JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 221 of 1784

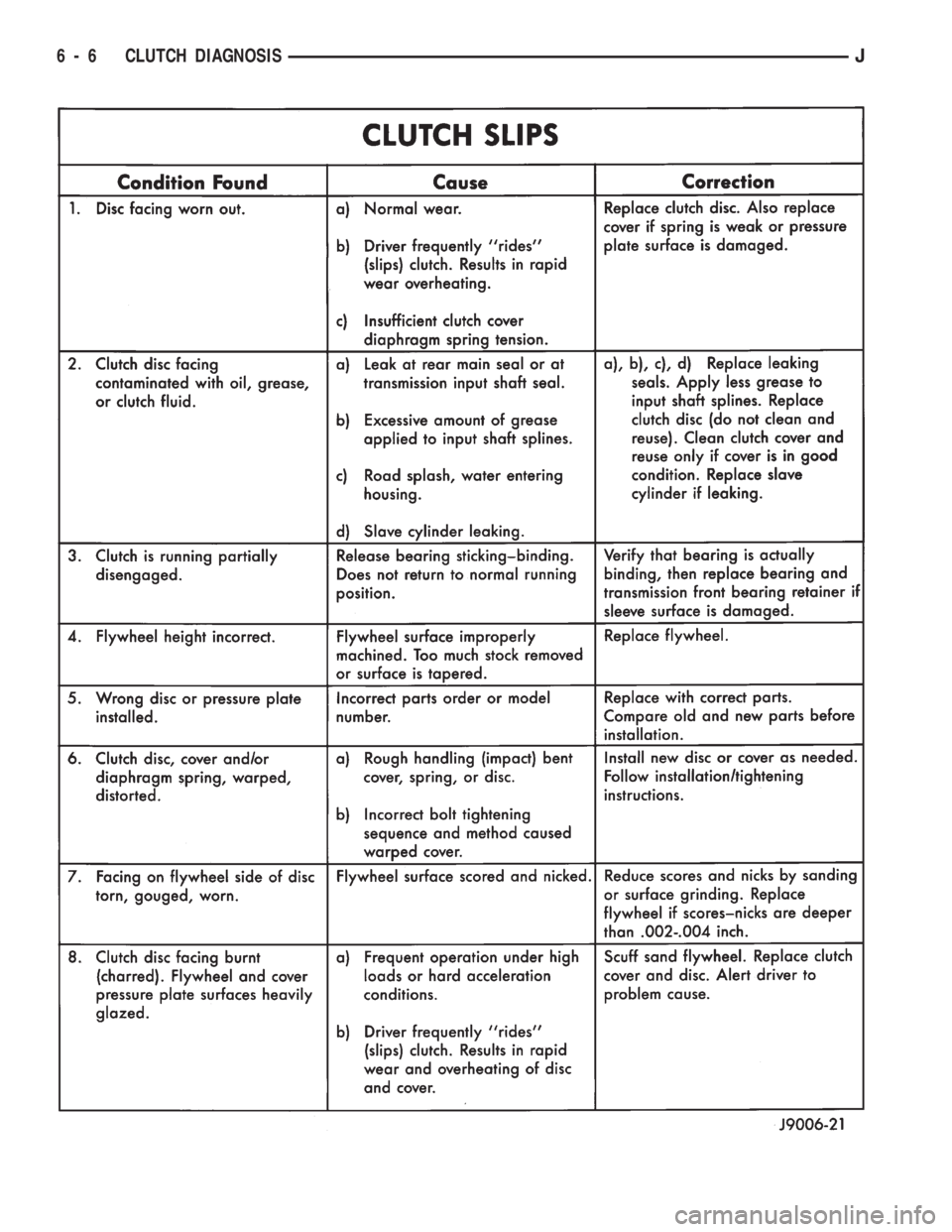

6 - 6 CLUTCH DIAGNOSISJ

Page 222 of 1784

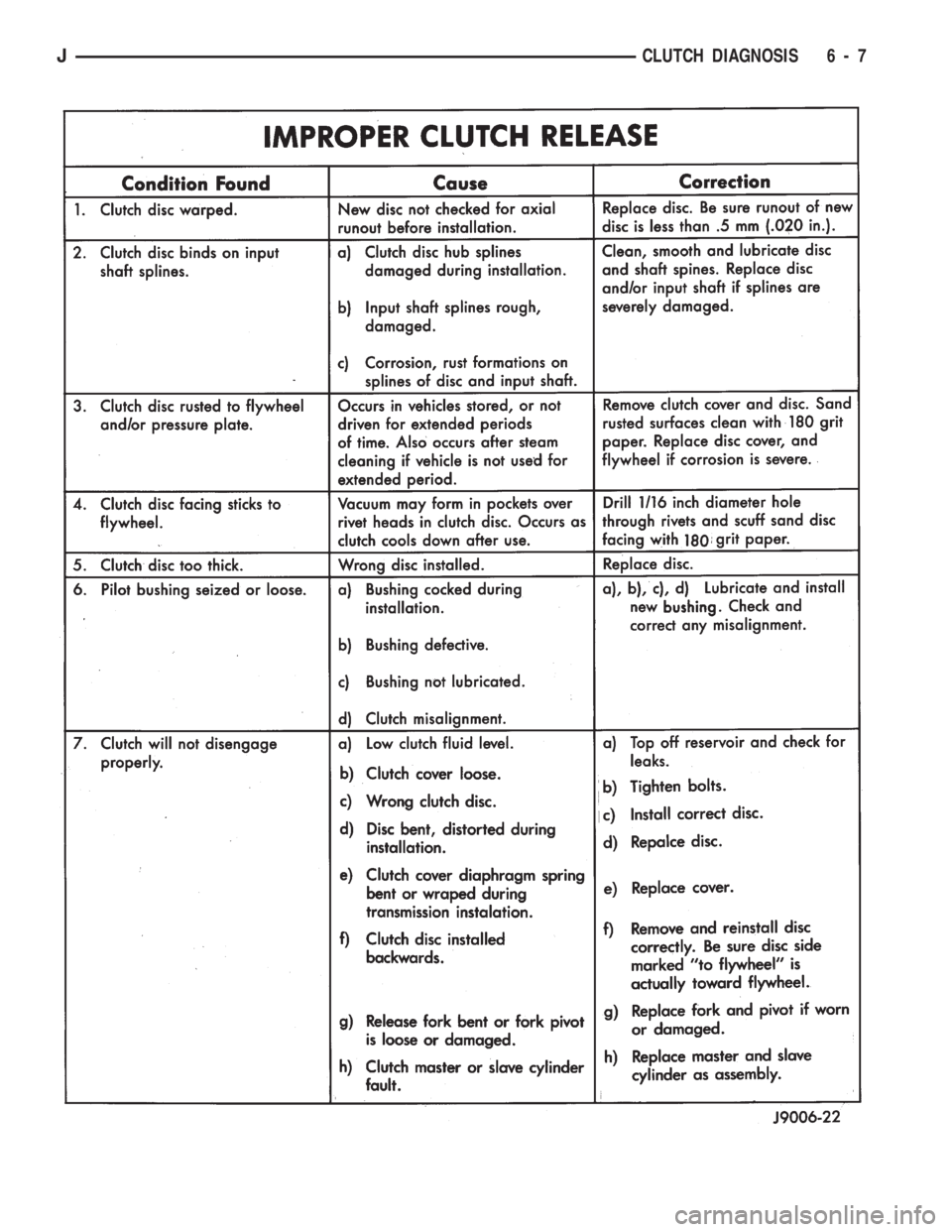

JCLUTCH DIAGNOSIS 6 - 7

Page 223 of 1784

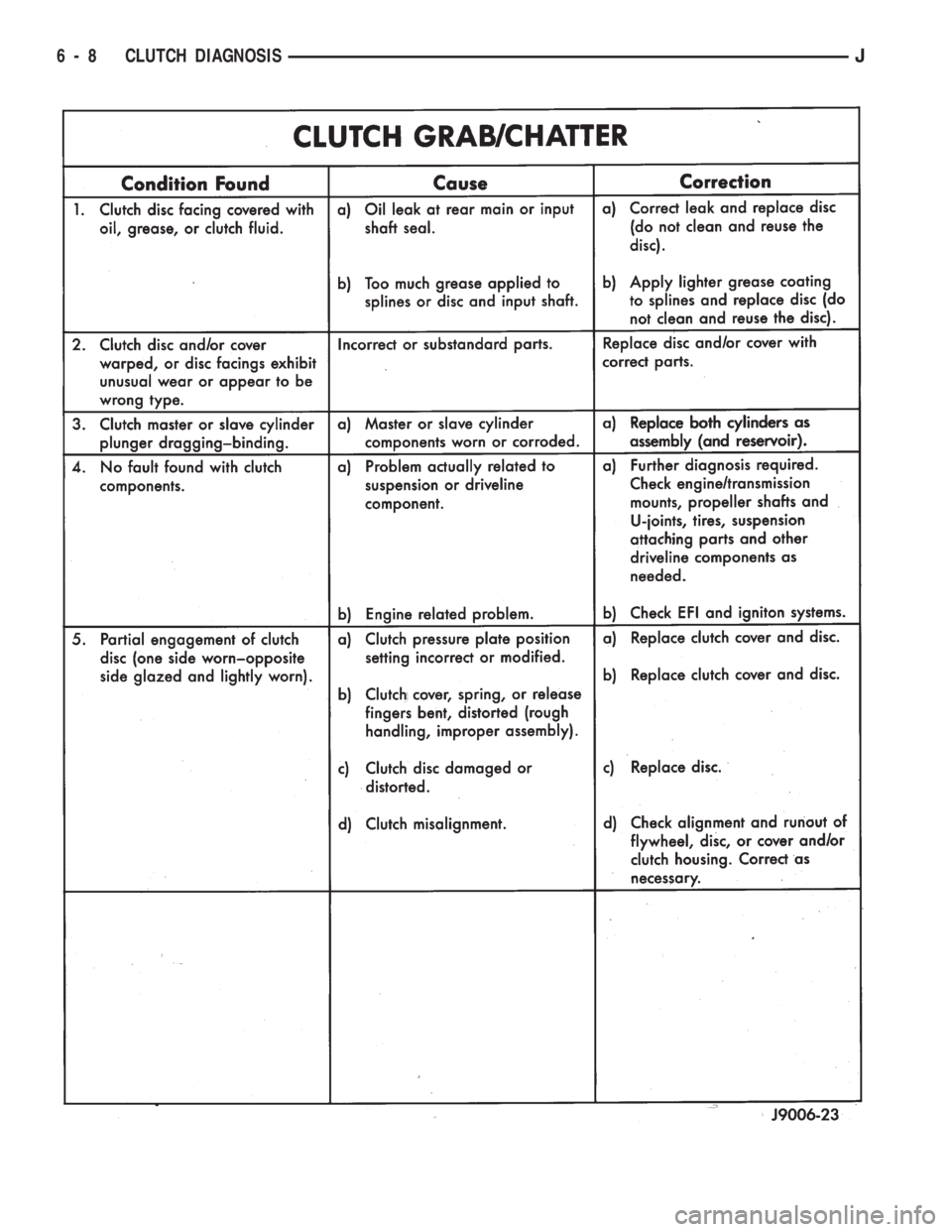

6 - 8 CLUTCH DIAGNOSISJ

Page 224 of 1784

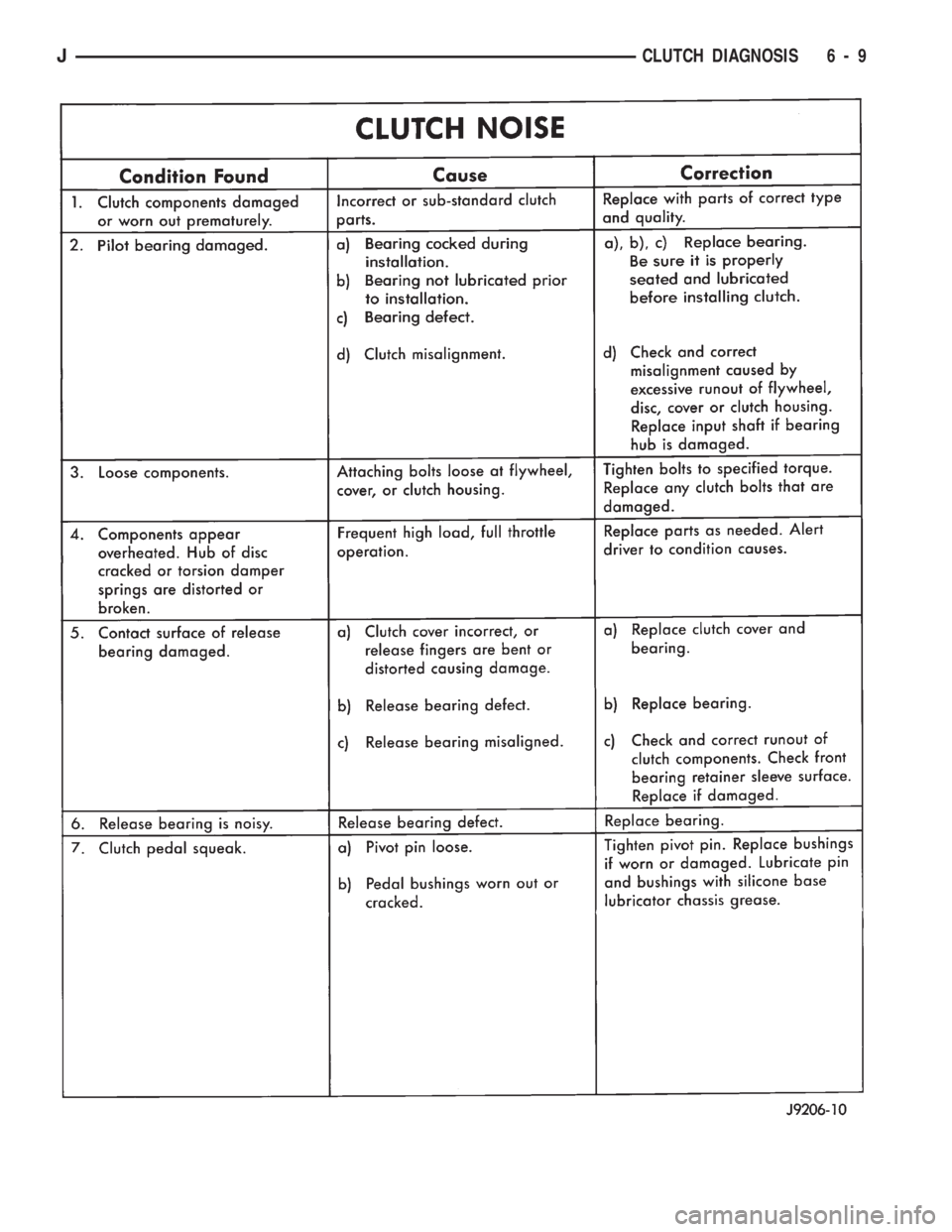

JCLUTCH DIAGNOSIS 6 - 9

Page 225 of 1784

CLUTCH SERVICE

INDEX

page page

Clutch Cover and Disc Installation............ 10

Clutch Cover and Disc Removal............. 10

Clutch Fluid Level........................ 14

Clutch Housing Replacement................ 11

Clutch Hydraulic Linkage Installation.......... 12

Clutch Hydraulic Linkage Removal........... 11Clutch Pedal Installation................... 15

Clutch Pedal Removal..................... 15

