warning JAGUAR XJ6 1997 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 123 of 227

3261 Jaguar XJ6

9

Chapter 9

Braking system

General

Brake fluid type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Minimum brake pad thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Brake disc minimum permissible thickness . . . . . . . . . . . . . . . . . . . . . . Cast into disc

Parallelism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.013 mm (0.0005 inch) maximum

Runout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.102 mm (0.004 inch) maximum

Torque wrench settingsNm lbf ft

Brake servo mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Caliper bolts (front and rear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 to 40 23 to 29

Caliper bracket bolts

Front bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 to 128 75 to 94

Rear bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 to 62 40 to 45

Master cylinder-to-brake servo nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 to 28 16 to 20

Wheel nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1 Specifications Anti-lock Brake System (ABS) - general information . . . . . . . . . . . . . 2

Brake check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Brake disc - inspection, removal and refitting . . . . . . . . . . . . . . . . . . 5

Brake fluid level check . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1

Brake hoses and lines - inspection and renewal . . . . . . . . . . . . . . . . 8

Brake hydraulic system - bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Brake light switch - check and renewal . . . . . . . . . . . . . . . . . . . . . . . 13

Brake servo - general information, removal and refitting . . . . . . . . . 7Disc brake caliper - removal, overhaul and refitting . . . . . . . . . . . . . 4

Disc brake pads - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Handbrake cable - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Handbrake cables - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Handbrake shoes - check and renewal . . . . . . . . . . . . . . . . . . . . . . 12

Master cylinder - removal, overhaul and refitting . . . . . . . . . . . . . . . 6

9•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 General information

All models covered by this manual are

equipped with hydraulically operated front

and rear disc brake systems. Both front and

rear brakes are self adjusting.

Hydraulic system

The hydraulic system is divided into

two separate circuits. The master cylinder has

separate reservoirs for the two circuits, and, in

the event of a leak or failure in one hydraulic

circuit, the other circuit will remain operative.

All models are equipped with an Anti-lock

Braking System (ABS).

Brake servo

A hydraulic brake servo system is used on

all models covered by this manual. Thissystem uses hydraulic pressure from an

engine-driven pump on models equipped with

a power hydraulic system, and an electric

pump on models without the power hydraulic

system.

Handbrake

The handbrake lever operates the rear

brakes through cable actuation. It’s activated

by a lever mounted in the centre console. The

handbrake assembly uses a pair of brake

shoes located inside the rear hub/brake disc.

Brake pad wear warning system

The brake pad wear warning system turns

on a red light in the instrument cluster when

the brake pads have worn down to the point

at which they must be replaced. Do NOT

ignore this reminder. If you don’t renew the

pads shortly after the brake pad wear warning

light comes on, the brake discs will be

damaged.The wear sensors are attached to the brake

pads. Once the pads wear down to the point

at which they’re flush with the sensor, the disc

grinds away the side of the sensor facing the

disc, the wire inside the sensor is broken, the

circuit is opened and the red light on the

instrument panel comes on.

Always check the sensor(s) when replacing

the pads. If you change the pads before the

warning light comes on, the sensor(s) may still

be good; once the light has come on, renew

the sensor.

Service

After completing any operation involving

dismantling of any part of the brake system,

always test drive the vehicle to check for

proper braking performance before resuming

normal driving. When testing the brakes,

perform the tests on a clean, dry, flat surface.

Conditions other than these can lead to

inaccurate test results.

Page 124 of 227

Test the brakes at various speeds with both

light and heavy pedal pressure. The vehicle

should stop evenly without pulling to one side

or the other. Avoid locking the brakes,

because this slides the tyres and diminishes

braking efficiency and control of the vehicle.

Tyres, vehicle load and wheel alignment are

factors which also affect braking performance.

2 Anti-lock Brake system

(ABS)- general information

The Anti-lock Brake System is designed to

maintain vehicle steerability, directional stability

and optimum deceleration under severe

braking conditions on most road surfaces. It

does so by monitoring the rotational speed of

each wheel and controlling the brake line

pressure to each wheel during braking. This

prevents the wheels from locking up.

The ABS system has three main units - the

wheel speed sensors, the electronic control unit

and the modulator (hydraulic control unit). The

sensors - one at each wheel - send a variable

voltage signal to the electronic control unit,

which monitors these signals, compares them

to its program and determines whether a wheel

is about to lock up. When a wheel is about to

lock up, the control unit signals the hydraulic

unit to reduce hydraulic pressure (or not

increase it further) at that wheel’s brake caliper.

Pressure modulation is handled by three

electrically-operated solenoid valves - one for

each front wheel and one for the rear wheels -

inside the modulator.

If a problem develops within the system, an

“ABS” warning light will glow on the dashboard.

Sometimes, a visual inspection of the ABS

system can help you locate the problem.

Carefully inspect the ABS wiring harness. Pay

particularly close attention to the harness and

connections near each wheel. Look for signs of

chafing and other damage caused by

incorrectly routed wires. If a wheel sensor

harness is damaged, the sensor should be

replaced (the harness and sensor are integral).

Warning: Do NOT try to repair an

ABS wiring harness. The ABS

system is sensitive to even thesmallest changes in resistance. Repairing

the harness could alter resistance values

and cause the system to malfunction. If the

ABS wiring harness is damaged in any way,

it must be replaced.

Caution: Make sure the ignition is turned

off before unplugging or reattaching any

electrical connections.

Diagnosis and repair

If a dashboard warning light comes on and

stays on while the vehicle is in operation, the

ABS system requires attention. Although

special electronic ABS diagnostic testing tools

are necessary to properly diagnose the system,

you can perform a few preliminary checks

before taking the vehicle to a dealer service

department or other qualified repair workshop.

a) Check the brake fluid level in the master

cylinder reservoir.

b) Verify that all ABS system electrical

connectors in the engine compartment

are plugged in.

c) Check the fuses.

d) Follow the wiring harness to each front

wheel and to the differential sensor and

verify that all connections are secure and

that the wiring is undamaged.

If the above preliminary checks do not

rectify the problem, the vehicle should be

diagnosed by a dealer service department.

Due to the complex nature of this system, all

actual repair work must be done by a dealer

service department or other qualified repair

workshop.

3 Disc brake pads- renewal

2

Warning: Disc brake pads must

be replaced on both front wheels

or both rear wheels at the same

time - never renew the pads on

only one wheel. Also, the dust created by

the brake system may contain asbestos,

which is harmful to your health. Never blow

it out with compressed air and don’t inhale

any of it. An approved filtering mask should

be worn when working on the brakes. Do

not, under any circumstances, use

petroleum-based solvents to clean brake

parts. Use brake system cleaner only!

Note:The following procedure applies to both

the front and rear brake pads.

1Remove the cap from the brake fluid

reservoir and siphon off about two-thirds of

the fluid from the reservoir. Failing to do this

could result in fluid overflowing when the

caliper pistons are pressed into their bores.

2Loosen the wheel nuts, raise the front of the

vehicle and support it securely on axle stands.

3Remove the front wheels. Work on one

brake assembly at a time, using the

assembled brake for reference if necessary.

4Inspect the brake disc (see Section 5).

5Follow the accompanying photos,

beginning with illustration 3.5a, for the pad

removal procedure. Be sure to stay in order

and read the caption under each illustration.

