ECO mode JEEP CHEROKEE 1994 Service Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 987 of 1784

ing the IAC motor pintle in and out of the air control

passage. The IAC motor is positioned when the igni-

tion key is turned to the On position.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

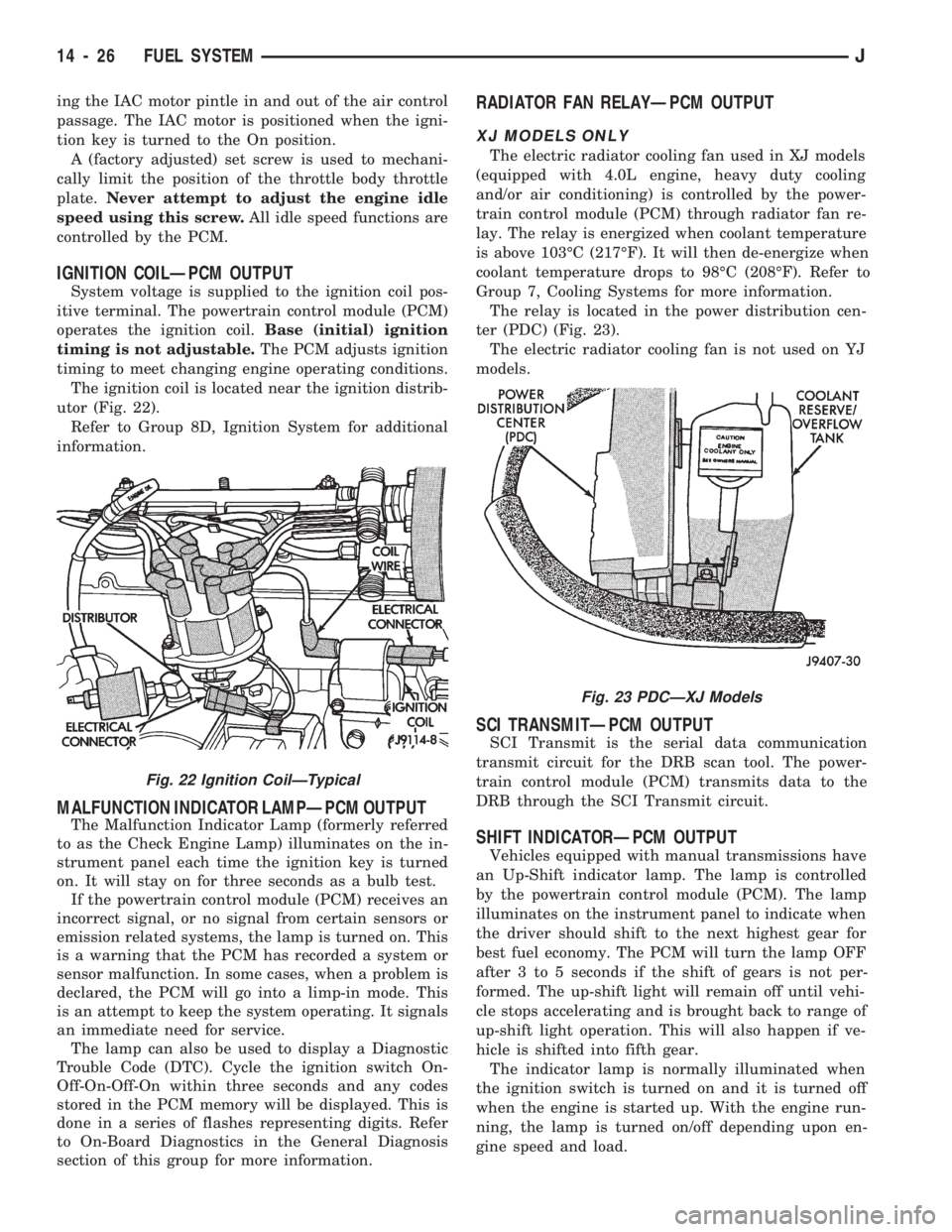

IGNITION COILÐPCM OUTPUT

System voltage is supplied to the ignition coil pos-

itive terminal. The powertrain control module (PCM)

operates the ignition coil.Base (initial) ignition

timing is not adjustable.The PCM adjusts ignition

timing to meet changing engine operating conditions.

