JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1521 of 1784

(7) Install the trim panel.

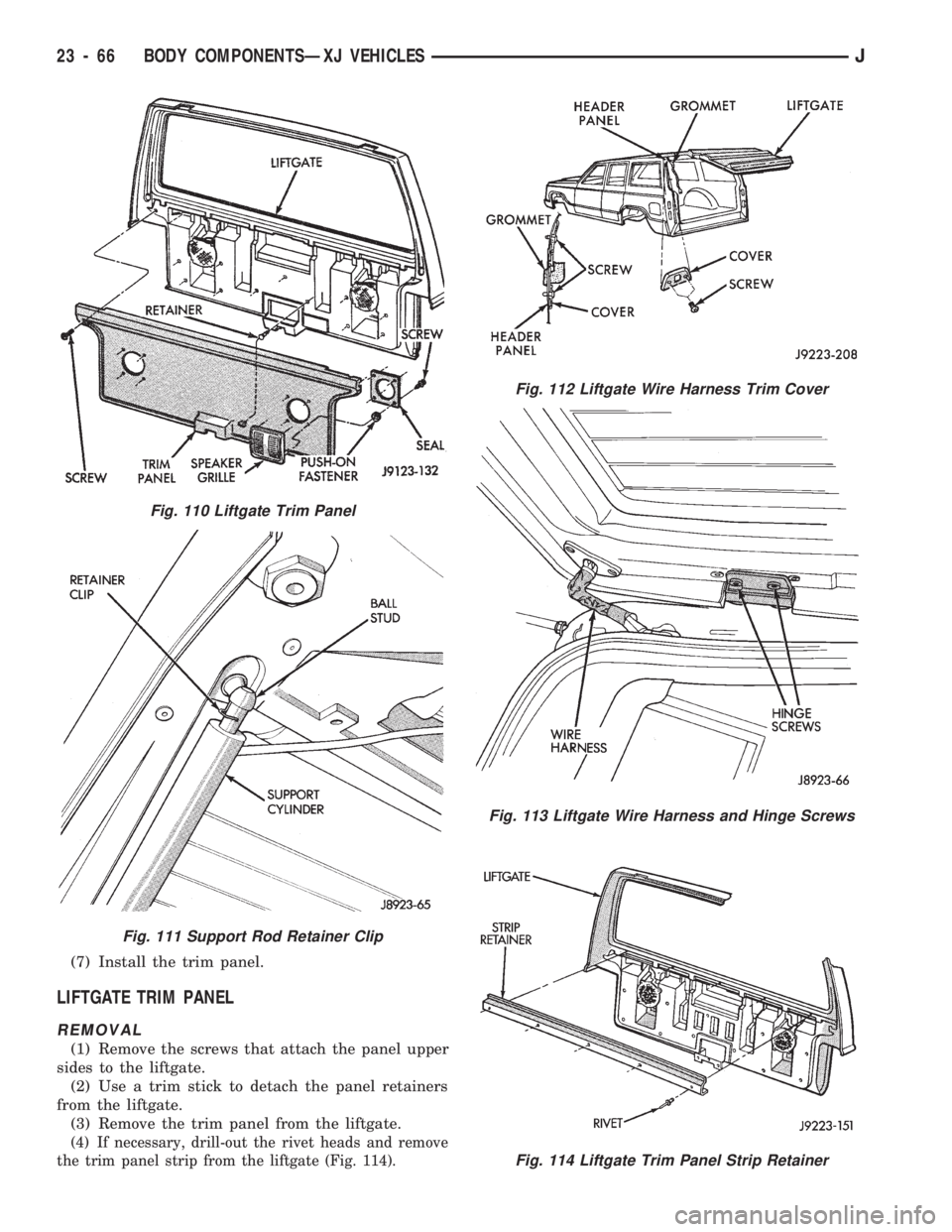

LIFTGATE TRIM PANEL

REMOVAL

(1) Remove the screws that attach the panel upper

sides to the liftgate.

(2) Use a trim stick to detach the panel retainers

from the liftgate.

(3) Remove the trim panel from the liftgate.

(4) If necessary, drill-out the rivet heads and remove

the trim panel strip from the liftgate (Fig. 114).

Fig. 112 Liftgate Wire Harness Trim Cover

Fig. 113 Liftgate Wire Harness and Hinge Screws

Fig. 114 Liftgate Trim Panel Strip Retainer

Fig. 110 Liftgate Trim Panel

Fig. 111 Support Rod Retainer Clip

23 - 66 BODY COMPONENTSÐXJ VEHICLESJ

Page 1522 of 1784

(5) If necessary, remove the screws and remove the

speaker grilles from the trim panel (Fig. 115).

INSTALLATION

(1) If removed, install the trim panel retainer strip

on the liftgate with replacement rivets.

(2) If removed, install the speaker grilles on trim

panel. Tighten the screws to 1 Nzm (11 in-lbs) torque.

(3) Position the trim panel on liftgate.

(4) Align the trim panel retainers with the holes

in the liftgate inner panel and force the trim panel

inward.

(5) Install the screws to attach the panel upper

sides to the liftgate.

