JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 191 of 1784

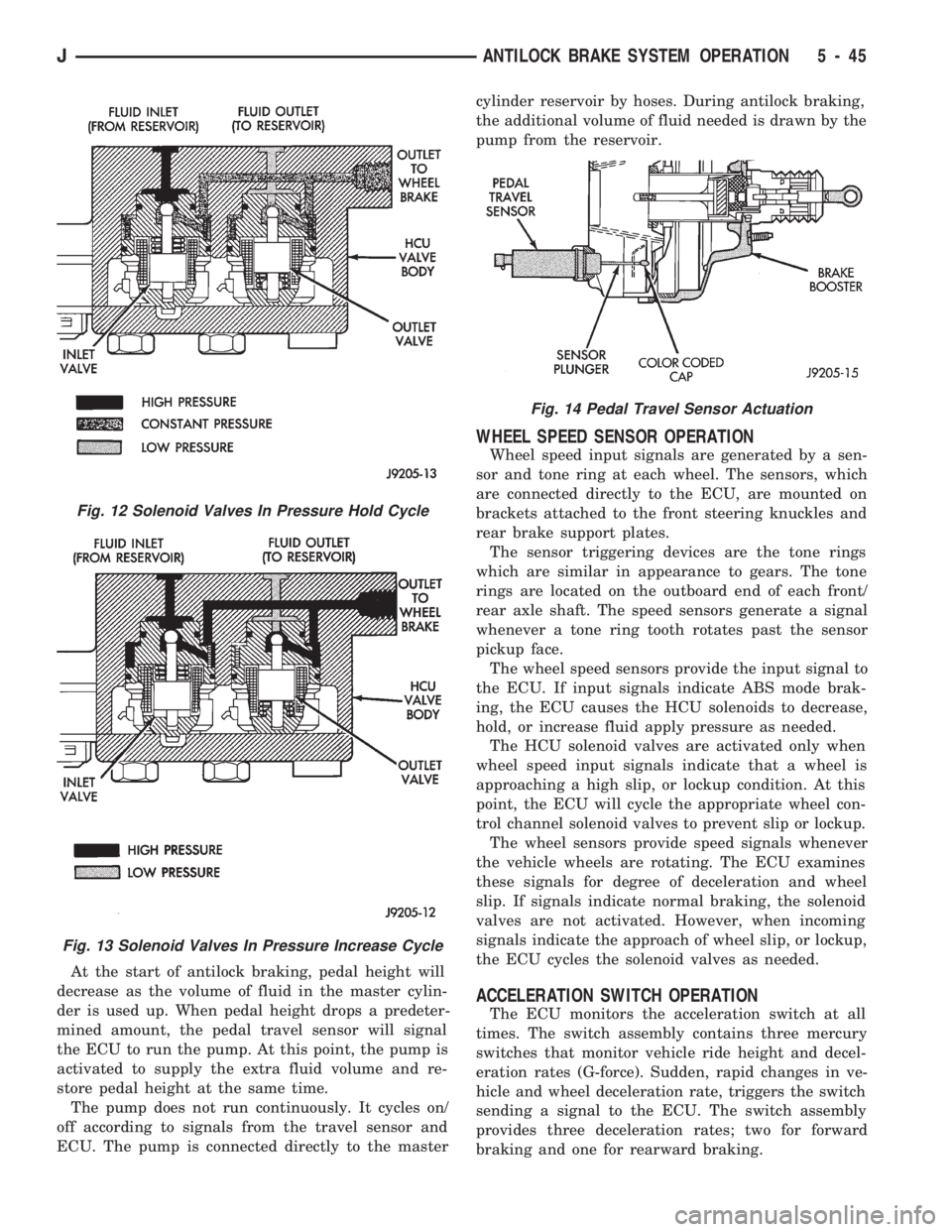

voir. Fluid pressure is allowed to bleed off (decrease)

as needed to prevent wheel lock.

Once the period of high wheel slip has ended, the

ECU closes the outlet valve and begins a pressure in-

crease or hold cycle as needed.

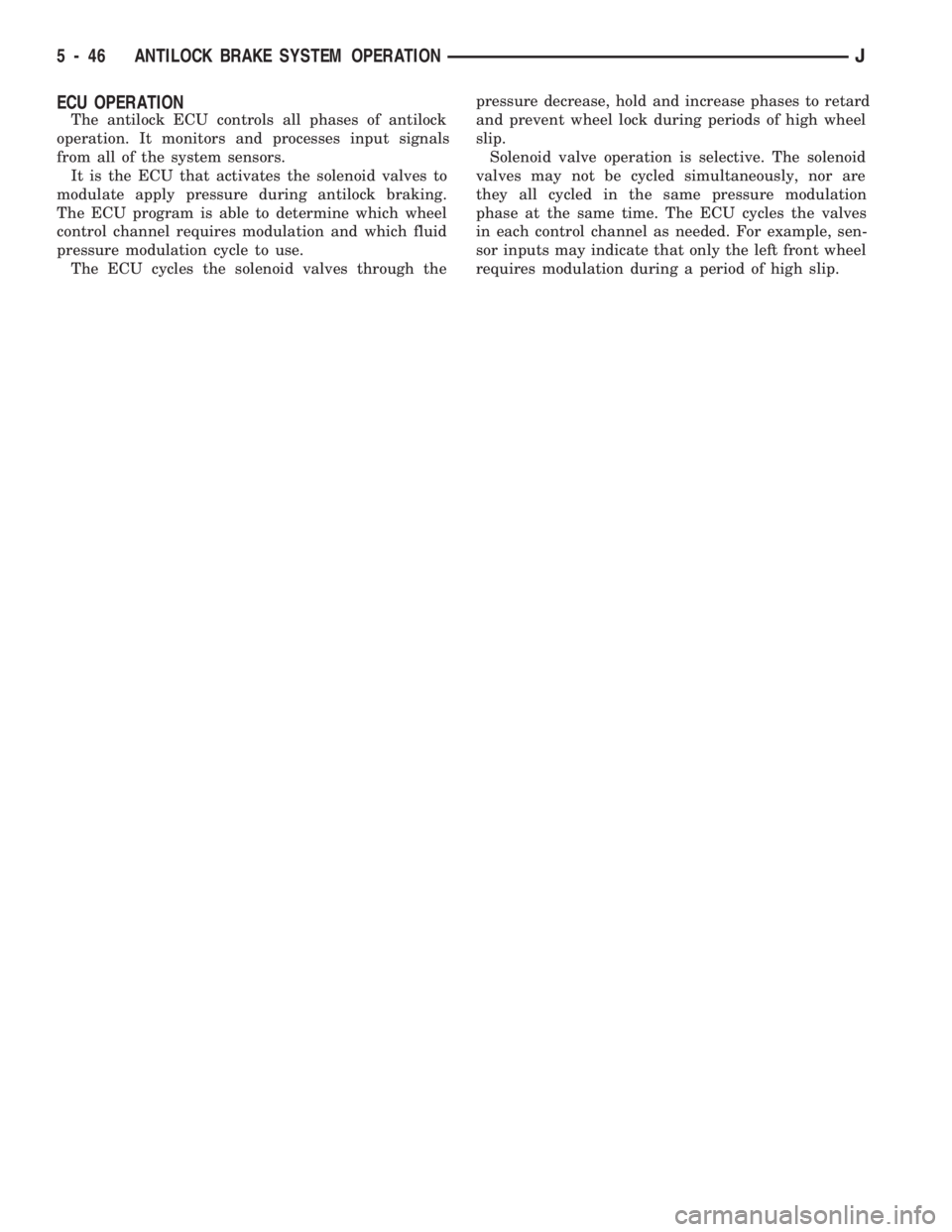

Pressure Hold

Both solenoid valves are closed in the pressure hold

cycle (Fig. 12). Fluid apply pressure in the control

channel is maintained at a constant rate. The ECU

maintains the hold cycle until sensor inputs indicate

a pressure change is necessary.