Clutch Safety Precautions.................. 10

Flywheel Service......................... 15

Pilot Bearing Replacement................. 11

Release Bearing Replacement............... 11

CLUTCH SAFETY PRECAUTIONS

WARNING: EXERCISE CARE WHEN SERVICING

CLUTCH COMPONENTS. DUST AND DIRT ON

CLUTCH PARTS USE MAY CONTAIN ASBESTOS FI-

BERS. BREATHING EXCESSIVE CONCENTRATIONS

OF THESE FIBERS CAN CAUSE SERIOUS BODILY

HARM. WEAR A RESPIRATOR DURING SERVICE

AND NEVER CLEAN CLUTCH COMPONENTS WITH

COMPRESSED AIR OR WITH A DRY BRUSH. EI-

THER CLEAN THE COMPONENTS WITH A WATER

DAMPENED RAGS OR USE A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR REMOVING ASBES-

TOS FIBERS AND DUST. DO NOT CREATE DUST

BY SANDING A CLUTCH DISC. REPLACE THE DISC

IF THE FRICTION MATERIAL IS DAMAGED OR

CONTAMINATED. DISPOSE OF ALL DUST AND

DIRT CONTAINING ASBESTOS FIBERS IN SEALED

BAGS OR CONTAINERS. THIS WILL HELP MINIMIZE

EXPOSURE TO YOURSELF AND TO OTHERS. FOL-

LOW ALL RECOMMENDED SAFETY PRACTICES

PRESCRIBED BY THE OCCUPATIONAL SAFETY

AND HEALTH ADMINISTRATION (OSHA) AND THE

ENVIRONMENTAL SAFETY AGENCY (EPA), FOR

THE HANDLING AND DISPOSAL OF PRODUCTS

CONTAINING ASBESTOS.

CLUTCH COVER AND DISC REMOVAL

(1) Remove transmission. Refer to procedures in

Group 21.

(2) If original clutch cover will be reinstalled,

mark position of cover on flywheel for assembly ref-

erence. Use paint or a scriber for this purpose.

(3) If clutch cover is to be replaced, cover bolts can

be removed in any sequence. However, if original

cover will be reinstalled, loosen cover bolts evenly

and in rotation to relieve spring tension equally.

This is necessary avoid warping cover.

