front JEEP CHEROKEE 1994 Service Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 199 of 1784

CAUTION: The pedal travel sensor and booster

must form a matched set. The cap on the sensor

plunger and the color dot on the booster shell are

color coded for identification, and to ensure they

are used as matched sets. Be sure the color on the

sensor cap and booster shell are the same before

installation. Refer to the Sensor Replacement infor-

mation before installing a new or original sensor.

(4) If new pedal travel sensor is being installed in

original booster, compare color dot on booster shell with

color of cap on sensor (Fig. 10). If both are same color,

proceed with installation. However, if colorsdo not

match, select correct color cap from kit supplied with

new sensor and install it on end of sensor plunger.

(5) Install O-ring on pedal travel sensor.

(6) Install sensor retaining ring on booster flange.

Be sure retaining ring is firmly seated.

(7) Insert sensor into booster. Be sure sensor is

fully seated and engaged in retaining ring.

(8) Connect booster push rod to brake pedal.

(9) Attach vacuum hose to booster check valve.

(10) Install master cylinder on booster. Tighten

cylinder attaching nuts to 25-30 Nzm (220-267 in.

lbs.) torque.

(11) Connect brakelines to master cylinder.

(12) Install combination valve bracket bolt if re-

moved.

(13) Connect reservoir hoses to HCU pipes.

(14) Connect sensor wires.

(15) Bleed brakes. Refer to procedure in this section.

(16) Install air cleaner and hoses.

ACCELERATION SENSOR REMOVAL

(1) On XJ models, tilt rear seat assembly forward

for access to sensor (Fig. 11).

(2) On YJ models, move driver seat forward or

rearward for access to sensor and mounting bracket

(Fig. 11).

(3) Disconnect sensor harness (Fig. 10).

(4) On XJ models, remove screws attaching sensor

to bracket. Then remove sensor.

(5) On YJ models, remove screws attaching sensor

bracket to floorpan. Then remove sensor from bracket.

ACCELERATION SENSOR INSTALLATION

(1) Note position of locating arrow on sensor. Sen-

sor must be positioned so arrow faces forward.

CAUTION: The sensor mercury switch will not func-

tion properly if the sensor is mispositioned. Verify

that the sensor locating arrow is pointing to the

front of the vehicle.

(2) Position sensor in mounting bracket (Fig. 10).

(3) Install and tighten sensor attaching screws to

2-4 Nzm (17-32 in. lbs.) torque.

(4) Connect harness to sensor. Be sure harness

connecter is firmly seated.

(5) Move seat back to normal position.

Fig. 10 Booster Push Rod And Pedal Travel Sensor

Fig. 11 Acceleration Sensor Mounting

5 - 52 ABS COMPONENT SERVICEJ

Page 203 of 1784

PARKING BRAKES

INDEX

page page

General Service Information................ 56

Parking Brake Adjustment (XJ/YJ)............ 63

Parking Brake Cable Tensioner Replacement (XJ).61

Parking Brake Front Cable Replacement (YJ) . . . 62

Parking Brake Lever Installation

(XJ with Full Console)................... 60

Parking Brake Lever Installation

(XJ with Mini Console)................... 58

Parking Brake Lever Installation

(XJ Without Console).................... 60

Parking Brake Lever Removal

(XJ with Full Console).................... 59

Parking Brake Lever Removal

(XJ with Mini Console)................... 58

Parking Brake Lever Removal (XJ Without Console).60

Parking Brake Operation................... 56

Parking Brake Pedal Installation (YJ).......... 61

Parking Brake Pedal Removal (YJ)........... 61

Parking Brake Rear Cable Replacement (XJ) . . . 62

Parking Brake Rear Cable Replacement (YJ) . . . 63

GENERAL SERVICE INFORMATION

Parking brake adjustment is controlled by a

cable tensioner mechanism. The tensioner mech-

anism is used on 1991 through 1994 YJ models

and XJ models starting with 1992 models. The

cable tensioner, once adjusted at the factory,

will not need further adjustment under normal

circumstances. There are only two instances

when adjustment is required. The first is when a

new tensioner, or cables have been installed.

And the second, is when the tensioner and ca-

bles are disconnected for access to other brake

components.

PARKING BRAKE OPERATION

The rear brakes are utilized for the parking brake

function. They are actuated hydraulically during nor-

mal brake operation but are mechanically actuated

for parking brake operation.

Parking Brake Components

The rear brakeshoes are applied by a system of le-

vers and cables for parking brake operation. A foot

or hand operated lever in the passenger compartment

is the main application device. Actuating levers on

the secondary brakeshoes move the shoes directly

into contact with the drum braking surface. The ac-

tuating levers are interconnected by a system of ca-

bles and a tensioner mechanism. The tensioner

mechanism controls parking brake adjustment.

On XJ models, the cable tensioner is part of the le-

ver assembly. On YJ models, the tensioner and

equalizer are mounted in a bracket attached to the

underbody.

On YJ models, the parking brake front cable is at-

tached to the foot pedal at one end and the cable ten-

sioner at the other. The tensioner is connected to the

equalizer which is the connecting device for the rear

cables (Fig. 1).

On XJ models, the cable tensioner is connected di-rectly to the hand lever (a front cable is not used).

The tensioner rod is attached to the equalizer which

is the connecting point for the rear cables (Fig. 2).

The rear cables are connected to the actuating le-

ver on each secondary brakeshoe. The levers are at-

tached to the brakeshoes by a pin either pressed into,

or welded to the lever. A clip is used to secure the

pin in the brakeshoe. The pin allows each lever to

pivot independently of the brakeshoe.

Struts, installed between each brakeshoe, are used

to maintain shoe alignment and equal motion when

the parking brakes are applied. Each strut is

equipped with a combination tension and anti-rattle

spring.

Parking Brake Application

To apply the parking brakes, the foot pedal is

pressed downward, or the hand lever is pulled up-

ward, to an engaged position. This pulls the rear

brakeshoe actuating levers forward, by means of the

interconnected tensioner and cables.

As the actuating lever is pulled forward, the park-

ing brake strut (which is connected to both shoes),

exerts a linear force against the primary brakeshoe.

This action presses the primary shoe into contact

with the drum.

Once the primary shoe contacts the brake drum,

force exerted through the strut does not end. Instead,

further lever movement continues to exert force

against the strut; only this time, in a reverse direc-

tion. The strut force then causes the secondary shoe

to pivot into contact with the drum as well.

The brakeshoes will remain engaged with the

drum until the levers and cables are released. A gear

type ratcheting mechanism is used to hold the pedal

or lever in an applied position. Parking brake release

is accomplished by means of the release handle on

YJ models. Or by the hand lever release button on

XJ models.

