warning JAGUAR XJ6 1997 2.G Manual PDF

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 172 of 227

5Pull the headlight out slightly and

disconnect the electrical connector from the

rear of the light, then remove the light from the

vehicle.

6To refit, position the new unit close enough

to connect the electrical connector. Make

sure that the numbers moulded into the lens

are at the top.

7Refit and tighten the retaining ring. Test the

headlight operation.

8The remainder of the refitting is the reverse

of removal.

Halogen gas-filled bulbs

9Disconnect the electrical connector from

the bulb assembly. Rotate the headlight bulb

connector 1/4-turn anti-clockwise (viewed

from the rear) (see illustration).

10Withdraw the bulb assembly from the

headlight housing.

11Without touching the glass with your bare

fingers (see the Warningat the start of the

Section), insert the new bulb assembly into

the headlight housing and rotate the bulb

socket 1/4-turn clockwise to refit it.

12Plug in the electrical connector and test

headlight operation.

18 Headlights- adjustment

5

Note:The following procedure is intended for

emergency use only, and we strongly

recommend that the headlight aim is only

checked using optical beam-setting

equipment. It is important that the headlights

are aimed correctly. If adjusted incorrectly

they could blind the driver of an oncoming

vehicle and cause a serious accident or

seriously reduce your ability to see the road.

The headlights should be checked for proper

aim every 12 months and any time a new

headlight is installed or front end body work is

performed.