The ignition coil is located near the ignition distrib-

utor (Fig. 22).

Refer to Group 8D, Ignition System for additional

information.

MALFUNCTION INDICATOR LAMPÐPCM OUTPUT

The Malfunction Indicator Lamp (formerly referred

to as the Check Engine Lamp) illuminates on the in-

strument panel each time the ignition key is turned

on. It will stay on for three seconds as a bulb test.

If the powertrain control module (PCM) receives an

incorrect signal, or no signal from certain sensors or

emission related systems, the lamp is turned on. This

is a warning that the PCM has recorded a system or

sensor malfunction. In some cases, when a problem is

declared, the PCM will go into a limp-in mode. This

is an attempt to keep the system operating. It signals

an immediate need for service.

The lamp can also be used to display a Diagnostic

Trouble Code (DTC). Cycle the ignition switch On-

Off-On-Off-On within three seconds and any codes

stored in the PCM memory will be displayed. This is

done in a series of flashes representing digits. Refer

to On-Board Diagnostics in the General Diagnosis

section of this group for more information.

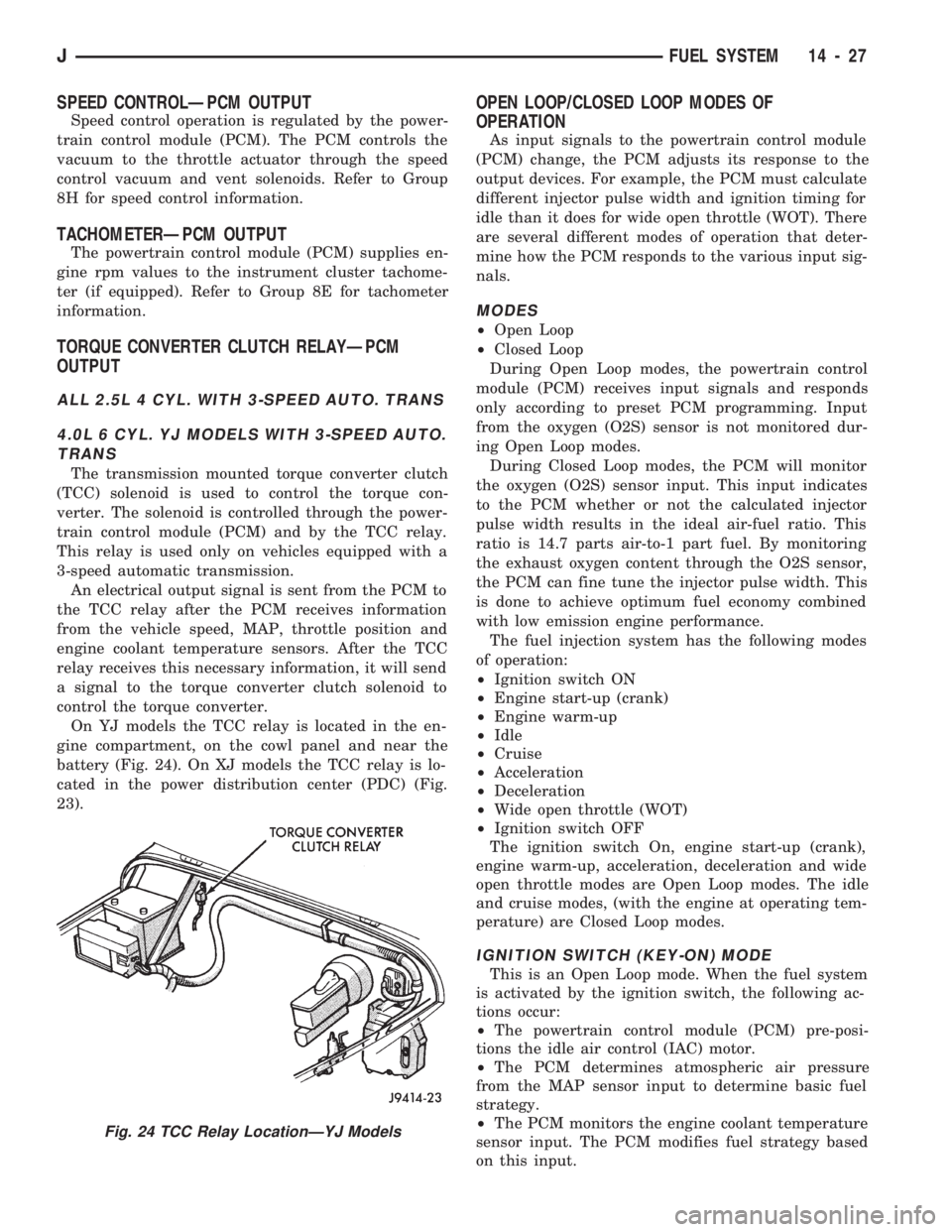

RADIATOR FAN RELAYÐPCM OUTPUT

XJ MODELS ONLY

The electric radiator cooling fan used in XJ models

(equipped with 4.0L engine, heavy duty cooling

and/or air conditioning) is controlled by the power-

train control module (PCM) through radiator fan re-

lay. The relay is energized when coolant temperature

is above 103ÉC (217ÉF). It will then de-energize when

coolant temperature drops to 98ÉC (208ÉF). Refer to

Group 7, Cooling Systems for more information.

The relay is located in the power distribution cen-