9•2 Braking system

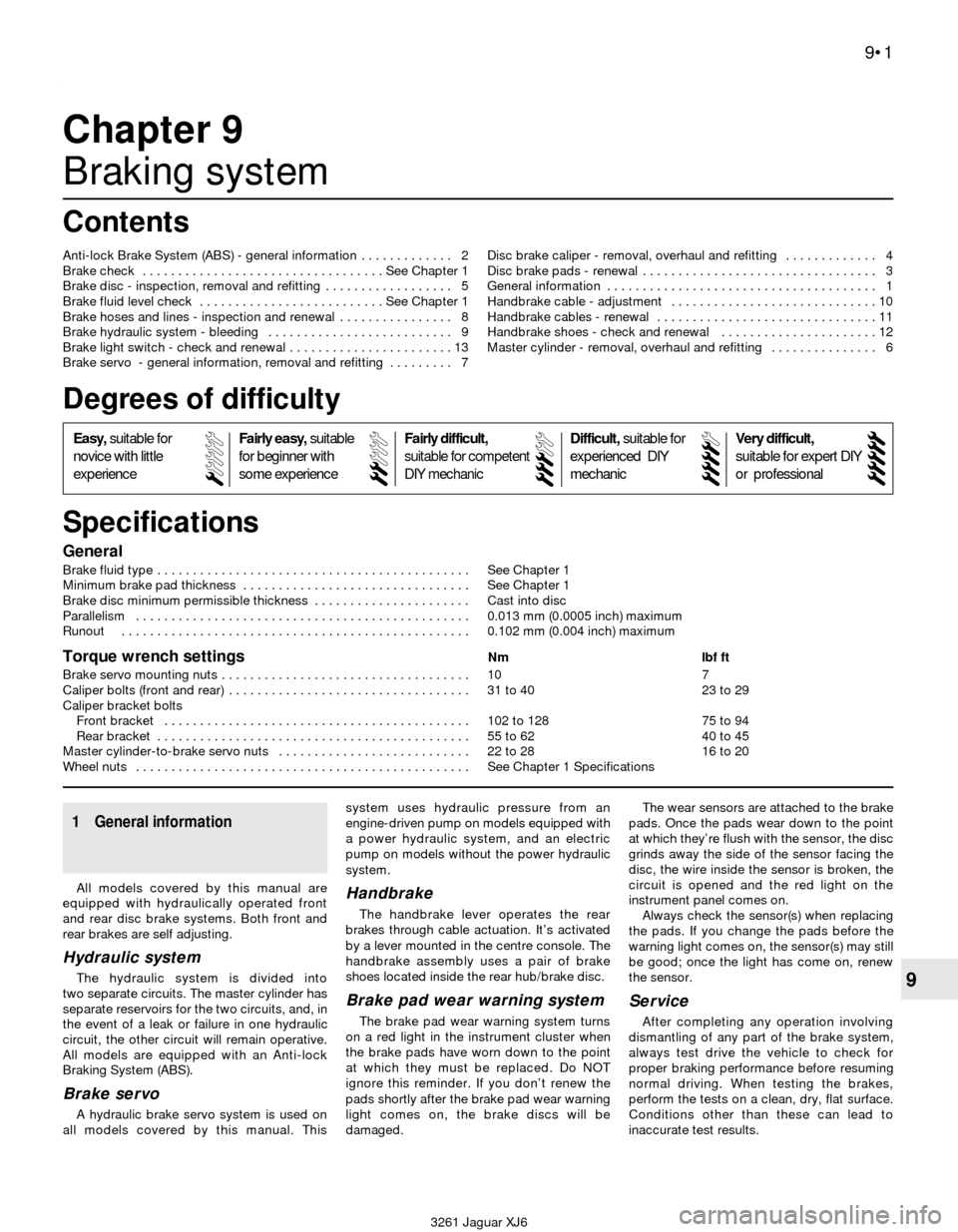

3.5a Before starting, wash down the

caliper and disc with brake cleaner

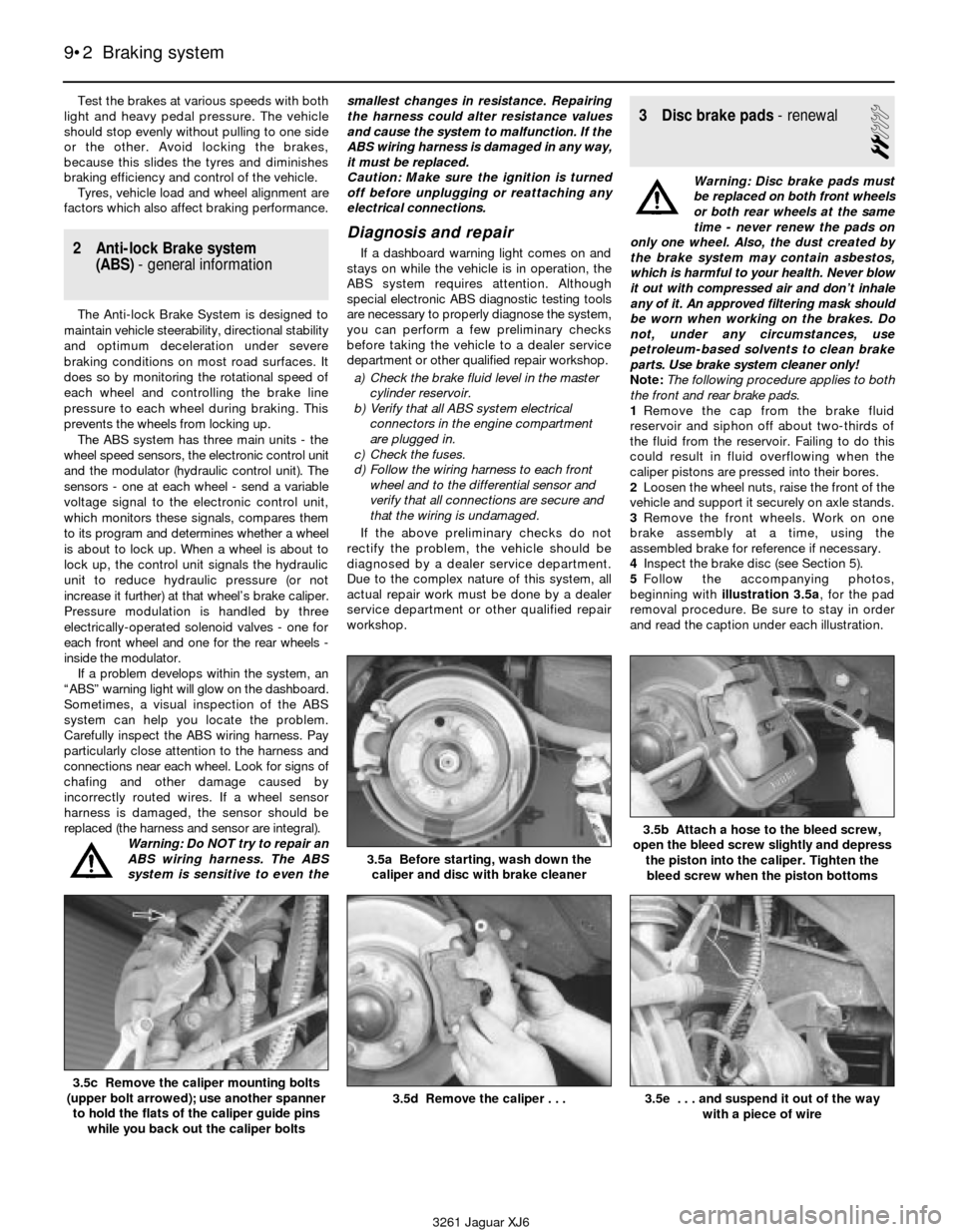

3.5b Attach a hose to the bleed screw,

open the bleed screw slightly and depress

the piston into the caliper. Tighten the

bleed screw when the piston bottoms

3.5c Remove the caliper mounting bolts

(upper bolt arrowed); use another spanner

to hold the flats of the caliper guide pins

while you back out the caliper bolts3.5d Remove the caliper . . .3.5e . . . and suspend it out of the way

with a piece of wire

3261 Jaguar XJ6

Page 125 of 227

6Be sure to buy new pads with wear

sensors. Pattern pads may not have wear

sensors; refitting pads without wear sensors

will cause the dash warning light to come on.

7To refit the new pads, reverse the removal

procedure. When refitting the caliper, be sure

to tighten the mounting bolts to the torque

listed in this Chapter’s Specifications.

8After the job is completed, depress the

brake pedal a few times to bring the pads into

contact with the discs. The pedal should be at

normal height above the floorpan and firm.

Check the brake fluid level and add enough to

top it up (see Chapter 1). Inspect carefully for

leaks and check the operation of the brakes

before placing the vehicle into normal service.

9Tighten the wheel nuts to the specified

torque.

4 Disc brake caliper- removal,

overhaul and refitting

3

Warning: Dust created by the

brake system may contain

asbestos, which is harmful to

your health. Never blow it out

with compressed air and don’t inhale any

of it. An approved filtering mask should be

worn when working on the brakes. Do not,

under any circumstances, use petroleum-

based solvents to clean brake parts. Use

brake system cleaner only!

Note 1:The following procedure applies to

both front and rear calipers.

Note 2:If an overhaul is indicated, explore all

options before beginning the job. New andfactory rebuilt calipers are available on an

exchange basis, which makes this job quite

easy. If you decide to rebuild the calipers,

make sure a rebuild kit is available before

proceeding. Always rebuild the calipers in

pairs - never rebuild just one of them.

Removal

1Loosen the wheel nuts, raise the front or

rear of the vehicle and place it securely on

axle stands. Remove the wheel.

2If you’re just removing the caliper for

access to other components, it isn’t

Braking system 9•3

9

3.5f Remove the outer brake pad3.5g Remove the inner brake pad

3.5h Pull out the wear sensor, trace the

sensor lead back to its plug, detach the

lead from the suspension, and discard it

3.5i Remove the caliper guide pins and

boots (lower pin and boot shown) . . .

