JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 341 of 1784

INSTALLATION

(1) Install MAP sensor to dash panel and secure

with mounting nuts.

(2) Install the MAP sensor vacuum supply hose.

(3) Connect the MAP sensor electrical connector.

OXYGEN (O2S) SENSOR

For diagnostics and removal/installation proce-

dures, refer to Group 14, Fuel Systems, in this man-

ual.

POWERTRAIN CONTROL MODULE (PCM)

The PCM was formerly referred to as the SBEC or

engine controller.

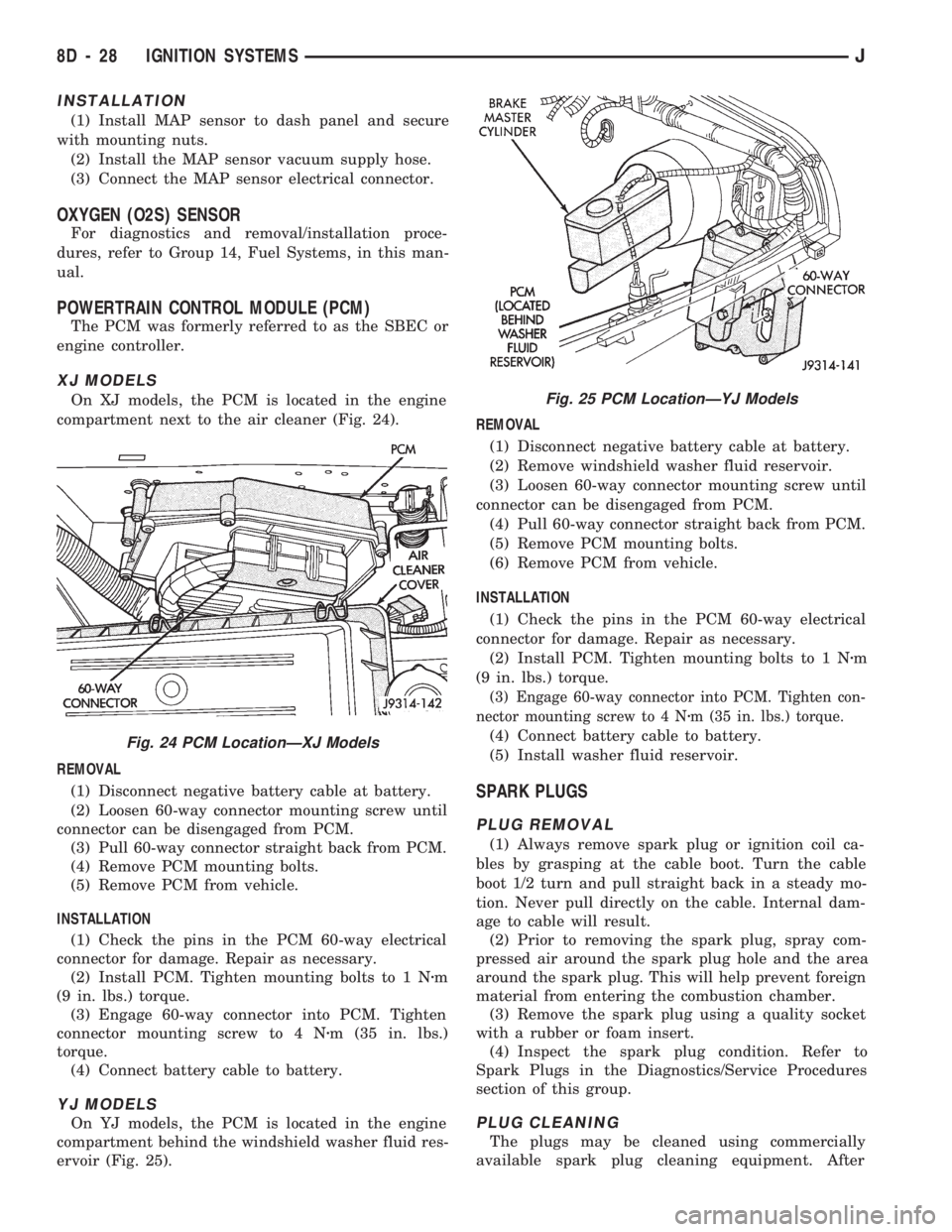

XJ MODELS

On XJ models, the PCM is located in the engine

compartment next to the air cleaner (Fig. 24).

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Loosen 60-way connector mounting screw until

connector can be disengaged from PCM.

(3) Pull 60-way connector straight back from PCM.

(4) Remove PCM mounting bolts.

(5) Remove PCM from vehicle.

INSTALLATION

(1) Check the pins in the PCM 60-way electrical

connector for damage. Repair as necessary.

(2) Install PCM. Tighten mounting bolts to 1 Nzm

(9 in. lbs.) torque.

(3) Engage 60-way connector into PCM. Tighten

connector mounting screw to 4 Nzm (35 in. lbs.)

torque.

(4) Connect battery cable to battery.

YJ MODELS

On YJ models, the PCM is located in the engine

compartment behind the windshield washer fluid res-

ervoir (Fig. 25).REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Remove windshield washer fluid reservoir.

(3) Loosen 60-way connector mounting screw until

connector can be disengaged from PCM.

(4) Pull 60-way connector straight back from PCM.

(5) Remove PCM mounting bolts.

(6) Remove PCM from vehicle.

INSTALLATION

(1) Check the pins in the PCM 60-way electrical

connector for damage. Repair as necessary.

(2) Install PCM. Tighten mounting bolts to 1 Nzm

(9 in. lbs.) torque.

(3) Engage 60-way connector into PCM. Tighten con-

nector mounting screw to 4 Nzm (35 in. lbs.) torque.

(4) Connect battery cable to battery.

(5) Install washer fluid reservoir.

SPARK PLUGS

PLUG REMOVAL

(1) Always remove spark plug or ignition coil ca-

bles by grasping at the cable boot. Turn the cable

boot 1/2 turn and pull straight back in a steady mo-

tion. Never pull directly on the cable. Internal dam-

age to cable will result.

(2) Prior to removing the spark plug, spray com-

pressed air around the spark plug hole and the area

around the spark plug. This will help prevent foreign

material from entering the combustion chamber.

(3) Remove the spark plug using a quality socket

with a rubber or foam insert.

(4) Inspect the spark plug condition. Refer to

Spark Plugs in the Diagnostics/Service Procedures

section of this group.

