JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 381 of 1784

INSTALLATION

(1) Connect speaker at wiring harness.

(2) Install speaker.

(3) Install trim panel by pushing in the plastic

trees.

(4) Install door panel screws.

YJ SERVICE PROCEDURES

RADIO REPLACEMENT

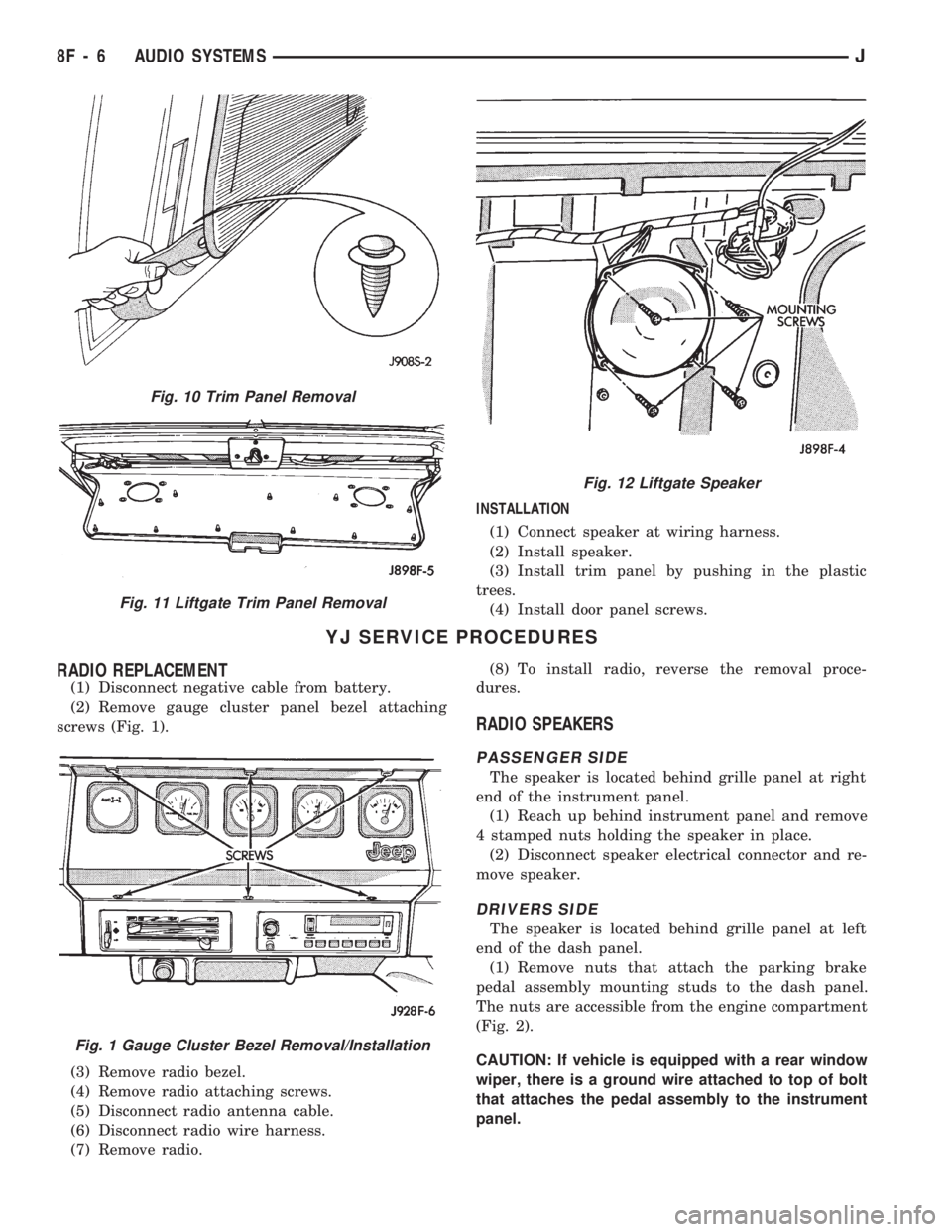

(1) Disconnect negative cable from battery.

(2) Remove gauge cluster panel bezel attaching

screws (Fig. 1).

(3) Remove radio bezel.

(4) Remove radio attaching screws.

(5) Disconnect radio antenna cable.

(6) Disconnect radio wire harness.

(7) Remove radio.(8) To install radio, reverse the removal proce-

dures.

RADIO SPEAKERS

PASSENGER SIDE

The speaker is located behind grille panel at right

end of the instrument panel.

(1) Reach up behind instrument panel and remove

4 stamped nuts holding the speaker in place.

(2) Disconnect speaker electrical connector and re-

move speaker.

DRIVERS SIDE

The speaker is located behind grille panel at left

end of the dash panel.

