JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 181 of 1784

DRUM BRAKES

INDEX

page page

Brake Drum Refinishing.................... 37

Drum Brake Adjustment................... 35

Drum Brakeshoe Installation................ 34

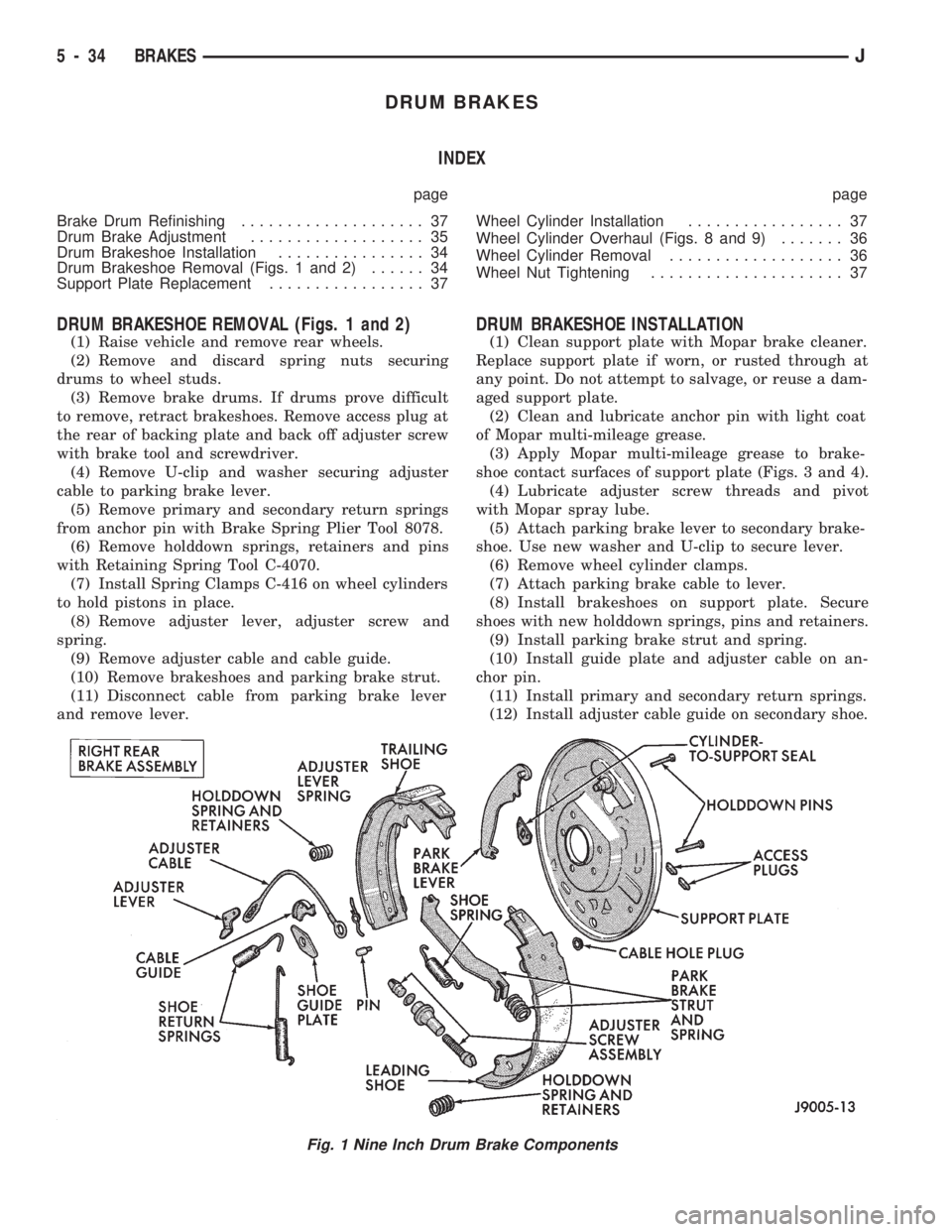

Drum Brakeshoe Removal (Figs. 1 and 2)...... 34

Support Plate Replacement................. 37Wheel Cylinder Installation................. 37

Wheel Cylinder Overhaul (Figs. 8 and 9)....... 36

Wheel Cylinder Removal................... 36

Wheel Nut Tightening..................... 37

DRUM BRAKESHOE REMOVAL (Figs. 1 and 2)

(1) Raise vehicle and remove rear wheels.

(2) Remove and discard spring nuts securing

drums to wheel studs.

(3) Remove brake drums. If drums prove difficult

to remove, retract brakeshoes. Remove access plug at

the rear of backing plate and back off adjuster screw

with brake tool and screwdriver.

(4) Remove U-clip and washer securing adjuster

cable to parking brake lever.

(5) Remove primary and secondary return springs

from anchor pin with Brake Spring Plier Tool 8078.

(6) Remove holddown springs, retainers and pins

with Retaining Spring Tool C-4070.

(7) Install Spring Clamps C-416 on wheel cylinders

to hold pistons in place.

(8) Remove adjuster lever, adjuster screw and

spring.

(9) Remove adjuster cable and cable guide.

(10) Remove brakeshoes and parking brake strut.

(11) Disconnect cable from parking brake lever

and remove lever.

DRUM BRAKESHOE INSTALLATION

(1) Clean support plate with Mopar brake cleaner.

Replace support plate if worn, or rusted through at

any point. Do not attempt to salvage, or reuse a dam-

aged support plate.

(2) Clean and lubricate anchor pin with light coat

of Mopar multi-mileage grease.

(3) Apply Mopar multi-mileage grease to brake-

shoe contact surfaces of support plate (Figs. 3 and 4).

(4) Lubricate adjuster screw threads and pivot

with Mopar spray lube.

(5) Attach parking brake lever to secondary brake-

shoe. Use new washer and U-clip to secure lever.

(6) Remove wheel cylinder clamps.

(7) Attach parking brake cable to lever.

(8) Install brakeshoes on support plate. Secure

shoes with new holddown springs, pins and retainers.

(9) Install parking brake strut and spring.

(10) Install guide plate and adjuster cable on an-

chor pin.

(11) Install primary and secondary return springs.

(12) Install adjuster cable guide on secondary shoe.

Fig. 1 Nine Inch Drum Brake Components

5 - 34 BRAKESJ

Page 182 of 1784

(13) Lubricate and assemble adjuster screw (Fig.

5).

(14) Install adjuster screw, spring and lever and

connect to adjuster cable.

(15) Adjust shoes to drum as described in following

procedure.

(16) Install wheel/tire assemblies and lower vehi-

cle.

(17) Verify firm brake pedal before moving vehicle.

DRUM BRAKE ADJUSTMENT

Rear drum brakes are equipped with a self adjust-

ing mechanism. Under normal circumstances, the

only time adjustment is required is when the shoes

are replaced, removed for access to other parts, or

when one or both drums are replaced.The only tool needed for adjustment is a standard

brake gauge.

