JEEP CHEROKEE 1994 Service Repair Manual

CHEROKEE 1994

JEEP

JEEP

https://www.carmanualsonline.info/img/16/57038/w960_57038-0.png

JEEP CHEROKEE 1994 Service Repair Manual

Trending: radio antenna, check oil, jump start, stop start, snow chains, Starter, heater

Page 1411 of 1784

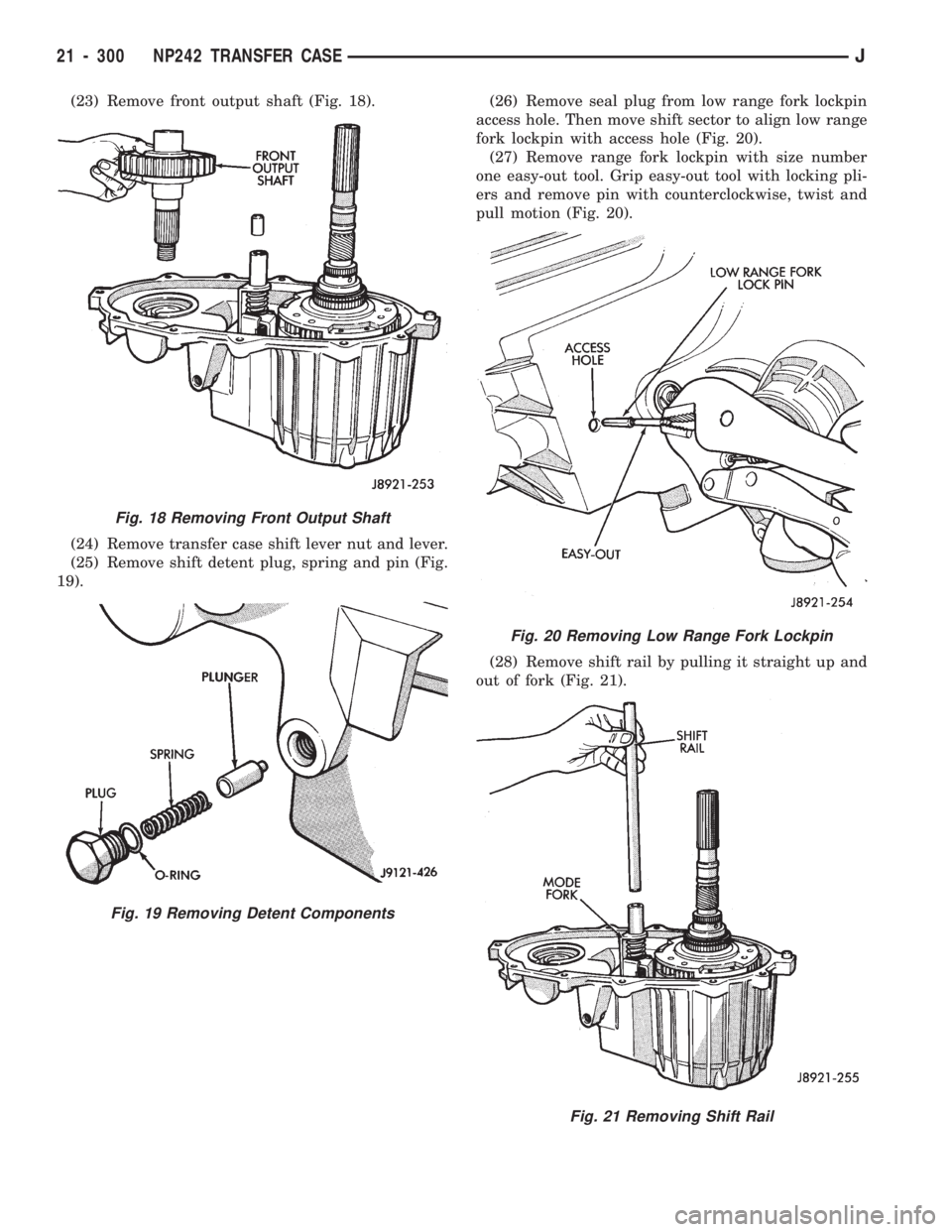

(23) Remove front output shaft (Fig. 18).

(24) Remove transfer case shift lever nut and lever.

(25) Remove shift detent plug, spring and pin (Fig.

19).(26) Remove seal plug from low range fork lockpin

access hole. Then move shift sector to align low range

fork lockpin with access hole (Fig. 20).

(27) Remove range fork lockpin with size number

one easy-out tool. Grip easy-out tool with locking pli-

ers and remove pin with counterclockwise, twist and

pull motion (Fig. 20).

(28) Remove shift rail by pulling it straight up and

out of fork (Fig. 21).