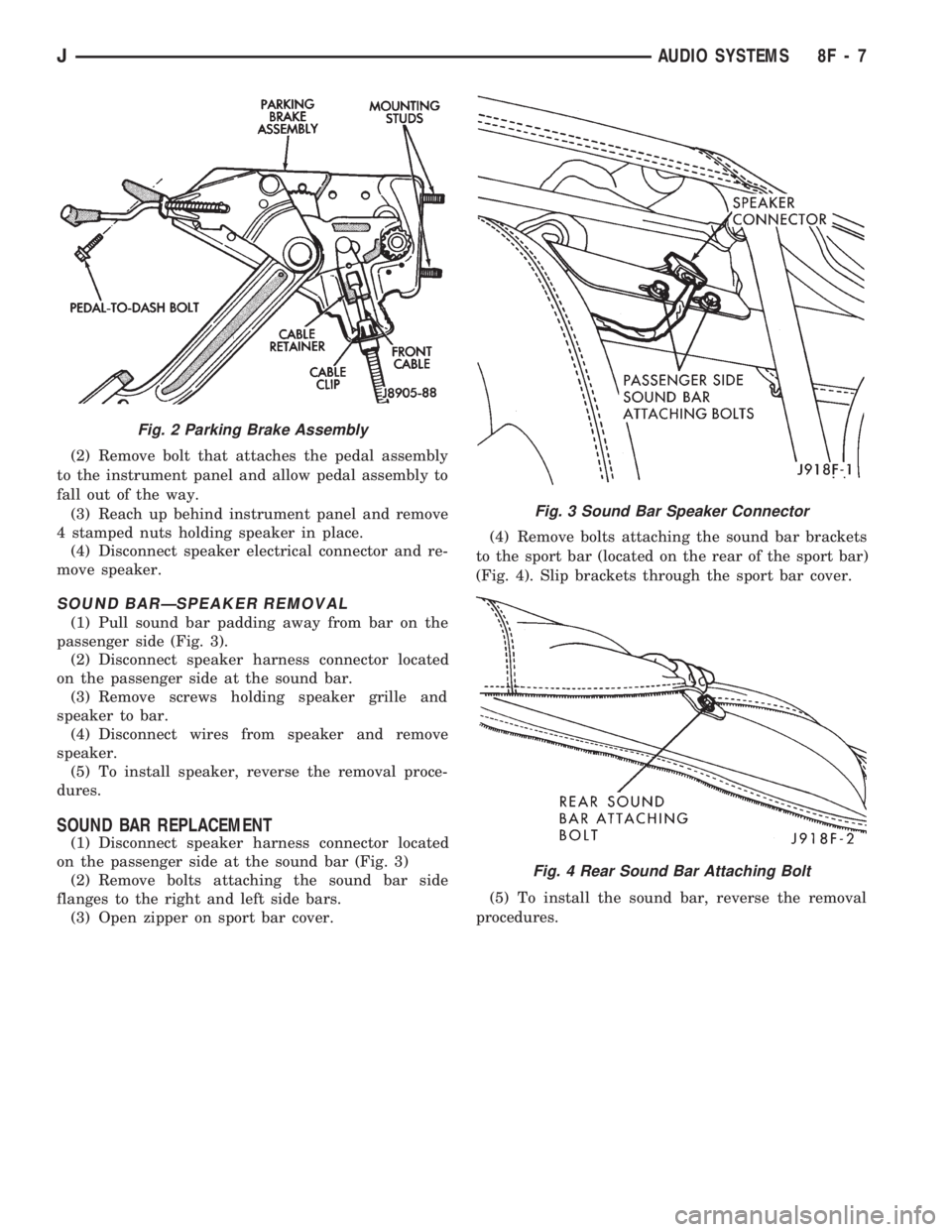

(1) Remove nuts that attach the parking brake

pedal assembly mounting studs to the dash panel.

The nuts are accessible from the engine compartment

(Fig. 2).

CAUTION: If vehicle is equipped with a rear window

wiper, there is a ground wire attached to top of bolt

that attaches the pedal assembly to the instrument

panel.

Fig. 10 Trim Panel Removal

Fig. 11 Liftgate Trim Panel Removal

Fig. 12 Liftgate Speaker

Fig. 1 Gauge Cluster Bezel Removal/Installation

8F - 6 AUDIO SYSTEMSJ

Page 382 of 1784

(2) Remove bolt that attaches the pedal assembly

to the instrument panel and allow pedal assembly to

fall out of the way.

(3) Reach up behind instrument panel and remove

4 stamped nuts holding speaker in place.

(4) Disconnect speaker electrical connector and re-

move speaker.

SOUND BARÐSPEAKER REMOVAL

(1) Pull sound bar padding away from bar on the

passenger side (Fig. 3).

(2) Disconnect speaker harness connector located

on the passenger side at the sound bar.

(3) Remove screws holding speaker grille and

speaker to bar.

(4) Disconnect wires from speaker and remove

speaker.

(5) To install speaker, reverse the removal proce-

dures.

SOUND BAR REPLACEMENT

(1) Disconnect speaker harness connector located

on the passenger side at the sound bar (Fig. 3)

(2) Remove bolts attaching the sound bar side

flanges to the right and left side bars.

(3) Open zipper on sport bar cover.(4) Remove bolts attaching the sound bar brackets

to the sport bar (located on the rear of the sport bar)

(Fig. 4). Slip brackets through the sport bar cover.

(5) To install the sound bar, reverse the removal

procedures.