1Adjustment should be made with the

vehicle sitting level, the petrol tank half-full

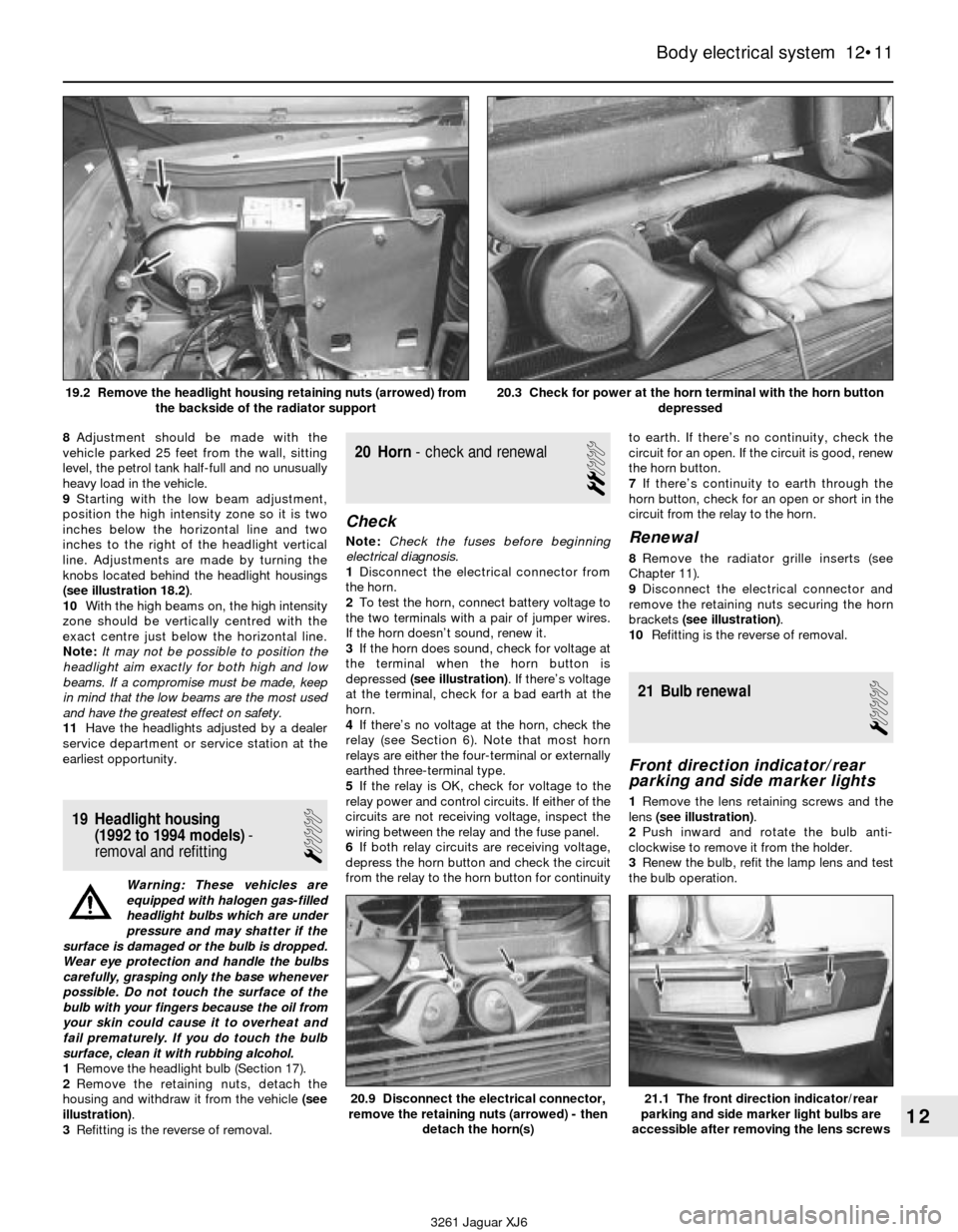

and no unusually heavy load in the vehicle.2Early models with sealed beam headlights

have four adjusting knobs protruding through

the backside of the radiator support. The

vertical (up and down) adjustment knobs are

located above the headlight and the horizontal

(left to right) adjusting knobs are located

below the headlight (see illustration).

3On later models with halogen bulbs,

adjustments are made in the same manner as

described in the previous step, except there

are only two adjusting knobs which tilt the

headlight housing to the desired angle.

4If the headlight housing has been replacedor the vehicle has suffered front-end damage,

refer to following procedure.

5This method requires a blank wall, masking

tape and a level floor.

6Position masking tape vertically on the wall

in reference to the vehicle centreline and the

centrelines of both headlights (see

illustration).

7Position a horizontal tape line in reference

to the centreline of all the headlights. Note:It

may be easier to position the tape on the wall

with the vehicle parked only a few inches

away.

