key JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 138 of 1784

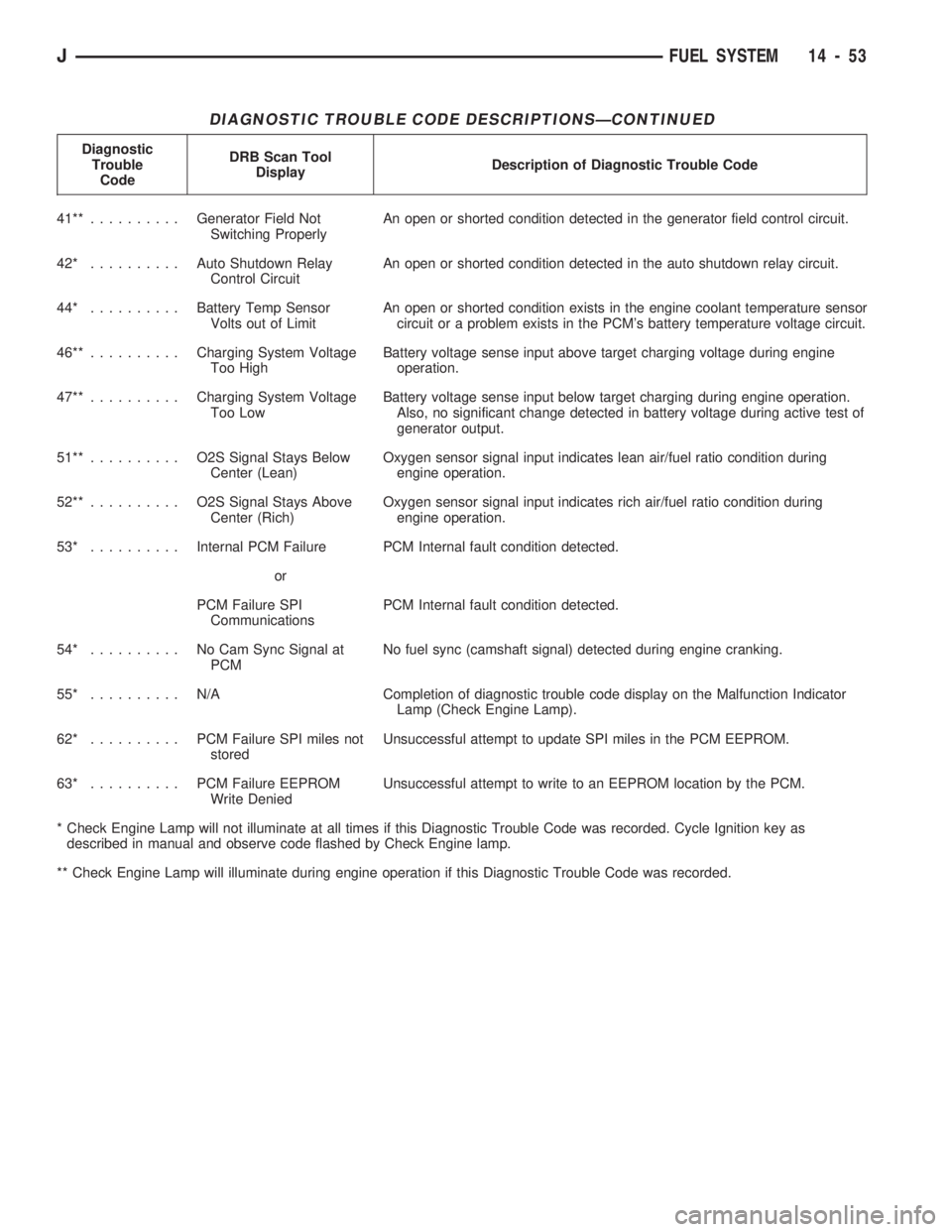

DIAGNOSTIC TROUBLE CODE DESCRIPTIONSÐCONTINUED

Diagnostic

Trouble

CodeDRB Scan Tool

DisplayDescription of Diagnostic Trouble Code

41**..........Generator Field Not

Switching ProperlyAn open or shorted condition detected in the generator field control circuit.

42* ..........Auto Shutdown Relay

Control CircuitAn open or shorted condition detected in the auto shutdown relay circuit.

44* ..........Battery Temp Sensor

Volts out of LimitAn open or shorted condition exists in the engine coolant temperature sensor

circuit or a problem exists in the PCM's battery temperature voltage circuit.

46**..........Charging System Voltage

Too HighBattery voltage sense input above target charging voltage during engine

operation.

47**..........Charging System Voltage

Too LowBattery voltage sense input below target charging during engine operation.

Also, no significant change detected in battery voltage during active test of

generator output.

51**.......... O2SSignal Stays Below

Center (Lean)Oxygen sensor signal input indicates lean air/fuel ratio condition during

engine operation.

52**.......... O2SSignal Stays Above

Center (Rich)Oxygen sensor signal input indicates rich air/fuel ratio condition during

engine operation.

53* ..........Internal PCM Failure PCM Internal fault condition detected.

or

PCM Failure SPI

CommunicationsPCM Internal fault condition detected.

54* .......... NoCamSync Signal at

PCMNo fuel sync (camshaft signal) detected during engine cranking.

55* .......... N/ACompletion of diagnostic trouble code display on the Malfunction Indicator

Lamp (Check Engine Lamp).

62* .......... PCMFailure SPI miles not

storedUnsuccessful attempt to update SPI miles in the PCM EEPROM.

63* .......... PCMFailure EEPROM

Write DeniedUnsuccessful attempt to write to an EEPROM location by the PCM.

* Check Engine Lamp will not illuminate at all times if this Diagnostic Trouble Code was recorded. Cycle Ignition key as

described in manual and observe code flashed by Check Engine lamp.