Fig. 2 Parking Brake Assembly

Fig. 3 Sound Bar Speaker Connector

Fig. 4 Rear Sound Bar Attaching Bolt

JAUDIO SYSTEMS 8F - 7

Page 383 of 1784

RADIO ANTENNA

INDEX

page page

Antenna Tests............................ 9

General Information........................ 8Replacement............................. 8

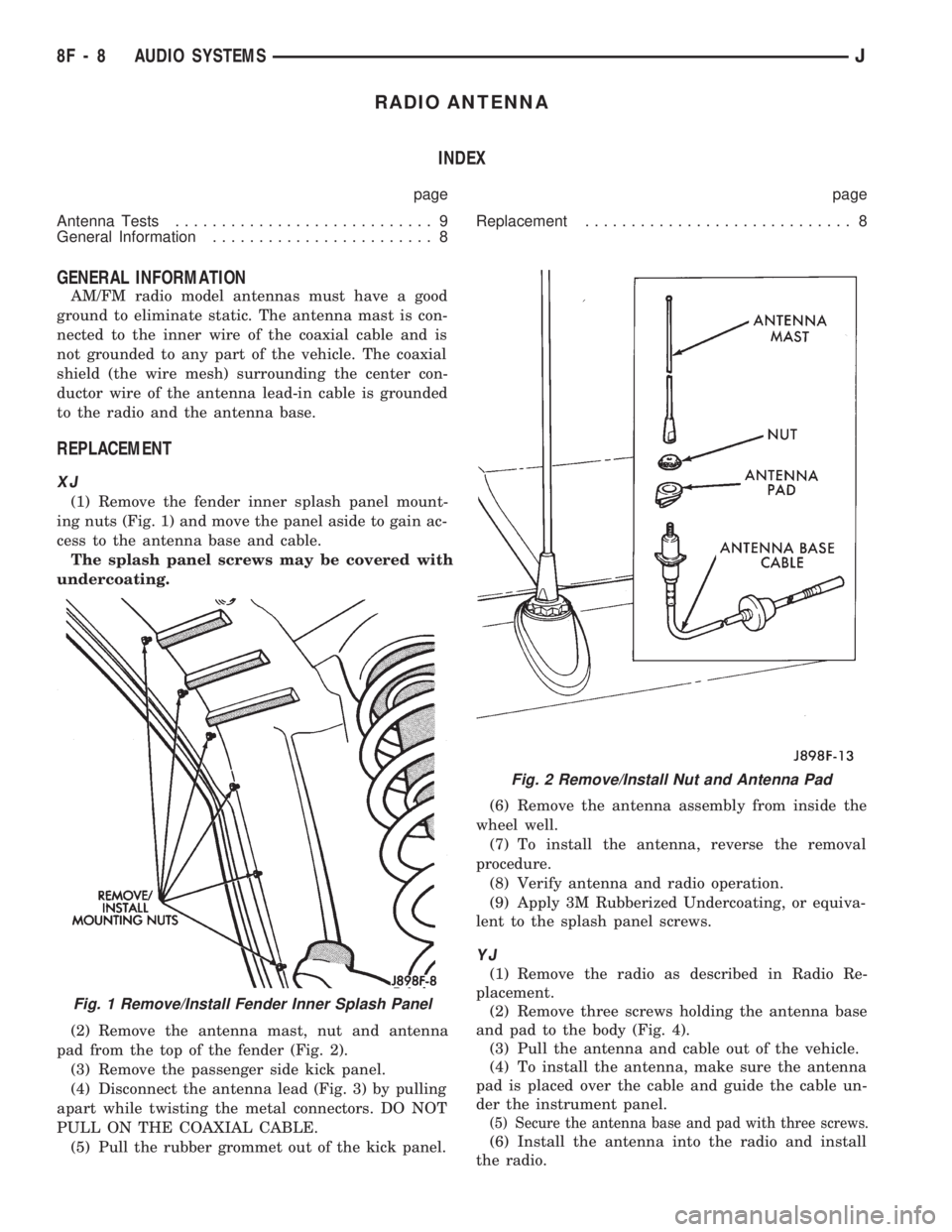

GENERAL INFORMATION

AM/FM radio model antennas must have a good

ground to eliminate static. The antenna mast is con-

nected to the inner wire of the coaxial cable and is

not grounded to any part of the vehicle. The coaxial

shield (the wire mesh) surrounding the center con-

ductor wire of the antenna lead-in cable is grounded

to the radio and the antenna base.

REPLACEMENT

XJ

(1) Remove the fender inner splash panel mount-

ing nuts (Fig. 1) and move the panel aside to gain ac-

cess to the antenna base and cable.

The splash panel screws may be covered with

undercoating.

(2) Remove the antenna mast, nut and antenna

pad from the top of the fender (Fig. 2).

(3) Remove the passenger side kick panel.

(4) Disconnect the antenna lead (Fig. 3) by pulling

apart while twisting the metal connectors. DO NOT

PULL ON THE COAXIAL CABLE.

(5) Pull the rubber grommet out of the kick panel.(6) Remove the antenna assembly from inside the

wheel well.

(7) To install the antenna, reverse the removal

procedure.

(8) Verify antenna and radio operation.

(9) Apply 3M Rubberized Undercoating, or equiva-

lent to the splash panel screws.

YJ

(1) Remove the radio as described in Radio Re-

placement.

(2) Remove three screws holding the antenna base

and pad to the body (Fig. 4).

(3) Pull the antenna and cable out of the vehicle.

(4) To install the antenna, make sure the antenna

pad is placed over the cable and guide the cable un-

der the instrument panel.

(5) Secure the antenna base and pad with three screws.

(6) Install the antenna into the radio and install

the radio.