12•10 Body electrical system

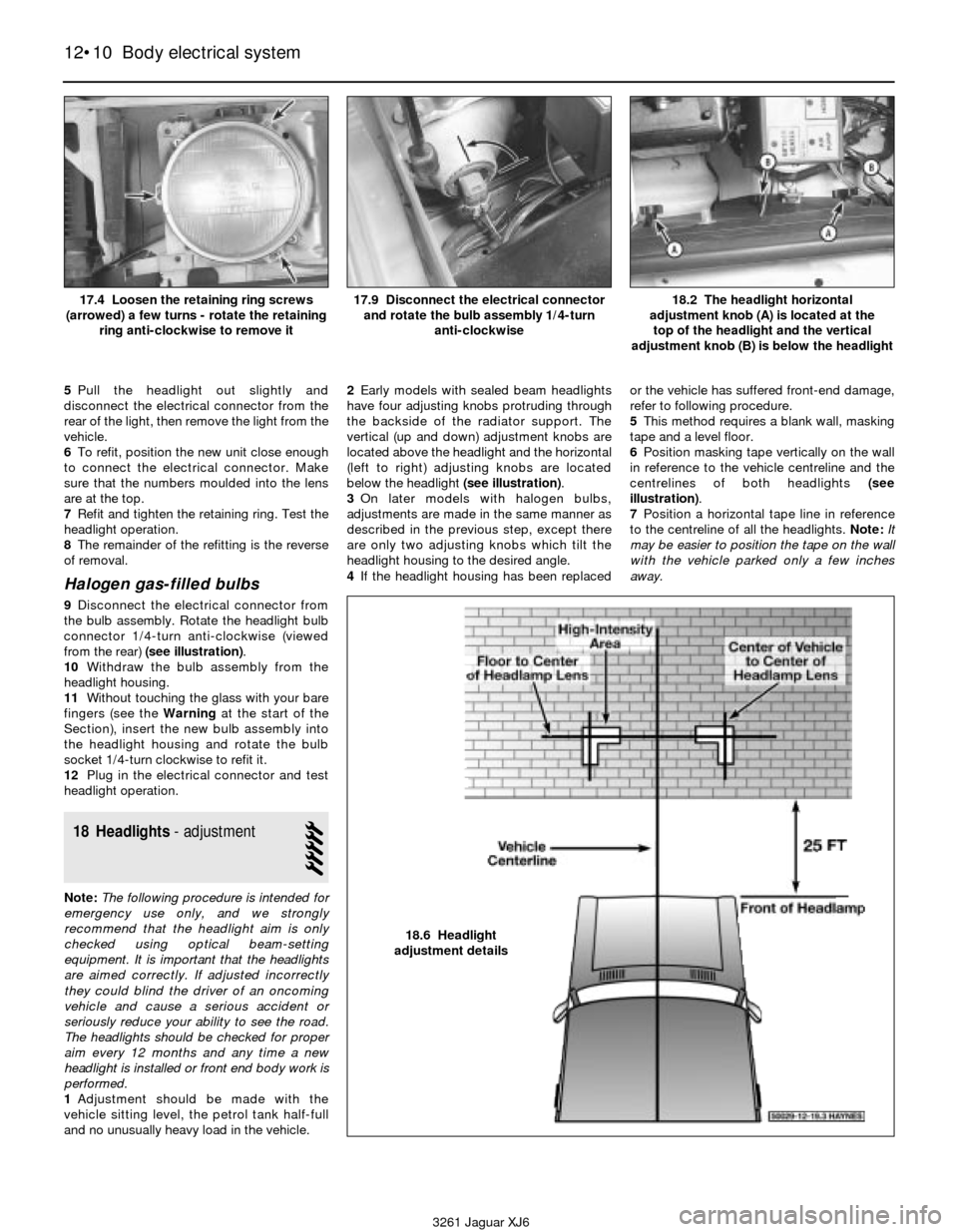

3261 Jaguar XJ618.2 The headlight horizontal

adjustment knob (A) is located at the

top of the headlight and the vertical

adjustment knob (B) is below the headlight

17.4 Loosen the retaining ring screws

(arrowed) a few turns - rotate the retaining

ring anti-clockwise to remove it17.9 Disconnect the electrical connector

and rotate the bulb assembly 1/4-turn

anti-clockwise

18.6 Headlight

adjustment details

Page 173 of 227

8Adjustment should be made with the

vehicle parked 25 feet from the wall, sitting

level, the petrol tank half-full and no unusually

heavy load in the vehicle.

9Starting with the low beam adjustment,

position the high intensity zone so it is two

inches below the horizontal line and two

inches to the right of the headlight vertical

line. Adjustments are made by turning the

knobs located behind the headlight housings

(see illustration 18.2).

10With the high beams on, the high intensity

zone should be vertically centred with the

exact centre just below the horizontal line.

Note:It may not be possible to position the

headlight aim exactly for both high and low

beams. If a compromise must be made, keep

in mind that the low beams are the most used

and have the greatest effect on safety.

11Have the headlights adjusted by a dealer

service department or service station at the

earliest opportunity.

19 Headlight housing

(1992 to 1994 models)-

removal and refitting

1

Warning: These vehicles are

equipped with halogen gas-filled

headlight bulbs which are under

pressure and may shatter if the

surface is damaged or the bulb is dropped.

Wear eye protection and handle the bulbs

carefully, grasping only the base whenever

possible. Do not touch the surface of the

bulb with your fingers because the oil from

your skin could cause it to overheat and

fail prematurely. If you do touch the bulb

surface, clean it with rubbing alcohol.