(4) Remove cover bolts and remove cover and disc

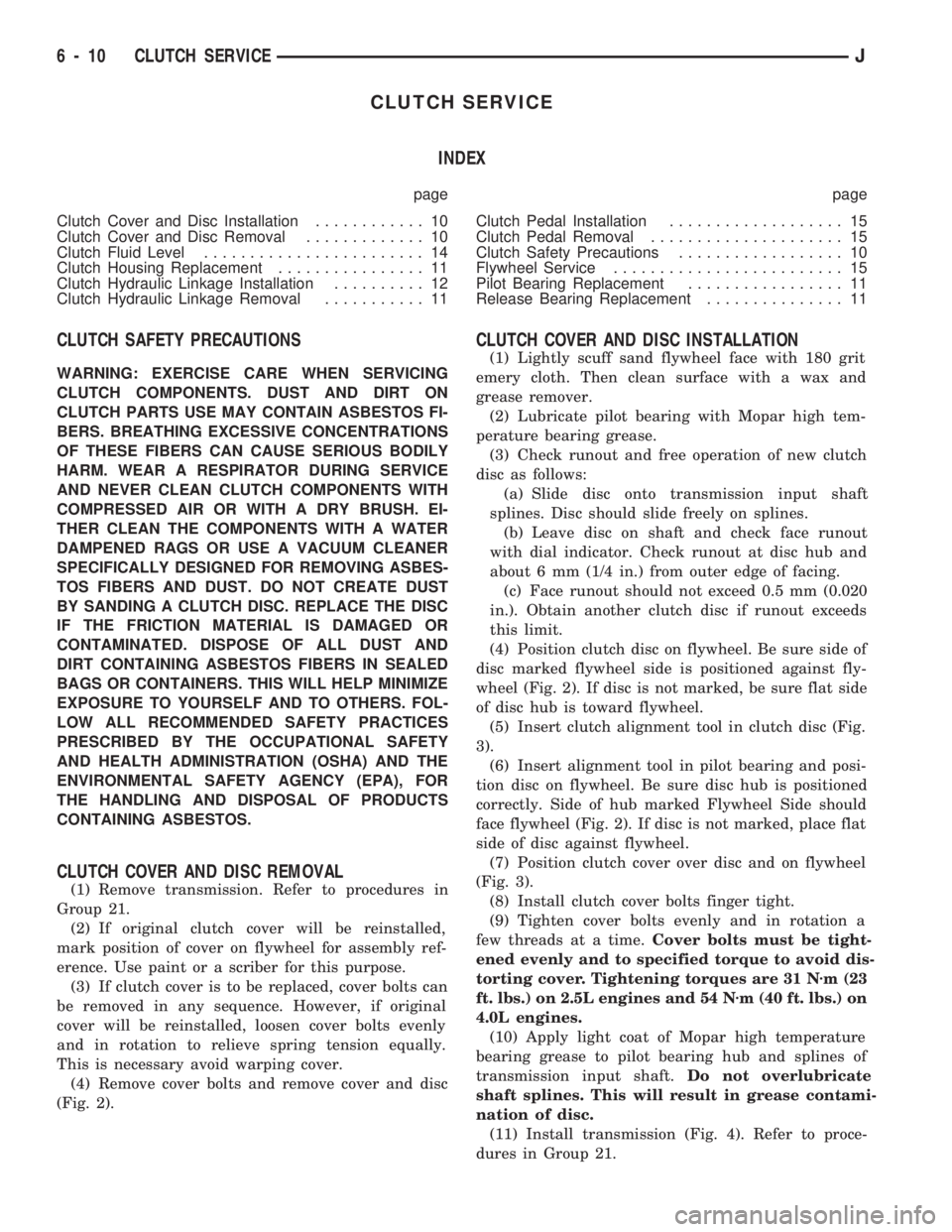

(Fig. 2).

CLUTCH COVER AND DISC INSTALLATION

(1) Lightly scuff sand flywheel face with 180 grit

emery cloth. Then clean surface with a wax and

grease remover.

(2) Lubricate pilot bearing with Mopar high tem-

perature bearing grease.

(3) Check runout and free operation of new clutch

disc as follows:

(a) Slide disc onto transmission input shaft

splines. Disc should slide freely on splines.

(b) Leave disc on shaft and check face runout

with dial indicator. Check runout at disc hub and

about 6 mm (1/4 in.) from outer edge of facing.

(c) Face runout should not exceed 0.5 mm (0.020

in.). Obtain another clutch disc if runout exceeds

this limit.

(4) Position clutch disc on flywheel. Be sure side of

disc marked flywheel side is positioned against fly-

wheel (Fig. 2). If disc is not marked, be sure flat side

of disc hub is toward flywheel.

(5) Insert clutch alignment tool in clutch disc (Fig.

3).

(6) Insert alignment tool in pilot bearing and posi-

tion disc on flywheel. Be sure disc hub is positioned

correctly. Side of hub marked Flywheel Side should

face flywheel (Fig. 2). If disc is not marked, place flat

side of disc against flywheel.

(7) Position clutch cover over disc and on flywheel

(Fig. 3).

(8) Install clutch cover bolts finger tight.

(9) Tighten cover bolts evenly and in rotation a

few threads at a time.Cover bolts must be tight-

ened evenly and to specified torque to avoid dis-

torting cover. Tightening torques are 31 Nzm (23

ft. lbs.) on 2.5L engines and 54 Nzm (40 ft. lbs.) on

4.0L engines.

(10) Apply light coat of Mopar high temperature

bearing grease to pilot bearing hub and splines of

transmission input shaft.Do not overlubricate

shaft splines. This will result in grease contami-

nation of disc.