Fig. 1 Remove/Install Fender Inner Splash Panel

Fig. 2 Remove/Install Nut and Antenna Pad

8F - 8 AUDIO SYSTEMSJ

Page 384 of 1784

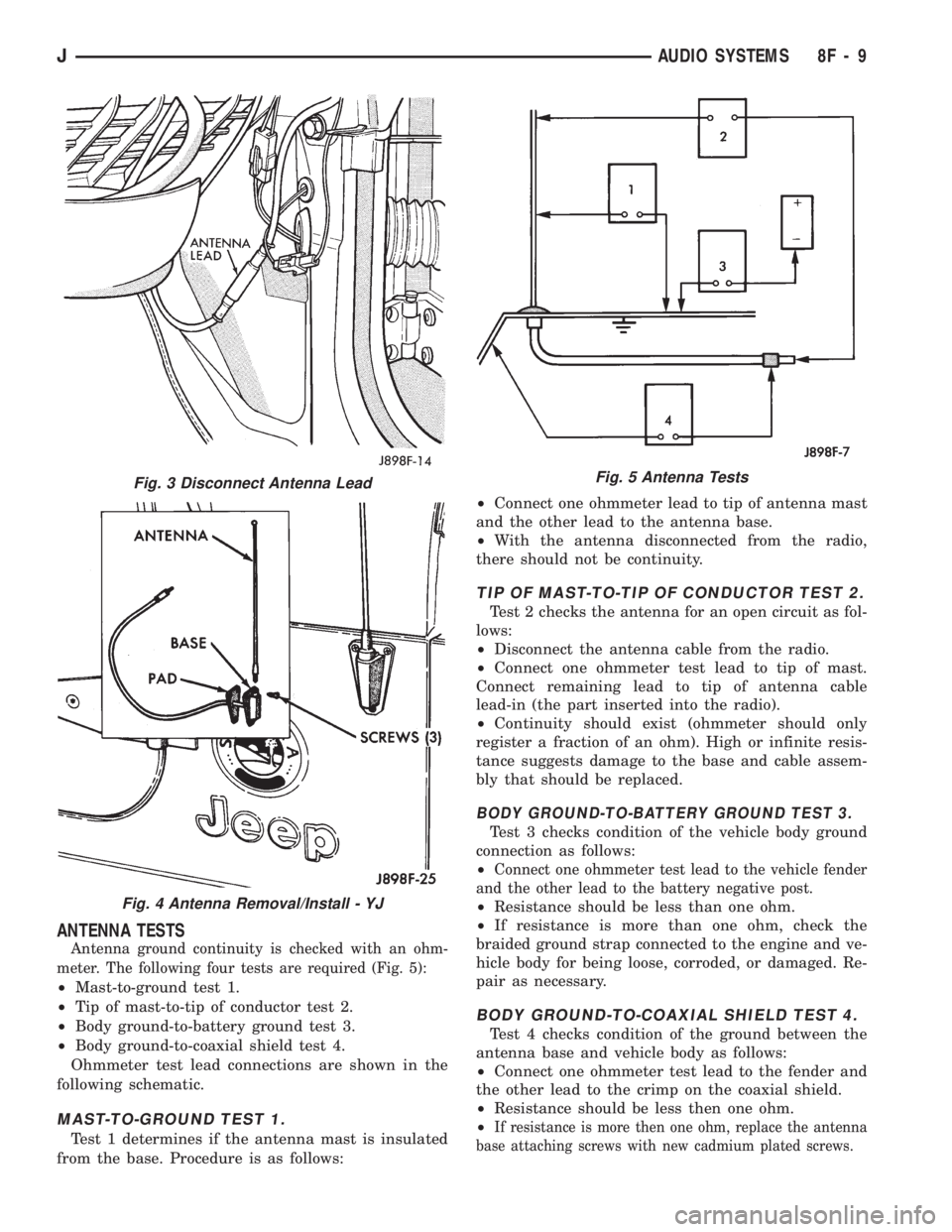

ANTENNA TESTS

Antenna ground continuity is checked with an ohm-

meter. The following four tests are required (Fig. 5):

²Mast-to-ground test 1.

²Tip of mast-to-tip of conductor test 2.

²Body ground-to-battery ground test 3.

²Body ground-to-coaxial shield test 4.

Ohmmeter test lead connections are shown in the

following schematic.

MAST-TO-GROUND TEST 1.

Test 1 determines if the antenna mast is insulated

from the base. Procedure is as follows:²Connect one ohmmeter lead to tip of antenna mast

and the other lead to the antenna base.

²With the antenna disconnected from the radio,

there should not be continuity.

TIP OF MAST-TO-TIP OF CONDUCTOR TEST 2.

Test 2 checks the antenna for an open circuit as fol-

lows:

²Disconnect the antenna cable from the radio.

²Connect one ohmmeter test lead to tip of mast.

Connect remaining lead to tip of antenna cable

lead-in (the part inserted into the radio).

²Continuity should exist (ohmmeter should only

register a fraction of an ohm). High or infinite resis-

tance suggests damage to the base and cable assem-

bly that should be replaced.

BODY GROUND-TO-BATTERY GROUND TEST 3.

Test 3 checks condition of the vehicle body ground

connection as follows:

²

Connect one ohmmeter test lead to the vehicle fender

and the other lead to the battery negative post.

²Resistance should be less than one ohm.