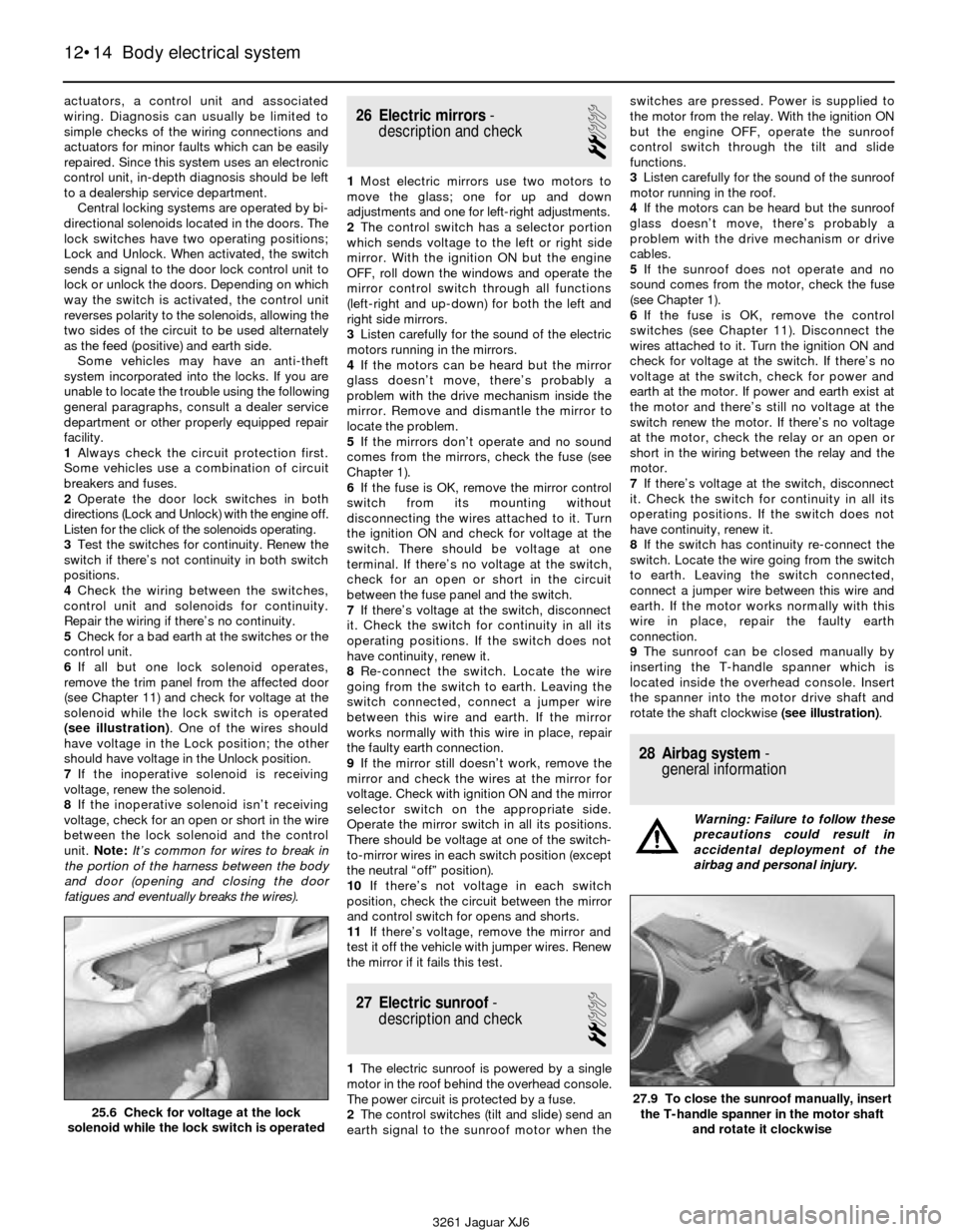

1Remove the headlight bulb (Section 17).

2Remove the retaining nuts, detach the

housing and withdraw it from the vehicle (see

illustration).

3Refitting is the reverse of removal.

20 Horn- check and renewal

2

Check

Note:Check the fuses before beginning

electrical diagnosis.

1Disconnect the electrical connector from

the horn.

2To test the horn, connect battery voltage to

the two terminals with a pair of jumper wires.

If the horn doesn’t sound, renew it.

3If the horn does sound, check for voltage at

the terminal when the horn button is

depressed (see illustration). If there’s voltage

at the terminal, check for a bad earth at the

horn.

4If there’s no voltage at the horn, check the

relay (see Section 6). Note that most horn

relays are either the four-terminal or externally

earthed three-terminal type.

5If the relay is OK, check for voltage to the

relay power and control circuits. If either of the

circuits are not receiving voltage, inspect the

wiring between the relay and the fuse panel.

6If both relay circuits are receiving voltage,

depress the horn button and check the circuit

from the relay to the horn button for continuityto earth. If there’s no continuity, check the

circuit for an open. If the circuit is good, renew

the horn button.

7If there’s continuity to earth through the

horn button, check for an open or short in the

circuit from the relay to the horn.Renewal

8Remove the radiator grille inserts (see

Chapter 11).

9Disconnect the electrical connector and

remove the retaining nuts securing the horn

brackets (see illustration).

10Refitting is the reverse of removal.

21 Bulb renewal

1

Front direction indicator/rear

parking and side marker lights

1Remove the lens retaining screws and the

lens (see illustration).

2Push inward and rotate the bulb anti-

clockwise to remove it from the holder.

3Renew the bulb, refit the lamp lens and test

the bulb operation.

Body electrical system 12•11

12

20.9 Disconnect the electrical connector,

remove the retaining nuts (arrowed) - then

detach the horn(s)21.1 The front direction indicator/rear

parking and side marker light bulbs are

accessible after removing the lens screws

3261 Jaguar XJ6 19.2 Remove the headlight housing retaining nuts (arrowed) from

the backside of the radiator support

20.3 Check for power at the horn terminal with the horn button

depressed

Page 176 of 227

actuators, a control unit and associated

wiring. Diagnosis can usually be limited to

simple checks of the wiring connections and

actuators for minor faults which can be easily

repaired. Since this system uses an electronic

control unit, in-depth diagnosis should be left

to a dealership service department.