5 - 56 PARKING BRAKESJ

Page 208 of 1784

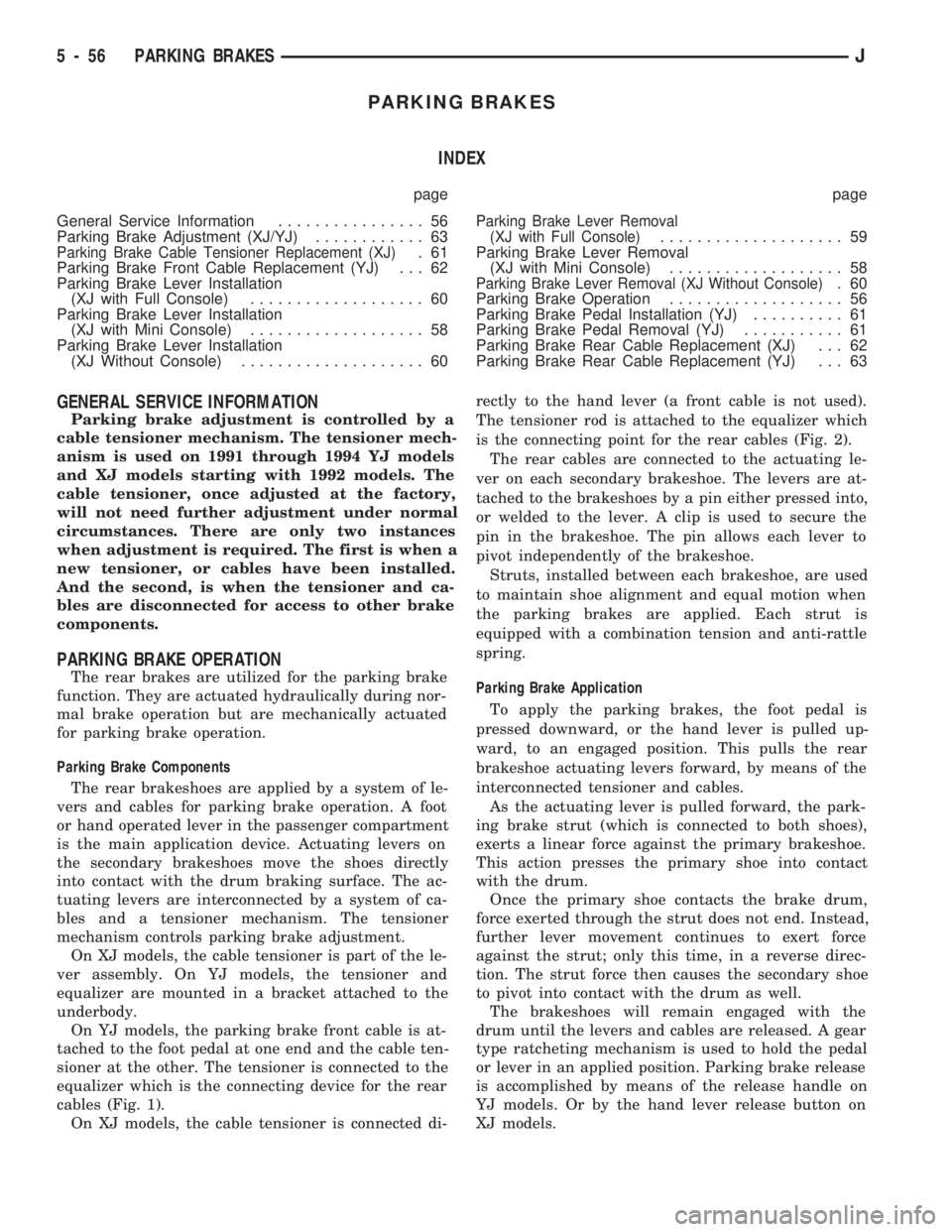

(5) Install lever cover. Secure cover with new riv-

ets, or original attaching screws.

(6) Raise vehicle.

(7) Connect tensioner to lever with retaining pin

and E-clip.

(8) Install nuts attaching lever support plate to le-

ver screws.

(9) Adjust parking brakes. Refer to procedure in

this section.

PARKING BRAKE CABLE TENSIONER

REPLACEMENT (XJ)

(1) Raise vehicle.

(2) Remove adjuster nut from tensioner rod. Secure

equalizer and cables to nearby chassis component

with wire.

(3) Remove nuts attaching lever assembly to sup-

port plate and floorpan.

(4) Lower vehicle.

(5) Remove console components and lever assembly

cover.

(6) Remove lever and tensioner assembly.

(7) Move cover and boot for access to tensioner re-

taining pin.

(8) Remove E-clip and pin that attach tensioner to

lever arm (Fig. 3).

(9) Remove tensioner from cover.

(10) Transfer boot to new tensioner if necessary.

(11) Attach tensioner to lever arm with pin and

E-clip.

(12) Verify that E-clip is fully engaged in pin (Fig.

3).(13) Align cover and seal on lever flange.

(14) Verify that tensioner boot is seated in cover

(Fig. 5).

(15) Install assembled lever and tensioner in floor-

pan.

(16) Install necessary console components.

(17) Adjust parking brakes as described in this sec-

tion.

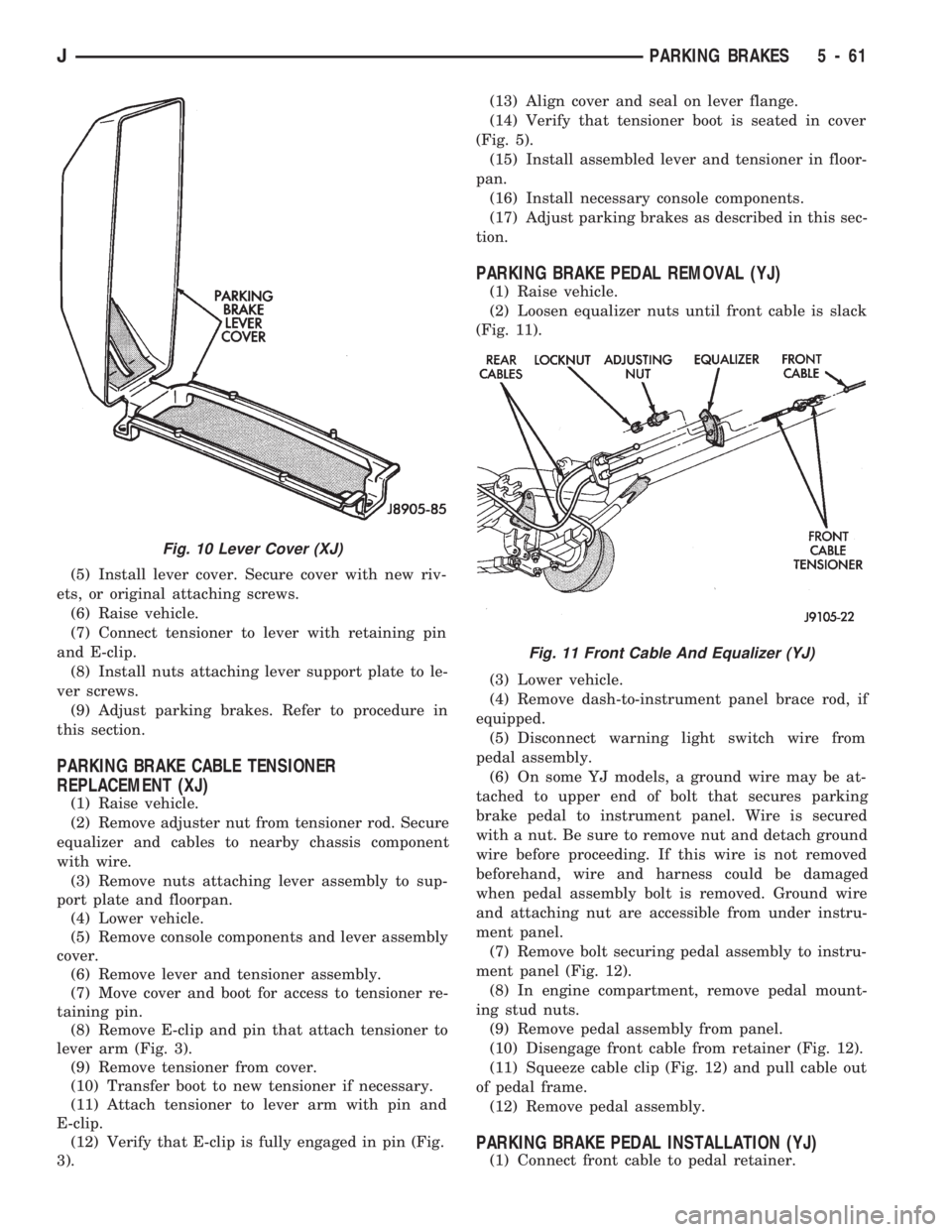

PARKING BRAKE PEDAL REMOVAL (YJ)

(1) Raise vehicle.