²If resistance is more than one ohm, check the

braided ground strap connected to the engine and ve-

hicle body for being loose, corroded, or damaged. Re-

pair as necessary.

BODY GROUND-TO-COAXIAL SHIELD TEST 4.

Test 4 checks condition of the ground between the

antenna base and vehicle body as follows:

²Connect one ohmmeter test lead to the fender and

the other lead to the crimp on the coaxial shield.

²Resistance should be less then one ohm.

²

If resistance is more then one ohm, replace the antenna

base attaching screws with new cadmium plated screws.

Fig. 3 Disconnect Antenna Lead

Fig. 4 Antenna Removal/Install - YJ

Fig. 5 Antenna Tests

JAUDIO SYSTEMS 8F - 9

Page 385 of 1784

Page 386 of 1784

HORNS

CONTENTS

page page

GENERAL INFORMATION.................. 1

HORN SWITCH (HORN PAD) REPLACEMENT . . 3

TORQUE SPECIFICATIONS................. 3XJ ..................................... 1

YJ ..................................... 2

GENERAL INFORMATION

For XJ/YJ vehicles battery voltage is applied to the

horn relay through a fuse.

When the horn switch is depressed, the horn relay

is grounded, pulling the contact closed and providing

battery voltage to the horns.

A slip ring and brush arrangement in the steering

wheel allows the switch circuit to maintain contact

while allowing rotation of the steering wheel.On XJ models, a cadmium-plated ground

screw is used to attach the horn(s) to the body.

Do not substitute other types of ground screws

as they may become corroded and cause a loss

of ground.

XJ

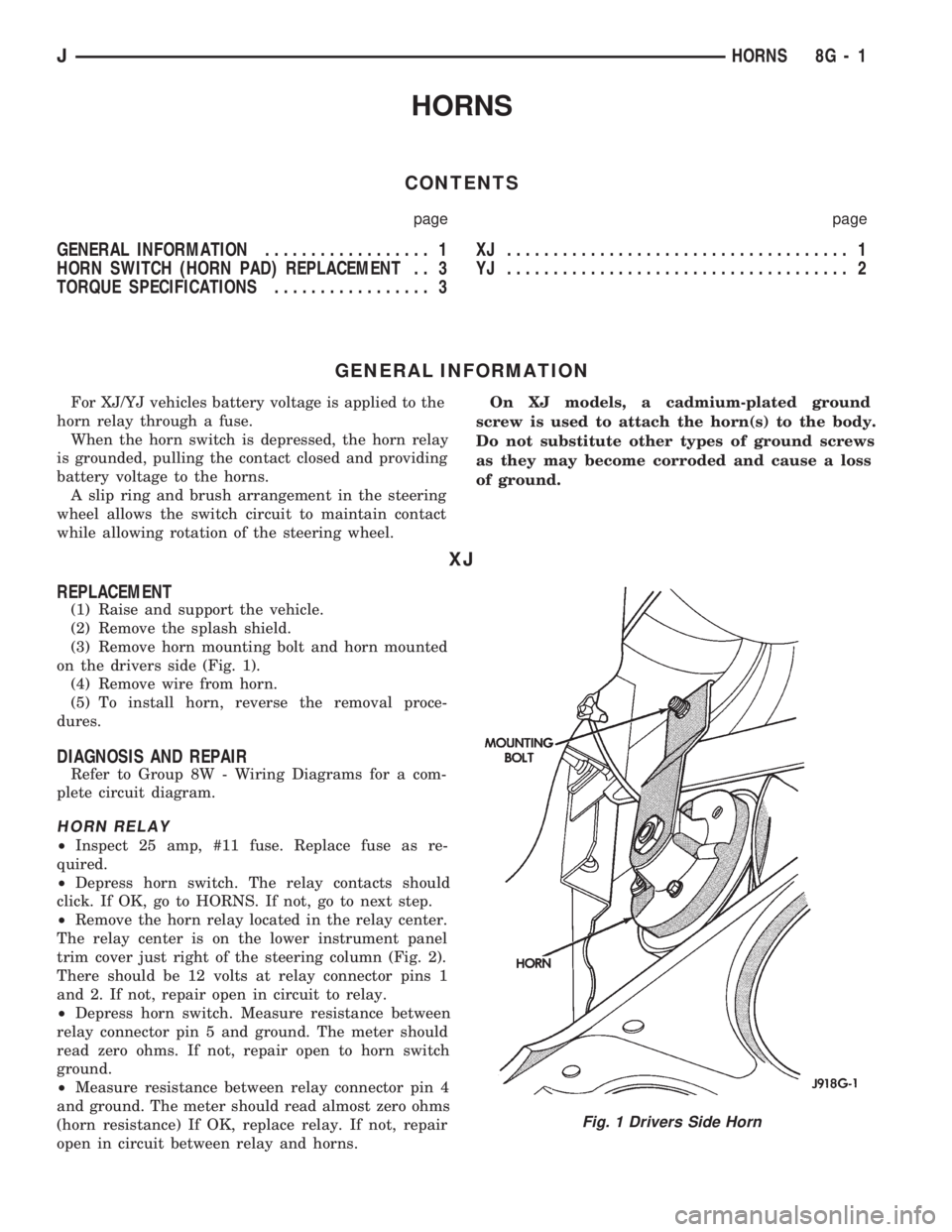

REPLACEMENT

(1) Raise and support the vehicle.

