JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1401 of 1784

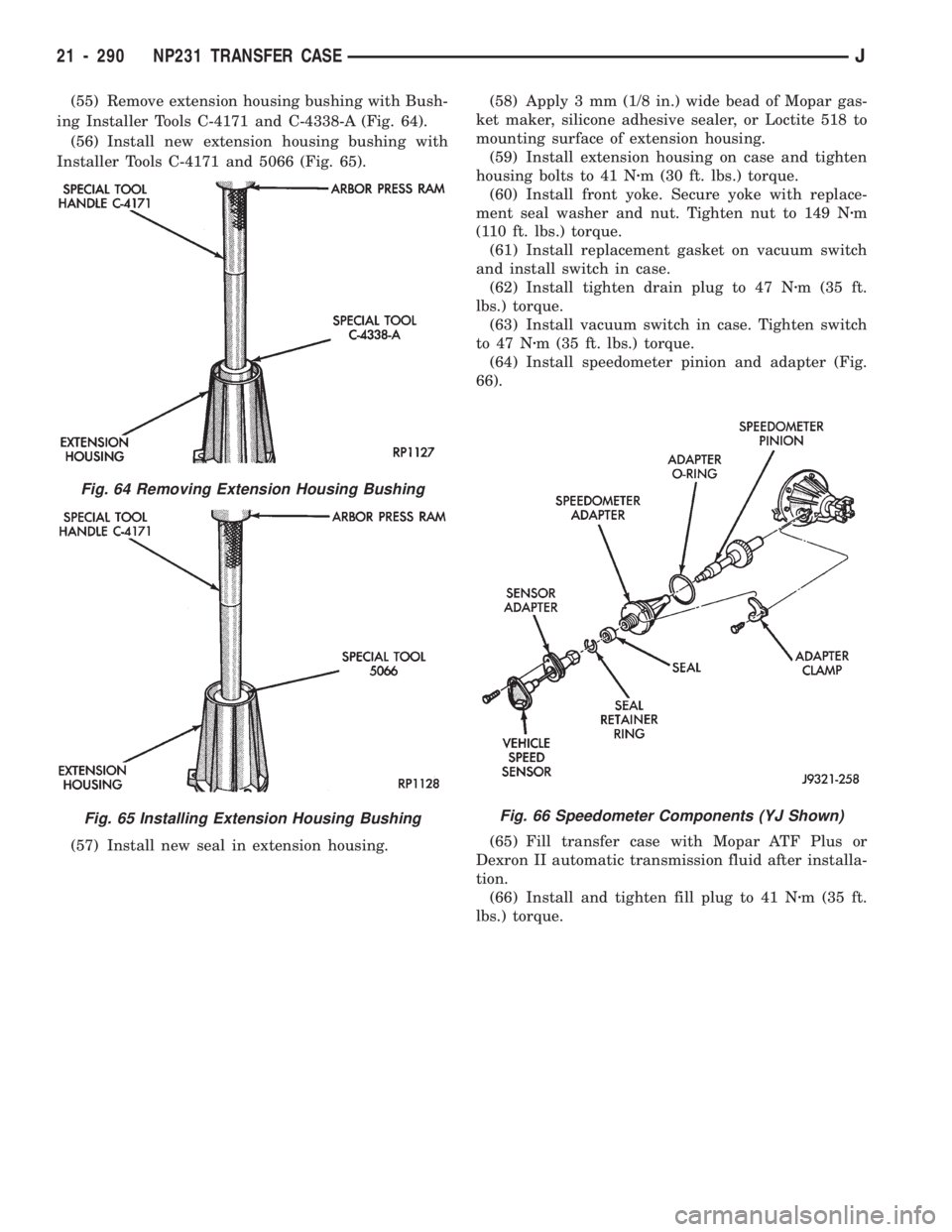

(55) Remove extension housing bushing with Bush-

ing Installer Tools C-4171 and C-4338-A (Fig. 64).

(56) Install new extension housing bushing with

Installer Tools C-4171 and 5066 (Fig. 65).

(57) Install new seal in extension housing.(58) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

mounting surface of extension housing.

(59) Install extension housing on case and tighten

housing bolts to 41 Nzm (30 ft. lbs.) torque.

(60) Install front yoke. Secure yoke with replace-

ment seal washer and nut. Tighten nut to 149 Nzm

(110 ft. lbs.) torque.

(61) Install replacement gasket on vacuum switch

and install switch in case.

(62) Install tighten drain plug to 47 Nzm (35 ft.

lbs.) torque.

(63) Install vacuum switch in case. Tighten switch

to 47 Nzm (35 ft. lbs.) torque.

(64) Install speedometer pinion and adapter (Fig.

66).

(65) Fill transfer case with Mopar ATF Plus or

Dexron II automatic transmission fluid after installa-

tion.

(66) Install and tighten fill plug to 41 Nzm (35 ft.

lbs.) torque.

Fig. 64 Removing Extension Housing Bushing

Fig. 65 Installing Extension Housing BushingFig. 66 Speedometer Components (YJ Shown)