(2) Loosen equalizer nuts until front cable is slack

(Fig. 11).

(3) Lower vehicle.

(4) Remove dash-to-instrument panel brace rod, if

equipped.

(5) Disconnect warning light switch wire from

pedal assembly.

(6) On some YJ models, a ground wire may be at-

tached to upper end of bolt that secures parking

brake pedal to instrument panel. Wire is secured

with a nut. Be sure to remove nut and detach ground

wire before proceeding. If this wire is not removed

beforehand, wire and harness could be damaged

when pedal assembly bolt is removed. Ground wire

and attaching nut are accessible from under instru-

ment panel.

(7) Remove bolt securing pedal assembly to instru-

ment panel (Fig. 12).

(8) In engine compartment, remove pedal mount-

ing stud nuts.

(9) Remove pedal assembly from panel.

(10) Disengage front cable from retainer (Fig. 12).

(11) Squeeze cable clip (Fig. 12) and pull cable out

of pedal frame.

(12) Remove pedal assembly.

PARKING BRAKE PEDAL INSTALLATION (YJ)

(1) Connect front cable to pedal retainer.

Fig. 10 Lever Cover (XJ)

Fig. 11 Front Cable And Equalizer (YJ)

JPARKING BRAKES 5 - 61

Page 209 of 1784

(2) Position pedal assembly on panel and install

mounting stud nuts and pedal-to-dash bolt.

(3) Install ground wire on upper end of pedal-to-

dash bolt and secure wire with attaching nut.

(4) Connect warning light switch wire to pedal

connector.

(5) Install dash-to-instrument panel brace rod, if

equipped.

(6) Raise vehicle and adjust brake cables. Refer to

procedure in Service Adjustment section.

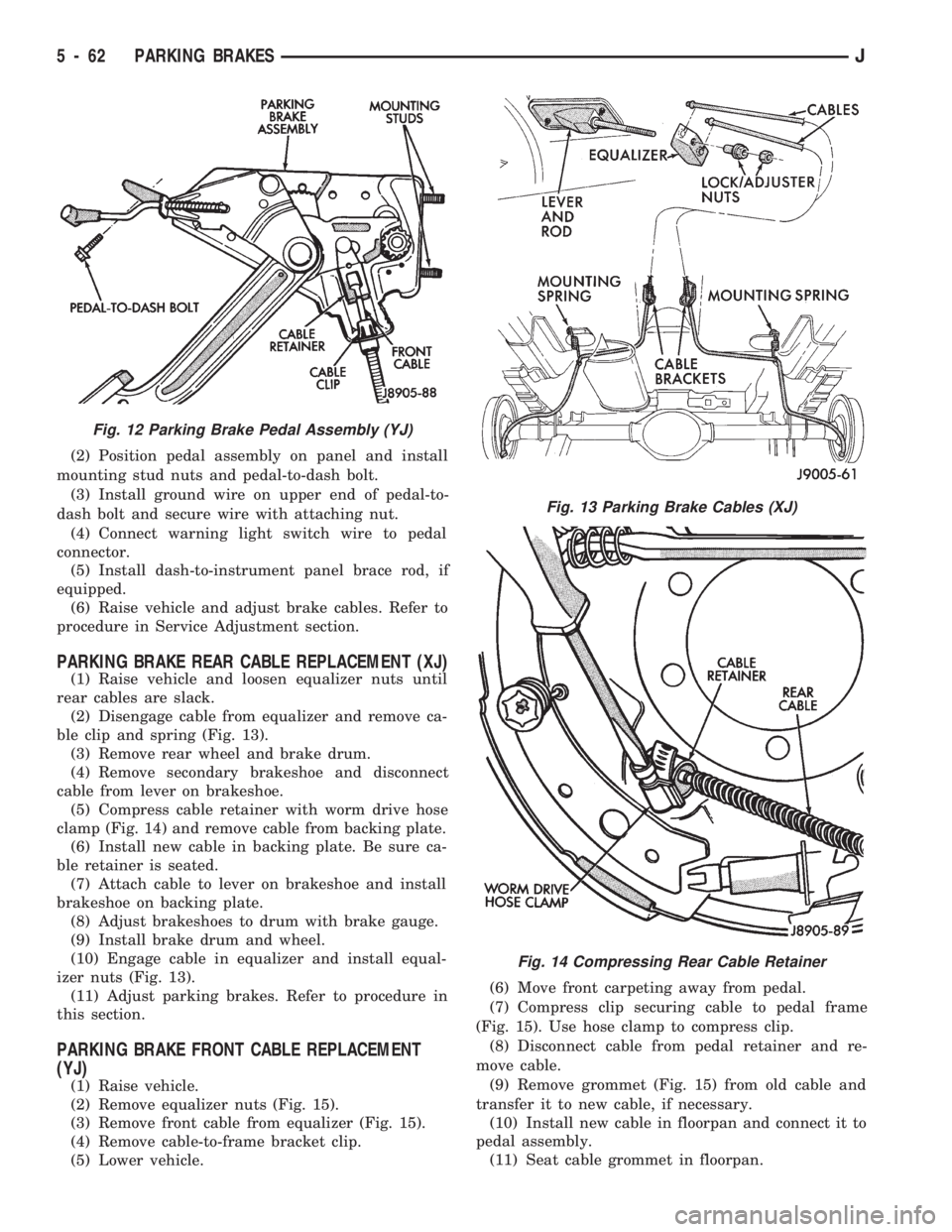

PARKING BRAKE REAR CABLE REPLACEMENT (XJ)

(1) Raise vehicle and loosen equalizer nuts until

rear cables are slack.

(2) Disengage cable from equalizer and remove ca-

ble clip and spring (Fig. 13).

(3) Remove rear wheel and brake drum.

(4) Remove secondary brakeshoe and disconnect

cable from lever on brakeshoe.