PLUG CLEANING

The plugs may be cleaned using commercially

available spark plug cleaning equipment. After

Fig. 24 PCM LocationÐXJ Models

Fig. 25 PCM LocationÐYJ Models

8D - 28 IGNITION SYSTEMSJ

Page 342 of 1784

cleaning, file the center electrode flat with a small

point file or jewelers file before adjusting gap.

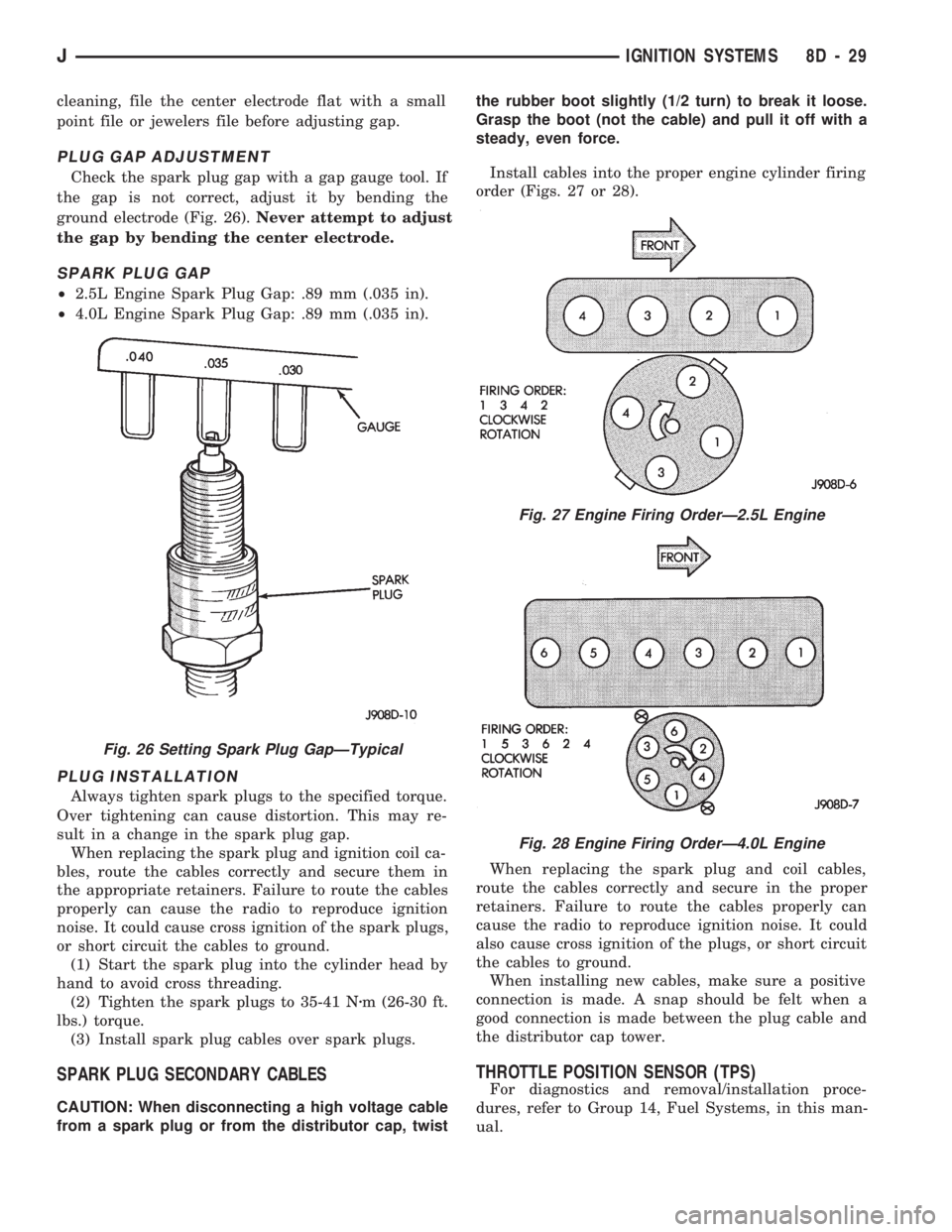

PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge tool. If

the gap is not correct, adjust it by bending the

ground electrode (Fig. 26).Never attempt to adjust

the gap by bending the center electrode.

SPARK PLUG GAP

²2.5L Engine Spark Plug Gap: .89 mm (.035 in).

²4.0L Engine Spark Plug Gap: .89 mm (.035 in).

PLUG INSTALLATION

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion. This may re-

sult in a change in the spark plug gap.

When replacing the spark plug and ignition coil ca-

bles, route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition

noise. It could cause cross ignition of the spark plugs,

or short circuit the cables to ground.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading.

(2) Tighten the spark plugs to 35-41 Nzm (26-30 ft.

lbs.) torque.

(3) Install spark plug cables over spark plugs.

SPARK PLUG SECONDARY CABLES

CAUTION: When disconnecting a high voltage cable

from a spark plug or from the distributor cap, twistthe rubber boot slightly (1/2 turn) to break it loose.

Grasp the boot (not the cable) and pull it off with a

steady, even force.

Install cables into the proper engine cylinder firing

order (Figs. 27 or 28).

When replacing the spark plug and coil cables,

route the cables correctly and secure in the proper

retainers. Failure to route the cables properly can

cause the radio to reproduce ignition noise. It could

also cause cross ignition of the plugs, or short circuit

the cables to ground.

When installing new cables, make sure a positive

connection is made. A snap should be felt when a

good connection is made between the plug cable and

the distributor cap tower.

THROTTLE POSITION SENSOR (TPS)

For diagnostics and removal/installation proce-

dures, refer to Group 14, Fuel Systems, in this man-

ual.

