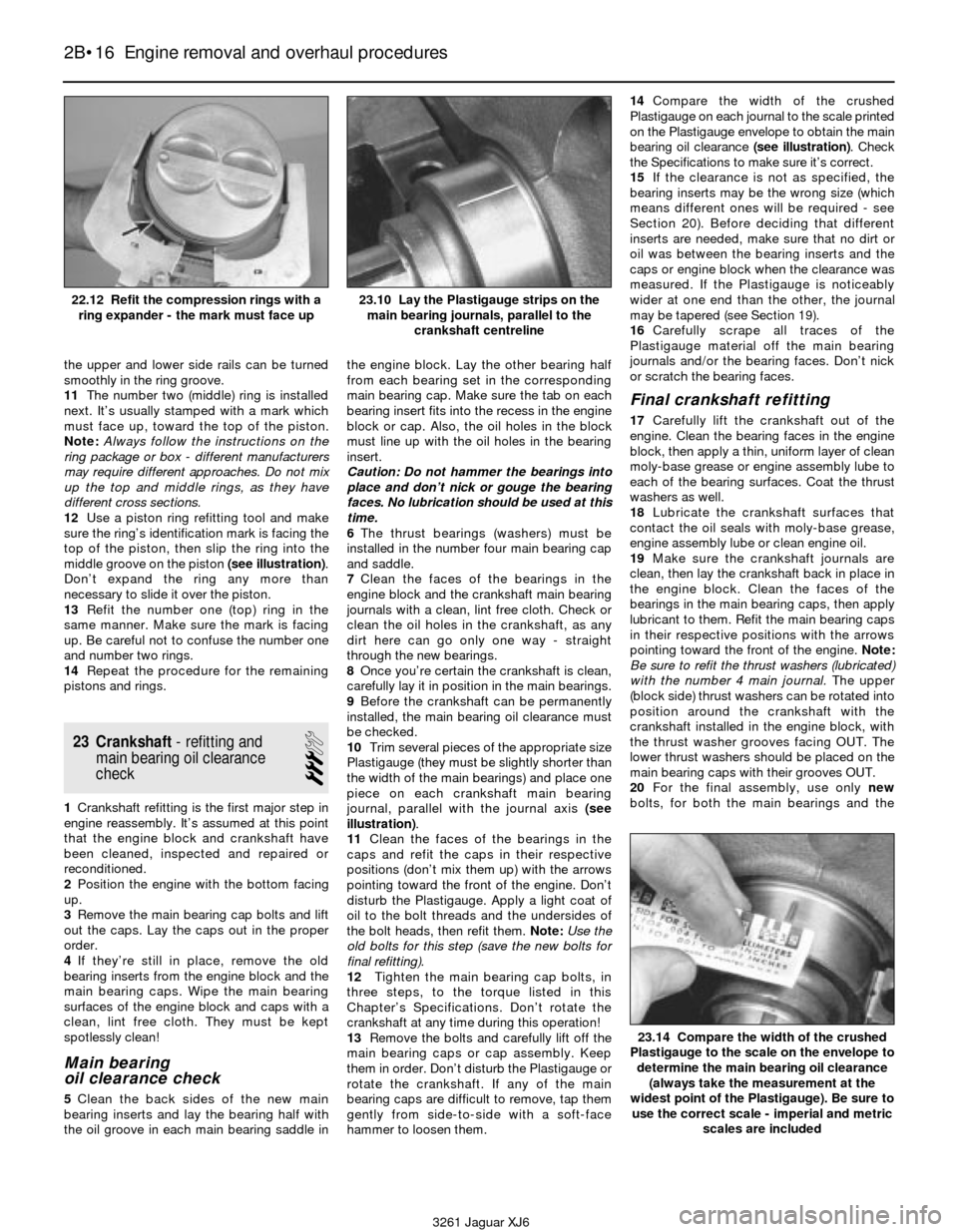

10Trim several pieces of the appropriate size

Plastigauge (they must be slightly shorter than

the width of the main bearings) and place one

piece on each crankshaft main bearing

journal, parallel with the journal axis (see

illustration).