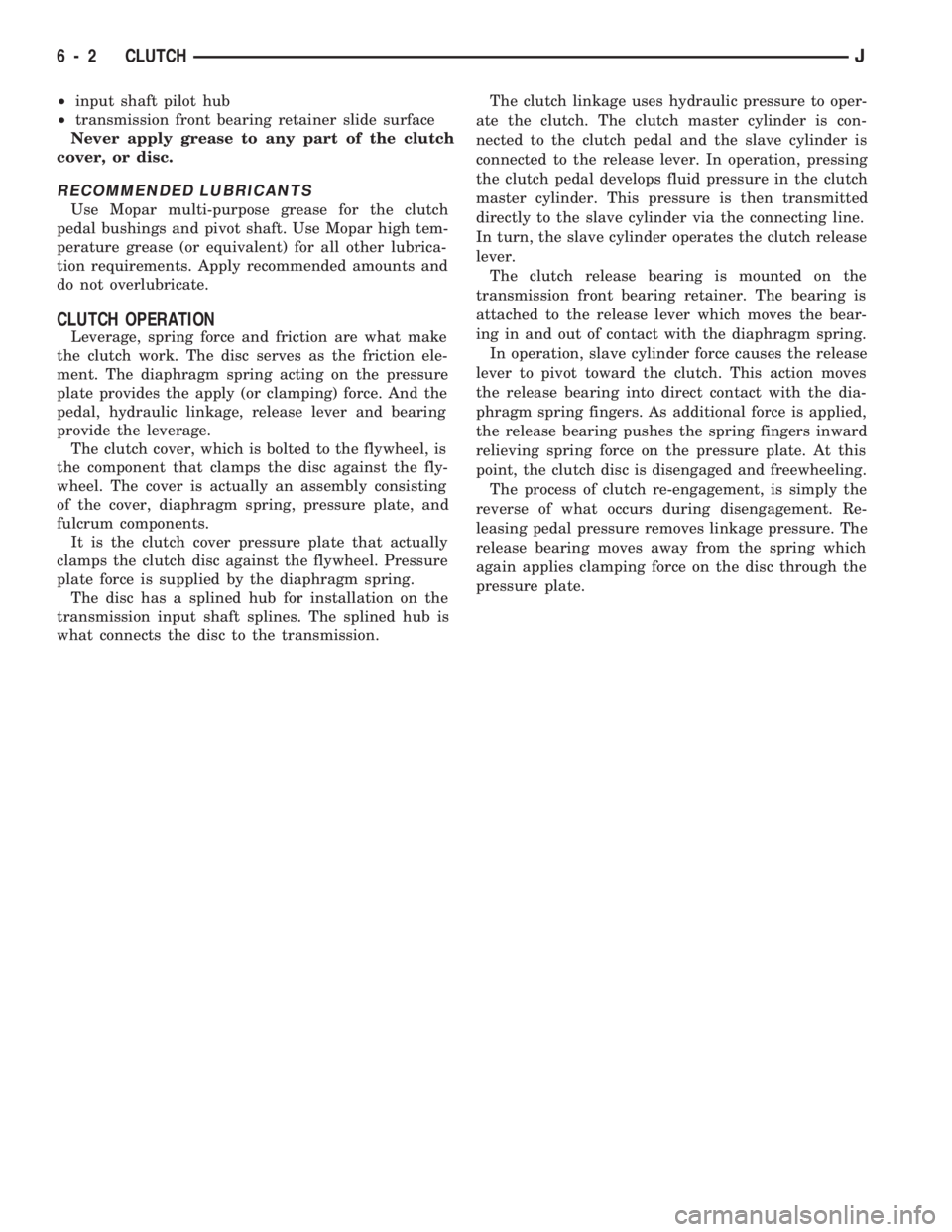

(5) Compress cable retainer with worm drive hose

clamp (Fig. 14) and remove cable from backing plate.

(6) Install new cable in backing plate. Be sure ca-

ble retainer is seated.

(7) Attach cable to lever on brakeshoe and install

brakeshoe on backing plate.

(8) Adjust brakeshoes to drum with brake gauge.

(9) Install brake drum and wheel.

(10) Engage cable in equalizer and install equal-

izer nuts (Fig. 13).

(11) Adjust parking brakes. Refer to procedure in

this section.

PARKING BRAKE FRONT CABLE REPLACEMENT

(YJ)

(1) Raise vehicle.

(2) Remove equalizer nuts (Fig. 15).

(3) Remove front cable from equalizer (Fig. 15).

(4) Remove cable-to-frame bracket clip.

(5) Lower vehicle.(6) Move front carpeting away from pedal.

(7) Compress clip securing cable to pedal frame

(Fig. 15). Use hose clamp to compress clip.

(8) Disconnect cable from pedal retainer and re-

move cable.

(9) Remove grommet (Fig. 15) from old cable and

transfer it to new cable, if necessary.

(10) Install new cable in floorpan and connect it to

pedal assembly.

(11) Seat cable grommet in floorpan.

Fig. 12 Parking Brake Pedal Assembly (YJ)

Fig. 13 Parking Brake Cables (XJ)

Fig. 14 Compressing Rear Cable Retainer

5 - 62 PARKING BRAKESJ

Page 217 of 1784

²input shaft pilot hub

²transmission front bearing retainer slide surface

Never apply grease to any part of the clutch

cover, or disc.

RECOMMENDED LUBRICANTS

Use Mopar multi-purpose grease for the clutch

pedal bushings and pivot shaft. Use Mopar high tem-

perature grease (or equivalent) for all other lubrica-

tion requirements. Apply recommended amounts and

do not overlubricate.

CLUTCH OPERATION

Leverage, spring force and friction are what make

the clutch work. The disc serves as the friction ele-

ment. The diaphragm spring acting on the pressure

plate provides the apply (or clamping) force. And the

pedal, hydraulic linkage, release lever and bearing

provide the leverage.

The clutch cover, which is bolted to the flywheel, is

the component that clamps the disc against the fly-

wheel. The cover is actually an assembly consisting

of the cover, diaphragm spring, pressure plate, and

fulcrum components.

It is the clutch cover pressure plate that actually

clamps the clutch disc against the flywheel. Pressure

plate force is supplied by the diaphragm spring.

The disc has a splined hub for installation on the

transmission input shaft splines. The splined hub is

what connects the disc to the transmission.The clutch linkage uses hydraulic pressure to oper-

ate the clutch. The clutch master cylinder is con-

nected to the clutch pedal and the slave cylinder is

connected to the release lever. In operation, pressing

the clutch pedal develops fluid pressure in the clutch

master cylinder. This pressure is then transmitted

directly to the slave cylinder via the connecting line.

In turn, the slave cylinder operates the clutch release

lever.

The clutch release bearing is mounted on the

transmission front bearing retainer. The bearing is

attached to the release lever which moves the bear-

ing in and out of contact with the diaphragm spring.

In operation, slave cylinder force causes the release

lever to pivot toward the clutch. This action moves

the release bearing into direct contact with the dia-

phragm spring fingers. As additional force is applied,

the release bearing pushes the spring fingers inward

relieving spring force on the pressure plate. At this

point, the clutch disc is disengaged and freewheeling.

The process of clutch re-engagement, is simply the

reverse of what occurs during disengagement. Re-

leasing pedal pressure removes linkage pressure. The

release bearing moves away from the spring which

again applies clamping force on the disc through the

pressure plate.

6 - 2 CLUTCHJ

Page 226 of 1784

RELEASE BEARING REPLACEMENT

(1) Remove transmission as described in Group 21.

(2) Disconnect release bearing from release lever

and remove bearing (Fig. 5).

(3) Inspect bearing slide surface of transmission

front bearing retainer. Replace retainer if slide sur-

face is scored, worn, or cracked.

(4) Inspect release fork and fork pivot. Be sure

pivot is secure and in good condition. Be sure fork is

not distorted or worn. Replace release fork retainer

spring if bent or damaged in any way.

(5) Lubricate crankshaft pilot bearing with Mopar

high temperature bearing grease. Apply grease to

end of long shank, small diameter flat blade screw-

driver. Then insert tool through clutch disc hub to

reach bearing.