Fig. 26 Setting Spark Plug GapÐTypical

Fig. 27 Engine Firing OrderÐ2.5L Engine

Fig. 28 Engine Firing OrderÐ4.0L Engine

JIGNITION SYSTEMS 8D - 29

Page 343 of 1784

IGNITION SWITCH

INDEX

page page

General Information....................... 30

Ignition Switch Installation/Adjustment......... 31Ignition Switch Removal................... 30

Ignition Switch Testing..................... 30

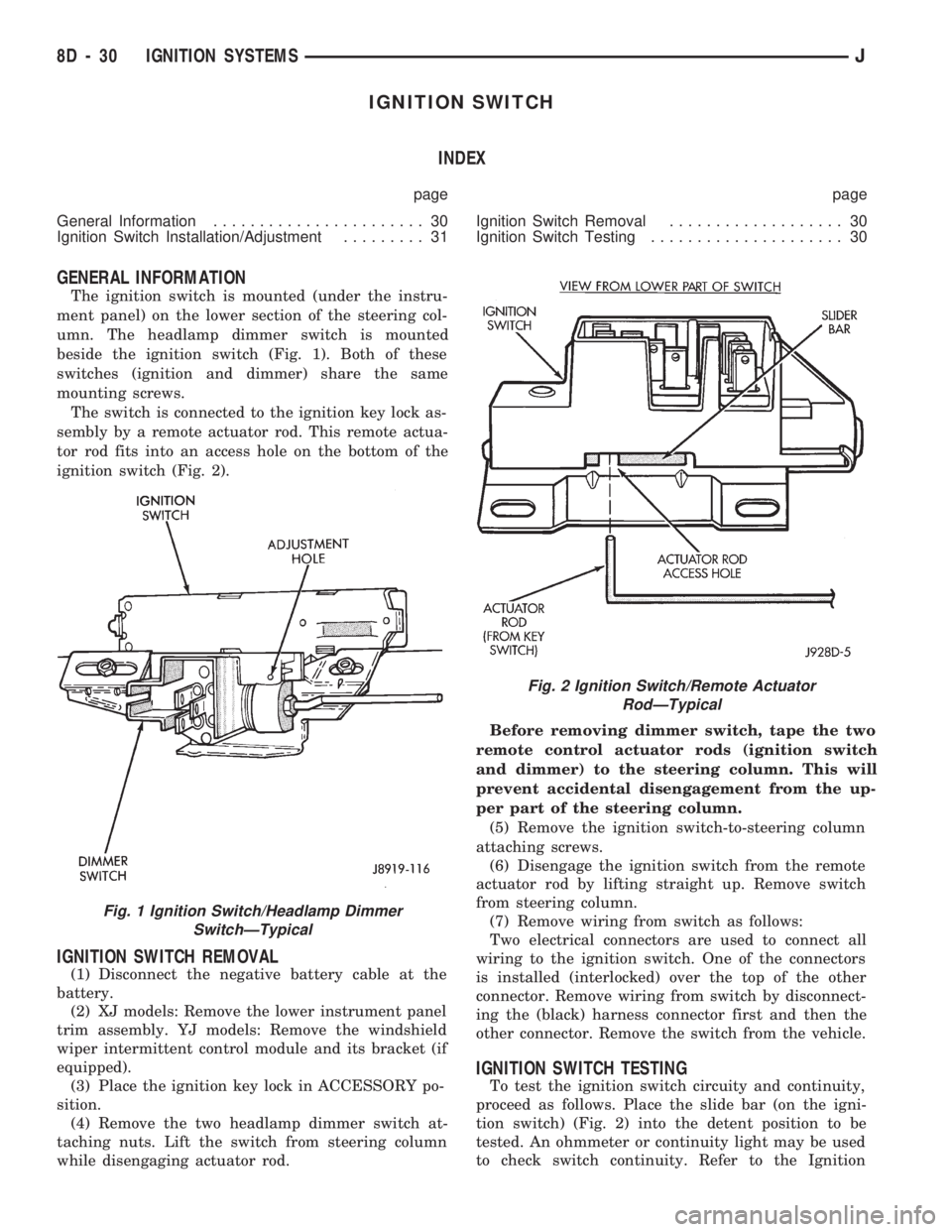

GENERAL INFORMATION

The ignition switch is mounted (under the instru-

ment panel) on the lower section of the steering col-

umn. The headlamp dimmer switch is mounted

beside the ignition switch (Fig. 1). Both of these

switches (ignition and dimmer) share the same

mounting screws.

The switch is connected to the ignition key lock as-

sembly by a remote actuator rod. This remote actua-

tor rod fits into an access hole on the bottom of the

ignition switch (Fig. 2).

IGNITION SWITCH REMOVAL

(1) Disconnect the negative battery cable at the

battery.

(2) XJ models: Remove the lower instrument panel

trim assembly. YJ models: Remove the windshield

wiper intermittent control module and its bracket (if

equipped).

(3) Place the ignition key lock in ACCESSORY po-

sition.

(4) Remove the two headlamp dimmer switch at-

taching nuts. Lift the switch from steering column

while disengaging actuator rod.Before removing dimmer switch, tape the two

remote control actuator rods (ignition switch

and dimmer) to the steering column. This will

prevent accidental disengagement from the up-

per part of the steering column.

(5) Remove the ignition switch-to-steering column

attaching screws.

(6) Disengage the ignition switch from the remote

actuator rod by lifting straight up. Remove switch

from steering column.

(7) Remove wiring from switch as follows:

Two electrical connectors are used to connect all

wiring to the ignition switch. One of the connectors

is installed (interlocked) over the top of the other

connector. Remove wiring from switch by disconnect-

ing the (black) harness connector first and then the

other connector. Remove the switch from the vehicle.