Pressure Increase

The inlet valve is open and the outlet valve is

closed during the pressure increase cycle (Fig. 13).

The pressure increase cycle is used to counteract un-

equal wheel speeds. This cycle controls reapplication

of fluid apply pressure after a pressure decrease cy-

cle.

HCU PUMP AND PEDAL TRAVEL SENSOR

OPERATION

The HCU pump has two functions during antilock

braking. First, the pump supplies the extra volume

of fluid needed. And second, the pump maintains

brake pedal height. The fluid source for the pump is

the master cylinder reservoir. The reservoir and

HCU are interconnected by hoses.

The pump motor is activated by the ECU. How-

ever, the signal to run the pump actually comes from

the pedal travel sensor.

The pedal travel sensor is mounted in the forward

face of the brake booster (Fig. 14). The sensorplunger is actuated by movement of the booster dia-

phragm plate. The sensor has a total of seven pedal

positions, six of which are monitored. The six pedal

positions monitored range from full release to full ap-

ply. Each pedal position (toward full apply), gener-

ates an increasing degree of electrical resistance in

the sensor.

The ECU continuously monitors electrical resis-

tance at the pedal travel sensor. The ECU activates

the pump whenever sensor electrical resistance in-

creases during ABS mode braking.

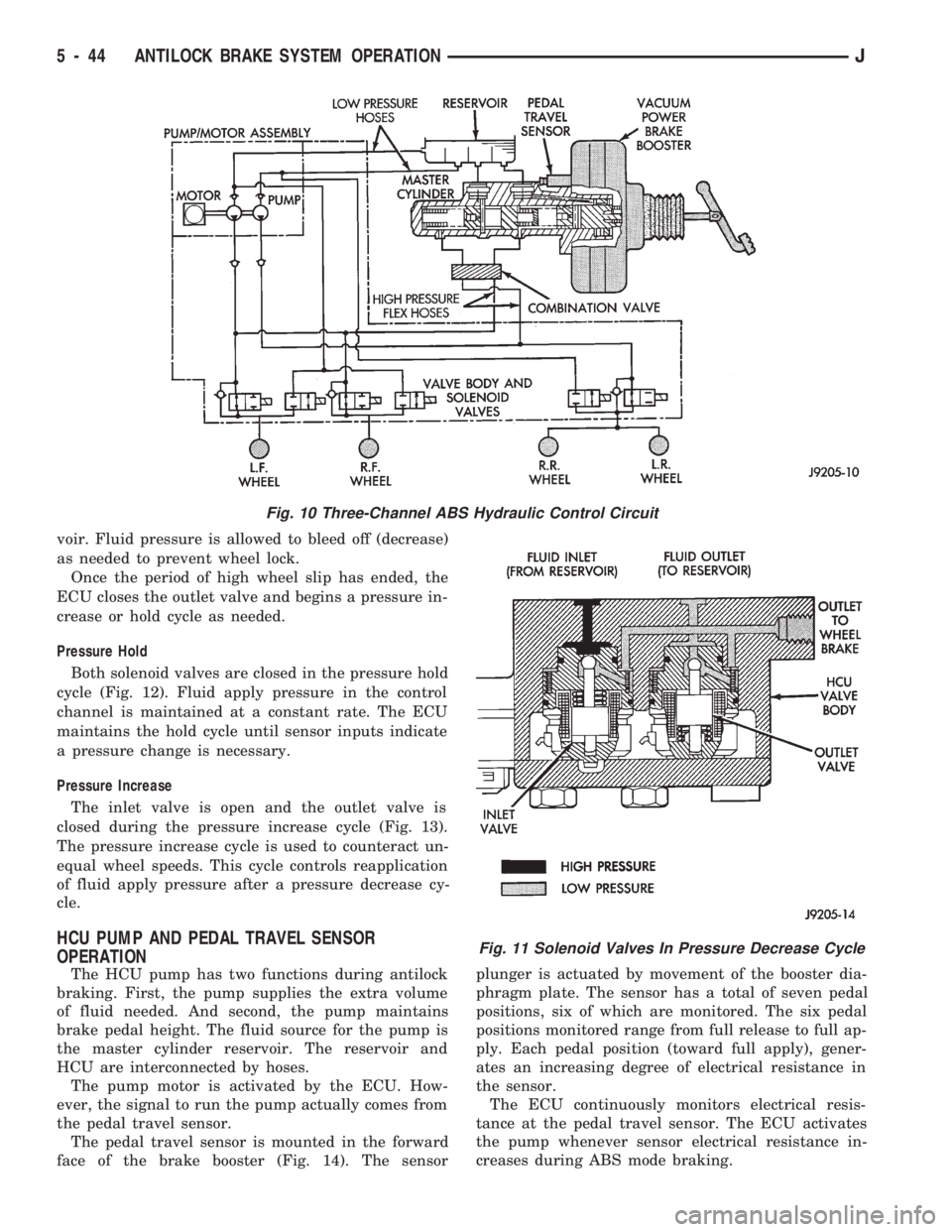

Fig. 10 Three-Channel ABS Hydraulic Control Circuit

Fig. 11 Solenoid Valves In Pressure Decrease Cycle

5 - 44 ANTILOCK BRAKE SYSTEM OPERATIONJ

Page 192 of 1784

At the start of antilock braking, pedal height will

decrease as the volume of fluid in the master cylin-

der is used up. When pedal height drops a predeter-

mined amount, the pedal travel sensor will signal

the ECU to run the pump. At this point, the pump is

activated to supply the extra fluid volume and re-

store pedal height at the same time.

The pump does not run continuously. It cycles on/

off according to signals from the travel sensor and

ECU. The pump is connected directly to the mastercylinder reservoir by hoses. During antilock braking,

the additional volume of fluid needed is drawn by the

pump from the reservoir.

WHEEL SPEED SENSOR OPERATION

Wheel speed input signals are generated by a sen-

sor and tone ring at each wheel. The sensors, which

are connected directly to the ECU, are mounted on

brackets attached to the front steering knuckles and

rear brake support plates.

The sensor triggering devices are the tone rings

which are similar in appearance to gears. The tone

rings are located on the outboard end of each front/

rear axle shaft. The speed sensors generate a signal

whenever a tone ring tooth rotates past the sensor

pickup face.

The wheel speed sensors provide the input signal to

the ECU. If input signals indicate ABS mode brak-

ing, the ECU causes the HCU solenoids to decrease,

hold, or increase fluid apply pressure as needed.