ter (PDC) (Fig. 23).

The electric radiator cooling fan is not used on YJ

models.

SCI TRANSMITÐPCM OUTPUT

SCI Transmit is the serial data communication

transmit circuit for the DRB scan tool. The power-

train control module (PCM) transmits data to the

DRB through the SCI Transmit circuit.

SHIFT INDICATORÐPCM OUTPUT

Vehicles equipped with manual transmissions have

an Up-Shift indicator lamp. The lamp is controlled

by the powertrain control module (PCM). The lamp

illuminates on the instrument panel to indicate when

the driver should shift to the next highest gear for

best fuel economy. The PCM will turn the lamp OFF

after 3 to 5 seconds if the shift of gears is not per-

formed. The up-shift light will remain off until vehi-

cle stops accelerating and is brought back to range of

up-shift light operation. This will also happen if ve-

hicle is shifted into fifth gear.

The indicator lamp is normally illuminated when

the ignition switch is turned on and it is turned off

when the engine is started up. With the engine run-

ning, the lamp is turned on/off depending upon en-

gine speed and load.

Fig. 23 PDCÐXJ Models

Fig. 22 Ignition CoilÐTypical

14 - 26 FUEL SYSTEMJ

Page 988 of 1784

SPEED CONTROLÐPCM OUTPUT

Speed control operation is regulated by the power-

train control module (PCM). The PCM controls the

vacuum to the throttle actuator through the speed

control vacuum and vent solenoids. Refer to Group

8H for speed control information.

TACHOMETERÐPCM OUTPUT

The powertrain control module (PCM) supplies en-

gine rpm values to the instrument cluster tachome-

ter (if equipped). Refer to Group 8E for tachometer

information.