11Clean the faces of the bearings in the

caps and refit the caps in their respective

positions (don’t mix them up) with the arrows

pointing toward the front of the engine. Don’t

disturb the Plastigauge. Apply a light coat of

oil to the bolt threads and the undersides of

the bolt heads, then refit them. Note:Use the

old bolts for this step (save the new bolts for

final refitting).

12Tighten the main bearing cap bolts, in

three steps, to the torque listed in this

Chapter’s Specifications. Don’t rotate the

crankshaft at any time during this operation!

13Remove the bolts and carefully lift off the

main bearing caps or cap assembly. Keep

them in order. Don’t disturb the Plastigauge or

rotate the crankshaft. If any of the main

bearing caps are difficult to remove, tap them

gently from side-to-side with a soft-face

hammer to loosen them.14Compare the width of the crushed

Plastigauge on each journal to the scale printed

on the Plastigauge envelope to obtain the main

bearing oil clearance (see illustration). Check

the Specifications to make sure it’s correct.

15If the clearance is not as specified, the

bearing inserts may be the wrong size (which

means different ones will be required - see

Section 20). Before deciding that different

inserts are needed, make sure that no dirt or

oil was between the bearing inserts and the

caps or engine block when the clearance was

measured. If the Plastigauge is noticeably

wider at one end than the other, the journal

may be tapered (see Section 19).

16Carefully scrape all traces of the

Plastigauge material off the main bearing

journals and/or the bearing faces. Don’t nick

or scratch the bearing faces.

Final crankshaft refitting

17Carefully lift the crankshaft out of the

engine. Clean the bearing faces in the engine

block, then apply a thin, uniform layer of clean

moly-base grease or engine assembly lube to

each of the bearing surfaces. Coat the thrust

washers as well.

18Lubricate the crankshaft surfaces that

contact the oil seals with moly-base grease,

engine assembly lube or clean engine oil.

19Make sure the crankshaft journals are

clean, then lay the crankshaft back in place in

the engine block. Clean the faces of the

bearings in the main bearing caps, then apply

lubricant to them. Refit the main bearing caps

in their respective positions with the arrows

pointing toward the front of the engine. Note:

Be sure to refit the thrust washers (lubricated)

with the number 4 main journal.The upper

(block side) thrust washers can be rotated into

position around the crankshaft with the

crankshaft installed in the engine block, with

the thrust washer grooves facing OUT. The

lower thrust washers should be placed on the

main bearing caps with their grooves OUT.

20For the final assembly, use only new

bolts, for both the main bearings and the

2B•16 Engine removal and overhaul procedures

23.10 Lay the Plastigauge strips on the

main bearing journals, parallel to the

crankshaft centreline

23.14 Compare the width of the crushed

Plastigauge to the scale on the envelope to

determine the main bearing oil clearance

(always take the measurement at the

widest point of the Plastigauge). Be sure to

use the correct scale - imperial and metric

scales are included

3261 Jaguar XJ6

22.12 Refit the compression rings with a

ring expander - the mark must face up

Page 72 of 227

connecting rods. Apply a light coat of oil to

the bolt threads and the under sides of the

bolt heads, then refit them. Tighten all main

bearing cap bolts to the torque listed in this

Chapter’s Specifications, starting in the centre

and working out to the ends.

21Rotate the crankshaft a number of times

by hand to check for any obvious binding.

22Check the crankshaft endplay with a

feeler gauge or a dial indicator as described in

Section 14. The endplay should be correct if

the crankshaft thrust faces aren’t worn or

damaged and new thrust washers have been

installed. Note:If the end-play is too great,

even with the new thrust bearings, oversized

thrust bearings are available. There are two

sizes, 0.005-inch and 0.010-inch oversize.

23Refit a new rear main oil seal, then bolt the

retainer to the engine block (see Section 24).

24 Rear main oil seal refitting

2

1The crankshaft must be installed first and

the main bearing caps bolted in place, then

the new seal should be installed in the retainer

and the retainer bolted to the engine block.