The HCU solenoid valves are activated only when

wheel speed input signals indicate that a wheel is

approaching a high slip, or lockup condition. At this

point, the ECU will cycle the appropriate wheel con-

trol channel solenoid valves to prevent slip or lockup.

The wheel sensors provide speed signals whenever

the vehicle wheels are rotating. The ECU examines

these signals for degree of deceleration and wheel

slip. If signals indicate normal braking, the solenoid

valves are not activated. However, when incoming

signals indicate the approach of wheel slip, or lockup,

the ECU cycles the solenoid valves as needed.

ACCELERATION SWITCH OPERATION

The ECU monitors the acceleration switch at all

times. The switch assembly contains three mercury

switches that monitor vehicle ride height and decel-

eration rates (G-force). Sudden, rapid changes in ve-

hicle and wheel deceleration rate, triggers the switch

sending a signal to the ECU. The switch assembly

provides three deceleration rates; two for forward

braking and one for rearward braking.

Fig. 12 Solenoid Valves In Pressure Hold Cycle

Fig. 13 Solenoid Valves In Pressure Increase Cycle

Fig. 14 Pedal Travel Sensor Actuation

JANTILOCK BRAKE SYSTEM OPERATION 5 - 45

Page 193 of 1784

ECU OPERATION

The antilock ECU controls all phases of antilock

operation. It monitors and processes input signals

from all of the system sensors.

It is the ECU that activates the solenoid valves to

modulate apply pressure during antilock braking.

The ECU program is able to determine which wheel

control channel requires modulation and which fluid

pressure modulation cycle to use.

The ECU cycles the solenoid valves through thepressure decrease, hold and increase phases to retard

and prevent wheel lock during periods of high wheel

slip.

Solenoid valve operation is selective. The solenoid

valves may not be cycled simultaneously, nor are

they all cycled in the same pressure modulation

phase at the same time. The ECU cycles the valves

in each control channel as needed. For example, sen-

sor inputs may indicate that only the left front wheel

requires modulation during a period of high slip.

5 - 46 ANTILOCK BRAKE SYSTEM OPERATIONJ

Page 194 of 1784

ABS COMPONENT SERVICE

INDEX

page page

Acceleration Sensor Installation.............. 52

Acceleration Sensor Removal............... 52

Combination Valve ReplacementÐXJ......... 55

Combination Valve ReplacementÐYJ......... 55

Component Serviceability................... 47

Correct Fluid Level....................... 48

ECU ReplacementÐXJ.................... 53

ECU ReplacementÐYJ.................... 53

Front Wheel Sensor Installation.............. 49

Front Wheel Sensor Removal............... 49

HCU InstallationÐXJ...................... 54

HCU InstallationÐYJ...................... 54HCU RemovalÐXJ....................... 53

