JEEP CHEROKEE 1994 Service Repair Manual

CHEROKEE 1994

JEEP

JEEP

https://www.carmanualsonline.info/img/16/57038/w960_57038-0.png

JEEP CHEROKEE 1994 Service Repair Manual

Trending: oil, clock, remote start, belt, navigation, fog light bulb, oil change

Page 1421 of 1784

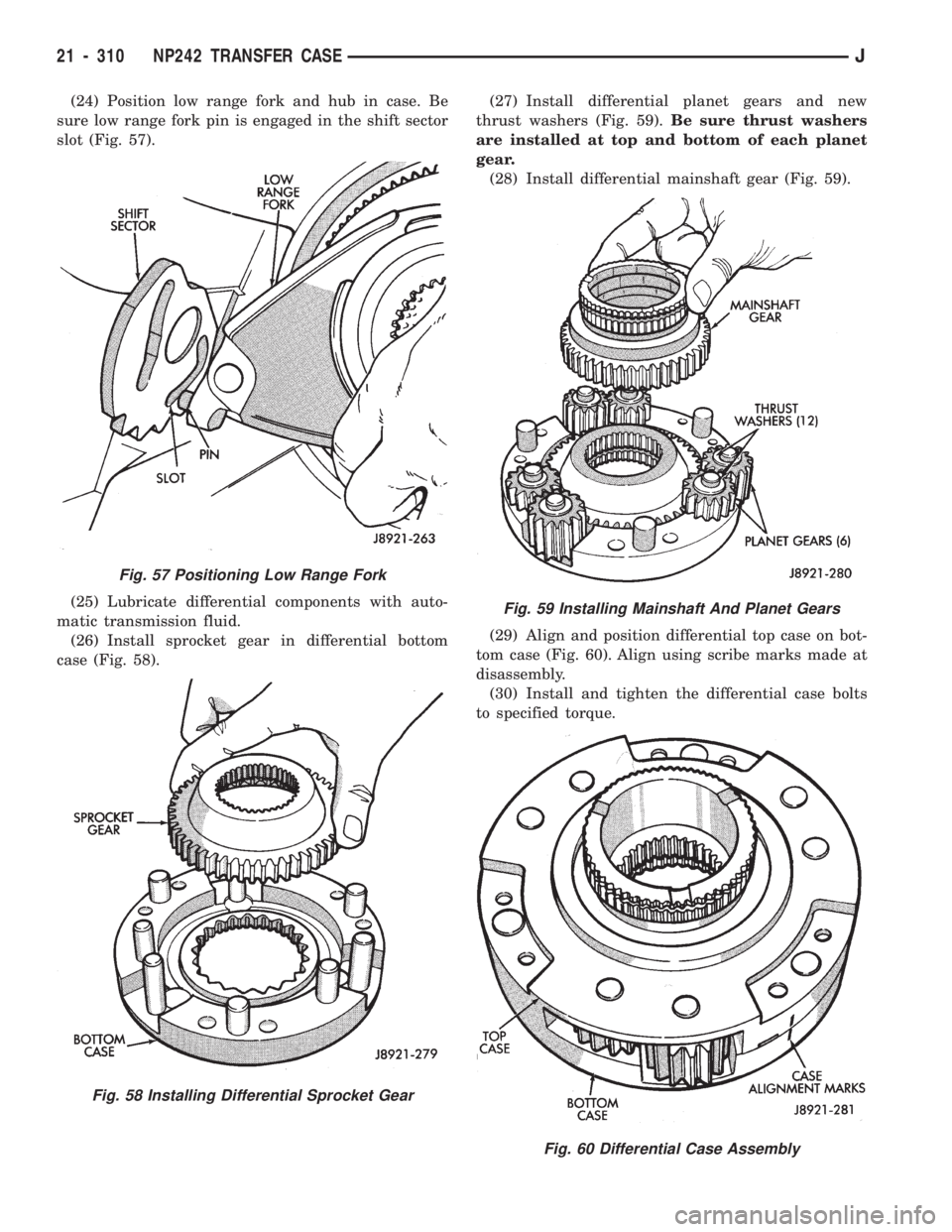

(24) Position low range fork and hub in case. Be

sure low range fork pin is engaged in the shift sector

slot (Fig. 57).

(25) Lubricate differential components with auto-

matic transmission fluid.

(26) Install sprocket gear in differential bottom

case (Fig. 58).(27) Install differential planet gears and new

thrust washers (Fig. 59).Be sure thrust washers

are installed at top and bottom of each planet

gear.

(28) Install differential mainshaft gear (Fig. 59).

(29) Align and position differential top case on bot-

tom case (Fig. 60). Align using scribe marks made at

disassembly.

(30) Install and tighten the differential case bolts

to specified torque.