3.5j . . . clean them off, inspect the pin and

boot for damage, renew as necessary,

then lubricate the pins with brake grease

and refit them in the caliper bracket

3.5k Apply anti-squeal compound to the

new brake pads

3261 Jaguar XJ6

3.5l Insert the new wear sensor into the

inner pad as shown . . .

3.5n Refit the outer pad

3.5m . . . then refit the inner pad onto the

caliper bracket

3.5o Refit the caliper, then tighten the

mounting bolts to the specified torque

Page 126 of 227

necessary to detach the brake line. If you’re

removing the caliper for overhaul, detach the

hose from the metal line at the frame bracket

(see Section 8), then disconnect the brake line

from the caliper with a flare-nut spanner to

protect the fitting (see illustration). Plug the

metal line to keep contaminants out of the

brake system and to prevent losing brake

fluid.

3Refer to illustration 3.5c and unbolt the

front or rear caliper.

Overhaul

4Before you remove the piston, place a

wood block between the piston and caliper to

prevent damage as it is removed.

5To remove the piston from the caliper,

apply compressed air to the brake fluid hose

connection on the caliper body (see

illustration). Use only enough pressure to

ease the piston out of its bore. Remove the

dust boot.

Warning: Be careful not to place

your fingers between the piston

and the caliper as the piston

may come out with some force.

Be sure to wear eye protection when using

compressed air.

6Inspect the mating surfaces of the piston

and caliper bore wall. If there is any scoring,

rust, pitting or bright areas, renew the

complete caliper unit with a new one.

7If these components are in good condition,

remove the piston seal from the caliper bore

using a wooden or plastic tool (see

illustration). Metal tools may damage the

cylinder bore.

8Remove the caliper guide pins and the

rubber dust boots from the caliper bracket.

9Wash all the components in brake system

cleaner.

10Using the correct rebuild kit for your

vehicle, reassemble the caliper as follows.11Submerge the new rubber seal in clean

brake fluid and refit it in the lower groove in

the caliper bore, making sure it isn’t twisted.

12Coat the piston with clean brake fluid and

stretch the new dust boot over the bottom of

the piston. Hold the piston over the caliper

bore and insert the rubber flange of the dust

boot into the upper groove in the bore. Start

with the side farthest from you and work your

way around toward the front until it is

completely seated. Push the piston into the

caliper bore until it is bottomed in the bore,

then seat the top of the dust boot in the

groove in the piston.

13Lubricate the sliding surfaces of the guide

pins with silicone-based grease (usually

supplied in the kit), then refit the new dust

boots and pins into the caliper bracket.

Refitting

14Refit the caliper by reversing the removal

procedure (see Section 3).

15If the brake hose was disconnected from

the caliper, bleed the brake system (see

Section 9).

5 Brake disc- inspection,

removal and refitting

2

Note:The following procedure applies to both

the front and rear brake discs.

Inspection

1Loosen the wheel nuts, raise the vehicle

and support it securely on axle stands.

Remove the wheel and refit three nuts to hold

the disc in place. If the rear brake disc is being

worked on, release the handbrake.

2Remove the brake caliper as outlined in

Section 4. It is not necessary to disconnect

the brake hose. After removing the caliper,

suspend it out of the way with a piece of wire.

3Visually inspect the disc surface for scoring

or damage. Light scratches and shallow

grooves are normal after use and may not

always be detrimental to brake operation, but

deep scoring - over 0.015 inch - requires disc

removal and refinishing by an automotive

machine shop. Be sure to check both sides of

the disc (see illustration). If pulsating has

9•4 Braking system

4.7 Remove the piston seal from the

caliper bore using a wooden or plastic tool

(metal tools may damage the

cylinder bore)5.3 The brake pads on this vehicle were

obviously neglected, as they wore down to

the rivets and cut deep grooves into the

disc - this disc must be replaced

3261 Jaguar XJ6 4.2 Use a flare-nut spanner to protect the brake hose fitting when

unscrewing it from the caliper

4.5 With the caliper padded to catch the piston, use compressed

air to force the piston out of its bore - make sure your fingers are

not between the piston and the caliper

Page 128 of 227

Refitting

8Place the disc on the hub and refit the disc

retaining screw. Tighten the screw securely.

9Refit the caliper mounting bracket, using a

new safety wire on the mounting bolts.

10Refit the brake pads and caliper (see

Section 3). Tighten all fasteners to the torque

listed in this Chapter’s Specifications.

11Refit the wheel and wheel nuts, then lower

the vehicle to the ground. Tighten the wheel

nuts to the specified torque (see Chapter 1

Specifications). Depress the brake pedal a

few times to bring the brake pads into contact

with the disc.

12Adjust the handbrake shoes, if necessary.

13Check the operation of the brakes

carefully, if possible before driving the vehicle

on public roads.

6 Master cylinder- removal,

overhaul and refitting

3

Note:Although master cylinder parts and

rebuild kits are available for most models, we

recommend replacing the master cylinder with

a new or remanufactured unit, if possible.

Removal

1The master cylinder is connected to the

brake servo, which is attached to the pedal

box, in front of the bulkhead on the driver’s

side of the engine compartment.

2Remove as much fluid as you can from the

reservoir with a syringe.

3Place rags under the line fittings and

prepare caps or plastic bags to cover the

ends of the lines once they are disconnected.

Caution: Brake fluid will damage paint.

Cover all body parts and be careful not to

spill fluid during this procedure.

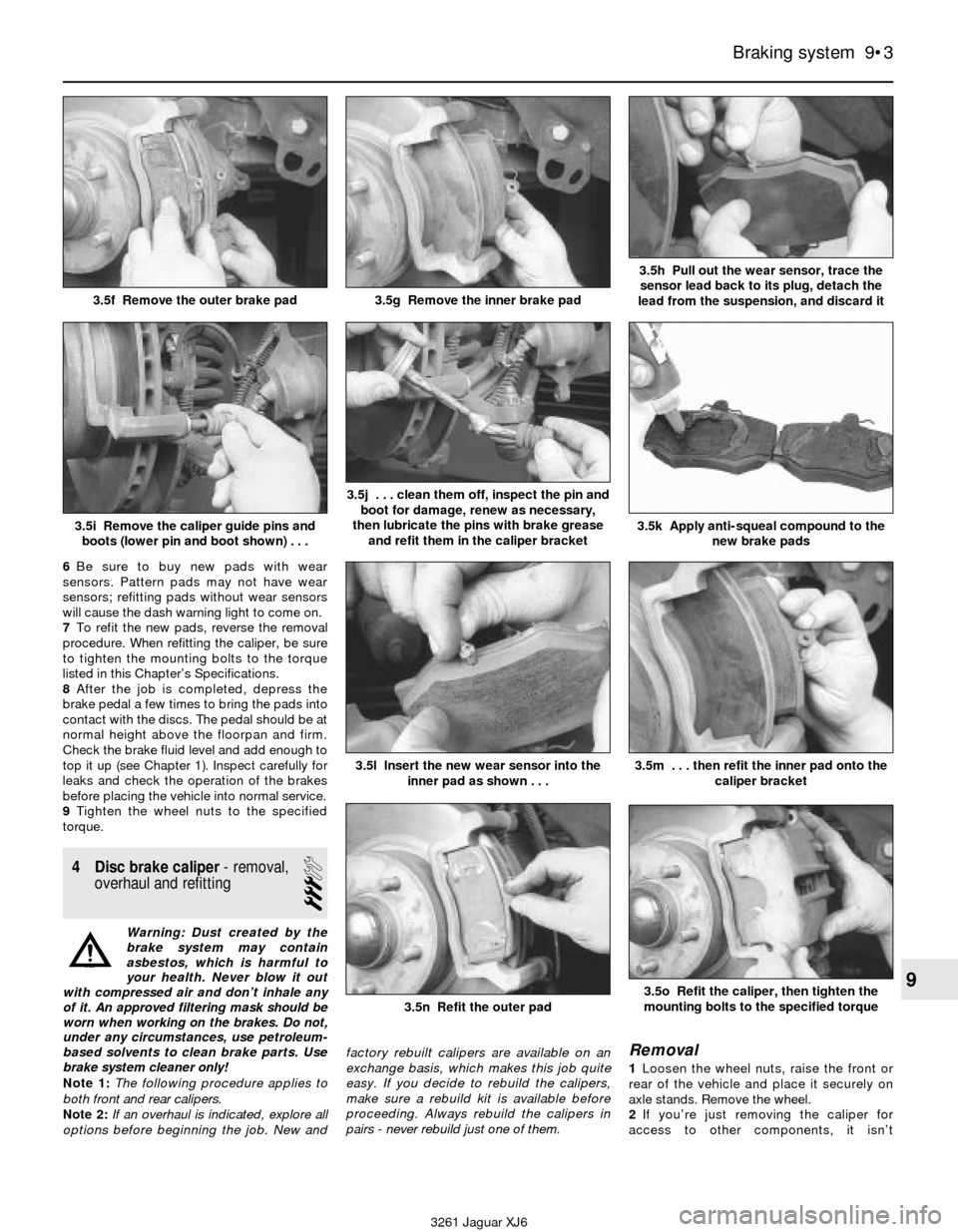

4Disconnect the electrical connector for the

low fluid level warning light (see illustration).