Adjustment is performed with the brakeshoes in-

stalled on the support plate. Procedure is as follows:

ADJUSTMENT PROCEDURE

(1) Raise and support vehicle rear end and remove

wheels and brake drums.

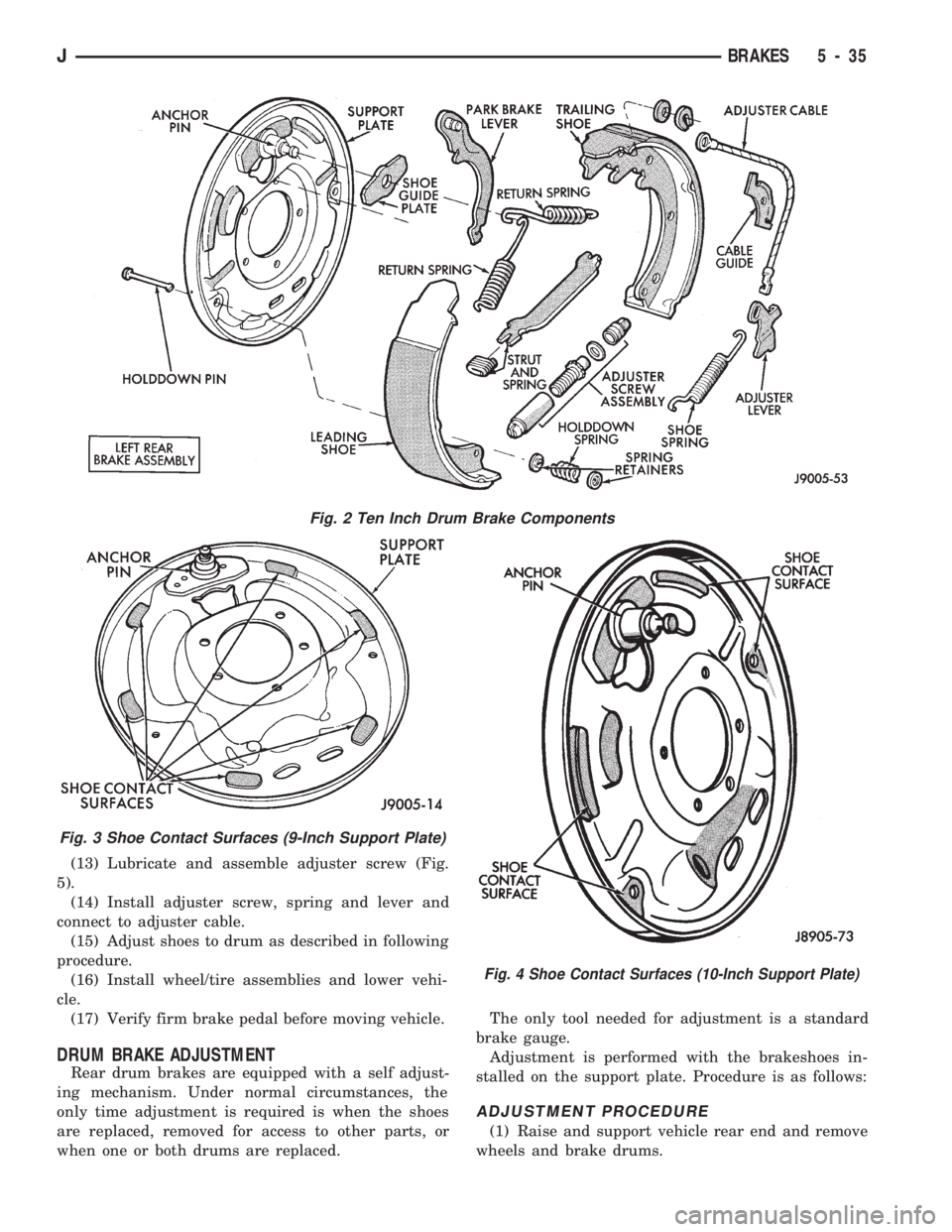

Fig. 2 Ten Inch Drum Brake Components

Fig. 3 Shoe Contact Surfaces (9-Inch Support Plate)

Fig. 4 Shoe Contact Surfaces (10-Inch Support Plate)

JBRAKES 5 - 35

Page 183 of 1784

(2) Verify that left/right automatic adjuster lever

and cable are properly connected.

(3) Insert brake gauge in drum. Expand gauge un-

til gauge inner legs contact drum braking surface.

Then lock gauge in position (Fig. 6).

(4) Reverse gauge and install it on brakeshoes

(Fig. 6). Position gauge legs at shoe centers as

shown. If gauge does not fit (too loose or tight), ad-

just shoes.

(5) Pull shoe adjuster star wheel away from ad-

juster lever.

(6) Turn adjuster star wheel (by hand) to expand

or retract brakeshoes. Continue adjustment until

gauge outside legs are light drag-fit on shoes (Fig. 7).

(7) Repeat adjustment at opposite brakeshoe as-

sembly.

(8) Install brake drums and wheels and lower ve-

hicle.

(9) Make final adjustment as follows:

(a) Drive vehicle and make one forward stop fol-

lowed by one reverse stop.

(b) Repeat procedure 8-10 times to actuate self

adjuster components and equalize adjustment.

(c)Bring vehicle to complete standstill at

each stop. Incomplete, rolling stops will NOT

activate adjuster mechanism.

WHEEL CYLINDER REMOVAL

(1) Raise vehicle and remove wheel.

(2) Disconnect brakeline at wheel cylinder.If cyl-

inder brakeline fitting is hard to break loose,

spray generous amount of Mopar Rust Pene-

trant between fitting and line and around fitting

threads in wheel cylinder. Note that it may re-

quire a few minutes for penetrant to work.

(3) Remove brakeshoes.

(4) Remove bolts attaching wheel cylinder to sup-

port plate and remove cylinder.

WHEEL CYLINDER OVERHAUL (Figs. 8 and 9)

(1) Remove links.

(2) Remove dust boots.

(3) Remove cups and pistons. Discard cups.

(4) Remove and discard spring and expander.

(5) Remove bleed screw.

(6) Clean cylinder, pistons and links with Mopar

brake cleaner.

(7) Inspect cylinder bore and pistons. Light discol-

oration of bore is acceptable. However, replace cylin-

der if bore and pistons are scored, pitted, or corroded.

Do not hone cylinder bores or polish pistons.

Replace cylinder as an assembly if bore is dam-

aged.

(8) Install bleed screw.