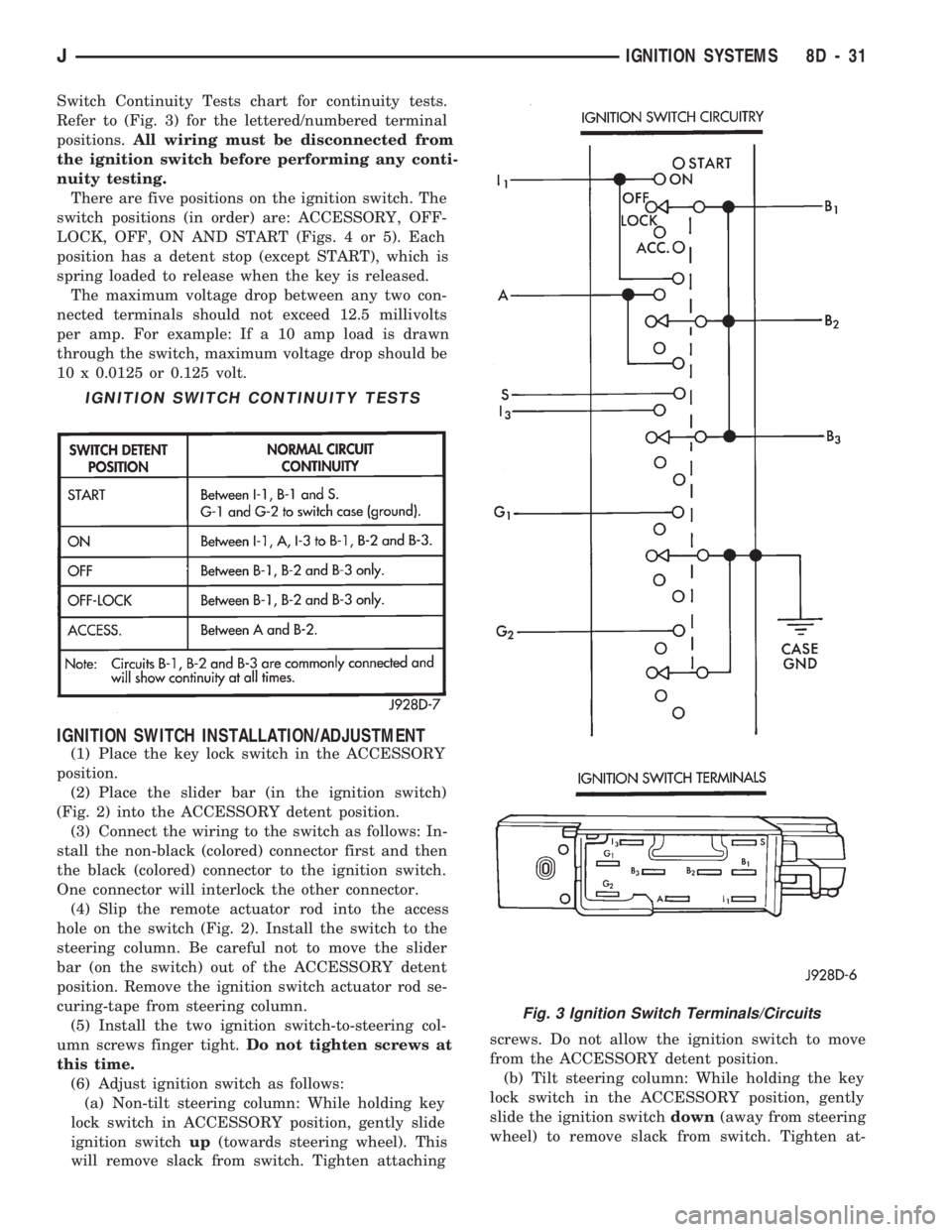

IGNITION SWITCH TESTING

To test the ignition switch circuity and continuity,

proceed as follows. Place the slide bar (on the igni-

tion switch) (Fig. 2) into the detent position to be

tested. An ohmmeter or continuity light may be used

to check switch continuity. Refer to the Ignition

Fig. 1 Ignition Switch/Headlamp Dimmer

SwitchÐTypical

Fig. 2 Ignition Switch/Remote Actuator

RodÐTypical

8D - 30 IGNITION SYSTEMSJ

Page 344 of 1784

Switch Continuity Tests chart for continuity tests.

Refer to (Fig. 3) for the lettered/numbered terminal

positions.All wiring must be disconnected from

the ignition switch before performing any conti-

nuity testing.