** Check Engine Lamp will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

JFUEL SYSTEM 14 - 53

Page 200 of 1784

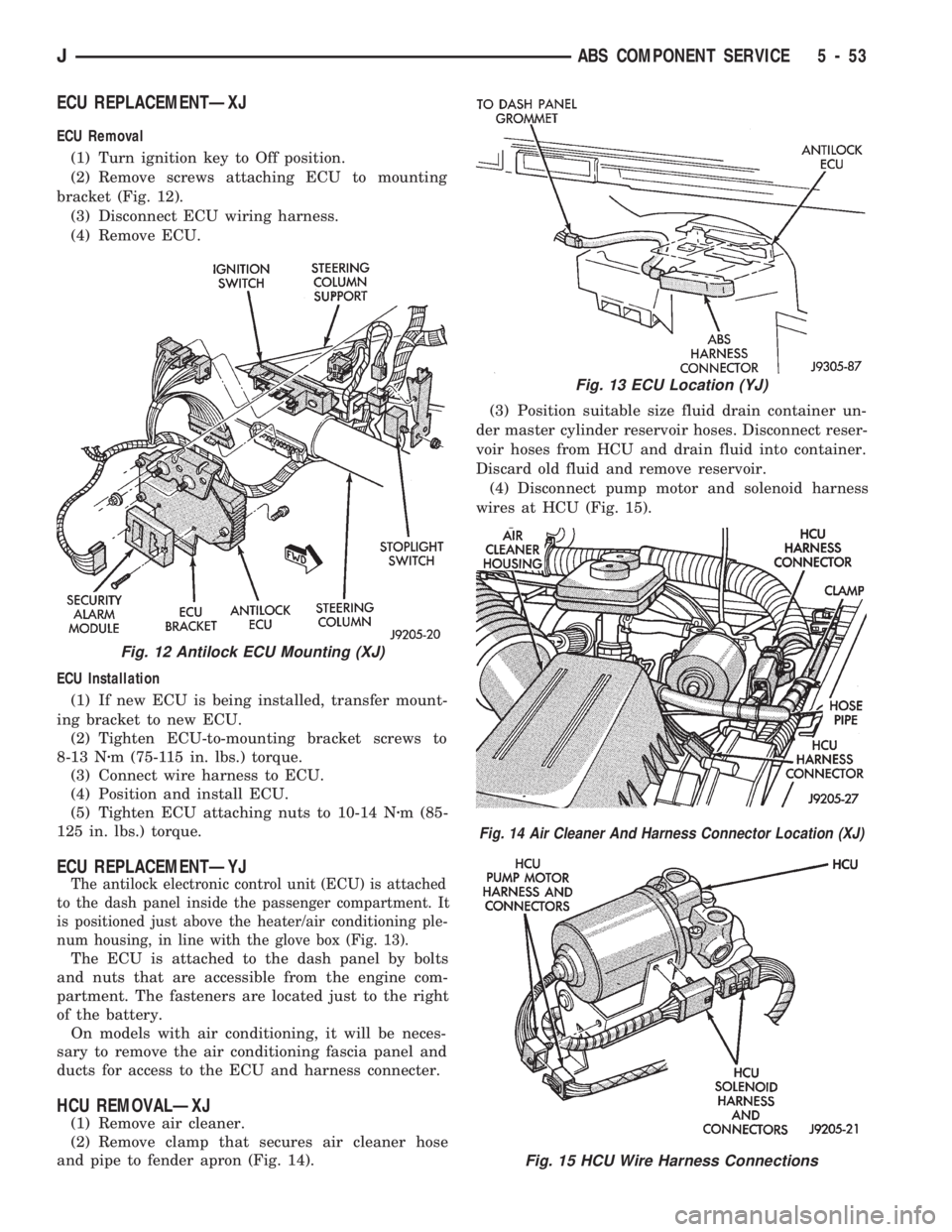

ECU REPLACEMENTÐXJ

ECU Removal

(1) Turn ignition key to Off position.

(2) Remove screws attaching ECU to mounting

bracket (Fig. 12).

(3) Disconnect ECU wiring harness.

(4) Remove ECU.

ECU Installation

(1) If new ECU is being installed, transfer mount-

ing bracket to new ECU.

(2) Tighten ECU-to-mounting bracket screws to

8-13 Nzm (75-115 in. lbs.) torque.

(3) Connect wire harness to ECU.

(4) Position and install ECU.

(5) Tighten ECU attaching nuts to 10-14 Nzm (85-

125 in. lbs.) torque.

ECU REPLACEMENTÐYJ

The antilock electronic control unit (ECU) is attached

to the dash panel inside the passenger compartment. It

is positioned just above the heater/air conditioning ple-

num housing, in line with the glove box (Fig. 13).

The ECU is attached to the dash panel by bolts

and nuts that are accessible from the engine com-

partment. The fasteners are located just to the right

of the battery.

On models with air conditioning, it will be neces-

sary to remove the air conditioning fascia panel and

ducts for access to the ECU and harness connecter.

HCU REMOVALÐXJ

(1) Remove air cleaner.

(2) Remove clamp that secures air cleaner hose

and pipe to fender apron (Fig. 14).(3) Position suitable size fluid drain container un-

der master cylinder reservoir hoses. Disconnect reser-

voir hoses from HCU and drain fluid into container.

Discard old fluid and remove reservoir.

(4) Disconnect pump motor and solenoid harness

wires at HCU (Fig. 15).

Fig. 12 Antilock ECU Mounting (XJ)

Fig. 13 ECU Location (YJ)

Fig. 14 Air Cleaner And Harness Connector Location (XJ)

Fig. 15 HCU Wire Harness Connections

JABS COMPONENT SERVICE 5 - 53

Page 237 of 1784

DIAGNOSIS

INDEX

page page

DRB Scan Tool........................... 5

On-Board Diagnostics (OBD)................. 4Preliminary Checks........................ 5

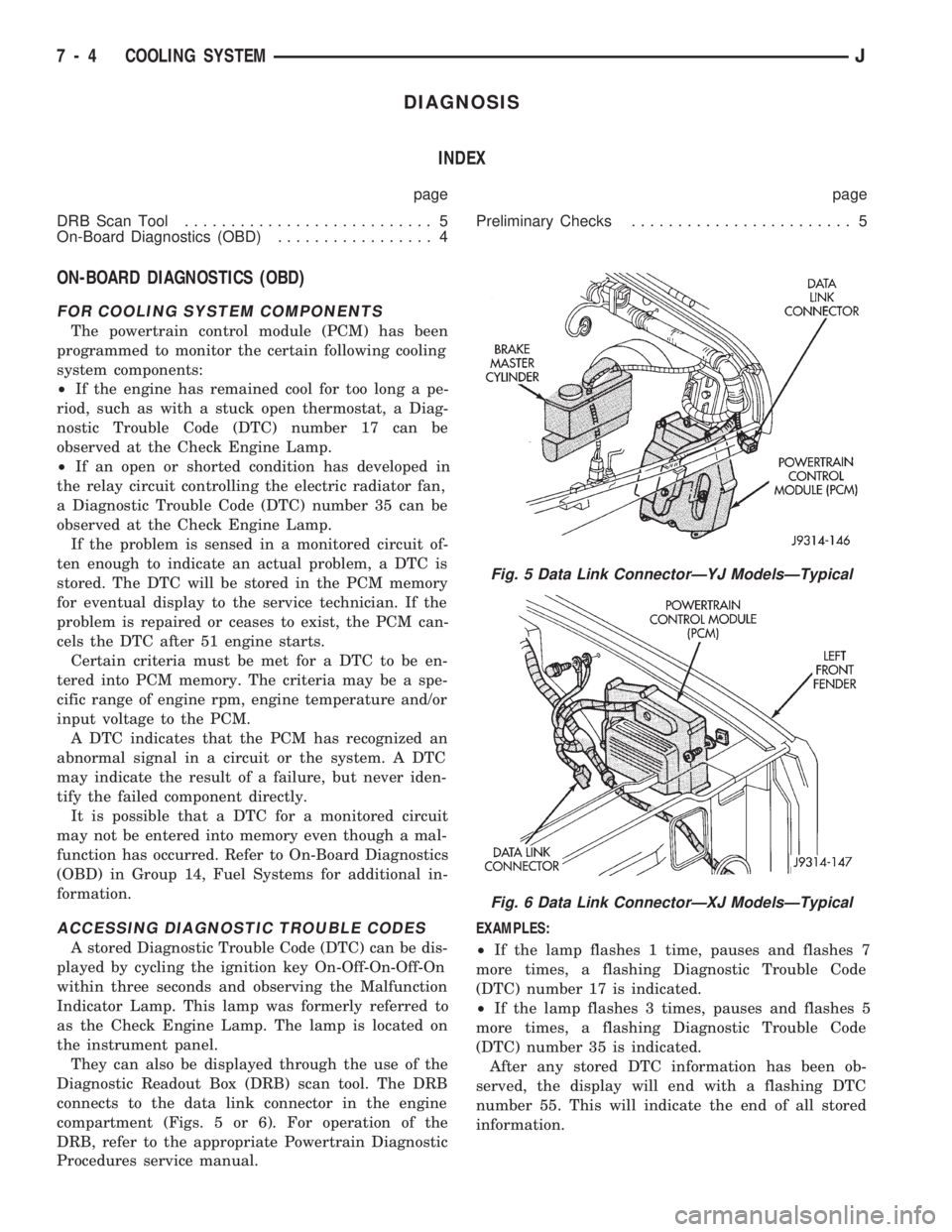

ON-BOARD DIAGNOSTICS (OBD)

FOR COOLING SYSTEM COMPONENTS

The powertrain control module (PCM) has been

programmed to monitor the certain following cooling

system components:

²If the engine has remained cool for too long a pe-

riod, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) number 17 can be

observed at the Check Engine Lamp.