(2) Remove the splash shield.

(3) Remove horn mounting bolt and horn mounted

on the drivers side (Fig. 1).

(4) Remove wire from horn.

(5) To install horn, reverse the removal proce-

dures.

DIAGNOSIS AND REPAIR

Refer to Group 8W - Wiring Diagrams for a com-

plete circuit diagram.

HORN RELAY

²Inspect 25 amp, #11 fuse. Replace fuse as re-

quired.

²Depress horn switch. The relay contacts should

click. If OK, go to HORNS. If not, go to next step.

²Remove the horn relay located in the relay center.

The relay center is on the lower instrument panel

trim cover just right of the steering column (Fig. 2).

There should be 12 volts at relay connector pins 1

and 2. If not, repair open in circuit to relay.

²Depress horn switch. Measure resistance between

relay connector pin 5 and ground. The meter should

read zero ohms. If not, repair open to horn switch

ground.

²Measure resistance between relay connector pin 4

and ground. The meter should read almost zero ohms

(horn resistance) If OK, replace relay. If not, repair

open in circuit between relay and horns.

Fig. 1 Drivers Side Horn

JHORNS 8G - 1

Page 387 of 1784

HORNS

²Disconnect horn connector. Depress horn switch.

There should be 12 volts at the horn connector. If

not, repair open to relay.

²Measure the resistance between the horn bracket

and chassis ground. The meter should read zero

ohms. If not, check mounting screw for corrosion and

replace as necessary.

²If above steps do not identify a problem, replace

horns.

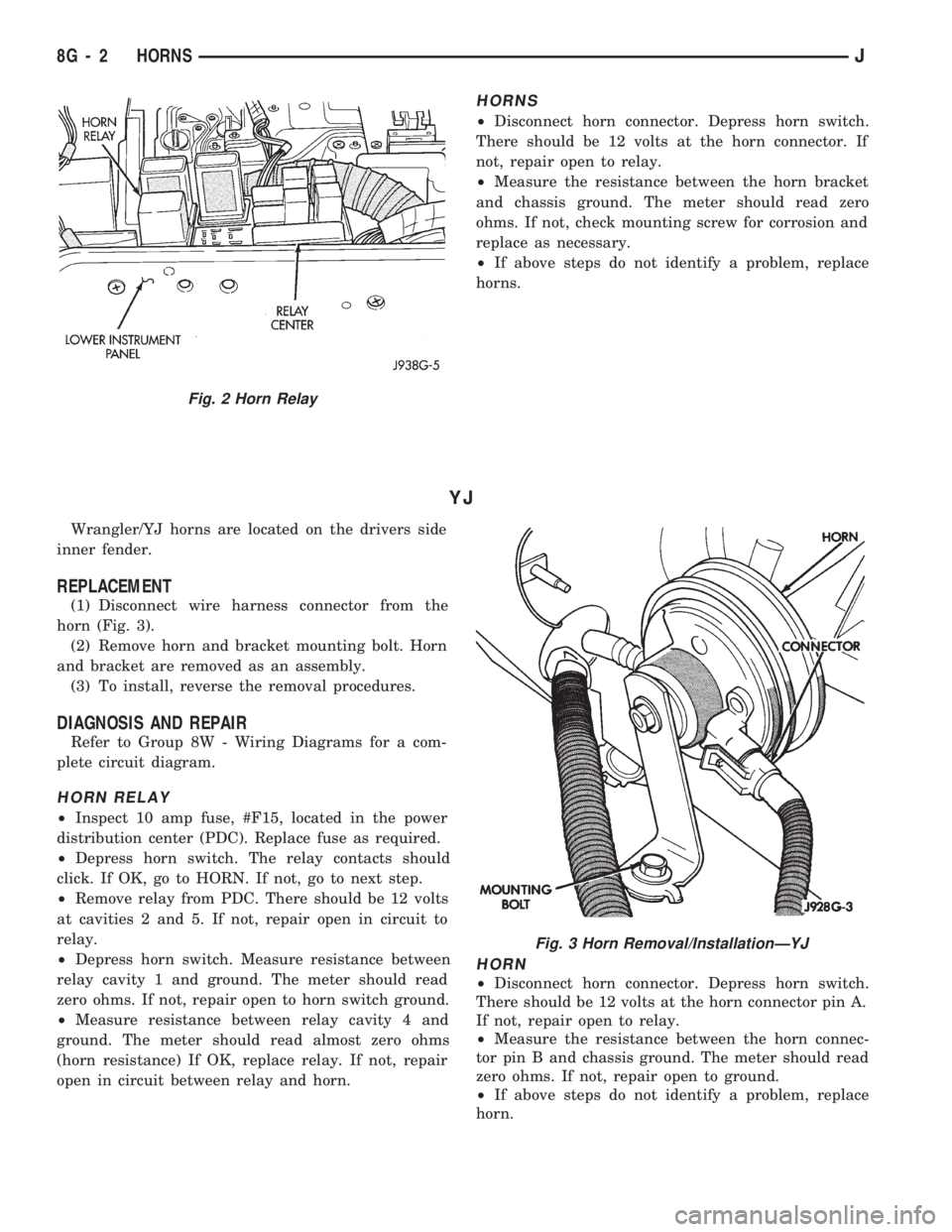

YJ

Wrangler/YJ horns are located on the drivers side

inner fender.