Fig. 57 Positioning Low Range Fork

Fig. 58 Installing Differential Sprocket Gear

Fig. 59 Installing Mainshaft And Planet Gears

Fig. 60 Differential Case Assembly

21 - 310 NP242 TRANSFER CASEJ

Page 1422 of 1784

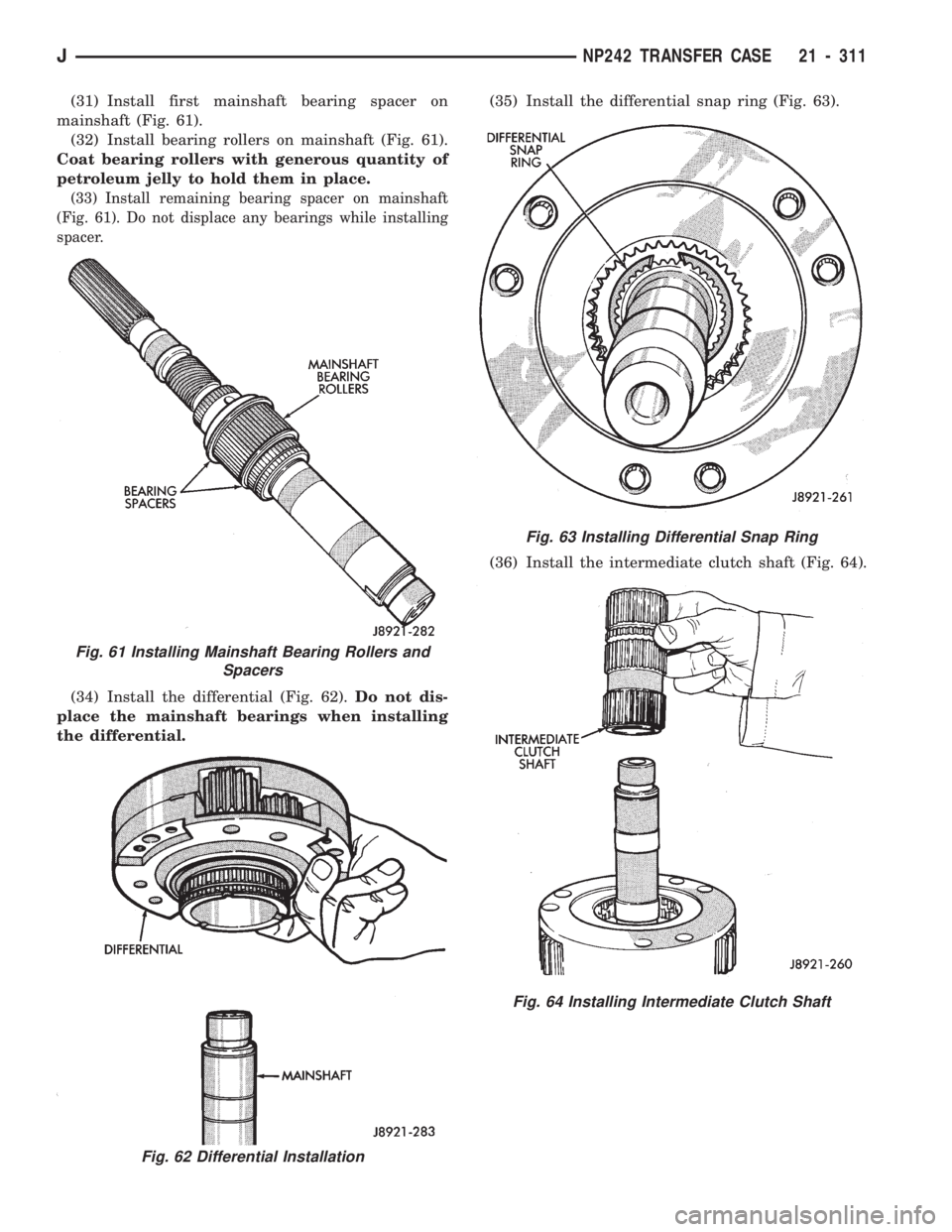

(31) Install first mainshaft bearing spacer on

mainshaft (Fig. 61).

(32) Install bearing rollers on mainshaft (Fig. 61).

Coat bearing rollers with generous quantity of

petroleum jelly to hold them in place.

(33) Install remaining bearing spacer on mainshaft

(Fig. 61). Do not displace any bearings while installing

spacer.

(34) Install the differential (Fig. 62).Do not dis-

place the mainshaft bearings when installing

the differential.(35) Install the differential snap ring (Fig. 63).

(36) Install the intermediate clutch shaft (Fig. 64).

Fig. 61 Installing Mainshaft Bearing Rollers and

Spacers

Fig. 62 Differential Installation

Fig. 63 Installing Differential Snap Ring

Fig. 64 Installing Intermediate Clutch Shaft

JNP242 TRANSFER CASE 21 - 311

Page 1423 of 1784

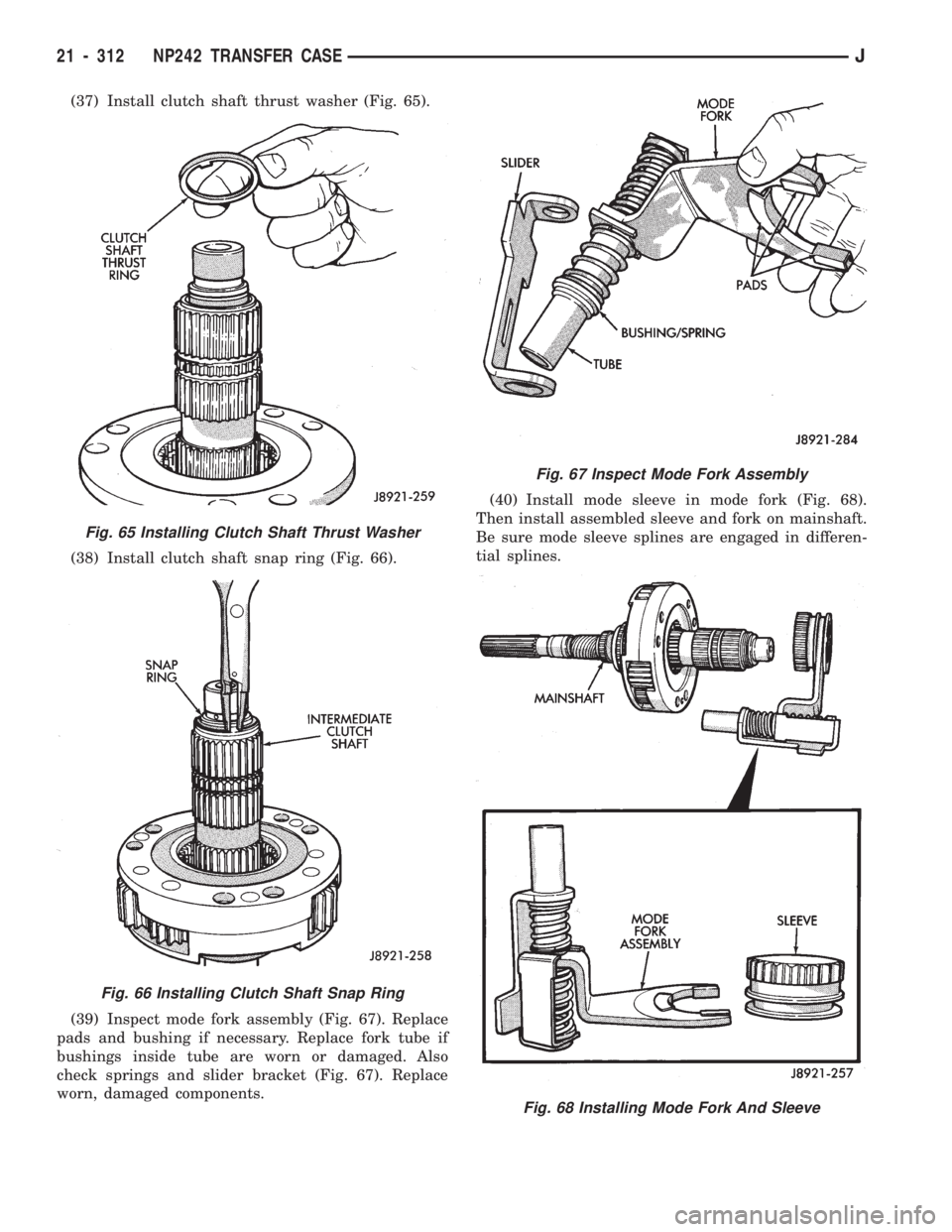

(37) Install clutch shaft thrust washer (Fig. 65).