Fig. 5 Adjuster Screw Components (9-Inch Brake)

Fig. 6 Adjusting Gauge To Brake Drum

Fig. 7 Adjusting Brakeshoes To Gauge

Fig. 8 Wheel Cylinder (9-Inch Brake)

5 - 36 BRAKESJ

Page 184 of 1784

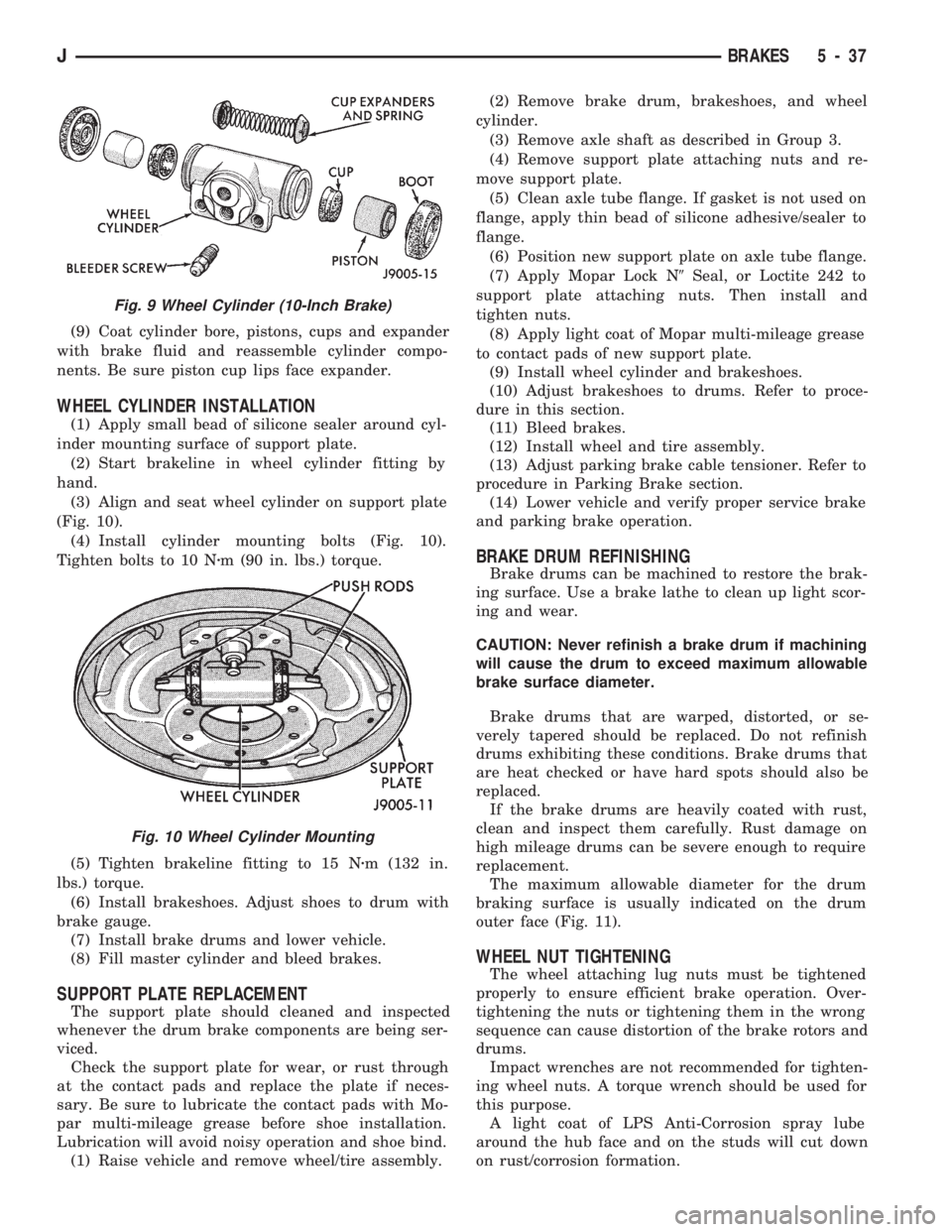

(9) Coat cylinder bore, pistons, cups and expander

with brake fluid and reassemble cylinder compo-

nents. Be sure piston cup lips face expander.

WHEEL CYLINDER INSTALLATION

(1) Apply small bead of silicone sealer around cyl-

inder mounting surface of support plate.

(2) Start brakeline in wheel cylinder fitting by

hand.

(3) Align and seat wheel cylinder on support plate

(Fig. 10).

(4) Install cylinder mounting bolts (Fig. 10).

Tighten bolts to 10 Nzm (90 in. lbs.) torque.

(5) Tighten brakeline fitting to 15 Nzm (132 in.

lbs.) torque.

(6) Install brakeshoes. Adjust shoes to drum with

brake gauge.

(7) Install brake drums and lower vehicle.

(8) Fill master cylinder and bleed brakes.

SUPPORT PLATE REPLACEMENT

The support plate should cleaned and inspected

whenever the drum brake components are being ser-

viced.

Check the support plate for wear, or rust through

at the contact pads and replace the plate if neces-

sary. Be sure to lubricate the contact pads with Mo-

par multi-mileage grease before shoe installation.

Lubrication will avoid noisy operation and shoe bind.

(1) Raise vehicle and remove wheel/tire assembly.(2) Remove brake drum, brakeshoes, and wheel

cylinder.

(3) Remove axle shaft as described in Group 3.

(4) Remove support plate attaching nuts and re-

move support plate.

(5) Clean axle tube flange. If gasket is not used on

flange, apply thin bead of silicone adhesive/sealer to

flange.

(6) Position new support plate on axle tube flange.

(7) Apply Mopar Lock N9Seal, or Loctite 242 to

support plate attaching nuts. Then install and

tighten nuts.

(8) Apply light coat of Mopar multi-mileage grease

to contact pads of new support plate.

(9) Install wheel cylinder and brakeshoes.

(10) Adjust brakeshoes to drums. Refer to proce-

dure in this section.

(11) Bleed brakes.

(12) Install wheel and tire assembly.

(13) Adjust parking brake cable tensioner. Refer to

procedure in Parking Brake section.

(14) Lower vehicle and verify proper service brake

and parking brake operation.