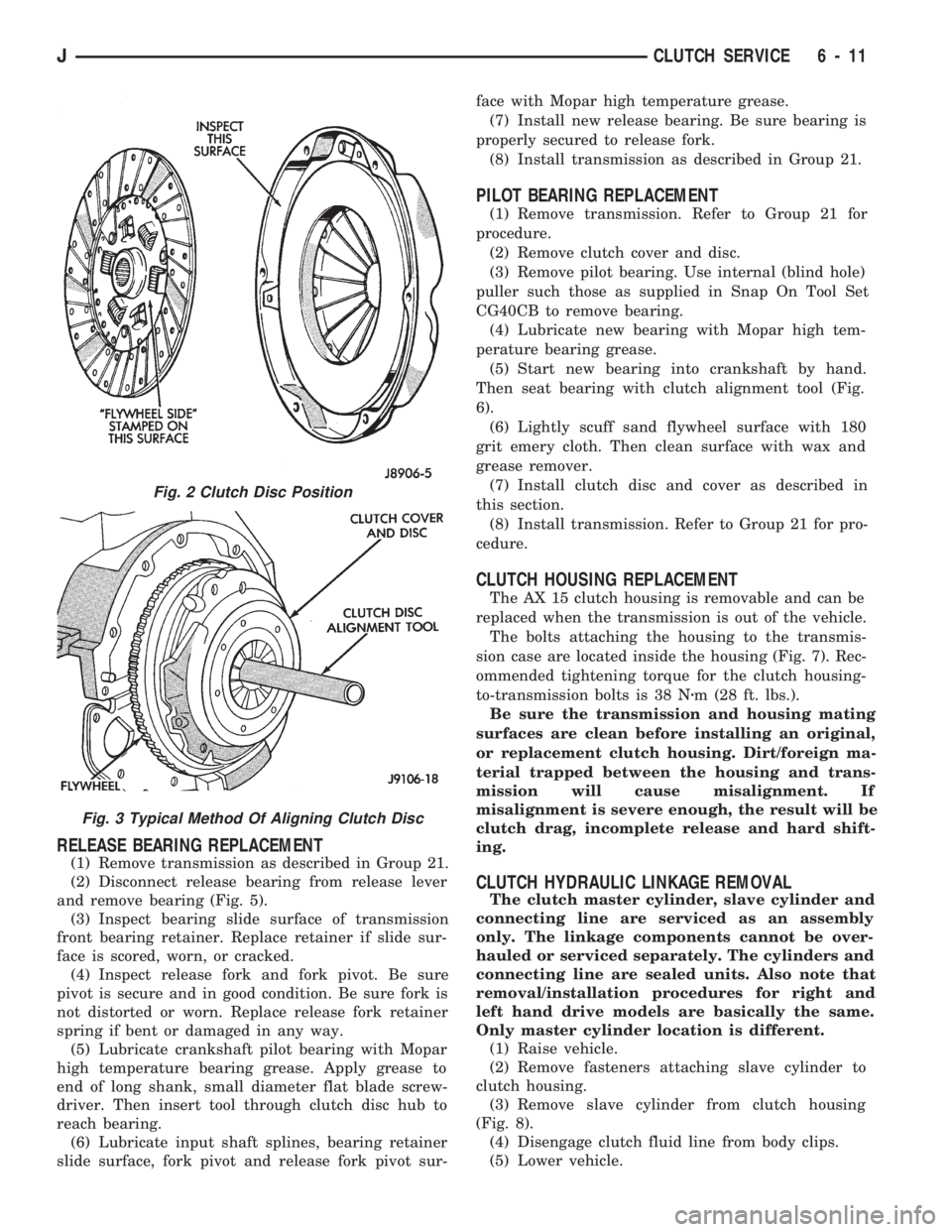

(11) Install transmission (Fig. 4). Refer to proce-

dures in Group 21.

6 - 10 CLUTCH SERVICEJ

Page 226 of 1784

RELEASE BEARING REPLACEMENT

(1) Remove transmission as described in Group 21.

(2) Disconnect release bearing from release lever

and remove bearing (Fig. 5).

(3) Inspect bearing slide surface of transmission

front bearing retainer. Replace retainer if slide sur-

face is scored, worn, or cracked.

(4) Inspect release fork and fork pivot. Be sure

pivot is secure and in good condition. Be sure fork is

not distorted or worn. Replace release fork retainer

spring if bent or damaged in any way.

(5) Lubricate crankshaft pilot bearing with Mopar

high temperature bearing grease. Apply grease to

end of long shank, small diameter flat blade screw-

driver. Then insert tool through clutch disc hub to

reach bearing.

(6) Lubricate input shaft splines, bearing retainer

slide surface, fork pivot and release fork pivot sur-face with Mopar high temperature grease.

(7) Install new release bearing. Be sure bearing is

properly secured to release fork.

(8) Install transmission as described in Group 21.

PILOT BEARING REPLACEMENT

(1) Remove transmission. Refer to Group 21 for

procedure.

(2) Remove clutch cover and disc.

(3) Remove pilot bearing. Use internal (blind hole)

puller such those as supplied in Snap On Tool Set

CG40CB to remove bearing.

(4) Lubricate new bearing with Mopar high tem-

perature bearing grease.

(5) Start new bearing into crankshaft by hand.

Then seat bearing with clutch alignment tool (Fig.

6).

(6) Lightly scuff sand flywheel surface with 180

grit emery cloth. Then clean surface with wax and

grease remover.

(7) Install clutch disc and cover as described in

this section.

(8) Install transmission. Refer to Group 21 for pro-

cedure.