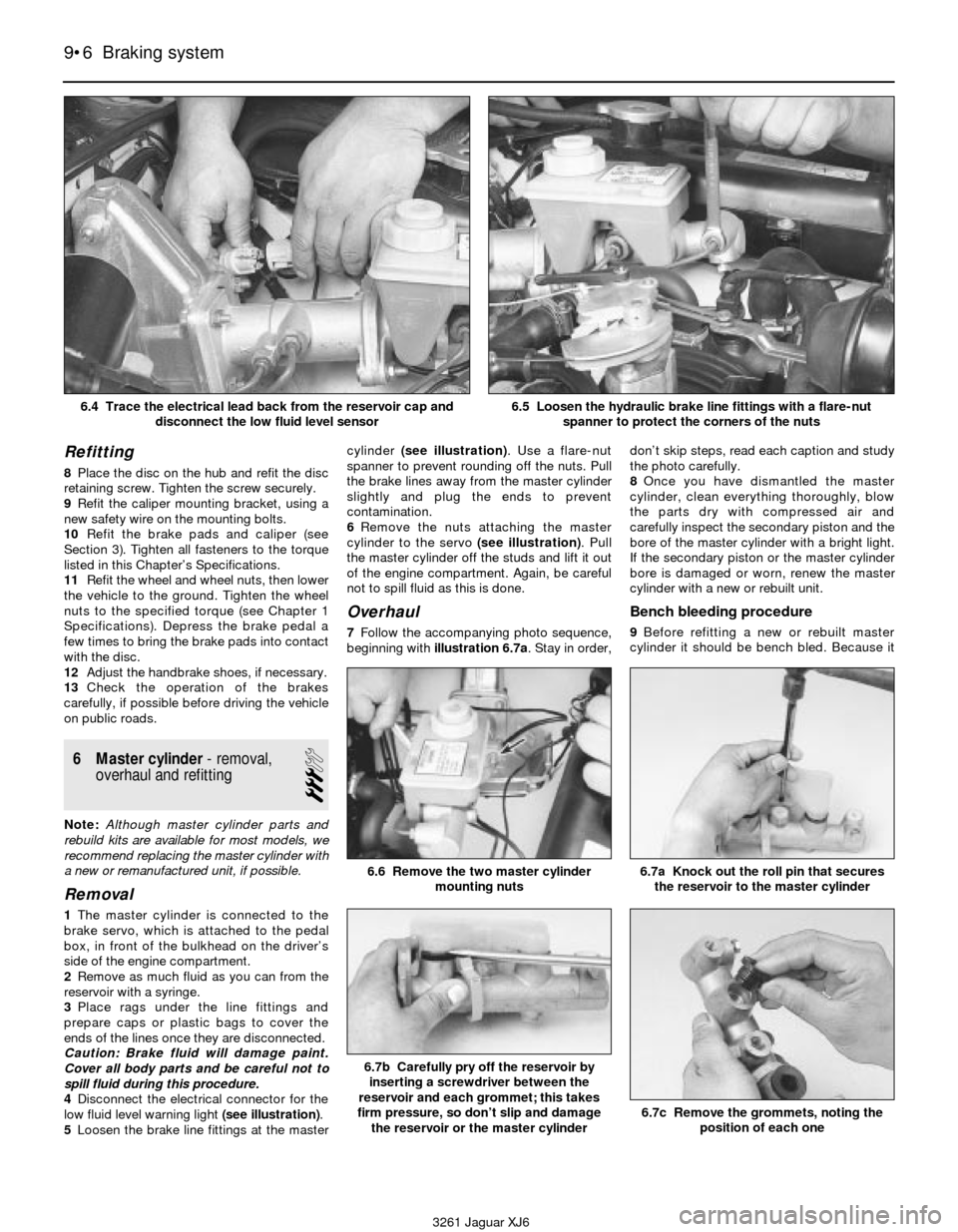

5Loosen the brake line fittings at the mastercylinder (see illustration). Use a flare-nut

spanner to prevent rounding off the nuts. Pull

the brake lines away from the master cylinder

slightly and plug the ends to prevent

contamination.

6Remove the nuts attaching the master

cylinder to the servo (see illustration). Pull

the master cylinder off the studs and lift it out

of the engine compartment. Again, be careful

not to spill fluid as this is done.

Overhaul

7Follow the accompanying photo sequence,

beginning with illustration 6.7a. Stay in order,don’t skip steps, read each caption and study

the photo carefully.

8Once you have dismantled the master

cylinder, clean everything thoroughly, blow

the parts dry with compressed air and

carefully inspect the secondary piston and the

bore of the master cylinder with a bright light.

If the secondary piston or the master cylinder

bore is damaged or worn, renew the master

cylinder with a new or rebuilt unit.

Bench bleeding procedure

9Before refitting a new or rebuilt master

cylinder it should be bench bled. Because it

9•6 Braking system

6.7a Knock out the roll pin that secures

the reservoir to the master cylinder

6.7b Carefully pry off the reservoir by

inserting a screwdriver between the

reservoir and each grommet; this takes

firm pressure, so don’t slip and damage

the reservoir or the master cylinder

6.7c Remove the grommets, noting the

position of each one

6.6 Remove the two master cylinder

mounting nuts

3261 Jaguar XJ6 6.4 Trace the electrical lead back from the reservoir cap and

disconnect the low fluid level sensor

6.5 Loosen the hydraulic brake line fittings with a flare-nut

spanner to protect the corners of the nuts

Page 132 of 227

6Carefully check to make sure the

suspension and steering components do not

make contact with the hoses. Have an

assistant push on the vehicle and also turn the

steering wheel from lock-to-lock during

inspection.

7Bleed the brake system (see Section 9).

Metal brake line renewal

8When replacing brake lines, use the proper

parts only. Do not use copper line for any

brake system connections. Purchase steel

brake lines from a dealer or motor factors..

9Unless you’re using factory renewal brake

lines, you may need a tubing bender to bend

the lines to the proper shape.

10First, remove the line you intend to renew,

lay it on a clean workbench and measure it

carefully. Obtain a new line of the same length

and bend it to match the pattern of the old

line.

Warning: Do not crimp or

damage the line. No bend should

have a smaller radius than

9/16-inch. Make sure the

protective coating on the new line is

undamaged at the bends.

11When refitting the new line, make sure it’s

well supported by the brackets, the routing

matches the original and there’s plenty of

clearance between moving or hot

components.

12After refitting, check the master cylinder

fluid level and add fluid as necessary. Bleed

the brake system as outlined in Section 9 and

test the brakes carefully before driving the

vehicle. Be sure there are no leaks.

9 Brake hydraulic system-

bleeding

2

Warning: Wear eye protection

when bleeding the brake

system. If the fluid comes in

contact with your eyes,

immediately rinse them with water and

seek medical attention.Note:Bleeding the hydraulic system is

necessary to remove any air which has entered

the system during removal and refitting of a

hose, line, caliper or master cylinder.

1It will probably be necessary to bleed the

system at all four brakes if air has entered the

system due to low fluid level or if the brake

lines have been disconnected at the master

cylinder.

2If a brake line was disconnected at only one

wheel, then only that caliper or wheel cylinder

must be bled.

3If a brake line is disconnected at a fitting

located between the master cylinder and any

of the brakes, that part of the system served

by the disconnected line must be bled.

4Bleed the right rear, the left rear, the right

front and the left front caliper, in that order,

when the entire system is involved.

5Remove any residual vacuum from the

servo and pressure in the anti-lock braking

system (if equipped) by applying the brake

about 30 times with the engine off.

6Remove the master cylinder reservoir cover

and fill the reservoir with brake fluid. Refit the

cover. Note:Check the fluid level often during

the bleeding operation and add fluid as

necessary to prevent the fluid level from falling

low enough to allow air into the master

cylinder.

7Have an assistant on hand, as well as a

supply of new brake fluid, an empty clear

plastic container, a length of 3/16-inch clear

tubing to fit over the bleed screws and a

spanner to open and close the bleed screws.