²If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan,

a Diagnostic Trouble Code (DTC) number 35 can be

observed at the Check Engine Lamp.

If the problem is sensed in a monitored circuit of-

ten enough to indicate an actual problem, a DTC is

stored. The DTC will be stored in the PCM memory

for eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a DTC to be en-

tered into PCM memory. The criteria may be a spe-

cific range of engine rpm, engine temperature and/or

input voltage to the PCM.

A DTC indicates that the PCM has recognized an

abnormal signal in a circuit or the system. A DTC

may indicate the result of a failure, but never iden-

tify the failed component directly.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. Refer to On-Board Diagnostics

(OBD) in Group 14, Fuel Systems for additional in-

formation.

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored Diagnostic Trouble Code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the Malfunction

Indicator Lamp. This lamp was formerly referred to

as the Check Engine Lamp. The lamp is located on

the instrument panel.

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

connects to the data link connector in the engine

compartment (Figs. 5 or 6). For operation of the

DRB, refer to the appropriate Powertrain Diagnostic

Procedures service manual.EXAMPLES:

²If the lamp flashes 1 time, pauses and flashes 7

more times, a flashing Diagnostic Trouble Code

(DTC) number 17 is indicated.

²If the lamp flashes 3 times, pauses and flashes 5

more times, a flashing Diagnostic Trouble Code

(DTC) number 35 is indicated.

After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored

information.

Fig. 5 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 6 Data Link ConnectorÐXJ ModelsÐTypical

7 - 4 COOLING SYSTEMJ

Page 281 of 1784

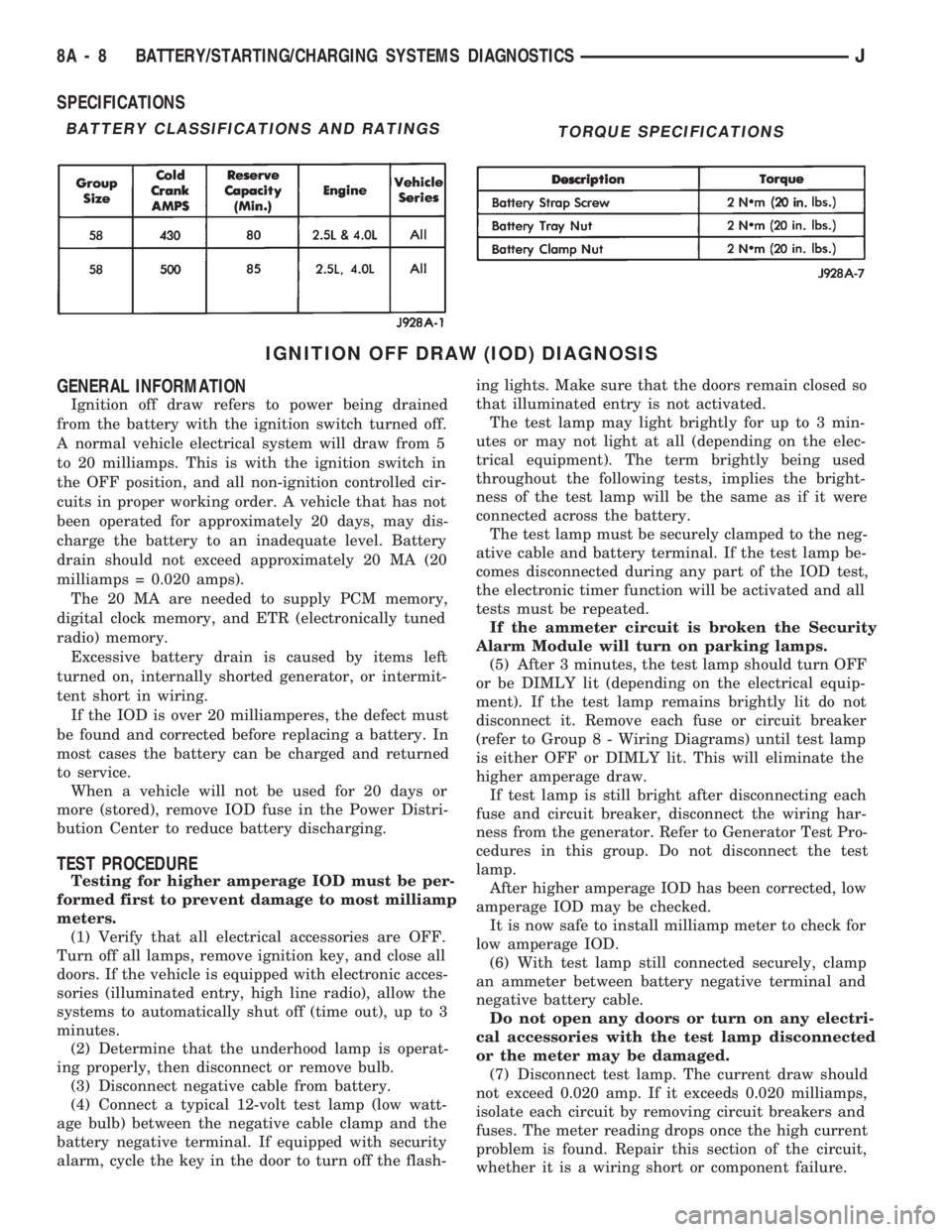

SPECIFICATIONS

IGNITION OFF DRAW (IOD) DIAGNOSIS

GENERAL INFORMATION

Ignition off draw refers to power being drained

from the battery with the ignition switch turned off.

A normal vehicle electrical system will draw from 5

to 20 milliamps. This is with the ignition switch in

the OFF position, and all non-ignition controlled cir-

cuits in proper working order. A vehicle that has not

been operated for approximately 20 days, may dis-

charge the battery to an inadequate level. Battery

drain should not exceed approximately 20 MA (20

milliamps = 0.020 amps).

The 20 MA are needed to supply PCM memory,

digital clock memory, and ETR (electronically tuned

radio) memory.

Excessive battery drain is caused by items left

turned on, internally shorted generator, or intermit-

tent short in wiring.

If the IOD is over 20 milliamperes, the defect must

be found and corrected before replacing a battery. In

most cases the battery can be charged and returned

to service.

When a vehicle will not be used for 20 days or

more (stored), remove IOD fuse in the Power Distri-

bution Center to reduce battery discharging.

TEST PROCEDURE

Testing for higher amperage IOD must be per-

formed first to prevent damage to most milliamp

meters.

(1) Verify that all electrical accessories are OFF.

Turn off all lamps, remove ignition key, and close all

doors. If the vehicle is equipped with electronic acces-

sories (illuminated entry, high line radio), allow the

systems to automatically shut off (time out), up to 3

minutes.

(2) Determine that the underhood lamp is operat-

ing properly, then disconnect or remove bulb.

(3) Disconnect negative cable from battery.

(4) Connect a typical 12-volt test lamp (low watt-

age bulb) between the negative cable clamp and the

battery negative terminal. If equipped with security

alarm, cycle the key in the door to turn off the flash-ing lights. Make sure that the doors remain closed so

that illuminated entry is not activated.

The test lamp may light brightly for up to 3 min-

utes or may not light at all (depending on the elec-

trical equipment). The term brightly being used

throughout the following tests, implies the bright-

ness of the test lamp will be the same as if it were

connected across the battery.

The test lamp must be securely clamped to the neg-

ative cable and battery terminal. If the test lamp be-

comes disconnected during any part of the IOD test,

the electronic timer function will be activated and all

tests must be repeated.

If the ammeter circuit is broken the Security

Alarm Module will turn on parking lamps.