2Check the seal contact surface on the

crankshaft very carefully for scratches and

nicks that could damage the new seal lip and

cause oil leaks. If the crankshaft is damaged,

the only alternative is a new or different

crankshaft.

3Refer to Part A of this Chapter for refitting

of the new rear seal, using the plastic

alignment tool supplied with the engine

overhaul gasket set.

25 Pistons/connecting rods-

refitting and big-end bearing

oil clearance check

3

1Before refitting the piston/connecting rod

assemblies, the cylinder walls must be

perfectly clean, the top edge of each cylinder

must be chamfered, and the crankshaft must

be in place.

2Remove the cap from the end of the

number one connecting rod (refer to the

marks made during removal). Remove the

original bearing inserts and wipe the bearing

surfaces of the connecting rod and cap with a

clean, lint-free cloth. They must be kept

spotlessly clean.

Big-end bearing

oil clearance check

3Clean the back side of the new upper

bearing insert, then lay it in place in the

connecting rod. Make sure the tab on the

bearing fits into the recess in the rod so the oil

holes line up. Don’t hammer the bearing insert

into place and be very careful not to nick or

gouge the bearing face. Don’t lubricate the

bearing at this time.4Clean the back side of the other bearing

insert and refit it in the rod cap. Again, make

sure the tab on the bearing fits into the recess

in the cap, and don’t apply any lubricant. It’s

critically important that the mating surfaces of

the bearing and connecting rod are perfectly

clean and oil free when they’re assembled.

5Position the piston ring gaps at staggered

intervals around the piston (see illustration).

6Slip a section of plastic or rubber hose over

each connecting rod cap bolt.

7Lubricate the piston and rings with clean

engine oil and attach a piston ring compressor

to the piston. Leave the skirt protruding about

1/4-inch to guide the piston into the cylinder.

The rings must be compressed until they’re

flush with the piston.

8Rotate the crankshaft until the number one

connecting rod journal is at BDC (bottom

dead centre) and apply a coat of engine oil to

the cylinder wall.

9With the word FRONT (or the arrow) on top

of the piston facing the front of the engine

(see illustration), gently insert the piston/

connecting rod assembly into the number one

cylinder bore and rest the bottom edge of the

ring compressor on the engine block.

10Tap the top edge of the ring compressor

to make sure it’s contacting the engine block

around its entire circumference.11Gently tap on the top of the piston with

the end of a wooden hammer handle (see

illustration) while guiding the end of the

connecting rod into place on the crankshaft

journal. The piston rings may try to pop out of

the ring compressor just before entering the

cylinder bore, so keep some downward

pressure on the ring compressor. Work

slowly, and if any resistance is felt as the

piston enters the cylinder, stop immediately.

Find out what’s hanging up and fix it before

proceeding.

Caution: Do not, for any reason, force the

piston into the cylinder - you might break a

ring and/or the piston.

12Once the piston/connecting rod assembly

is installed, the big-end bearing oil clearance

must be checked before the rod cap is

permanently bolted in place.

13Cut a piece of the appropriate size

Plastigauge slightly shorter than the width of

the big-end bearing and lay it in place on the

number one connecting rod journal, parallel

with the journal axis (see illustration).

14Clean the connecting rod cap bearing

face, remove the protective hoses from the

connecting rod bolts and refit the rod cap.

Make sure the mating mark on the cap is on

the same side as the mark on the connecting

rod. Check the cap to make sure the front

mark is facing the timing chain of the engine.