REPLACEMENT

(1) Disconnect wire harness connector from the

horn (Fig. 3).

(2) Remove horn and bracket mounting bolt. Horn

and bracket are removed as an assembly.

(3) To install, reverse the removal procedures.

DIAGNOSIS AND REPAIR

Refer to Group 8W - Wiring Diagrams for a com-

plete circuit diagram.

HORN RELAY

²Inspect 10 amp fuse, #F15, located in the power

distribution center (PDC). Replace fuse as required.

²Depress horn switch. The relay contacts should

click. If OK, go to HORN. If not, go to next step.

²Remove relay from PDC. There should be 12 volts

at cavities 2 and 5. If not, repair open in circuit to

relay.

²Depress horn switch. Measure resistance between

relay cavity 1 and ground. The meter should read

zero ohms. If not, repair open to horn switch ground.

²Measure resistance between relay cavity 4 and

ground. The meter should read almost zero ohms

(horn resistance) If OK, replace relay. If not, repair

open in circuit between relay and horn.

HORN

²Disconnect horn connector. Depress horn switch.

There should be 12 volts at the horn connector pin A.

If not, repair open to relay.

²Measure the resistance between the horn connec-

tor pin B and chassis ground. The meter should read

zero ohms. If not, repair open to ground.

²If above steps do not identify a problem, replace

horn.

Fig. 2 Horn Relay

Fig. 3 Horn Removal/InstallationÐYJ

8G - 2 HORNSJ

Page 388 of 1784

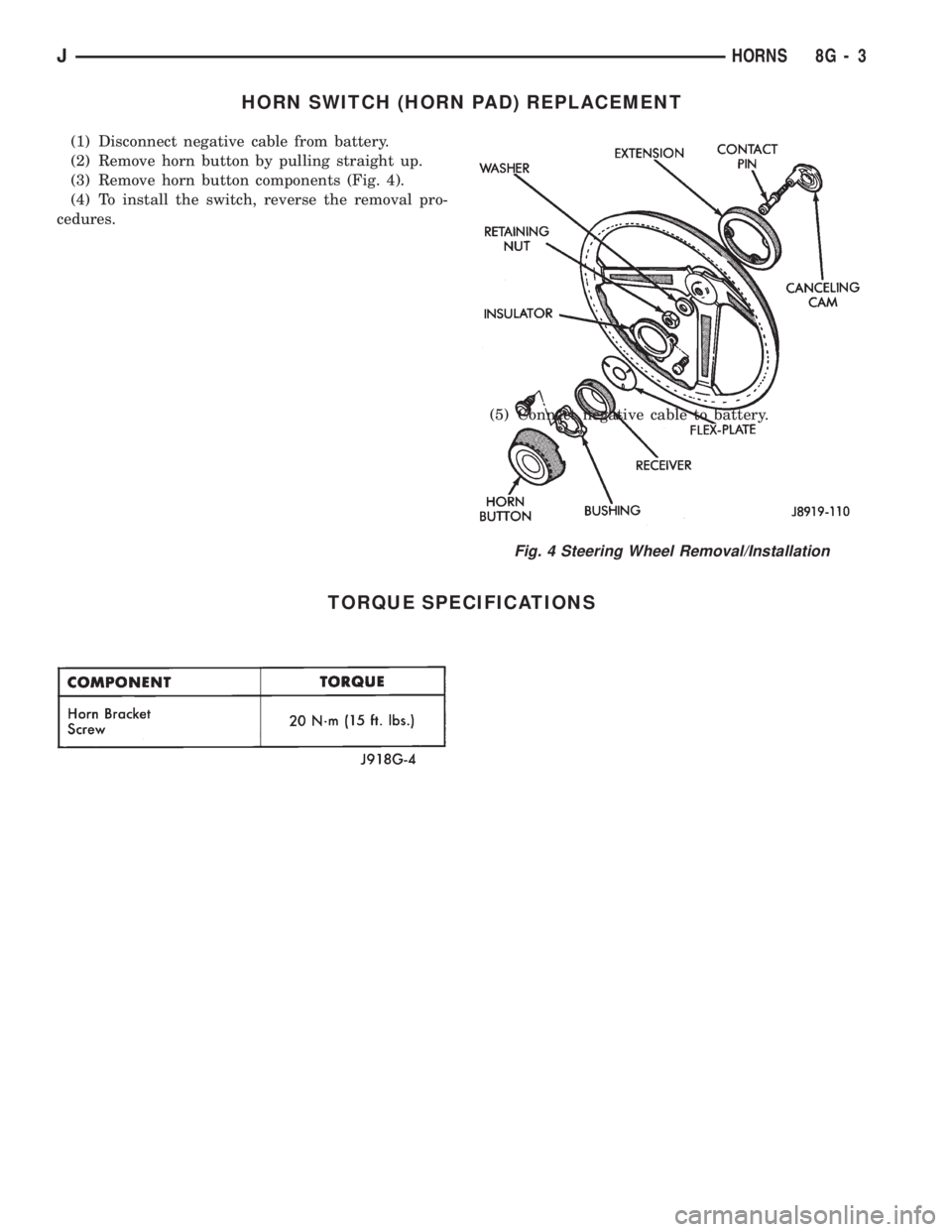

HORN SWITCH (HORN PAD) REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove horn button by pulling straight up.