(38) Install clutch shaft snap ring (Fig. 66).

(39) Inspect mode fork assembly (Fig. 67). Replace

pads and bushing if necessary. Replace fork tube if

bushings inside tube are worn or damaged. Also

check springs and slider bracket (Fig. 67). Replace

worn, damaged components.(40) Install mode sleeve in mode fork (Fig. 68).

Then install assembled sleeve and fork on mainshaft.

Be sure mode sleeve splines are engaged in differen-

tial splines.

Fig. 65 Installing Clutch Shaft Thrust Washer

Fig. 66 Installing Clutch Shaft Snap Ring

Fig. 67 Inspect Mode Fork Assembly

Fig. 68 Installing Mode Fork And Sleeve

21 - 312 NP242 TRANSFER CASEJ

Page 1424 of 1784

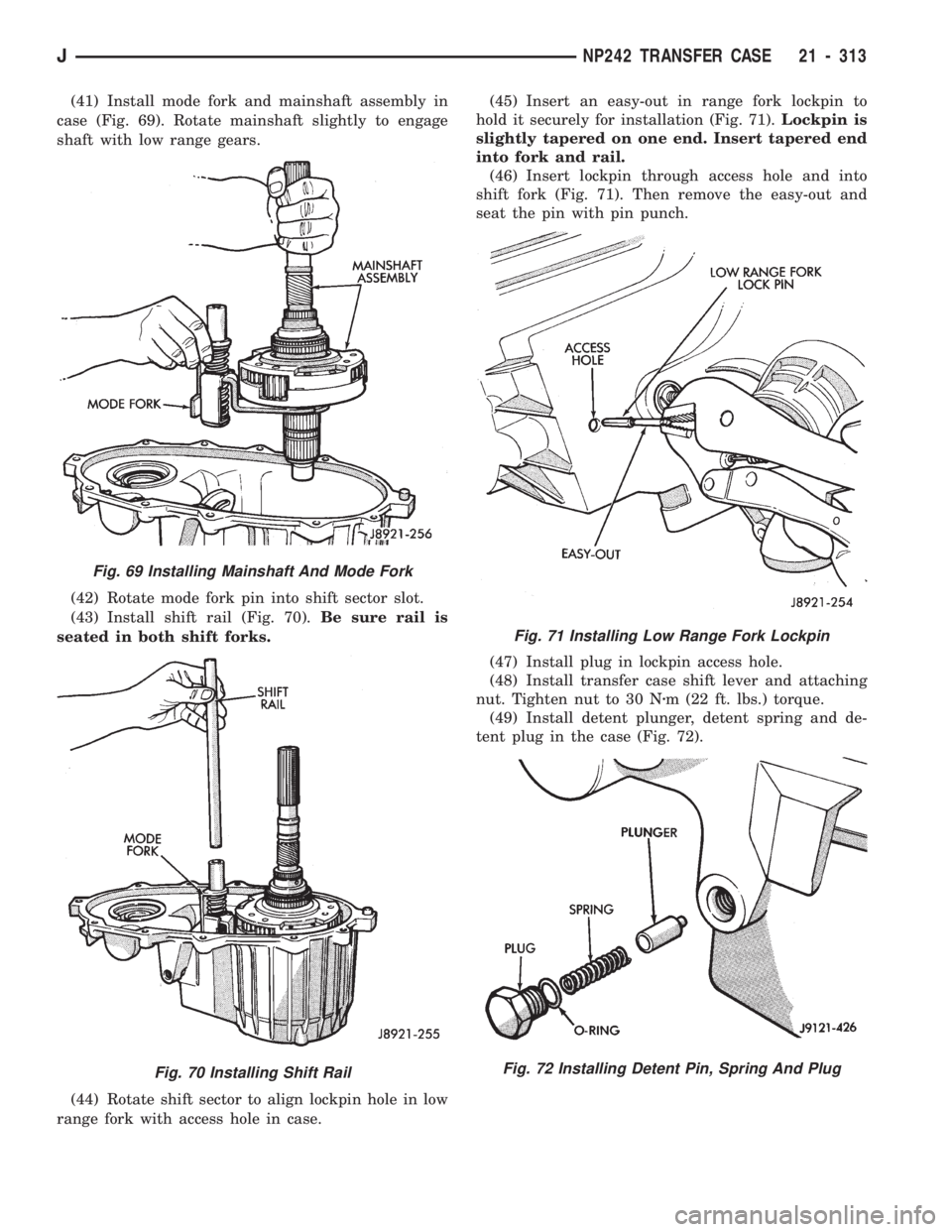

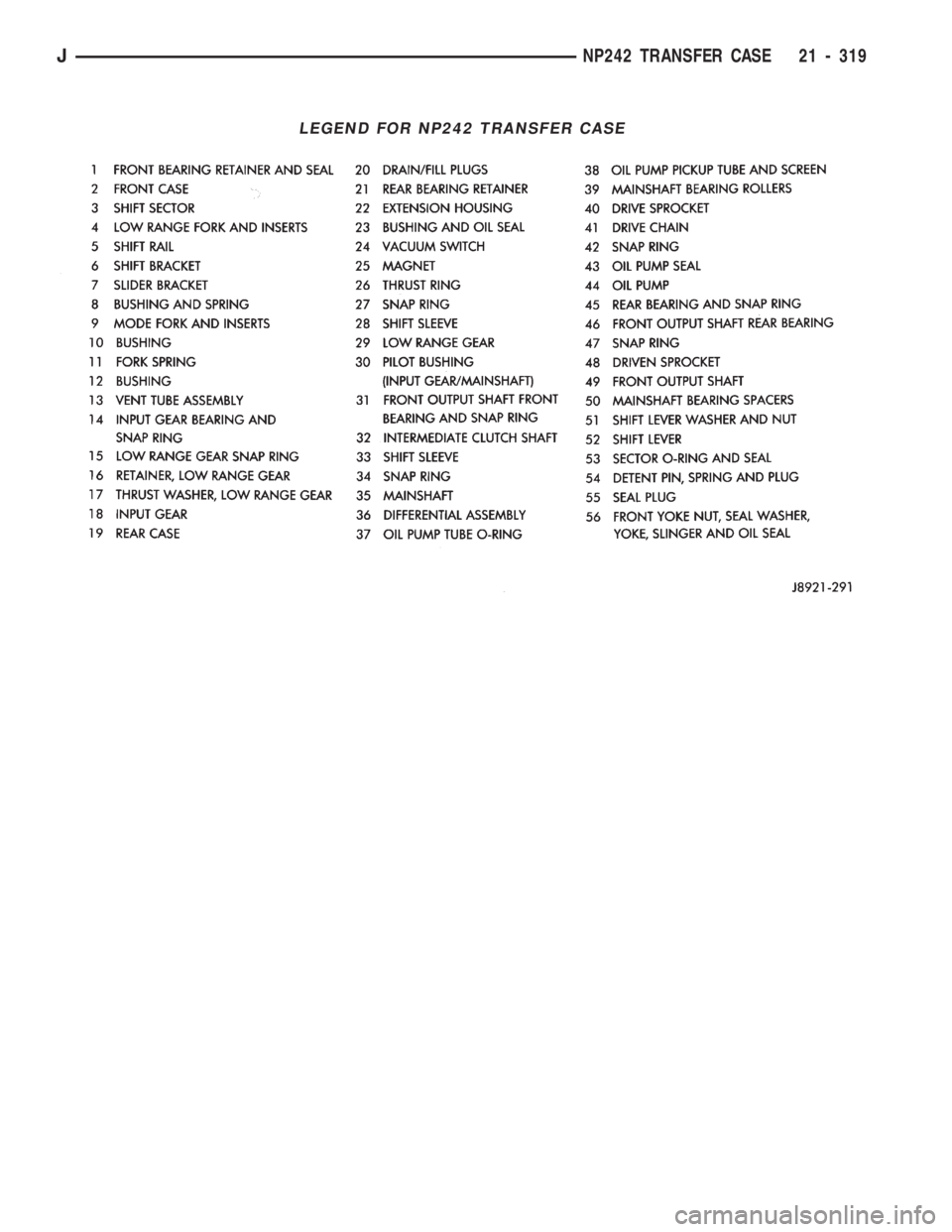

(41) Install mode fork and mainshaft assembly in

case (Fig. 69). Rotate mainshaft slightly to engage

shaft with low range gears.

(42) Rotate mode fork pin into shift sector slot.

(43) Install shift rail (Fig. 70).Be sure rail is