Fig. 18 Removing Front Output Shaft

Fig. 19 Removing Detent Components

Fig. 20 Removing Low Range Fork Lockpin

Fig. 21 Removing Shift Rail

21 - 300 NP242 TRANSFER CASEJ

Page 1412 of 1784

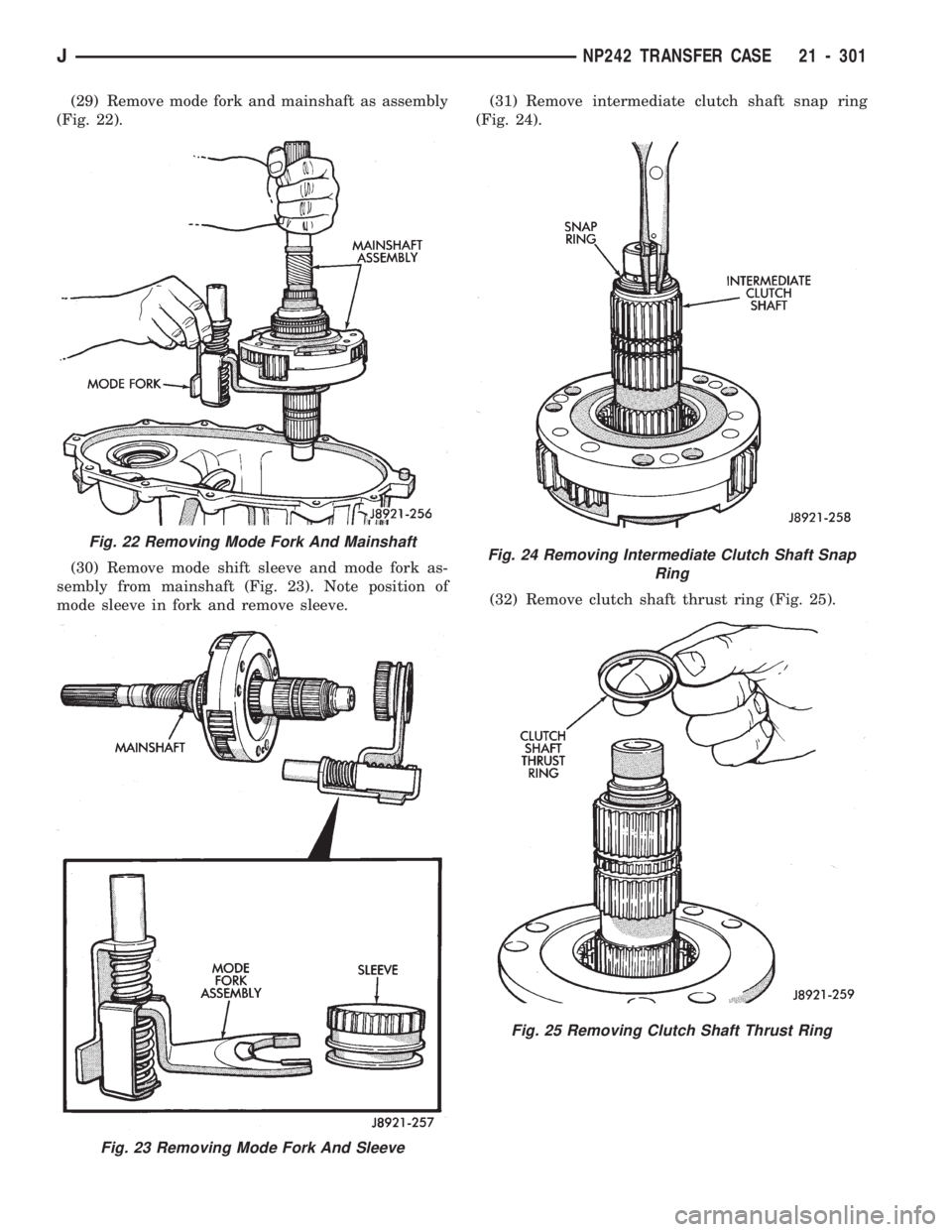

(29) Remove mode fork and mainshaft as assembly

(Fig. 22).

(30) Remove mode shift sleeve and mode fork as-

sembly from mainshaft (Fig. 23). Note position of

mode sleeve in fork and remove sleeve.(31) Remove intermediate clutch shaft snap ring

(Fig. 24).

(32) Remove clutch shaft thrust ring (Fig. 25).

Fig. 22 Removing Mode Fork And Mainshaft

Fig. 23 Removing Mode Fork And Sleeve

Fig. 24 Removing Intermediate Clutch Shaft Snap

Ring

Fig. 25 Removing Clutch Shaft Thrust Ring

JNP242 TRANSFER CASE 21 - 301

Page 1413 of 1784

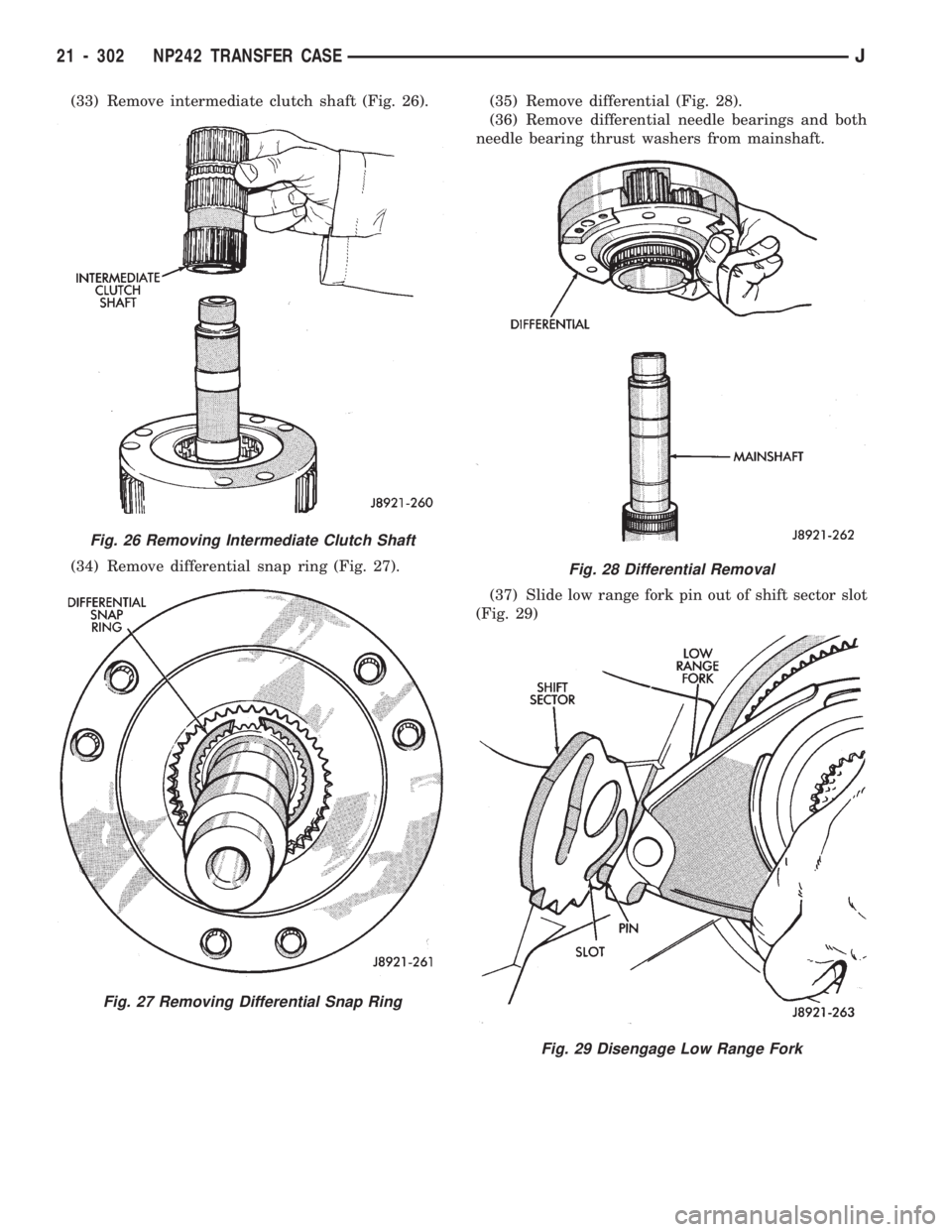

(33) Remove intermediate clutch shaft (Fig. 26).

(34) Remove differential snap ring (Fig. 27).(35) Remove differential (Fig. 28).

(36) Remove differential needle bearings and both

needle bearing thrust washers from mainshaft.