HCU RemovalÐYJ....................... 54

Importance of Clean Brake Fluid............. 48

Master Cylinder Installation................. 50

Master Cylinder Removal.................. 50

Pedal Travel Sensor Service................ 51

Power Brake Booster Installation............. 51

Power Brake Booster Removal.............. 51

Rear Wheel Sensor Installation.............. 50

Rear Wheel Sensor Removal............... 49

Recommended Brake Fluid................. 48

Wheel Sensor Air Gap Adjustment........... 49

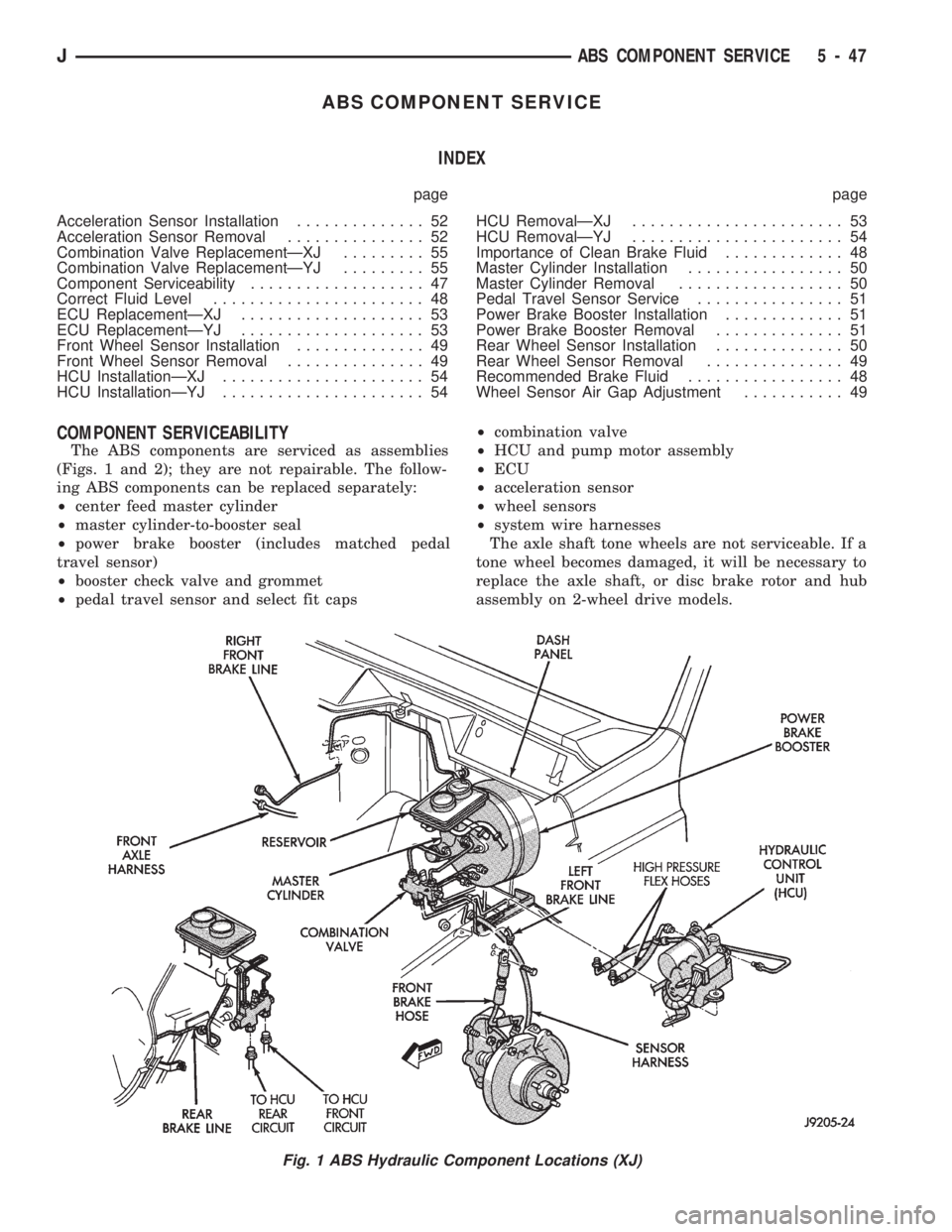

COMPONENT SERVICEABILITY

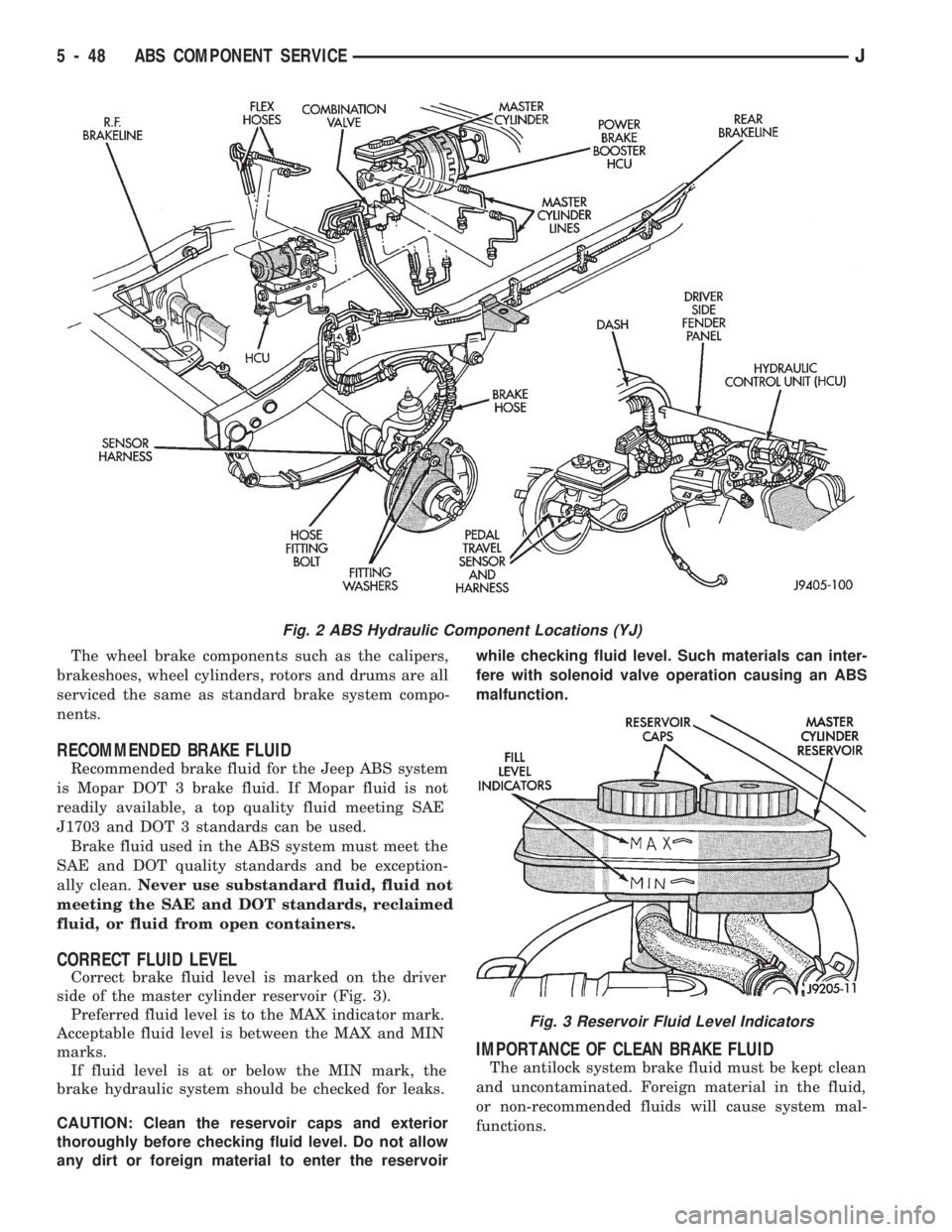

The ABS components are serviced as assemblies

(Figs. 1 and 2); they are not repairable. The follow-

ing ABS components can be replaced separately:

²center feed master cylinder

²master cylinder-to-booster seal

²power brake booster (includes matched pedal

travel sensor)

²booster check valve and grommet

²pedal travel sensor and select fit caps²combination valve

²HCU and pump motor assembly

²ECU

²acceleration sensor

²wheel sensors

²system wire harnesses

The axle shaft tone wheels are not serviceable. If a

tone wheel becomes damaged, it will be necessary to

replace the axle shaft, or disc brake rotor and hub

assembly on 2-wheel drive models.

Fig. 1 ABS Hydraulic Component Locations (XJ)

JABS COMPONENT SERVICE 5 - 47

Page 195 of 1784

The wheel brake components such as the calipers,

brakeshoes, wheel cylinders, rotors and drums are all

serviced the same as standard brake system compo-

nents.

RECOMMENDED BRAKE FLUID

Recommended brake fluid for the Jeep ABS system

is Mopar DOT 3 brake fluid. If Mopar fluid is not

readily available, a top quality fluid meeting SAE

J1703 and DOT 3 standards can be used.

Brake fluid used in the ABS system must meet the

SAE and DOT quality standards and be exception-

ally clean.Never use substandard fluid, fluid not

meeting the SAE and DOT standards, reclaimed

fluid, or fluid from open containers.

