JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1301 of 1784

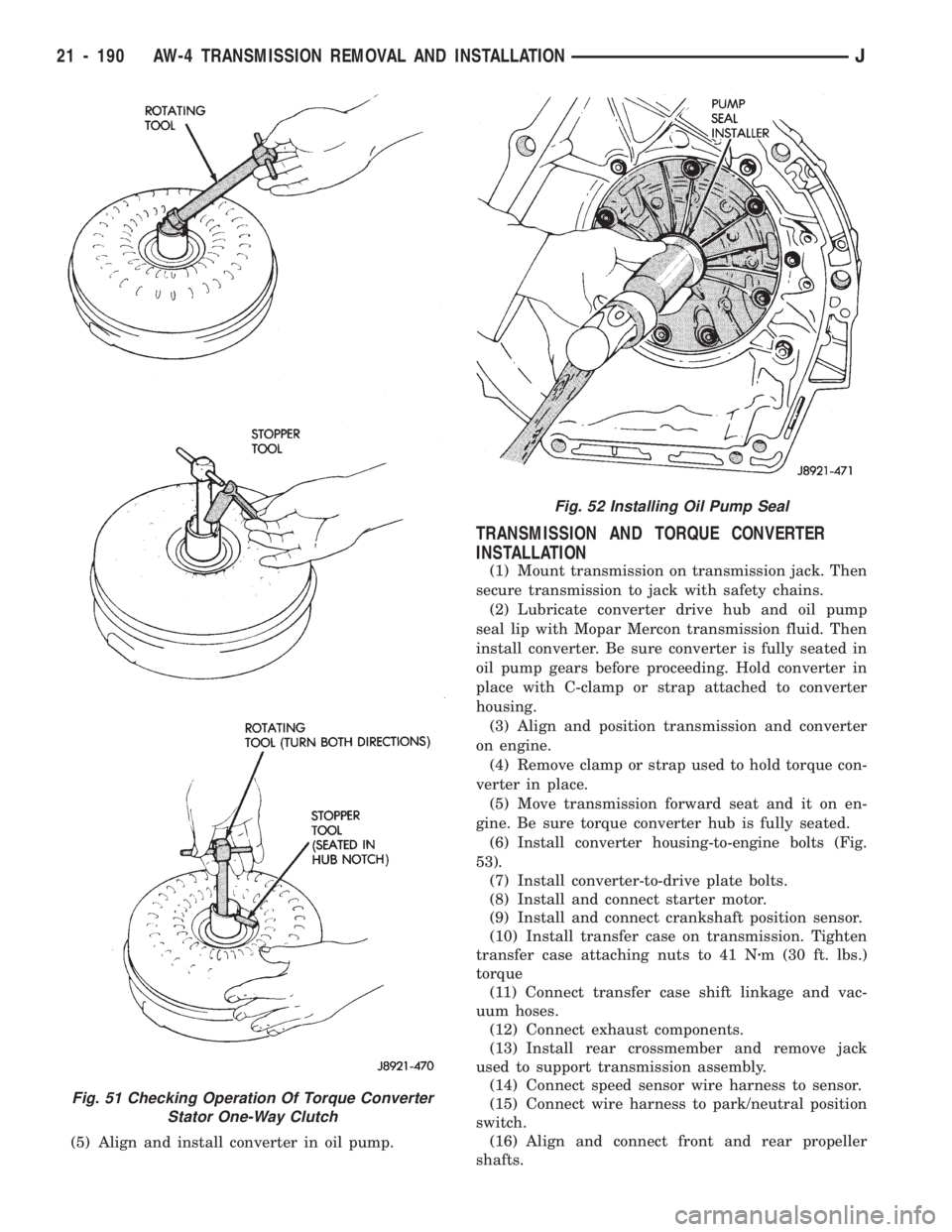

(5) Align and install converter in oil pump.

TRANSMISSION AND TORQUE CONVERTER

INSTALLATION

(1) Mount transmission on transmission jack. Then

secure transmission to jack with safety chains.