(37) Slide low range fork pin out of shift sector slot

(Fig. 29)

Fig. 26 Removing Intermediate Clutch Shaft

Fig. 27 Removing Differential Snap Ring

Fig. 28 Differential Removal

Fig. 29 Disengage Low Range Fork

21 - 302 NP242 TRANSFER CASEJ

Page 1414 of 1784

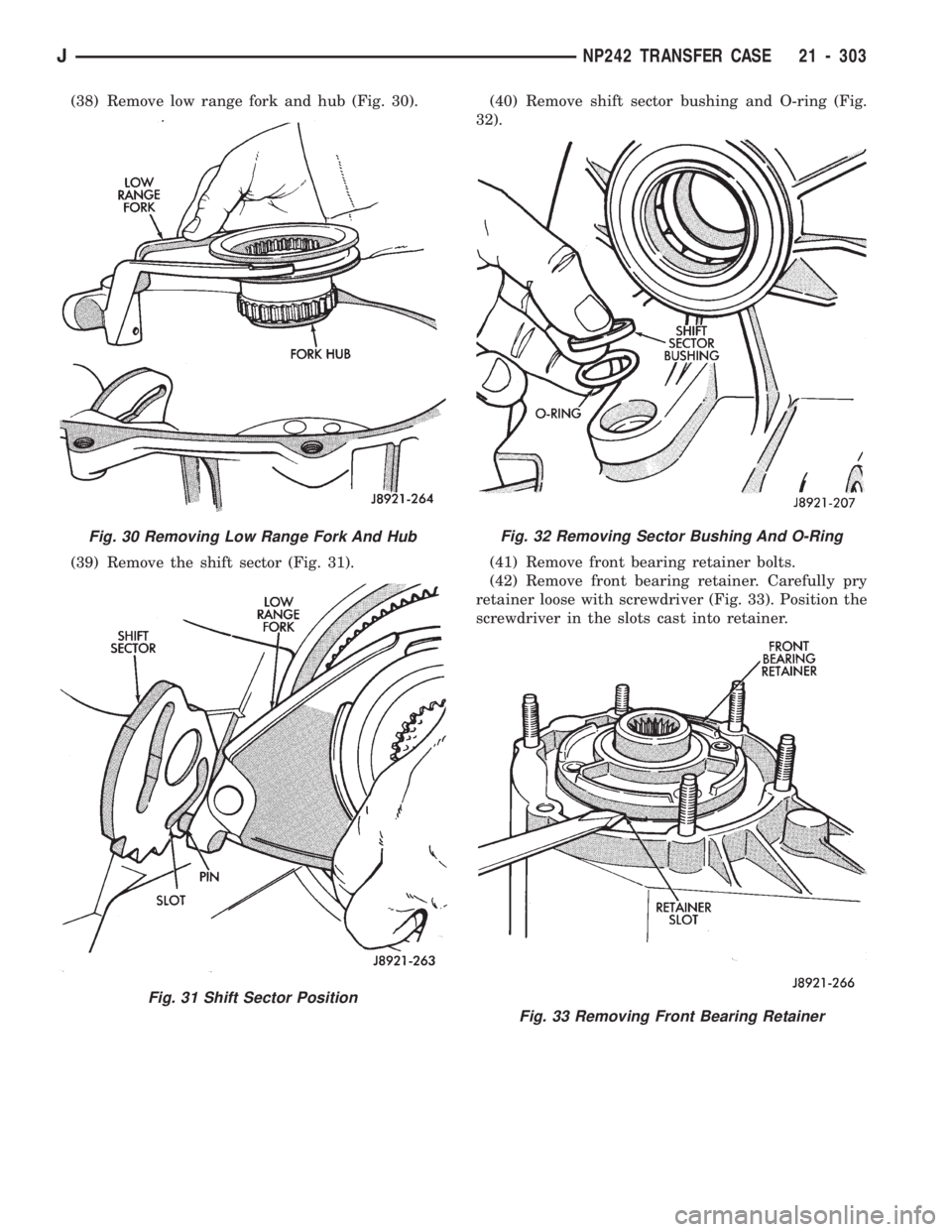

(38) Remove low range fork and hub (Fig. 30).

(39) Remove the shift sector (Fig. 31).(40) Remove shift sector bushing and O-ring (Fig.

32).

(41) Remove front bearing retainer bolts.

(42) Remove front bearing retainer. Carefully pry

retainer loose with screwdriver (Fig. 33). Position the

screwdriver in the slots cast into retainer.

