JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 361 of 1784

INSTRUMENT PANEL AND GAUGESÐYJE

CONTENTS

page page

GAUGE PACKAGE DIAGNOSIS............ 22

GAUGE PACKAGE GENERAL INFORMATION . 22

GAUGE PACKAGE SERVICE PROCEDURES . . 24

INSTRUMENT CLUSTER DIAGNOSIS....... 14INSTRUMENT CLUSTER GENERAL INFORMATION.14

INSTRUMENT CLUSTER SERVICE PROCEDURES.. 17

SPECIFICATIONS....................... 27

INSTRUMENT CLUSTER GENERAL INFORMATION

SPEEDOMETER/ODOMETER SYSTEM

The speedometer/odometer system consists of an

electric speedometer and pushbutton reset odometer

mounted in the cluster. The system also includes the

wire harness from the cluster to the vehicle speed

sensor at the transmission, and the adapter and pin-

ion in the transmission. A signal is sent from a

transmission mounted vehicle speed sensor to the

speedometer/odometer circuitry through the wiring

harness. Refer to Group 21 - Transmission for select-

ing the proper pinion, and selecting and indexing the

proper adapter.

TACHOMETER

The tachometer displays the engine speed (RPM).

With the engine running, the tachometer receives anengine speed signal from the Powertrain Control

Module pin 43 (values shown in Specifications chart).

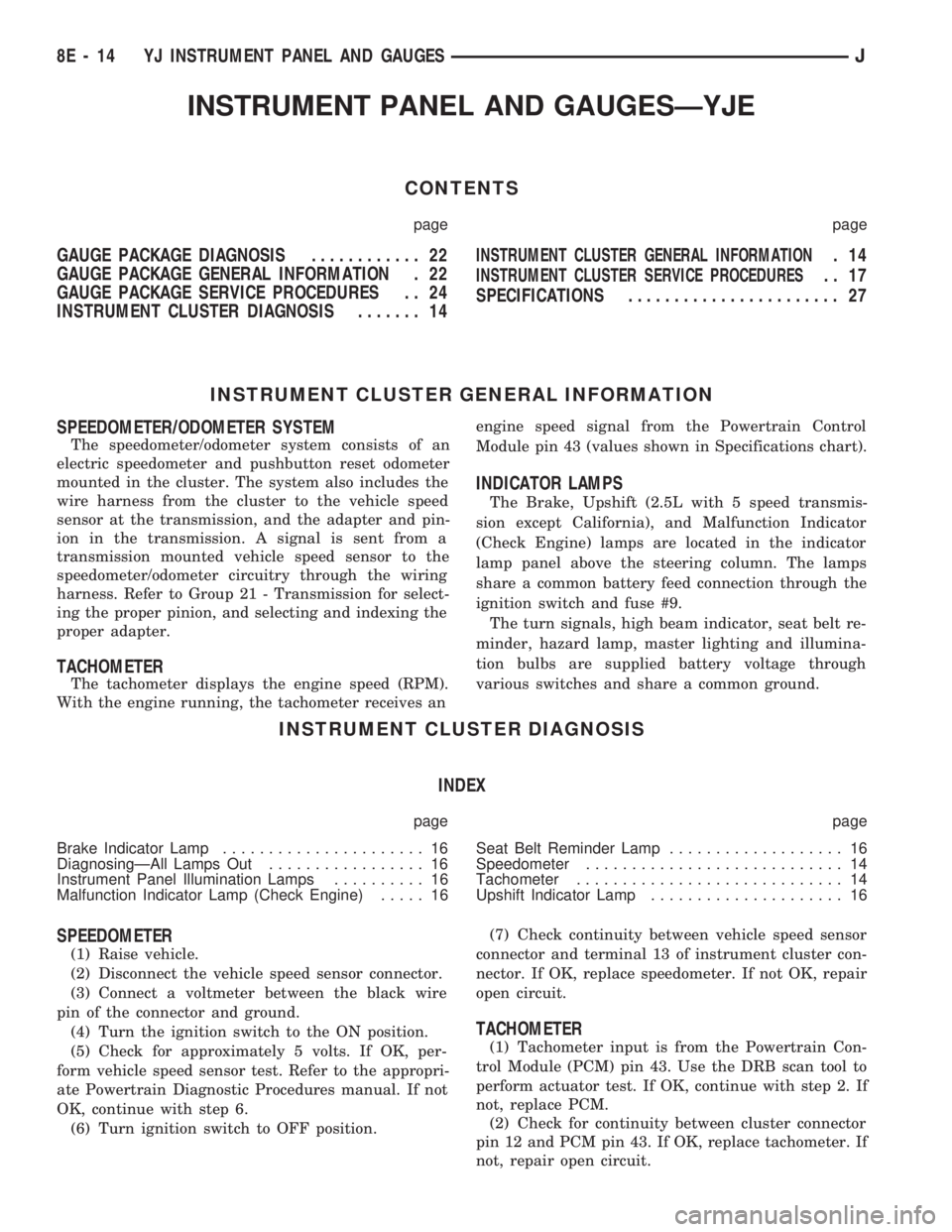

INDICATOR LAMPS

The Brake, Upshift (2.5L with 5 speed transmis-

sion except California), and Malfunction Indicator

(Check Engine) lamps are located in the indicator

lamp panel above the steering column. The lamps

share a common battery feed connection through the

ignition switch and fuse #9.

The turn signals, high beam indicator, seat belt re-

minder, hazard lamp, master lighting and illumina-

tion bulbs are supplied battery voltage through

various switches and share a common ground.

INSTRUMENT CLUSTER DIAGNOSIS

INDEX

page page

Brake Indicator Lamp...................... 16

DiagnosingÐAll Lamps Out................. 16

Instrument Panel Illumination Lamps.......... 16

Malfunction Indicator Lamp (Check Engine)..... 16Seat Belt Reminder Lamp................... 16

Speedometer............................ 14

Tachometer............................. 14

Upshift Indicator Lamp..................... 16

SPEEDOMETER

(1) Raise vehicle.

(2) Disconnect the vehicle speed sensor connector.

(3) Connect a voltmeter between the black wire

pin of the connector and ground.

(4) Turn the ignition switch to the ON position.

(5) Check for approximately 5 volts. If OK, per-

form vehicle speed sensor test. Refer to the appropri-

ate Powertrain Diagnostic Procedures manual. If not

OK, continue with step 6.

(6) Turn ignition switch to OFF position.(7) Check continuity between vehicle speed sensor

connector and terminal 13 of instrument cluster con-

nector. If OK, replace speedometer. If not OK, repair

open circuit.