(3) Remove horn button components (Fig. 4).

(4) To install the switch, reverse the removal pro-

cedures.

(5) Connect negative cable to battery.

TORQUE SPECIFICATIONS

Fig. 4 Steering Wheel Removal/Installation

JHORNS 8G - 3

Page 389 of 1784

Page 390 of 1784

VEHICLE SPEED CONTROL SYSTEM

CONTENTS

page page

SERVICE PROCEDURES................... 9TEST PROCEDURES...................... 5

GENERAL INFORMATION

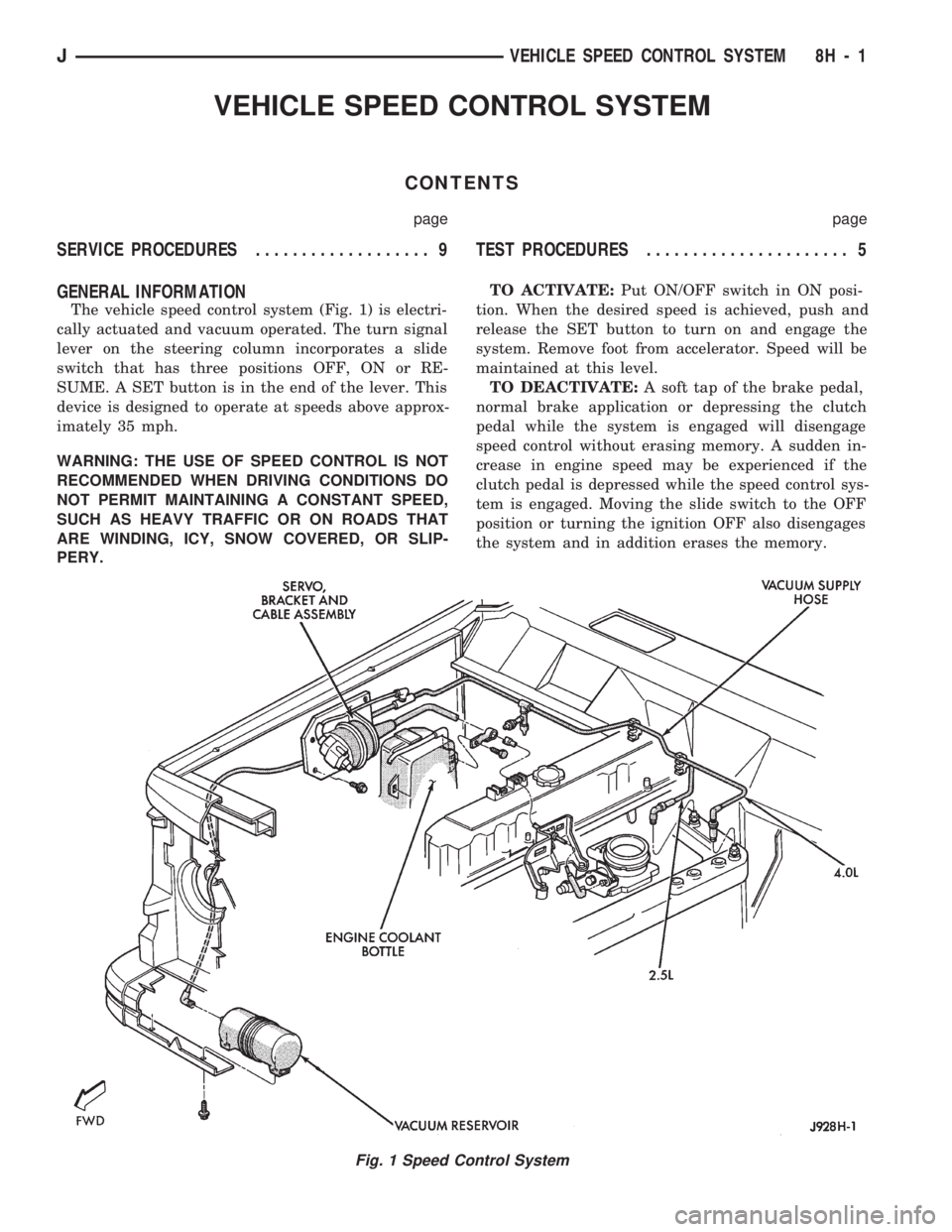

The vehicle speed control system (Fig. 1) is electri-

cally actuated and vacuum operated. The turn signal

lever on the steering column incorporates a slide

switch that has three positions OFF, ON or RE-

SUME. A SET button is in the end of the lever. This

device is designed to operate at speeds above approx-

imately 35 mph.

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.TO ACTIVATE:Put ON/OFF switch in ON posi-

tion. When the desired speed is achieved, push and

release the SET button to turn on and engage the

system. Remove foot from accelerator. Speed will be

maintained at this level.

TO DEACTIVATE:A soft tap of the brake pedal,

normal brake application or depressing the clutch

pedal while the system is engaged will disengage

speed control without erasing memory. A sudden in-

crease in engine speed may be experienced if the

clutch pedal is depressed while the speed control sys-

tem is engaged. Moving the slide switch to the OFF

position or turning the ignition OFF also disengages

the system and in addition erases the memory.

Fig. 1 Speed Control System

JVEHICLE SPEED CONTROL SYSTEM 8H - 1