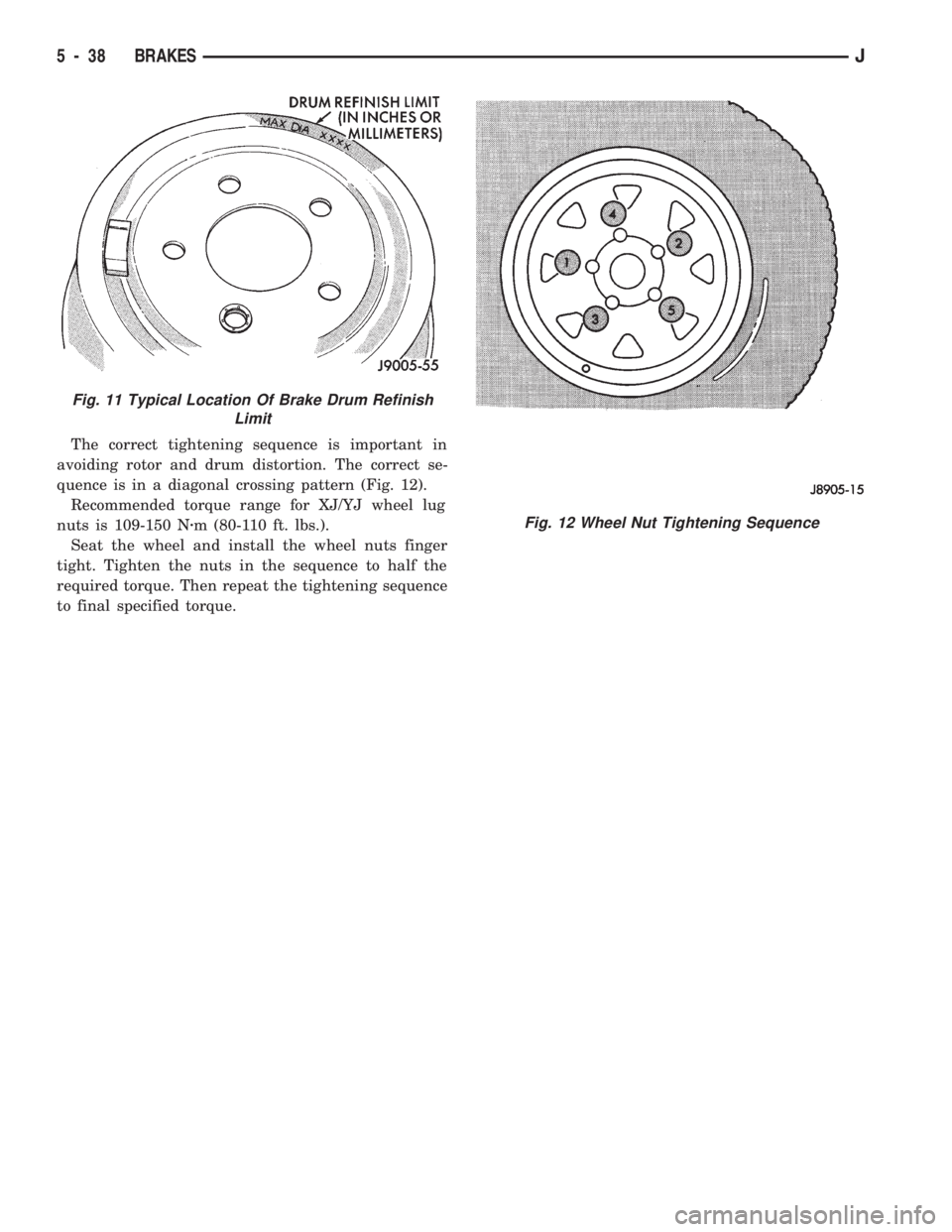

BRAKE DRUM REFINISHING

Brake drums can be machined to restore the brak-

ing surface. Use a brake lathe to clean up light scor-

ing and wear.

CAUTION: Never refinish a brake drum if machining

will cause the drum to exceed maximum allowable

brake surface diameter.

Brake drums that are warped, distorted, or se-

verely tapered should be replaced. Do not refinish

drums exhibiting these conditions. Brake drums that

are heat checked or have hard spots should also be

replaced.

If the brake drums are heavily coated with rust,

clean and inspect them carefully. Rust damage on

high mileage drums can be severe enough to require

replacement.

The maximum allowable diameter for the drum

braking surface is usually indicated on the drum

outer face (Fig. 11).

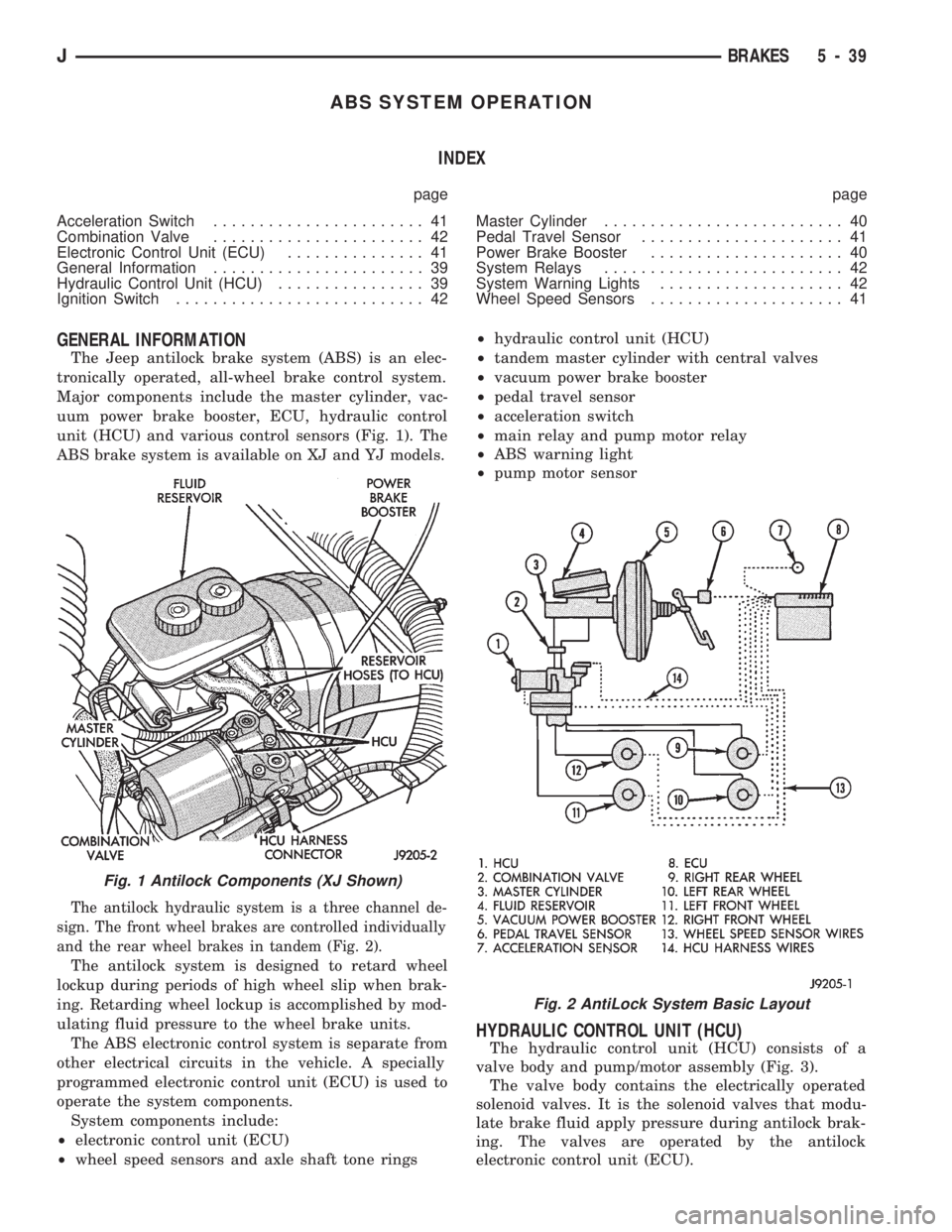

WHEEL NUT TIGHTENING

The wheel attaching lug nuts must be tightened

properly to ensure efficient brake operation. Over-

tightening the nuts or tightening them in the wrong

sequence can cause distortion of the brake rotors and

drums.