8Beginning at the right rear wheel, loosen the

bleed screw slightly, then tighten it to a point

where it is snug but can still be loosened

quickly and easily.

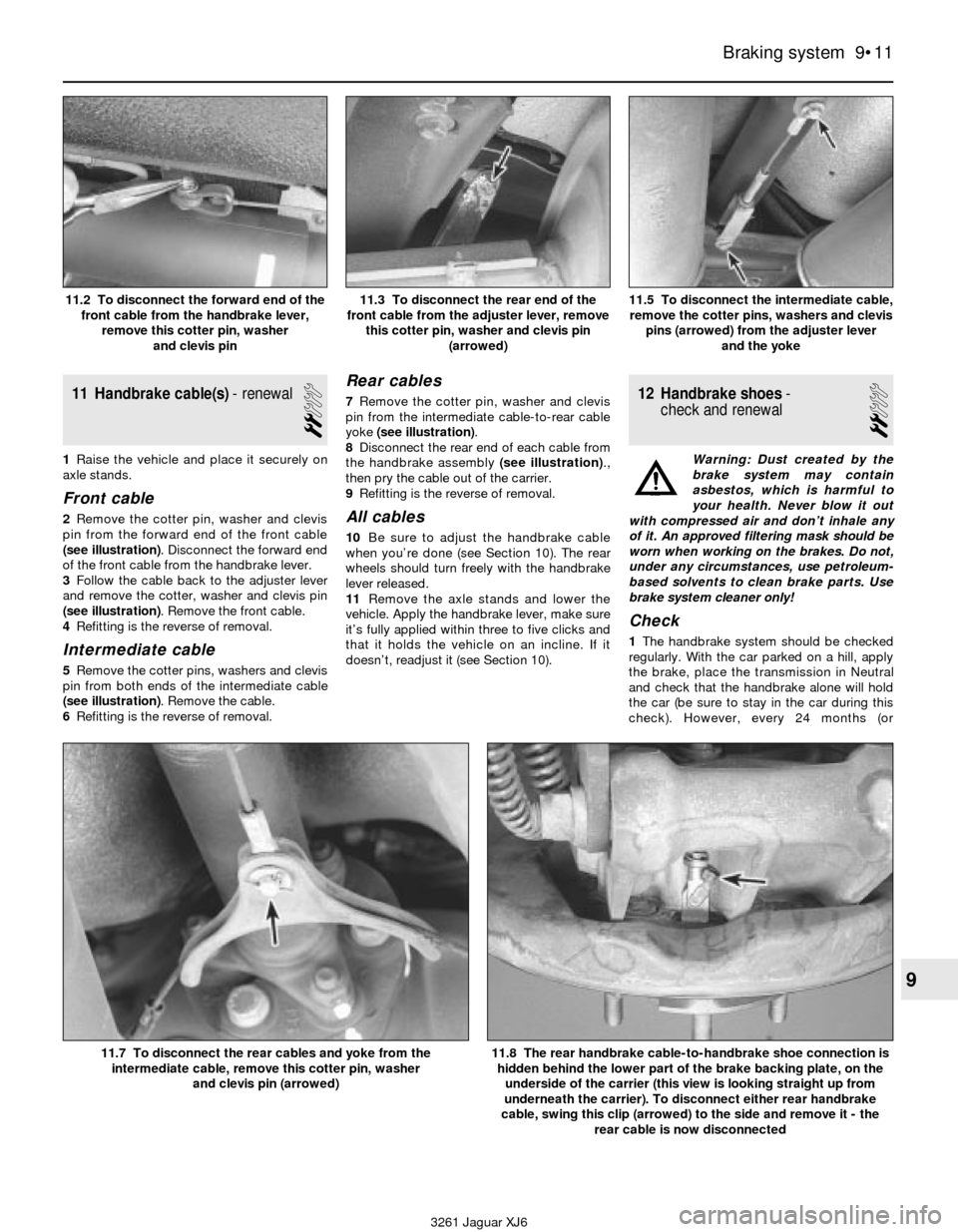

9Place one end of the tubing over the bleed

valve and submerge the other end in brake

fluid in the container (see illustration).

10Have the assistant pump the brakes a few

times to build pressure in the system, then

hold the pedal firmly depressed.

11While the pedal is held depressed, open

the bleed screw just enough to allow fluid to

flow from the caliper. Watch for air bubbles toexit the submerged end of the tube. When the

fluid flow slows after a couple of seconds,

close the screw and have your assistant

release the pedal.

12Repeat Steps 10 and 11 until no more air

is seen leaving the tube, then tighten the

bleed screw and proceed to the left rear

wheel, the right front wheel and the left

front wheel, in that order, and perform the

same procedure. Be sure to check the fluid in

the master cylinder reservoir frequently.

13Never reuse old brake fluid. It contains

contaminates and moisture which could

damage the braking system.

14Refill the master cylinder with fluid at the

end of the operation.

15Check the operation of the brakes. The

pedal should feel solid when depressed, with

no sponginess. If necessary, repeat the entire

process.

Warning: Do not drive the car if

in doubt about the effectiveness

of the brake system.

10 Handbrake cable-

adjustment

1

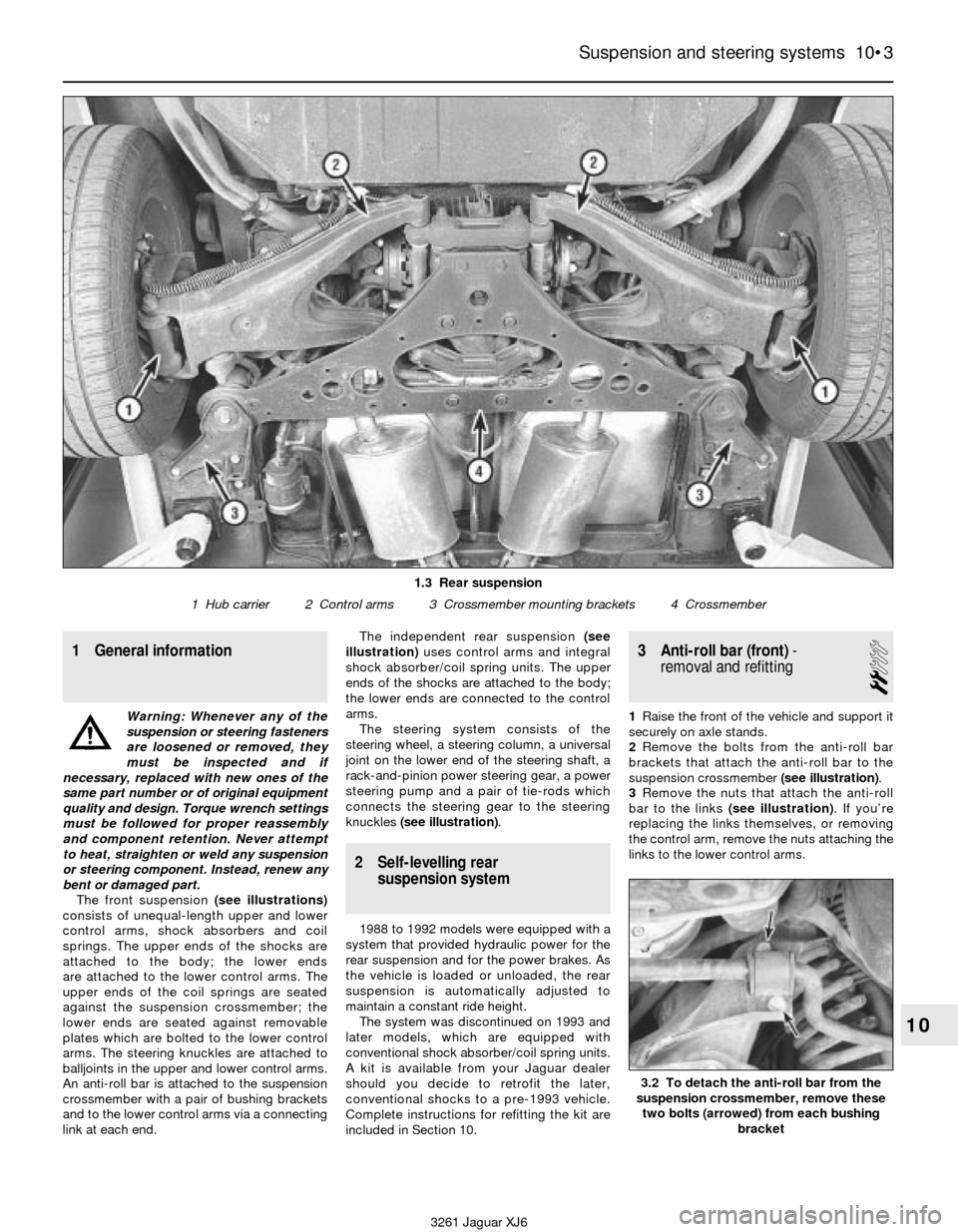

1Slowly apply the handbrake and count the

number of clicks at the lever. It should be fully

applied within three to five clicks. If the lever is

still not fully applied by the fifth click, adjust

the handbrake cable as follows:

2Raise the vehicle and place it securely on

axle stands.