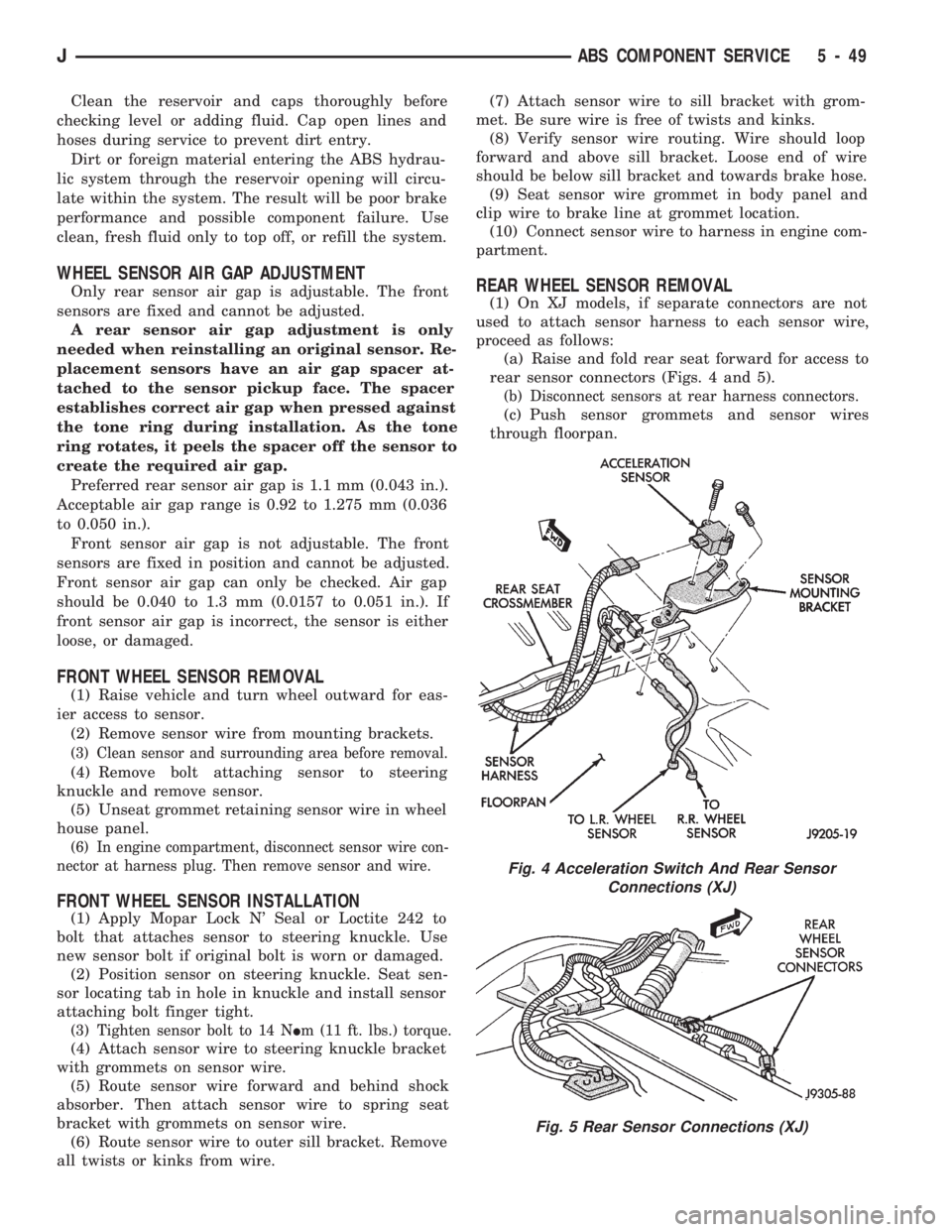

CORRECT FLUID LEVEL

Correct brake fluid level is marked on the driver

side of the master cylinder reservoir (Fig. 3).

Preferred fluid level is to the MAX indicator mark.

Acceptable fluid level is between the MAX and MIN

marks.

If fluid level is at or below the MIN mark, the

brake hydraulic system should be checked for leaks.

CAUTION: Clean the reservoir caps and exterior

thoroughly before checking fluid level. Do not allow

any dirt or foreign material to enter the reservoirwhile checking fluid level. Such materials can inter-

fere with solenoid valve operation causing an ABS

malfunction.

IMPORTANCE OF CLEAN BRAKE FLUID

The antilock system brake fluid must be kept clean

and uncontaminated. Foreign material in the fluid,

or non-recommended fluids will cause system mal-

functions.

Fig. 2 ABS Hydraulic Component Locations (YJ)

Fig. 3 Reservoir Fluid Level Indicators

5 - 48 ABS COMPONENT SERVICEJ

Page 196 of 1784

Clean the reservoir and caps thoroughly before

checking level or adding fluid. Cap open lines and

hoses during service to prevent dirt entry.

Dirt or foreign material entering the ABS hydrau-

lic system through the reservoir opening will circu-

late within the system. The result will be poor brake

performance and possible component failure. Use

clean, fresh fluid only to top off, or refill the system.

WHEEL SENSOR AIR GAP ADJUSTMENT

Only rear sensor air gap is adjustable. The front

sensors are fixed and cannot be adjusted.

A rear sensor air gap adjustment is only

needed when reinstalling an original sensor. Re-

placement sensors have an air gap spacer at-

tached to the sensor pickup face. The spacer

establishes correct air gap when pressed against

the tone ring during installation. As the tone

ring rotates, it peels the spacer off the sensor to

create the required air gap.

Preferred rear sensor air gap is 1.1 mm (0.043 in.).

Acceptable air gap range is 0.92 to 1.275 mm (0.036

to 0.050 in.).

Front sensor air gap is not adjustable. The front

sensors are fixed in position and cannot be adjusted.

Front sensor air gap can only be checked. Air gap

should be 0.040 to 1.3 mm (0.0157 to 0.051 in.). If

front sensor air gap is incorrect, the sensor is either

loose, or damaged.

FRONT WHEEL SENSOR REMOVAL

(1) Raise vehicle and turn wheel outward for eas-

ier access to sensor.

(2) Remove sensor wire from mounting brackets.

(3) Clean sensor and surrounding area before removal.

(4) Remove bolt attaching sensor to steering

knuckle and remove sensor.

(5) Unseat grommet retaining sensor wire in wheel

house panel.

(6) In engine compartment, disconnect sensor wire con-

nector at harness plug. Then remove sensor and wire.

FRONT WHEEL SENSOR INSTALLATION

(1) Apply Mopar Lock N' Seal or Loctite 242 to

bolt that attaches sensor to steering knuckle. Use

new sensor bolt if original bolt is worn or damaged.

(2) Position sensor on steering knuckle. Seat sen-

sor locating tab in hole in knuckle and install sensor

attaching bolt finger tight.

(3) Tighten sensor bolt to 14 NIm (11 ft. lbs.) torque.

(4) Attach sensor wire to steering knuckle bracket

with grommets on sensor wire.

(5) Route sensor wire forward and behind shock

absorber. Then attach sensor wire to spring seat

bracket with grommets on sensor wire.

(6) Route sensor wire to outer sill bracket. Remove

all twists or kinks from wire.(7) Attach sensor wire to sill bracket with grom-

met. Be sure wire is free of twists and kinks.

(8) Verify sensor wire routing. Wire should loop

forward and above sill bracket. Loose end of wire

should be below sill bracket and towards brake hose.

(9) Seat sensor wire grommet in body panel and

clip wire to brake line at grommet location.

(10) Connect sensor wire to harness in engine com-

partment.