(6) Lubricate input shaft splines, bearing retainer

slide surface, fork pivot and release fork pivot sur-face with Mopar high temperature grease.

(7) Install new release bearing. Be sure bearing is

properly secured to release fork.

(8) Install transmission as described in Group 21.

PILOT BEARING REPLACEMENT

(1) Remove transmission. Refer to Group 21 for

procedure.

(2) Remove clutch cover and disc.

(3) Remove pilot bearing. Use internal (blind hole)

puller such those as supplied in Snap On Tool Set

CG40CB to remove bearing.

(4) Lubricate new bearing with Mopar high tem-

perature bearing grease.

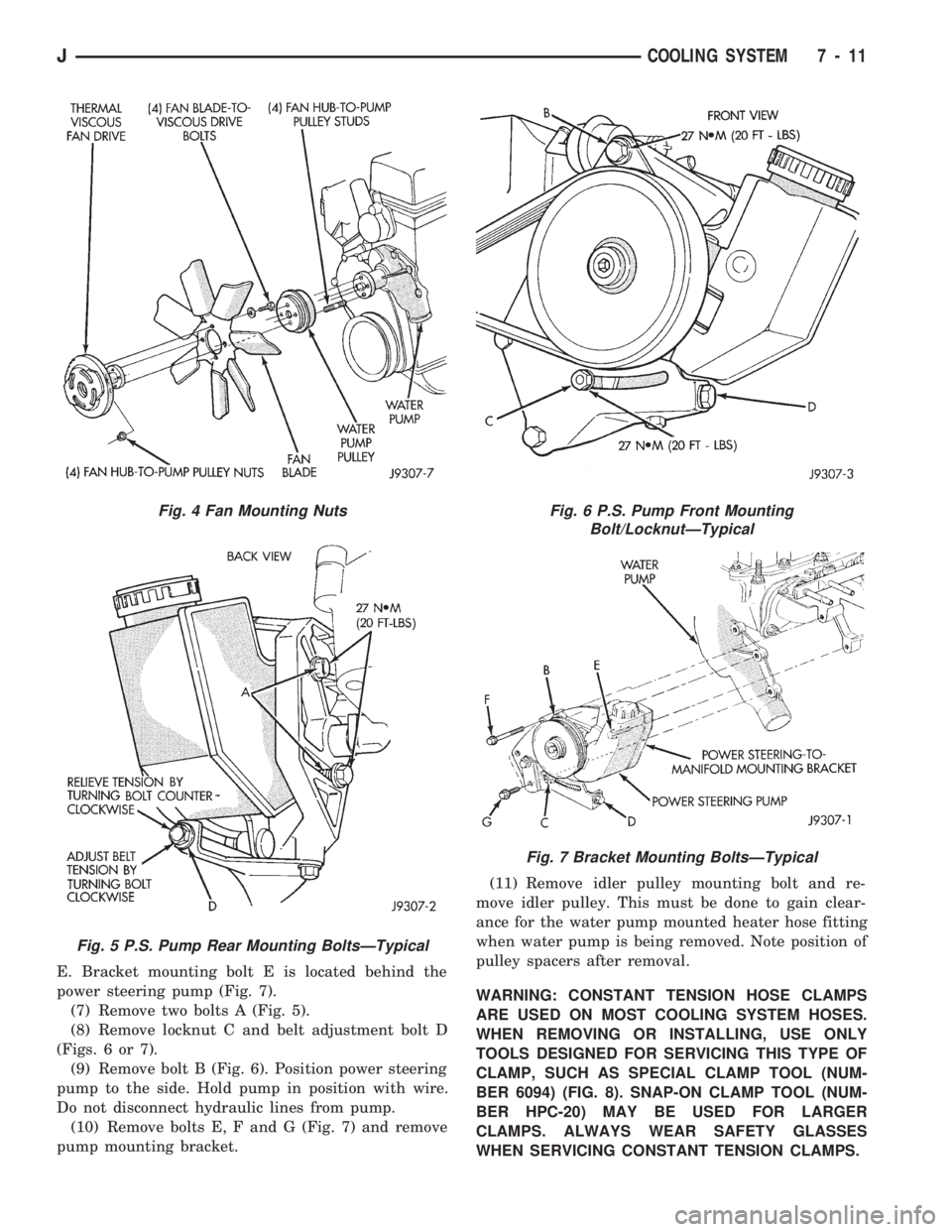

(5) Start new bearing into crankshaft by hand.

Then seat bearing with clutch alignment tool (Fig.

6).

(6) Lightly scuff sand flywheel surface with 180

grit emery cloth. Then clean surface with wax and

grease remover.

(7) Install clutch disc and cover as described in

this section.

(8) Install transmission. Refer to Group 21 for pro-

cedure.

CLUTCH HOUSING REPLACEMENT

The AX 15 clutch housing is removable and can be

replaced when the transmission is out of the vehicle.

The bolts attaching the housing to the transmis-

sion case are located inside the housing (Fig. 7). Rec-

ommended tightening torque for the clutch housing-

to-transmission bolts is 38 Nzm (28 ft. lbs.).

Be sure the transmission and housing mating

surfaces are clean before installing an original,

or replacement clutch housing. Dirt/foreign ma-

terial trapped between the housing and trans-

mission will cause misalignment. If

misalignment is severe enough, the result will be

clutch drag, incomplete release and hard shift-

ing.

CLUTCH HYDRAULIC LINKAGE REMOVAL

The clutch master cylinder, slave cylinder and

connecting line are serviced as an assembly

only. The linkage components cannot be over-

hauled or serviced separately. The cylinders and

connecting line are sealed units. Also note that

removal/installation procedures for right and

left hand drive models are basically the same.

Only master cylinder location is different.

(1) Raise vehicle.

(2) Remove fasteners attaching slave cylinder to

clutch housing.

(3) Remove slave cylinder from clutch housing

(Fig. 8).

(4) Disengage clutch fluid line from body clips.

(5) Lower vehicle.