Impact wrenches are not recommended for tighten-

ing wheel nuts. A torque wrench should be used for

this purpose.

A light coat of LPS Anti-Corrosion spray lube

around the hub face and on the studs will cut down

on rust/corrosion formation.

Fig. 9 Wheel Cylinder (10-Inch Brake)

Fig. 10 Wheel Cylinder Mounting

JBRAKES 5 - 37

Page 185 of 1784

The correct tightening sequence is important in

avoiding rotor and drum distortion. The correct se-

quence is in a diagonal crossing pattern (Fig. 12).

Recommended torque range for XJ/YJ wheel lug

nuts is 109-150 Nzm (80-110 ft. lbs.).

Seat the wheel and install the wheel nuts finger

tight. Tighten the nuts in the sequence to half the

required torque. Then repeat the tightening sequence

to final specified torque.

Fig. 11 Typical Location Of Brake Drum Refinish

Limit

Fig. 12 Wheel Nut Tightening Sequence

5 - 38 BRAKESJ

Page 186 of 1784

ABS SYSTEM OPERATION

INDEX

page page

Acceleration Switch....................... 41

Combination Valve....................... 42

Electronic Control Unit (ECU)............... 41

General Information....................... 39

Hydraulic Control Unit (HCU)................ 39

Ignition Switch........................... 42Master Cylinder.......................... 40

Pedal Travel Sensor...................... 41

Power Brake Booster..................... 40

System Relays.......................... 42

System Warning Lights.................... 42

Wheel Speed Sensors..................... 41

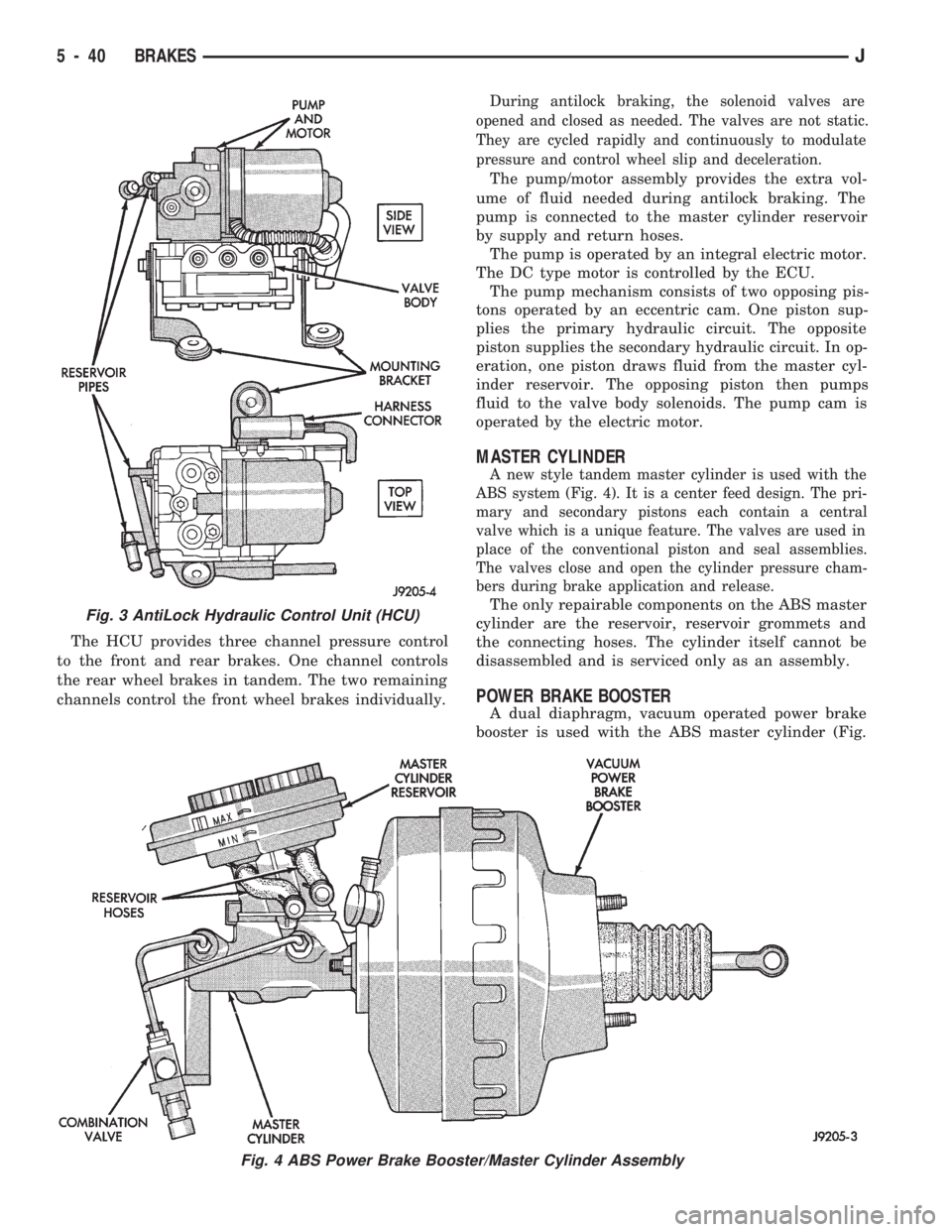

GENERAL INFORMATION

The Jeep antilock brake system (ABS) is an elec-

tronically operated, all-wheel brake control system.

Major components include the master cylinder, vac-

uum power brake booster, ECU, hydraulic control

unit (HCU) and various control sensors (Fig. 1). The

ABS brake system is available on XJ and YJ models.