3Loosen the locknut (see illustration)and

tighten the cable adjuster until all slack has

been removed. Tighten the locknut. Make

sure the wheels turn freely with the handbrake

lever released

4Lower the vehicle and recheck the

handbrake lever. It should now be properly

adjusted. If it’s now fully applied within three

to five clicks, raise the vehicle again and

readjust the cable at the adjuster.

5Make sure the handbrake holds the vehicle

on an incline.

9•10 Braking system

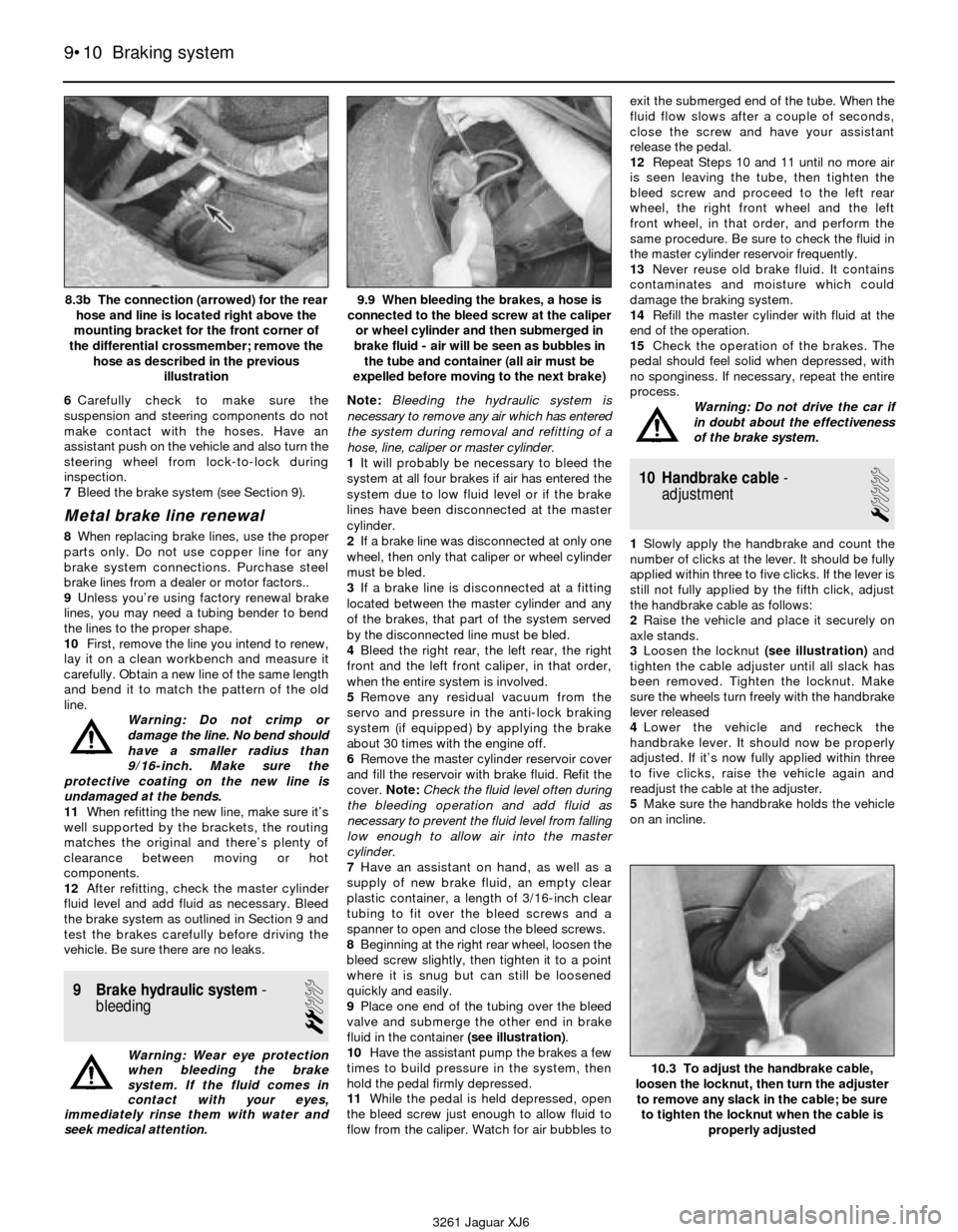

8.3b The connection (arrowed) for the rear

hose and line is located right above the

mounting bracket for the front corner of

the differential crossmember; remove the

hose as described in the previous

illustration9.9 When bleeding the brakes, a hose is

connected to the bleed screw at the caliper

or wheel cylinder and then submerged in

brake fluid - air will be seen as bubbles in

the tube and container (all air must be

expelled before moving to the next brake)

10.3 To adjust the handbrake cable,

loosen the locknut, then turn the adjuster

to remove any slack in the cable; be sure

to tighten the locknut when the cable is

properly adjusted

3261 Jaguar XJ6

Page 133 of 227

11 Handbrake cable(s)- renewal

2

1Raise the vehicle and place it securely on

axle stands.

Front cable

2Remove the cotter pin, washer and clevis

pin from the forward end of the front cable

(see illustration). Disconnect the forward end

of the front cable from the handbrake lever.

3Follow the cable back to the adjuster lever

and remove the cotter, washer and clevis pin

(see illustration). Remove the front cable.

4Refitting is the reverse of removal.

Intermediate cable

5Remove the cotter pins, washers and clevis

pin from both ends of the intermediate cable

(see illustration). Remove the cable.

6Refitting is the reverse of removal.

Rear cables

7Remove the cotter pin, washer and clevis

pin from the intermediate cable-to-rear cable

yoke (see illustration).

8Disconnect the rear end of each cable from

the handbrake assembly (see illustration).,

then pry the cable out of the carrier.

9Refitting is the reverse of removal.

All cables

10Be sure to adjust the handbrake cable

when you’re done (see Section 10). The rear

wheels should turn freely with the handbrake

lever released.

11Remove the axle stands and lower the

vehicle. Apply the handbrake lever, make sure

it’s fully applied within three to five clicks and

that it holds the vehicle on an incline. If it

doesn’t, readjust it (see Section 10).

12 Handbrake shoes-

check and renewal

2

Warning: Dust created by the

brake system may contain

asbestos, which is harmful to

your health. Never blow it out

with compressed air and don’t inhale any

of it. An approved filtering mask should be

worn when working on the brakes. Do not,

under any circumstances, use petroleum-

based solvents to clean brake parts. Use

brake system cleaner only!

Check

1The handbrake system should be checked

regularly. With the car parked on a hill, apply

the brake, place the transmission in Neutral

and check that the handbrake alone will hold

the car (be sure to stay in the car during this

check). However, every 24 months (or

Braking system 9•11

9

3261 Jaguar XJ6 11.2 To disconnect the forward end of the

front cable from the handbrake lever,

remove this cotter pin, washer

and clevis pin

11.3 To disconnect the rear end of the

front cable from the adjuster lever, remove

this cotter pin, washer and clevis pin

(arrowed)11.5 To disconnect the intermediate cable,

remove the cotter pins, washers and clevis

pins (arrowed) from the adjuster lever

and the yoke

11.7 To disconnect the rear cables and yoke from the

intermediate cable, remove this cotter pin, washer

and clevis pin (arrowed)11.8 The rear handbrake cable-to-handbrake shoe connection is

hidden behind the lower part of the brake backing plate, on the

underside of the carrier (this view is looking straight up from

underneath the carrier). To disconnect either rear handbrake

cable, swing this clip (arrowed) to the side and remove it - the

rear cable is now disconnected

Page 139 of 227

1 General information

Warning: Whenever any of the

suspension or steering fasteners

are loosened or removed, they

must be inspected and if

necessary, replaced with new ones of the

same part number or of original equipment

quality and design. Torque wrench settings

must be followed for proper reassembly

and component retention. Never attempt

to heat, straighten or weld any suspension

or steering component. Instead, renew any

bent or damaged part.