seated in both shift forks.

(44) Rotate shift sector to align lockpin hole in low

range fork with access hole in case.(45) Insert an easy-out in range fork lockpin to

hold it securely for installation (Fig. 71).Lockpin is

slightly tapered on one end. Insert tapered end

into fork and rail.

(46) Insert lockpin through access hole and into

shift fork (Fig. 71). Then remove the easy-out and

seat the pin with pin punch.

(47) Install plug in lockpin access hole.

(48) Install transfer case shift lever and attaching

nut. Tighten nut to 30 Nzm (22 ft. lbs.) torque.

(49) Install detent plunger, detent spring and de-

tent plug in the case (Fig. 72).

Fig. 69 Installing Mainshaft And Mode Fork

Fig. 70 Installing Shift Rail

Fig. 71 Installing Low Range Fork Lockpin

Fig. 72 Installing Detent Pin, Spring And Plug

JNP242 TRANSFER CASE 21 - 313

Page 1425 of 1784

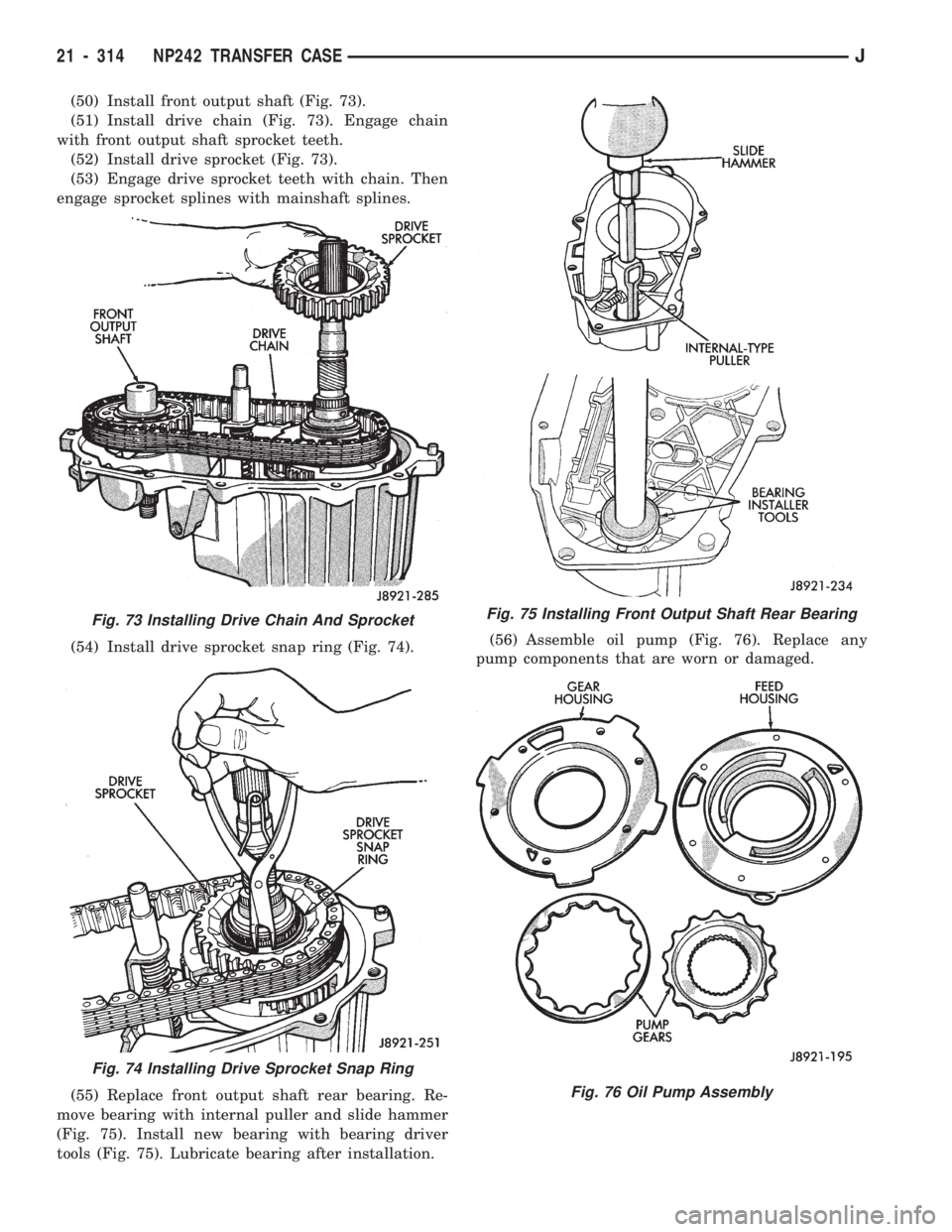

(50) Install front output shaft (Fig. 73).