21 - 290 NP231 TRANSFER CASEJ

Page 1402 of 1784

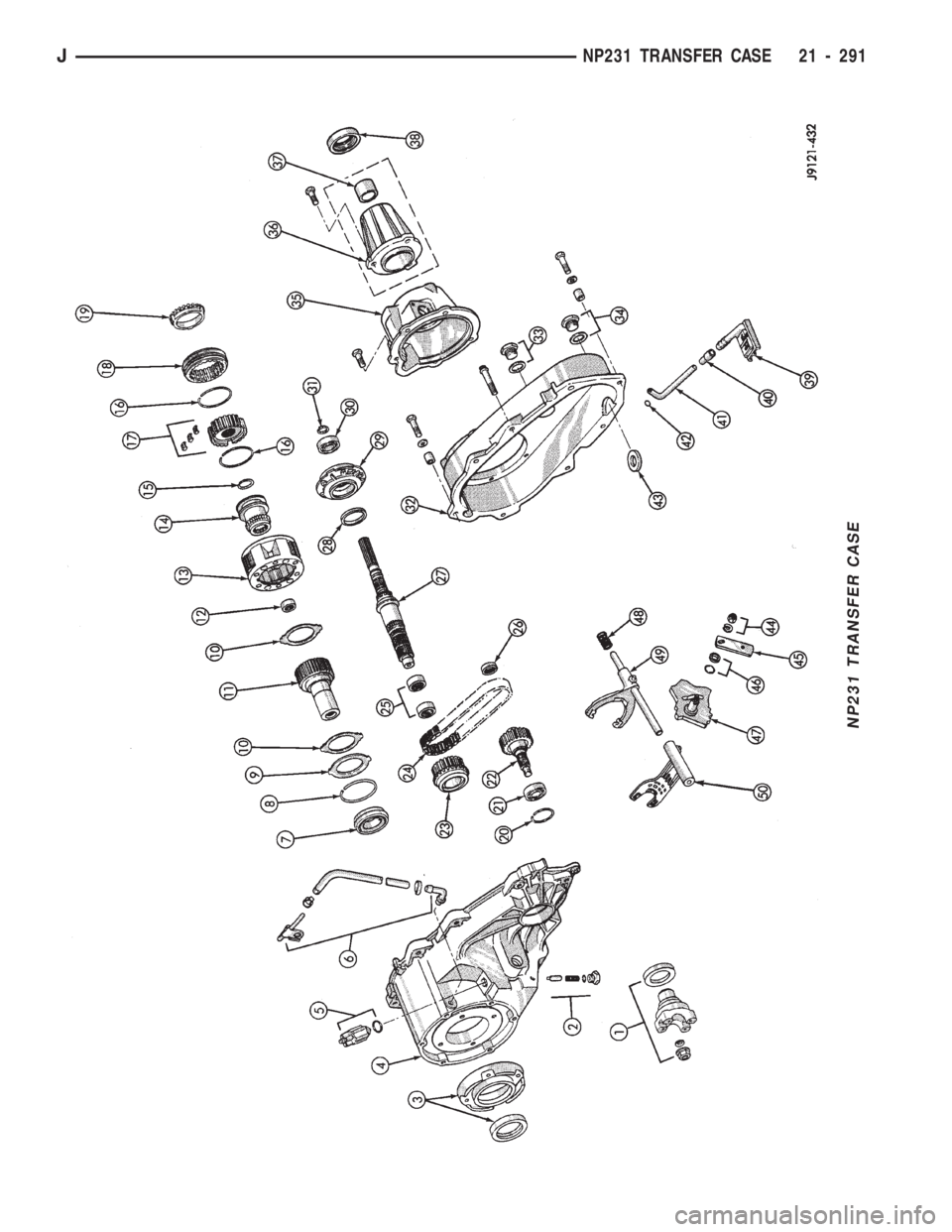

NP231 TRANSFER CASE

JNP231 TRANSFER CASE 21 - 291

Page 1403 of 1784

LEGEND FOR NP231 TRANSFER CASE

21 - 292 NP231 TRANSFER CASEJ

Page 1404 of 1784

NP242 TRANSFER CASE

INDEX

page page

Cleaning and Inspection.................. 305

General Information...................... 293

Shift Linkage Adjustment.................. 296

Speedometer Service.................... 296

Transfer Case Assembly.................. 306

Transfer Case Disassembly and Overhaul..... 297Transfer Case Fill Level.................. 294