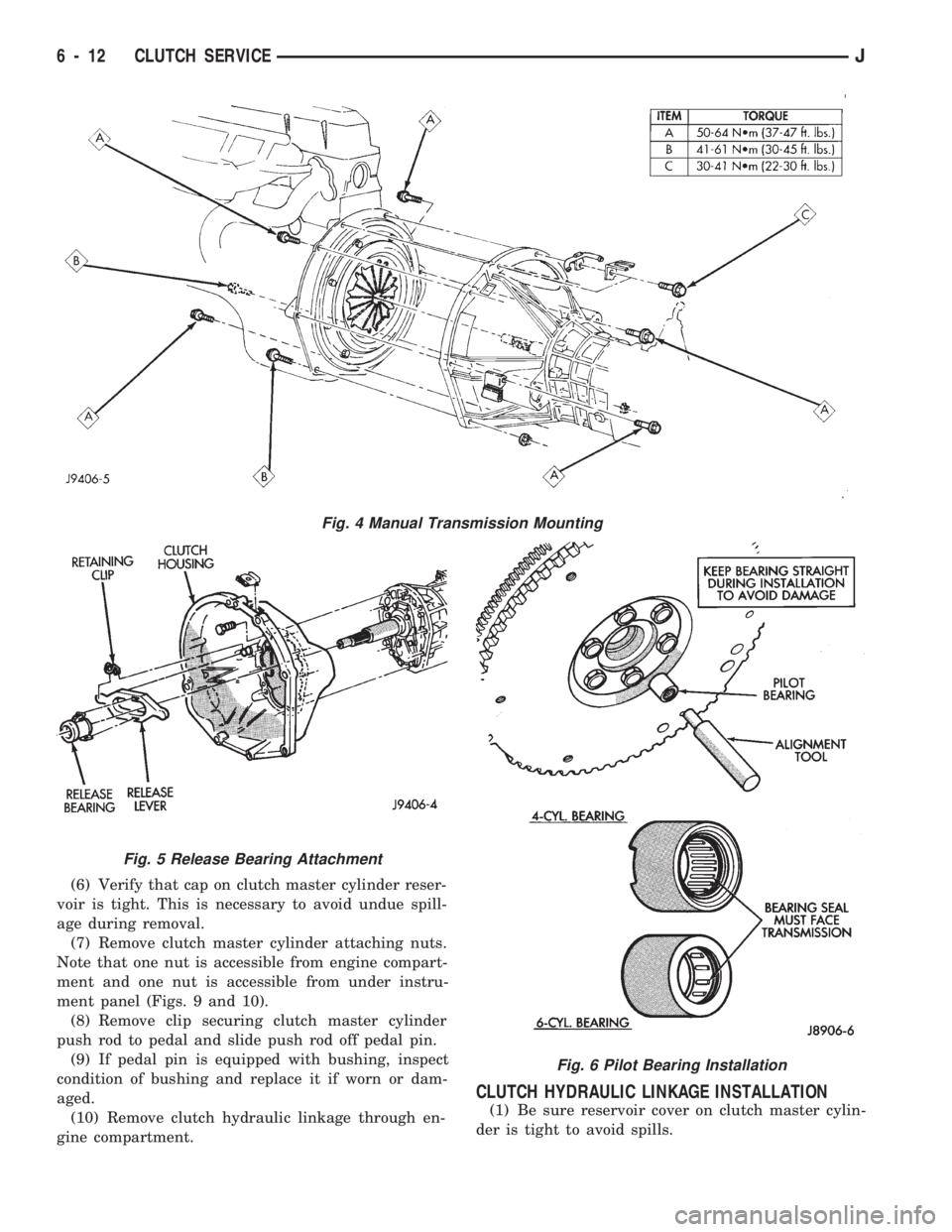

CLUTCH HOUSING REPLACEMENT

The AX 15 clutch housing is removable and can be

replaced when the transmission is out of the vehicle.

The bolts attaching the housing to the transmis-

sion case are located inside the housing (Fig. 7). Rec-

ommended tightening torque for the clutch housing-

to-transmission bolts is 38 Nzm (28 ft. lbs.).

Be sure the transmission and housing mating

surfaces are clean before installing an original,

or replacement clutch housing. Dirt/foreign ma-

terial trapped between the housing and trans-

mission will cause misalignment. If

misalignment is severe enough, the result will be

clutch drag, incomplete release and hard shift-

ing.

CLUTCH HYDRAULIC LINKAGE REMOVAL

The clutch master cylinder, slave cylinder and

connecting line are serviced as an assembly

only. The linkage components cannot be over-

hauled or serviced separately. The cylinders and

connecting line are sealed units. Also note that

removal/installation procedures for right and

left hand drive models are basically the same.

Only master cylinder location is different.

(1) Raise vehicle.

(2) Remove fasteners attaching slave cylinder to

clutch housing.

(3) Remove slave cylinder from clutch housing

(Fig. 8).

(4) Disengage clutch fluid line from body clips.

(5) Lower vehicle.