(5) After 3 minutes, the test lamp should turn OFF

or be DIMLY lit (depending on the electrical equip-

ment). If the test lamp remains brightly lit do not

disconnect it. Remove each fuse or circuit breaker

(refer to Group 8 - Wiring Diagrams) until test lamp

is either OFF or DIMLY lit. This will eliminate the

higher amperage draw.

If test lamp is still bright after disconnecting each

fuse and circuit breaker, disconnect the wiring har-

ness from the generator. Refer to Generator Test Pro-

cedures in this group. Do not disconnect the test

lamp.

After higher amperage IOD has been corrected, low

amperage IOD may be checked.

It is now safe to install milliamp meter to check for

low amperage IOD.

(6) With test lamp still connected securely, clamp

an ammeter between battery negative terminal and

negative battery cable.

Do not open any doors or turn on any electri-

cal accessories with the test lamp disconnected

or the meter may be damaged.

(7) Disconnect test lamp. The current draw should

not exceed 0.020 amp. If it exceeds 0.020 milliamps,

isolate each circuit by removing circuit breakers and

fuses. The meter reading drops once the high current

problem is found. Repair this section of the circuit,

whether it is a wiring short or component failure.

BATTERY CLASSIFICATIONS AND RATINGSTORQUE SPECIFICATIONS

8A - 8 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 306 of 1784

OVERHEAD CONSOLE

CONTENTS

page page

COMPASS REPAIR PROCEDURES.......... 4

CONSOLE REPAIR PROCEDURES........... 6

DESCRIPTION........................... 1DIAGNOSTIC PROCEDURES............... 1

THERMOMETER AND SENSOR SYSTEM REPAIR

PROCEDURES......................... 6

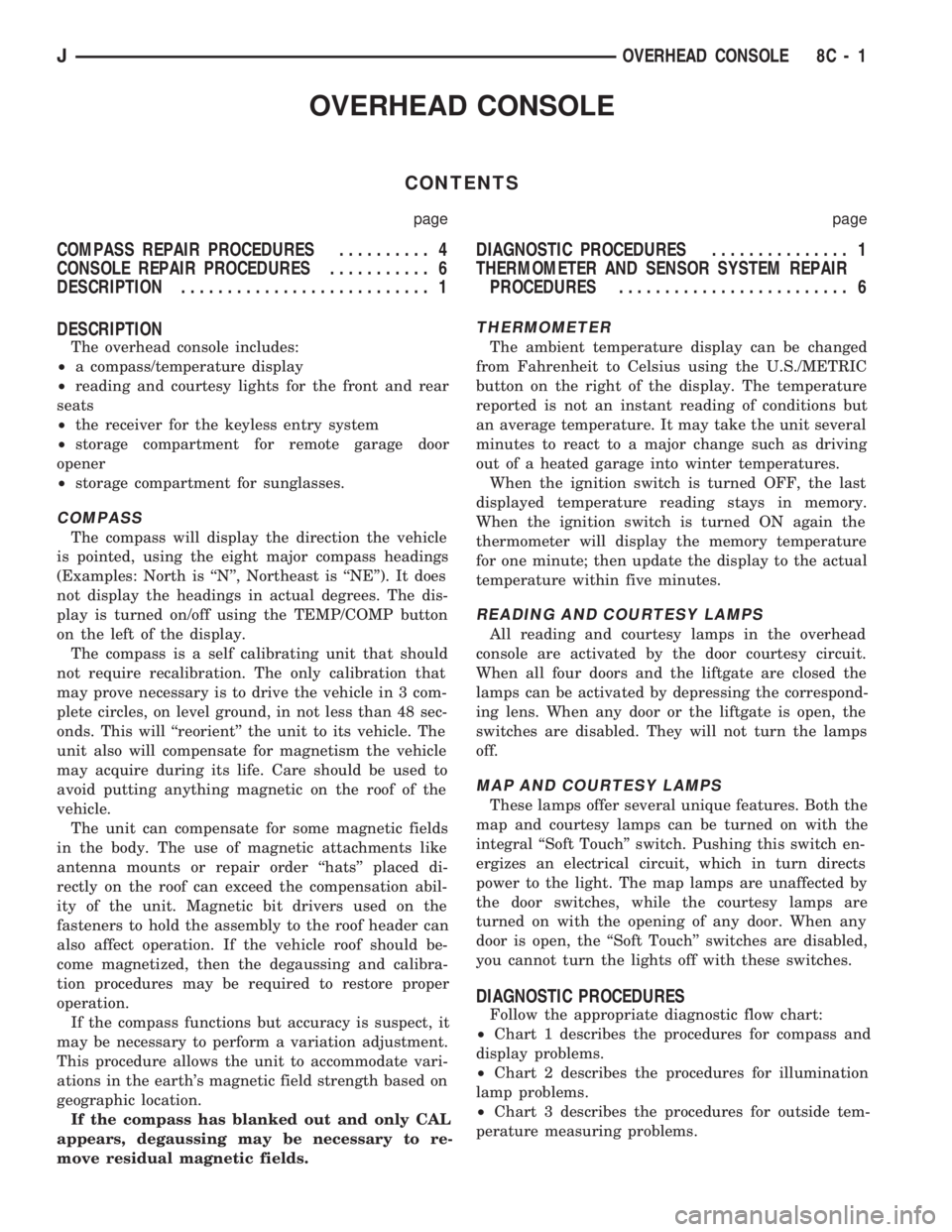

DESCRIPTION

The overhead console includes:

²a compass/temperature display

²reading and courtesy lights for the front and rear

seats

²the receiver for the keyless entry system

²storage compartment for remote garage door

opener

²storage compartment for sunglasses.

COMPASS

The compass will display the direction the vehicle

is pointed, using the eight major compass headings

(Examples: North is ``N'', Northeast is ``NE''). It does

not display the headings in actual degrees. The dis-

play is turned on/off using the TEMP/COMP button

on the left of the display.

The compass is a self calibrating unit that should

not require recalibration. The only calibration that

may prove necessary is to drive the vehicle in 3 com-

plete circles, on level ground, in not less than 48 sec-

onds. This will ``reorient'' the unit to its vehicle. The

unit also will compensate for magnetism the vehicle

may acquire during its life. Care should be used to

avoid putting anything magnetic on the roof of the

vehicle.

The unit can compensate for some magnetic fields

in the body. The use of magnetic attachments like

antenna mounts or repair order ``hats'' placed di-

rectly on the roof can exceed the compensation abil-

ity of the unit. Magnetic bit drivers used on the

fasteners to hold the assembly to the roof header can

also affect operation. If the vehicle roof should be-

come magnetized, then the degaussing and calibra-

tion procedures may be required to restore proper

operation.

If the compass functions but accuracy is suspect, it

may be necessary to perform a variation adjustment.

This procedure allows the unit to accommodate vari-

ations in the earth's magnetic field strength based on

geographic location.

If the compass has blanked out and only CAL

appears, degaussing may be necessary to re-

move residual magnetic fields.

THERMOMETER

The ambient temperature display can be changed

from Fahrenheit to Celsius using the U.S./METRIC

button on the right of the display. The temperature

reported is not an instant reading of conditions but

an average temperature. It may take the unit several

minutes to react to a major change such as driving

out of a heated garage into winter temperatures.

When the ignition switch is turned OFF, the last

displayed temperature reading stays in memory.

When the ignition switch is turned ON again the

thermometer will display the memory temperature

for one minute; then update the display to the actual

temperature within five minutes.

READING AND COURTESY LAMPS

All reading and courtesy lamps in the overhead

console are activated by the door courtesy circuit.

When all four doors and the liftgate are closed the

lamps can be activated by depressing the correspond-

ing lens. When any door or the liftgate is open, the

switches are disabled. They will not turn the lamps

off.