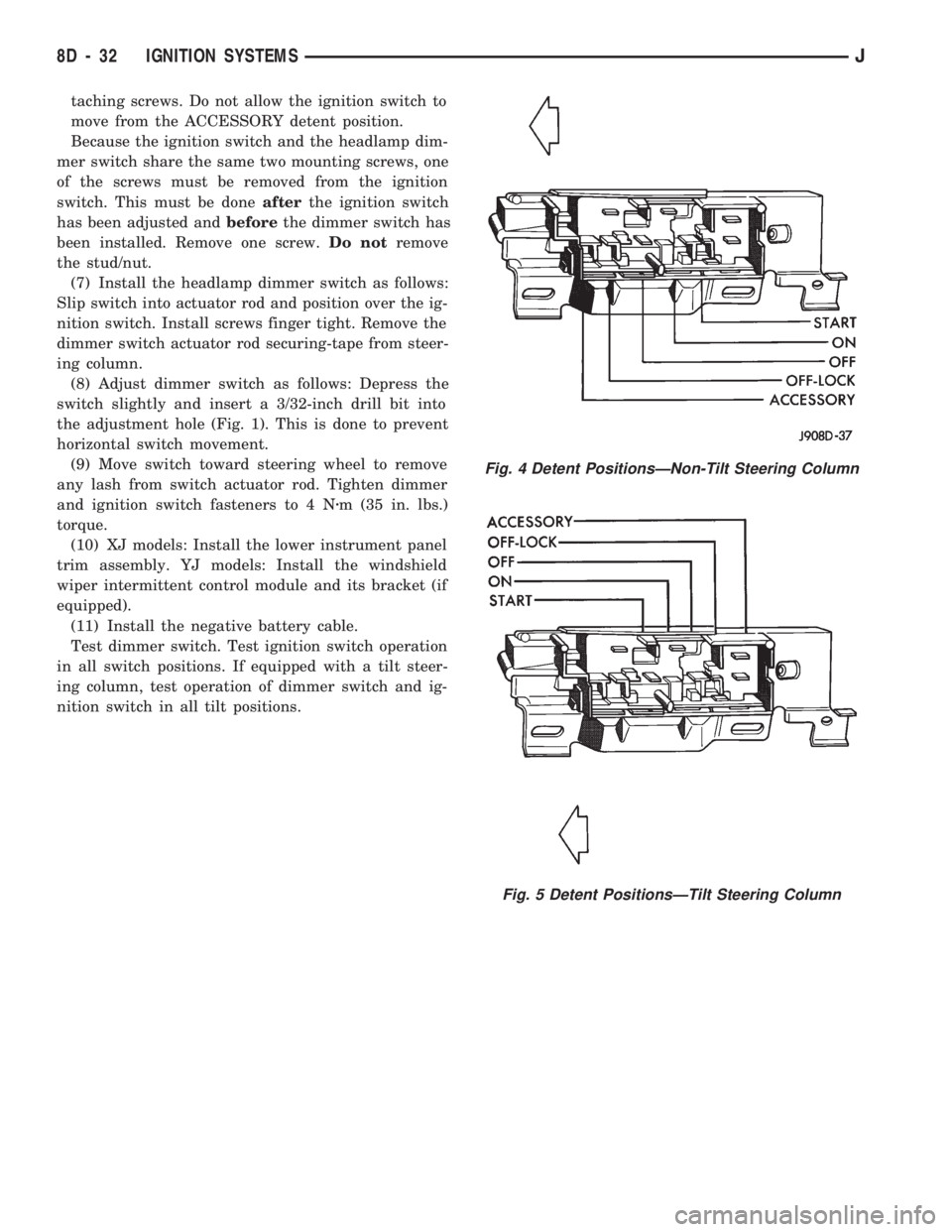

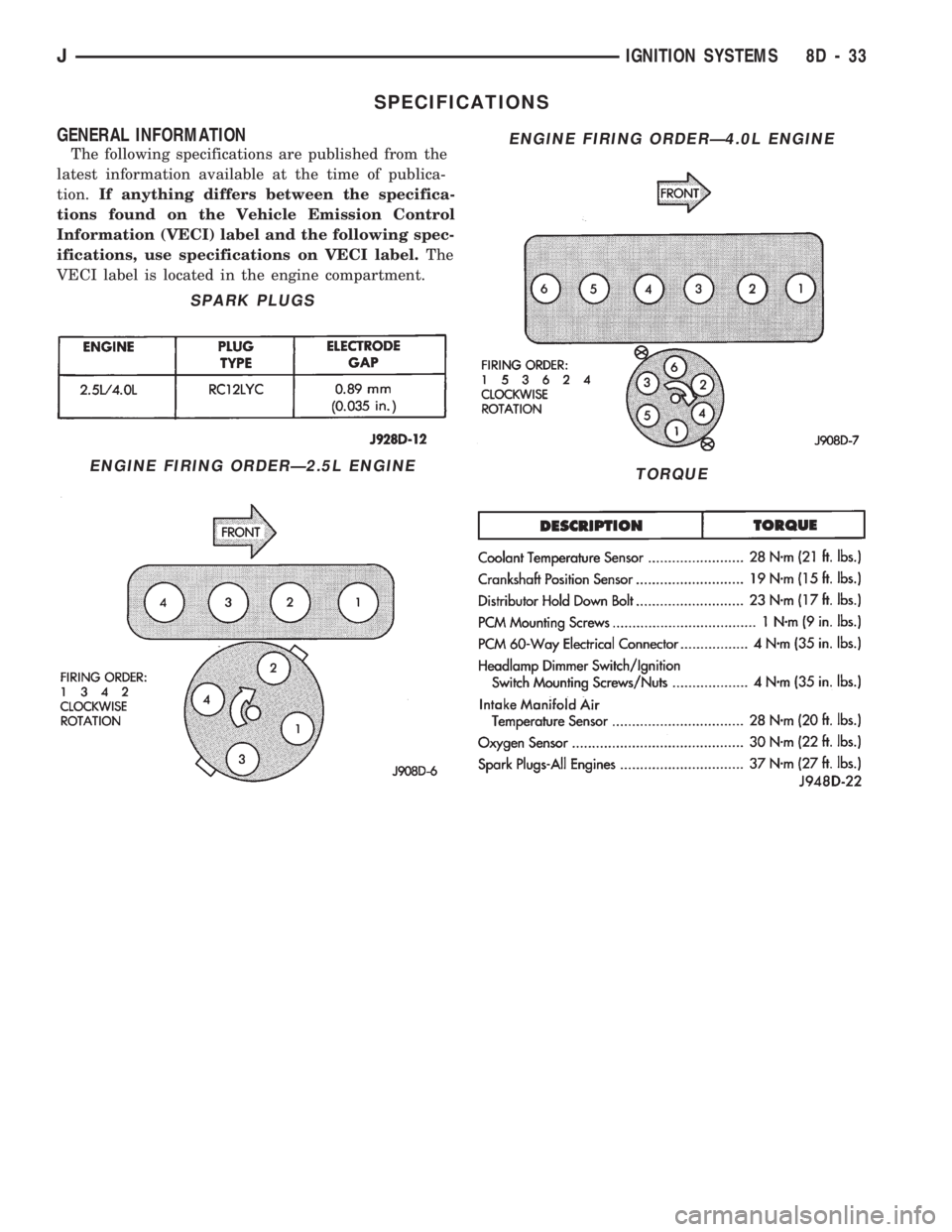

There are five positions on the ignition switch. The

switch positions (in order) are: ACCESSORY, OFF-

LOCK, OFF, ON AND START (Figs. 4 or 5). Each

position has a detent stop (except START), which is

spring loaded to release when the key is released.

The maximum voltage drop between any two con-

nected terminals should not exceed 12.5 millivolts

per amp. For example: If a 10 amp load is drawn

through the switch, maximum voltage drop should be

10 x 0.0125 or 0.125 volt.

IGNITION SWITCH INSTALLATION/ADJUSTMENT

(1) Place the key lock switch in the ACCESSORY

position.

(2) Place the slider bar (in the ignition switch)

(Fig. 2) into the ACCESSORY detent position.

(3) Connect the wiring to the switch as follows: In-

stall the non-black (colored) connector first and then

the black (colored) connector to the ignition switch.

One connector will interlock the other connector.

(4) Slip the remote actuator rod into the access

hole on the switch (Fig. 2). Install the switch to the

steering column. Be careful not to move the slider

bar (on the switch) out of the ACCESSORY detent

position. Remove the ignition switch actuator rod se-

curing-tape from steering column.

(5) Install the two ignition switch-to-steering col-

umn screws finger tight.Do not tighten screws at

this time.

(6) Adjust ignition switch as follows:

(a) Non-tilt steering column: While holding key

lock switch in ACCESSORY position, gently slide

ignition switchup(towards steering wheel). This

will remove slack from switch. Tighten attachingscrews. Do not allow the ignition switch to move

from the ACCESSORY detent position.

(b) Tilt steering column: While holding the key

lock switch in the ACCESSORY position, gently

slide the ignition switchdown(away from steering

wheel) to remove slack from switch. Tighten at-

IGNITION SWITCH CONTINUITY TESTS

Fig. 3 Ignition Switch Terminals/Circuits

JIGNITION SYSTEMS 8D - 31

Page 345 of 1784

taching screws. Do not allow the ignition switch to

move from the ACCESSORY detent position.

Because the ignition switch and the headlamp dim-

mer switch share the same two mounting screws, one

of the screws must be removed from the ignition

switch. This must be doneafterthe ignition switch

has been adjusted andbeforethe dimmer switch has

been installed. Remove one screw.Do notremove

the stud/nut.

(7) Install the headlamp dimmer switch as follows:

Slip switch into actuator rod and position over the ig-

nition switch. Install screws finger tight. Remove the

dimmer switch actuator rod securing-tape from steer-

ing column.

(8) Adjust dimmer switch as follows: Depress the

switch slightly and insert a 3/32-inch drill bit into

the adjustment hole (Fig. 1). This is done to prevent

horizontal switch movement.

(9) Move switch toward steering wheel to remove

any lash from switch actuator rod. Tighten dimmer

and ignition switch fasteners to 4 Nzm (35 in. lbs.)

torque.

(10) XJ models: Install the lower instrument panel

trim assembly. YJ models: Install the windshield

wiper intermittent control module and its bracket (if

equipped).