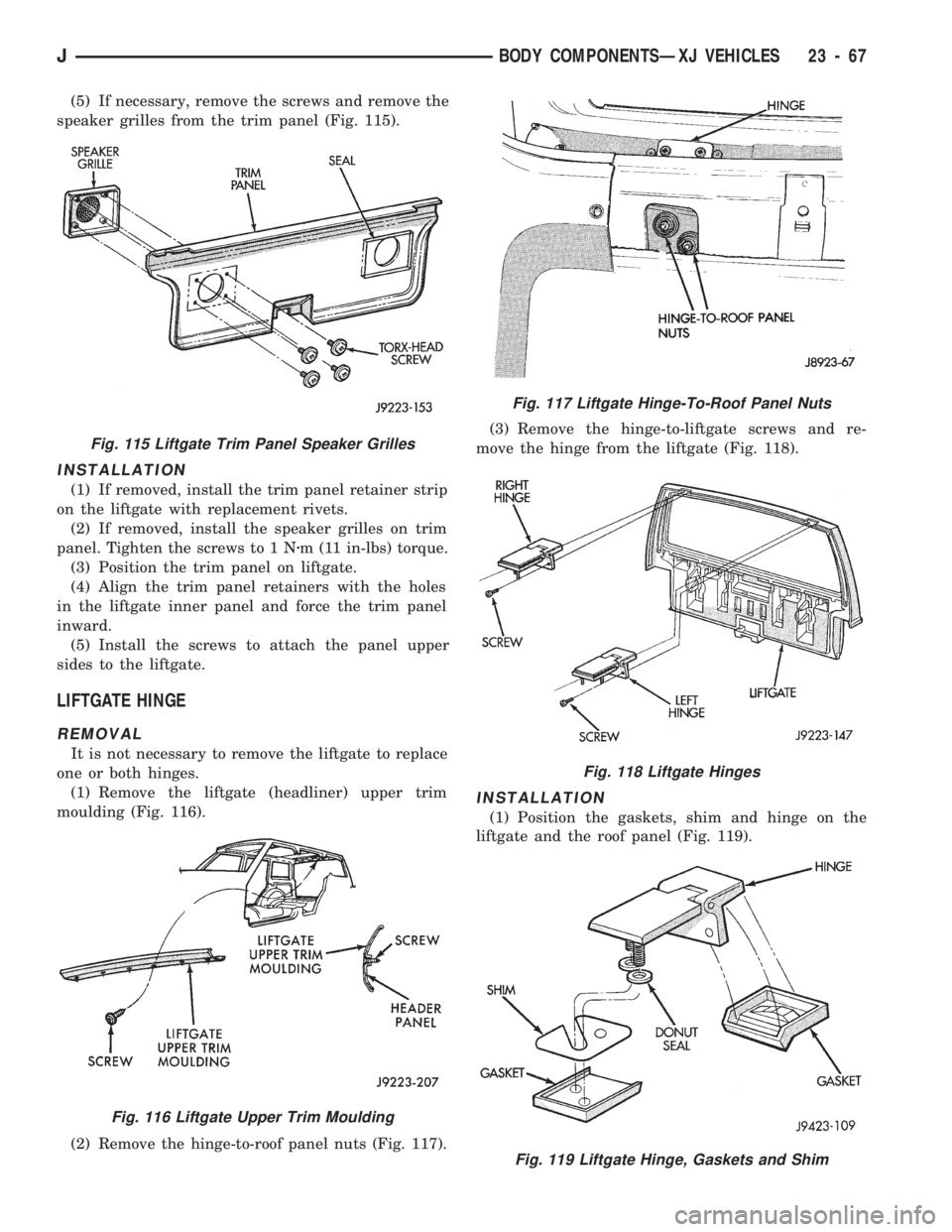

LIFTGATE HINGE

REMOVAL

It is not necessary to remove the liftgate to replace

one or both hinges.

(1) Remove the liftgate (headliner) upper trim

moulding (Fig. 116).

(2) Remove the hinge-to-roof panel nuts (Fig. 117).(3) Remove the hinge-to-liftgate screws and re-

move the hinge from the liftgate (Fig. 118).

INSTALLATION

(1) Position the gaskets, shim and hinge on the

liftgate and the roof panel (Fig. 119).

Fig. 115 Liftgate Trim Panel Speaker Grilles

Fig. 116 Liftgate Upper Trim Moulding

Fig. 117 Liftgate Hinge-To-Roof Panel Nuts

Fig. 118 Liftgate Hinges

Fig. 119 Liftgate Hinge, Gaskets and Shim

JBODY COMPONENTSÐXJ VEHICLES 23 - 67

Page 1523 of 1784

(2) Install and tighten hinge-to-roof panel nuts to 9

Nzm (7 ft-lbs) torque.

(3) Install the liftgate-to-hinge screws. Tighten

screws to 9 Nzm (7 ft-lbs) torque.

(4) Install the liftgate (headliner) upper trim moul-

ding (Fig. 111).

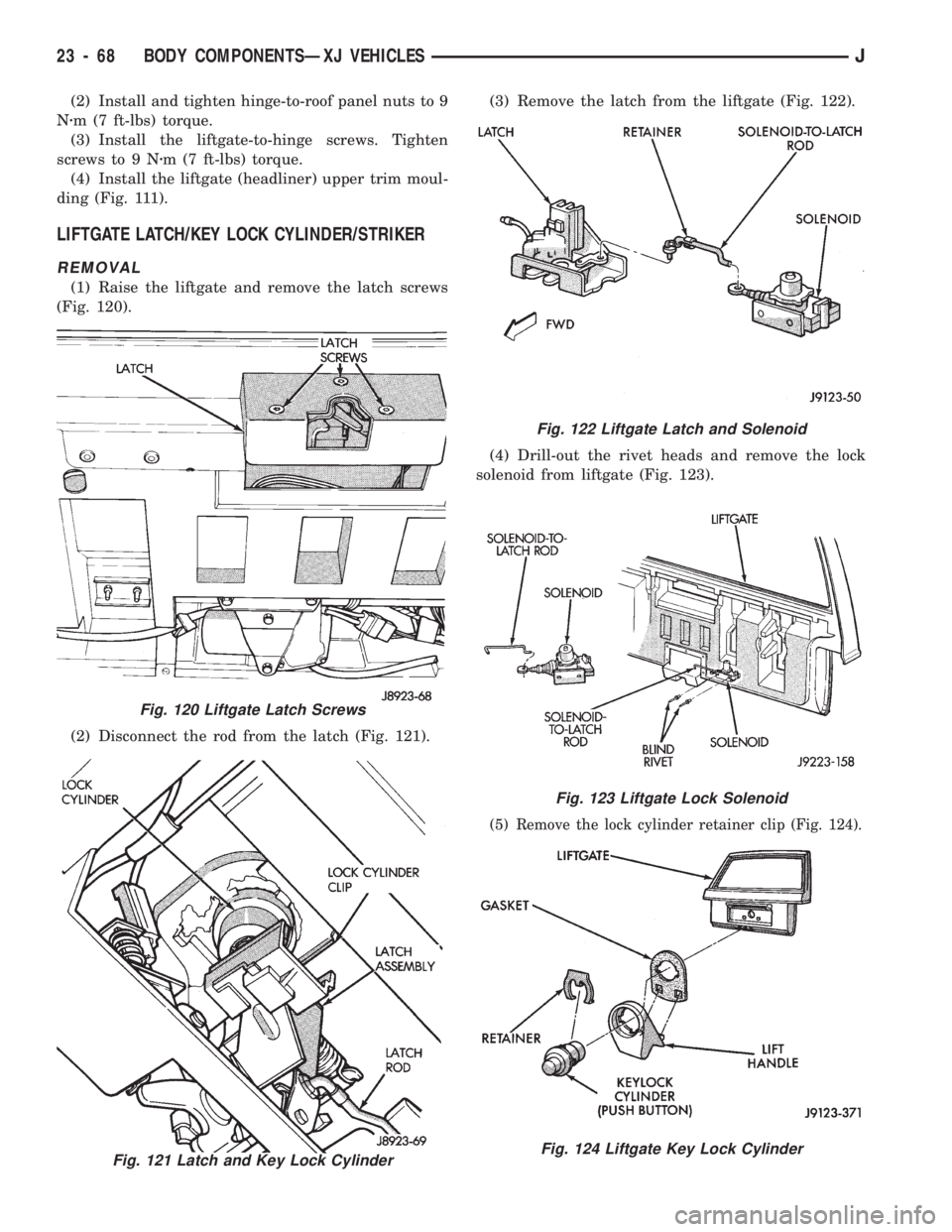

LIFTGATE LATCH/KEY LOCK CYLINDER/STRIKER

REMOVAL

(1) Raise the liftgate and remove the latch screws

(Fig. 120).