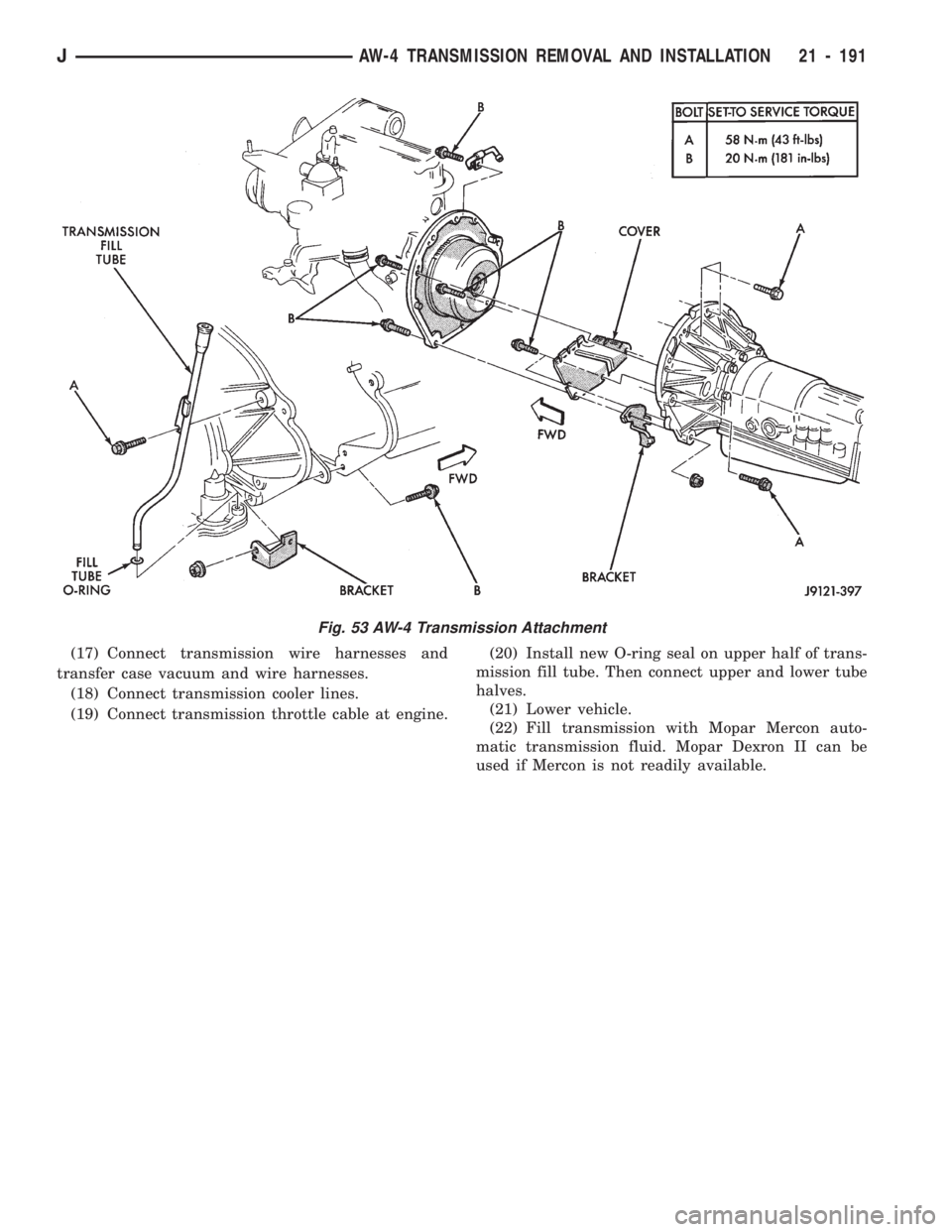

(2) Lubricate converter drive hub and oil pump

seal lip with Mopar Mercon transmission fluid. Then

install converter. Be sure converter is fully seated in

oil pump gears before proceeding. Hold converter in

place with C-clamp or strap attached to converter

housing.

(3) Align and position transmission and converter

on engine.

(4) Remove clamp or strap used to hold torque con-

verter in place.

(5) Move transmission forward seat and it on en-

gine. Be sure torque converter hub is fully seated.

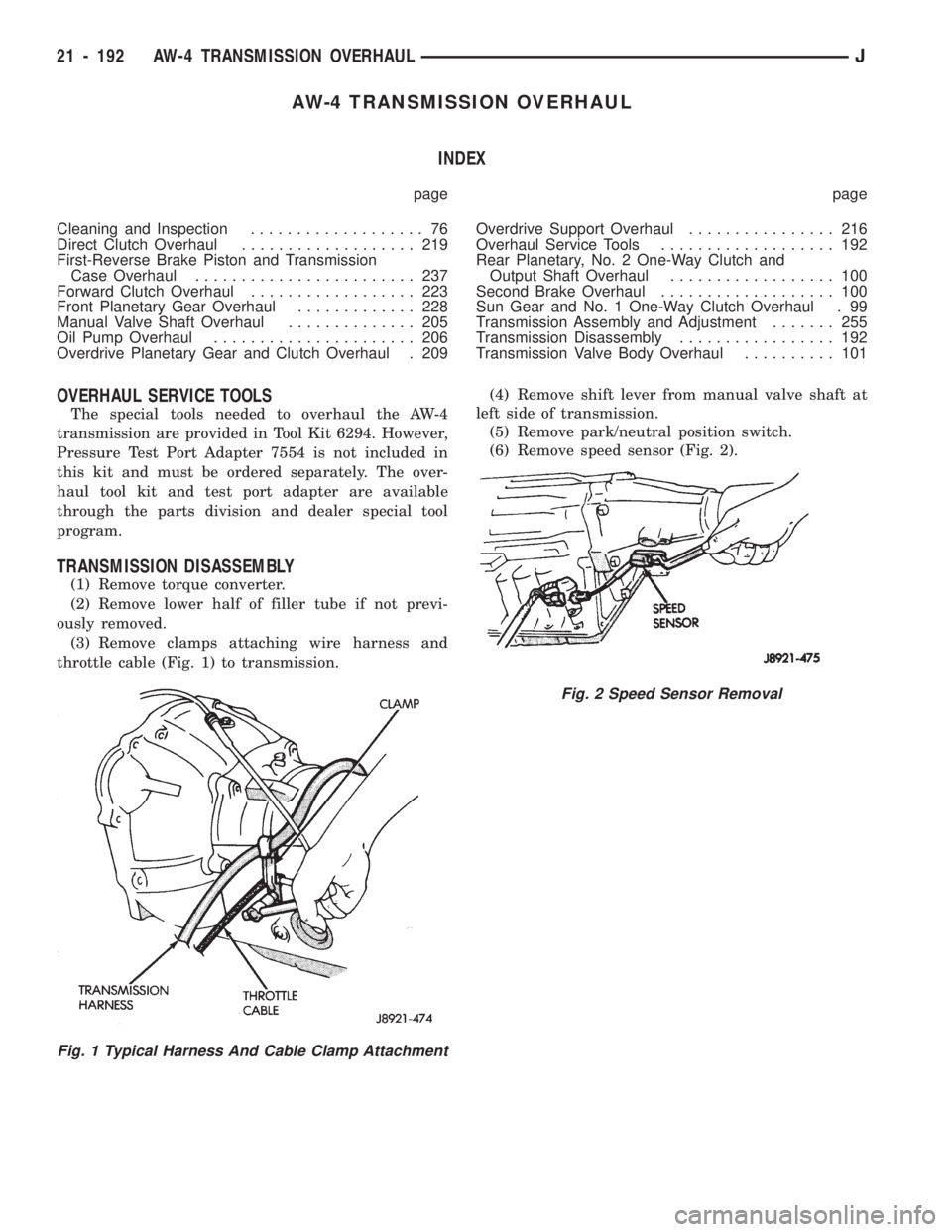

(6)

Install converter housing-to-engine bolts (Fig.