Transfer Case Identification................ 293

Transfer Case Installation................. 296

Transfer Case Lubricant.................. 294

Transfer Case Removal................... 296

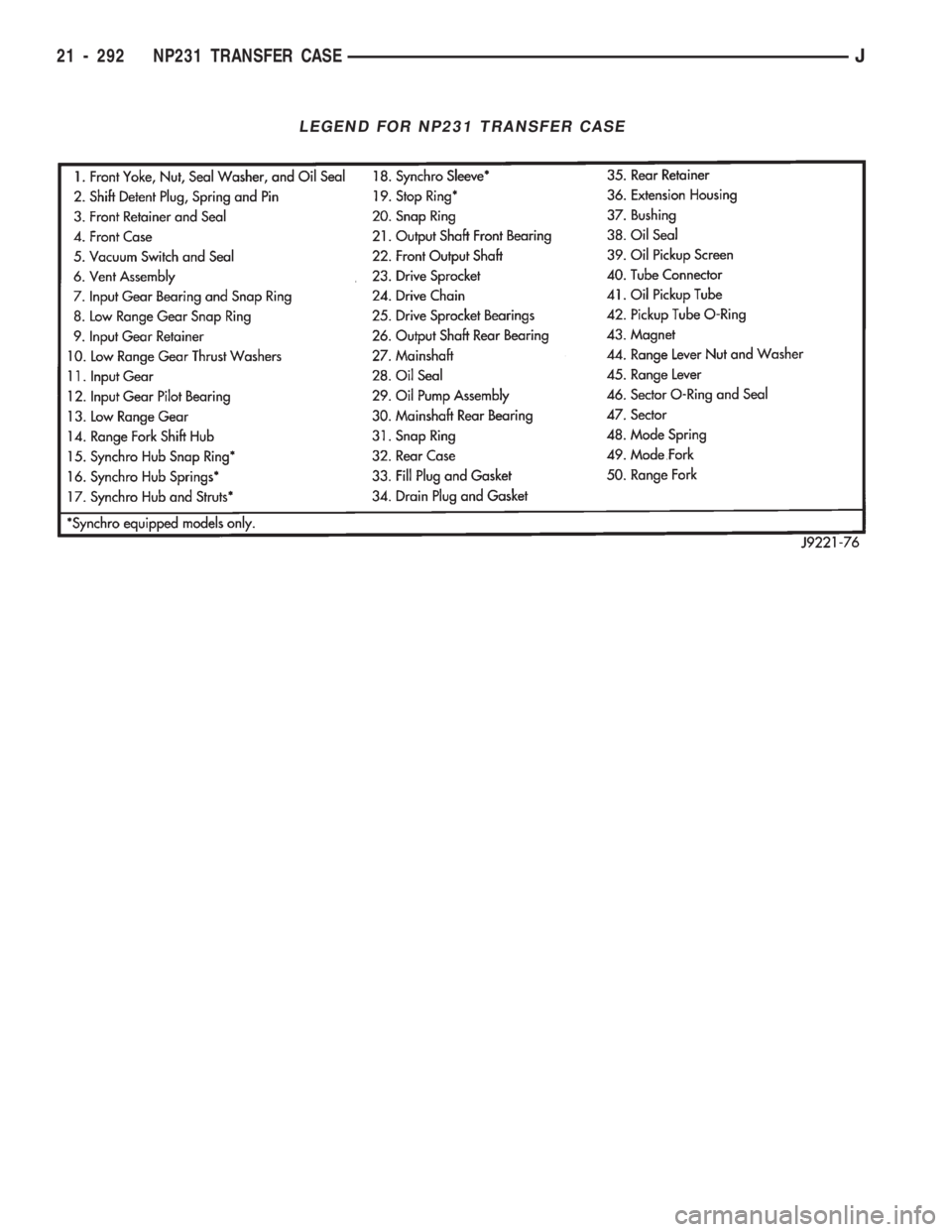

GENERAL INFORMATION

The NP242 is a both a full and part time transfer

case with four operating ranges (Fig. 1). The NP242

provides either 2-wheel drive or full time 4-wheel

drive operation. An interaxle differential is used to

control torque transfer to the front and rear axles. A

low range gear reduction system provides increased

low speed torque capability.

OPERATING RANGES

The NP242 transfer case operating ranges are: 2-

wheel drive, part-time 4-wheel drive, full time 4-

wheel drive and 4-wheel drive low.

The2Hand4x4full time ranges are for all road

surfaces. The 2H range provides 2-wheel drive. The 4

x 4 full time range provides differentiated, 4-wheel

drive. The vehicle can be operated on any road sur-

face in either of these ranges if desired.

The transfer case differential also has a locking

mechanism for undifferentiated operation in:4x4

part time and,4x4lowranges. These ranges are

only for use on low traction surfaces.

The4x4full time range is fully differentiated and

can be used at any time and on any road surface. The 4x 4 part time and low ranges are not differentiated.

They are for off road use only.

The low range reduction gear system is operative in

4-low range only. Low range reduction ratio is 2.72:1.

In summary, 2H and4x4full time ranges are for

normal on-road, highway operation. The4x4part-

time and low ranges are for off road operation exclu-

sively. Or, or when the vehicle is driven on surfaces

covered by snow, ice or similar low traction elements.

SHIFT MECHANISM

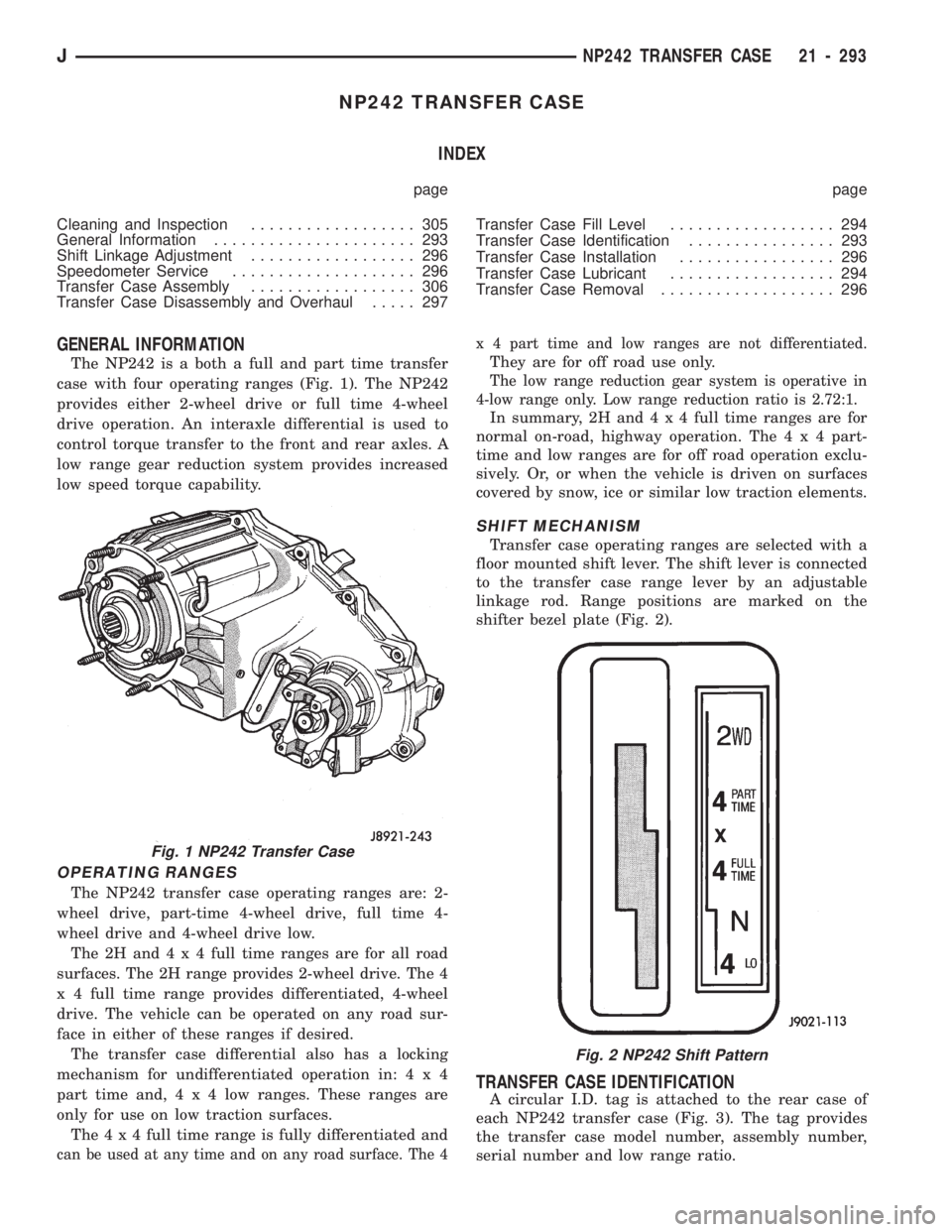

Transfer case operating ranges are selected with a

floor mounted shift lever. The shift lever is connected

to the transfer case range lever by an adjustable

linkage rod. Range positions are marked on the

shifter bezel plate (Fig. 2).