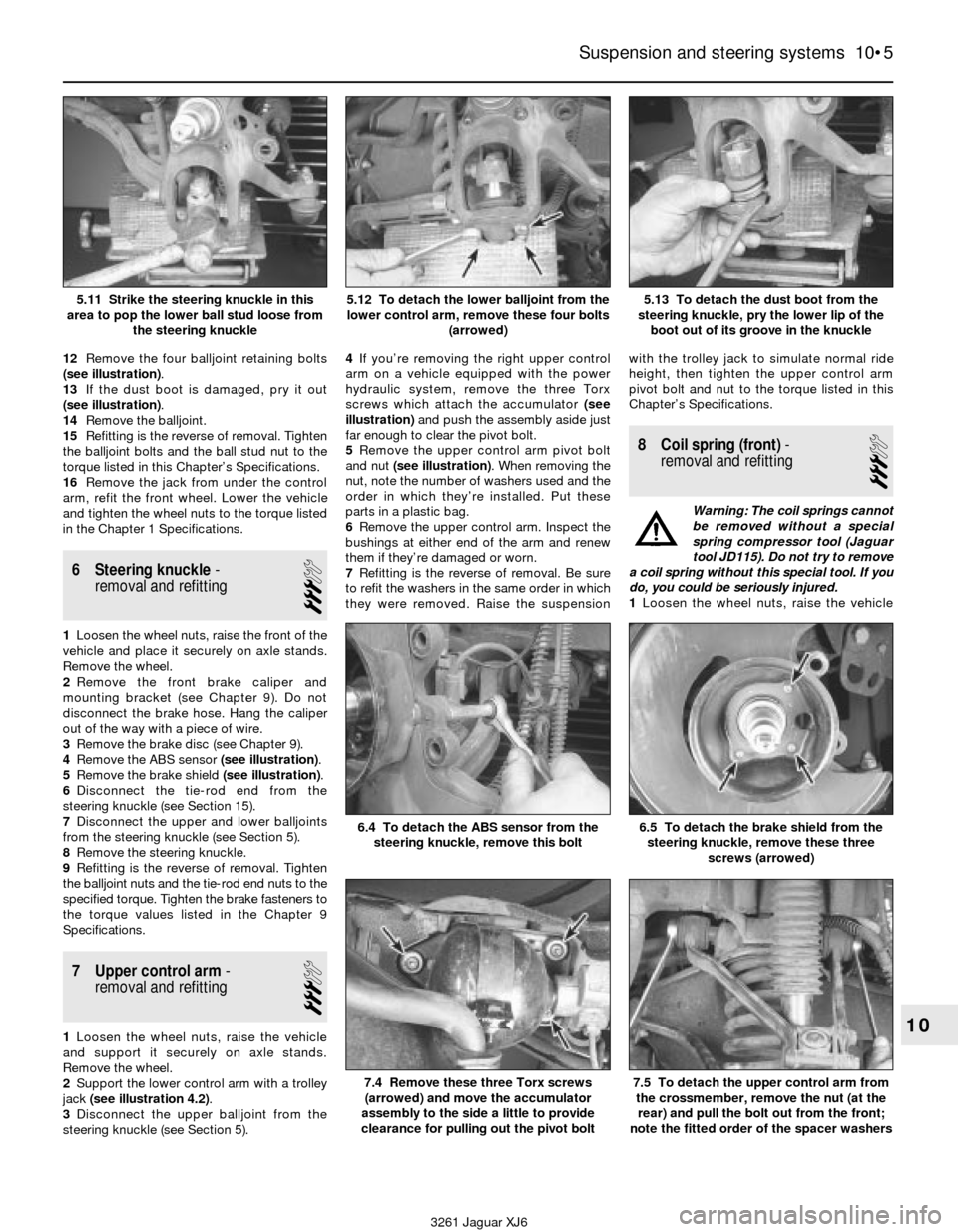

The front suspension (see illustrations)

consists of unequal-length upper and lower

control arms, shock absorbers and coil

springs. The upper ends of the shocks are

attached to the body; the lower ends

are attached to the lower control arms. The

upper ends of the coil springs are seated

against the suspension crossmember; the

lower ends are seated against removable

plates which are bolted to the lower control

arms. The steering knuckles are attached to

balljoints in the upper and lower control arms.

An anti-roll bar is attached to the suspension

crossmember with a pair of bushing brackets

and to the lower control arms via a connecting

link at each end.The independent rear suspension (see

illustration)uses control arms and integral

shock absorber/coil spring units. The upper

ends of the shocks are attached to the body;

the lower ends are connected to the control

arms.

The steering system consists of the

steering wheel, a steering column, a universal

joint on the lower end of the steering shaft, a

rack-and-pinion power steering gear, a power

steering pump and a pair of tie-rods which

connects the steering gear to the steering

knuckles (see illustration).

2 Self-levelling rear

suspension system

1988 to 1992 models were equipped with a

system that provided hydraulic power for the

rear suspension and for the power brakes. As

the vehicle is loaded or unloaded, the rear

suspension is automatically adjusted to

maintain a constant ride height.

The system was discontinued on 1993 and

later models, which are equipped with

conventional shock absorber/coil spring units.

A kit is available from your Jaguar dealer

should you decide to retrofit the later,

conventional shocks to a pre-1993 vehicle.

Complete instructions for refitting the kit are

included in Section 10.

3 Anti-roll bar (front)-

removal and refitting

2

1Raise the front of the vehicle and support it

securely on axle stands.

2Remove the bolts from the anti-roll bar

brackets that attach the anti-roll bar to the

suspension crossmember (see illustration).

3Remove the nuts that attach the anti-roll

bar to the links (see illustration). If you’re

replacing the links themselves, or removing

the control arm, remove the nuts attaching the

links to the lower control arms.

Suspension and steering systems 10•3

10

1.3 Rear suspension

1 Hub carrier 2 Control arms 3 Crossmember mounting brackets 4 Crossmember

3.2 To detach the anti-roll bar from the

suspension crossmember, remove these

two bolts (arrowed) from each bushing

bracket

3261 Jaguar XJ6

Page 141 of 227

12Remove the four balljoint retaining bolts

(see illustration).

13If the dust boot is damaged, pry it out

(see illustration).

14Remove the balljoint.

15Refitting is the reverse of removal. Tighten

the balljoint bolts and the ball stud nut to the

torque listed in this Chapter’s Specifications.

16Remove the jack from under the control

arm, refit the front wheel. Lower the vehicle

and tighten the wheel nuts to the torque listed

in the Chapter 1 Specifications.

6 Steering knuckle-

removal and refitting

3

1Loosen the wheel nuts, raise the front of the

vehicle and place it securely on axle stands.

Remove the wheel.

2Remove the front brake caliper and

mounting bracket (see Chapter 9). Do not

disconnect the brake hose. Hang the caliper

out of the way with a piece of wire.

3Remove the brake disc (see Chapter 9).

4Remove the ABS sensor (see illustration).

5Remove the brake shield (see illustration).

6Disconnect the tie-rod end from the

steering knuckle (see Section 15).

7Disconnect the upper and lower balljoints

from the steering knuckle (see Section 5).

8Remove the steering knuckle.

9Refitting is the reverse of removal. Tighten

the balljoint nuts and the tie-rod end nuts to the

specified torque. Tighten the brake fasteners to

the torque values listed in the Chapter 9

Specifications.

7 Upper control arm-

removal and refitting

3

1Loosen the wheel nuts, raise the vehicle

and support it securely on axle stands.

Remove the wheel.

2Support the lower control arm with a trolley

jack (see illustration 4.2).

3Disconnect the upper balljoint from the

steering knuckle (see Section 5).4If you’re removing the right upper control

arm on a vehicle equipped with the power

hydraulic system, remove the three Torx

screws which attach the accumulator (see

illustration)and push the assembly aside just

far enough to clear the pivot bolt.

5Remove the upper control arm pivot bolt

and nut (see illustration). When removing the

nut, note the number of washers used and the

order in which they’re installed. Put these

parts in a plastic bag.

6Remove the upper control arm. Inspect the

bushings at either end of the arm and renew

them if they’re damaged or worn.

7Refitting is the reverse of removal. Be sure

to refit the washers in the same order in which

they were removed. Raise the suspensionwith the trolley jack to simulate normal ride

height, then tighten the upper control arm

pivot bolt and nut to the torque listed in this

Chapter’s Specifications.

8 Coil spring (front)-

removal and refitting

3

Warning: The coil springs cannot

be removed without a special

spring compressor tool (Jaguar

tool JD115). Do not try to remove

a coil spring without this special tool. If you

do, you could be seriously injured.