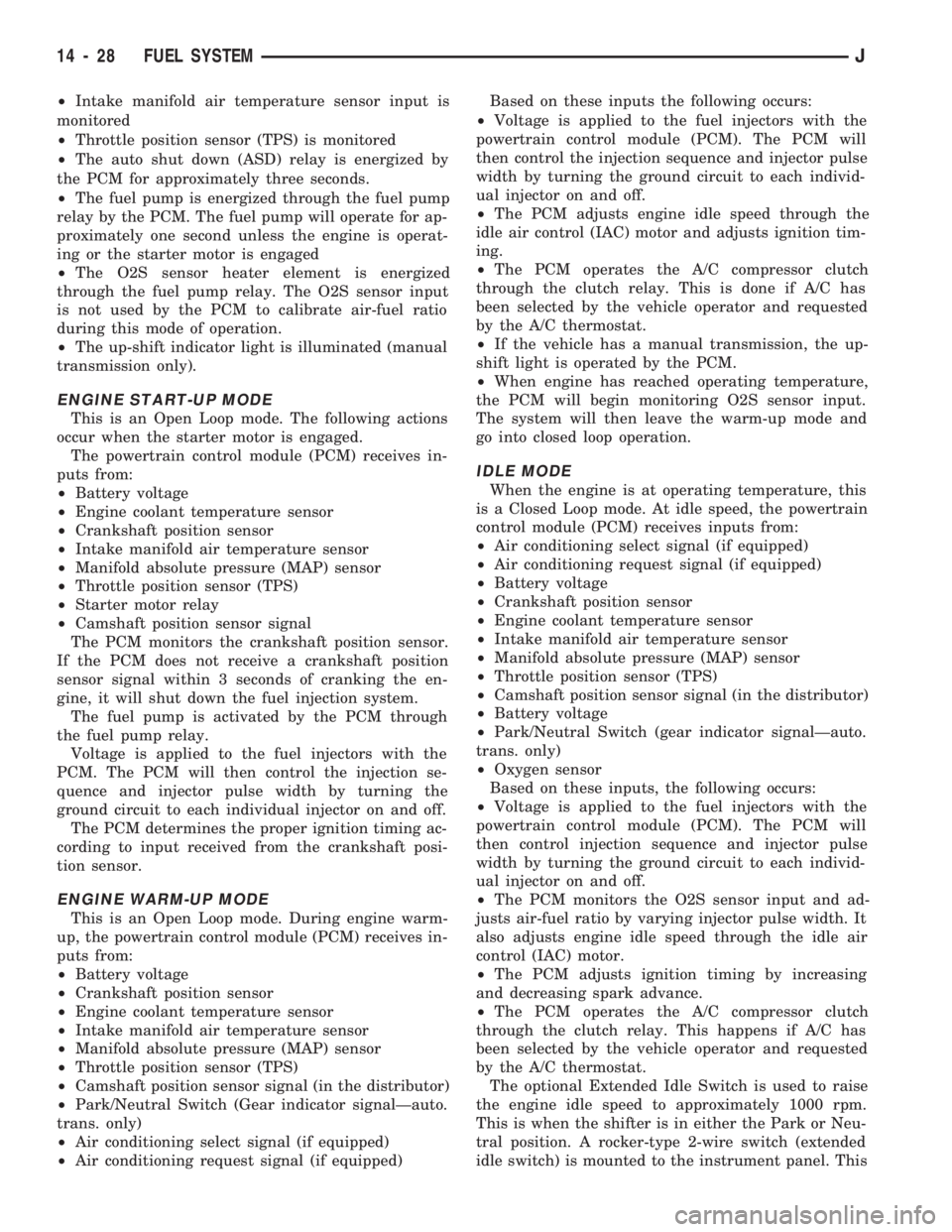

TORQUE CONVERTER CLUTCH RELAYÐPCM

OUTPUT

ALL 2.5L 4 CYL. WITH 3-SPEED AUTO. TRANS

4.0L 6 CYL. YJ MODELS WITH 3-SPEED AUTO.

TRANS

The transmission mounted torque converter clutch

(TCC) solenoid is used to control the torque con-

verter. The solenoid is controlled through the power-

train control module (PCM) and by the TCC relay.

This relay is used only on vehicles equipped with a

3-speed automatic transmission.

An electrical output signal is sent from the PCM to

the TCC relay after the PCM receives information

from the vehicle speed, MAP, throttle position and

engine coolant temperature sensors. After the TCC

relay receives this necessary information, it will send

a signal to the torque converter clutch solenoid to

control the torque converter.