Central locking systems are operated by bi-

directional solenoids located in the doors. The

lock switches have two operating positions;

Lock and Unlock. When activated, the switch

sends a signal to the door lock control unit to

lock or unlock the doors. Depending on which

way the switch is activated, the control unit

reverses polarity to the solenoids, allowing the

two sides of the circuit to be used alternately

as the feed (positive) and earth side.

Some vehicles may have an anti-theft

system incorporated into the locks. If you are

unable to locate the trouble using the following

general paragraphs, consult a dealer service

department or other properly equipped repair

facility.

1Always check the circuit protection first.

Some vehicles use a combination of circuit

breakers and fuses.

2Operate the door lock switches in both

directions (Lock and Unlock) with the engine off.

Listen for the click of the solenoids operating.

3Test the switches for continuity. Renew the

switch if there’s not continuity in both switch

positions.

4Check the wiring between the switches,

control unit and solenoids for continuity.

Repair the wiring if there’s no continuity.

5Check for a bad earth at the switches or the

control unit.

6If all but one lock solenoid operates,

remove the trim panel from the affected door

(see Chapter 11) and check for voltage at the

solenoid while the lock switch is operated

(see illustration). One of the wires should

have voltage in the Lock position; the other

should have voltage in the Unlock position.

7If the inoperative solenoid is receiving

voltage, renew the solenoid.

8If the inoperative solenoid isn’t receiving

voltage, check for an open or short in the wire

between the lock solenoid and the control

unit. Note:It’s common for wires to break in

the portion of the harness between the body

and door (opening and closing the door

fatigues and eventually breaks the wires).26 Electric mirrors-

description and check

2

1Most electric mirrors use two motors to

move the glass; one for up and down

adjustments and one for left-right adjustments.

2The control switch has a selector portion

which sends voltage to the left or right side

mirror. With the ignition ON but the engine

OFF, roll down the windows and operate the

mirror control switch through all functions

(left-right and up-down) for both the left and

right side mirrors.

3Listen carefully for the sound of the electric

motors running in the mirrors.

4If the motors can be heard but the mirror

glass doesn’t move, there’s probably a

problem with the drive mechanism inside the

mirror. Remove and dismantle the mirror to

locate the problem.

5If the mirrors don’t operate and no sound

comes from the mirrors, check the fuse (see

Chapter 1).

6If the fuse is OK, remove the mirror control

switch from its mounting without

disconnecting the wires attached to it. Turn

the ignition ON and check for voltage at the

switch. There should be voltage at one

terminal. If there’s no voltage at the switch,

check for an open or short in the circuit

between the fuse panel and the switch.

7If there’s voltage at the switch, disconnect

it. Check the switch for continuity in all its

operating positions. If the switch does not

have continuity, renew it.

8Re-connect the switch. Locate the wire

going from the switch to earth. Leaving the

switch connected, connect a jumper wire

between this wire and earth. If the mirror

works normally with this wire in place, repair

the faulty earth connection.

9If the mirror still doesn’t work, remove the

mirror and check the wires at the mirror for

voltage. Check with ignition ON and the mirror

selector switch on the appropriate side.

Operate the mirror switch in all its positions.

There should be voltage at one of the switch-

to-mirror wires in each switch position (except

the neutral “off” position).

10If there’s not voltage in each switch

position, check the circuit between the mirror

and control switch for opens and shorts.

11If there’s voltage, remove the mirror and

test it off the vehicle with jumper wires. Renew

the mirror if it fails this test.

27 Electric sunroof-

description and check

2

1The electric sunroof is powered by a single

motor in the roof behind the overhead console.

The power circuit is protected by a fuse.

2The control switches (tilt and slide) send an

earth signal to the sunroof motor when theswitches are pressed. Power is supplied to

the motor from the relay. With the ignition ON

but the engine OFF, operate the sunroof

control switch through the tilt and slide

functions.

3Listen carefully for the sound of the sunroof

motor running in the roof.

4If the motors can be heard but the sunroof

glass doesn’t move, there’s probably a

problem with the drive mechanism or drive

cables.

5If the sunroof does not operate and no

sound comes from the motor, check the fuse

(see Chapter 1).

6If the fuse is OK, remove the control

switches (see Chapter 11). Disconnect the

wires attached to it. Turn the ignition ON and

check for voltage at the switch. If there’s no

voltage at the switch, check for power and

earth at the motor. If power and earth exist at

the motor and there’s still no voltage at the

switch renew the motor. If there’s no voltage

at the motor, check the relay or an open or

short in the wiring between the relay and the

motor.

7If there’s voltage at the switch, disconnect

it. Check the switch for continuity in all its

operating positions. If the switch does not

have continuity, renew it.