1Loosen the wheel nuts, raise the vehicle

Suspension and steering systems 10•5

10

5.11 Strike the steering knuckle in this

area to pop the lower ball stud loose from

the steering knuckle5.12 To detach the lower balljoint from the

lower control arm, remove these four bolts

(arrowed)5.13 To detach the dust boot from the

steering knuckle, pry the lower lip of the

boot out of its groove in the knuckle

6.5 To detach the brake shield from the

steering knuckle, remove these three

screws (arrowed)6.4 To detach the ABS sensor from the

steering knuckle, remove this bolt

7.4 Remove these three Torx screws

(arrowed) and move the accumulator

assembly to the side a little to provide

clearance for pulling out the pivot bolt7.5 To detach the upper control arm from

the crossmember, remove the nut (at the

rear) and pull the bolt out from the front;

note the fitted order of the spacer washers

3261 Jaguar XJ6

Page 142 of 227

and support it securely on axle stands.

Remove the wheel.

2Refit the special spring compressor tool

(JD115) as shown (see illustrations).

3Tighten the tool until the spacer is tight

against the spring pan, then remove the

spring pan bolts (see illustration).

4Slowly back off the wingnut on the special

tool until all tension is relieved from the spring.

Remove the tool, remove the pan, and remove

the coil spring.

5Refitting is the reverse of removal. Place the

coil spring in position with the spring pan

below it, refit the special tool and carefully

tighten the wingnut until the spring is

compressed enough to allow the pan to be

positioned and bolted to the lower control

arm. Be sure to tighten the pan bolts to the

torque listed in this Chapter’s Specifications.

9 Lower control arm-

removal and refitting

3

Warning: The lower control arms

cannot be removed without a

special spring compressor tool

(Jaguar tool JD115). Do not try to

remove a lower control arm without this

tool, or you could be seriously injured.1Loosen the wheel nuts, raise the vehicle

and support it securely on axle stands.

Remove the wheel.

2Remove the spring pan and the coil spring

(see Section 8).

3Detach the steering gear (see Section 17)

and lower it far enough to provide clearance

for the lower control arm pivot bolt.

4Remove the pivot bolt and nut (see

illustration). Note any washers behind the nut

and store them in a plastic bag.

5Remove the lower control arm.

6Refitting is the reverse of removal. Be sure

to refit any washers removed. Raise the

suspension with the trolley jack to simulate

normal ride height, then tighten the pivot bolt

and nut to the torque listed in this Chapter’s

Specifications. Refer to Section 8 for coil

spring refitting.

10 Shock absorber/coil spring

(rear)- removal and refitting

3

Note 1: Always renew both left and right

shocks at the same time to prevent handling

peculiarities and abnormal ride quality.

Note 2:If you’re replacing the shock absorbers

on an earlier vehicle with the self-levelling

system, we strongly recommend (and so doesJaguar) that you renew the self-levelling units

with conventional units (available at the dealer

as a retrofit kit for older vehicles equipped with

the self-levelling system).

1Loosen the rear wheel nuts. Raise the rear

of the vehicle and support it securely on axle

stands. Remove the rear wheels. Support the

control arm with a trolley jack. Place a block of

wood on the jack head to serve as a cushion.

2If you are removing/replacing the shocks on

a vehicle equipped with the self-levelling rear

suspension system, depressurise the system

by pumping the brake pedal until it feels hard

to push (this dissipates the pressure inside the

accumulator), then locate the hydraulic line

valve block just in front of the upper end of the

left rear shock (see illustration). Attach a

plastic hose to the bleeder screw (see

illustration), put the other end of the hose in a

catch bottle, crack the bleeder and drain off

as much fluid as possible. Disconnect the

hydraulic line that connects the left shock to

the valve block. Now locate the other valve

block just in front of the right rear shock;

disconnect the hydraulic line that connects

the right shock to this valve block too.

3Remove the lower shock absorber-to-

control arm nut and bolt (see illustration).

4Remove the upper mounting bolts (see

illustration)and remove the shock

absorber/coil spring assembly.

10•6 Suspension and steering systems

9.4 To detach the lower control arm from

the crossmember, remove this nut and bolt

(arrowed) (unbolt and lower the steering

gear before you can pull out the pivot bolt)10.2a On a vehicle equipped with self-

levelling rear suspension, the valve block

(arrowed) for the left rear shock is located

just in front of the shock absorber10.2b After depressurising the system,

attach a bleed hose to the bleed screw on

the left valve block, open the bleed and

drain any residual fluid into a catch bottle

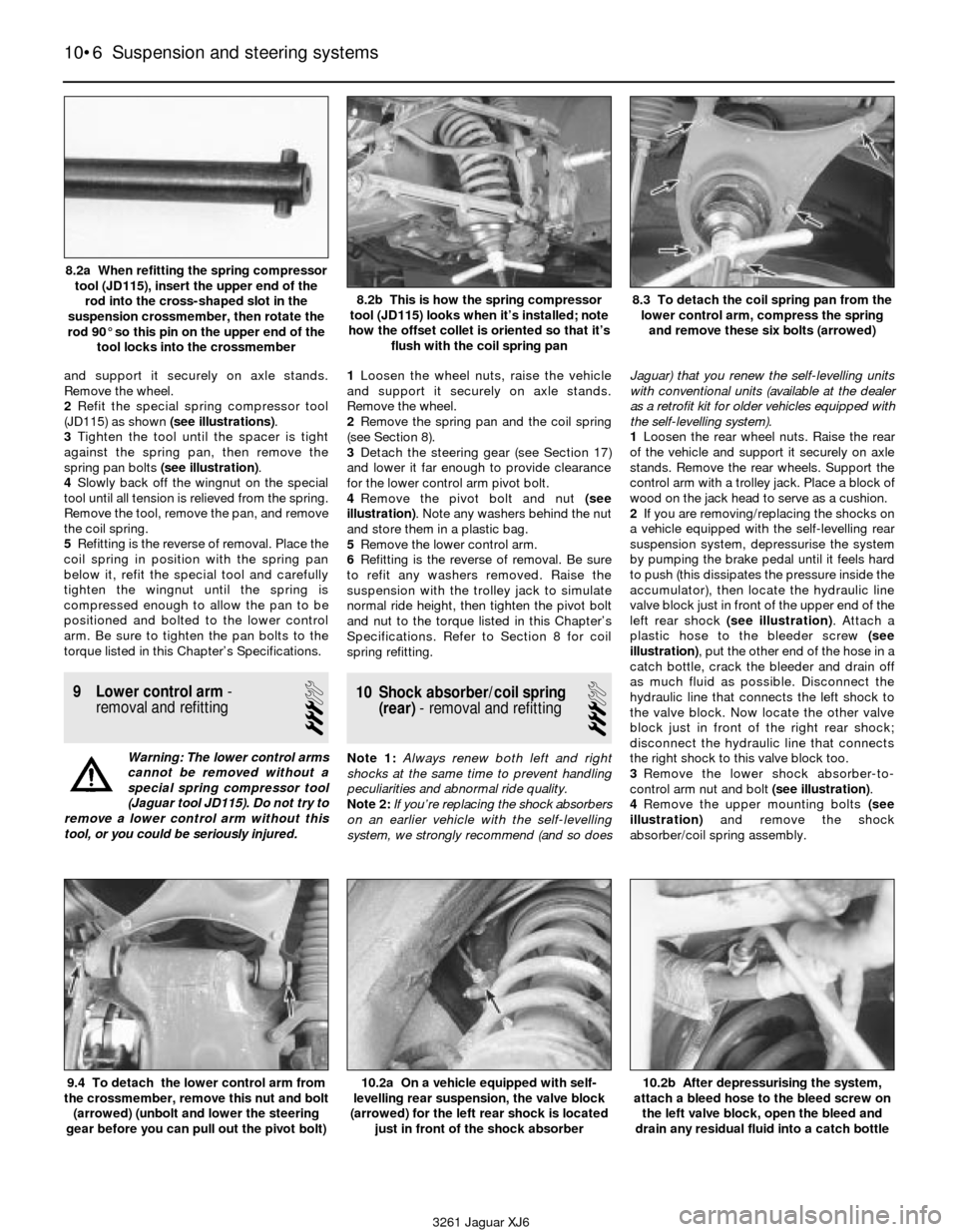

3261 Jaguar XJ6 8.2a When refitting the spring compressor

tool (JD115), insert the upper end of the

rod into the cross-shaped slot in the

suspension crossmember, then rotate the

rod 90° so this pin on the upper end of the

tool locks into the crossmember

8.2b This is how the spring compressor

tool (JD115) looks when it’s installed; note

how the offset collet is oriented so that it’s

flush with the coil spring pan8.3 To detach the coil spring pan from the

lower control arm, compress the spring

and remove these six bolts (arrowed)