(2) Disconnect the rod from the latch (Fig. 121).(3) Remove the latch from the liftgate (Fig. 122).

(4) Drill-out the rivet heads and remove the lock

solenoid from liftgate (Fig. 123).

(5) Remove the lock cylinder retainer clip (Fig. 124).

Fig. 121 Latch and Key Lock Cylinder

Fig. 122 Liftgate Latch and Solenoid

Fig. 123 Liftgate Lock Solenoid

Fig. 124 Liftgate Key Lock Cylinder

Fig. 120 Liftgate Latch Screws

23 - 68 BODY COMPONENTSÐXJ VEHICLESJ

Page 1524 of 1784

(6) Remove the key lock cylinder.

(7) Remove the latch striker screws from the scuff

plate and cross sill (Fig. 125)

(8) Remove the striker and shim from the retainer.

INSTALLATION

(1) Install the key lock cylinder. Secure the lock

cylinder with the retainer clip (Fig. 126).

(2) Position the latch in the liftgate.

(3) Connect the latch rod.

(4) Install and tighten the latch screws to 12 Nzm

(110 in-lbs) torque.

(5) Install the striker retainer, shim, striker and

screws in the scuff plate cross sill.

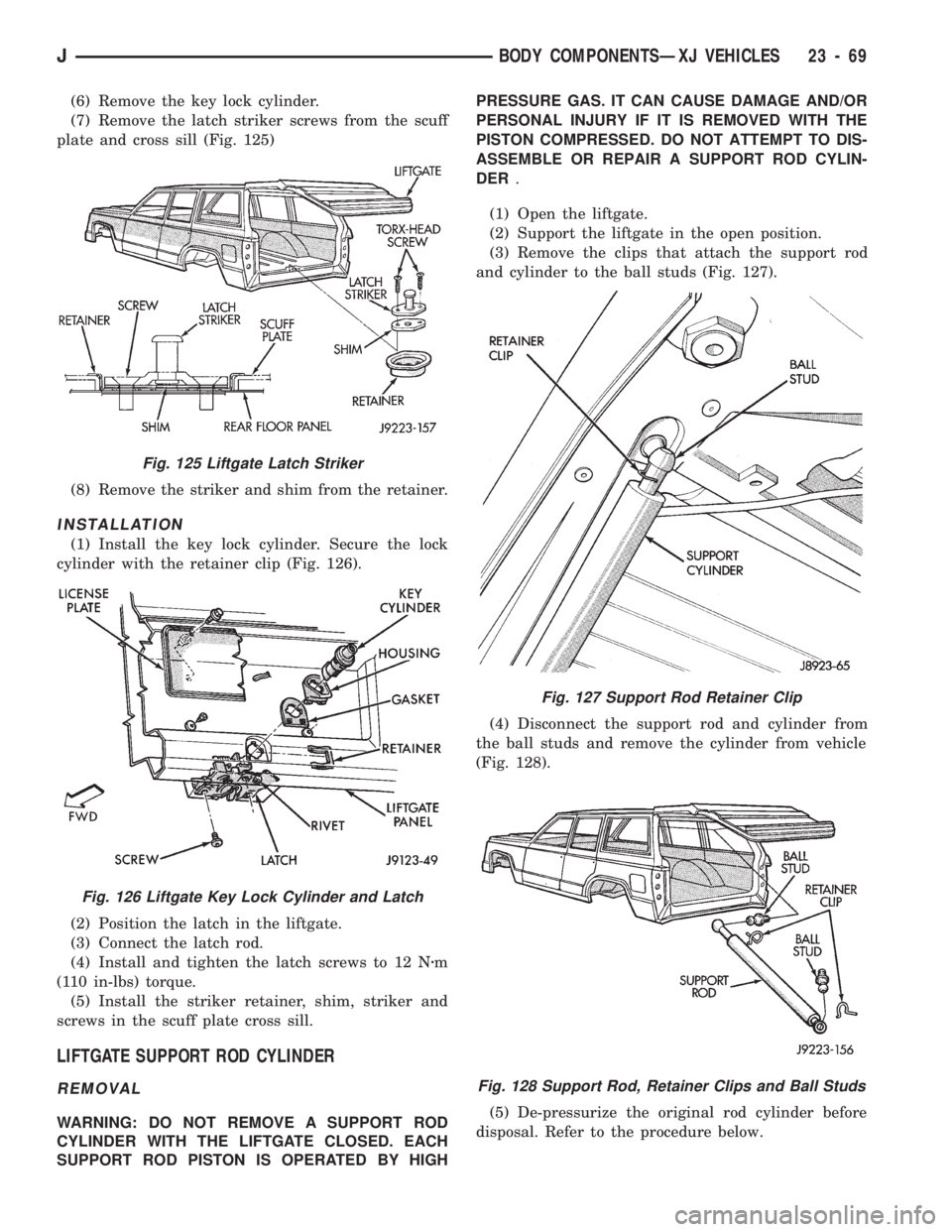

LIFTGATE SUPPORT ROD CYLINDER

REMOVAL

WARNING: DO NOT REMOVE A SUPPORT ROD

CYLINDER WITH THE LIFTGATE CLOSED. EACH

SUPPORT ROD PISTON IS OPERATED BY HIGHPRESSURE GAS. IT CAN CAUSE DAMAGE AND/OR

PERSONAL INJURY IF IT IS REMOVED WITH THE

PISTON COMPRESSED. DO NOT ATTEMPT TO DIS-

ASSEMBLE OR REPAIR A SUPPORT ROD CYLIN-

DER.

(1) Open the liftgate.

(2) Support the liftgate in the open position.

(3) Remove the clips that attach the support rod

and cylinder to the ball studs (Fig. 127).

(4) Disconnect the support rod and cylinder from

the ball studs and remove the cylinder from vehicle

(Fig. 128).

(5) De-pressurize the original rod cylinder before

disposal. Refer to the procedure below.

Fig. 127 Support Rod Retainer Clip

Fig. 128 Support Rod, Retainer Clips and Ball Studs

Fig. 125 Liftgate Latch Striker

Fig. 126 Liftgate Key Lock Cylinder and Latch

JBODY COMPONENTSÐXJ VEHICLES 23 - 69

Page 1525 of 1784

INSTALLATION

(1) Connect the replacement support rod and cylin-

der to the ball studs.

(2) Secure the support rod and cylinder to the ball

studs with the retainer clips.

(3) Remove the support from the liftgate and test

the operation of the support rod.