8If the switch has continuity re-connect the

switch. Locate the wire going from the switch

to earth. Leaving the switch connected,

connect a jumper wire between this wire and

earth. If the motor works normally with this

wire in place, repair the faulty earth

connection.

9The sunroof can be closed manually by

inserting the T-handle spanner which is

located inside the overhead console. Insert

the spanner into the motor drive shaft and

rotate the shaft clockwise (see illustration).

28 Airbag system-

general information

Warning: Failure to follow these

precautions could result in

accidental deployment of the

airbag and personal injury.

12•14 Body electrical system

25.6 Check for voltage at the lock

solenoid while the lock switch is operated27.9 To close the sunroof manually, insert

the T-handle spanner in the motor shaft

and rotate it clockwise

3261 Jaguar XJ6

Page 181 of 227

Wiring diagrams 12•19

12

3261 Jaguar XJ6

Typical engine cooling fan system

Typical 1988 instrument warning light system

Page 182 of 227

12•20 Wiring diagrams

3261 Jaguar XJ6

Typical 1989 to 1994 instrument warning light system

Page 210 of 227

3261 Jaguar XJ6

MOT test checksREF•9

Seat belts and seats

Note: The following checks are applicable to

all seat belts, front and rear.

MExamine the webbing of all the belts

(including rear belts if fitted) for cuts, serious

fraying or deterioration. Fasten and unfasten

each belt to check the buckles. If applicable,

check the retracting mechanism. Check the

security of all seat belt mountings accessible

from inside the vehicle.

MThe front seats themselves must be

securely attached and the backrests must

lock in the upright position.

Doors

MBoth front doors must be able to be opened

and closed from outside and inside, and must

latch securely when closed.

Vehicle identification

MNumber plates must be in good condition,

secure and legible, with letters and numbers

correctly spaced – spacing at (A) should be

twice that at (B).

MThe VIN plate and/or homologation plate

must be legible.

Electrical equipment

MSwitch on the ignition and check the

operation of the horn.

MCheck the windscreen washers and wipers,

examining the wiper blades; renew damaged

or perished blades. Also check the operation

of the stop-lights.

MCheck the operation of the sidelights and

number plate lights. The lenses and reflectors

must be secure, clean and undamaged.

MCheck the operation and alignment of the

headlights. The headlight reflectors must not

be tarnished and the lenses must be

undamaged.

MSwitch on the ignition and check the

operation of the direction indicators (including

the instrument panel tell-tale) and the hazard

warning lights. Operation of the sidelights and

stop-lights must not affect the indicators - if it

does, the cause is usually a bad earth at the

rear light cluster.

MCheck the operation of the rear foglight(s),

including the warning light on the instrument

panel or in the switch.

Footbrake

MExamine the master cylinder, brake pipes

and servo unit for leaks, loose mountings,

corrosion or other damage.

MThe fluid reservoir must be secure and the

fluid level must be between the upper (A) and

lower (B) markings.MInspect both front brake flexible hoses for

cracks or deterioration of the rubber. Turn the

steering from lock to lock, and ensure that the

hoses do not contact the wheel, tyre, or any

part of the steering or suspension mechanism.

With the brake pedal firmly depressed, check

the hoses for bulges or leaks under pressure.

Steering and suspension

MHave your assistant turn the steering wheel

from side to side slightly, up to the point where

the steering gear just begins to transmit this

movement to the roadwheels. Check for

excessive free play between the steering

wheel and the steering gear, indicating wear or

insecurity of the steering column joints, the

column-to-steering gear coupling, or the

steering gear itself.

MHave your assistant turn the steering wheel

more vigorously in each direction, so that the

roadwheels just begin to turn. As this is done,

examine all the steering joints, linkages,

fittings and attachments. Renew any

component that shows signs of wear or

damage. On vehicles with power steering,

check the security and condition of the

steering pump, drivebelt and hoses.

MCheck that the vehicle is standing level,

and at approximately the correct ride height.

Shock absorbers

MDepress each corner of the vehicle in turn,

then release it. The vehicle should rise and

then settle in its normal position. If the vehicle

continues to rise and fall, the shock absorber

is defective. A shock absorber which has

seized will also cause the vehicle to fail.