Fig. 30 Removing Low Range Fork And Hub

Fig. 31 Shift Sector Position

Fig. 32 Removing Sector Bushing And O-Ring

Fig. 33 Removing Front Bearing Retainer

JNP242 TRANSFER CASE 21 - 303

Page 1415 of 1784

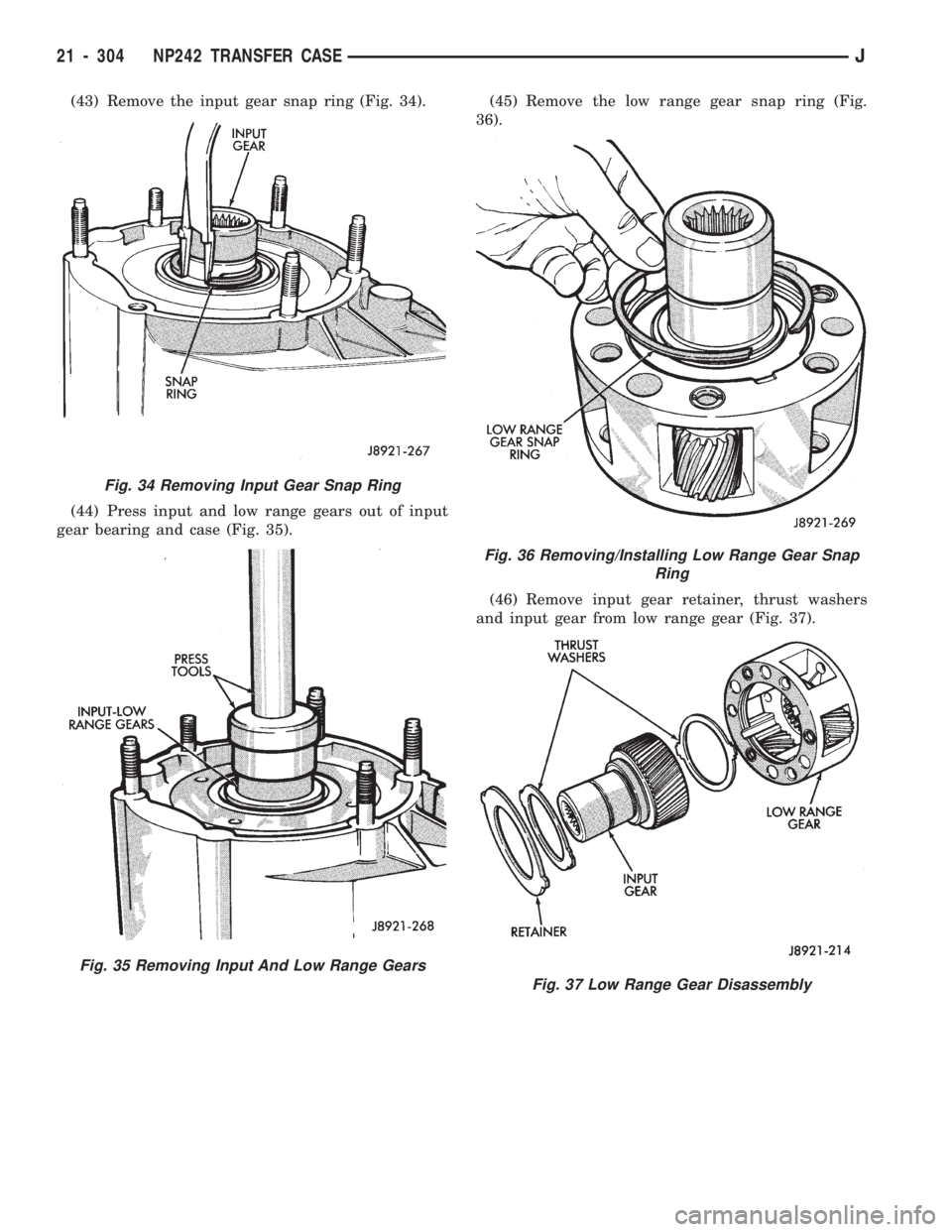

(43) Remove the input gear snap ring (Fig. 34).

(44) Press input and low range gears out of input

gear bearing and case (Fig. 35).(45) Remove the low range gear snap ring (Fig.

36).

(46) Remove input gear retainer, thrust washers

and input gear from low range gear (Fig. 37).