(51) Install drive chain (Fig. 73). Engage chain

with front output shaft sprocket teeth.

(52) Install drive sprocket (Fig. 73).

(53) Engage drive sprocket teeth with chain. Then

engage sprocket splines with mainshaft splines.

(54) Install drive sprocket snap ring (Fig. 74).

(55) Replace front output shaft rear bearing. Re-

move bearing with internal puller and slide hammer

(Fig. 75). Install new bearing with bearing driver

tools (Fig. 75). Lubricate bearing after installation.(56) Assemble oil pump (Fig. 76). Replace any

pump components that are worn or damaged.

Fig. 73 Installing Drive Chain And Sprocket

Fig. 74 Installing Drive Sprocket Snap Ring

Fig. 75 Installing Front Output Shaft Rear Bearing

Fig. 76 Oil Pump Assembly

21 - 314 NP242 TRANSFER CASEJ

Page 1426 of 1784

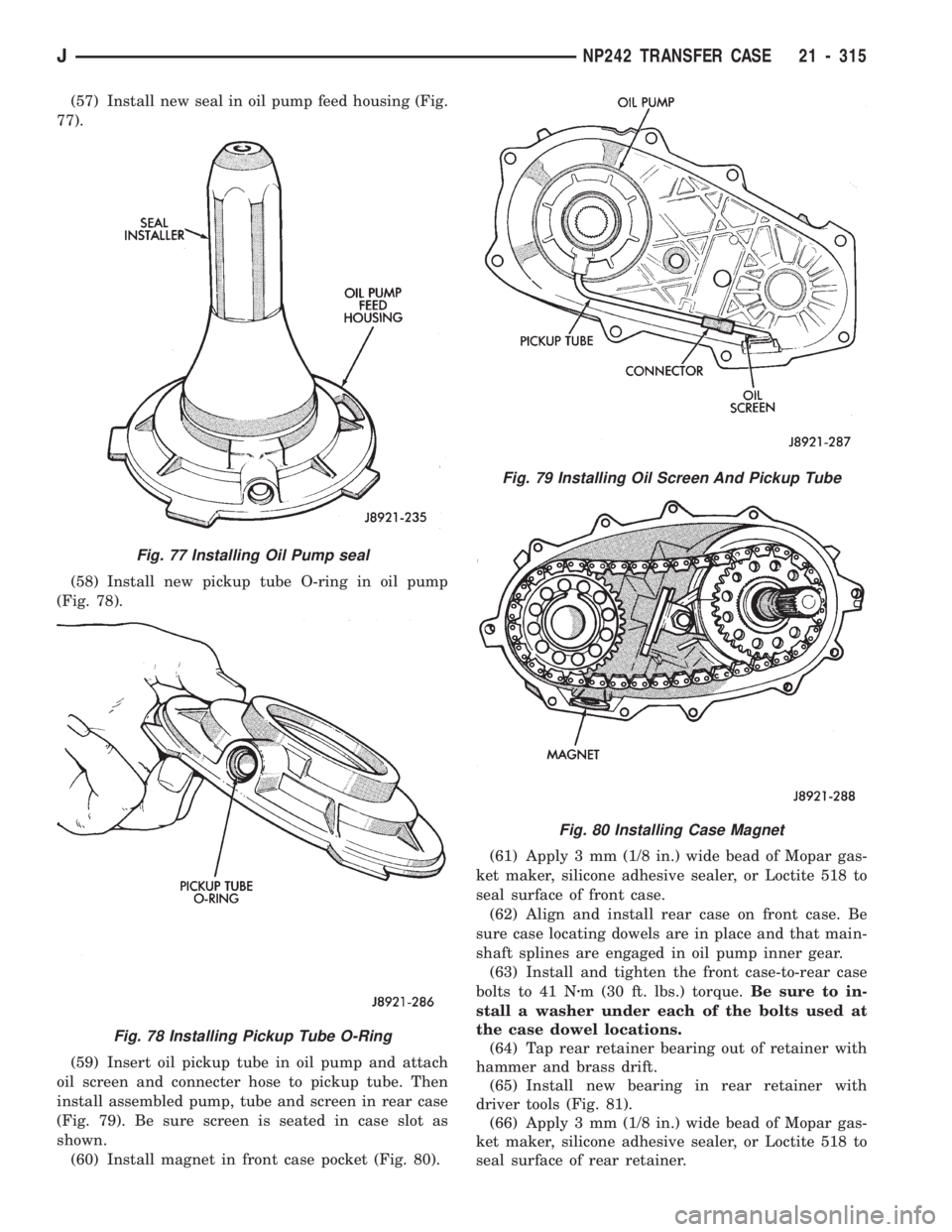

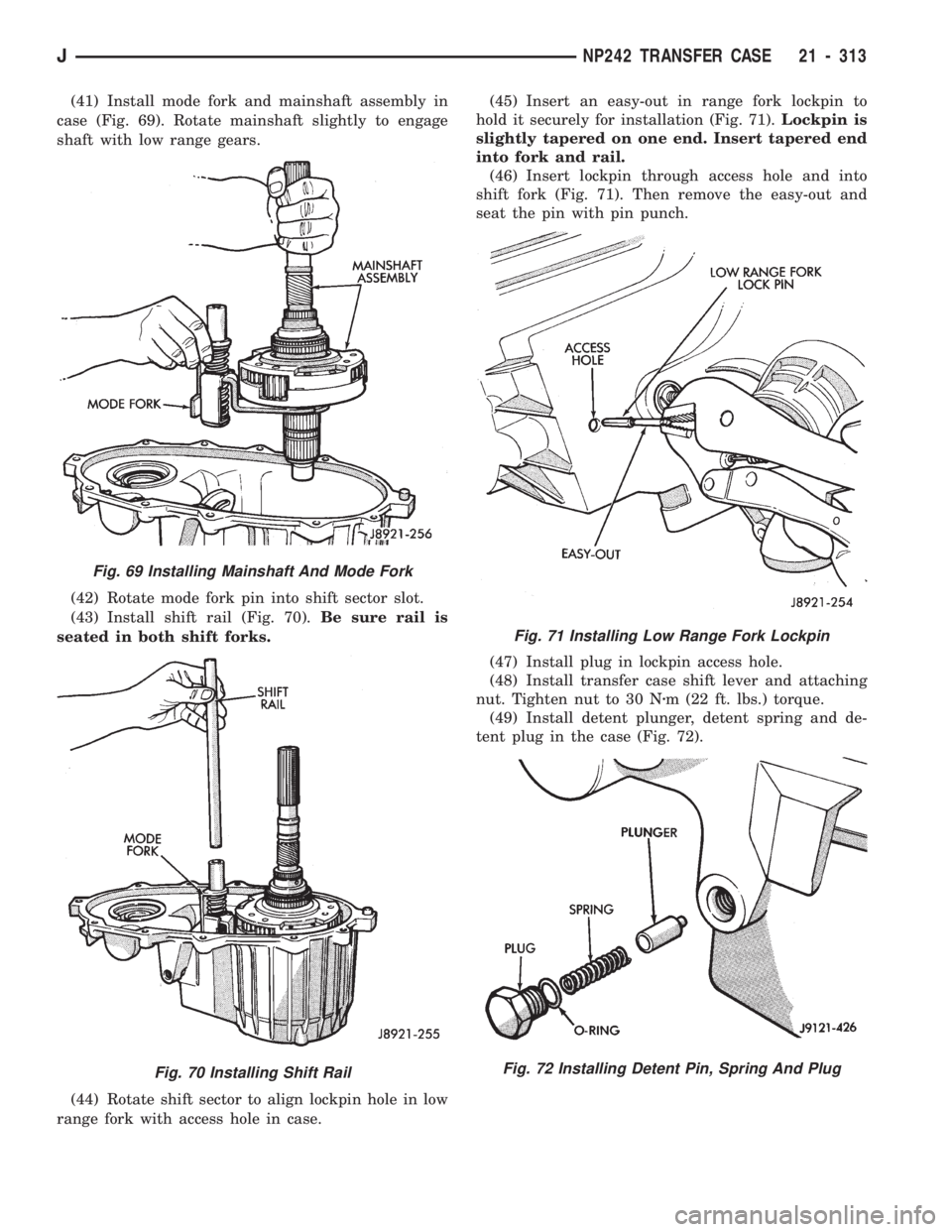

(57) Install new seal in oil pump feed housing (Fig.

77).

(58) Install new pickup tube O-ring in oil pump

(Fig. 78).

(59) Insert oil pickup tube in oil pump and attach

oil screen and connecter hose to pickup tube. Then

install assembled pump, tube and screen in rear case