15Apply a light coat of oil to the under sides

of the nuts, then refit and tighten them to the

torque listed in this Chapter’s Specifications,

Engine removal and overhaul procedures 2B•17

2B

25.13 Lay the Plastigauge strips on each

big-end bearing journal, parallel to the

crankshaft centreline

3261 Jaguar XJ6

25.5 Stagger the ring end gaps around the

piston as shown25.9 Pistons must be installed with the

arrow (right arrow) or FRONT facing the

front of the engine - left arrow indicates

piston size letter

25.11 The piston can be driven (gently)

into the cylinder bore with the end of a

wooden or plastic hammer handle

A Oil ring rail gaps

B Second compression ring gap

C Oil ring spacer gap

D Top compression ring gap

Page 73 of 227

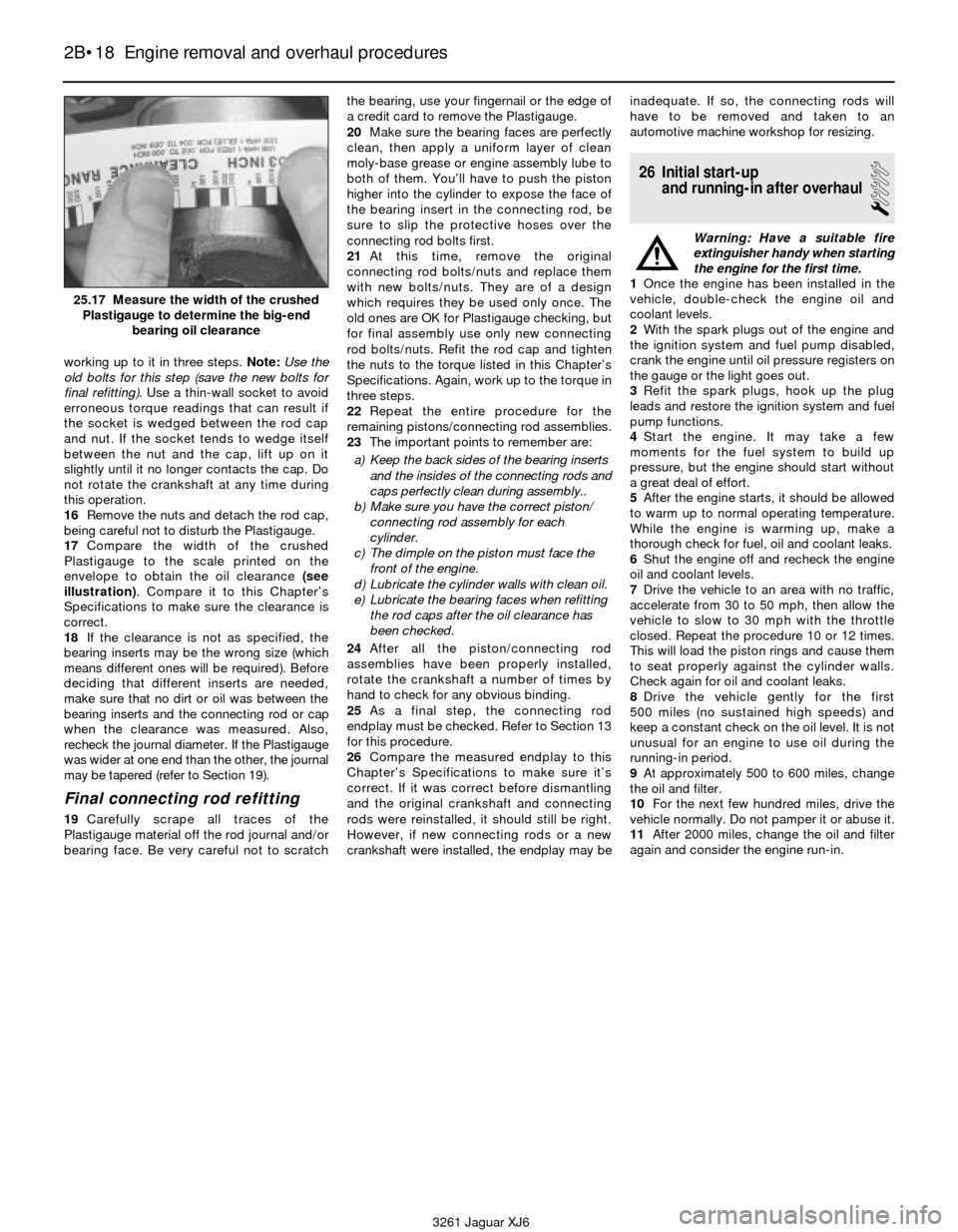

working up to it in three steps. Note:Use the

old bolts for this step (save the new bolts for

final refitting).Use a thin-wall socket to avoid

erroneous torque readings that can result if

the socket is wedged between the rod cap

and nut. If the socket tends to wedge itself

between the nut and the cap, lift up on it

slightly until it no longer contacts the cap. Do

not rotate the crankshaft at any time during

this operation.