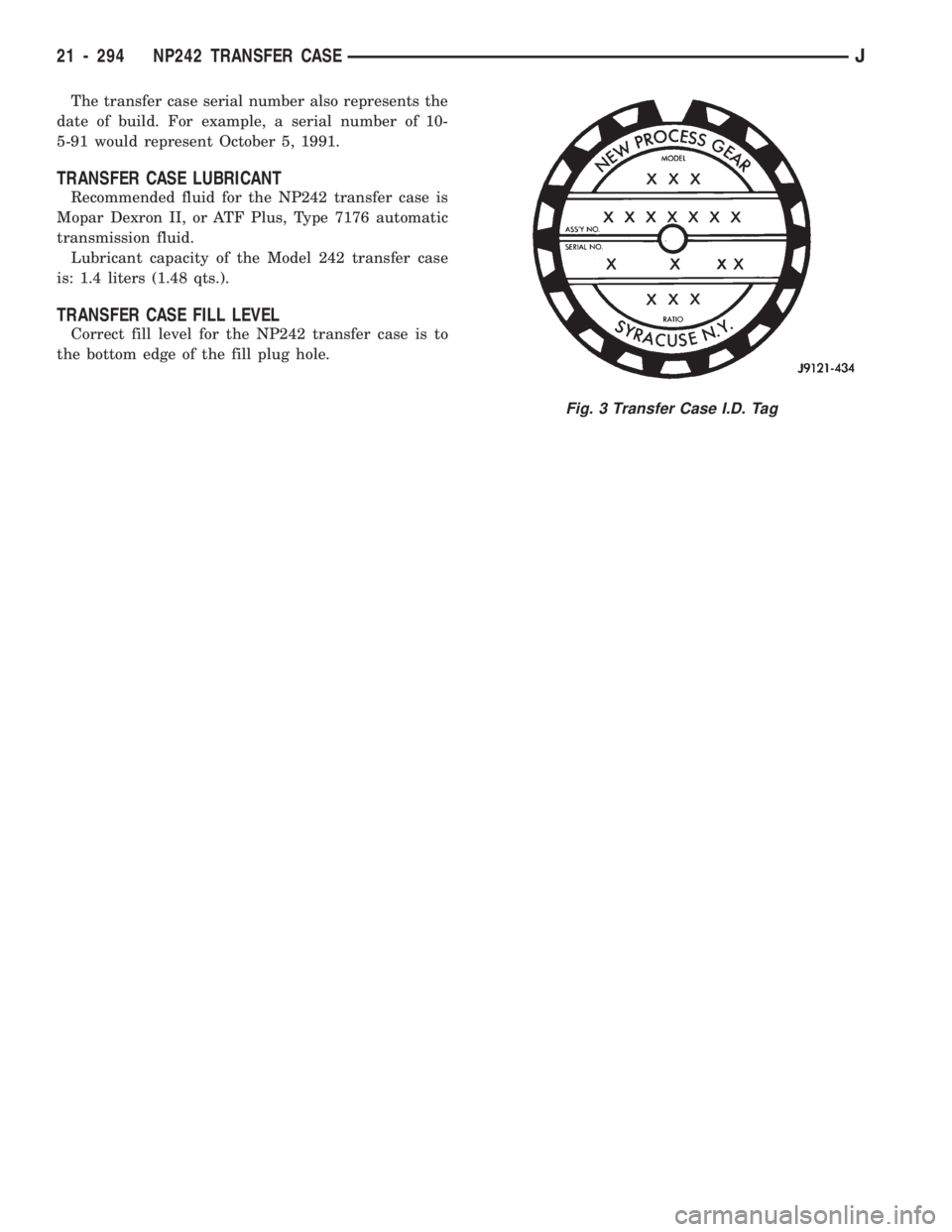

TRANSFER CASE IDENTIFICATION

A circular I.D. tag is attached to the rear case of

each NP242 transfer case (Fig. 3). The tag provides

the transfer case model number, assembly number,

serial number and low range ratio.

Fig. 1 NP242 Transfer Case

Fig. 2 NP242 Shift Pattern

JNP242 TRANSFER CASE 21 - 293

Page 1405 of 1784

The transfer case serial number also represents the

date of build. For example, a serial number of 10-

5-91 would represent October 5, 1991.

TRANSFER CASE LUBRICANT

Recommended fluid for the NP242 transfer case is

Mopar Dexron II, or ATF Plus, Type 7176 automatic

transmission fluid.

Lubricant capacity of the Model 242 transfer case

is: 1.4 liters (1.48 qts.).

TRANSFER CASE FILL LEVEL

Correct fill level for the NP242 transfer case is to

the bottom edge of the fill plug hole.