TACHOMETER

(1) Tachometer input is from the Powertrain Con-

trol Module (PCM) pin 43. Use the DRB scan tool to

perform actuator test. If OK, continue with step 2. If

not, replace PCM.

(2) Check for continuity between cluster connector

pin 12 and PCM pin 43. If OK, replace tachometer. If

not, repair open circuit.

8E - 14 YJ INSTRUMENT PANEL AND GAUGESJ

Page 362 of 1784

INSTRUMENT CLUSTER

JYJ INSTRUMENT PANEL AND GAUGES 8E - 15

Page 363 of 1784

DIAGNOSINGÐALL LAMPS OUT

(1) Inspect fuse #9. Replace as required.

(2) Measure voltage at instrument cluster connec-

tor terminal 20. Meter should read zero ohms. If not,

repair open to ground.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have

an optional upshift indicator lamp. The lamp is con-

trolled by the PCM. The lamp lights to indicate when

the driver should shift to the next highest gear for best

fuel economy. The PCM will turn the lamp off after 3 to

5 seconds if the upshift is not performed. The lamp will

remain off until the vehicle stops accelerating and is

brought back to the range of lamp operation or shifted

into another gear.

The indicator lamp is normally illuminated when

the ignition switch is turned ON and it is turned off

when the engine is started. The lamp will be lighted

during engine operation according to engine speed

and load.

(1) Turn ignition switch to ON.

(2) Ground pin 2 of cluster connector. Lamp should

light. If not, replace bulb. If OK, continue with step 3.

(3) Turn ignition switch to OFF. Check for conti-

nuity between cluster connector pin 2 and pin 54 of

the PCM. If not, repair open. If OK, refer to DRB

scan tool actuator test of upshift indicator.

BRAKE INDICATOR LAMP

The brake indicator is a dual function lamp. It will in-

dicate an unequal pressure condition in the split brake

hydraulic system and it also will indicate when the park-

ing brake is engaged. Separate switches are used for each

indicator lamp function. A switch mounted on the brake

pedal assembly will close a ground circuit whenever the

parking brakes are applied. A second switch is installed

in the brake hydraulic lines near the master cylinder. If

the switch is balanced by equal pressure on both ends of

the switch valve, the valve remains centered and the

lamp remains off. If the valve is shifted by unequal pres-

sure between the front or rear brake hydraulic systems,

the lamp circuit is connected to ground. To make sure

the brake lamp is functional before the vehicle is driven,

it is illuminated through a ground circuit when the igni-

tion switch is turned to the START position.

(1) Turn ignition switch to ON.

(2) Ground pin 1 of the cluster connector. Lamp

should light. If not, replace bulb. If OK, continue

with step 3.

(3) Turn ignition switch to OFF. Check for continuity to

park brake switch and brake warning switch.

MALFUNCTION INDICATOR LAMP (CHECK ENGINE)

The Malfunction Indicator Lamp (Check Engine) il-

luminates each time the ignition switch is turned

ON and stays on for 3 seconds as a bulb test.If the PCM receives an incorrect signal or no signal

from certain sensors or emission related systems the

lamp is turned on (pin 32 of PCM). This is a warning

that the PCM has recorded a system or sensor mal-

function. In some cases when a diagnostic fault is de-

clared the PCM will go into a limp-in mode in an

attempt to keep the system operating. It signals an

immediate need for service.

The lamp also can be used to display diagnostic

trouble codes (DTC). Cycle the ignition switch ON,

OFF, ON, OFF, ON within 5 seconds. This will allow

any DTC's stored in the PCM memory to be dis-

played in a series of flashes representing digits.

(1) Turn ignition switch to ON.

(2) Ground pin 4 of cluster connector. Lamp should

light. If not, replace bulb. If OK, continue with step 3.

(3) Turn ignition switch to OFF. Check for conti-

nuity between cluster connector pin 4 and PCM cav-

ity 32. If OK, replace PCM. If not, repair open.

SEAT BELT REMINDER LAMP

Apply 12 volts to terminal 16 of cluster connector.

Lamp should light. If not, replace bulb. If OK, check

wiring for an open to buzzer module. Refer to Group

8U - Chime/Buzzer Warning Systems.

INSTRUMENT PANEL ILLUMINATION LAMPS

The instrument panel illumination lamps share

two common connections. There is a splice after fuse

#10 that connects the lamps to battery feed. There is

also a splice that connects all lamps to ground. Be-

cause they share these common connection points in

a parallel circuit, the illumination lamps will all

come on at the same time. It also means one or more

lamps can be out without affecting the operation of

the other lamps.

On the battery side of the circuit, the headlamp

switch illumination rheostat/switch and panel lamps

fuse receive battery feed in series from the park/tail

fuse. In the park lamp position, the headlamp switch

completes the circuit from the park/tail fuse to the il-

lumination rheostat/switch and panel lamps fuse.

The illumination rheostat contains a variable resis-

tor that allows the driver to vary illumination inten-

sity from off to full brightness.

DIAGNOSIS

(1) Turn parking lamps ON.

(2) Check fuse #10. Replace as required.

(3) Measure voltage at battery side of fuse #10

with rheostat turned counterclockwise to clockwise

(LO to HI). Meter should read zero volts to battery

voltage. If not, replace headlamp switch.

(4) Measure resistance at ground side of fuse #10

with parking lamps OFF. Meter should read almost

zero ohms (except bulb filament). If not, repair open

to ground. If zero ohms, 12 volt supply wire from fuse

is shorted to ground, repair short.