16Remove the nuts and detach the rod cap,

being careful not to disturb the Plastigauge.

17Compare the width of the crushed

Plastigauge to the scale printed on the

envelope to obtain the oil clearance (see

illustration). Compare it to this Chapter’s

Specifications to make sure the clearance is

correct.

18If the clearance is not as specified, the

bearing inserts may be the wrong size (which

means different ones will be required). Before

deciding that different inserts are needed,

make sure that no dirt or oil was between the

bearing inserts and the connecting rod or cap

when the clearance was measured. Also,

recheck the journal diameter. If the Plastigauge

was wider at one end than the other, the journal

may be tapered (refer to Section 19).

Final connecting rod refitting

19Carefully scrape all traces of the

Plastigauge material off the rod journal and/or

bearing face. Be very careful not to scratchthe bearing, use your fingernail or the edge of

a credit card to remove the Plastigauge.

20Make sure the bearing faces are perfectly

clean, then apply a uniform layer of clean

moly-base grease or engine assembly lube to

both of them. You’ll have to push the piston

higher into the cylinder to expose the face of

the bearing insert in the connecting rod, be

sure to slip the protective hoses over the

connecting rod bolts first.

21At this time, remove the original

connecting rod bolts/nuts and replace them

with new bolts/nuts. They are of a design

which requires they be used only once. The

old ones are OK for Plastigauge checking, but

for final assembly use only new connecting

rod bolts/nuts. Refit the rod cap and tighten

the nuts to the torque listed in this Chapter’s

Specifications. Again, work up to the torque in

three steps.

22Repeat the entire procedure for the

remaining pistons/connecting rod assemblies.

23The important points to remember are:

a) Keep the back sides of the bearing inserts

and the insides of the connecting rods and

caps perfectly clean during assembly..

b) Make sure you have the correct piston/

connecting rod assembly for each

cylinder.

c) The dimple on the piston must face the

front of the engine.

d) Lubricate the cylinder walls with clean oil.

e) Lubricate the bearing faces when refitting

the rod caps after the oil clearance has

been checked.

24After all the piston/connecting rod

assemblies have been properly installed,

rotate the crankshaft a number of times by

hand to check for any obvious binding.

25As a final step, the connecting rod

endplay must be checked. Refer to Section 13

for this procedure.

26Compare the measured endplay to this

Chapter’s Specifications to make sure it’s

correct. If it was correct before dismantling

and the original crankshaft and connecting

rods were reinstalled, it should still be right.

However, if new connecting rods or a new

crankshaft were installed, the endplay may beinadequate. If so, the connecting rods will

have to be removed and taken to an

automotive machine workshop for resizing.

26 Initial start-up

and running-in after overhaul

1

Warning: Have a suitable fire

extinguisher handy when starting

the engine for the first time.

1Once the engine has been installed in the

vehicle, double-check the engine oil and

coolant levels.

2With the spark plugs out of the engine and

the ignition system and fuel pump disabled,

crank the engine until oil pressure registers on

the gauge or the light goes out.

3Refit the spark plugs, hook up the plug

leads and restore the ignition system and fuel

pump functions.

4Start the engine. It may take a few

moments for the fuel system to build up

pressure, but the engine should start without

a great deal of effort.

5After the engine starts, it should be allowed

to warm up to normal operating temperature.

While the engine is warming up, make a

thorough check for fuel, oil and coolant leaks.

6Shut the engine off and recheck the engine

oil and coolant levels.

7Drive the vehicle to an area with no traffic,

accelerate from 30 to 50 mph, then allow the

vehicle to slow to 30 mph with the throttle

closed. Repeat the procedure 10 or 12 times.

This will load the piston rings and cause them

to seat properly against the cylinder walls.