Fig. 3 Transfer Case I.D. Tag

21 - 294 NP242 TRANSFER CASEJ

Page 1406 of 1784

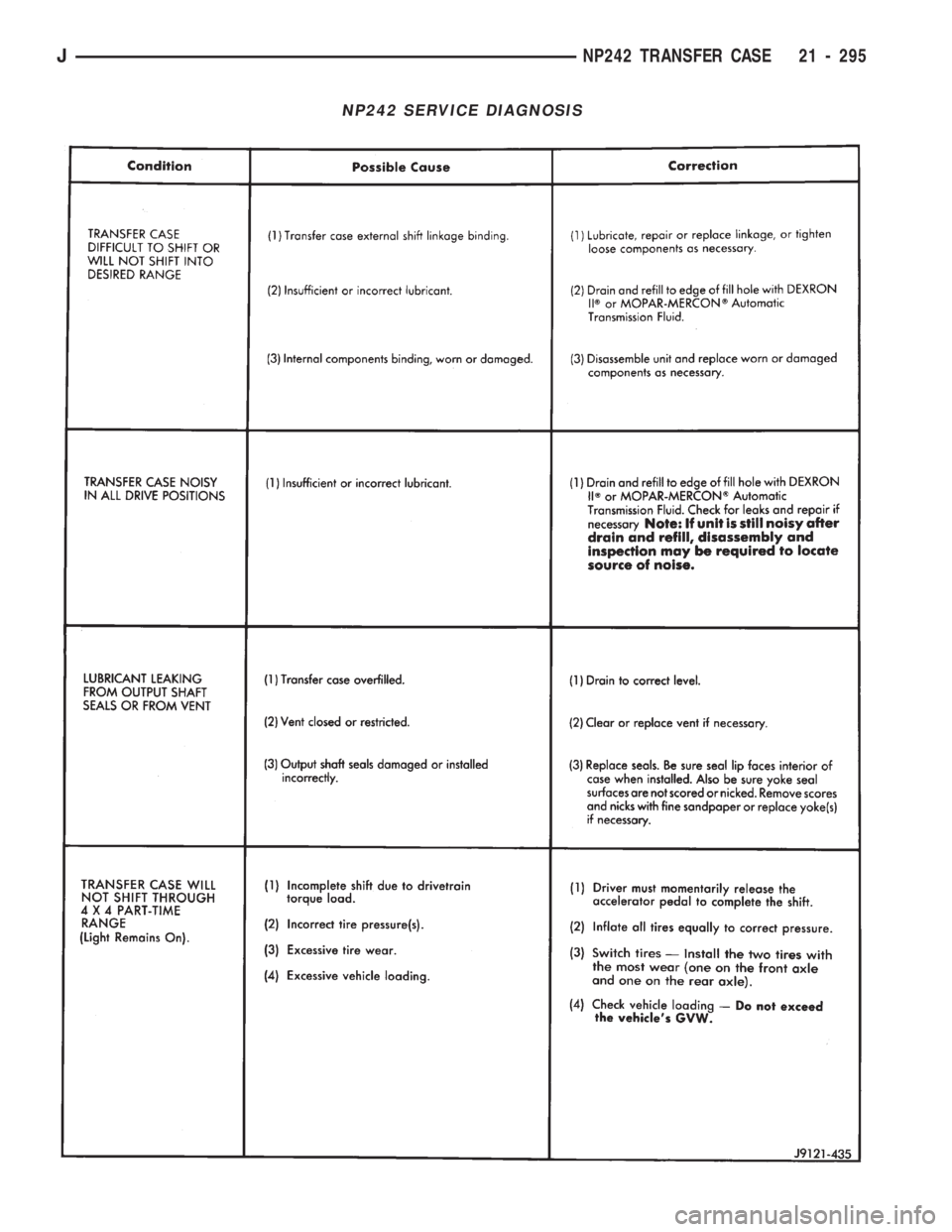

NP242 SERVICE DIAGNOSIS

JNP242 TRANSFER CASE 21 - 295

Page 1407 of 1784

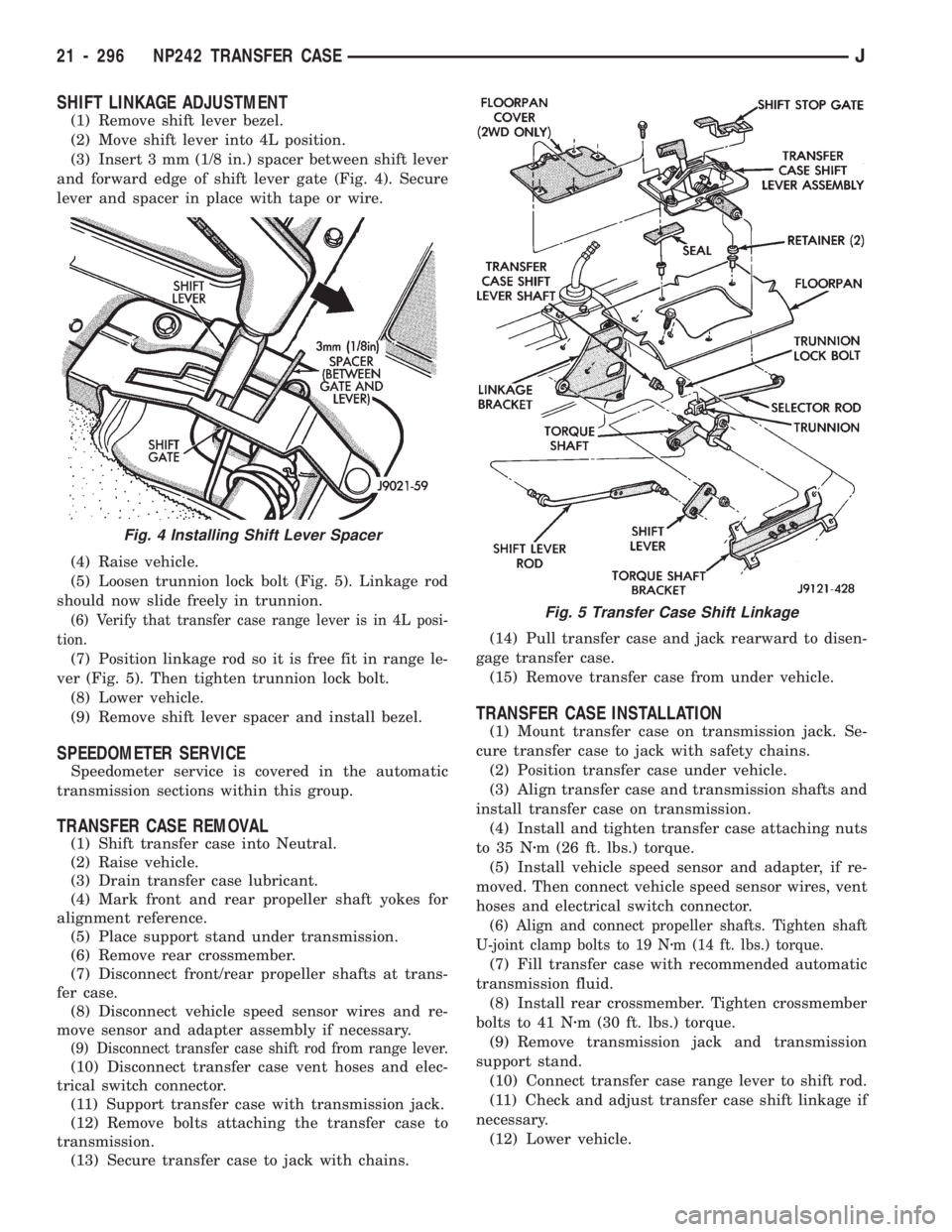

SHIFT LINKAGE ADJUSTMENT

(1) Remove shift lever bezel.

(2) Move shift lever into 4L position.

(3) Insert 3 mm (1/8 in.) spacer between shift lever

and forward edge of shift lever gate (Fig. 4). Secure

lever and spacer in place with tape or wire.

(4) Raise vehicle.

(5) Loosen trunnion lock bolt (Fig. 5). Linkage rod

should now slide freely in trunnion.

(6) Verify that transfer case range lever is in 4L posi-

tion.

(7) Position linkage rod so it is free fit in range le-

ver (Fig. 5). Then tighten trunnion lock bolt.

(8) Lower vehicle.

(9) Remove shift lever spacer and install bezel.

SPEEDOMETER SERVICE

Speedometer service is covered in the automatic

transmission sections within this group.

TRANSFER CASE REMOVAL

(1) Shift transfer case into Neutral.

(2) Raise vehicle.

(3) Drain transfer case lubricant.

(4) Mark front and rear propeller shaft yokes for

alignment reference.

(5) Place support stand under transmission.

(6) Remove rear crossmember.

(7) Disconnect front/rear propeller shafts at trans-

fer case.

(8) Disconnect vehicle speed sensor wires and re-

move sensor and adapter assembly if necessary.