(11) Install the negative battery cable.

Test dimmer switch. Test ignition switch operation

in all switch positions. If equipped with a tilt steer-

ing column, test operation of dimmer switch and ig-

nition switch in all tilt positions.

Fig. 4 Detent PositionsÐNon-Tilt Steering Column

Fig. 5 Detent PositionsÐTilt Steering Column

8D - 32 IGNITION SYSTEMSJ

Page 346 of 1784

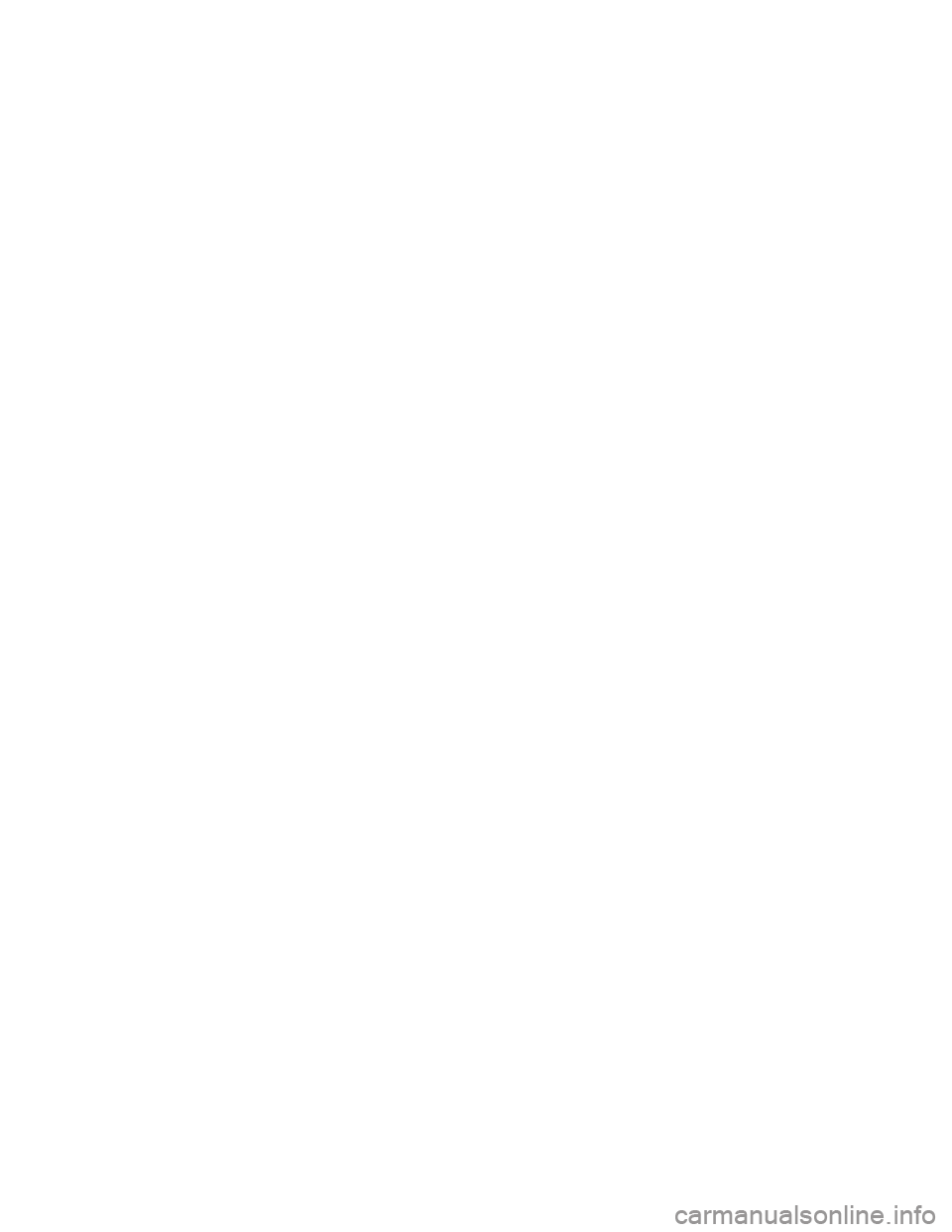

SPECIFICATIONS

GENERAL INFORMATION

The following specifications are published from the

latest information available at the time of publica-

tion.If anything differs between the specifica-

tions found on the Vehicle Emission Control

Information (VECI) label and the following spec-

ifications, use specifications on VECI label.The

VECI label is located in the engine compartment.

SPARK PLUGS

ENGINE FIRING ORDERÐ2.5L ENGINE

ENGINE FIRING ORDERÐ4.0L ENGINE

TORQUE

JIGNITION SYSTEMS 8D - 33

Page 347 of 1784

Page 348 of 1784

INSTRUMENT PANEL AND GAUGES

GROUP INDEX

page page

INSTRUMENT PANEL AND GAUGESÐXJ..... 1INSTRUMENT PANEL AND GAUGESÐYJ.... 14

INSTRUMENT PANEL AND GAUGESÐXJE

CONTENTS

page page

INSTRUMENT CLUSTER DIAGNOSIS........ 3

INSTRUMENT CLUSTER GENERAL INFORMATION.. 1

INSTRUMENT CLUSTER SERVICE PROCEDURES... 5

SPECIFICATIONS....................... 13

INSTRUMENT CLUSTER GENERAL INFORMATION

INDEX

page page

4WD Indicator Lamp........................ 2

Anti-Lock Brake Indicator Lamp............... 2

Brake Indicator Lamp....................... 2

Coolant Temperature Gauge................. 1

Coolant Temperature Indicator Lamp........... 1

Fuel Gauge.............................. 2

Low Fuel Warning Lamp..................... 2Malfunction Indicator Lamp (Check Engine)...... 2

Oil Pressure Gauge....................... 1

Oil Pressure Indicator Lamp.................. 1

Speedometer/Odometer System.............. 2

Tachometer.............................. 2

Upshift Indicator Lamp...................... 2

Voltmeter............................... 1

With the ignition switch in the ON or START posi-

tion, voltage supplied to the instrument cluster is lim-

ited by fuse #17. The voltage is supplied to all the

gauges and indicator lamps through the instrument

cluster printed circuit.

With the ignition switch in the OFF position, volt-

age is not supplied to the instrument cluster and the

gauges do not indicate any vehicle condition.

VOLTMETER

The voltmeter measures battery or generator out-

put voltage, whichever is greater.