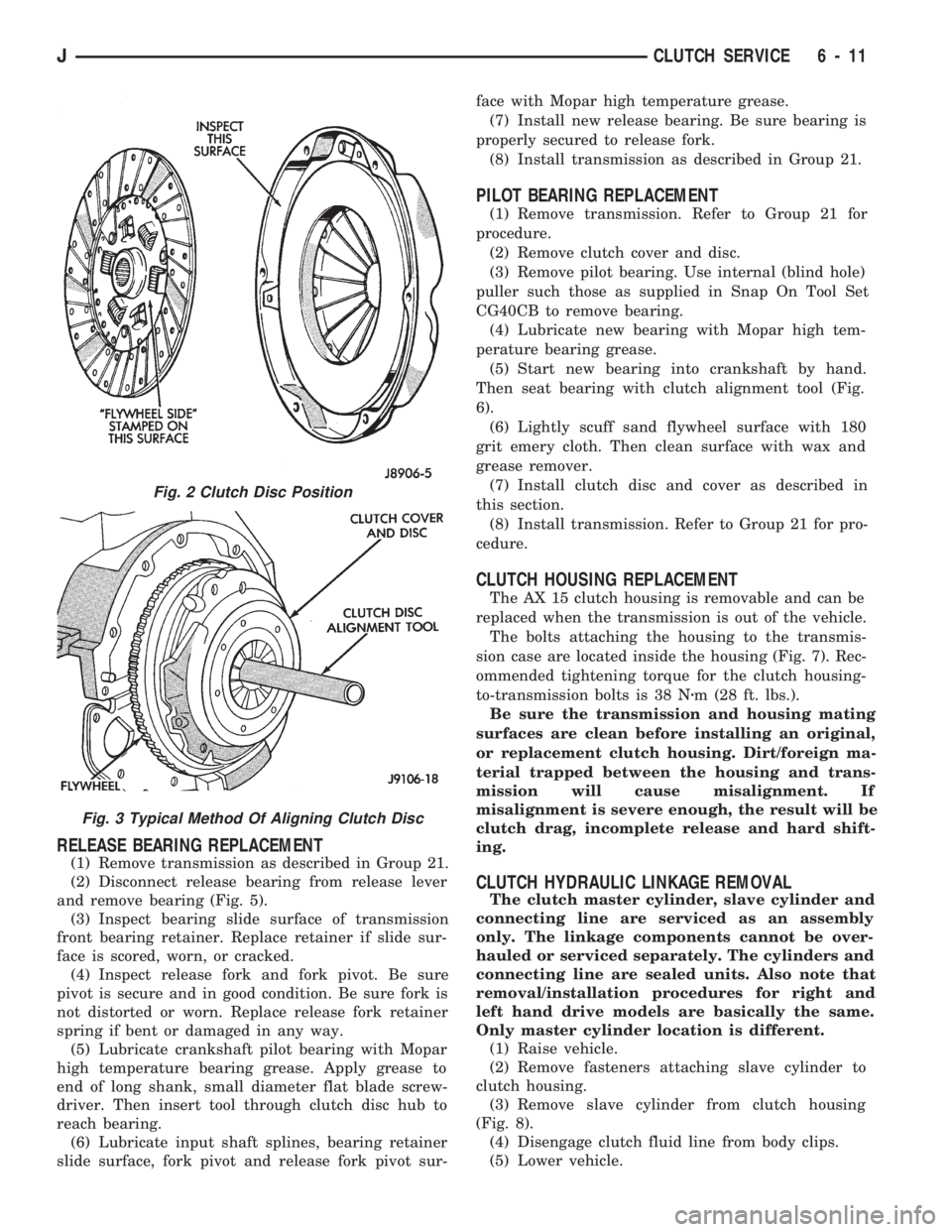

Fig. 2 Clutch Disc Position

Fig. 3 Typical Method Of Aligning Clutch Disc

JCLUTCH SERVICE 6 - 11

Page 244 of 1784

E. Bracket mounting bolt E is located behind the

power steering pump (Fig. 7).

(7) Remove two bolts A (Fig. 5).

(8) Remove locknut C and belt adjustment bolt D

(Figs. 6 or 7).

(9) Remove bolt B (Fig. 6). Position power steering

pump to the side. Hold pump in position with wire.

Do not disconnect hydraulic lines from pump.

(10) Remove bolts E, F and G (Fig. 7) and remove

pump mounting bracket.(11) Remove idler pulley mounting bolt and re-

move idler pulley. This must be done to gain clear-

ance for the water pump mounted heater hose fitting

when water pump is being removed. Note position of

pulley spacers after removal.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUM-

BER 6094) (FIG. 8). SNAP-ON CLAMP TOOL (NUM-

BER HPC-20) MAY BE USED FOR LARGER

CLAMPS. ALWAYS WEAR SAFETY GLASSES

WHEN SERVICING CONSTANT TENSION CLAMPS.

Fig. 4 Fan Mounting Nuts

Fig. 5 P.S. Pump Rear Mounting BoltsÐTypical

Fig. 6 P.S. Pump Front Mounting

Bolt/LocknutÐTypical

Fig. 7 Bracket Mounting BoltsÐTypical

JCOOLING SYSTEM 7 - 11

Page 246 of 1784

(14) Tighten pivot bolt B (Fig. 6) to 27 Nzm (20 ft.

lbs.) torque.

(15) Tighten locknut C (Fig. 6) to 27 Nzm (20 ft.

lbs.) torque.

(16) After the power steering pump has been tight-

ened, recheck belt tension.

(17) Fill cooling system with coolant and check for

leaks. Refer to Refilling Cooling System in this

group.

(18) Connect battery cable to battery.

(19) Start and warm the engine. Check for leaks.

THERMOSTAT

DESCRIPTION AND OPERATION

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator. On all engines the

thermostat is closed below 195ÉF (90ÉC). Above this

temperature, coolant is allowed to flow to the radia-

tor. This provides quick engine warmup and overall

temperature control.

An arrow plus the wordUPis stamped on the

front flange next to the air bleed. The wordsTO

RADare stamped on one arm of the thermostat.

They indicate the proper installed position.

The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes other prob-

lems. These are: longer engine warmup time, unreli-

able warmup performance, increased exhaust

emissions and crankcase condensation. This conden-

sation can result in sludge formation.