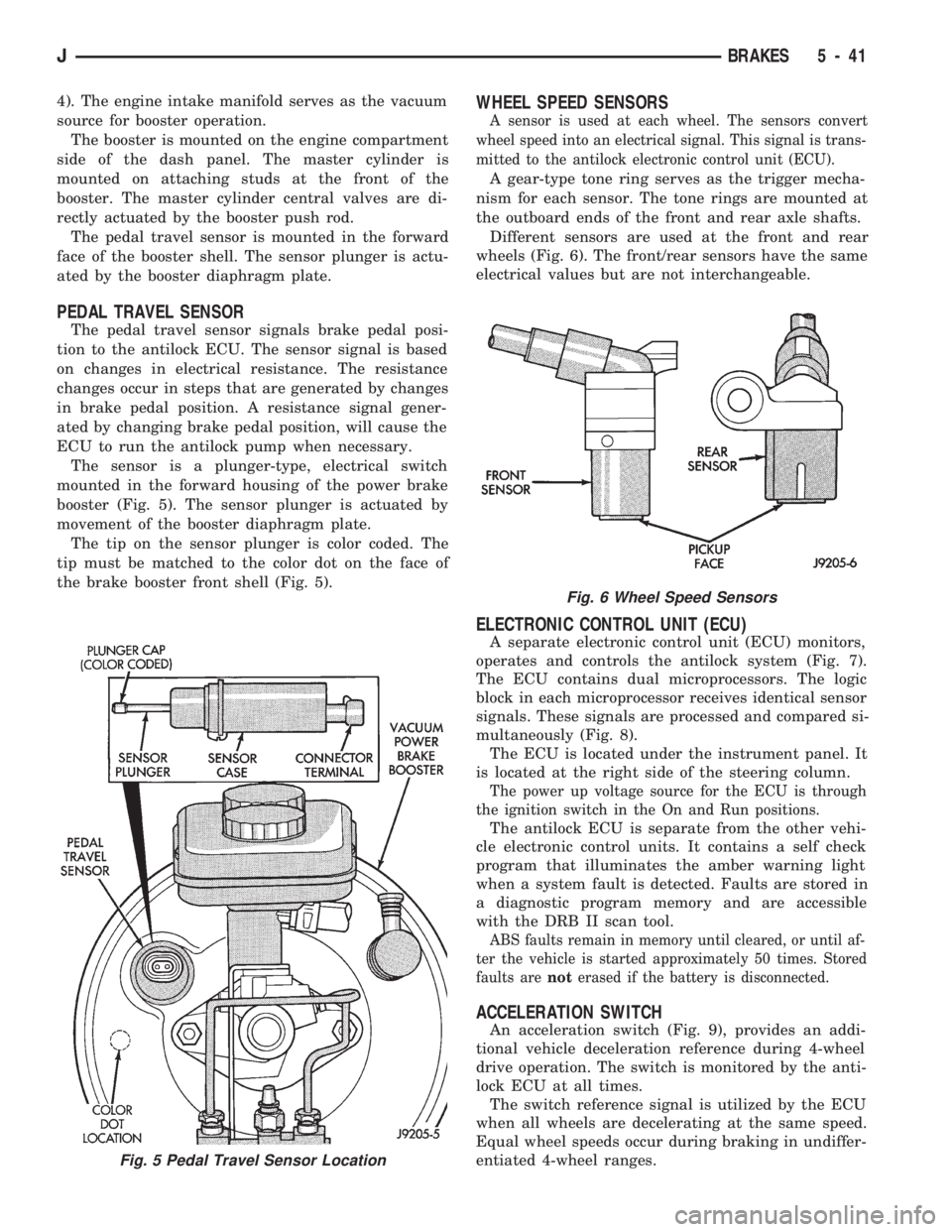

The antilock hydraulic system is a three channel de-

sign. The front wheel brakes are controlled individually

and the rear wheel brakes in tandem (Fig. 2).

The antilock system is designed to retard wheel

lockup during periods of high wheel slip when brak-

ing. Retarding wheel lockup is accomplished by mod-

ulating fluid pressure to the wheel brake units.

The ABS electronic control system is separate from

other electrical circuits in the vehicle. A specially

programmed electronic control unit (ECU) is used to

operate the system components.

System components include:

²electronic control unit (ECU)

²wheel speed sensors and axle shaft tone rings²hydraulic control unit (HCU)

²tandem master cylinder with central valves

²vacuum power brake booster

²pedal travel sensor

²acceleration switch

²main relay and pump motor relay

²ABS warning light

²pump motor sensor

HYDRAULIC CONTROL UNIT (HCU)

The hydraulic control unit (HCU) consists of a

valve body and pump/motor assembly (Fig. 3).

The valve body contains the electrically operated

solenoid valves. It is the solenoid valves that modu-

late brake fluid apply pressure during antilock brak-

ing. The valves are operated by the antilock

electronic control unit (ECU).

Fig. 1 Antilock Components (XJ Shown)

Fig. 2 AntiLock System Basic Layout

JBRAKES 5 - 39

Page 187 of 1784

The HCU provides three channel pressure control

to the front and rear brakes. One channel controls

the rear wheel brakes in tandem. The two remaining

channels control the front wheel brakes individually.

During antilock braking, the solenoid valves are

opened and closed as needed. The valves are not static.

They are cycled rapidly and continuously to modulate

pressure and control wheel slip and deceleration.

The pump/motor assembly provides the extra vol-

ume of fluid needed during antilock braking. The

pump is connected to the master cylinder reservoir

by supply and return hoses.

The pump is operated by an integral electric motor.

The DC type motor is controlled by the ECU.

The pump mechanism consists of two opposing pis-

tons operated by an eccentric cam. One piston sup-

plies the primary hydraulic circuit. The opposite

piston supplies the secondary hydraulic circuit. In op-

eration, one piston draws fluid from the master cyl-

inder reservoir. The opposing piston then pumps

fluid to the valve body solenoids. The pump cam is

operated by the electric motor.

MASTER CYLINDER

A new style tandem master cylinder is used with the

ABS system (Fig. 4). It is a center feed design. The pri-

mary and secondary pistons each contain a central

valve which is a unique feature. The valves are used in

place of the conventional piston and seal assemblies.

The valves close and open the cylinder pressure cham-

bers during brake application and release.

The only repairable components on the ABS master

cylinder are the reservoir, reservoir grommets and

the connecting hoses. The cylinder itself cannot be

disassembled and is serviced only as an assembly.

POWER BRAKE BOOSTER

A dual diaphragm, vacuum operated power brake

booster is used with the ABS master cylinder (Fig.

Fig. 3 AntiLock Hydraulic Control Unit (HCU)

Fig. 4 ABS Power Brake Booster/Master Cylinder Assembly

5 - 40 BRAKESJ

Page 188 of 1784

4). The engine intake manifold serves as the vacuum

source for booster operation.

The booster is mounted on the engine compartment

side of the dash panel. The master cylinder is

mounted on attaching studs at the front of the

booster. The master cylinder central valves are di-

rectly actuated by the booster push rod.

The pedal travel sensor is mounted in the forward

face of the booster shell. The sensor plunger is actu-

ated by the booster diaphragm plate.

PEDAL TRAVEL SENSOR

The pedal travel sensor signals brake pedal posi-

tion to the antilock ECU. The sensor signal is based

on changes in electrical resistance. The resistance

changes occur in steps that are generated by changes

in brake pedal position. A resistance signal gener-

ated by changing brake pedal position, will cause the

ECU to run the antilock pump when necessary.

The sensor is a plunger-type, electrical switch

mounted in the forward housing of the power brake

booster (Fig. 5). The sensor plunger is actuated by

movement of the booster diaphragm plate.

The tip on the sensor plunger is color coded. The

tip must be matched to the color dot on the face of

the brake booster front shell (Fig. 5).

WHEEL SPEED SENSORS

A sensor is used at each wheel. The sensors convert

wheel speed into an electrical signal. This signal is trans-

mitted to the antilock electronic control unit (ECU).

A gear-type tone ring serves as the trigger mecha-

nism for each sensor. The tone rings are mounted at

the outboard ends of the front and rear axle shafts.

Different sensors are used at the front and rear

wheels (Fig. 6). The front/rear sensors have the same

electrical values but are not interchangeable.