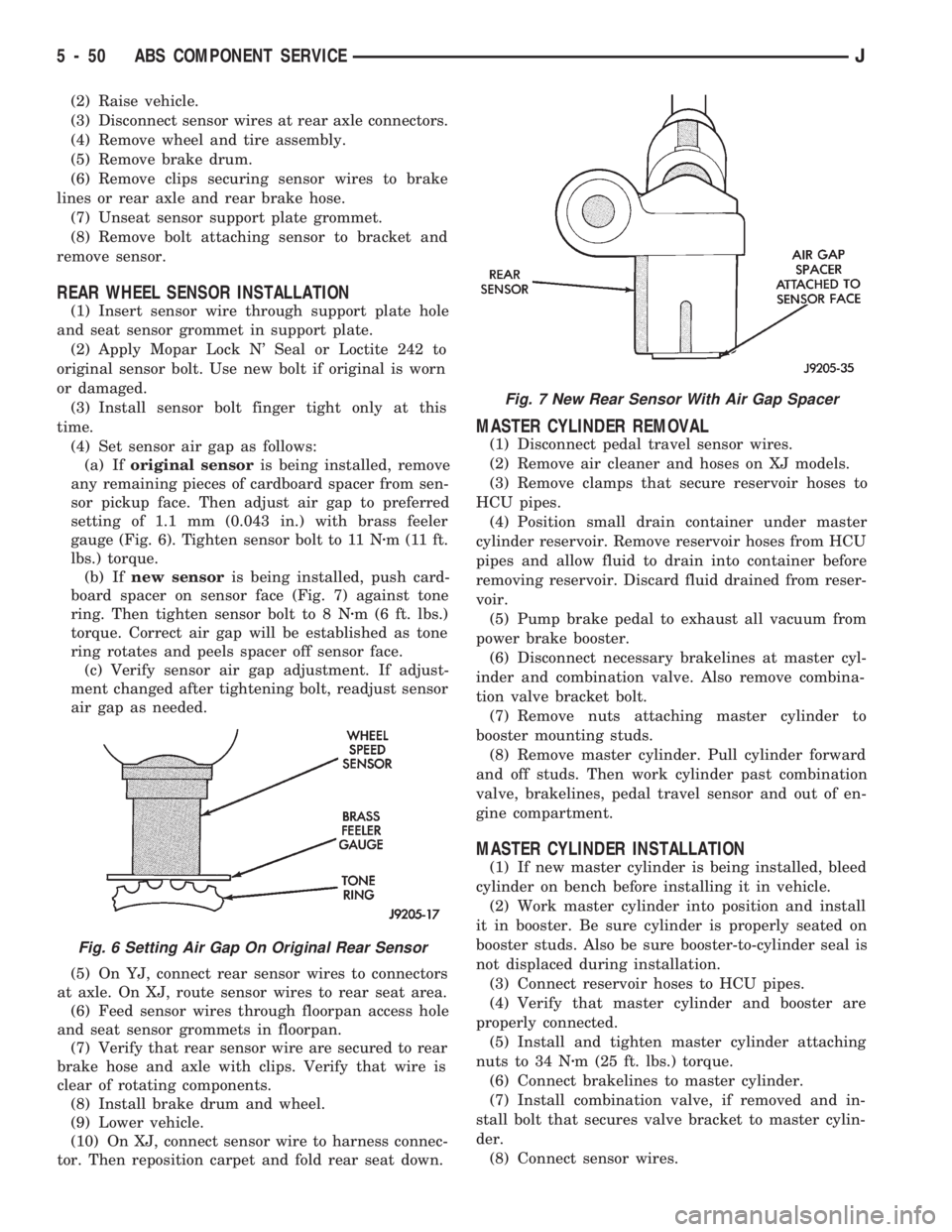

REAR WHEEL SENSOR REMOVAL

(1) On XJ models, if separate connectors are not

used to attach sensor harness to each sensor wire,

proceed as follows:

(a) Raise and fold rear seat forward for access to

rear sensor connectors (Figs. 4 and 5).

(b) Disconnect sensors at rear harness connectors.

(c) Push sensor grommets and sensor wires

through floorpan.

Fig. 4 Acceleration Switch And Rear Sensor

Connections (XJ)

Fig. 5 Rear Sensor Connections (XJ)

JABS COMPONENT SERVICE 5 - 49

Page 197 of 1784

(2) Raise vehicle.

(3) Disconnect sensor wires at rear axle connectors.

(4) Remove wheel and tire assembly.

(5) Remove brake drum.

(6) Remove clips securing sensor wires to brake

lines or rear axle and rear brake hose.

(7) Unseat sensor support plate grommet.

(8) Remove bolt attaching sensor to bracket and

remove sensor.

REAR WHEEL SENSOR INSTALLATION

(1) Insert sensor wire through support plate hole

and seat sensor grommet in support plate.

(2) Apply Mopar Lock N' Seal or Loctite 242 to

original sensor bolt. Use new bolt if original is worn

or damaged.

(3) Install sensor bolt finger tight only at this

time.

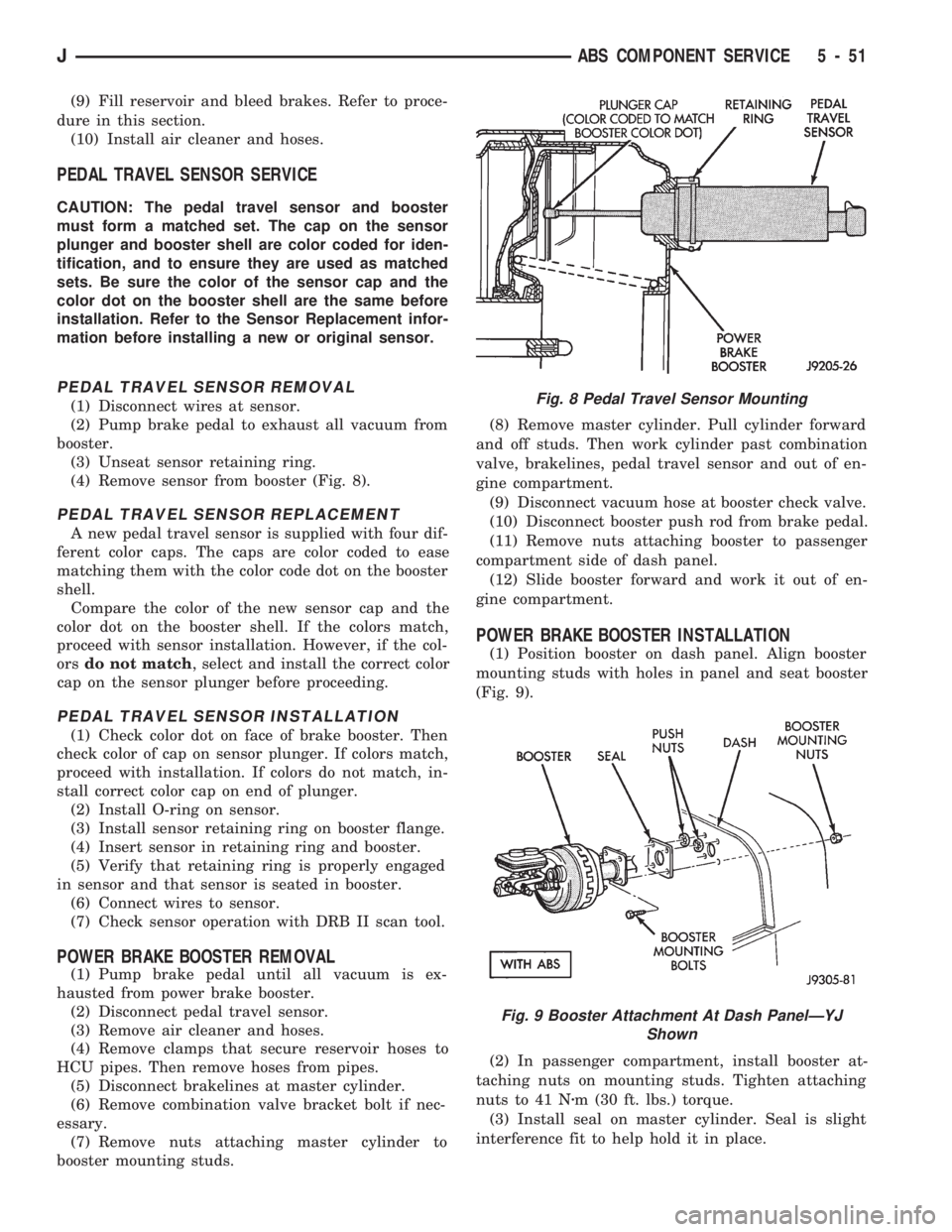

(4) Set sensor air gap as follows:

(a) Iforiginal sensoris being installed, remove

any remaining pieces of cardboard spacer from sen-

sor pickup face. Then adjust air gap to preferred

setting of 1.1 mm (0.043 in.) with brass feeler

gauge (Fig. 6). Tighten sensor bolt to 11 Nzm (11 ft.

lbs.) torque.