2Checks carried out

WITH THE VEHICLE ON THE

GROUND

Page 213 of 227

3261 Jaguar XJ6

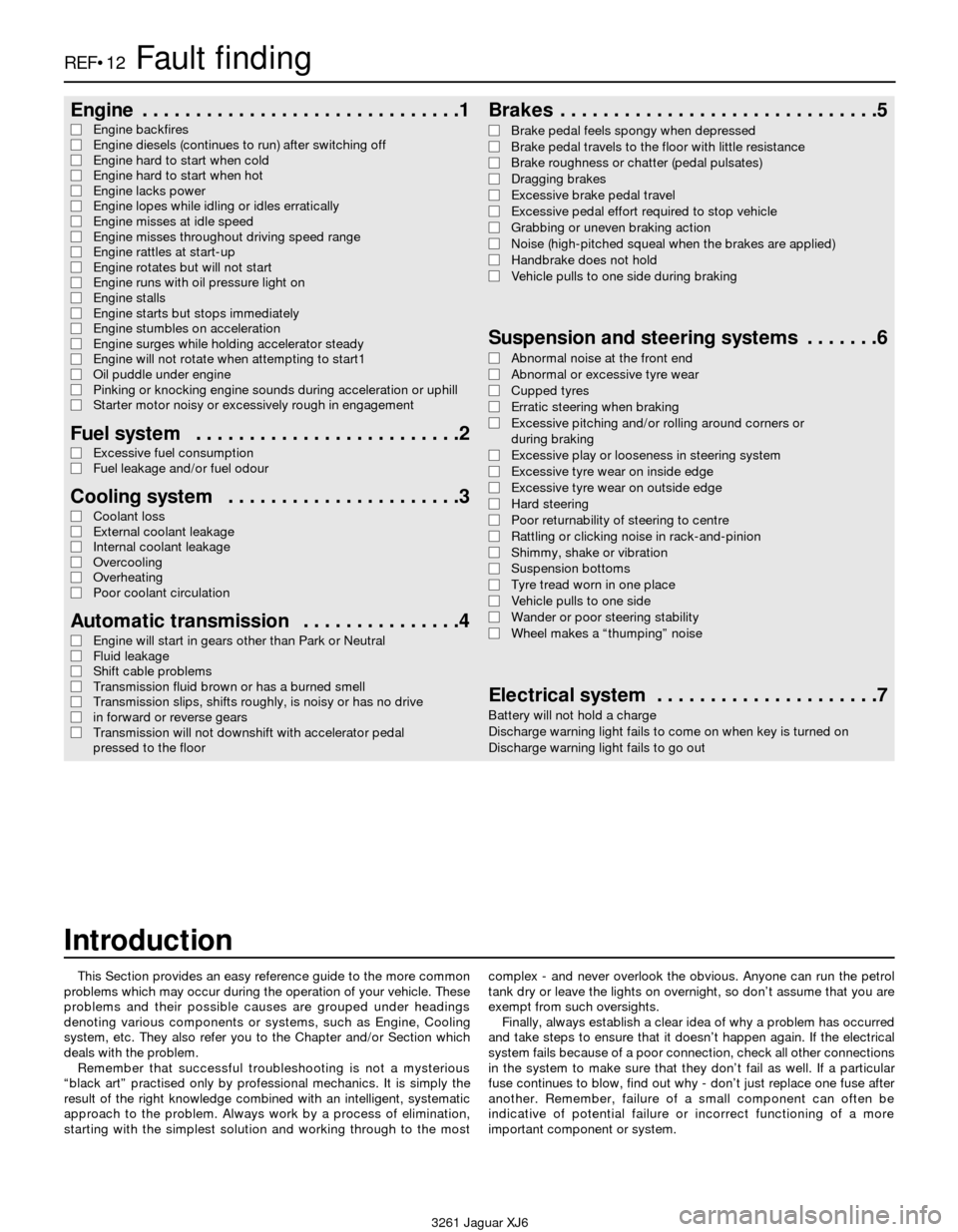

REF•12Fault finding

Introduction

This Section provides an easy reference guide to the more common

problems which may occur during the operation of your vehicle. These

problems and their possible causes are grouped under headings

denoting various components or systems, such as Engine, Cooling

system, etc. They also refer you to the Chapter and/or Section which

deals with the problem.

Remember that successful troubleshooting is not a mysterious

“black art” practised only by professional mechanics. It is simply the

result of the right knowledge combined with an intelligent, systematic

approach to the problem. Always work by a process of elimination,

starting with the simplest solution and working through to the mostcomplex - and never overlook the obvious. Anyone can run the petrol

tank dry or leave the lights on overnight, so don’t assume that you are

exempt from such oversights.