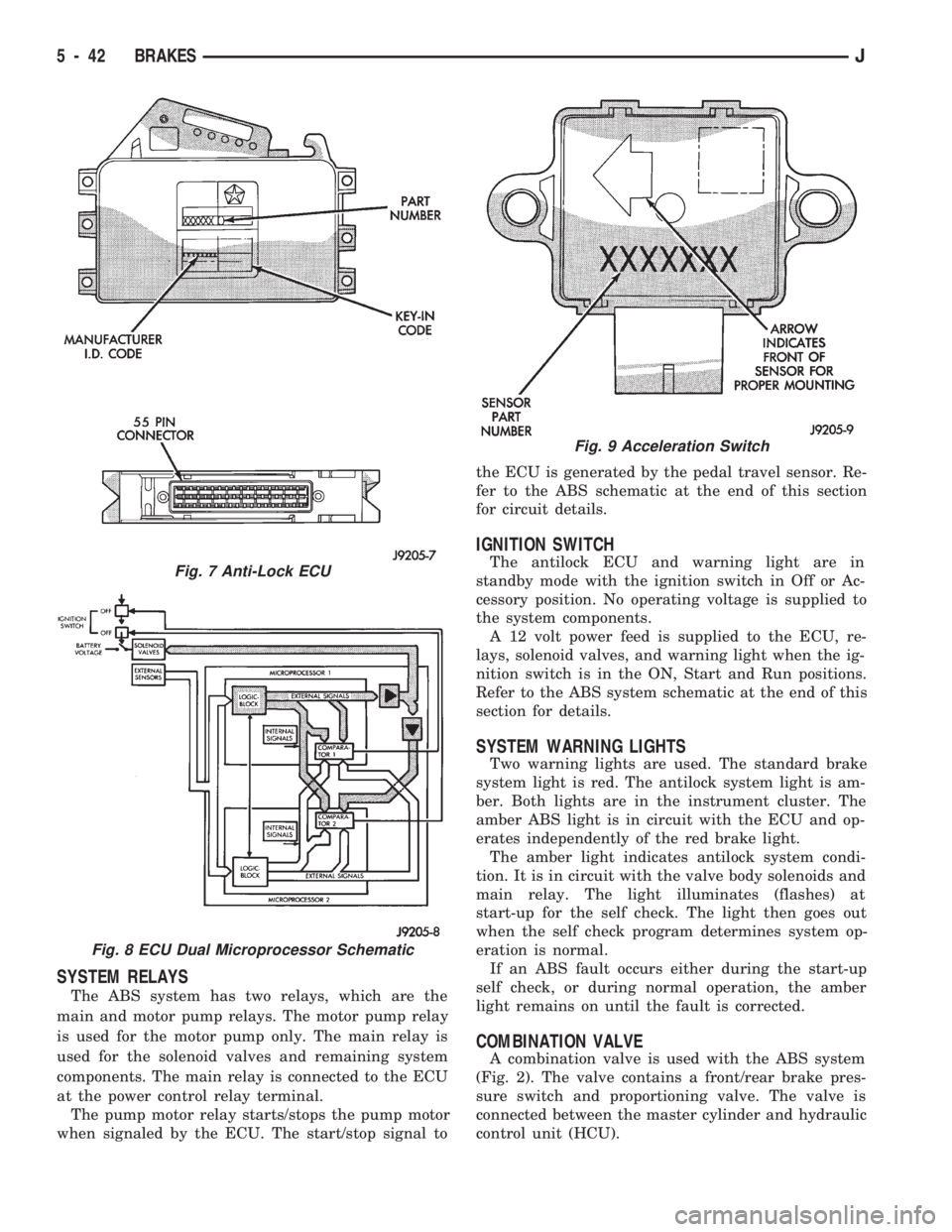

ELECTRONIC CONTROL UNIT (ECU)

A separate electronic control unit (ECU) monitors,

operates and controls the antilock system (Fig. 7).

The ECU contains dual microprocessors. The logic

block in each microprocessor receives identical sensor

signals. These signals are processed and compared si-

multaneously (Fig. 8).

The ECU is located under the instrument panel. It

is located at the right side of the steering column.

The power up voltage source for the ECU is through

the ignition switch in the On and Run positions.

The antilock ECU is separate from the other vehi-

cle electronic control units. It contains a self check

program that illuminates the amber warning light

when a system fault is detected. Faults are stored in

a diagnostic program memory and are accessible

with the DRB II scan tool.

ABS faults remain in memory until cleared, or until af-

ter the vehicle is started approximately 50 times. Stored

faults arenoterased if the battery is disconnected.