Fig. 34 Removing Input Gear Snap Ring

Fig. 35 Removing Input And Low Range Gears

Fig. 36 Removing/Installing Low Range Gear Snap

Ring

Fig. 37 Low Range Gear Disassembly

21 - 304 NP242 TRANSFER CASEJ

Page 1416 of 1784

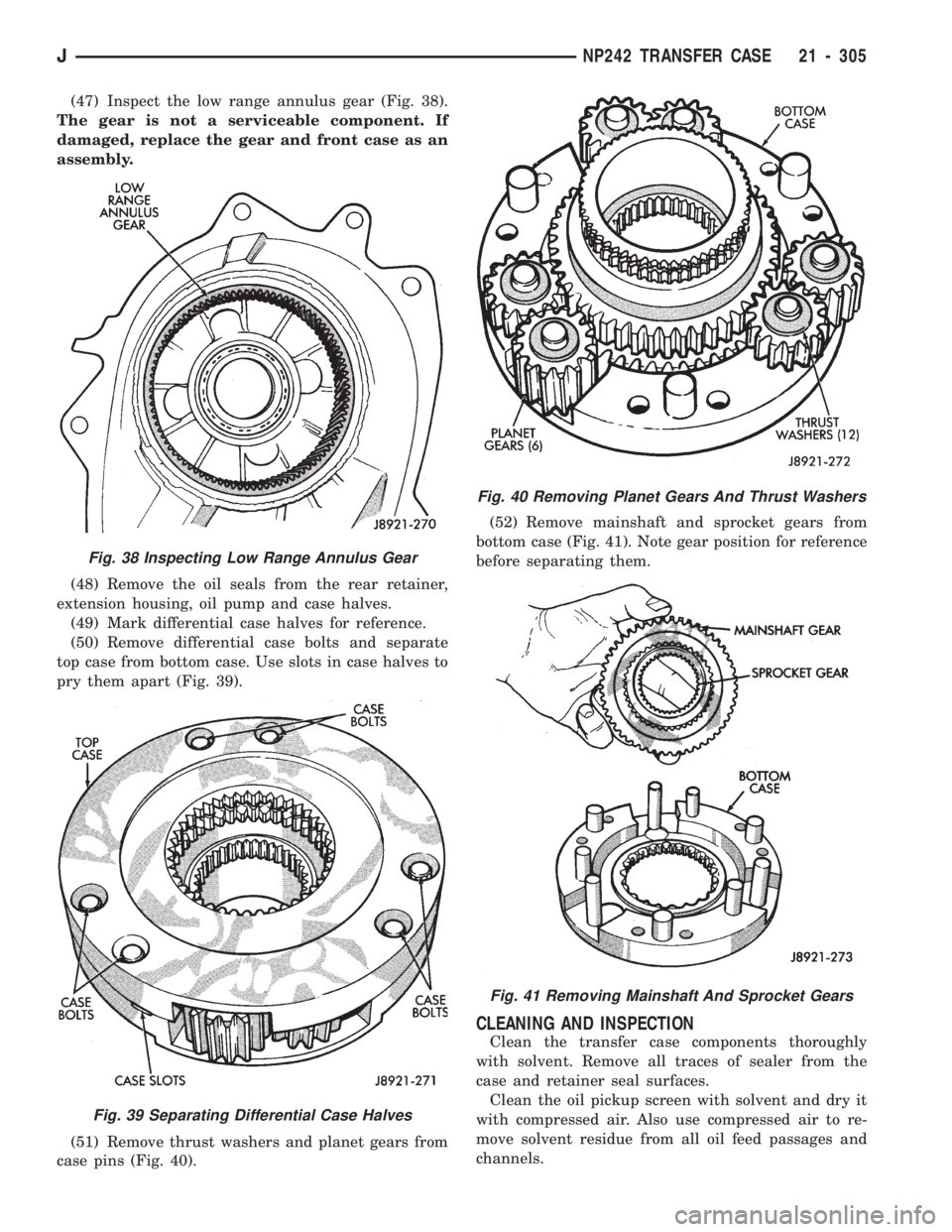

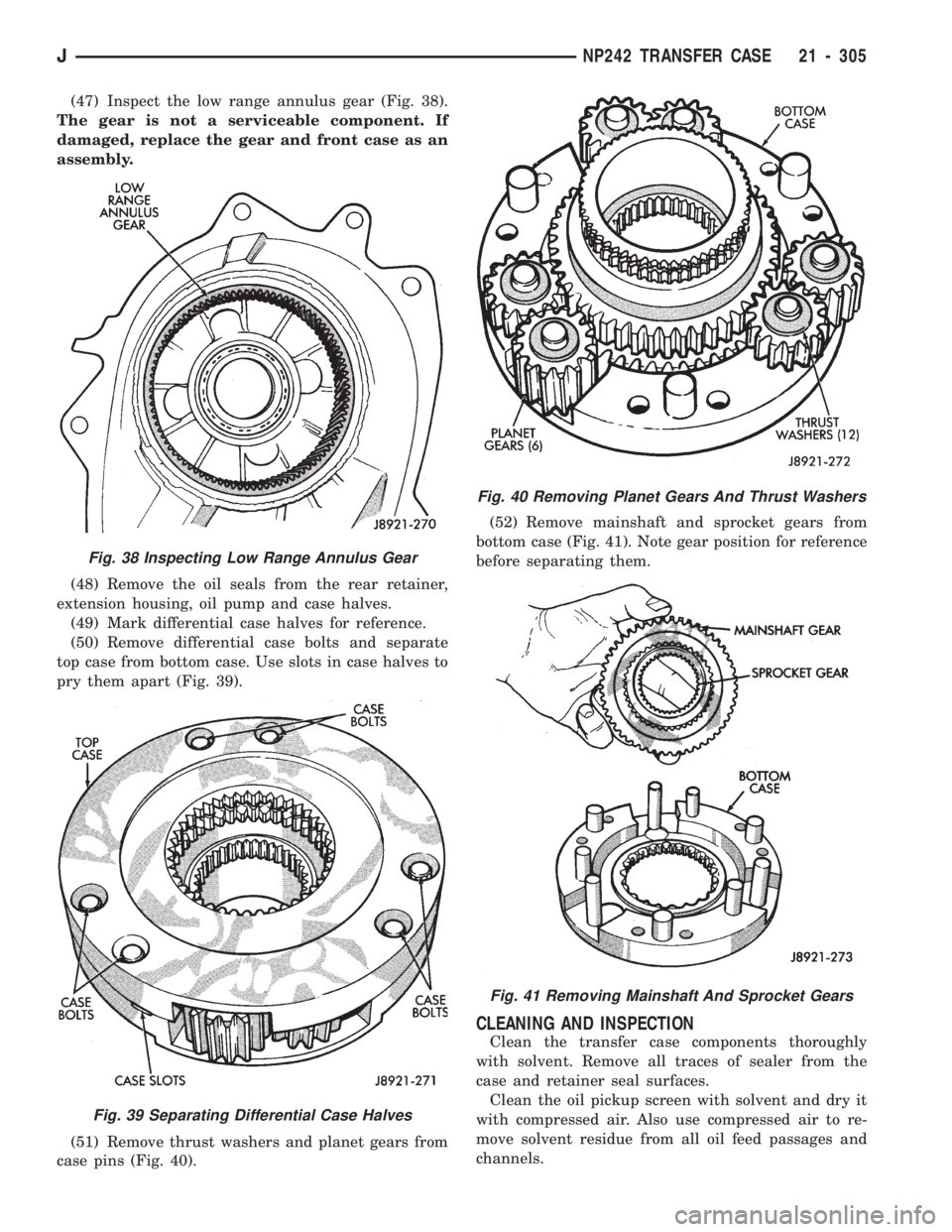

(47) Inspect the low range annulus gear (Fig. 38).

The gear is not a serviceable component. If

damaged, replace the gear and front case as an

assembly.

(48) Remove the oil seals from the rear retainer,

extension housing, oil pump and case halves.

(49) Mark differential case halves for reference.

(50) Remove differential case bolts and separate

top case from bottom case. Use slots in case halves to

pry them apart (Fig. 39).

(51) Remove thrust washers and planet gears from

case pins (Fig. 40).(52) Remove mainshaft and sprocket gears from

bottom case (Fig. 41). Note gear position for reference

before separating them.

CLEANING AND INSPECTION

Clean the transfer case components thoroughly

with solvent. Remove all traces of sealer from the

case and retainer seal surfaces.

Clean the oil pickup screen with solvent and dry it

with compressed air. Also use compressed air to re-

move solvent residue from all oil feed passages and

channels.