(Fig. 79). Be sure screen is seated in case slot as

shown.

(60) Install magnet in front case pocket (Fig. 80).(61) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

seal surface of front case.

(62) Align and install rear case on front case. Be

sure case locating dowels are in place and that main-

shaft splines are engaged in oil pump inner gear.

(63) Install and tighten the front case-to-rear case

bolts to 41 Nzm (30 ft. lbs.) torque.Be sure to in-

stall a washer under each of the bolts used at

the case dowel locations.

(64) Tap rear retainer bearing out of retainer with

hammer and brass drift.

(65) Install new bearing in rear retainer with

driver tools (Fig. 81).

(66) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

seal surface of rear retainer.

Fig. 77 Installing Oil Pump seal

Fig. 78 Installing Pickup Tube O-Ring

Fig. 79 Installing Oil Screen And Pickup Tube

Fig. 80 Installing Case Magnet

JNP242 TRANSFER CASE 21 - 315

Page 1427 of 1784

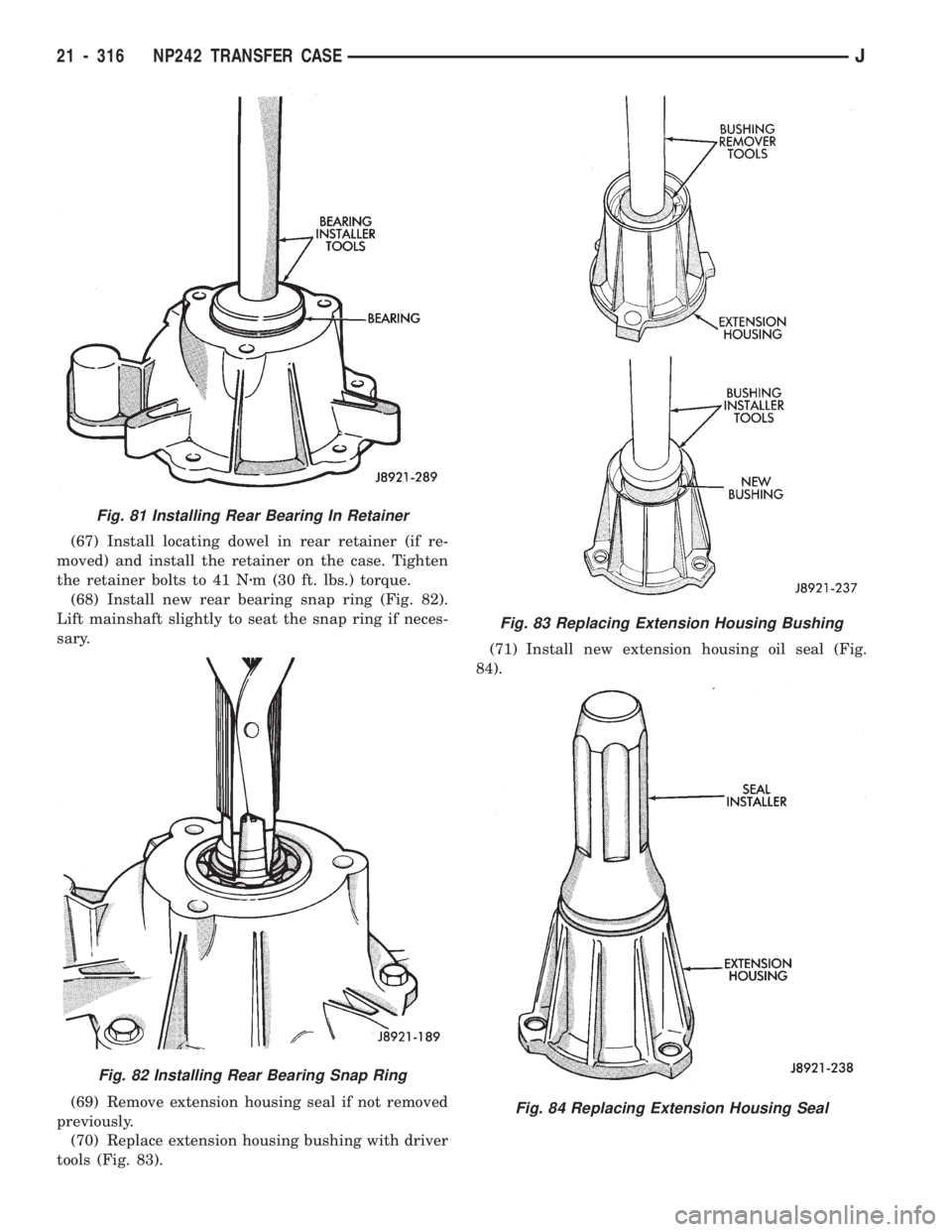

(67) Install locating dowel in rear retainer (if re-

moved) and install the retainer on the case. Tighten

the retainer bolts to 41 Nzm (30 ft. lbs.) torque.