8E - 16 YJ INSTRUMENT PANEL AND GAUGESJ

Page 364 of 1784

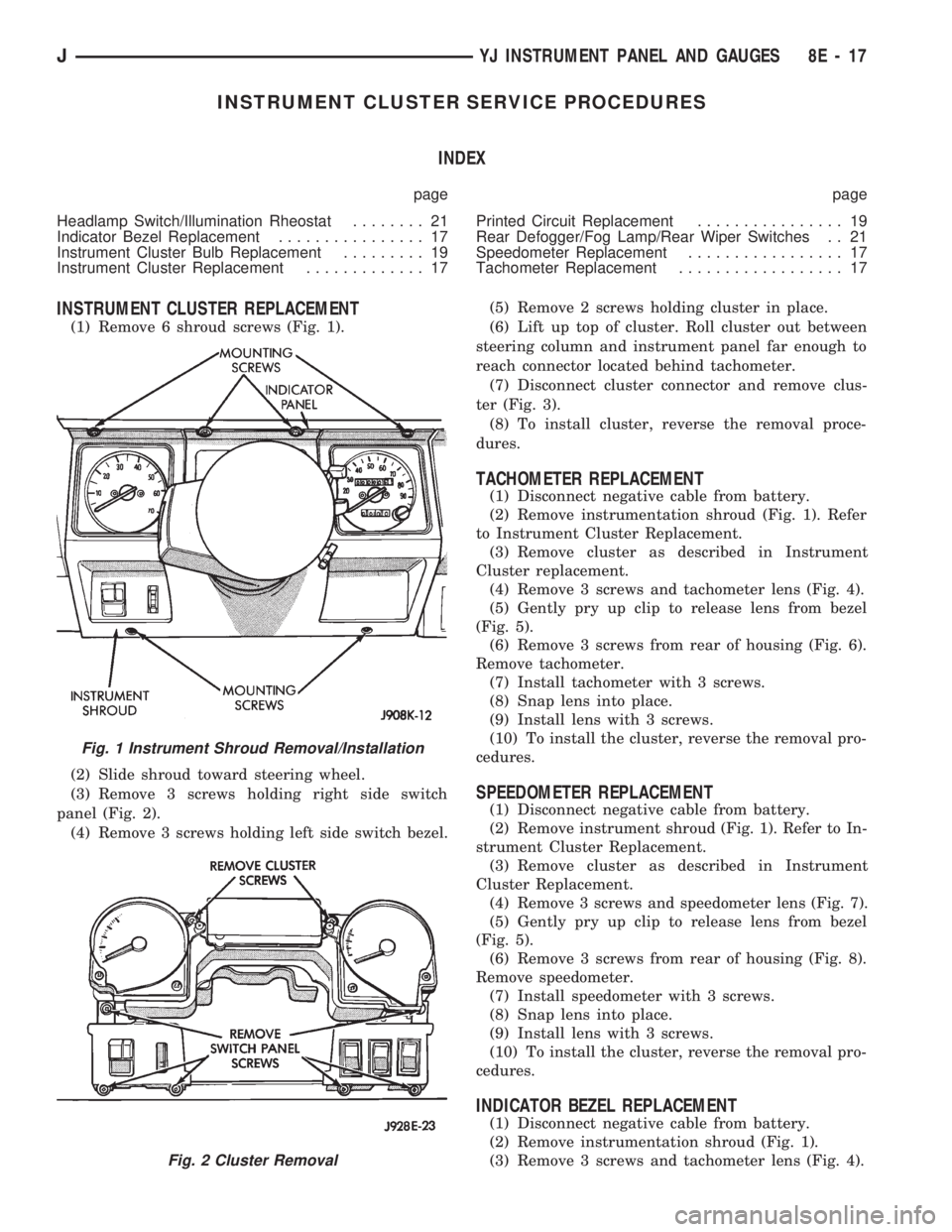

INSTRUMENT CLUSTER SERVICE PROCEDURES

INDEX

page page

Headlamp Switch/Illumination Rheostat........ 21

Indicator Bezel Replacement................ 17

Instrument Cluster Bulb Replacement......... 19

Instrument Cluster Replacement............. 17Printed Circuit Replacement................ 19