(b) Ifnew sensoris being installed, push card-

board spacer on sensor face (Fig. 7) against tone

ring. Then tighten sensor bolt to 8 Nzm (6 ft. lbs.)

torque. Correct air gap will be established as tone

ring rotates and peels spacer off sensor face.

(c) Verify sensor air gap adjustment. If adjust-

ment changed after tightening bolt, readjust sensor

air gap as needed.

(5) On YJ, connect rear sensor wires to connectors

at axle. On XJ, route sensor wires to rear seat area.

(6) Feed sensor wires through floorpan access hole

and seat sensor grommets in floorpan.

(7) Verify that rear sensor wire are secured to rear

brake hose and axle with clips. Verify that wire is

clear of rotating components.

(8) Install brake drum and wheel.

(9) Lower vehicle.

(10) On XJ, connect sensor wire to harness connec-

tor. Then reposition carpet and fold rear seat down.

MASTER CYLINDER REMOVAL

(1) Disconnect pedal travel sensor wires.

(2) Remove air cleaner and hoses on XJ models.

(3) Remove clamps that secure reservoir hoses to

HCU pipes.

(4) Position small drain container under master

cylinder reservoir. Remove reservoir hoses from HCU

pipes and allow fluid to drain into container before

removing reservoir. Discard fluid drained from reser-

voir.

(5) Pump brake pedal to exhaust all vacuum from

power brake booster.

(6) Disconnect necessary brakelines at master cyl-

inder and combination valve. Also remove combina-

tion valve bracket bolt.

(7) Remove nuts attaching master cylinder to

booster mounting studs.

(8) Remove master cylinder. Pull cylinder forward

and off studs. Then work cylinder past combination

valve, brakelines, pedal travel sensor and out of en-

gine compartment.

MASTER CYLINDER INSTALLATION

(1) If new master cylinder is being installed, bleed

cylinder on bench before installing it in vehicle.

(2) Work master cylinder into position and install

it in booster. Be sure cylinder is properly seated on

booster studs. Also be sure booster-to-cylinder seal is

not displaced during installation.

(3) Connect reservoir hoses to HCU pipes.

(4) Verify that master cylinder and booster are

properly connected.

(5) Install and tighten master cylinder attaching

nuts to 34 Nzm (25 ft. lbs.) torque.

(6) Connect brakelines to master cylinder.

(7) Install combination valve, if removed and in-

stall bolt that secures valve bracket to master cylin-

der.

(8) Connect sensor wires.

Fig. 6 Setting Air Gap On Original Rear Sensor

Fig. 7 New Rear Sensor With Air Gap Spacer

5 - 50 ABS COMPONENT SERVICEJ

Page 198 of 1784

(9) Fill reservoir and bleed brakes. Refer to proce-

dure in this section.

(10) Install air cleaner and hoses.

PEDAL TRAVEL SENSOR SERVICE

CAUTION: The pedal travel sensor and booster

must form a matched set. The cap on the sensor

plunger and booster shell are color coded for iden-

tification, and to ensure they are used as matched

sets. Be sure the color of the sensor cap and the

color dot on the booster shell are the same before

installation. Refer to the Sensor Replacement infor-

mation before installing a new or original sensor.

PEDAL TRAVEL SENSOR REMOVAL

(1) Disconnect wires at sensor.

(2) Pump brake pedal to exhaust all vacuum from

booster.

(3) Unseat sensor retaining ring.

(4) Remove sensor from booster (Fig. 8).

PEDAL TRAVEL SENSOR REPLACEMENT

A new pedal travel sensor is supplied with four dif-

ferent color caps. The caps are color coded to ease

matching them with the color code dot on the booster

shell.

Compare the color of the new sensor cap and the

color dot on the booster shell. If the colors match,

proceed with sensor installation. However, if the col-

orsdo not match, select and install the correct color

cap on the sensor plunger before proceeding.

PEDAL TRAVEL SENSOR INSTALLATION

(1) Check color dot on face of brake booster. Then

check color of cap on sensor plunger. If colors match,

proceed with installation. If colors do not match, in-

stall correct color cap on end of plunger.

(2) Install O-ring on sensor.

(3) Install sensor retaining ring on booster flange.

(4) Insert sensor in retaining ring and booster.

(5) Verify that retaining ring is properly engaged

in sensor and that sensor is seated in booster.

(6) Connect wires to sensor.

(7) Check sensor operation with DRB II scan tool.

POWER BRAKE BOOSTER REMOVAL

(1) Pump brake pedal until all vacuum is ex-

hausted from power brake booster.

(2) Disconnect pedal travel sensor.

(3) Remove air cleaner and hoses.

(4) Remove clamps that secure reservoir hoses to

HCU pipes. Then remove hoses from pipes.

(5) Disconnect brakelines at master cylinder.

(6) Remove combination valve bracket bolt if nec-

essary.

(7) Remove nuts attaching master cylinder to

booster mounting studs.(8) Remove master cylinder. Pull cylinder forward

and off studs. Then work cylinder past combination

valve, brakelines, pedal travel sensor and out of en-

gine compartment.

(9) Disconnect vacuum hose at booster check valve.

(10) Disconnect booster push rod from brake pedal.

(11) Remove nuts attaching booster to passenger

compartment side of dash panel.

(12) Slide booster forward and work it out of en-

gine compartment.

POWER BRAKE BOOSTER INSTALLATION

(1) Position booster on dash panel. Align booster

mounting studs with holes in panel and seat booster

(Fig. 9).

(2) In passenger compartment, install booster at-

taching nuts on mounting studs. Tighten attaching

nuts to 41 Nzm (30 ft. lbs.) torque.

(3) Install seal on master cylinder. Seal is slight

interference fit to help hold it in place.

Fig. 8 Pedal Travel Sensor Mounting

Fig. 9 Booster Attachment At Dash PanelÐYJ

Shown

JABS COMPONENT SERVICE 5 - 51

Page 199 of 1784

CAUTION: The pedal travel sensor and booster

must form a matched set. The cap on the sensor

plunger and the color dot on the booster shell are

color coded for identification, and to ensure they

are used as matched sets. Be sure the color on the

sensor cap and booster shell are the same before

installation. Refer to the Sensor Replacement infor-

mation before installing a new or original sensor.

(4) If new pedal travel sensor is being installed in

original booster, compare color dot on booster shell with

color of cap on sensor (Fig. 10). If both are same color,

proceed with installation. However, if colorsdo not

match, select correct color cap from kit supplied with

new sensor and install it on end of sensor plunger.

(5) Install O-ring on pedal travel sensor.

(6) Install sensor retaining ring on booster flange.

Be sure retaining ring is firmly seated.

(7) Insert sensor into booster. Be sure sensor is

fully seated and engaged in retaining ring.

(8) Connect booster push rod to brake pedal.

(9) Attach vacuum hose to booster check valve.

(10) Install master cylinder on booster. Tighten

cylinder attaching nuts to 25-30 Nzm (220-267 in.

lbs.) torque.