(68) Install new rear bearing snap ring (Fig. 82).

Lift mainshaft slightly to seat the snap ring if neces-

sary.

(69) Remove extension housing seal if not removed

previously.

(70) Replace extension housing bushing with driver

tools (Fig. 83).(71) Install new extension housing oil seal (Fig.

84).

Fig. 83 Replacing Extension Housing Bushing

Fig. 84 Replacing Extension Housing Seal

Fig. 81 Installing Rear Bearing In Retainer

Fig. 82 Installing Rear Bearing Snap Ring

21 - 316 NP242 TRANSFER CASEJ

Page 1428 of 1784

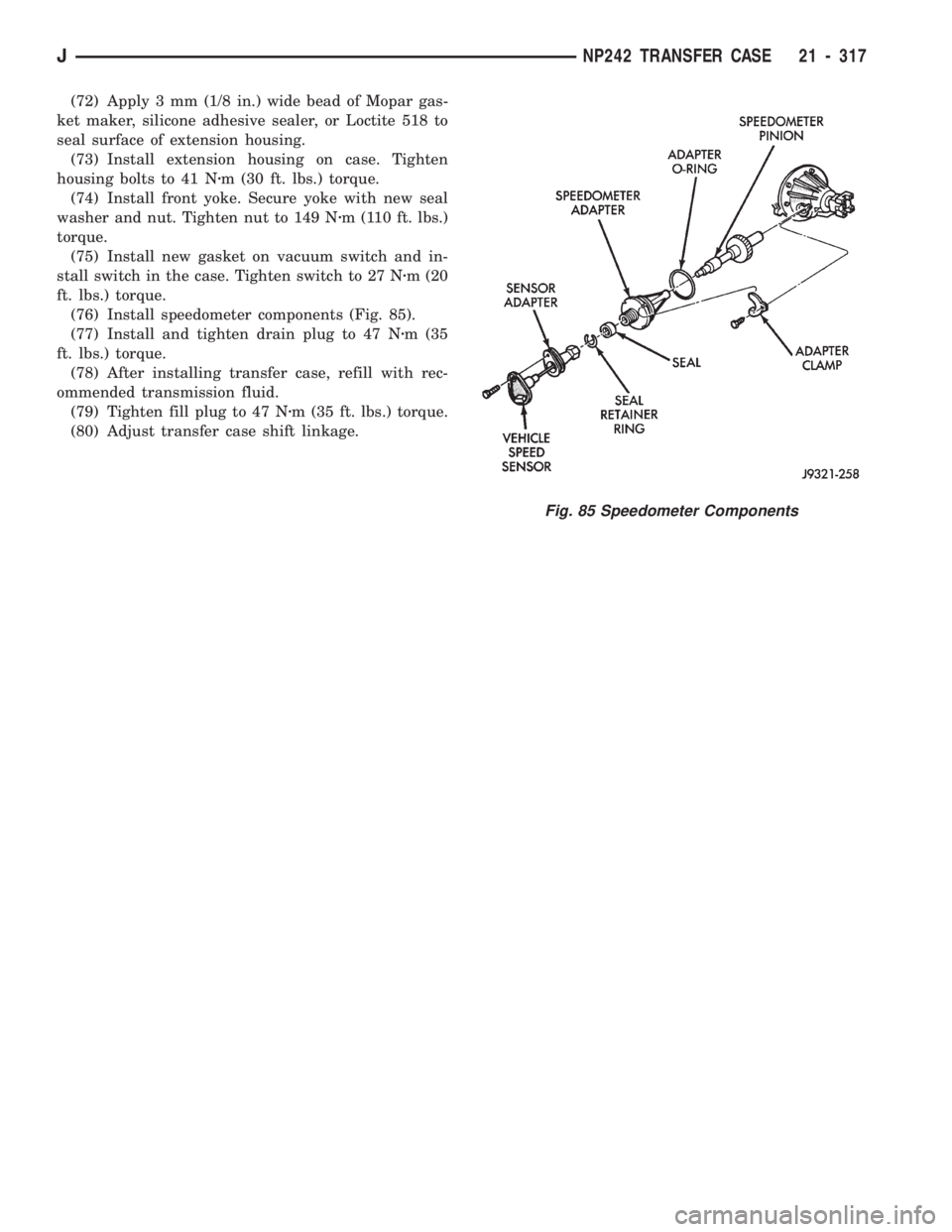

(72) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

seal surface of extension housing.

(73) Install extension housing on case. Tighten

housing bolts to 41 Nzm (30 ft. lbs.) torque.

(74) Install front yoke. Secure yoke with new seal

washer and nut. Tighten nut to 149 Nzm (110 ft. lbs.)

torque.

(75) Install new gasket on vacuum switch and in-

stall switch in the case. Tighten switch to 27 Nzm (20

ft. lbs.) torque.

(76) Install speedometer components (Fig. 85).

(77) Install and tighten drain plug to 47 Nzm (35

ft. lbs.) torque.

(78) After installing transfer case, refill with rec-

ommended transmission fluid.

(79) Tighten fill plug to 47 Nzm (35 ft. lbs.) torque.

(80) Adjust transfer case shift linkage.