OIL PRESSURE GAUGE

The oil pressure gauge pointer position is controlled

by a magnetic field created by electrical current flow

through the coils within the gauge. A change in current

flow will change the magnetic field which changes the

pointer position. The oil pressure sender is a variable

resistor that changes electrical resistance with a change

in oil pressure (values shown in Specifications chart).

OIL PRESSURE INDICATOR LAMP

Voltage is supplied to one side of the indicator bulb

and the oil pressure switch is connected to the other

side. When oil pressure is too low the switch closes

providing a path to ground, and the indicator bulb

lights.

COOLANT TEMPERATURE GAUGE

The coolant temperature gauge pointer position is

controlled by a magnetic field created by electrical

current flow through the coils within the gauge. A

change in current flow will change the magnetic field

which changes the pointer position. The coolant tem-

perature sensor is a thermistor that changes electri-

cal resistance with a change in coolant temperature

(values shown in Specifications chart).

COOLANT TEMPERATURE INDICATOR LAMP

Voltage is supplied to one side of the indicator bulb

and the coolant temperature switch is connected to the

JINSTRUMENT PANEL AND GAUGES 8E - 1

Page 349 of 1784

other side. When coolant temperature is too high the

switch closes providing a path to ground, and the indi-

cator bulb lights.

TACHOMETER

The tachometer displays the engine speed (RPM).

With the engine running, the tachometer receives an

engine speed signal from the Powertrain Control

Module pin 43 (values shown in Specifications chart).

SPEEDOMETER/ODOMETER SYSTEM

The speedometer/odometer system consists of an elec-

tric speedometer and pushbutton reset odometer

mounted in the cluster. The system also includes the

wire harness from the cluster to the vehicle speed sen-

sor at the transmission, and the adapter and pinion in

the transmission. A signal is sent from a transmission

mounted vehicle speed sensor to the speedometer/odom-

eter circuitry through the wiring harness. Refer to

Group 21 - Transmission for selecting the proper pinion,

and selecting and indexing the proper adapter.

FUEL GAUGE

The fuel gauge pointer position is controlled by a

magnetic field created by electrical current flow through

the coils within the gauge. A change in current flow will

change the magnetic field which changes the pointer po-

sition. The fuel level sender is a variable resistor that

changes electrical resistance with a change of the level

of fuel in the tank (values shown in Specifications

chart).

LOW FUEL WARNING LAMP

The low fuel warning lamp will light when the fuel

level falls below approximately 4 gallons. A low fuel

warning module controls when the lamp will light.

When the module senses 66.5 ohms or less from the

fuel level sender for 10 continuous seconds, the lamp

will light. The lamp will remain on until the module

senses 63.5 ohms or more from the fuel level sender

for 20 continuous seconds.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have an

optional upshift indicator lamp. The lamp is controlled

by the Powertrain Control Module. The lamp lights to

indicate when the driver should shift to the next high-

est gear for best fuel economy. The Powertrain Control

Module will turn the lamp off after 3 to 5 seconds if the

upshift is not performed. The lamp will remain off until

the vehicle stops accelerating and is brought back to the

range of lamp operation or shifted into another gear.

The indicator lamp is normally illuminated when

the ignition switch is turned ON and is turned off

when the engine is started. The lamp will be lighted

during engine operation according to engine speed

and load.

BRAKE INDICATOR LAMP

The brake indicator lamp warns the driver that the

parking brake is applied or that hydraulic pressure in

the split brake system is unequal.

Voltage is supplied through the brake indicator

bulb to 3 switches. A path to ground for the current

is available if:

²The brake warning switch is closed (with unequal

brake system hydraulic pressures), or

²

The ignition switch is in the START position (to test

the bulb), or

²The park brake switch is closed (with the parking

brake applied).

ANTI-LOCK BRAKE SYSTEM (ABS) INDICATOR

LAMP

The anti-lock brake system (ABS) lamp lights to in-

dicate a system self-check is in process at vehicle

start-up. If light remains on after start-up or comes

on and stays on while driving, it may indicate that

the ABS system has detected a malfunction or has

become inoperative.

4WD INDICATOR LAMP

COMMAND-TRAC 4WD

The PART TIME lamp lights when the vehicle is en-

gaged in four-wheel drive mode. Voltage is supplied to

one side of the indicator bulb. A switch in the transfer

case area is connected to the other side of the indicator

bulb. When the switch is closed, a path to ground is pro-

vided and the indicator bulb lights.

SELECT-TRAC 4WD

The four-wheel drive icon or FULL TIME lamp

lights when the vehicle is engaged in full time four-

wheel drive mode. The PART TIME lamp lights when

the vehicle is in part time four-wheel drive mode.

Voltage is supplied to one side of the indicators.

Switches in the transfer case area are connected to

the other side of the indicator bulbs. When a switch

is closed, a path to ground is provided and the indi-

cator bulb lights.

MALFUNCTION INDICATOR LAMP (CHECK ENGINE)

The Malfunction Indicator Lamp (Check Engine)

lights each time the ignition switch is turned ON and

stays on for 3 seconds as a bulb test.

If the PCM receives an incorrect signal or no signal

from certain sensors or emission related systems the

lamp is turned on (pin 32 of PCM). This is a warning

that the PCM has recorded a system or sensor mal-

function. In some cases when a diagnostic trouble

code is declared the PCM will go into a limp-in mode

in an attempt to keep the system operating. It sig-

nals an immediate need for service.

The lamp also can be used to display diagnostic

trouble codes (DTC). Cycle the ignition switch ON,

OFF, ON, OFF, ON within 5 seconds. This will allow

any trouble codes stored in the PCM memory to be

displayed in a series of flashes representing digits.

8E - 2 XJ INSTRUMENT PANEL AND GAUGESJ

Page 350 of 1784

INSTRUMENT CLUSTER DIAGNOSIS

INDEX

page page

4WD Indicator Inoperative................... 4

Anti-Lock Indicator......................... 4

Brake Indicator Inoperative.................. 4

Coolant Temperature Gauge Inoperative........ 3

Coolant Temperature Indicator Inoperative....... 3

Fuel Gauge Inoperative..................... 3

Gauges and Indicators Inoperative............ 3

Instrument Panel Lamps.................... 4

Low Fuel Warning Inoperative................ 4

Low Washer Indicator Inoperative............. 4Malfunction Indicator Lamp (Check Engine)...... 4

Oil Pressure Gauge Inoperative............... 3

Oil Pressure Indicator Inoperative............. 3

Radio/Clock Illumination.................... 4

Seat Belt Indicator........................ 4

Speedomete/Odometer Inoperative............. 3

Tachometer Inoperative..................... 3

Upshift Indicator Inoperative................. 4

Voltmeter Inoperative....................... 3

SPEEDOMETER/ODOMETER INOPERATIVE

(1) Check for continuity in the wire between the

vehicle speed sensor and cluster connector pin A5.