MAP AND COURTESY LAMPS

These lamps offer several unique features. Both the

map and courtesy lamps can be turned on with the

integral ``Soft Touch'' switch. Pushing this switch en-

ergizes an electrical circuit, which in turn directs

power to the light. The map lamps are unaffected by

the door switches, while the courtesy lamps are

turned on with the opening of any door. When any

door is open, the ``Soft Touch'' switches are disabled,

you cannot turn the lights off with these switches.

DIAGNOSTIC PROCEDURES

Follow the appropriate diagnostic flow chart:

²Chart 1 describes the procedures for compass and

display problems.

²Chart 2 describes the procedures for illumination

lamp problems.

²Chart 3 describes the procedures for outside tem-

perature measuring problems.

JOVERHEAD CONSOLE 8C - 1

Page 312 of 1784

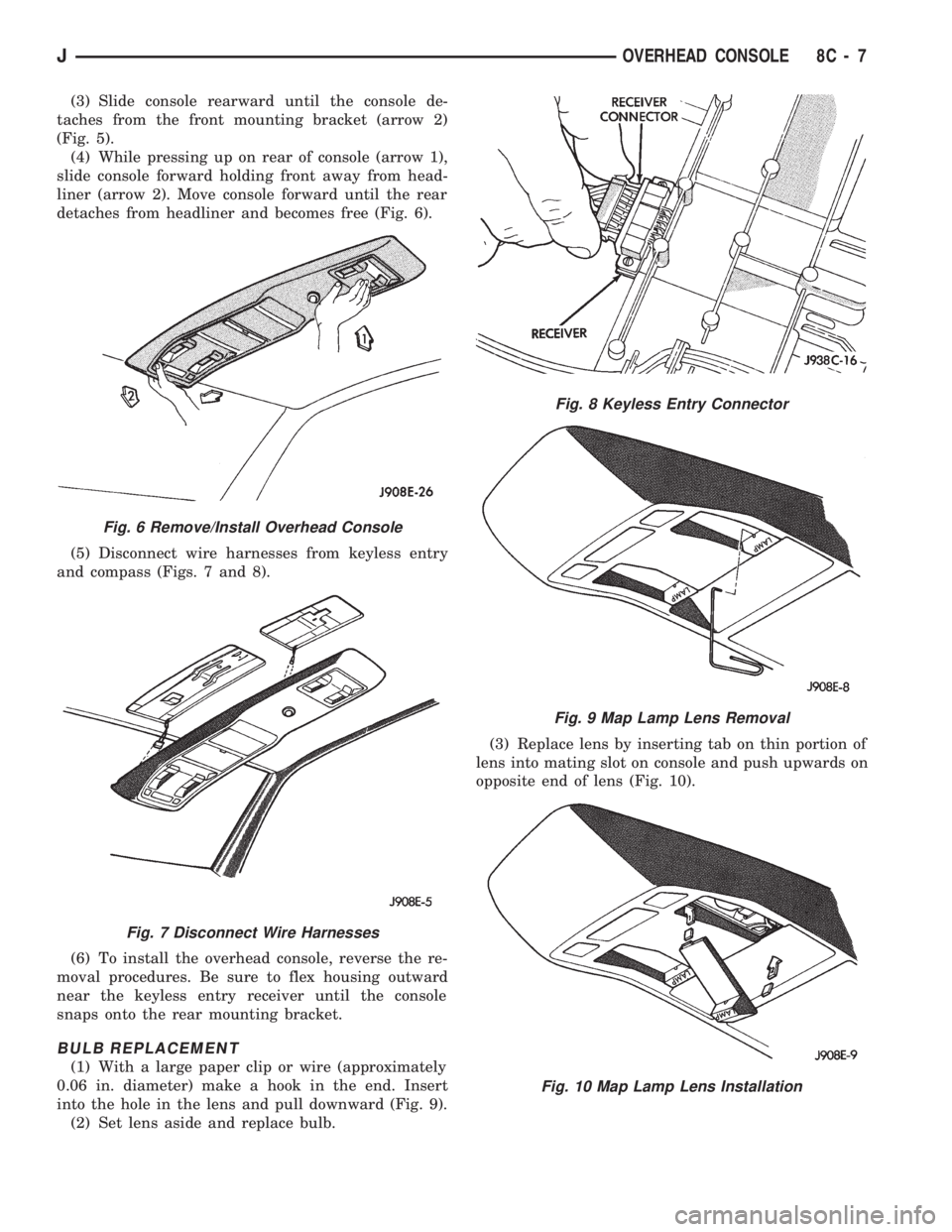

(3) Slide console rearward until the console de-

taches from the front mounting bracket (arrow 2)

(Fig. 5).

(4) While pressing up on rear of console (arrow 1),

slide console forward holding front away from head-

liner (arrow 2). Move console forward until the rear

detaches from headliner and becomes free (Fig. 6).

(5) Disconnect wire harnesses from keyless entry

and compass (Figs. 7 and 8).

(6) To install the overhead console, reverse the re-

moval procedures. Be sure to flex housing outward

near the keyless entry receiver until the console

snaps onto the rear mounting bracket.

BULB REPLACEMENT

(1) With a large paper clip or wire (approximately

0.06 in. diameter) make a hook in the end. Insert

into the hole in the lens and pull downward (Fig. 9).

(2) Set lens aside and replace bulb.(3) Replace lens by inserting tab on thin portion of

lens into mating slot on console and push upwards on

opposite end of lens (Fig. 10).

Fig. 6 Remove/Install Overhead Console

Fig. 7 Disconnect Wire Harnesses

Fig. 8 Keyless Entry Connector

Fig. 9 Map Lamp Lens Removal

Fig. 10 Map Lamp Lens Installation

JOVERHEAD CONSOLE 8C - 7

Page 321 of 1784

DIAGNOSTICS/SERVICE PROCEDURES

INDEX

page page

Automatic Shut Down (ASD) Relay............ 8

Camshaft Position Sensor Test............... 8

Crankshaft Position Sensor Test.............. 9

Distributor Cap........................... 9

Distributor Rotor......................... 10

DRB Scan Tool.......................... 10

Engine Coolant Temperature Sensor Test...... 12

General Information........................ 8

Ignition Coil............................. 11

Ignition Secondary Circuit Diagnosis.......... 12Ignition Timing........................... 14

Intake Manifold Air Temperature Sensor Test . . . 14

Manifold Absolute Pressure (MAP) Sensor Test . 14

On-Board Diagnostics (OBD)................ 19

Oxygen Sensor Tests..................... 19

Powertrain Control Module (PCM)............ 15

Spark Plug Secondary Cables............... 17

Spark Plugs............................ 16

Throttle Position Sensor Test............... 18

GENERAL INFORMATION

This section of the group, Diagnostics/Service Pro-

cedures, will discuss basic ignition system diagnos-

tics and service adjustments.

For system operation and component identification,

refer to the Component Identification/System Opera-

tion section of this group.

For removal or installation of ignition system com-

ponents, refer to the Component Removal/Installa-

tion section of this group.

For other useful information, refer to On-Board Di-

agnostics in the General Diagnosis sections of Group

14, Fuel System in this manual.

For operation of the DRB Scan Tool, refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice manual.

AUTOMATIC SHUT DOWN (ASD) RELAY

Refer to RelaysÐOperation/Testing in the Group

14, Fuel System section of this service manual.