Fig. 85 Speedometer Components

JNP242 TRANSFER CASE 21 - 317

Page 1429 of 1784

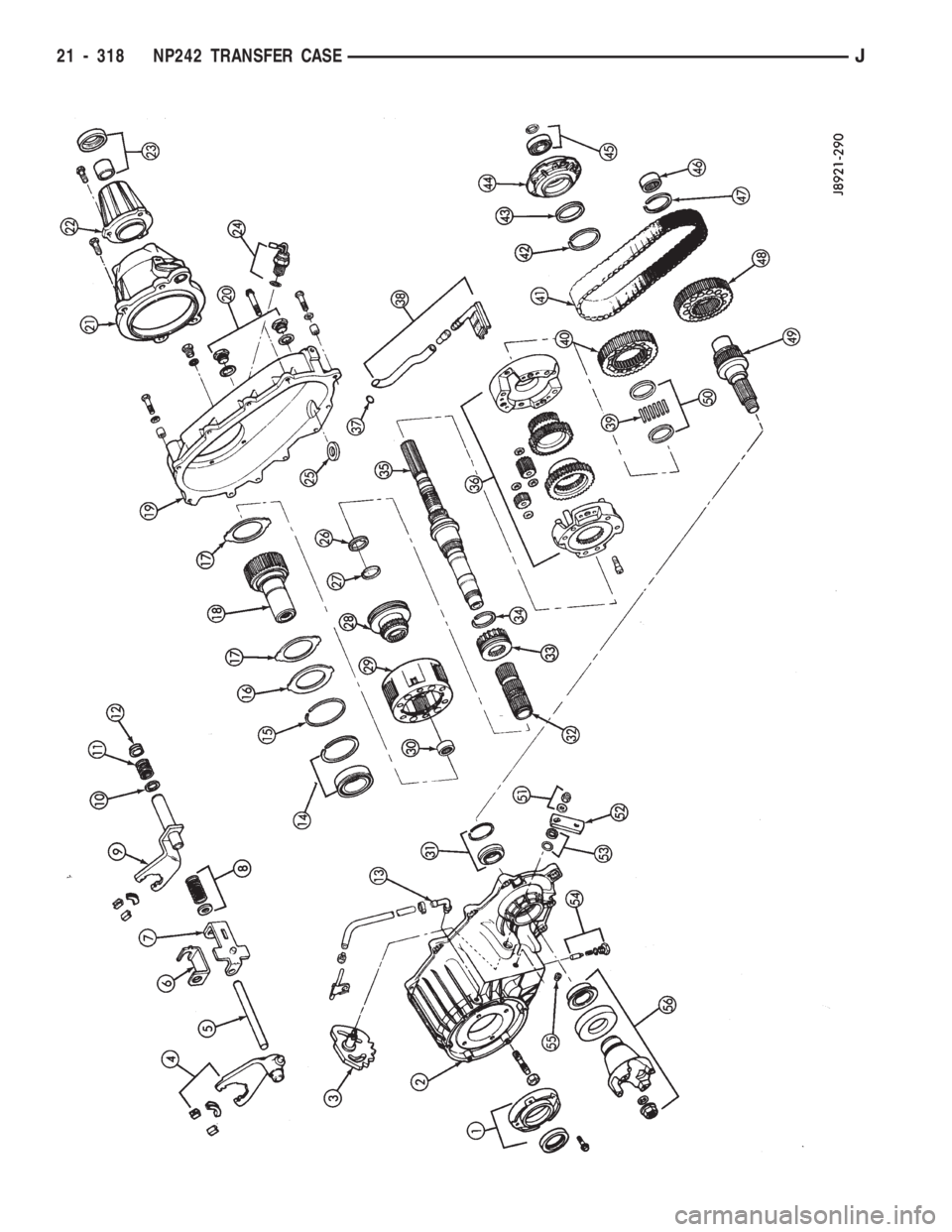

21 - 318 NP242 TRANSFER CASEJ

Page 1430 of 1784

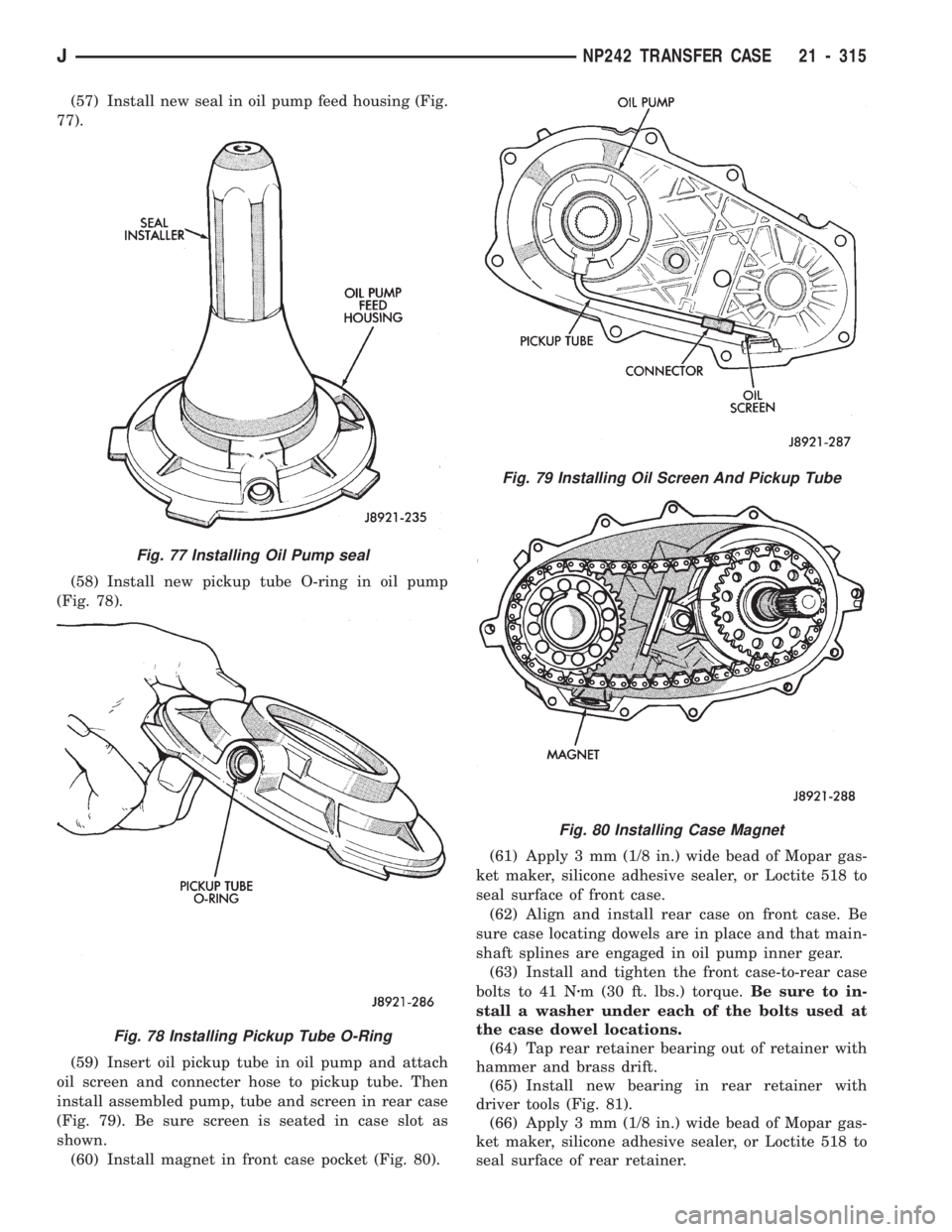

LEGEND FOR NP242 TRANSFER CASE

JNP242 TRANSFER CASE 21 - 319

Trending: buttons, clock setting, run flat, cruise control, warning light, wheel, drain bolt