Check again for oil and coolant leaks.

8Drive the vehicle gently for the first

500 miles (no sustained high speeds) and

keep a constant check on the oil level. It is not

unusual for an engine to use oil during the

running-in period.

9At approximately 500 to 600 miles, change

the oil and filter.

10For the next few hundred miles, drive the

vehicle normally. Do not pamper it or abuse it.

11After 2000 miles, change the oil and filter

again and consider the engine run-in.

2B•18 Engine removal and overhaul procedures

25.17 Measure the width of the crushed

Plastigauge to determine the big-end

bearing oil clearance

3261 Jaguar XJ6

Page 74 of 227

3261 Jaguar XJ6

3

Chapter 3

Cooling, heating and air conditioning systems

General

Radiator cap pressure rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.5 to 117.5 psi

Thermostat rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 to 207° F

Torque wrench settingsNm lbf ft

Coolant pipe to block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21

Fan assembly-to-drive hub nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21

Fan clutch-to-fan blade bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21

Thermostat cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21

Thermostat housing-to-block bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21

Water pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 21 Air conditioning and heating system - check and maintenance . . . . 13

Air conditioning compressor - removal and refitting . . . . . . . . . . . . . 15

Air conditioning condenser - removal and refitting . . . . . . . . . . . . . . 16

Air conditioning evaporator and expansion valve - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Air conditioning receiver/drier - removal and refitting . . . . . . . . . . . . 14

Antifreeze/coolant - general information . . . . . . . . . . . . . . . . . . . . . . 2

Coolant level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Coolant temperature sender unit - check and renewal . . . . . . . . . . . .9

Cooling system check . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Cooling system draining, flushing and refilling . . . . . . . . See Chapter 1

Drivebelt check, adjustment and renewal . . . . . . . . . . . See Chapter 1

Engine cooling fans - check and renewal . . . . . . . . . . . . . . . . . . . . . 4Engine oil cooler - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Heater and air conditioning blower motors -circuit check

and component renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Heater and air conditioning control assembly -

check, removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Heater core - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Radiator, expansion tank and coolant reservoir -

removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Thermostat - check and renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Underbonnet hose check and renewal . . . . . . . . . . . . . . See Chapter 1

Water pump - check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Water pump and pipes - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 General information

Engine cooling system

All vehicles covered by this manual employ a

pressurised engine cooling system with

thermostatically-controlled coolant circulation.

An impeller type water pump mounted on the

front of the block pumps coolant through the

engine. The coolant flows around each cylinder

and toward the rear of the engine. Cast-in

coolant passages direct coolant around the

intake and exhaust ports, near the spark plug

areas and in proximity to the exhaust valve

guides.A wax-pellet type thermostat is located in

the thermostat housing at the front of the

engine. During warm up, the closed

thermostat prevents coolant from circulating

through the radiator. When the engine

reaches normal operating temperature, the

thermostat opens and allows hot coolant to

travel through the radiator, where it is cooled

before returning to the engine.

The cooling system is sealed by a pressure-

type radiator cap. This raises the boiling point

of the coolant, and the higher boiling point of

the coolant increases the cooling efficiency

of the radiator. If the system pressure exceeds

the cap pressure-relief value, the excess

pressure in the system forces the spring-

loaded valve inside the cap off its seat and

allows the coolant to escape through the

overflow tube into a coolant reservoir. Whenthe system cools, the excess coolant is

automatically drawn from the reservoir back

into the radiator. This type of cooling system is

known as a closed design because coolant

that escapes past the pressure cap is saved

and reused.

The Jaguar cooling system on 1988 and

1989 models has both a manifold tank and a

coolant recovery tank. The manifold tank is the

highest point in the cooling system and is the

location of the “radiator” cap (the cap is not on

the radiator). The recovery tank down in the

passenger’s footwell collects heated coolant

as described above. Models from 1990 to

1994 do not have a coolant recovery tank, but

have an enlarged manifold tank. In all models,

the recovery tank has a sensor in it to detect a

low coolant level, and the instrument panel has

a warning light to that effect.