53).

(7) Install converter-to-drive plate bolts.

(8) Install and connect starter motor.

(9) Install and connect crankshaft position sensor.

(10) Install transfer case on transmission. Tighten

transfer case attaching nuts to 41 Nzm (30 ft. lbs.)

torque

(11) Connect transfer case shift linkage and vac-

uum hoses.

(12) Connect exhaust components.

(13) Install rear crossmember and remove jack

used to support transmission assembly.

(14) Connect speed sensor wire harness to sensor.

(15) Connect wire harness to park/neutral position

switch.

(16) Align and connect front and rear propeller

shafts.

Fig. 51 Checking Operation Of Torque Converter

Stator One-Way Clutch

Fig. 52 Installing Oil Pump Seal

21 - 190 AW-4 TRANSMISSION REMOVAL AND INSTALLATIONJ

Page 1302 of 1784

(17) Connect transmission wire harnesses and

transfer case vacuum and wire harnesses.

(18) Connect transmission cooler lines.

(19) Connect transmission throttle cable at engine.(20) Install new O-ring seal on upper half of trans-

mission fill tube. Then connect upper and lower tube

halves.

(21) Lower vehicle.

(22) Fill transmission with Mopar Mercon auto-

matic transmission fluid. Mopar Dexron II can be

used if Mercon is not readily available.

Fig. 53 AW-4 Transmission Attachment

JAW-4 TRANSMISSION REMOVAL AND INSTALLATION 21 - 191

Page 1303 of 1784

AW-4 TRANSMISSION OVERHAUL

INDEX

page page

Cleaning and Inspection................... 76

Direct Clutch Overhaul................... 219

First-Reverse Brake Piston and Transmission

Case Overhaul........................ 237

Forward Clutch Overhaul.................. 223

Front Planetary Gear Overhaul............. 228

Manual Valve Shaft Overhaul.............. 205

Oil Pump Overhaul...................... 206

Overdrive Planetary Gear and Clutch Overhaul . 209Overdrive Support Overhaul................ 216

Overhaul Service Tools................... 192

Rear Planetary, No. 2 One-Way Clutch and

Output Shaft Overhaul.................. 100

Second Brake Overhaul................... 100

Sun Gear and No. 1 One-Way Clutch Overhaul . 99

Transmission Assembly and Adjustment....... 255

Transmission Disassembly................. 192

Transmission Valve Body Overhaul.......... 101

OVERHAUL SERVICE TOOLS

The special tools needed to overhaul the AW-4

transmission are provided in Tool Kit 6294. However,

Pressure Test Port Adapter 7554 is not included in

this kit and must be ordered separately. The over-

haul tool kit and test port adapter are available

through the parts division and dealer special tool

program.

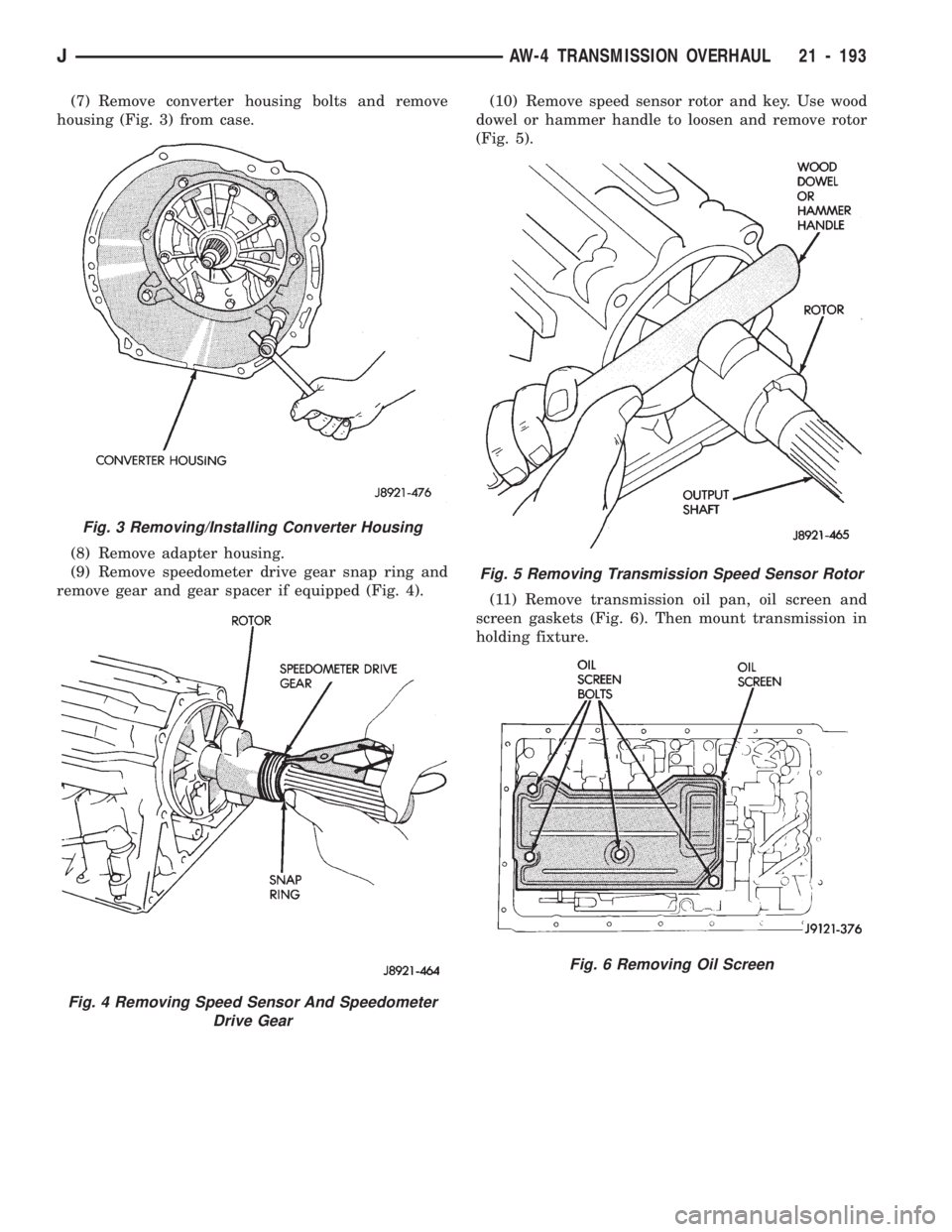

TRANSMISSION DISASSEMBLY

(1) Remove torque converter.