Rear Defogger/Fog Lamp/Rear Wiper Switches . . 21

Speedometer Replacement................. 17

Tachometer Replacement.................. 17

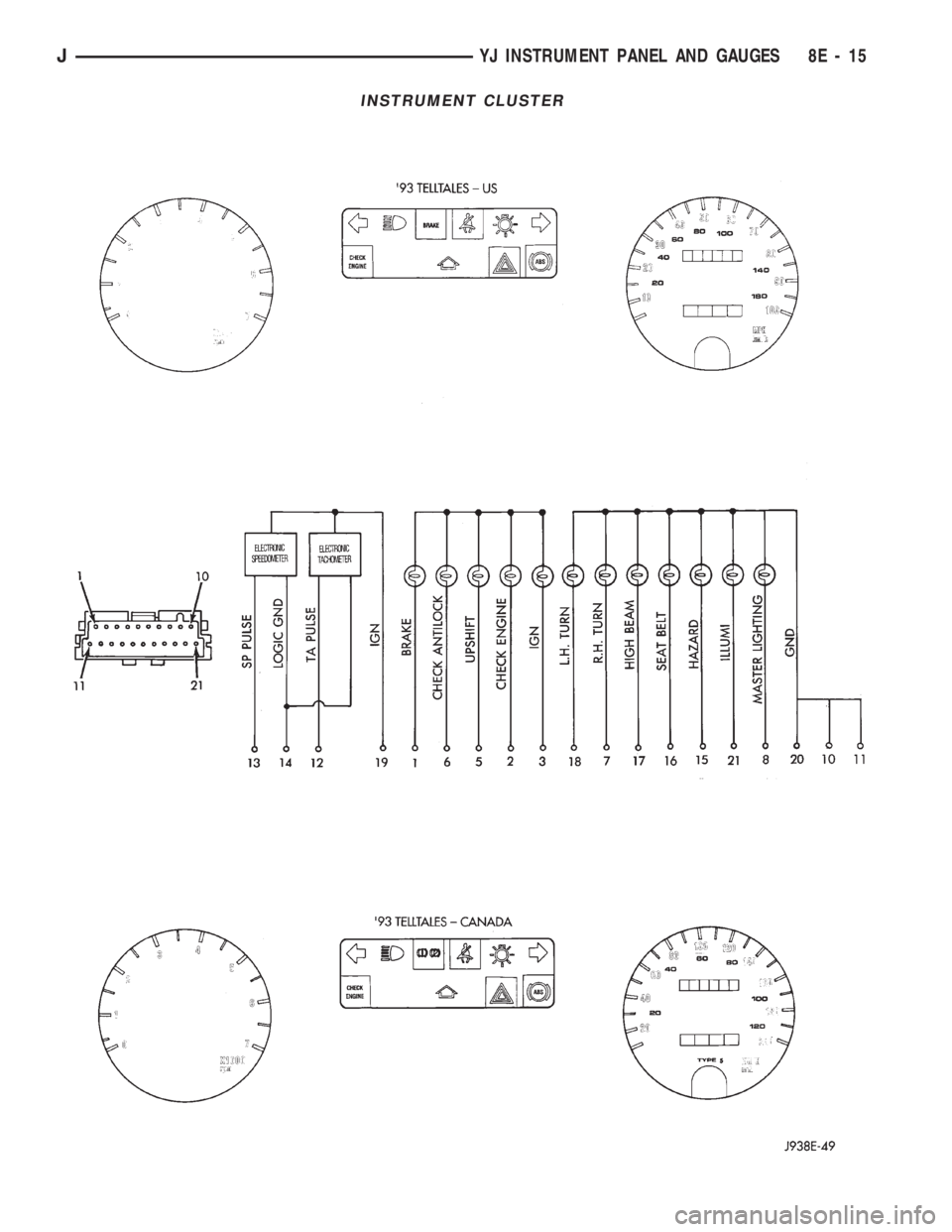

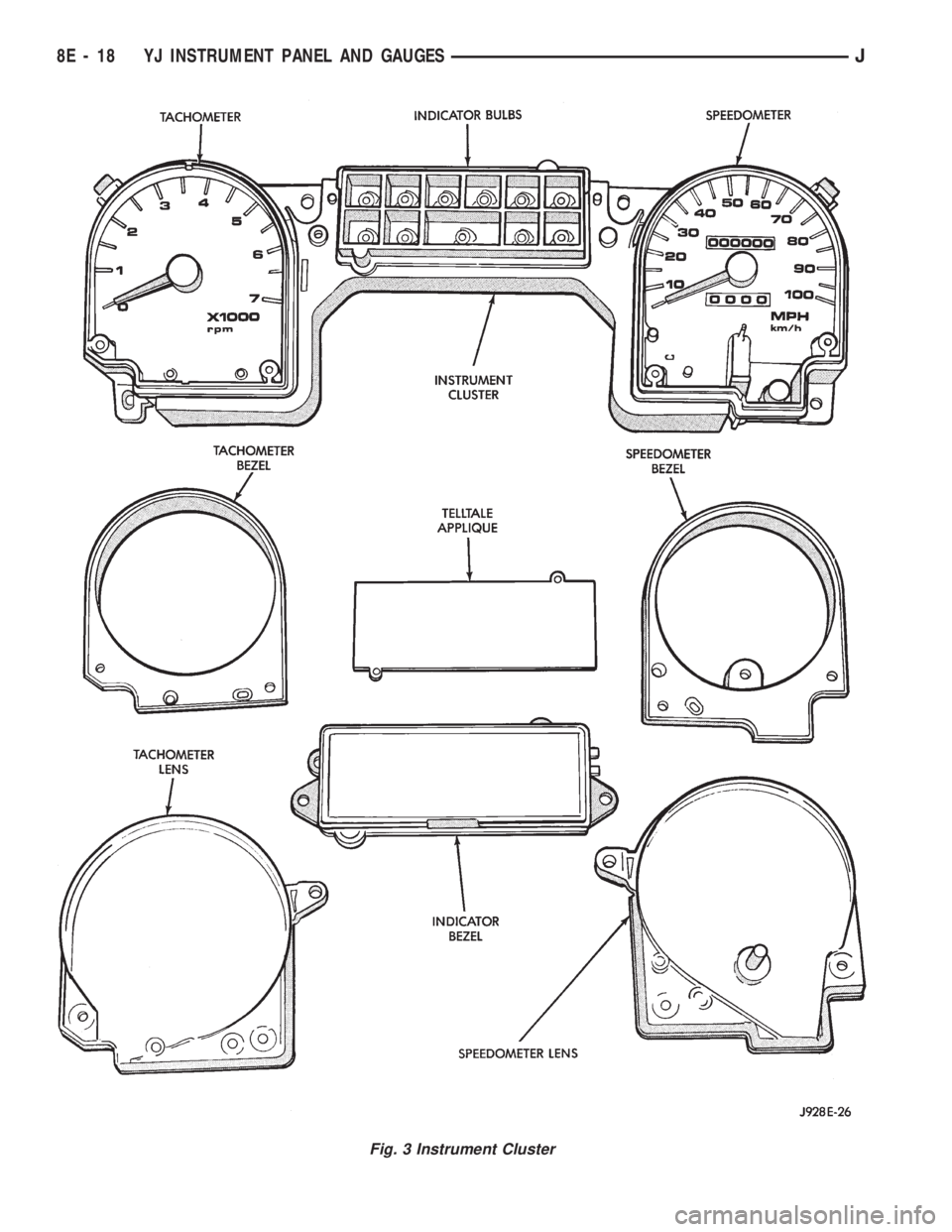

INSTRUMENT CLUSTER REPLACEMENT

(1) Remove 6 shroud screws (Fig. 1).