LIFTGATE SUPPORT ROD CYLINDER DISPOSAL

WARNING: SAFETY GOGGLES MUST BE WORN

DURING THE DISPOSAL PROCEDURE. THE HIGH

PRESSURE GAS CHARGE IN THE SUPPORT ROD

CYLINDERS WILL BE RELEASED DURING THE

PROCEDURE.

(1) Remove the support rod cylinder(s) from the

liftgate.

(2) Position the support rod cylinder horizontally

in a vise and clamp the cylinder securely.

(3) Wrap the cylinder with 4-5 layers of shop tow-

els.

(4) Measure 1 and 1/2 inches inward from the end

of the cylinder. Mark this location on the towels with

chalk. The cylinder will be punctured at this location

to release the gas charge.

(5) Use a punch and hammer to puncture cylinder.

Force the punch through towels and into the cylinder

with a hammer. Continue striking the punch until

the gas begins to escapebut do not remove the

punch.

(6) Hold the towels and punch in position until all

the gas has escaped. Complete de-pressurization will

require about 4 to 10 seconds. After all the gas has

escaped, slowly remove the punch.

(7) Hold a towel over the hole in cylinder and press

the support rod piston all the way into the cylinder

to purge remaining oil.

(8) Remove the support rod cylinder from the vise

and discard it.

(9) If both support rod cylinders are being re-

placed, repeat this procedure for the remaining cylin-

der.

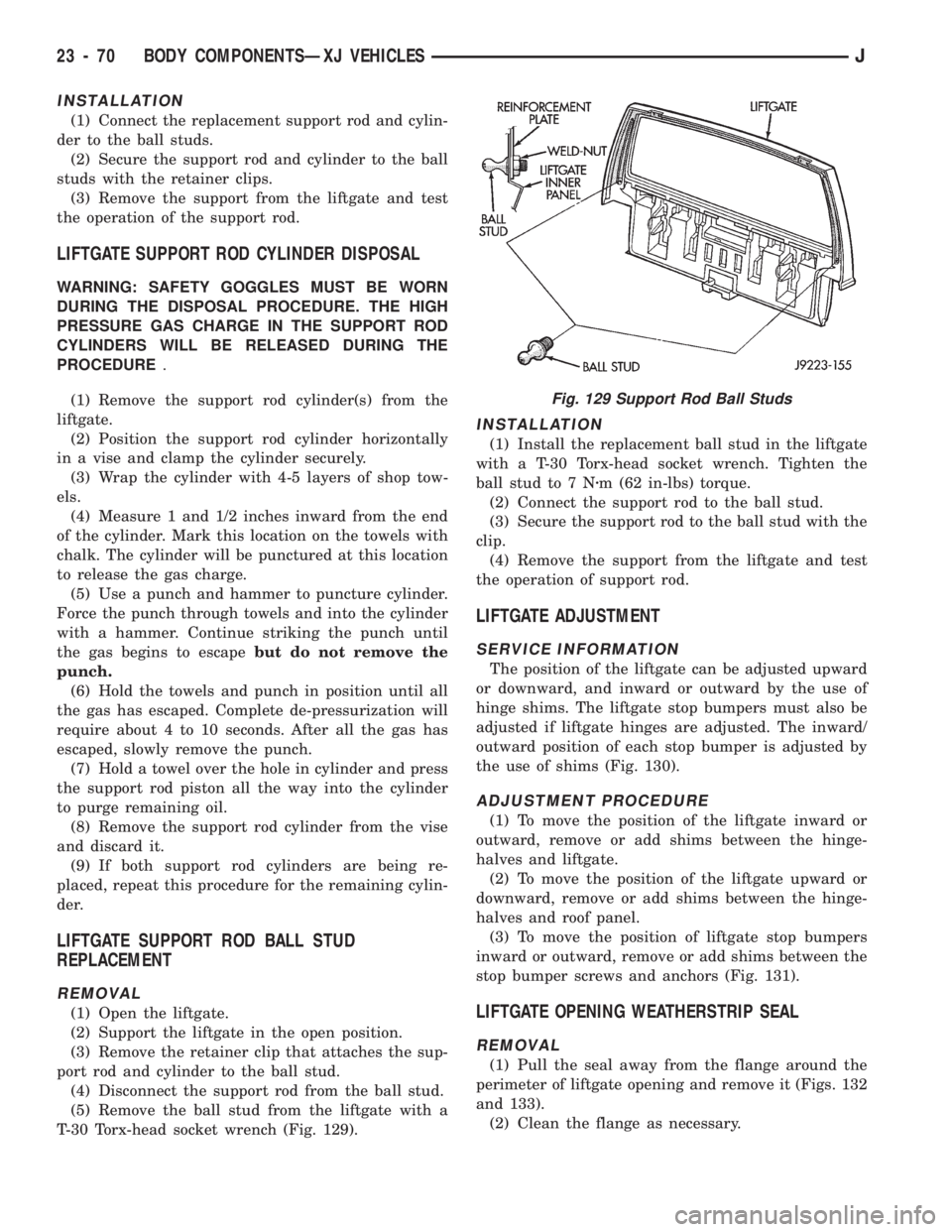

LIFTGATE SUPPORT ROD BALL STUD

REPLACEMENT

REMOVAL

(1) Open the liftgate.

(2) Support the liftgate in the open position.

(3) Remove the retainer clip that attaches the sup-

port rod and cylinder to the ball stud.

(4) Disconnect the support rod from the ball stud.

(5) Remove the ball stud from the liftgate with a

T-30 Torx-head socket wrench (Fig. 129).

INSTALLATION

(1) Install the replacement ball stud in the liftgate

with a T-30 Torx-head socket wrench. Tighten the

ball stud to 7 Nzm (62 in-lbs) torque.

(2) Connect the support rod to the ball stud.

(3) Secure the support rod to the ball stud with the

clip.

(4) Remove the support from the liftgate and test

the operation of support rod.