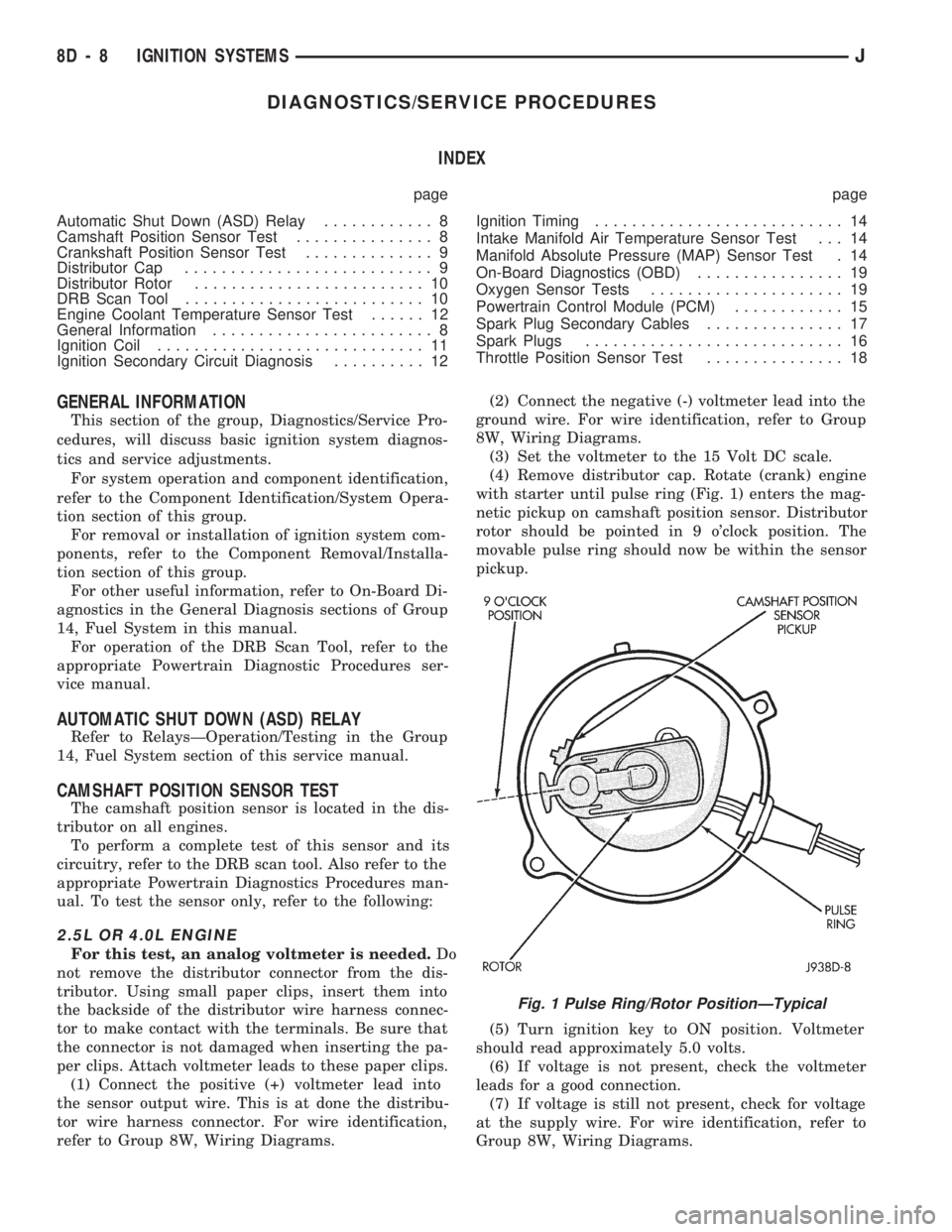

CAMSHAFT POSITION SENSOR TEST

The camshaft position sensor is located in the dis-

tributor on all engines.

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

2.5L OR 4.0L ENGINE

For this test, an analog voltmeter is needed.Do

not remove the distributor connector from the dis-

tributor. Using small paper clips, insert them into

the backside of the distributor wire harness connec-

tor to make contact with the terminals. Be sure that

the connector is not damaged when inserting the pa-

per clips. Attach voltmeter leads to these paper clips.

(1) Connect the positive (+) voltmeter lead into

the sensor output wire. This is at done the distribu-

tor wire harness connector. For wire identification,

refer to Group 8W, Wiring Diagrams.(2) Connect the negative (-) voltmeter lead into the

ground wire. For wire identification, refer to Group

8W, Wiring Diagrams.

(3) Set the voltmeter to the 15 Volt DC scale.

(4) Remove distributor cap. Rotate (crank) engine

with starter until pulse ring (Fig. 1) enters the mag-

netic pickup on camshaft position sensor. Distributor

rotor should be pointed in 9 o'clock position. The

movable pulse ring should now be within the sensor

pickup.

(5) Turn ignition key to ON position. Voltmeter

should read approximately 5.0 volts.

(6) If voltage is not present, check the voltmeter

leads for a good connection.

(7) If voltage is still not present, check for voltage

at the supply wire. For wire identification, refer to

Group 8W, Wiring Diagrams.

Fig. 1 Pulse Ring/Rotor PositionÐTypical

8D - 8 IGNITION SYSTEMSJ

Page 326 of 1784

(4) Using insulated pliers, hold the cable terminal

approximately 12 mm (1/2 in.) from the engine cylin-

der head or block while rotating the engine with the

starter motor. Observe the spark plug cable terminal

for an arc. If steady arcing occurs, it can be expected

that the ignition secondary system is operating cor-

rectly. If steady arcing occurs at the spark plug ca-

bles, but the engine will not start, connect the DRB

scan tool. Refer to the Powertrain Diagnostic Proce-

dures service manual for DRB operation.