On YJ models the TCC relay is located in the en-

gine compartment, on the cowl panel and near the

battery (Fig. 24). On XJ models the TCC relay is lo-

cated in the power distribution center (PDC) (Fig.

23).

OPEN LOOP/CLOSED LOOP MODES OF

OPERATION

As input signals to the powertrain control module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT). There

are several different modes of operation that deter-

mine how the PCM responds to the various input sig-

nals.

MODES

²Open Loop

²Closed Loop

During Open Loop modes, the powertrain control

module (PCM) receives input signals and responds

only according to preset PCM programming. Input

from the oxygen (O2S) sensor is not monitored dur-

ing Open Loop modes.

During Closed Loop modes, the PCM will monitor

the oxygen (O2S) sensor input. This input indicates

to the PCM whether or not the calculated injector

pulse width results in the ideal air-fuel ratio. This

ratio is 14.7 parts air-to-1 part fuel. By monitoring

the exhaust oxygen content through the O2S sensor,

the PCM can fine tune the injector pulse width. This

is done to achieve optimum fuel economy combined

with low emission engine performance.

The fuel injection system has the following modes

of operation:

²Ignition switch ON

²Engine start-up (crank)

²Engine warm-up

²Idle

²Cruise

²Acceleration

²Deceleration

²Wide open throttle (WOT)

²Ignition switch OFF

The ignition switch On, engine start-up (crank),

engine warm-up, acceleration, deceleration and wide

open throttle modes are Open Loop modes. The idle

and cruise modes, (with the engine at operating tem-

perature) are Closed Loop modes.

IGNITION SWITCH (KEY-ON) MODE

This is an Open Loop mode. When the fuel system

is activated by the ignition switch, the following ac-

tions occur:

²The powertrain control module (PCM) pre-posi-

tions the idle air control (IAC) motor.

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the engine coolant temperature

sensor input. The PCM modifies fuel strategy based

on this input.

Fig. 24 TCC Relay LocationÐYJ Models

JFUEL SYSTEM 14 - 27

Page 989 of 1784

²Intake manifold air temperature sensor input is

monitored

²Throttle position sensor (TPS) is monitored

²The auto shut down (ASD) relay is energized by

the PCM for approximately three seconds.

²The fuel pump is energized through the fuel pump

relay by the PCM. The fuel pump will operate for ap-

proximately one second unless the engine is operat-

ing or the starter motor is engaged

²The O2S sensor heater element is energized

through the fuel pump relay. The O2S sensor input

is not used by the PCM to calibrate air-fuel ratio

during this mode of operation.

²The up-shift indicator light is illuminated (manual

transmission only).

ENGINE START-UP MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The powertrain control module (PCM) receives in-

puts from:

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Starter motor relay

²Camshaft position sensor signal

The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position

sensor signal within 3 seconds of cranking the en-

gine, it will shut down the fuel injection system.

The fuel pump is activated by the PCM through

the fuel pump relay.

Voltage is applied to the fuel injectors with the

PCM. The PCM will then control the injection se-

quence and injector pulse width by turning the

ground circuit to each individual injector on and off.

The PCM determines the proper ignition timing ac-

cording to input received from the crankshaft posi-

tion sensor.

ENGINE WARM-UP MODE

This is an Open Loop mode. During engine warm-

up, the powertrain control module (PCM) receives in-

puts from:

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distributor)

²Park/Neutral Switch (Gear indicator signalÐauto.

trans. only)

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)Based on these inputs the following occurs:

²Voltage is applied to the fuel injectors with the

powertrain control module (PCM). The PCM will

then control the injection sequence and injector pulse

width by turning the ground circuit to each individ-

ual injector on and off.

²The PCM adjusts engine idle speed through the

idle air control (IAC) motor and adjusts ignition tim-

ing.

²The PCM operates the A/C compressor clutch

through the clutch relay. This is done if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

²If the vehicle has a manual transmission, the up-

shift light is operated by the PCM.