(9) Disconnect transfer case shift rod from range lever.

(10) Disconnect transfer case vent hoses and elec-

trical switch connector.

(11) Support transfer case with transmission jack.

(12) Remove bolts attaching the transfer case to

transmission.

(13) Secure transfer case to jack with chains.(14) Pull transfer case and jack rearward to disen-

gage transfer case.

(15) Remove transfer case from under vehicle.

TRANSFER CASE INSTALLATION

(1) Mount transfer case on transmission jack. Se-

cure transfer case to jack with safety chains.

(2) Position transfer case under vehicle.

(3) Align transfer case and transmission shafts and

install transfer case on transmission.

(4) Install and tighten transfer case attaching nuts

to 35 Nzm (26 ft. lbs.) torque.

(5) Install vehicle speed sensor and adapter, if re-

moved. Then connect vehicle speed sensor wires, vent

hoses and electrical switch connector.

(6) Align and connect propeller shafts. Tighten shaft

U-joint clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(7) Fill transfer case with recommended automatic

transmission fluid.

(8) Install rear crossmember. Tighten crossmember

bolts to 41 Nzm (30 ft. lbs.) torque.

(9) Remove transmission jack and transmission

support stand.

(10) Connect transfer case range lever to shift rod.

(11) Check and adjust transfer case shift linkage if

necessary.

(12) Lower vehicle.