Fig. 38 Inspecting Low Range Annulus Gear

Fig. 39 Separating Differential Case Halves

Fig. 40 Removing Planet Gears And Thrust Washers

Fig. 41 Removing Mainshaft And Sprocket Gears

JNP242 TRANSFER CASE 21 - 305

Page 1417 of 1784

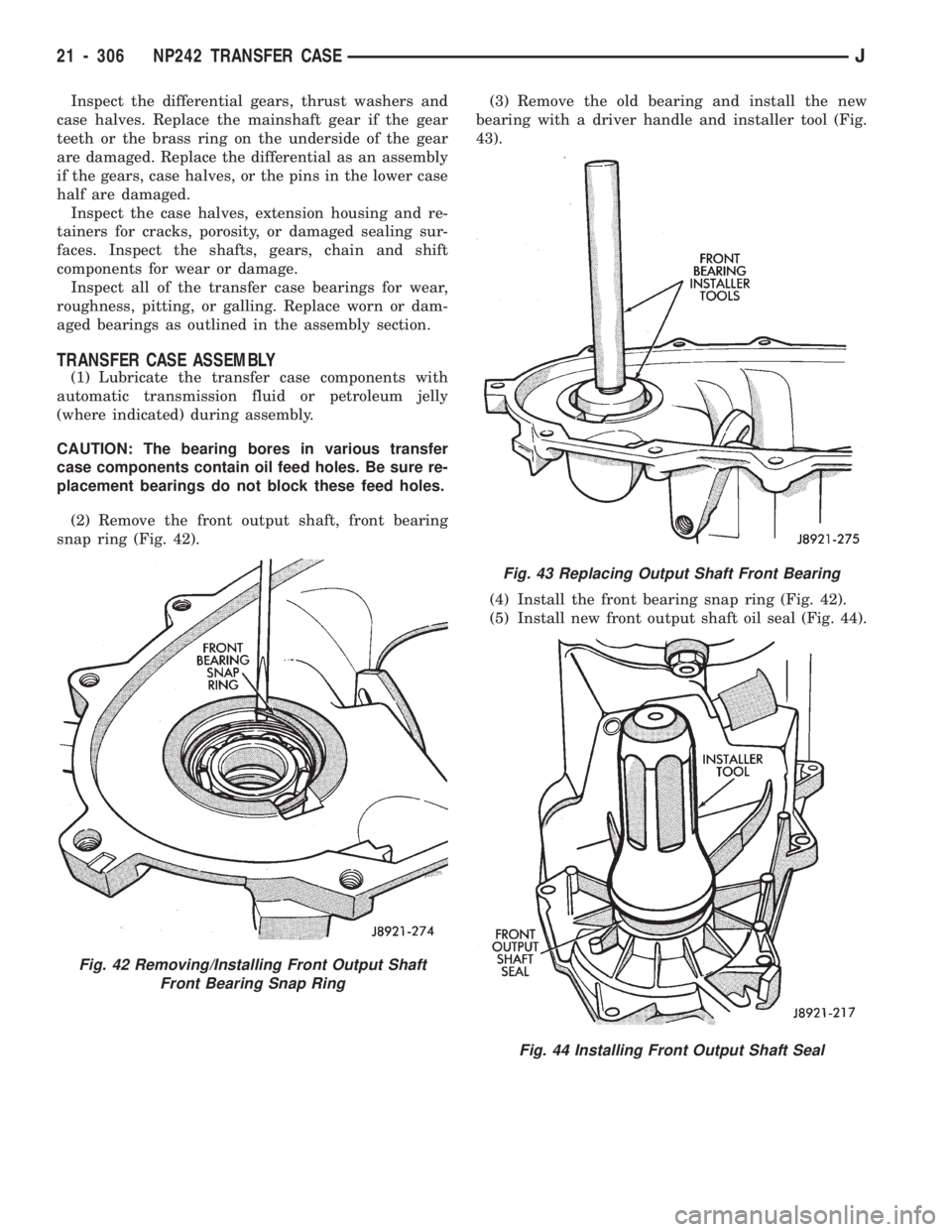

Inspect the differential gears, thrust washers and

case halves. Replace the mainshaft gear if the gear

teeth or the brass ring on the underside of the gear

are damaged. Replace the differential as an assembly

if the gears, case halves, or the pins in the lower case

half are damaged.

Inspect the case halves, extension housing and re-

tainers for cracks, porosity, or damaged sealing sur-

faces. Inspect the shafts, gears, chain and shift

components for wear or damage.

Inspect all of the transfer case bearings for wear,

roughness, pitting, or galling. Replace worn or dam-

aged bearings as outlined in the assembly section.

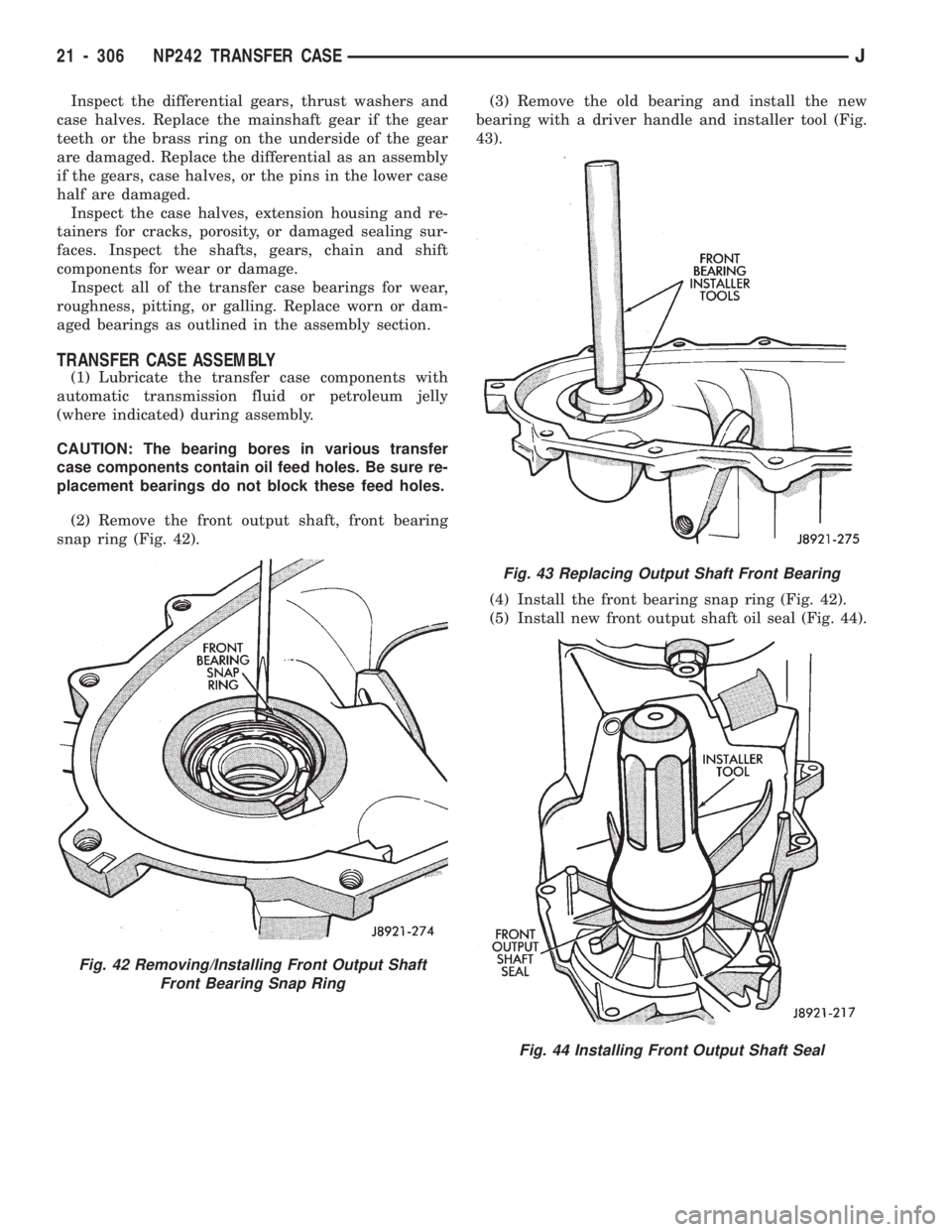

TRANSFER CASE ASSEMBLY

(1) Lubricate the transfer case components with

automatic transmission fluid or petroleum jelly

(where indicated) during assembly.

CAUTION: The bearing bores in various transfer

case components contain oil feed holes. Be sure re-

placement bearings do not block these feed holes.

(2) Remove the front output shaft, front bearing

snap ring (Fig. 42).(3) Remove the old bearing and install the new

bearing with a driver handle and installer tool (Fig.

43).

(4) Install the front bearing snap ring (Fig. 42).

(5) Install new front output shaft oil seal (Fig. 44).