(2) With the ignition switch in the ON position,

check for battery voltage across pin A8 (B+) and pin

B2 (ground).

(3) Perform vehicle speed sensor test. Refer to the

appropriate vehicle Diagnostic Test Procedures man-

ual.

(4) If all the previous tests prove good, replace

speedometer/odometer.

GAUGES AND INDICATORS INOPERATIVE

(1) Remove and inspect fuse #17. Replace as re-

quired.

(2) Measure resistance at instrument cluster con-

nector terminal A3. Meter should read zero ohms. If

not, repair open to ground.

VOLTMETER INOPERATIVE

(1) Turn ignition switch to ON. Voltmeter should

read battery voltage. If not, go to step 2.

(2) Measure voltage at instrument cluster connec-

tor terminal A8. Meter should read battery voltage.

If OK, replace meter. If not, repair open to fuse #17.

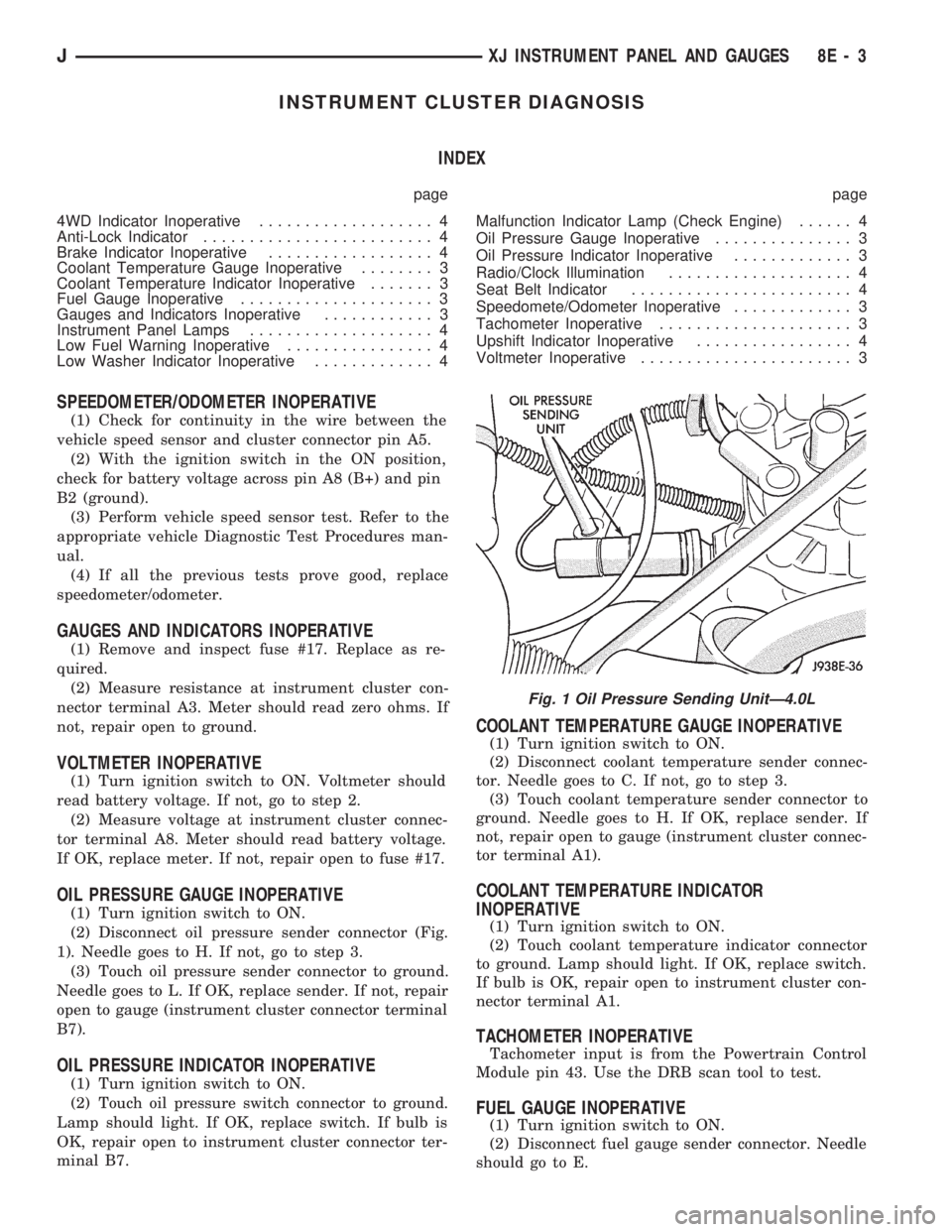

OIL PRESSURE GAUGE INOPERATIVE

(1) Turn ignition switch to ON.

(2) Disconnect oil pressure sender connector (Fig.

1). Needle goes to H. If not, go to step 3.

(3) Touch oil pressure sender connector to ground.

Needle goes to L. If OK, replace sender. If not, repair

open to gauge (instrument cluster connector terminal

B7).

OIL PRESSURE INDICATOR INOPERATIVE

(1) Turn ignition switch to ON.

(2) Touch oil pressure switch connector to ground.

Lamp should light. If OK, replace switch. If bulb is

OK, repair open to instrument cluster connector ter-

minal B7.

COOLANT TEMPERATURE GAUGE INOPERATIVE

(1) Turn ignition switch to ON.

(2) Disconnect coolant temperature sender connec-

tor. Needle goes to C. If not, go to step 3.

(3) Touch coolant temperature sender connector to

ground. Needle goes to H. If OK, replace sender. If

not, repair open to gauge (instrument cluster connec-

tor terminal A1).

COOLANT TEMPERATURE INDICATOR

INOPERATIVE

(1) Turn ignition switch to ON.

(2) Touch coolant temperature indicator connector

to ground. Lamp should light. If OK, replace switch.

If bulb is OK, repair open to instrument cluster con-

nector terminal A1.

TACHOMETER INOPERATIVE

Tachometer input is from the Powertrain Control

Module pin 43. Use the DRB scan tool to test.

FUEL GAUGE INOPERATIVE

(1) Turn ignition switch to ON.

(2) Disconnect fuel gauge sender connector. Needle

should go to E.

Fig. 1 Oil Pressure Sending UnitÐ4.0L

JXJ INSTRUMENT PANEL AND GAUGES 8E - 3