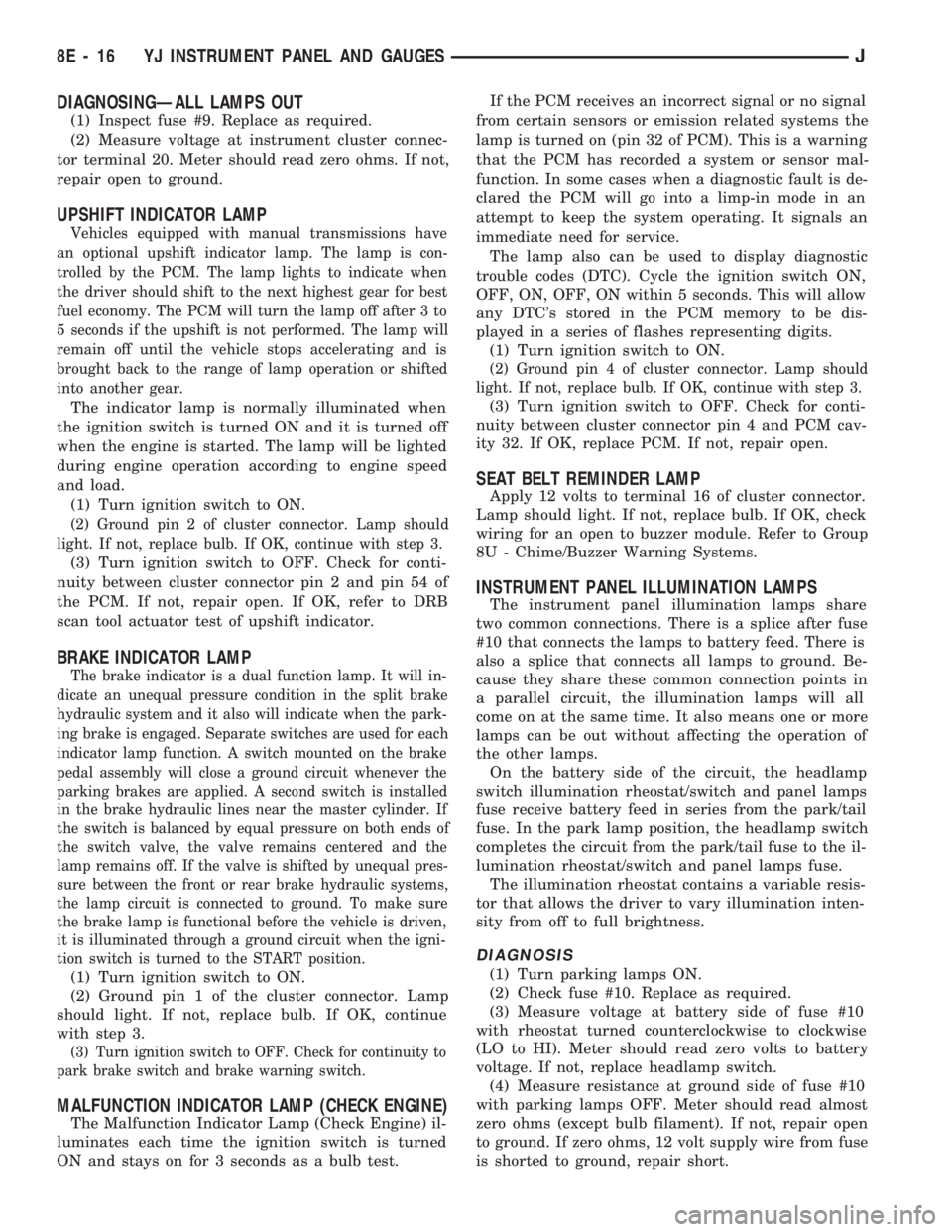

(2) Slide shroud toward steering wheel.

(3) Remove 3 screws holding right side switch

panel (Fig. 2).

(4) Remove 3 screws holding left side switch bezel.(5) Remove 2 screws holding cluster in place.

(6) Lift up top of cluster. Roll cluster out between

steering column and instrument panel far enough to

reach connector located behind tachometer.

(7) Disconnect cluster connector and remove clus-

ter (Fig. 3).

(8) To install cluster, reverse the removal proce-

dures.

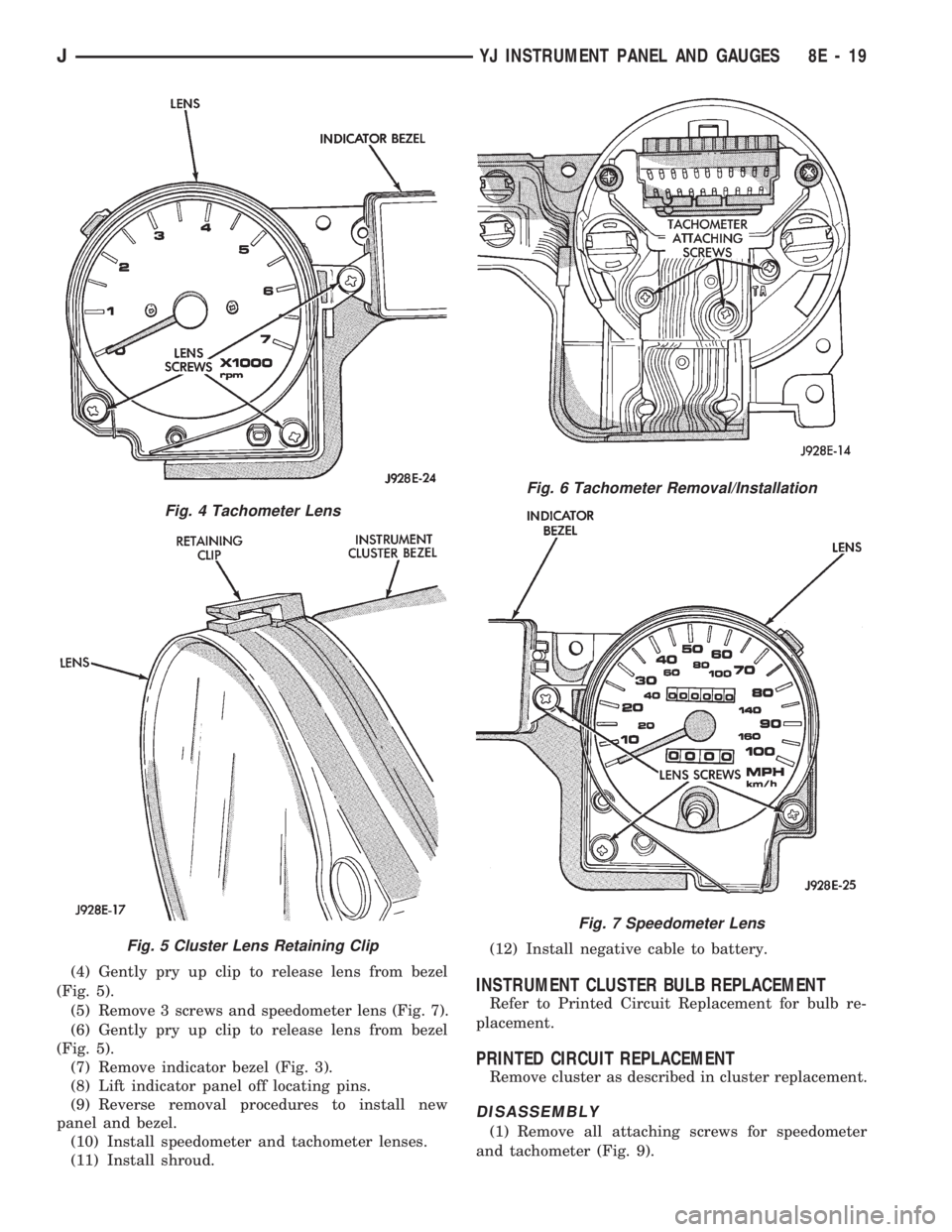

TACHOMETER REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove instrumentation shroud (Fig. 1). Refer

to Instrument Cluster Replacement.

(3) Remove cluster as described in Instrument

Cluster replacement.

(4) Remove 3 screws and tachometer lens (Fig. 4).

(5) Gently pry up clip to release lens from bezel

(Fig. 5).

(6) Remove 3 screws from rear of housing (Fig. 6).

Remove tachometer.

(7) Install tachometer with 3 screws.

(8) Snap lens into place.

(9) Install lens with 3 screws.

(10) To install the cluster, reverse the removal pro-

cedures.

SPEEDOMETER REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove instrument shroud (Fig. 1). Refer to In-

strument Cluster Replacement.

(3) Remove cluster as described in Instrument

Cluster Replacement.