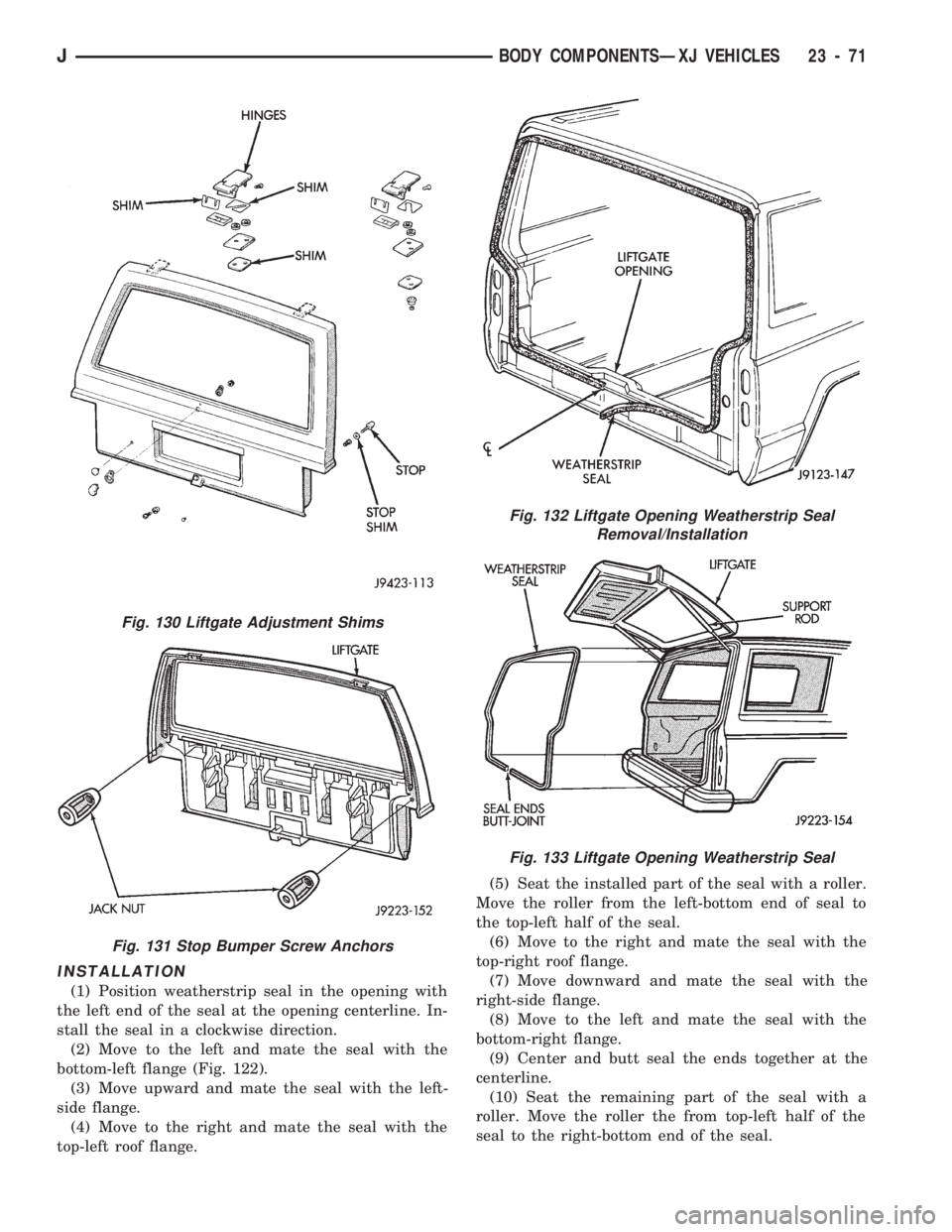

LIFTGATE ADJUSTMENT

SERVICE INFORMATION

The position of the liftgate can be adjusted upward

or downward, and inward or outward by the use of

hinge shims. The liftgate stop bumpers must also be

adjusted if liftgate hinges are adjusted. The inward/

outward position of each stop bumper is adjusted by

the use of shims (Fig. 130).

ADJUSTMENT PROCEDURE

(1) To move the position of the liftgate inward or

outward, remove or add shims between the hinge-

halves and liftgate.

(2) To move the position of the liftgate upward or

downward, remove or add shims between the hinge-

halves and roof panel.

(3) To move the position of liftgate stop bumpers

inward or outward, remove or add shims between the

stop bumper screws and anchors (Fig. 131).

LIFTGATE OPENING WEATHERSTRIP SEAL

REMOVAL

(1) Pull the seal away from the flange around the

perimeter of liftgate opening and remove it (Figs. 132

and 133).

(2) Clean the flange as necessary.

Fig. 129 Support Rod Ball Studs

23 - 70 BODY COMPONENTSÐXJ VEHICLESJ

Page 1526 of 1784

INSTALLATION

(1) Position weatherstrip seal in the opening with

the left end of the seal at the opening centerline. In-

stall the seal in a clockwise direction.

(2) Move to the left and mate the seal with the

bottom-left flange (Fig. 122).

(3) Move upward and mate the seal with the left-

side flange.

(4) Move to the right and mate the seal with the

top-left roof flange.(5) Seat the installed part of the seal with a roller.

Move the roller from the left-bottom end of seal to

the top-left half of the seal.

(6) Move to the right and mate the seal with the

top-right roof flange.

(7) Move downward and mate the seal with the

right-side flange.

(8) Move to the left and mate the seal with the

bottom-right flange.

(9) Center and butt seal the ends together at the

centerline.

(10) Seat the remaining part of the seal with a

roller. Move the roller the from top-left half of the

seal to the right-bottom end of the seal.