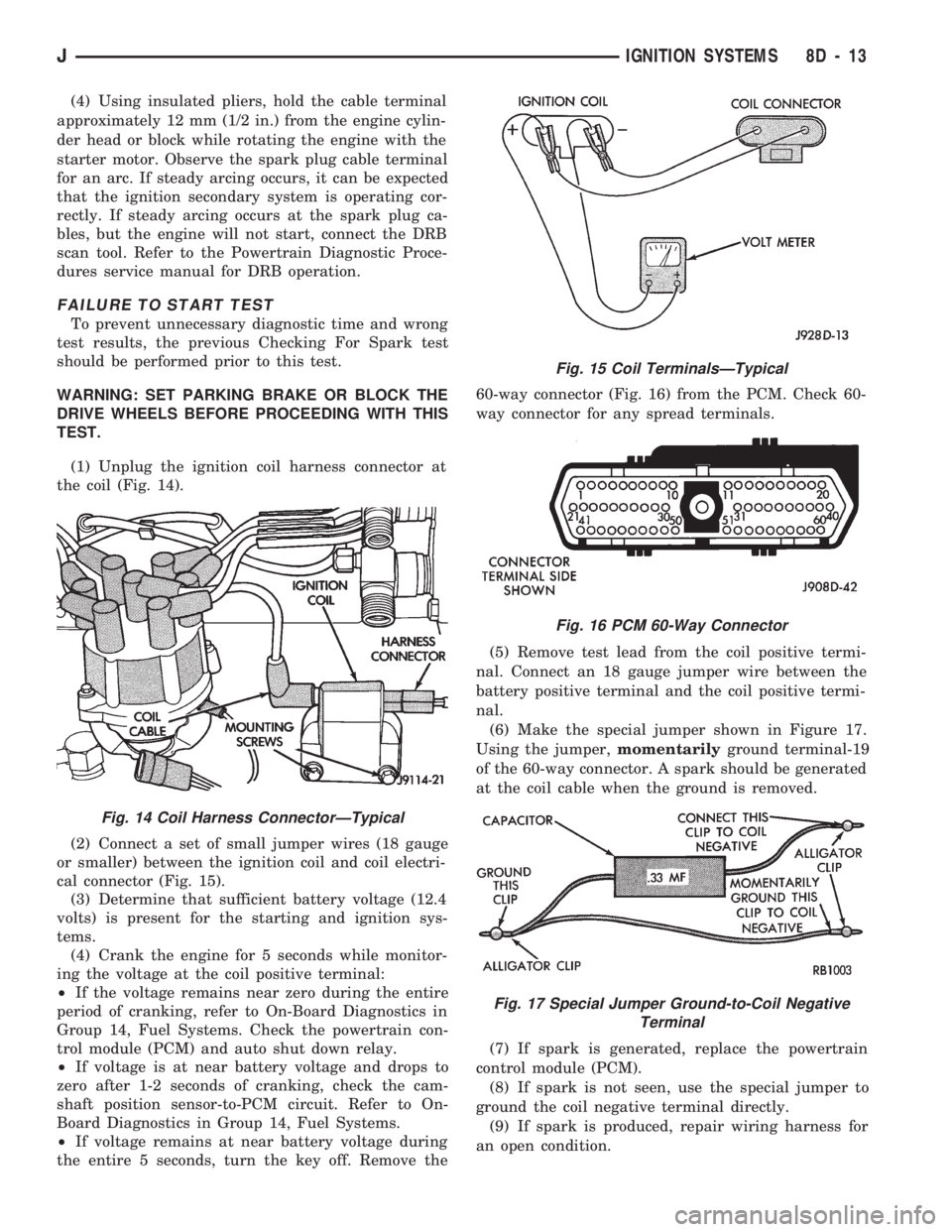

FAILURE TO START TEST

To prevent unnecessary diagnostic time and wrong

test results, the previous Checking For Spark test

should be performed prior to this test.

WARNING: SET PARKING BRAKE OR BLOCK THE

DRIVE WHEELS BEFORE PROCEEDING WITH THIS

TEST.

(1) Unplug the ignition coil harness connector at

the coil (Fig. 14).

(2) Connect a set of small jumper wires (18 gauge

or smaller) between the ignition coil and coil electri-

cal connector (Fig. 15).

(3) Determine that sufficient battery voltage (12.4

volts) is present for the starting and ignition sys-

tems.

(4) Crank the engine for 5 seconds while monitor-

ing the voltage at the coil positive terminal:

²If the voltage remains near zero during the entire

period of cranking, refer to On-Board Diagnostics in

Group 14, Fuel Systems. Check the powertrain con-

trol module (PCM) and auto shut down relay.

²If voltage is at near battery voltage and drops to

zero after 1-2 seconds of cranking, check the cam-

shaft position sensor-to-PCM circuit. Refer to On-

Board Diagnostics in Group 14, Fuel Systems.

²If voltage remains at near battery voltage during

the entire 5 seconds, turn the key off. Remove the60-way connector (Fig. 16) from the PCM. Check 60-

way connector for any spread terminals.

(5) Remove test lead from the coil positive termi-

nal. Connect an 18 gauge jumper wire between the

battery positive terminal and the coil positive termi-

nal.

(6) Make the special jumper shown in Figure 17.

Using the jumper,momentarilyground terminal-19

of the 60-way connector. A spark should be generated

at the coil cable when the ground is removed.

(7) If spark is generated, replace the powertrain

control module (PCM).

(8) If spark is not seen, use the special jumper to

ground the coil negative terminal directly.

(9) If spark is produced, repair wiring harness for

an open condition.

Fig. 14 Coil Harness ConnectorÐTypical

Fig. 15 Coil TerminalsÐTypical

Fig. 16 PCM 60-Way Connector

Fig. 17 Special Jumper Ground-to-Coil Negative

Terminal

JIGNITION SYSTEMS 8D - 13

Page 332 of 1784

With the ignition key in the ON position and en-

gine not running, check the sensor output voltage at

the center terminal wire of the connector. Check this

at idle (throttle plate closed) and at wide open throt-

tle (WOT). At idle, sensor output voltage should be

greater than 200 millivolts. At wide open throttle,

sensor output voltage must be less than 4.8 volts.

The output voltage should increase gradually as the

throttle plate is slowly opened from idle to WOT.

OXYGEN SENSOR TESTS

For diagnosis, removal or installation, refer to

Group 14, Fuel Systems in this manual.

ON-BOARD DIAGNOSTICS (OBD)

FOR IGNITION SYSTEM COMPONENTS

The powertrain control module (PCM) has been

programmed to monitor certain ignition system cir-

cuits:

EXAMPLE:

If a reference signal is not being detected during

engine cranking from the crankshaft position sensor,

a Diagnostic Trouble Code (DTC) number 11 can be

observed at the Check Engine Lamp.

If the problem is sensed in a monitored circuit of-

ten enough to indicate an actual problem, a DTC is

stored. The DTC will be stored in the PCM memory

for eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a DTC to be en-

tered into PCM memory. The criteria may be a spe-

cific range of engine rpm, engine temperature and/or

input voltage to the PCM.

A DTC indicates that the PCM has recognized an

abnormal signal in a circuit or the system. A DTC

may indicate the result of a failure, but never iden-

tify the failed component directly.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. Refer to On-Board Diagnostics

(OBD) in Group 14, Fuel Systems for additional in-

formation.

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored Diagnostic Trouble Code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the Malfunction

Indicator Lamp. This lamp was formerly referred to

as the Check Engine Lamp. The lamp is located on

the instrument panel.

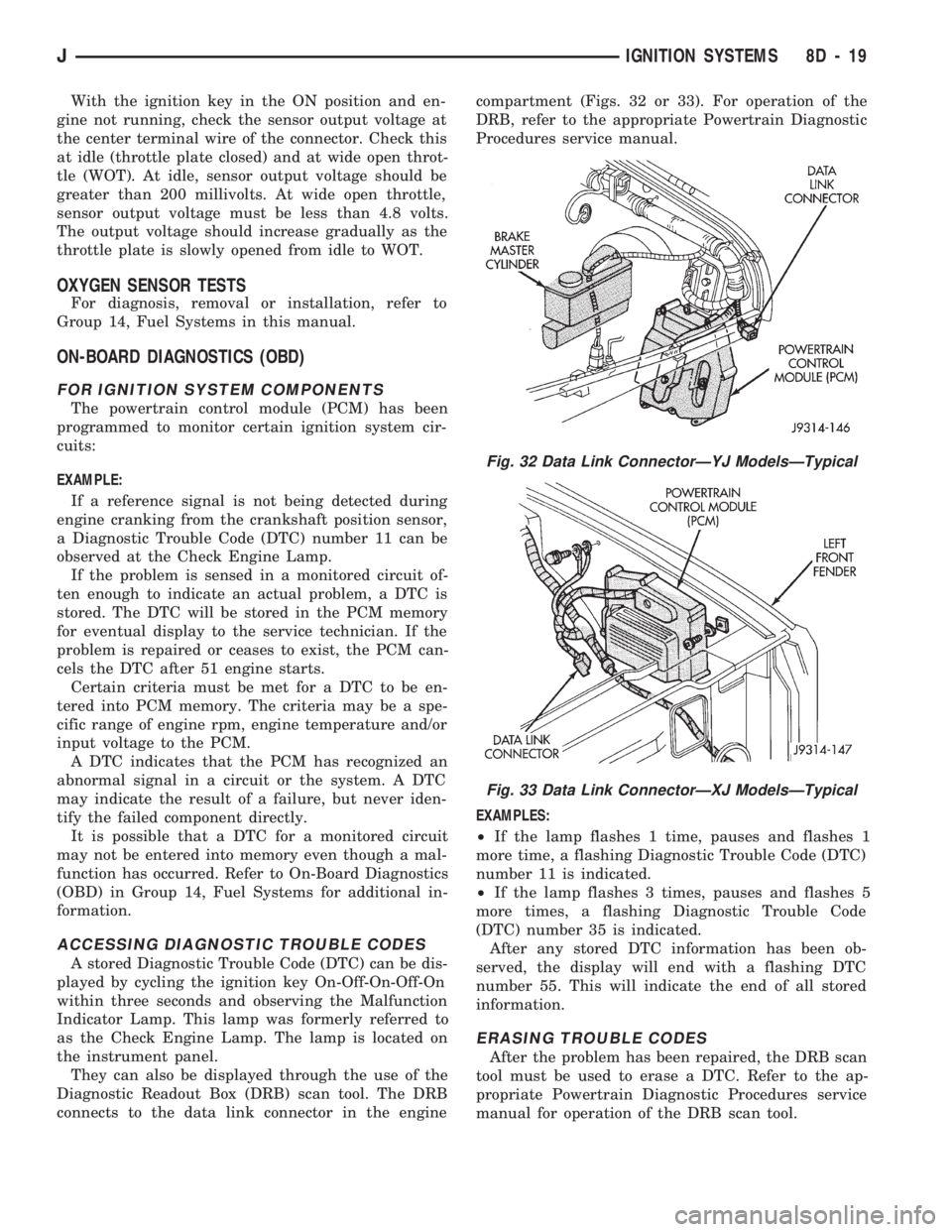

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

connects to the data link connector in the enginecompartment (Figs. 32 or 33). For operation of the