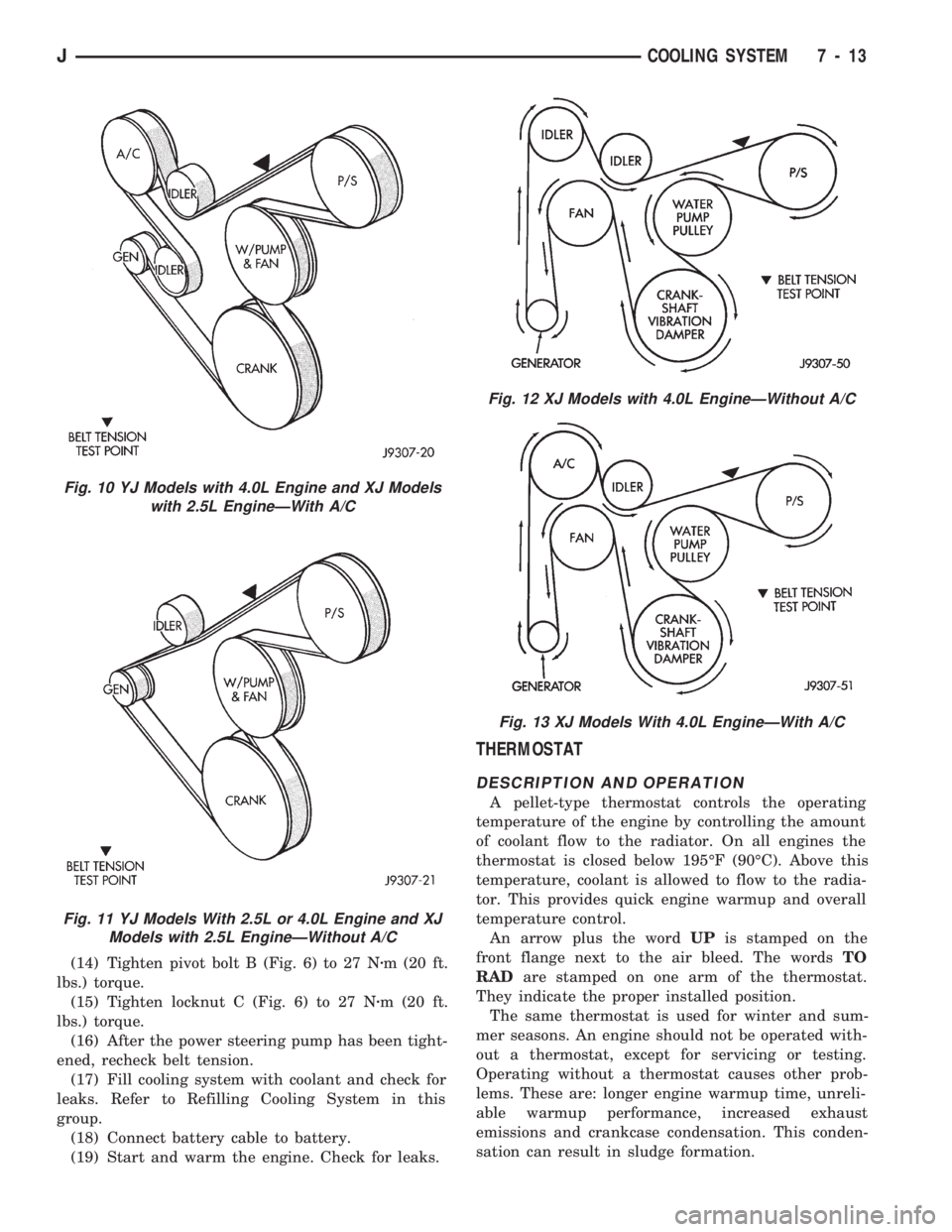

Fig. 10 YJ Models with 4.0L Engine and XJ Models

with 2.5L EngineÐWith A/C

Fig. 11 YJ Models With 2.5L or 4.0L Engine and XJ

Models with 2.5L EngineÐWithout A/C

Fig. 12 XJ Models with 4.0L EngineÐWithout A/C

Fig. 13 XJ Models With 4.0L EngineÐWith A/C

JCOOLING SYSTEM 7 - 13

Page 255 of 1784

RADIATORS

GENERAL INFORMATION

All radiators are down flow types except XJ models

with 4.0L engines. Radiators in XJ models equipped

with the 4.0L six-cylinder engine, are the cross flow

type. Plastic tanks are used on all radiators.

CAUTION: Plastic tanks, while stronger than brass,

are subject to damage by impact, such as

wrenches.

If plastic tank has been damaged, plastic tank

and/or O-rings are available for service repair. Tank

replacement should be done by qualified personal

with proper equipment.

RADIATOR COOLANT FLOW CHECK

The following procedure will determine if coolant is

flowing through the cooling system.

If engine is cold, idle engine until normal operating

temperature is reached. Then feel the upper radiator

hose. If hose is hot, the thermostat is open and water

is circulating through cooling system.

RADIATOR REMOVAL/INSTALLATION

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS, RADIATOR CAP, OR

LOOSEN THE RADIATOR DRAINCOCK WITH THE

SYSTEM HOT AND PRESSURIZED. SERIOUS

BURNS FROM THE COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUM-

BER 6094) (FIG. 26). SNAP-ON CLAMP TOOL (NUM-

BER HPC-20) MAY BE USED FOR LARGER

CLAMPS. ALWAYS WEAR SAFETY GLASSES

WHEN SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with matching number or letter.

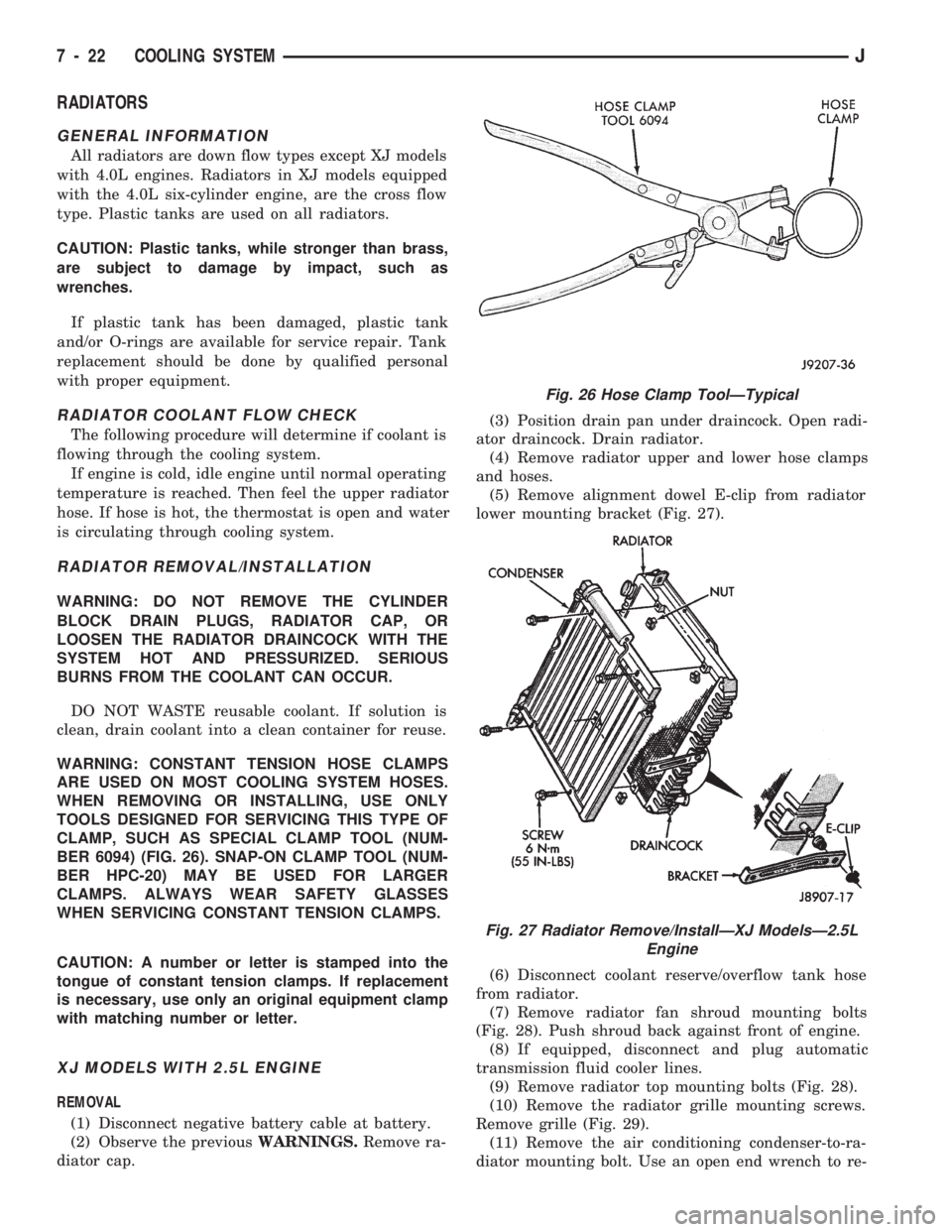

XJ MODELS WITH 2.5L ENGINE

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Observe the previousWARNINGS.Remove ra-

diator cap.(3) Position drain pan under draincock. Open radi-

ator draincock. Drain radiator.

(4) Remove radiator upper and lower hose clamps

and hoses.

(5) Remove alignment dowel E-clip from radiator

lower mounting bracket (Fig. 27).

(6) Disconnect coolant reserve/overflow tank hose

from radiator.

(7) Remove radiator fan shroud mounting bolts

(Fig. 28). Push shroud back against front of engine.

(8) If equipped, disconnect and plug automatic

transmission fluid cooler lines.

(9) Remove radiator top mounting bolts (Fig. 28).

(10) Remove the radiator grille mounting screws.

Remove grille (Fig. 29).