(2) Remove lower half of filler tube if not previ-

ously removed.

(3) Remove clamps attaching wire harness and

throttle cable (Fig. 1) to transmission.(4) Remove shift lever from manual valve shaft at

left side of transmission.

(5) Remove park/neutral position switch.

(6) Remove speed sensor (Fig. 2).

Fig. 1 Typical Harness And Cable Clamp Attachment

Fig. 2 Speed Sensor Removal

21 - 192 AW-4 TRANSMISSION OVERHAULJ

Page 1304 of 1784

(7) Remove converter housing bolts and remove

housing (Fig. 3) from case.

(8) Remove adapter housing.

(9) Remove speedometer drive gear snap ring and

remove gear and gear spacer if equipped (Fig. 4).(10) Remove speed sensor rotor and key. Use wood

dowel or hammer handle to loosen and remove rotor

(Fig. 5).

(11) Remove transmission oil pan, oil screen and

screen gaskets (Fig. 6). Then mount transmission in

holding fixture.

Fig. 3 Removing/Installing Converter Housing

Fig. 4 Removing Speed Sensor And Speedometer

Drive Gear

Fig. 5 Removing Transmission Speed Sensor Rotor

Fig. 6 Removing Oil Screen

JAW-4 TRANSMISSION OVERHAUL 21 - 193

Page 1305 of 1784

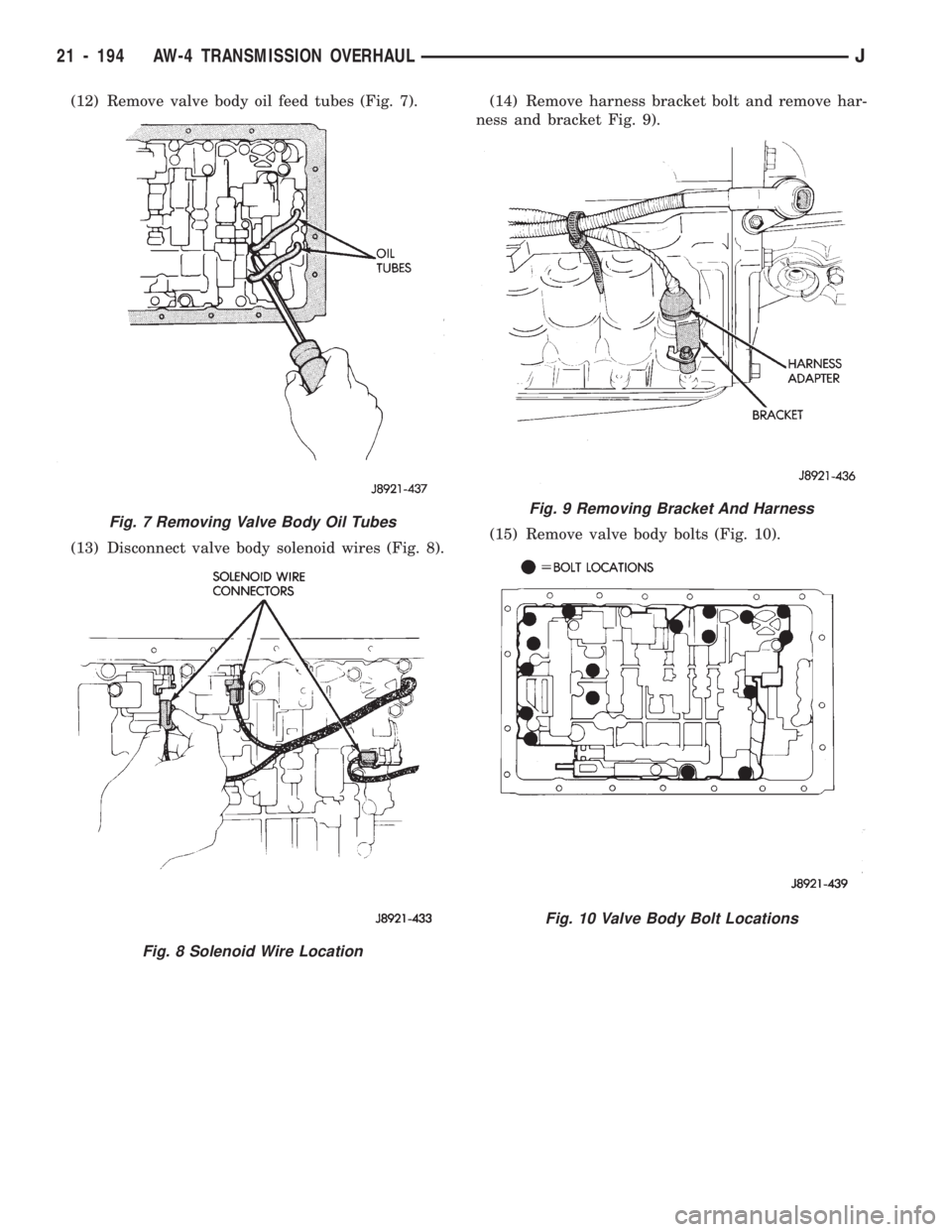

(12) Remove valve body oil feed tubes (Fig. 7).

(13) Disconnect valve body solenoid wires (Fig. 8).(14) Remove harness bracket bolt and remove har-

ness and bracket Fig. 9).