Fig. 4 Installing Shift Lever Spacer

Fig. 5 Transfer Case Shift Linkage

21 - 296 NP242 TRANSFER CASEJ

Page 1408 of 1784

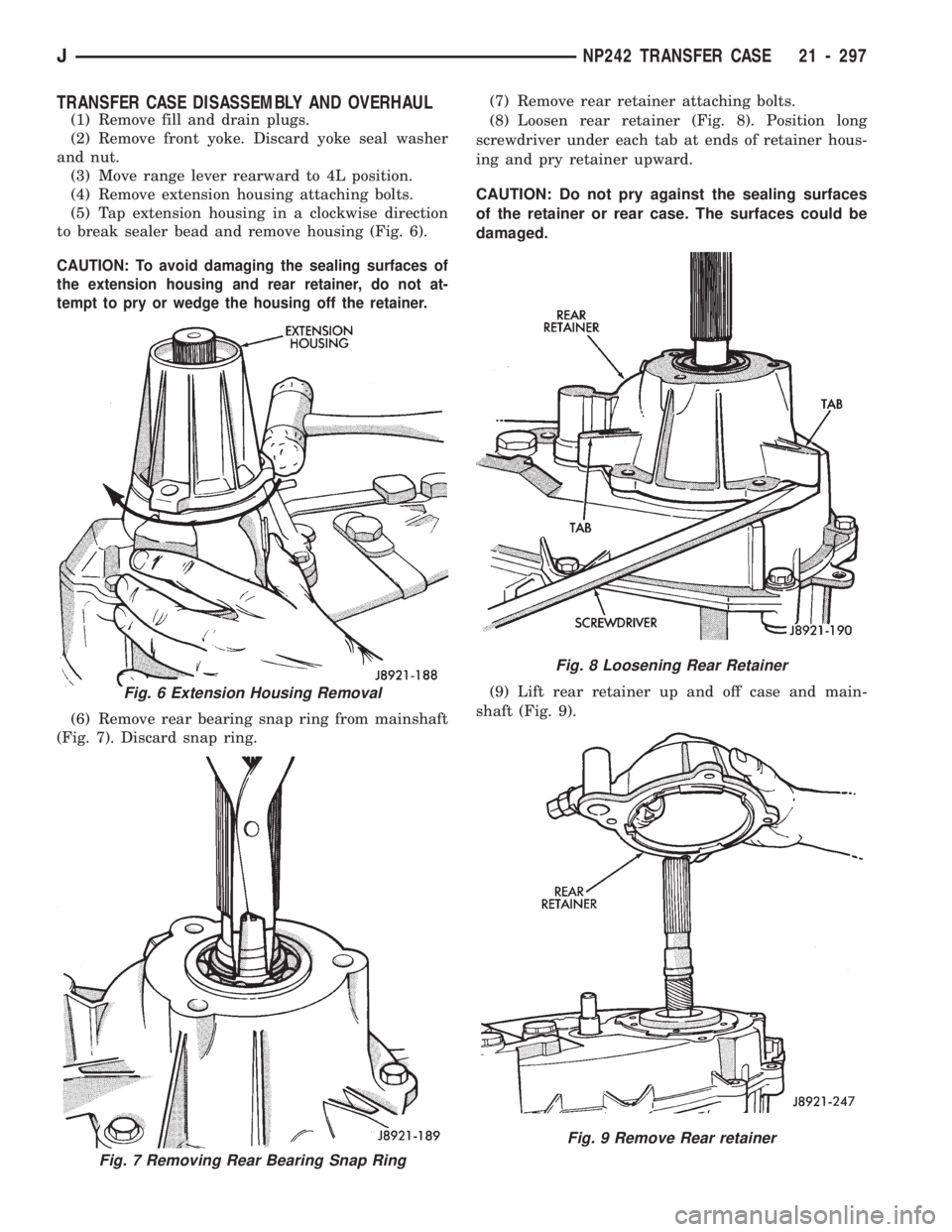

TRANSFER CASE DISASSEMBLY AND OVERHAUL

(1) Remove fill and drain plugs.

(2) Remove front yoke. Discard yoke seal washer

and nut.

(3) Move range lever rearward to 4L position.

(4) Remove extension housing attaching bolts.

(5) Tap extension housing in a clockwise direction

to break sealer bead and remove housing (Fig. 6).

CAUTION: To avoid damaging the sealing surfaces of

the extension housing and rear retainer, do not at-

tempt to pry or wedge the housing off the retainer.

(6) Remove rear bearing snap ring from mainshaft

(Fig. 7). Discard snap ring.(7) Remove rear retainer attaching bolts.

(8) Loosen rear retainer (Fig. 8). Position long

screwdriver under each tab at ends of retainer hous-

ing and pry retainer upward.

CAUTION: Do not pry against the sealing surfaces

of the retainer or rear case. The surfaces could be

damaged.

(9) Lift rear retainer up and off case and main-

shaft (Fig. 9).

Fig. 7 Removing Rear Bearing Snap Ring

Fig. 6 Extension Housing Removal

Fig. 8 Loosening Rear Retainer

Fig. 9 Remove Rear retainer

JNP242 TRANSFER CASE 21 - 297

Page 1409 of 1784

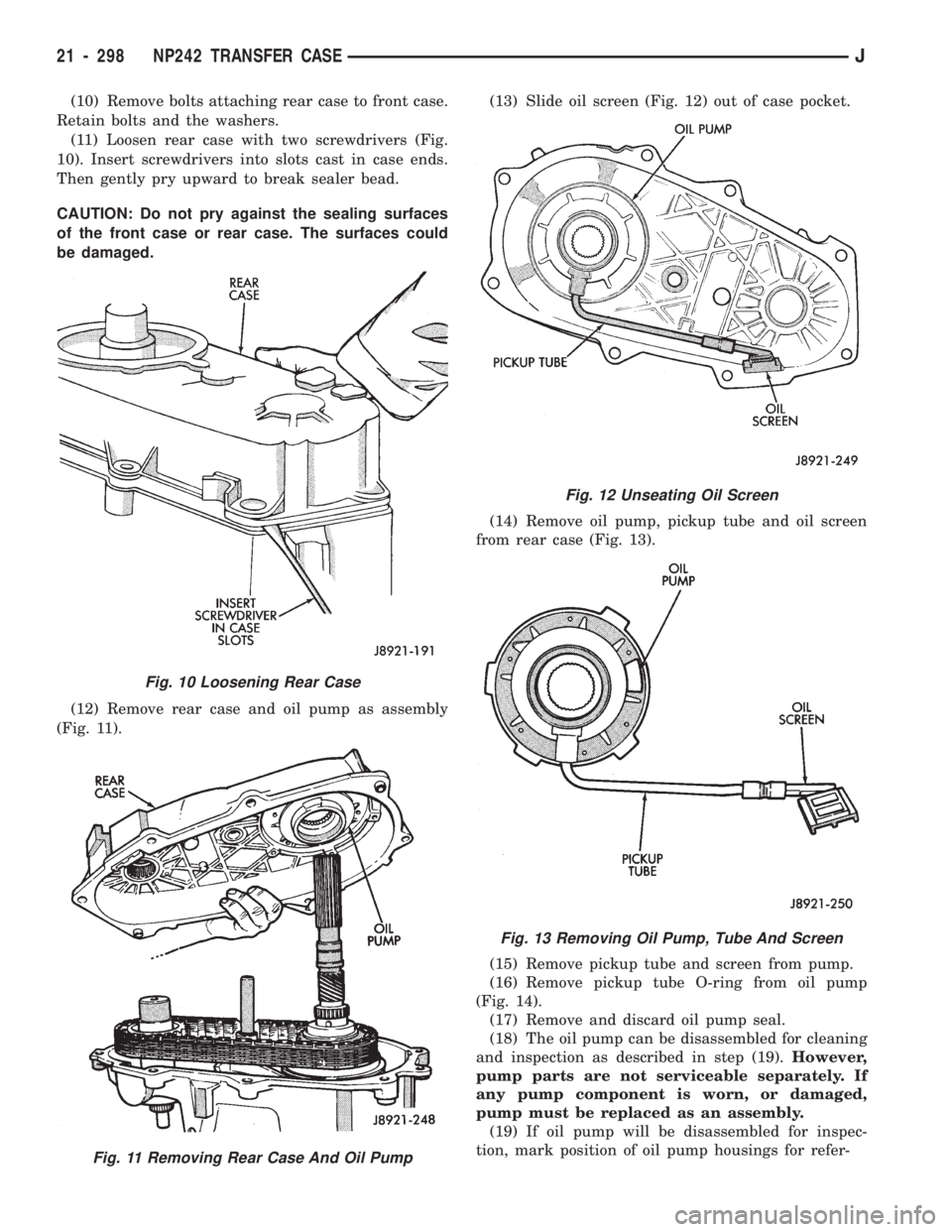

(10) Remove bolts attaching rear case to front case.