(4) Remove 3 screws and speedometer lens (Fig. 7).

(5) Gently pry up clip to release lens from bezel

(Fig. 5).

(6) Remove 3 screws from rear of housing (Fig. 8).

Remove speedometer.

(7) Install speedometer with 3 screws.

(8) Snap lens into place.

(9) Install lens with 3 screws.

(10) To install the cluster, reverse the removal pro-

cedures.

INDICATOR BEZEL REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove instrumentation shroud (Fig. 1).

(3) Remove 3 screws and tachometer lens (Fig. 4).

Fig. 2 Cluster Removal

Fig. 1 Instrument Shroud Removal/Installation

JYJ INSTRUMENT PANEL AND GAUGES 8E - 17

Page 365 of 1784

Fig. 3 Instrument Cluster

8E - 18 YJ INSTRUMENT PANEL AND GAUGESJ

Page 366 of 1784

(4) Gently pry up clip to release lens from bezel

(Fig. 5).

(5) Remove 3 screws and speedometer lens (Fig. 7).

(6) Gently pry up clip to release lens from bezel

(Fig. 5).

(7) Remove indicator bezel (Fig. 3).

(8) Lift indicator panel off locating pins.

(9) Reverse removal procedures to install new

panel and bezel.

(10) Install speedometer and tachometer lenses.

(11) Install shroud.(12) Install negative cable to battery.INSTRUMENT CLUSTER BULB REPLACEMENT

Refer to Printed Circuit Replacement for bulb re-

placement.

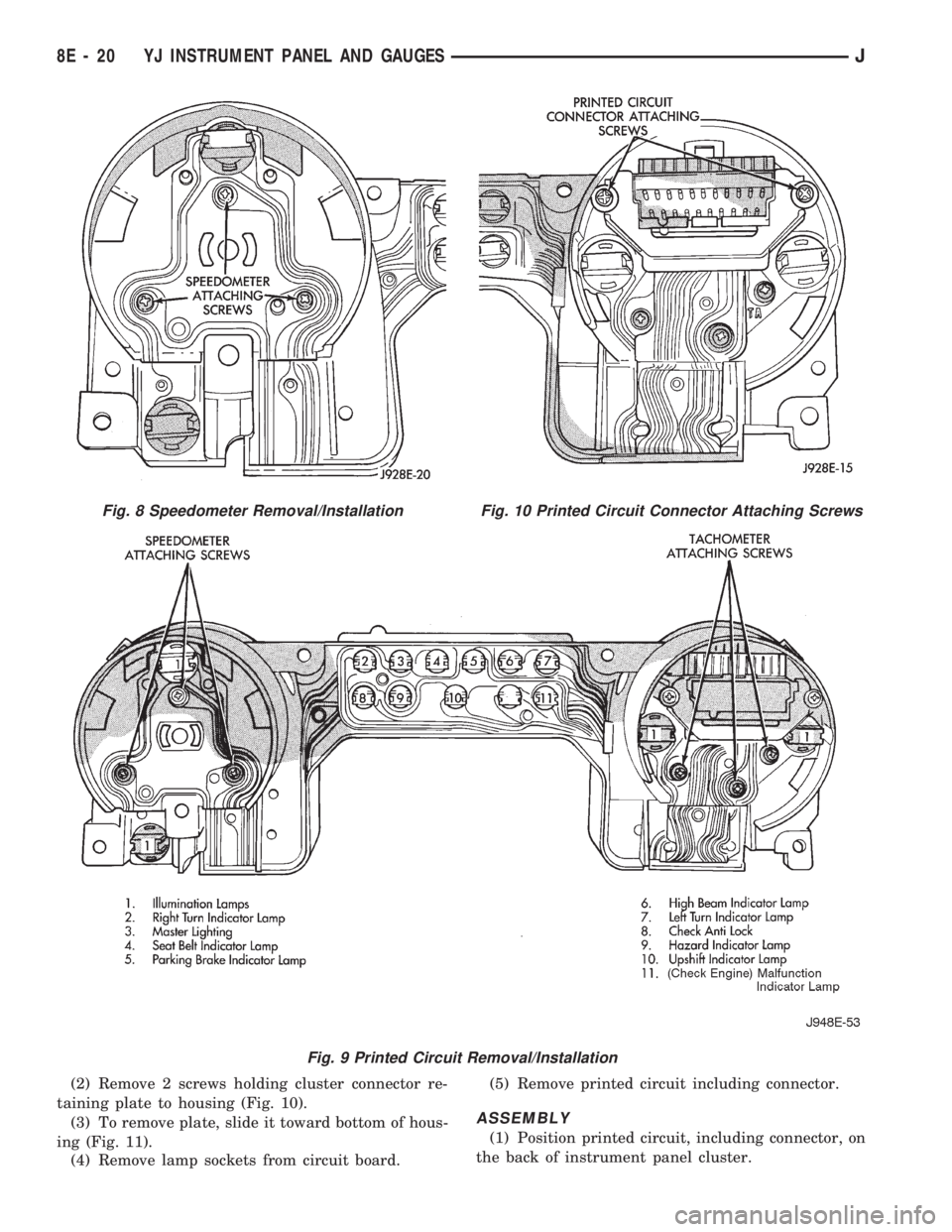

PRINTED CIRCUIT REPLACEMENT

Remove cluster as described in cluster replacement.

DISASSEMBLY

(1) Remove all attaching screws for speedometer

and tachometer (Fig. 9).

Fig. 4 Tachometer Lens

Fig. 5 Cluster Lens Retaining Clip

Fig. 6 Tachometer Removal/Installation

Fig. 7 Speedometer Lens

JYJ INSTRUMENT PANEL AND GAUGES 8E - 19

Page 367 of 1784

(2) Remove 2 screws holding cluster connector re-

taining plate to housing (Fig. 10).

(3) To remove plate, slide it toward bottom of hous-

ing (Fig. 11).

(4) Remove lamp sockets from circuit board.(5) Remove printed circuit including connector.

ASSEMBLY

(1) Position printed circuit, including connector, on

the back of instrument panel cluster.

Fig. 8 Speedometer Removal/Installation

Fig. 9 Printed Circuit Removal/Installation

Fig. 10 Printed Circuit Connector Attaching Screws

8E - 20 YJ INSTRUMENT PANEL AND GAUGESJ

Page 368 of 1784

(2) Remove gauge bezel and lens.

(3) Hold components in place and install screws.

(4) Install lamp sockets.

(5) Pivot connector up and install retaining plate.

(6) Install gauge bezel and cluster lens.