(15) Remove valve body bolts (Fig. 10).

Fig. 7 Removing Valve Body Oil Tubes

Fig. 8 Solenoid Wire Location

Fig. 9 Removing Bracket And Harness

Fig. 10 Valve Body Bolt Locations

21 - 194 AW-4 TRANSMISSION OVERHAULJ

Page 1306 of 1784

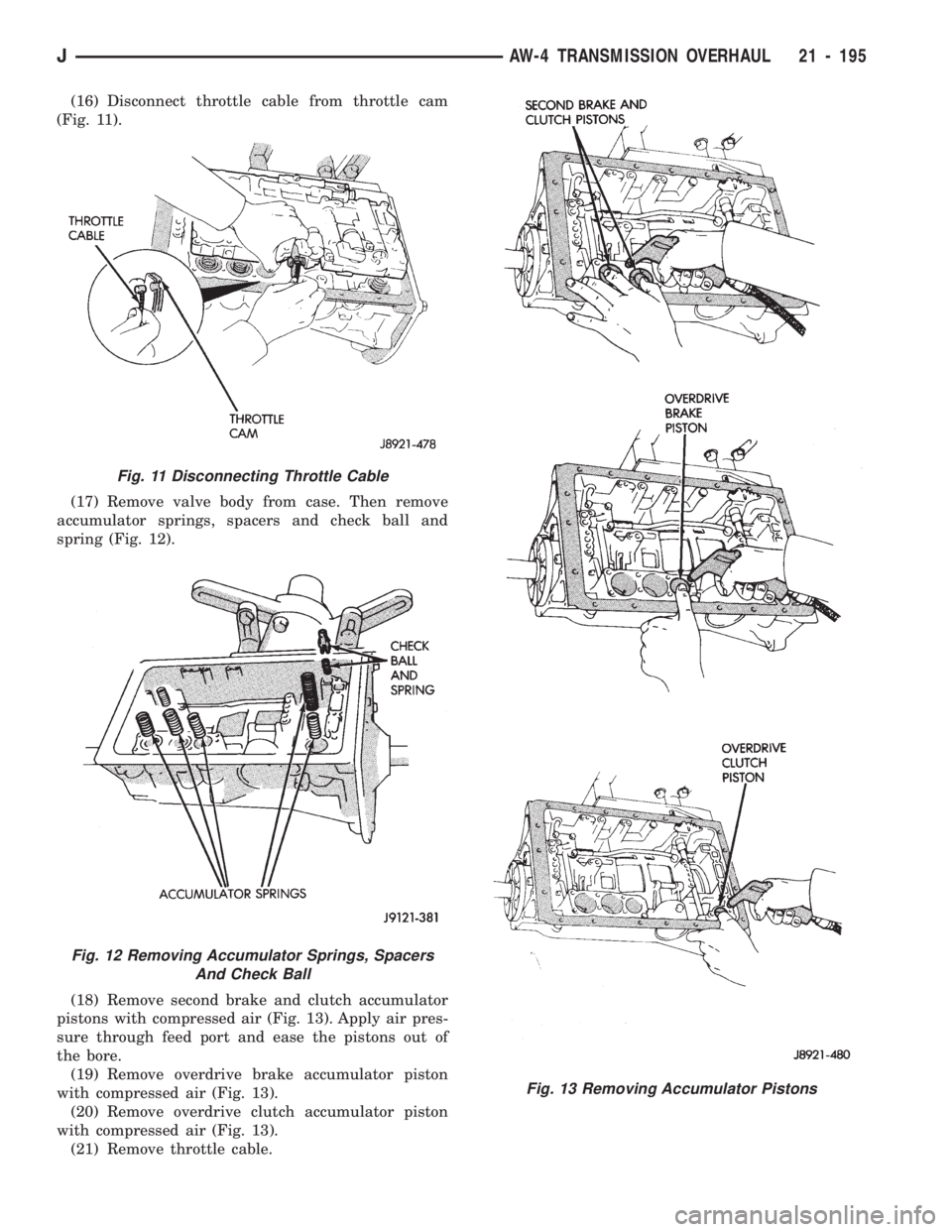

(16) Disconnect throttle cable from throttle cam

(Fig. 11).

(17) Remove valve body from case. Then remove

accumulator springs, spacers and check ball and

spring (Fig. 12).

(18) Remove second brake and clutch accumulator

pistons with compressed air (Fig. 13). Apply air pres-

sure through feed port and ease the pistons out of

the bore.

(19) Remove overdrive brake accumulator piston

with compressed air (Fig. 13).

(20) Remove overdrive clutch accumulator piston

with compressed air (Fig. 13).

(21) Remove throttle cable.