Retain bolts and the washers.

(11) Loosen rear case with two screwdrivers (Fig.

10). Insert screwdrivers into slots cast in case ends.

Then gently pry upward to break sealer bead.

CAUTION: Do not pry against the sealing surfaces

of the front case or rear case. The surfaces could

be damaged.

(12) Remove rear case and oil pump as assembly

(Fig. 11).(13) Slide oil screen (Fig. 12) out of case pocket.

(14) Remove oil pump, pickup tube and oil screen

from rear case (Fig. 13).

(15) Remove pickup tube and screen from pump.

(16) Remove pickup tube O-ring from oil pump

(Fig. 14).

(17) Remove and discard oil pump seal.

(18) The oil pump can be disassembled for cleaning

and inspection as described in step (19).However,

pump parts are not serviceable separately. If

any pump component is worn, or damaged,

pump must be replaced as an assembly.

(19) If oil pump will be disassembled for inspec-

tion, mark position of oil pump housings for refer-

Fig. 10 Loosening Rear Case

Fig. 11 Removing Rear Case And Oil Pump

Fig. 12 Unseating Oil Screen

Fig. 13 Removing Oil Pump, Tube And Screen

21 - 298 NP242 TRANSFER CASEJ

Page 1410 of 1784

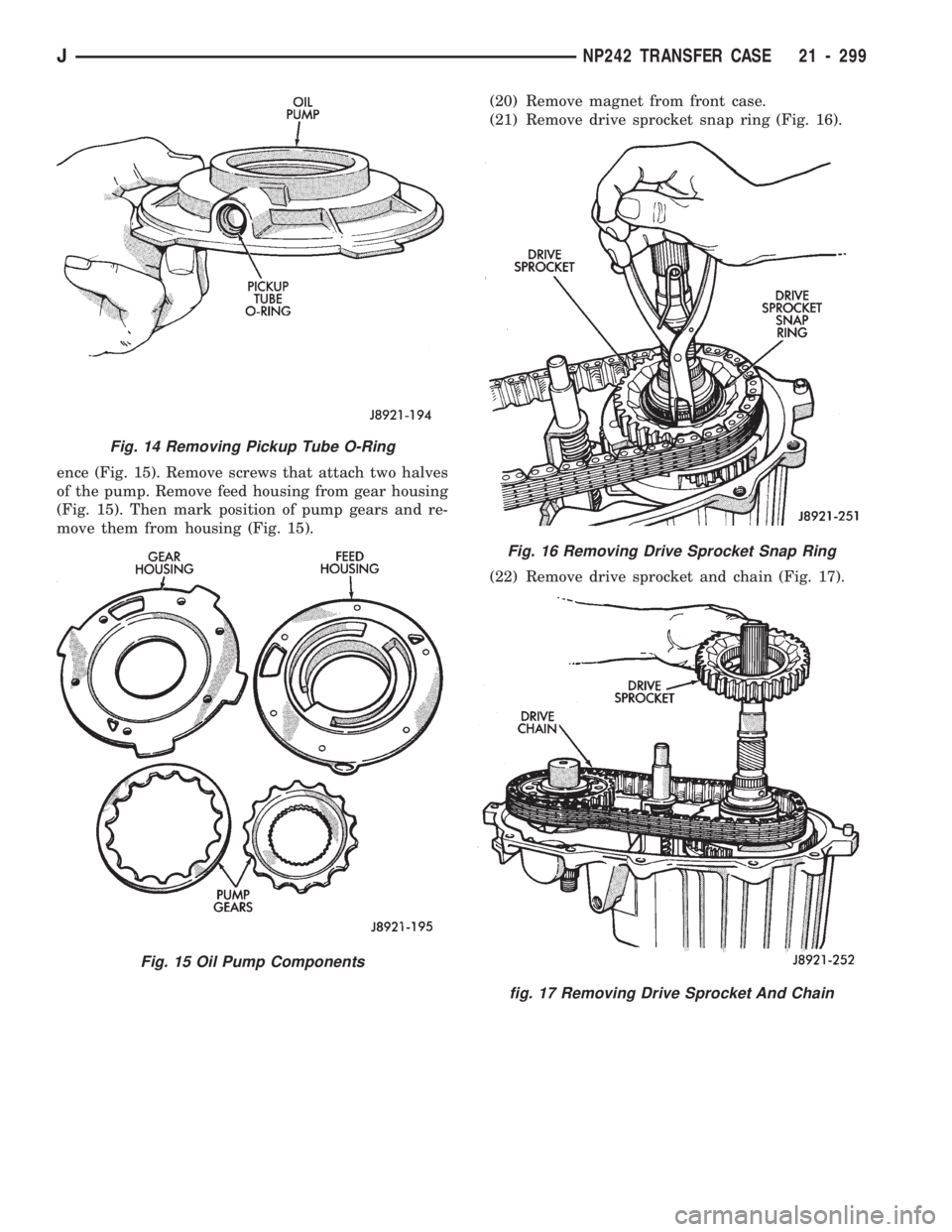

ence (Fig. 15). Remove screws that attach two halves

of the pump. Remove feed housing from gear housing

(Fig. 15). Then mark position of pump gears and re-

move them from housing (Fig. 15).(20) Remove magnet from front case.

(21) Remove drive sprocket snap ring (Fig. 16).

(22) Remove drive sprocket and chain (Fig. 17).

Fig. 14 Removing Pickup Tube O-Ring

Fig. 15 Oil Pump Components

Fig. 16 Removing Drive Sprocket Snap Ring

fig. 17 Removing Drive Sprocket And Chain

JNP242 TRANSFER CASE 21 - 299