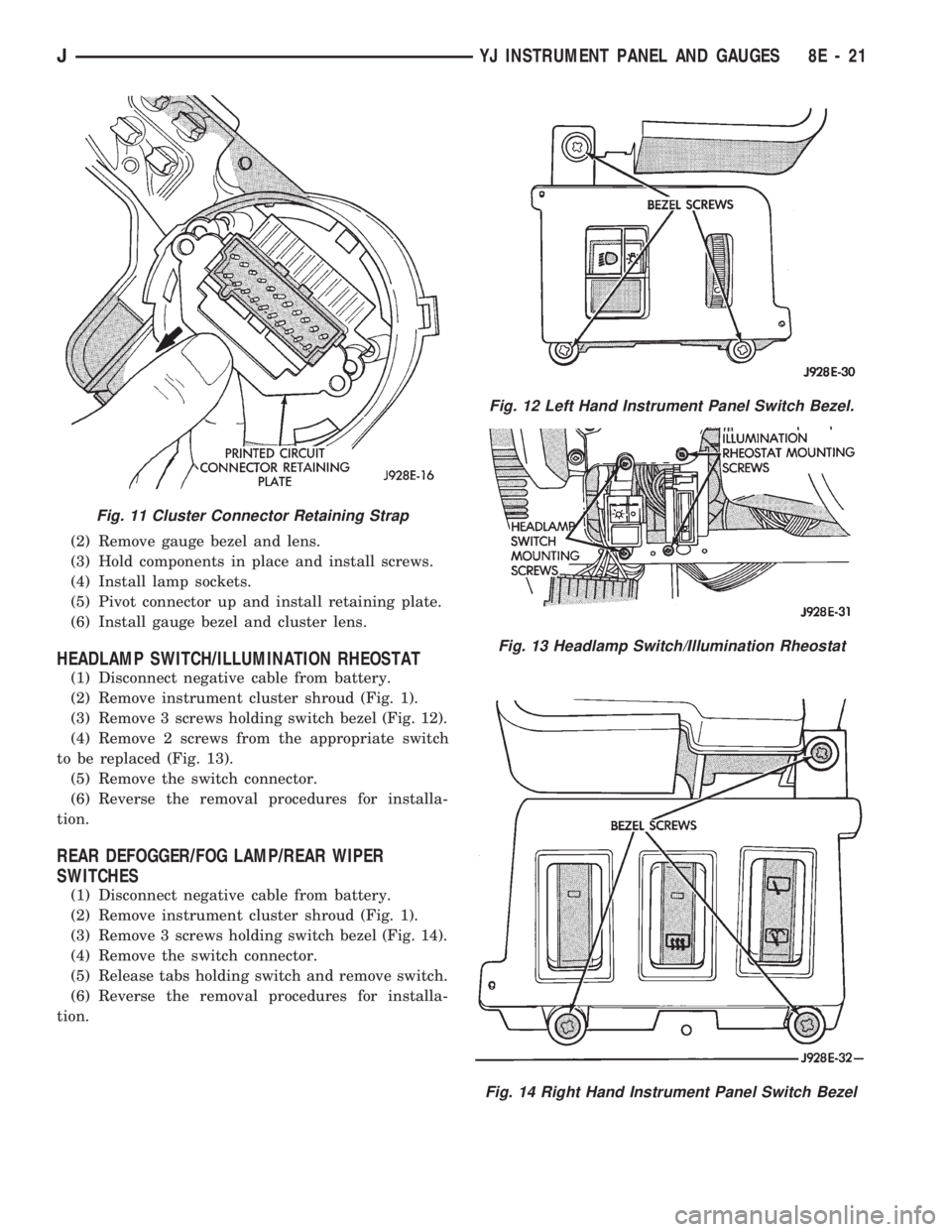

HEADLAMP SWITCH/ILLUMINATION RHEOSTAT

(1) Disconnect negative cable from battery.

(2) Remove instrument cluster shroud (Fig. 1).

(3) Remove 3 screws holding switch bezel (Fig. 12).

(4) Remove 2 screws from the appropriate switch

to be replaced (Fig. 13).

(5) Remove the switch connector.

(6) Reverse the removal procedures for installa-

tion.

REAR DEFOGGER/FOG LAMP/REAR WIPER

SWITCHES

(1) Disconnect negative cable from battery.

(2) Remove instrument cluster shroud (Fig. 1).

(3) Remove 3 screws holding switch bezel (Fig. 14).

(4) Remove the switch connector.

(5) Release tabs holding switch and remove switch.

(6) Reverse the removal procedures for installa-

tion.

Fig. 11 Cluster Connector Retaining Strap

Fig. 12 Left Hand Instrument Panel Switch Bezel.