Fig. 11 Disconnecting Throttle Cable

Fig. 12 Removing Accumulator Springs, Spacers

And Check Ball

Fig. 13 Removing Accumulator Pistons

JAW-4 TRANSMISSION OVERHAUL 21 - 195

Page 1307 of 1784

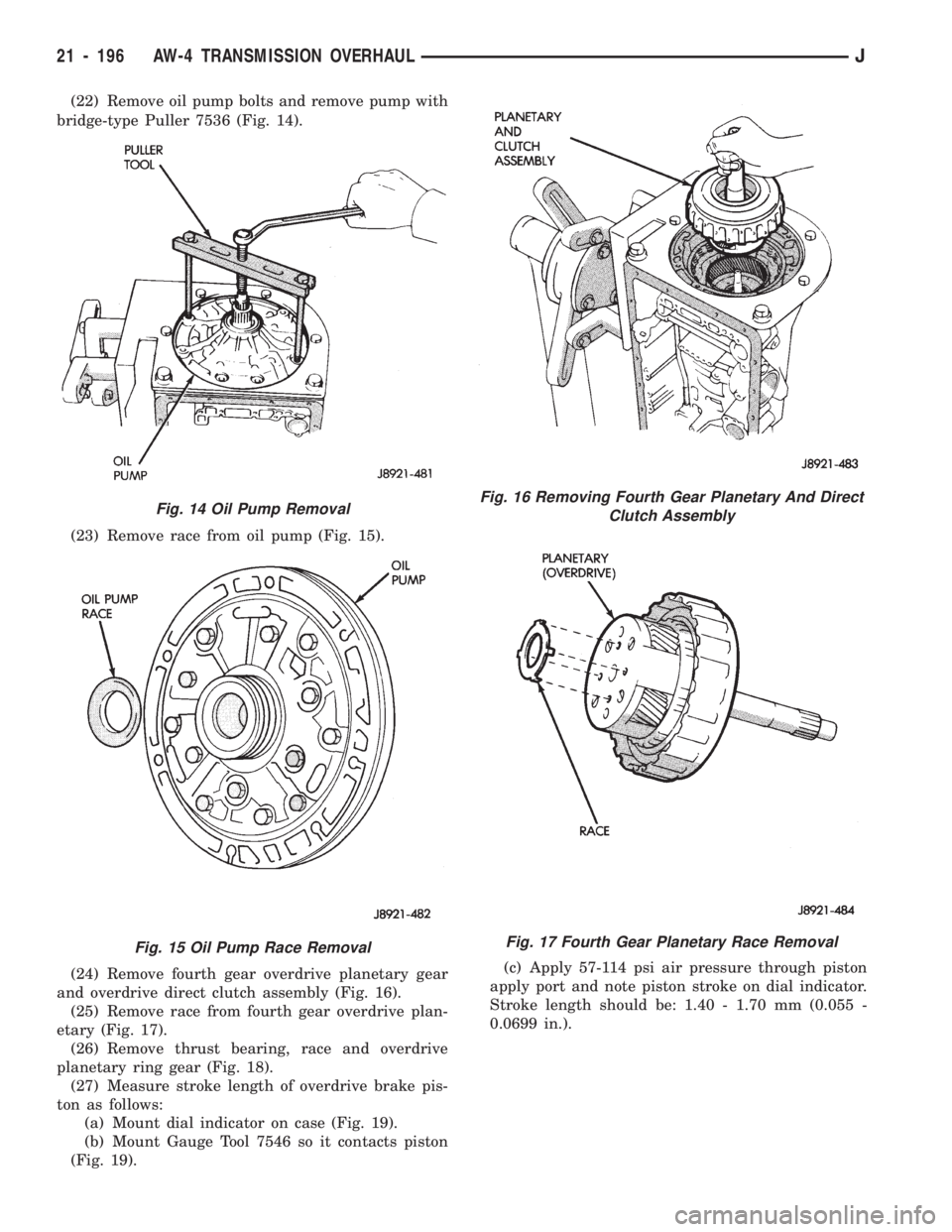

(22) Remove oil pump bolts and remove pump with

bridge-type Puller 7536 (Fig. 14).

(23) Remove race from oil pump (Fig. 15).

(24) Remove fourth gear overdrive planetary gear

and overdrive direct clutch assembly (Fig. 16).

(25) Remove race from fourth gear overdrive plan-

etary (Fig. 17).

(26) Remove thrust bearing, race and overdrive

planetary ring gear (Fig. 18).

(27) Measure stroke length of overdrive brake pis-

ton as follows:

(a) Mount dial indicator on case (Fig. 19).

(b) Mount Gauge Tool 7546 so it contacts piston

(Fig. 19).(c) Apply 57-114 psi air pressure through piston

apply port and note piston stroke on dial indicator.

Stroke length should be: 1.40 - 1.70 mm (0.055 -

0.0699 in.).