Fig. 2 Clutch Disc Position

Fig. 3 Typical Method Of Aligning Clutch Disc

JCLUTCH SERVICE 6 - 11

Page 227 of 1784

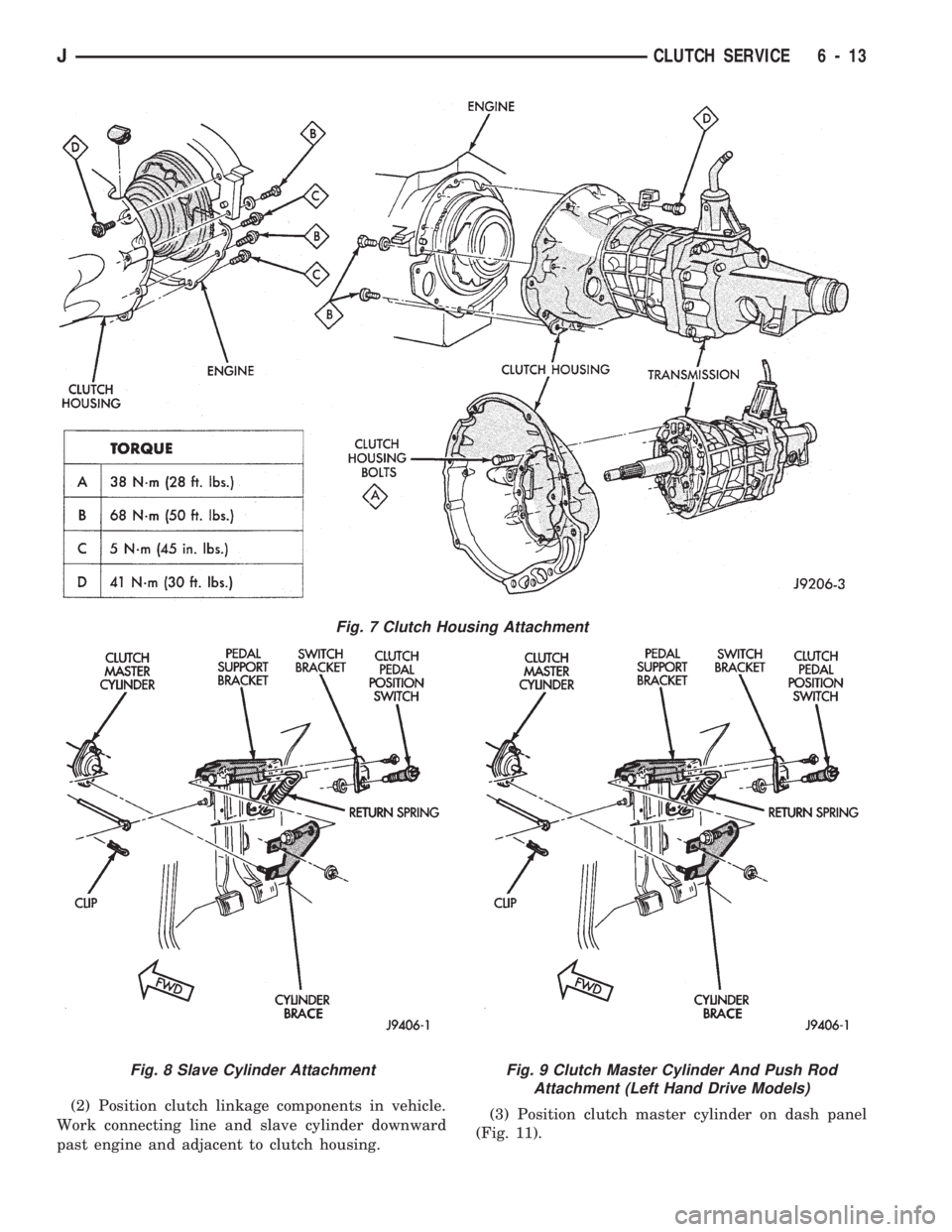

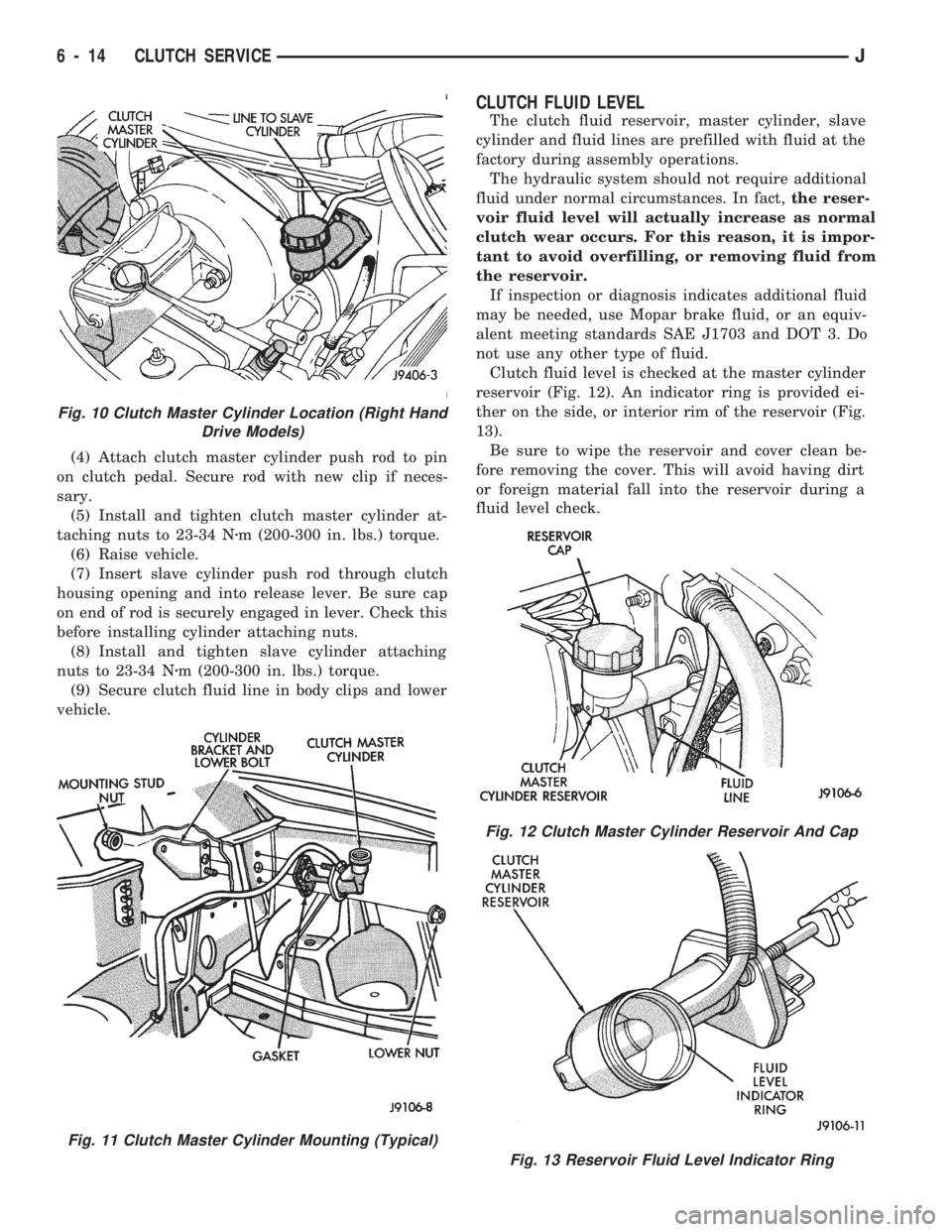

(6) Verify that cap on clutch master cylinder reser-

voir is tight. This is necessary to avoid undue spill-

age during removal.

(7) Remove clutch master cylinder attaching nuts.

Note that one nut is accessible from engine compart-

ment and one nut is accessible from under instru-

ment panel (Figs. 9 and 10).

(8) Remove clip securing clutch master cylinder

push rod to pedal and slide push rod off pedal pin.

(9) If pedal pin is equipped with bushing, inspect

condition of bushing and replace it if worn or dam-

aged.

(10) Remove clutch hydraulic linkage through en-

gine compartment.

CLUTCH HYDRAULIC LINKAGE INSTALLATION

(1) Be sure reservoir cover on clutch master cylin-

der is tight to avoid spills.

Fig. 4 Manual Transmission Mounting

Fig. 5 Release Bearing Attachment

Fig. 6 Pilot Bearing Installation

6 - 12 CLUTCH SERVICEJ

Page 228 of 1784

(2) Position clutch linkage components in vehicle.

Work connecting line and slave cylinder downward

past engine and adjacent to clutch housing.(3) Position clutch master cylinder on dash panel

(Fig. 11).

Fig. 7 Clutch Housing Attachment

Fig. 8 Slave Cylinder AttachmentFig. 9 Clutch Master Cylinder And Push Rod

Attachment (Left Hand Drive Models)

JCLUTCH SERVICE 6 - 13

Page 229 of 1784

(4) Attach clutch master cylinder push rod to pin

on clutch pedal. Secure rod with new clip if neces-

sary.

(5) Install and tighten clutch master cylinder at-

taching nuts to 23-34 Nzm (200-300 in. lbs.) torque.

(6) Raise vehicle.

(7) Insert slave cylinder push rod through clutch

housing opening and into release lever. Be sure cap

on end of rod is securely engaged in lever. Check this

before installing cylinder attaching nuts.

(8) Install and tighten slave cylinder attaching

nuts to 23-34 Nzm (200-300 in. lbs.) torque.

(9) Secure clutch fluid line in body clips and lower

vehicle.

CLUTCH FLUID LEVEL

The clutch fluid reservoir, master cylinder, slave

cylinder and fluid lines are prefilled with fluid at the

factory during assembly operations.

The hydraulic system should not require additional

fluid under normal circumstances. In fact,the reser-

voir fluid level will actually increase as normal

clutch wear occurs. For this reason, it is impor-

tant to avoid overfilling, or removing fluid from

the reservoir.

If inspection or diagnosis indicates additional fluid

may be needed, use Mopar brake fluid, or an equiv-

alent meeting standards SAE J1703 and DOT 3. Do

not use any other type of fluid.