Fig. 42 Removing/Installing Front Output Shaft

Front Bearing Snap Ring

Fig. 43 Replacing Output Shaft Front Bearing

Fig. 44 Installing Front Output Shaft Seal

21 - 306 NP242 TRANSFER CASEJ

Page 1418 of 1784

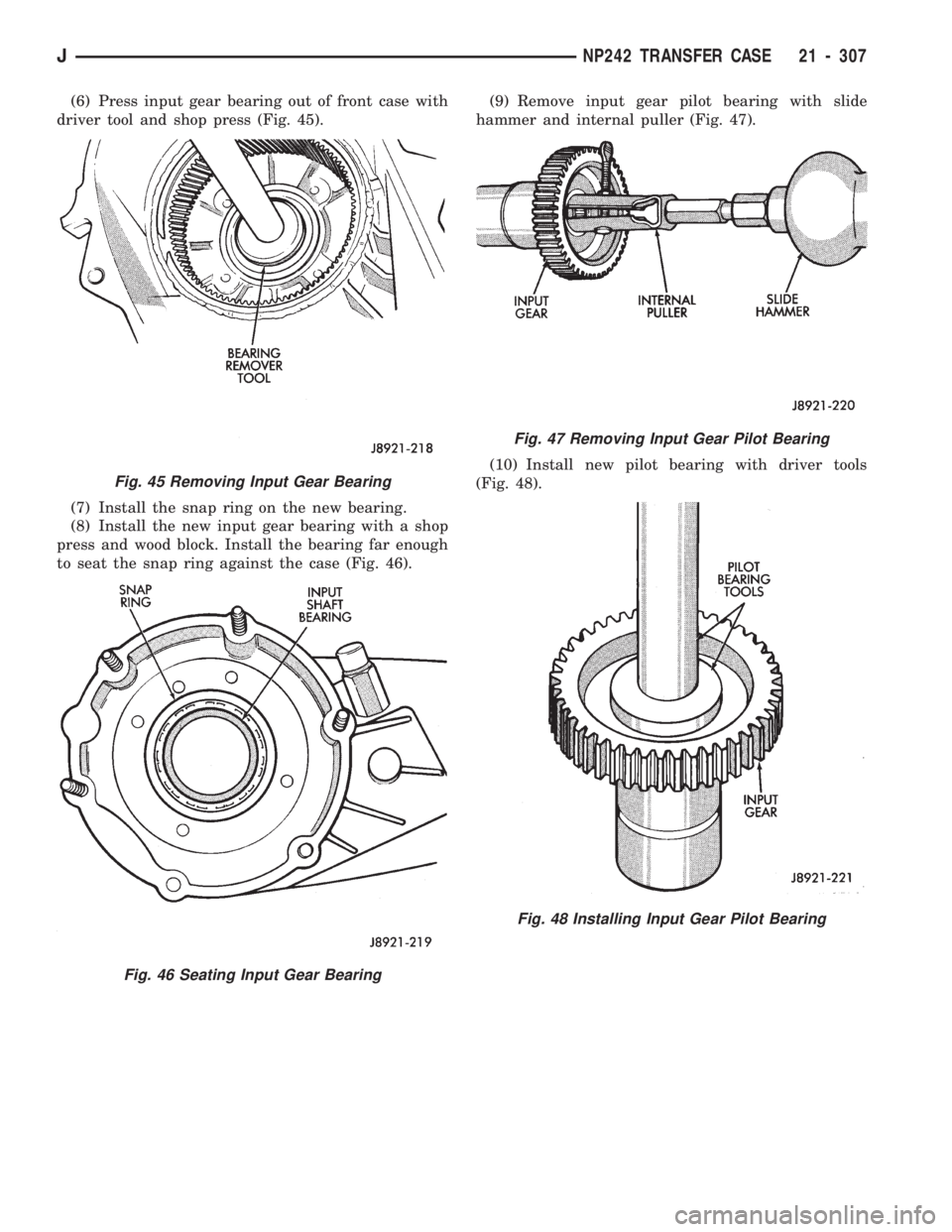

(6) Press input gear bearing out of front case with

driver tool and shop press (Fig. 45).

(7) Install the snap ring on the new bearing.

(8) Install the new input gear bearing with a shop

press and wood block. Install the bearing far enough

to seat the snap ring against the case (Fig. 46).(9) Remove input gear pilot bearing with slide

hammer and internal puller (Fig. 47).

(10) Install new pilot bearing with driver tools

(Fig. 48).