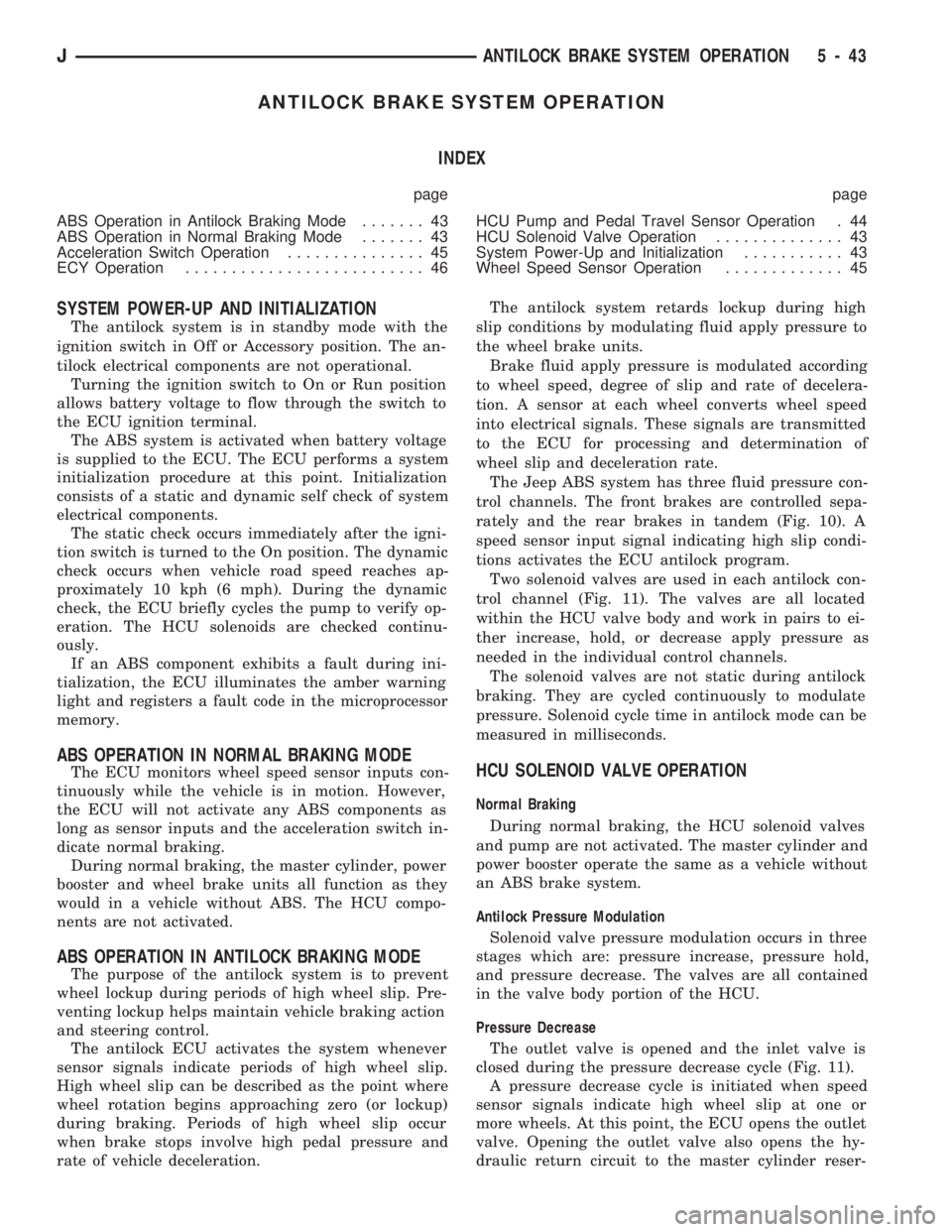

ACCELERATION SWITCH

An acceleration switch (Fig. 9), provides an addi-

tional vehicle deceleration reference during 4-wheel

drive operation. The switch is monitored by the anti-

lock ECU at all times.

The switch reference signal is utilized by the ECU

when all wheels are decelerating at the same speed.

Equal wheel speeds occur during braking in undiffer-

entiated 4-wheel ranges.

Fig. 5 Pedal Travel Sensor Location

Fig. 6 Wheel Speed Sensors

JBRAKES 5 - 41

Page 189 of 1784

SYSTEM RELAYS

The ABS system has two relays, which are the

main and motor pump relays. The motor pump relay

is used for the motor pump only. The main relay is

used for the solenoid valves and remaining system

components. The main relay is connected to the ECU

at the power control relay terminal.

The pump motor relay starts/stops the pump motor

when signaled by the ECU. The start/stop signal tothe ECU is generated by the pedal travel sensor. Re-

fer to the ABS schematic at the end of this section

for circuit details.

IGNITION SWITCH

The antilock ECU and warning light are in

standby mode with the ignition switch in Off or Ac-

cessory position. No operating voltage is supplied to

the system components.

A 12 volt power feed is supplied to the ECU, re-

lays, solenoid valves, and warning light when the ig-

nition switch is in the ON, Start and Run positions.

Refer to the ABS system schematic at the end of this

section for details.

SYSTEM WARNING LIGHTS

Two warning lights are used. The standard brake

system light is red. The antilock system light is am-

ber. Both lights are in the instrument cluster. The

amber ABS light is in circuit with the ECU and op-

erates independently of the red brake light.

The amber light indicates antilock system condi-

tion. It is in circuit with the valve body solenoids and

main relay. The light illuminates (flashes) at

start-up for the self check. The light then goes out

when the self check program determines system op-

eration is normal.

If an ABS fault occurs either during the start-up

self check, or during normal operation, the amber

light remains on until the fault is corrected.

COMBINATION VALVE

A combination valve is used with the ABS system

(Fig. 2). The valve contains a front/rear brake pres-

sure switch and proportioning valve. The valve is

connected between the master cylinder and hydraulic

control unit (HCU).

Fig. 7 Anti-Lock ECU

Fig. 8 ECU Dual Microprocessor Schematic

Fig. 9 Acceleration Switch

5 - 42 BRAKESJ

Page 190 of 1784

ANTILOCK BRAKE SYSTEM OPERATION

INDEX

page page

ABS Operation in Antilock Braking Mode....... 43

ABS Operation in Normal Braking Mode....... 43

Acceleration Switch Operation............... 45

ECY Operation.......................... 46HCU Pump and Pedal Travel Sensor Operation . 44

HCU Solenoid Valve Operation.............. 43

System Power-Up and Initialization........... 43

Wheel Speed Sensor Operation............. 45

SYSTEM POWER-UP AND INITIALIZATION

The antilock system is in standby mode with the

ignition switch in Off or Accessory position. The an-

tilock electrical components are not operational.

Turning the ignition switch to On or Run position

allows battery voltage to flow through the switch to

the ECU ignition terminal.

The ABS system is activated when battery voltage

is supplied to the ECU. The ECU performs a system

initialization procedure at this point. Initialization

consists of a static and dynamic self check of system

electrical components.

The static check occurs immediately after the igni-

tion switch is turned to the On position. The dynamic

check occurs when vehicle road speed reaches ap-

proximately 10 kph (6 mph). During the dynamic

check, the ECU briefly cycles the pump to verify op-

eration. The HCU solenoids are checked continu-

ously.

If an ABS component exhibits a fault during ini-

tialization, the ECU illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

ABS OPERATION IN NORMAL BRAKING MODE

The ECU monitors wheel speed sensor inputs con-

tinuously while the vehicle is in motion. However,

the ECU will not activate any ABS components as

long as sensor inputs and the acceleration switch in-

dicate normal braking.

During normal braking, the master cylinder, power

booster and wheel brake units all function as they

would in a vehicle without ABS. The HCU compo-

nents are not activated.

ABS OPERATION IN ANTILOCK BRAKING MODE

The purpose of the antilock system is to prevent

wheel lockup during periods of high wheel slip. Pre-

venting lockup helps maintain vehicle braking action

and steering control.

The antilock ECU activates the system whenever

sensor signals indicate periods of high wheel slip.

High wheel slip can be described as the point where

wheel rotation begins approaching zero (or lockup)

during braking. Periods of high wheel slip occur

when brake stops involve high pedal pressure and

rate of vehicle deceleration.The antilock system retards lockup during high

slip conditions by modulating fluid apply pressure to

the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. A sensor at each wheel converts wheel speed

into electrical signals. These signals are transmitted

to the ECU for processing and determination of

wheel slip and deceleration rate.

The Jeep ABS system has three fluid pressure con-

trol channels. The front brakes are controlled sepa-

rately and the rear brakes in tandem (Fig. 10). A

speed sensor input signal indicating high slip condi-

tions activates the ECU antilock program.

Two solenoid valves are used in each antilock con-

trol channel (Fig. 11). The valves are all located

within the HCU valve body and work in pairs to ei-

ther increase, hold, or decrease apply pressure as

needed in the individual control channels.

The solenoid valves are not static during antilock

braking. They are cycled continuously to modulate

pressure. Solenoid cycle time in antilock mode can be

measured in milliseconds.

HCU SOLENOID VALVE OPERATION

Normal Braking

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

Antilock Pressure Modulation

Solenoid valve pressure modulation occurs in three

stages which are: pressure increase, pressure hold,

and pressure decrease. The valves are all contained

in the valve body portion of the HCU.

Pressure Decrease

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle (Fig. 11).

A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the ECU opens the outlet

valve. Opening the outlet valve also opens the hy-

draulic return circuit to the master cylinder reser-

JANTILOCK BRAKE SYSTEM OPERATION 5 - 43