Finally, always establish a clear idea of why a problem has occurred

and take steps to ensure that it doesn’t happen again. If the electrical

system fails because of a poor connection, check all other connections

in the system to make sure that they don’t fail as well. If a particular

fuse continues to blow, find out why - don’t just replace one fuse after

another. Remember, failure of a small component can often be

indicative of potential failure or incorrect functioning of a more

important component or system.

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

m mEngine backfires

m mEngine diesels (continues to run) after switching off

m mEngine hard to start when cold

m mEngine hard to start when hot

m mEngine lacks power

m mEngine lopes while idling or idles erratically

m mEngine misses at idle speed

m mEngine misses throughout driving speed range

m mEngine rattles at start-up

m mEngine rotates but will not start

m mEngine runs with oil pressure light on

m mEngine stalls

m mEngine starts but stops immediately

m mEngine stumbles on acceleration

m mEngine surges while holding accelerator steady

m mEngine will not rotate when attempting to start1

m mOil puddle under engine

m mPinking or knocking engine sounds during acceleration or uphill

m mStarter motor noisy or excessively rough in engagement

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . .2

m

mExcessive fuel consumption

m mFuel leakage and/or fuel odour

Cooling system . . . . . . . . . . . . . . . . . . . . . .3

m

mCoolant loss

m mExternal coolant leakage

m mInternal coolant leakage

m mOvercooling

m mOverheating

m mPoor coolant circulation

Automatic transmission . . . . . . . . . . . . . . .4

m

mEngine will start in gears other than Park or Neutral

m mFluid leakage

m mShift cable problems

m mTransmission fluid brown or has a burned smell

m mTransmission slips, shifts roughly, is noisy or has no drive

m min forward or reverse gears

m mTransmission will not downshift with accelerator pedal

pressed to the floor

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

m mBrake pedal feels spongy when depressed

m mBrake pedal travels to the floor with little resistance

m mBrake roughness or chatter (pedal pulsates)

m mDragging brakes

m mExcessive brake pedal travel

m mExcessive pedal effort required to stop vehicle

m mGrabbing or uneven braking action

m mNoise (high-pitched squeal when the brakes are applied)

m mHandbrake does not hold

m mVehicle pulls to one side during braking

Suspension and steering systems . . . . . . .6

m

mAbnormal noise at the front end

m mAbnormal or excessive tyre wear

m mCupped tyres

m mErratic steering when braking

m mExcessive pitching and/or rolling around corners or

during braking

m mExcessive play or looseness in steering system

m mExcessive tyre wear on inside edge

m mExcessive tyre wear on outside edge

m mHard steering

m mPoor returnability of steering to centre

m mRattling or clicking noise in rack-and-pinion

m mShimmy, shake or vibration

m mSuspension bottoms

m mTyre tread worn in one place

m mVehicle pulls to one side

m mWander or poor steering stability

m mWheel makes a “thumping” noise

Electrical system . . . . . . . . . . . . . . . . . . . . .7

Battery will not hold a charge

Discharge warning light fails to come on when key is turned on

Discharge warning light fails to go out

Page 218 of 227

3261 Jaguar XJ6

Fault findingREF•17

6 Suspension and steering systems (continued)

Tyre tread worn in one place

m mTyres out-of-balance.

m mDamaged or buckled wheel. Inspect and replace if necessary.

m mDefective tyre (Chapter 1).

Excessive play or looseness in steering system

m

mWheel bearing(s) worn (Chapter 10.m mTie-rod end loose or worn (Chapter 10).

m mSteering gear loose or worn (Chapter 10).

Rattling or clicking noise in rack-and-pinion

m

mInsufficient or improper power steering fluid in steering system

(Chapter 10).

m mSteering gear mounts loose (Chapter 10).

7 Electrical system

Battery will not hold a charge

m

mAlternator drivebelt defective or not adjusted properly (Chapter 1).

m mElectrolyte level low (Chapter 1).

m mBattery terminals loose or corroded (Chapter 1).

m mAlternator not charging properly (Chapter 5).

m mLoose, broken or faulty wiring in the charging circuit (Chapter 5).

m mShort in vehicle wiring (Chapters 5 and 12).

m mInternally defective battery (Chapters 1 and 5).

m mDamaged left rear window harness shorting against glass rail

inside door, causing battery to drain (Chapter 12).

Charge warning light fails to go out

m mFaulty alternator or charging circuit (Chapter 5).

m mAlternator drivebelt defective or out of adjustment (Chapter 1).

m mAlternator voltage regulator inoperative (Chapter 5).

Charge warning light fails to come on

when key is turned on

m mWarning light bulb defective (Chapter 12).

m mFault in the printed circuit, dash wiring or bulb holder (Chapter 12).