Fig. 130 Liftgate Adjustment Shims

Fig. 131 Stop Bumper Screw Anchors

Fig. 132 Liftgate Opening Weatherstrip Seal

Removal/Installation

Fig. 133 Liftgate Opening Weatherstrip Seal

JBODY COMPONENTSÐXJ VEHICLES 23 - 71

Page 1527 of 1784

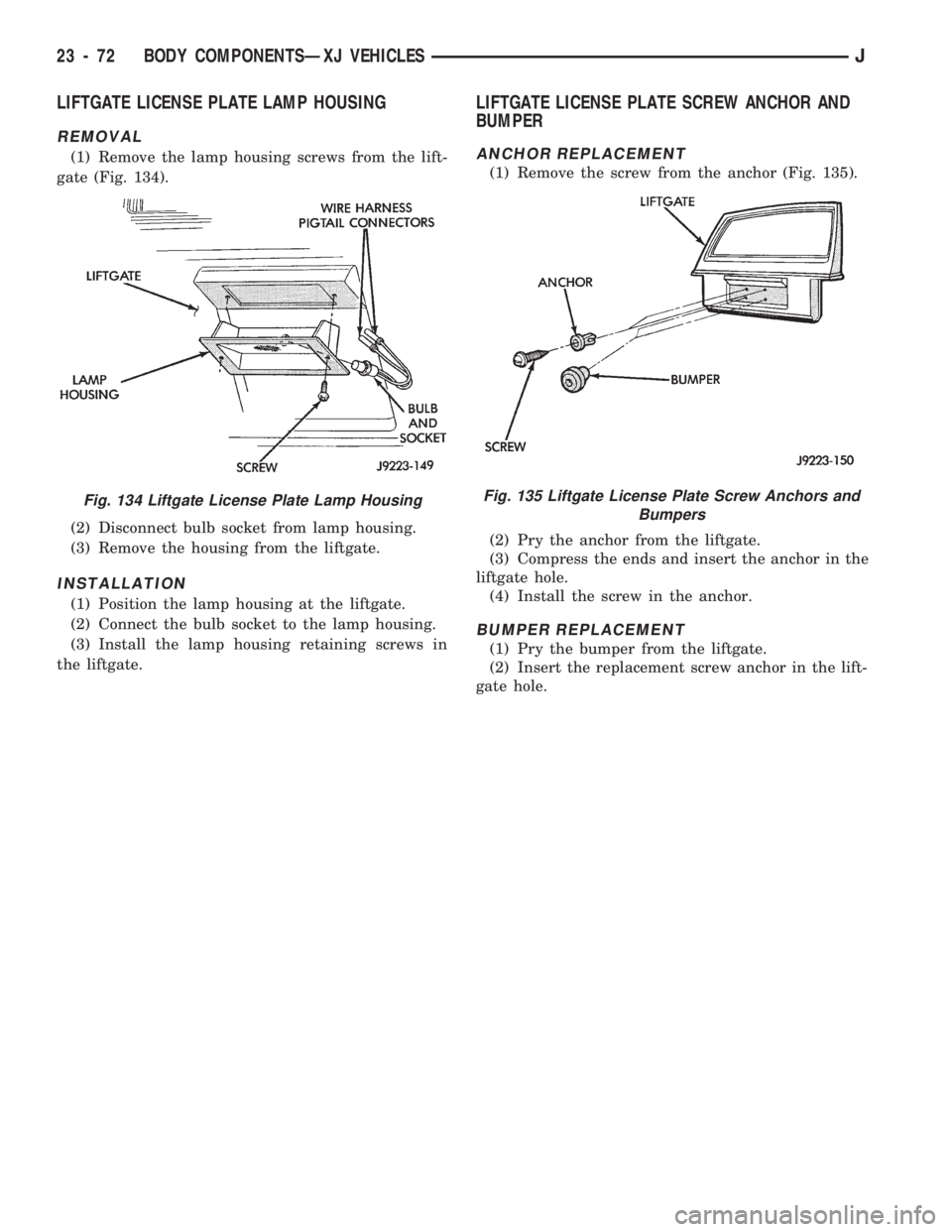

LIFTGATE LICENSE PLATE LAMP HOUSING

REMOVAL

(1) Remove the lamp housing screws from the lift-

gate (Fig. 134).

(2) Disconnect bulb socket from lamp housing.

(3) Remove the housing from the liftgate.

INSTALLATION

(1) Position the lamp housing at the liftgate.

(2) Connect the bulb socket to the lamp housing.

(3) Install the lamp housing retaining screws in

the liftgate.

LIFTGATE LICENSE PLATE SCREW ANCHOR AND

BUMPER

ANCHOR REPLACEMENT

(1) Remove the screw from the anchor (Fig. 135).

(2) Pry the anchor from the liftgate.

(3) Compress the ends and insert the anchor in the

liftgate hole.

(4) Install the screw in the anchor.

BUMPER REPLACEMENT

(1) Pry the bumper from the liftgate.

(2) Insert the replacement screw anchor in the lift-

gate hole.

Fig. 134 Liftgate License Plate Lamp HousingFig. 135 Liftgate License Plate Screw Anchors and

Bumpers

23 - 72 BODY COMPONENTSÐXJ VEHICLESJ

Page 1528 of 1784

FIXED WINDOW GLASS

INDEX

page page

Fixed Glass Water Leak Detection and Repair . . 83

Interior Rearview Mirror.................... 74

Interior Rearview Mirror Support Bracket

Replacement.......................... 75

Liftgate Window GlassÐXJ Vehicles.......... 81

Rear Quarter Vent Window GlassÐXJ Vehicles . 80Rear Quarter Window Glass/Rear Quarter

Plastic Insert ÐXJ Vehicles............... 80

Service Information....................... 73

Windshield Glass Replacement.............. 75

Windshield Reveal Moulding................ 73

Windshield Service Information.............. 75

SERVICE INFORMATION

The following service procedures include removal

and installation of the:

²windshield reveal moulding,

²interior rearview mirror,

²windshield glass (using both the short and the ex-

tended installation method),

²rear quarter vent window glass,

²rear quarter window glass,

²liftgate window glass,

²cab rear window, and

²leak detection and repair.

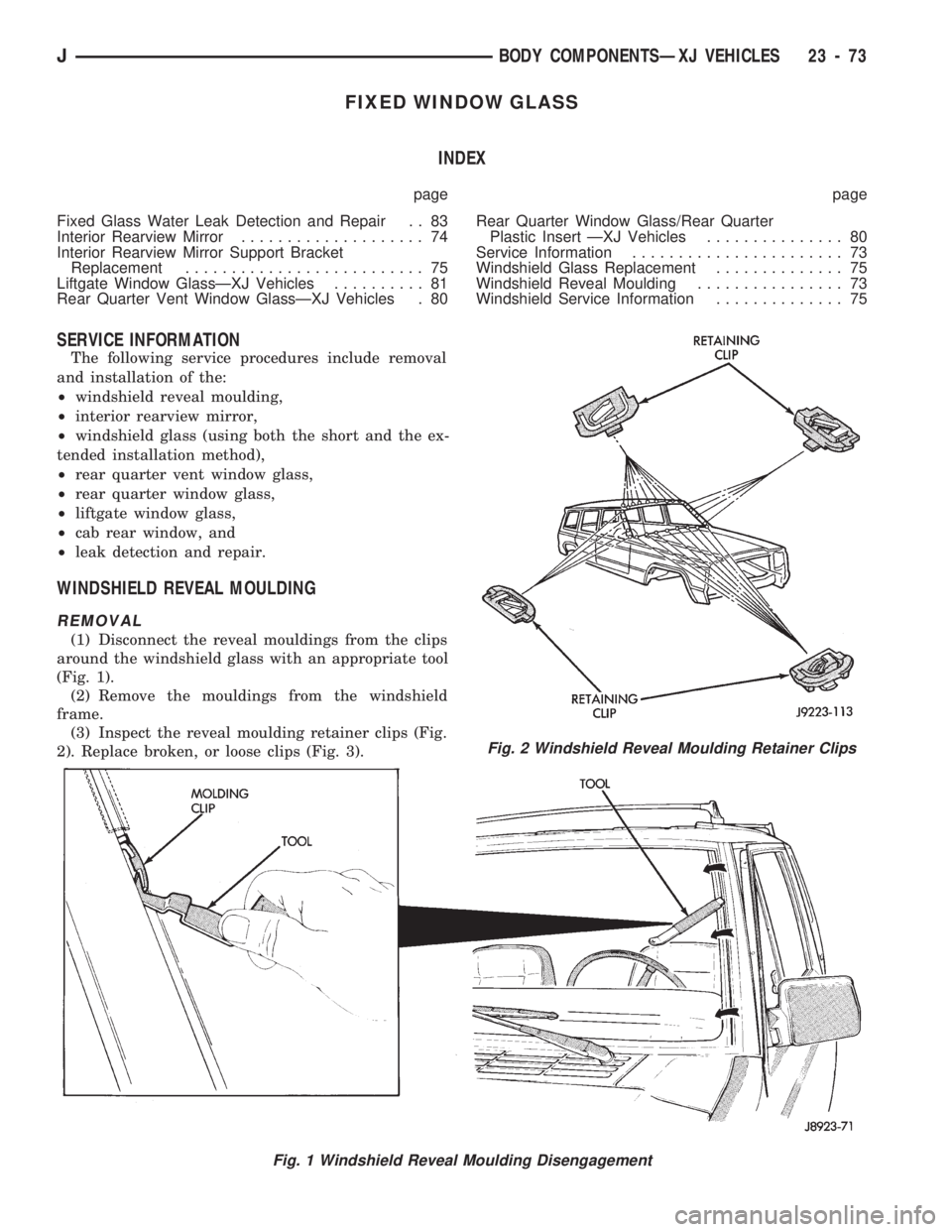

WINDSHIELD REVEAL MOULDING

REMOVAL

(1) Disconnect the reveal mouldings from the clips

around the windshield glass with an appropriate tool

(Fig. 1).