DRB, refer to the appropriate Powertrain Diagnostic

Procedures service manual.

EXAMPLES:

²If the lamp flashes 1 time, pauses and flashes 1

more time, a flashing Diagnostic Trouble Code (DTC)

number 11 is indicated.

²If the lamp flashes 3 times, pauses and flashes 5

more times, a flashing Diagnostic Trouble Code

(DTC) number 35 is indicated.

After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored

information.

ERASING TROUBLE CODES

After the problem has been repaired, the DRB scan

tool must be used to erase a DTC. Refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual for operation of the DRB scan tool.

Fig. 32 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 33 Data Link ConnectorÐXJ ModelsÐTypical

JIGNITION SYSTEMS 8D - 19

Page 343 of 1784

IGNITION SWITCH

INDEX

page page

General Information....................... 30

Ignition Switch Installation/Adjustment......... 31Ignition Switch Removal................... 30

Ignition Switch Testing..................... 30

GENERAL INFORMATION

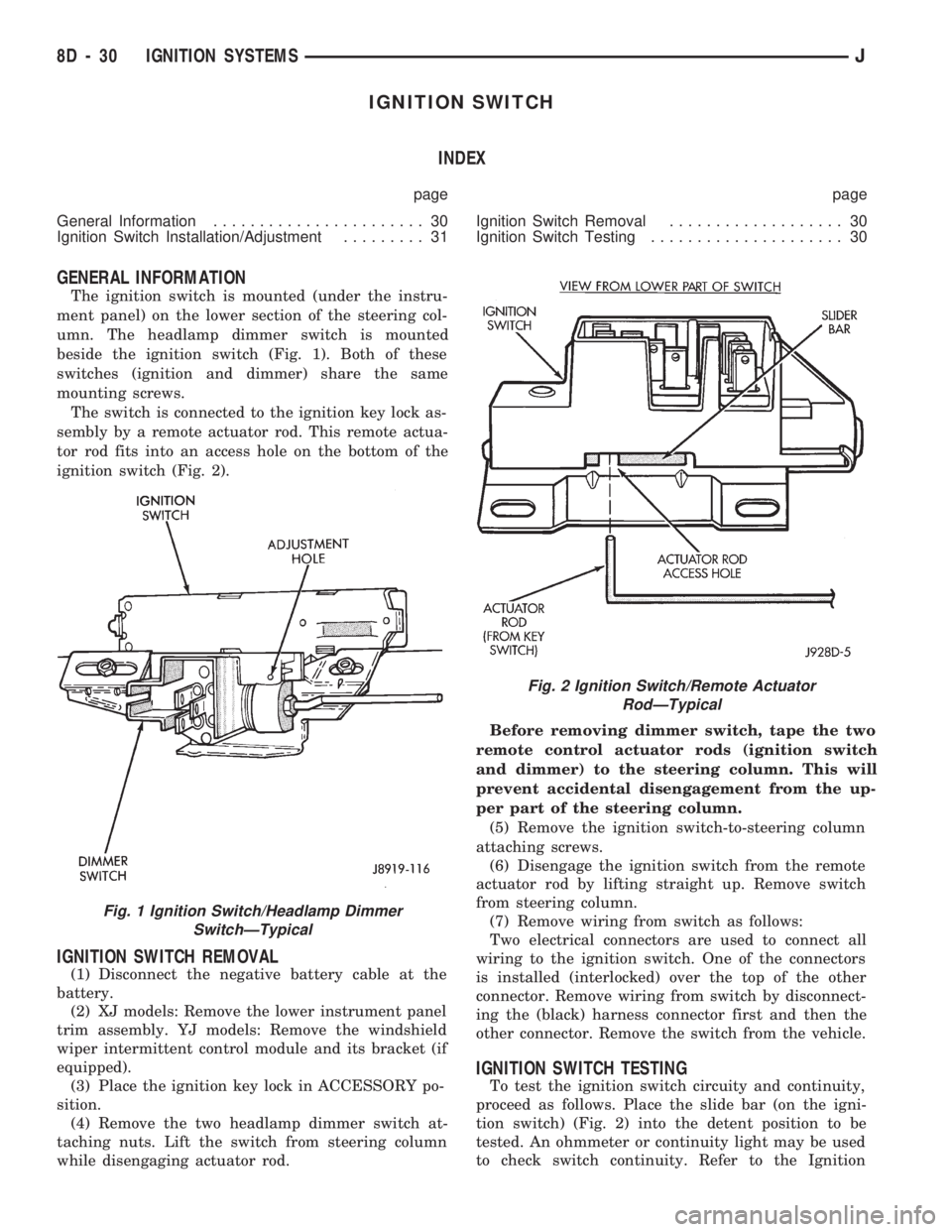

The ignition switch is mounted (under the instru-

ment panel) on the lower section of the steering col-

umn. The headlamp dimmer switch is mounted

beside the ignition switch (Fig. 1). Both of these

switches (ignition and dimmer) share the same

mounting screws.

The switch is connected to the ignition key lock as-

sembly by a remote actuator rod. This remote actua-

tor rod fits into an access hole on the bottom of the

ignition switch (Fig. 2).

IGNITION SWITCH REMOVAL

(1) Disconnect the negative battery cable at the

battery.

(2) XJ models: Remove the lower instrument panel

trim assembly. YJ models: Remove the windshield

wiper intermittent control module and its bracket (if

equipped).

(3) Place the ignition key lock in ACCESSORY po-

sition.

(4) Remove the two headlamp dimmer switch at-

taching nuts. Lift the switch from steering column

while disengaging actuator rod.Before removing dimmer switch, tape the two

remote control actuator rods (ignition switch

and dimmer) to the steering column. This will

prevent accidental disengagement from the up-

per part of the steering column.

(5) Remove the ignition switch-to-steering column

attaching screws.

(6) Disengage the ignition switch from the remote

actuator rod by lifting straight up. Remove switch

from steering column.

(7) Remove wiring from switch as follows:

Two electrical connectors are used to connect all

wiring to the ignition switch. One of the connectors

is installed (interlocked) over the top of the other

connector. Remove wiring from switch by disconnect-

ing the (black) harness connector first and then the

other connector. Remove the switch from the vehicle.

IGNITION SWITCH TESTING

To test the ignition switch circuity and continuity,

proceed as follows. Place the slide bar (on the igni-

tion switch) (Fig. 2) into the detent position to be

tested. An ohmmeter or continuity light may be used

to check switch continuity. Refer to the Ignition

Fig. 1 Ignition Switch/Headlamp Dimmer

SwitchÐTypical

Fig. 2 Ignition Switch/Remote Actuator

RodÐTypical

8D - 30 IGNITION SYSTEMSJ