Fig. 13 Headlamp Switch/Illumination Rheostat

Fig. 14 Right Hand Instrument Panel Switch Bezel

JYJ INSTRUMENT PANEL AND GAUGES 8E - 21

Page 369 of 1784

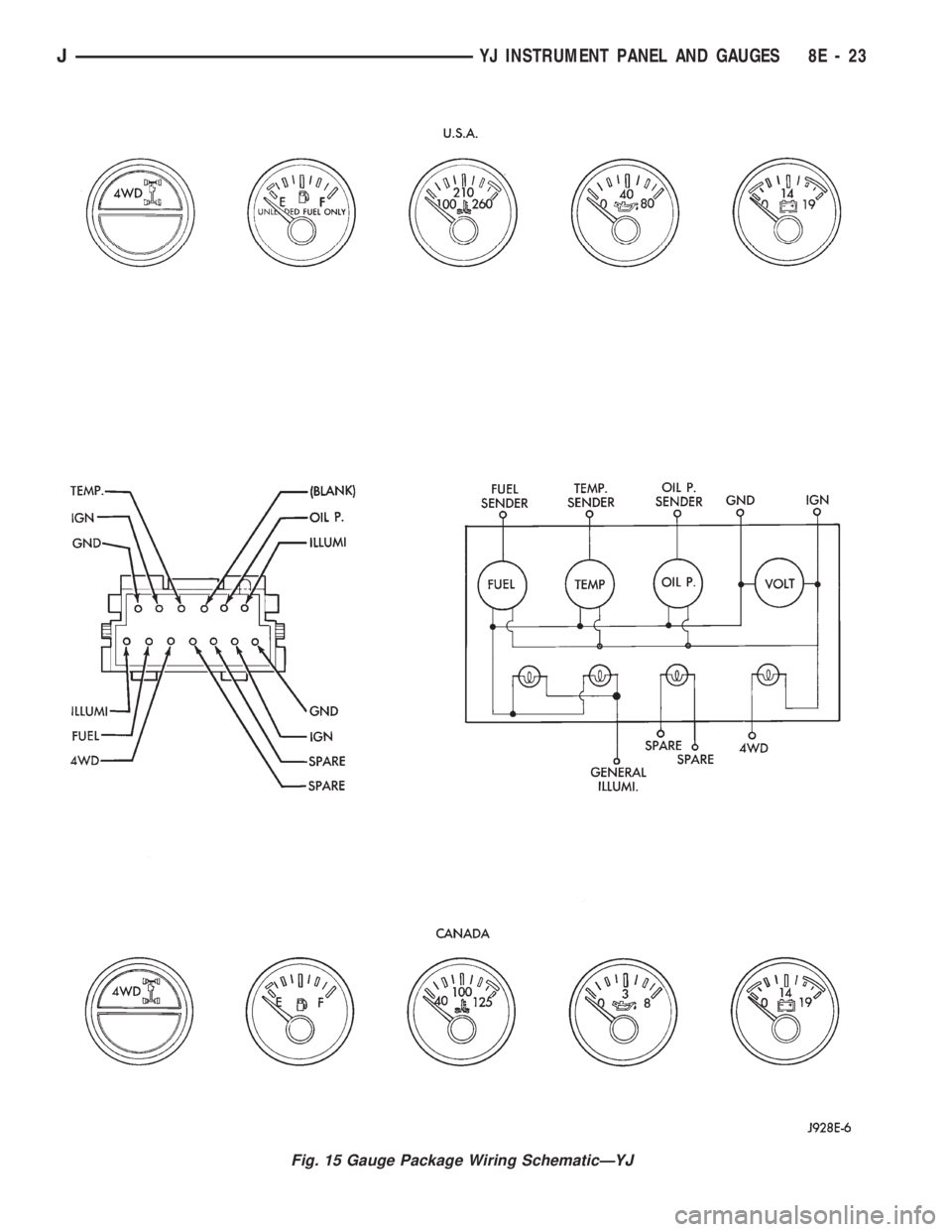

GAUGE PACKAGE GENERAL INFORMATION

The gauge package contains 4 gauges and the 4

wheel drive indicator. The gauges have a common

battery feed from fuse #9 and ignition switch. Al-

though they have separate power sources, the 4

gauges share a common ground connection.

The voltmeter indicates electrical system voltage.

When the engine is not running, the voltage regis-

tered is from the battery. After the engine is started,

charging system voltage is indicated. In the gauge

package, the voltmeter forms a parallel connectionacross the battery feed and ground.

The remaining gauges - oil pressure, fuel and cool-

ant temperature - are connected to individual sender

units. Variable resistors in the senders will change

the amount of current allowed to flow through the

gauge coils. As current flow through the coils varies,

the position of the indicator needle also will vary.

The 4 gauges are connected to battery feed, ground

and the sender units through a printed circuit

mounted on the back of the gauge housing.

GAUGE PACKAGE DIAGNOSIS

ALL GAUGES INOPERATIVE (Fig. 15)

(1) Check the fuse #9. Replace as required.

(2) Turn ignition switch to ON and measure volt-

age at battery side of fuse #9. Meter should read bat-

tery voltage. If not, repair open from ignition switch.

(3) Unplug gauge package connector from gauge

package.

(4) Turn ignition switch to OFF and measure resis-

tance from instrument cluster connector terminals 1

and 13 to a clean chassis ground. Meter should read

zero ohms. If not, repair open to ground.

(5) Turn ignition switch to ON and measure volt-

age at instrument cluster connector terminals 2 and

12. Meter should read battery voltage. If not, repair

open from fuse panel.

ONE GAUGE INOPERATIVE

Does not apply to voltmeter.

OIL PRESSURE SENDER

(1) Turn ignition switch to ON.

(2) Unplug oil pressure sender connector from oil

pressure sender.

(3) Touch connector to engine block (ground).

Gauge should read at low end of scale.

(4) When connector is NOT touching ground (open

circuit) gauge should read at high end of scale. If OK

replace sender. If not, proceed with step 5.

(5) Check circuit between sender and gauge for an

open. Repair as required. If wiring is OK, replace

gauge.

COOLANT TEMPERATURE SENDER

(1) Turn ignition switch to ON.

(2) Unplug coolant temperature sender connector

from coolant temperature sender.

(3) Touch connector to engine block (ground).

Gauge should read at high end of scale.

(4) When connector is NOT touching ground (open

circuit) gauge should read at low end of scale. If OK

replace sender. If not, proceed with step 5.

(5) Check circuit between sender and gauge for an

open. Repair as required. If wiring is OK, replace

gauge.

FUEL GAUGE SENDER

(1) Turn ignition switch to ON.

(2) Separate fuel gauge sender connector from fuel

gauge sender near tank.

(3) Ground the center wire of the body harness

side of the connector. The gauge should read at low

end of scale. If OK, check sending unit (step 4). If

not, check circuit between connector and gauge. Re-

pair as required. If circuit is OK, replace gauge.

(4) Turn ignition switch to OFF.

(5) Measure resistance from fuel gauge sender con-

nector center terminal to a clean chassis ground.

Meter readings should correspond to those shown in

Specifications. If not OK, replace sender. If OK, re-

pair open from fuel gauge sender connector to

ground.

PRINTED CIRCUIT

(1) Turn ignition switch to ON.

(2) Unplug gauge package connector from gauge

package.

(3) Measure resistance from gauge package termi-

nal 12 (fuel and coolant temperature gauge) or from

terminal 2 (voltmeter and oil pressure gauge) to

gauge battery terminal. Meter should read zero

ohms. If not, replace/repair printed circuit.

(4) Measure resistance from gauge package termi-

nal 13 (fuel and coolant temperature gauge) or from

terminal 1 (voltmeter and oil pressure gauge) to

gauge ground terminal. Meter should read zero

ohms. If not, replace/repair printed circuit. If zero

ohms, replace gauge.

GAUGE CALIBRATION VALUES

Use the charts in Specifications. The calibration of

the gauge can be checked. If the indicator needle is

not in the correct position, replace the gauge.

4WD INDICATOR

The four-wheel drive indicator lamp circuit is com-

pleted by the Command-Trac switch located below

the battery.

8E - 22 YJ INSTRUMENT PANEL AND GAUGESJ

Page 370 of 1784

Fig. 15 Gauge Package Wiring SchematicÐYJ

JYJ INSTRUMENT PANEL AND GAUGES 8E - 23