Fig. 14 Oil Pump Removal

Fig. 15 Oil Pump Race Removal

Fig. 16 Removing Fourth Gear Planetary And Direct

Clutch Assembly

Fig. 17 Fourth Gear Planetary Race Removal

21 - 196 AW-4 TRANSMISSION OVERHAULJ

Page 1308 of 1784

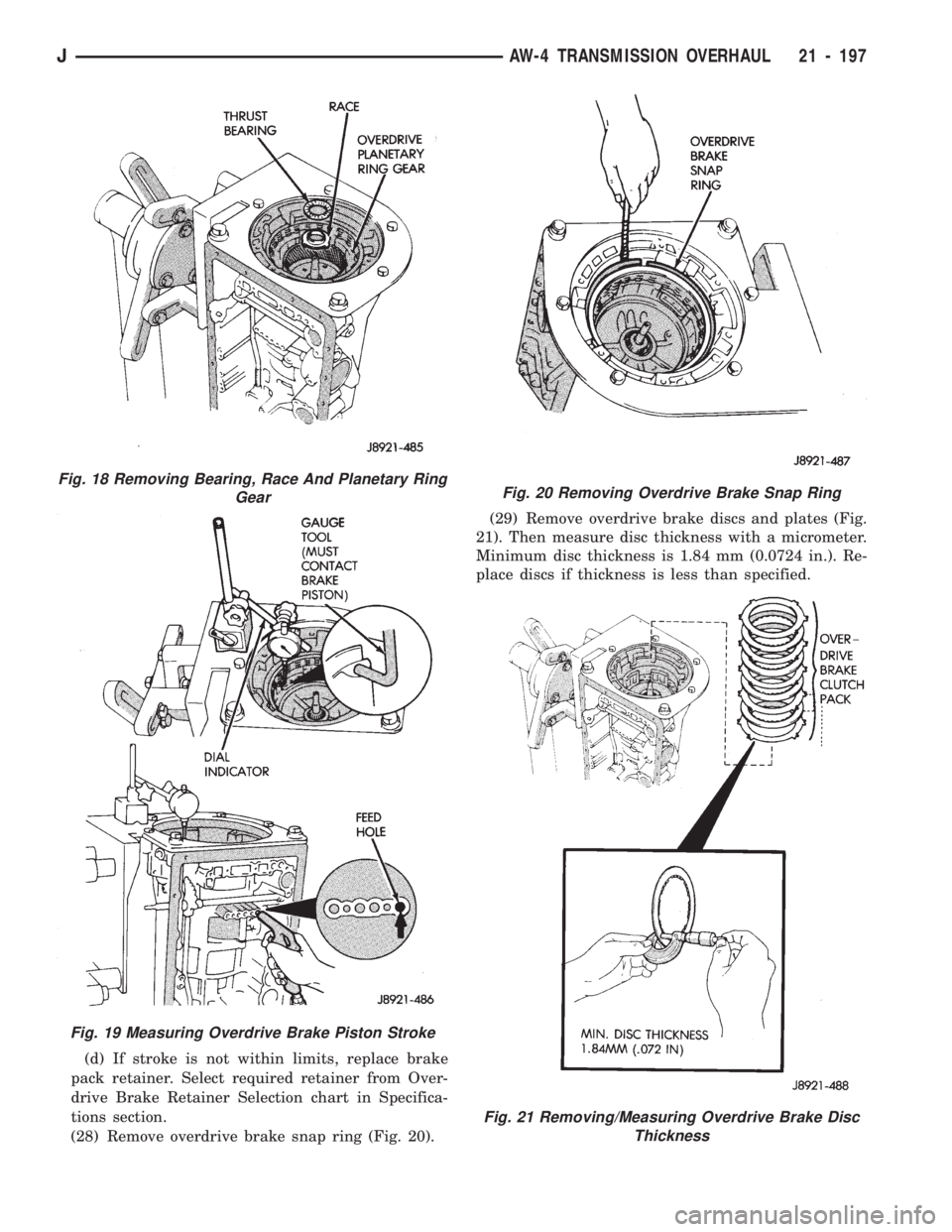

(d) If stroke is not within limits, replace brake

pack retainer. Select required retainer from Over-

drive Brake Retainer Selection chart in Specifica-

tions section.

(28) Remove overdrive brake snap ring (Fig. 20).(29) Remove overdrive brake discs and plates (Fig.

21). Then measure disc thickness with a micrometer.

Minimum disc thickness is 1.84 mm (0.0724 in.). Re-

place discs if thickness is less than specified.

Fig. 19 Measuring Overdrive Brake Piston Stroke

Fig. 18 Removing Bearing, Race And Planetary Ring

GearFig. 20 Removing Overdrive Brake Snap Ring

Fig. 21 Removing/Measuring Overdrive Brake Disc

Thickness

JAW-4 TRANSMISSION OVERHAUL 21 - 197

Page 1309 of 1784

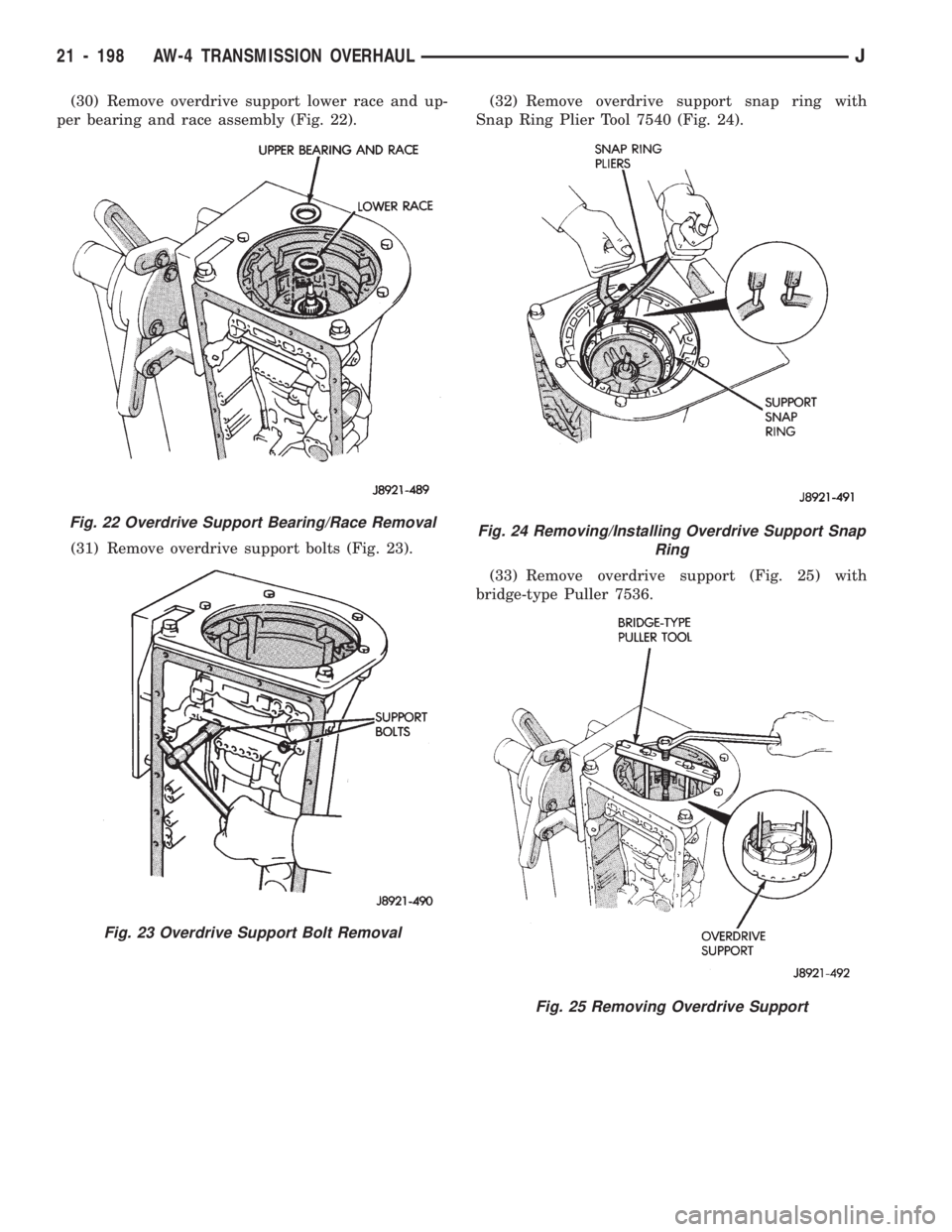

(30) Remove overdrive support lower race and up-

per bearing and race assembly (Fig. 22).