(11) Connect brakelines to master cylinder.

(12) Install combination valve bracket bolt if re-

moved.

(13) Connect reservoir hoses to HCU pipes.

(14) Connect sensor wires.

(15) Bleed brakes. Refer to procedure in this section.

(16) Install air cleaner and hoses.

ACCELERATION SENSOR REMOVAL

(1) On XJ models, tilt rear seat assembly forward

for access to sensor (Fig. 11).

(2) On YJ models, move driver seat forward or

rearward for access to sensor and mounting bracket

(Fig. 11).

(3) Disconnect sensor harness (Fig. 10).

(4) On XJ models, remove screws attaching sensor

to bracket. Then remove sensor.

(5) On YJ models, remove screws attaching sensor

bracket to floorpan. Then remove sensor from bracket.

ACCELERATION SENSOR INSTALLATION

(1) Note position of locating arrow on sensor. Sen-

sor must be positioned so arrow faces forward.

CAUTION: The sensor mercury switch will not func-

tion properly if the sensor is mispositioned. Verify

that the sensor locating arrow is pointing to the

front of the vehicle.

(2) Position sensor in mounting bracket (Fig. 10).

(3) Install and tighten sensor attaching screws to

2-4 Nzm (17-32 in. lbs.) torque.

(4) Connect harness to sensor. Be sure harness

connecter is firmly seated.

(5) Move seat back to normal position.

Fig. 10 Booster Push Rod And Pedal Travel Sensor

Fig. 11 Acceleration Sensor Mounting

5 - 52 ABS COMPONENT SERVICEJ

Page 200 of 1784

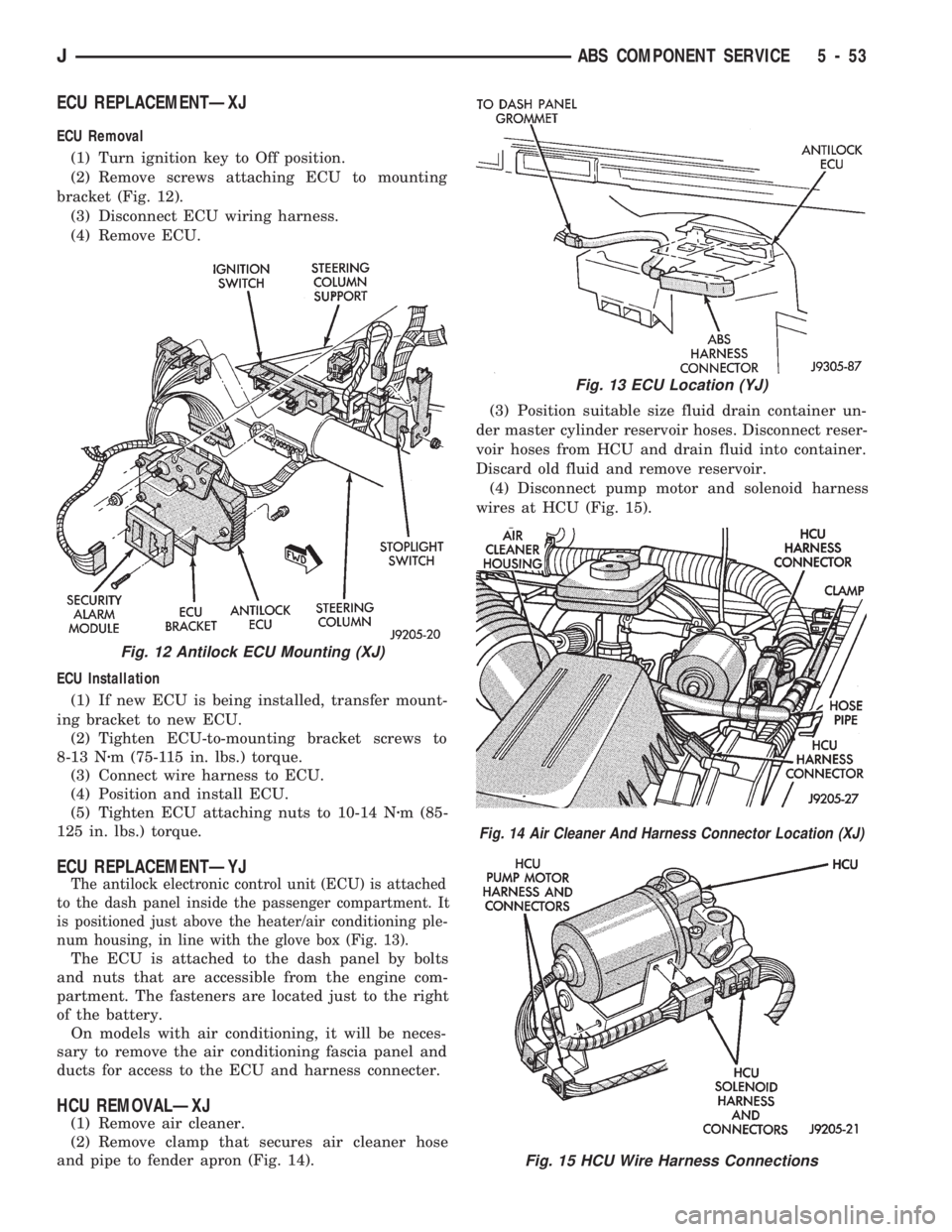

ECU REPLACEMENTÐXJ

ECU Removal

(1) Turn ignition key to Off position.

(2) Remove screws attaching ECU to mounting

bracket (Fig. 12).

(3) Disconnect ECU wiring harness.

(4) Remove ECU.

ECU Installation

(1) If new ECU is being installed, transfer mount-

ing bracket to new ECU.

(2) Tighten ECU-to-mounting bracket screws to

8-13 Nzm (75-115 in. lbs.) torque.

(3) Connect wire harness to ECU.

(4) Position and install ECU.

(5) Tighten ECU attaching nuts to 10-14 Nzm (85-

125 in. lbs.) torque.

ECU REPLACEMENTÐYJ

The antilock electronic control unit (ECU) is attached

to the dash panel inside the passenger compartment. It

is positioned just above the heater/air conditioning ple-

num housing, in line with the glove box (Fig. 13).

The ECU is attached to the dash panel by bolts

and nuts that are accessible from the engine com-

partment. The fasteners are located just to the right

of the battery.

On models with air conditioning, it will be neces-

sary to remove the air conditioning fascia panel and

ducts for access to the ECU and harness connecter.

HCU REMOVALÐXJ

(1) Remove air cleaner.

(2) Remove clamp that secures air cleaner hose

and pipe to fender apron (Fig. 14).(3) Position suitable size fluid drain container un-

der master cylinder reservoir hoses. Disconnect reser-

voir hoses from HCU and drain fluid into container.

Discard old fluid and remove reservoir.

(4) Disconnect pump motor and solenoid harness

wires at HCU (Fig. 15).

Fig. 12 Antilock ECU Mounting (XJ)

Fig. 13 ECU Location (YJ)

Fig. 14 Air Cleaner And Harness Connector Location (XJ)

Fig. 15 HCU Wire Harness Connections

JABS COMPONENT SERVICE 5 - 53