(11) Remove the air conditioning condenser-to-ra-

diator mounting bolt. Use an open end wrench to re-

Fig. 26 Hose Clamp ToolÐTypical

Fig. 27 Radiator Remove/InstallÐXJ ModelsÐ2.5L

Engine

7 - 22 COOLING SYSTEMJ

Page 260 of 1784

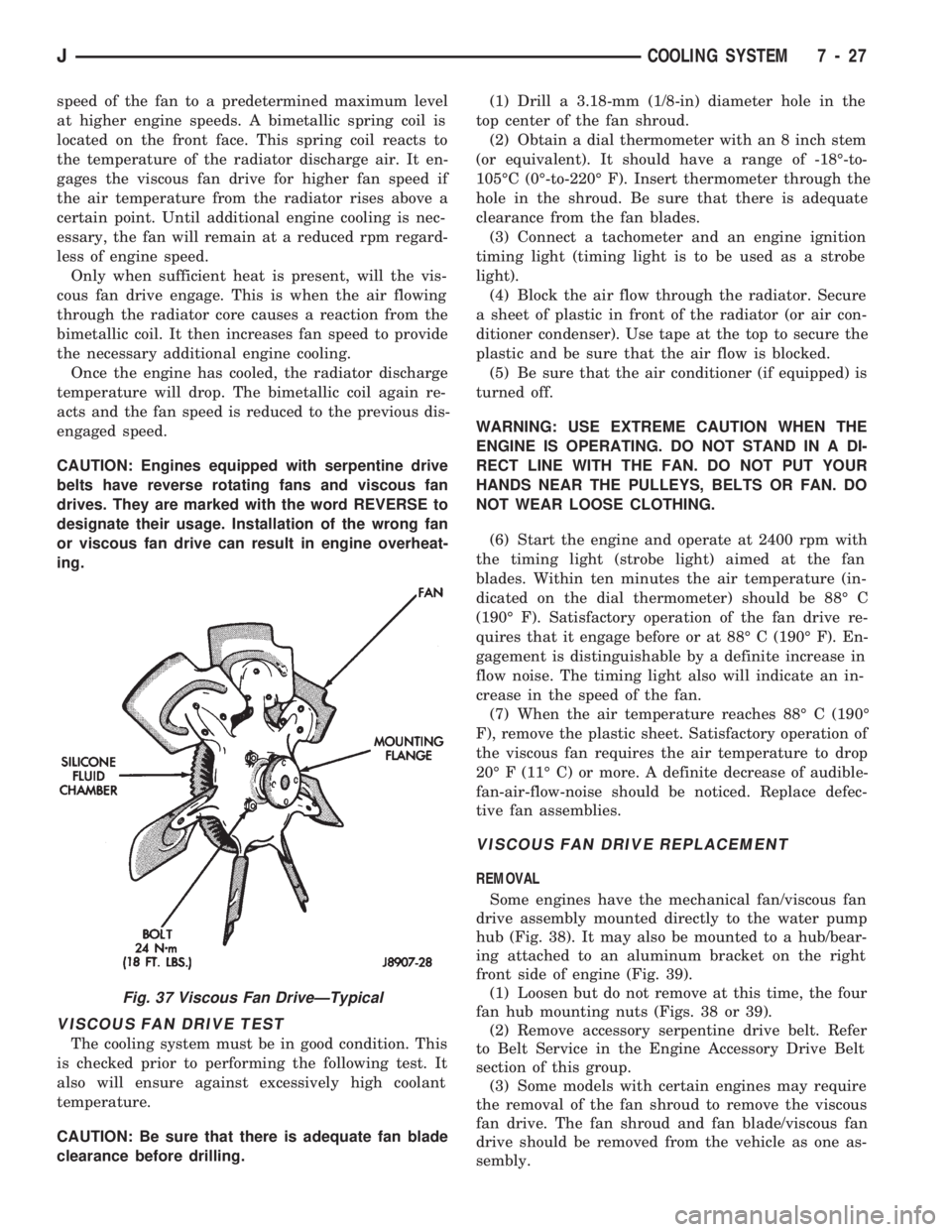

speed of the fan to a predetermined maximum level

at higher engine speeds. A bimetallic spring coil is

located on the front face. This spring coil reacts to

the temperature of the radiator discharge air. It en-

gages the viscous fan drive for higher fan speed if

the air temperature from the radiator rises above a

certain point. Until additional engine cooling is nec-

essary, the fan will remain at a reduced rpm regard-

less of engine speed.

Only when sufficient heat is present, will the vis-

cous fan drive engage. This is when the air flowing

through the radiator core causes a reaction from the

bimetallic coil. It then increases fan speed to provide

the necessary additional engine cooling.

Once the engine has cooled, the radiator discharge

temperature will drop. The bimetallic coil again re-

acts and the fan speed is reduced to the previous dis-

engaged speed.

CAUTION: Engines equipped with serpentine drive

belts have reverse rotating fans and viscous fan

drives. They are marked with the word REVERSE to

designate their usage. Installation of the wrong fan

or viscous fan drive can result in engine overheat-

ing.

VISCOUS FAN DRIVE TEST

The cooling system must be in good condition. This

is checked prior to performing the following test. It

also will ensure against excessively high coolant

temperature.

CAUTION: Be sure that there is adequate fan blade

clearance before drilling.(1) Drill a 3.18-mm (1/8-in) diameter hole in the

top center of the fan shroud.

(2) Obtain a dial thermometer with an 8 inch stem

(or equivalent). It should have a range of -18É-to-

105ÉC (0É-to-220É F). Insert thermometer through the

hole in the shroud. Be sure that there is adequate

clearance from the fan blades.

(3) Connect a tachometer and an engine ignition

timing light (timing light is to be used as a strobe

light).

(4) Block the air flow through the radiator. Secure

a sheet of plastic in front of the radiator (or air con-

ditioner condenser). Use tape at the top to secure the

plastic and be sure that the air flow is blocked.

(5) Be sure that the air conditioner (if equipped) is

turned off.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A DI-

RECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(6) Start the engine and operate at 2400 rpm with

the timing light (strobe light) aimed at the fan

blades. Within ten minutes the air temperature (in-

dicated on the dial thermometer) should be 88É C

(190É F). Satisfactory operation of the fan drive re-

quires that it engage before or at 88É C (190É F). En-

gagement is distinguishable by a definite increase in

flow noise. The timing light also will indicate an in-

crease in the speed of the fan.

(7) When the air temperature reaches 88É C (190É

F), remove the plastic sheet. Satisfactory operation of

the viscous fan requires the air temperature to drop

20É F (11É C) or more. A definite decrease of audible-

fan-air-flow-noise should be noticed. Replace defec-

tive fan assemblies.

VISCOUS FAN DRIVE REPLACEMENT

REMOVAL

Some engines have the mechanical fan/viscous fan

drive assembly mounted directly to the water pump

hub (Fig. 38). It may also be mounted to a hub/bear-

ing attached to an aluminum bracket on the right

front side of engine (Fig. 39).

(1) Loosen but do not remove at this time, the four

fan hub mounting nuts (Figs. 38 or 39).

(2) Remove accessory serpentine drive belt. Refer

to Belt Service in the Engine Accessory Drive Belt

section of this group.

(3) Some models with certain engines may require

the removal of the fan shroud to remove the viscous

fan drive. The fan shroud and fan blade/viscous fan

drive should be removed from the vehicle as one as-

sembly.

Fig. 37 Viscous Fan DriveÐTypical

JCOOLING SYSTEM 7 - 27