(31) Remove overdrive support bolts (Fig. 23).(32) Remove overdrive support snap ring with

Snap Ring Plier Tool 7540 (Fig. 24).

(33) Remove overdrive support (Fig. 25) with

bridge-type Puller 7536.

Fig. 22 Overdrive Support Bearing/Race Removal

Fig. 23 Overdrive Support Bolt Removal

Fig. 24 Removing/Installing Overdrive Support Snap

Ring

Fig. 25 Removing Overdrive Support

21 - 198 AW-4 TRANSMISSION OVERHAULJ

Page 1310 of 1784

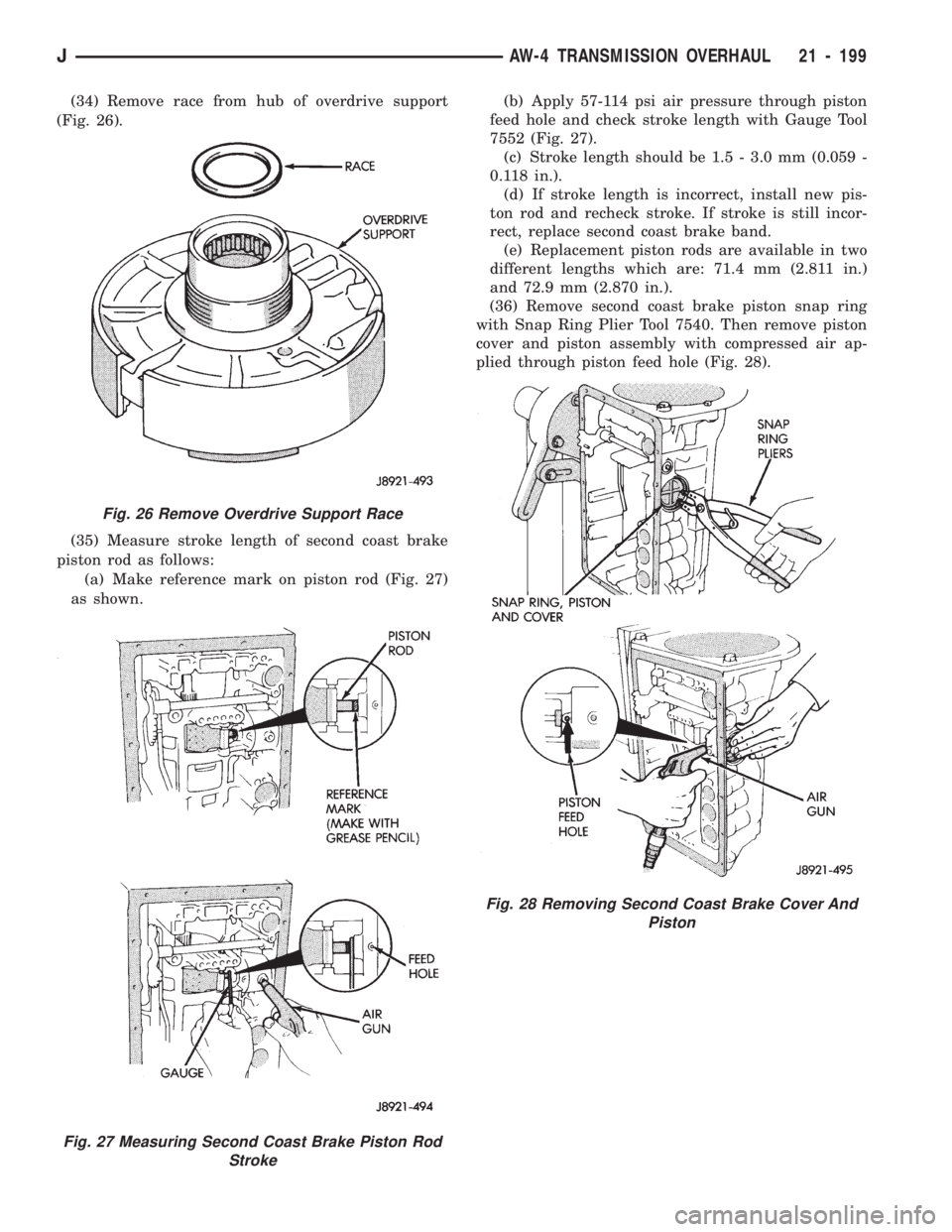

(34) Remove race from hub of overdrive support

(Fig. 26).

(35) Measure stroke length of second coast brake

piston rod as follows:

(a) Make reference mark on piston rod (Fig. 27)

as shown.(b) Apply 57-114 psi air pressure through piston

feed hole and check stroke length with Gauge Tool

7552 (Fig. 27).

(c) Stroke length should be 1.5 - 3.0 mm (0.059 -

0.118 in.).

(d) If stroke length is incorrect, install new pis-

ton rod and recheck stroke. If stroke is still incor-

rect, replace second coast brake band.

(e) Replacement piston rods are available in two

different lengths which are: 71.4 mm (2.811 in.)

and 72.9 mm (2.870 in.).

(36) Remove second coast brake piston snap ring

with Snap Ring Plier Tool 7540. Then remove piston

cover and piston assembly with compressed air ap-

plied through piston feed hole (Fig. 28).

Fig. 27 Measuring Second Coast Brake Piston Rod

Stroke

Fig. 26 Remove Overdrive Support Race

Fig. 28 Removing Second Coast Brake Cover And

Piston

JAW-4 TRANSMISSION OVERHAUL 21 - 199