Clutch fluid level is checked at the master cylinder

reservoir (Fig. 12). An indicator ring is provided ei-

ther on the side, or interior rim of the reservoir (Fig.

13).

Be sure to wipe the reservoir and cover clean be-

fore removing the cover. This will avoid having dirt

or foreign material fall into the reservoir during a

fluid level check.

Fig. 10 Clutch Master Cylinder Location (Right Hand

Drive Models)

Fig. 11 Clutch Master Cylinder Mounting (Typical)

Fig. 12 Clutch Master Cylinder Reservoir And Cap

Fig. 13 Reservoir Fluid Level Indicator Ring

6 - 14 CLUTCH SERVICEJ

Page 230 of 1784

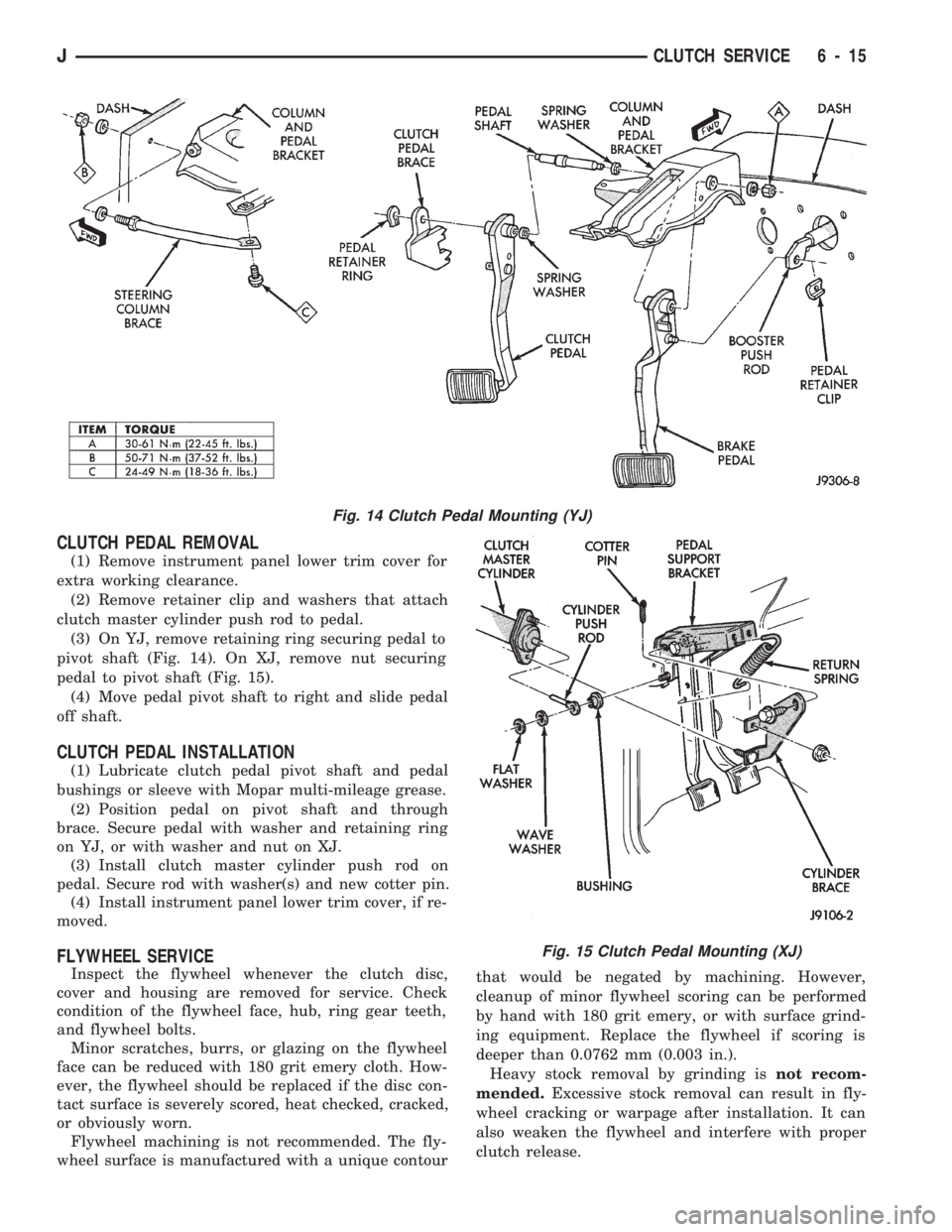

CLUTCH PEDAL REMOVAL

(1) Remove instrument panel lower trim cover for

extra working clearance.

(2) Remove retainer clip and washers that attach

clutch master cylinder push rod to pedal.

(3) On YJ, remove retaining ring securing pedal to

pivot shaft (Fig. 14). On XJ, remove nut securing

pedal to pivot shaft (Fig. 15).

(4) Move pedal pivot shaft to right and slide pedal

off shaft.

CLUTCH PEDAL INSTALLATION

(1) Lubricate clutch pedal pivot shaft and pedal

bushings or sleeve with Mopar multi-mileage grease.

(2) Position pedal on pivot shaft and through

brace. Secure pedal with washer and retaining ring

on YJ, or with washer and nut on XJ.

(3) Install clutch master cylinder push rod on

pedal. Secure rod with washer(s) and new cotter pin.

(4) Install instrument panel lower trim cover, if re-

moved.

FLYWHEEL SERVICE

Inspect the flywheel whenever the clutch disc,

cover and housing are removed for service. Check

condition of the flywheel face, hub, ring gear teeth,

and flywheel bolts.

Minor scratches, burrs, or glazing on the flywheel

face can be reduced with 180 grit emery cloth. How-

ever, the flywheel should be replaced if the disc con-

tact surface is severely scored, heat checked, cracked,

or obviously worn.

Flywheel machining is not recommended. The fly-

wheel surface is manufactured with a unique contourthat would be negated by machining. However,

cleanup of minor flywheel scoring can be performed

by hand with 180 grit emery, or with surface grind-

ing equipment. Replace the flywheel if scoring is

deeper than 0.0762 mm (0.003 in.).

Heavy stock removal by grinding isnot recom-

mended.Excessive stock removal can result in fly-

wheel cracking or warpage after installation. It can

also weaken the flywheel and interfere with proper

clutch release.

Fig. 14 Clutch Pedal Mounting (YJ)

Fig. 15 Clutch Pedal Mounting (XJ)

JCLUTCH SERVICE 6 - 15