(2) Remove the mouldings from the windshield

frame.

(3) Inspect the reveal moulding retainer clips (Fig.

2). Replace broken, or loose clips (Fig. 3).

Fig. 1 Windshield Reveal Moulding Disengagement

Fig. 2 Windshield Reveal Moulding Retainer Clips

JBODY COMPONENTSÐXJ VEHICLES 23 - 73

Page 1529 of 1784

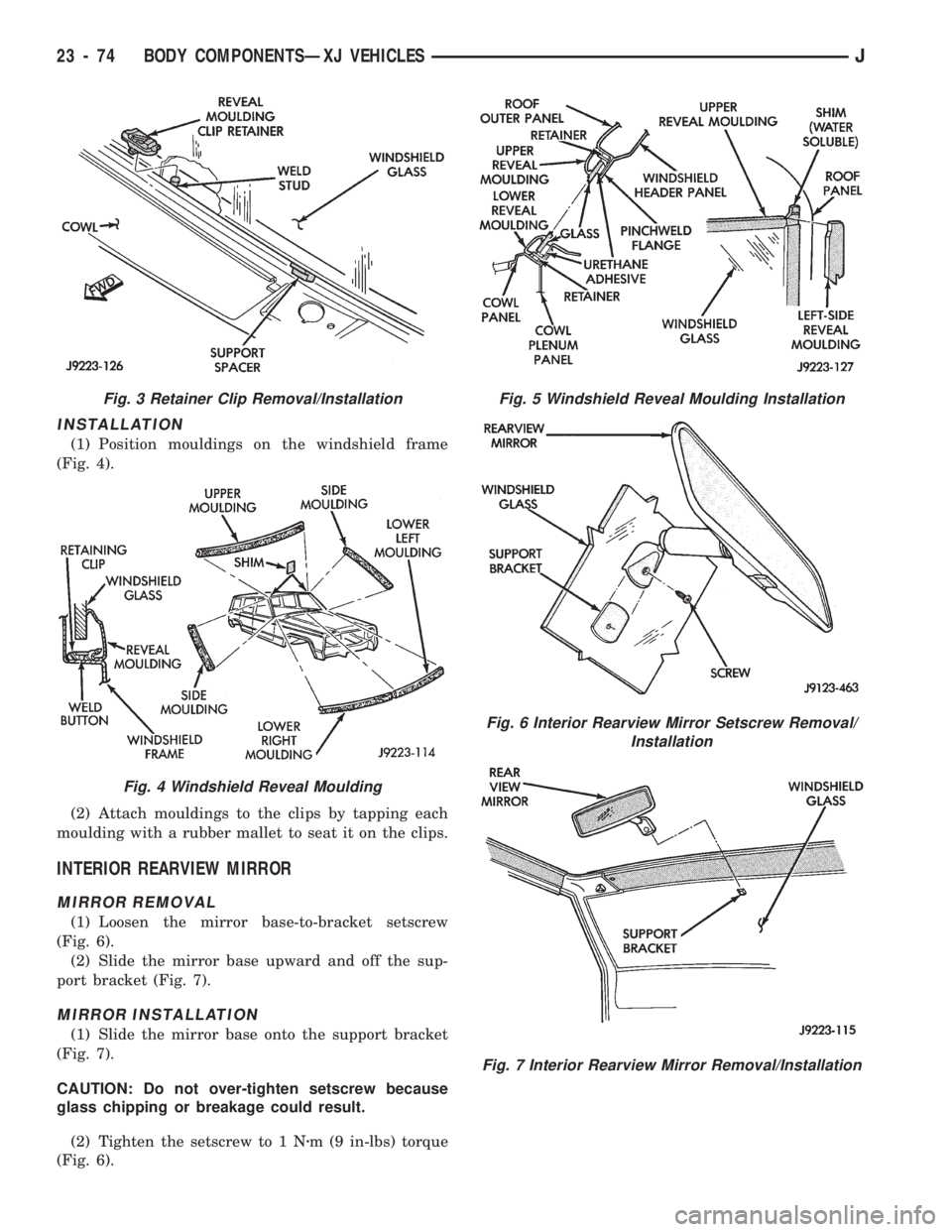

INSTALLATION

(1) Position mouldings on the windshield frame

(Fig. 4).

(2) Attach mouldings to the clips by tapping each

moulding with a rubber mallet to seat it on the clips.