Fig. 45 Removing Input Gear Bearing

Fig. 46 Seating Input Gear Bearing

Fig. 47 Removing Input Gear Pilot Bearing

Fig. 48 Installing Input Gear Pilot Bearing

JNP242 TRANSFER CASE 21 - 307

Page 1419 of 1784

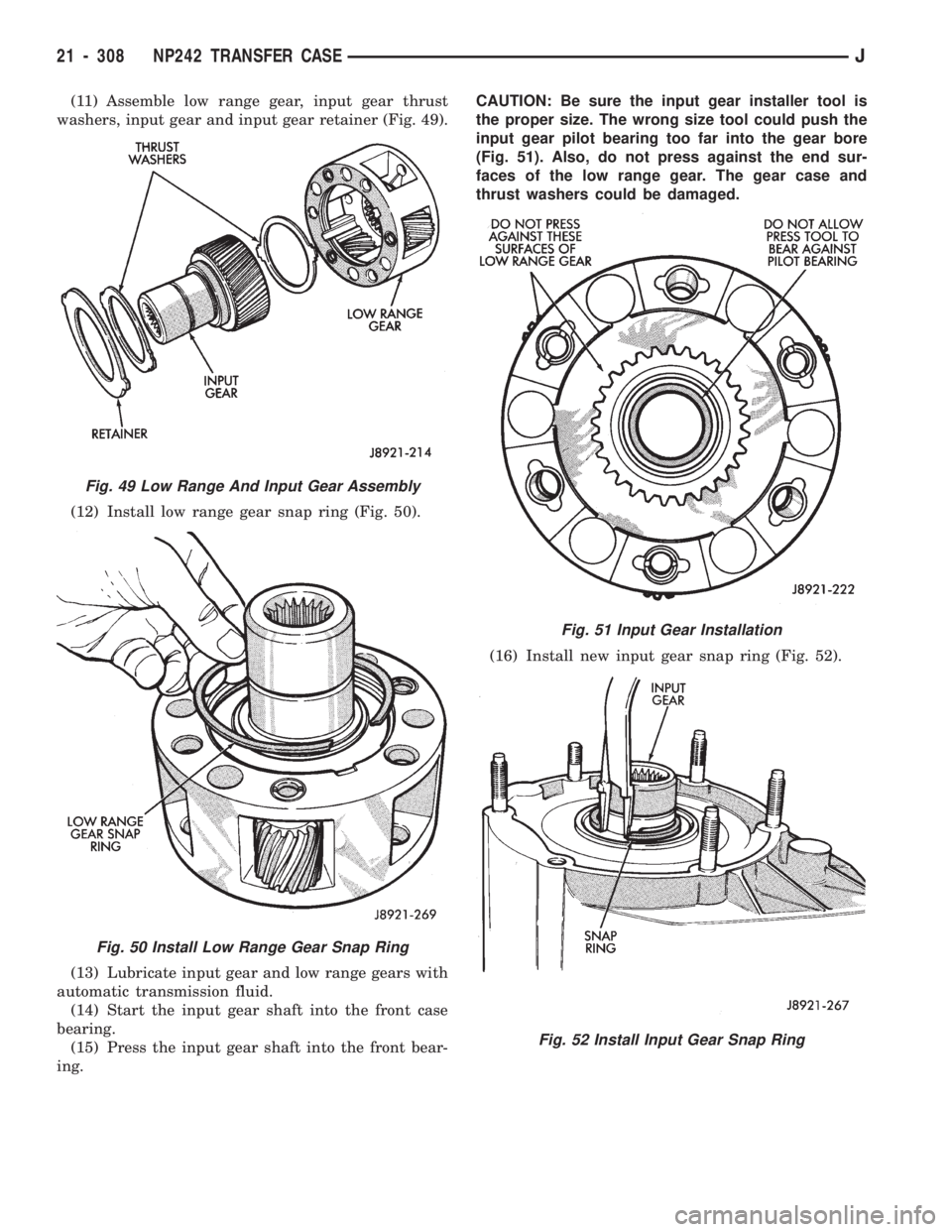

(11) Assemble low range gear, input gear thrust

washers, input gear and input gear retainer (Fig. 49).

(12) Install low range gear snap ring (Fig. 50).

(13) Lubricate input gear and low range gears with

automatic transmission fluid.

(14) Start the input gear shaft into the front case

bearing.

(15) Press the input gear shaft into the front bear-

ing.CAUTION: Be sure the input gear installer tool is

the proper size. The wrong size tool could push the

input gear pilot bearing too far into the gear bore

(Fig. 51). Also, do not press against the end sur-

faces of the low range gear. The gear case and

thrust washers could be damaged.

(16) Install new input gear snap ring (Fig. 52).

Fig. 49 Low Range And Input Gear Assembly

Fig. 50 Install Low Range Gear Snap Ring

Fig. 51 Input Gear Installation

Fig. 52 Install Input Gear Snap Ring

21 - 308 NP242 TRANSFER CASEJ

Page 1420 of 1784

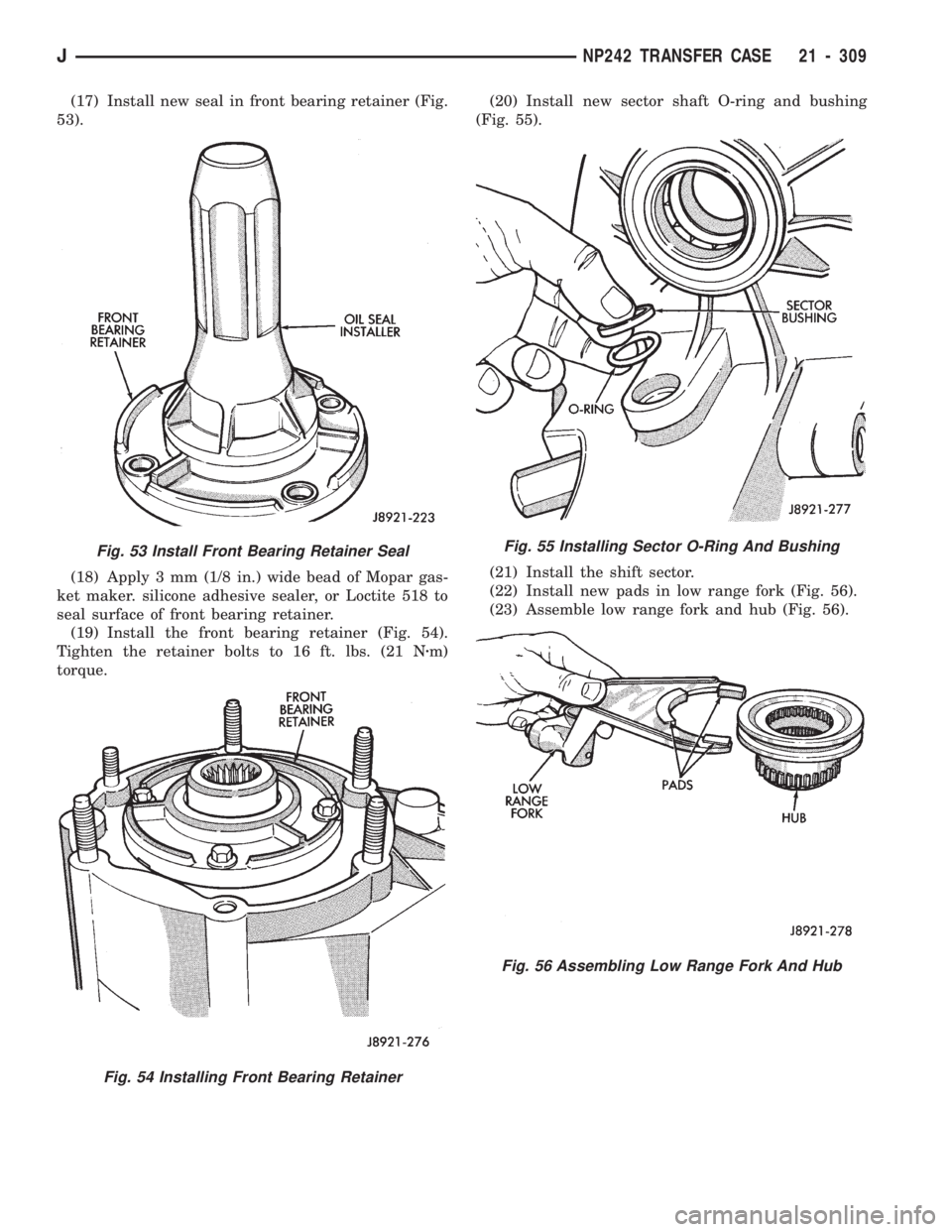

(17) Install new seal in front bearing retainer (Fig.

53).

(18) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker. silicone adhesive sealer, or Loctite 518 to

seal surface of front bearing retainer.

(19) Install the front bearing retainer (Fig. 54).

Tighten the retainer bolts to 16 ft. lbs. (21 Nzm)

torque.(20) Install new sector shaft O-ring and bushing

(Fig. 55).

(21) Install the shift sector.

(22) Install new pads in low range fork (Fig. 56).

(23) Assemble low range fork and hub (Fig. 56).

Fig. 55 Installing Sector O-Ring And Bushing

Fig. 56 Assembling Low Range Fork And Hub

Fig. 53 Install Front Bearing Retainer Seal

Fig. 54 Installing Front Bearing Retainer

JNP242 TRANSFER CASE 21 - 309

Trending: boot, brakes, fuel additives, fog light bulb, check transmission fluid, high beam, oil pressure