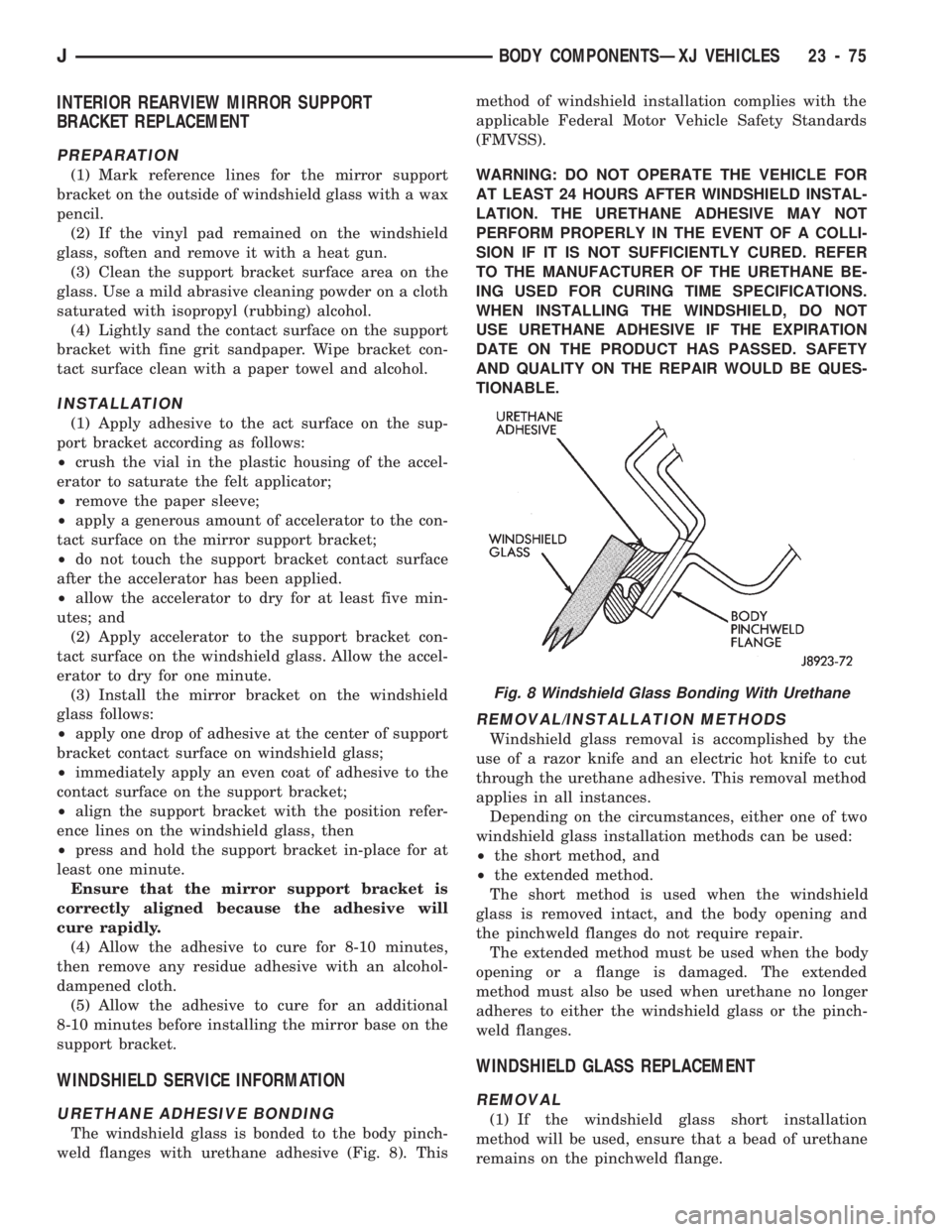

INTERIOR REARVIEW MIRROR

MIRROR REMOVAL

(1) Loosen the mirror base-to-bracket setscrew

(Fig. 6).

(2) Slide the mirror base upward and off the sup-

port bracket (Fig. 7).

MIRROR INSTALLATION

(1) Slide the mirror base onto the support bracket

(Fig. 7).

CAUTION: Do not over-tighten setscrew because

glass chipping or breakage could result.

(2) Tighten the setscrew to 1 Nzm (9 in-lbs) torque

(Fig. 6).

Fig. 5 Windshield Reveal Moulding Installation

Fig. 6 Interior Rearview Mirror Setscrew Removal/

Installation

Fig. 7 Interior Rearview Mirror Removal/Installation

Fig. 3 Retainer Clip Removal/Installation

Fig. 4 Windshield Reveal Moulding

23 - 74 BODY COMPONENTSÐXJ VEHICLESJ

Page 1530 of 1784

INTERIOR REARVIEW MIRROR SUPPORT

BRACKET REPLACEMENT

PREPARATION

(1) Mark reference lines for the mirror support

bracket on the outside of windshield glass with a wax

pencil.

(2) If the vinyl pad remained on the windshield

glass, soften and remove it with a heat gun.

(3) Clean the support bracket surface area on the

glass. Use a mild abrasive cleaning powder on a cloth

saturated with isopropyl (rubbing) alcohol.

(4) Lightly sand the contact surface on the support

bracket with fine grit sandpaper. Wipe bracket con-

tact surface clean with a paper towel and alcohol.

INSTALLATION

(1) Apply adhesive to the act surface on the sup-

port bracket according as follows:

²crush the vial in the plastic housing of the accel-

erator to saturate the felt applicator;

²remove the paper sleeve;

²apply a generous amount of accelerator to the con-

tact surface on the mirror support bracket;

²do not touch the support bracket contact surface

after the accelerator has been applied.

²allow the accelerator to dry for at least five min-

utes; and

(2) Apply accelerator to the support bracket con-

tact surface on the windshield glass. Allow the accel-

erator to dry for one minute.

(3) Install the mirror bracket on the windshield

glass follows:

²apply one drop of adhesive at the center of support

bracket contact surface on windshield glass;

²immediately apply an even coat of adhesive to the

contact surface on the support bracket;

²align the support bracket with the position refer-

ence lines on the windshield glass, then

²press and hold the support bracket in-place for at

least one minute.

Ensure that the mirror support bracket is

correctly aligned because the adhesive will

cure rapidly.

(4) Allow the adhesive to cure for 8-10 minutes,

then remove any residue adhesive with an alcohol-

dampened cloth.

(5) Allow the adhesive to cure for an additional

8-10 minutes before installing the mirror base on the

support bracket.

WINDSHIELD SERVICE INFORMATION

URETHANE ADHESIVE BONDING

The windshield glass is bonded to the body pinch-

weld flanges with urethane adhesive (Fig. 8). Thismethod of windshield installation complies with the

applicable Federal Motor Vehicle Safety Standards

(FMVSS).

WARNING: DO NOT OPERATE THE VEHICLE FOR

AT LEAST 24 HOURS AFTER WINDSHIELD INSTAL-

LATION. THE URETHANE ADHESIVE MAY NOT

PERFORM PROPERLY IN THE EVENT OF A COLLI-

SION IF IT IS NOT SUFFICIENTLY CURED. REFER

TO THE MANUFACTURER OF THE URETHANE BE-

ING USED FOR CURING TIME SPECIFICATIONS.

WHEN INSTALLING THE WINDSHIELD, DO NOT

USE URETHANE ADHESIVE IF THE EXPIRATION

DATE ON THE PRODUCT HAS PASSED. SAFETY

AND QUALITY ON THE REPAIR WOULD BE QUES-

TIONABLE.

REMOVAL/INSTALLATION METHODS

Windshield glass removal is accomplished by the

use of a razor knife and an electric hot knife to cut

through the urethane adhesive. This removal method

applies in all instances.

Depending on the circumstances, either one of two

windshield glass installation methods can be used:

²the short method, and

²the extended method.

The short method is used when the windshield

glass is removed intact, and the body opening and

the pinchweld flanges do not require repair.

The extended method must be used when the body

opening or a flange is damaged. The extended

method must also be used when urethane no longer

adheres to either the windshield glass or the pinch-

weld flanges.

WINDSHIELD GLASS REPLACEMENT

REMOVAL

(1) If the windshield glass short installation

method will be used, ensure that a bead of urethane

remains on the pinchweld flange.

Fig. 8 Windshield Glass Bonding With Urethane

JBODY COMPONENTSÐXJ VEHICLES 23 - 75