²When engine has reached operating temperature,

the PCM will begin monitoring O2S sensor input.

The system will then leave the warm-up mode and

go into closed loop operation.

IDLE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At idle speed, the powertrain

control module (PCM) receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distributor)

²Battery voltage

²Park/Neutral Switch (gear indicator signalÐauto.

trans. only)

²Oxygen sensor

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

powertrain control module (PCM). The PCM will

then control injection sequence and injector pulse

width by turning the ground circuit to each individ-

ual injector on and off.

²The PCM monitors the O2S sensor input and ad-

justs air-fuel ratio by varying injector pulse width. It

also adjusts engine idle speed through the idle air

control (IAC) motor.

²The PCM adjusts ignition timing by increasing

and decreasing spark advance.

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

The optional Extended Idle Switch is used to raise

the engine idle speed to approximately 1000 rpm.

This is when the shifter is in either the Park or Neu-

tral position. A rocker-type 2-wire switch (extended

idle switch) is mounted to the instrument panel. This

14 - 28 FUEL SYSTEMJ

Page 990 of 1784

switch will supply a ground circuit to the powertrain

control module (PCM).The switch is available

only with 4.0L engine when supplied with the

optional police package.

CRUISE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the power-

train control module (PCM) receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distributor)

²Park/Neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen (O2S) sensor

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

PCM. The PCM will then adjust the injector pulse

width by turning the ground circuit to each individ-

ual injector on and off.

²The PCM monitors the O2S sensor input and ad-

justs air-fuel ratio. It also adjusts engine idle speed

through the idle air control (IAC) motor.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

ACCELERATION MODE

This is an Open Loop mode. The powertrain control

module (PCM) recognizes an abrupt increase in

throttle position or MAP pressure as a demand for

increased engine output and vehicle acceleration.

The PCM increases injector pulse width in response

to increased throttle opening.

DECELERATION MODE

When the engine is at operating temperature, this

is an Open Loop mode. During hard deceleration, the

powertrain control module (PCM) receives the follow-

ing inputs.

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distributor)²Park/Neutral switch (gear indicator signalÐauto.

trans. only)

If the vehicle is under hard deceleration with the

proper rpm and closed throttle conditions, the PCM

will ignore the oxygen sensor input signal. The PCM

will enter a fuel cut-off strategy in which it will not

supply battery voltage to the injectors. If a hard de-

celeration does not exist, the PCM will determine the

proper injector pulse width and continue injection.

Based on the above inputs, the PCM will adjust en-

gine idle speed through the idle air control (IAC) mo-

tor.

The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

The PCM opens the ground circuit to the A/C

clutch relay to disengage the A/C compressor clutch.

This is done until the vehicle is no longer under de-

celeration (if the A/C system is operating).

WIDE OPEN THROTTLE MODE

This is an Open Loop mode. During wide open

throttle operation, the powertrain control module

(PCM) receives the following inputs.

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distributor)

During wide open throttle conditions, the following

occurs:

²Voltage is applied to the fuel injectors with the

powertrain control module (PCM). The PCM will

then control the injection sequence and injector pulse

width by turning the ground circuit to each individ-

ual injector on and off. The PCM ignores the oxygen

sensor input signal and provides a predetermined

amount of additional fuel. This is done by adjusting

injector pulse width.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

²The PCM opens the ground circuit to the A/C

clutch relay to disengage the A/C compressor clutch.

This will be done for approximately 15 seconds (if the

air conditioning system is operating).

If the vehicle has a manual transmission, the up-

shift light is operated by the PCM.

IGNITION SWITCH OFF MODE

When ignition switch is turned to OFF position,

the PCM stops operating the injectors, ignition coil,

ASD relay and fuel pump relay.

THROTTLE BODY

Filtered air from the air cleaner enters the intake

manifold through the throttle body (Fig. 25). Fuel

does not enter the intake manifold through the throt-

JFUEL SYSTEM 14 - 29

Page 994 of 1784

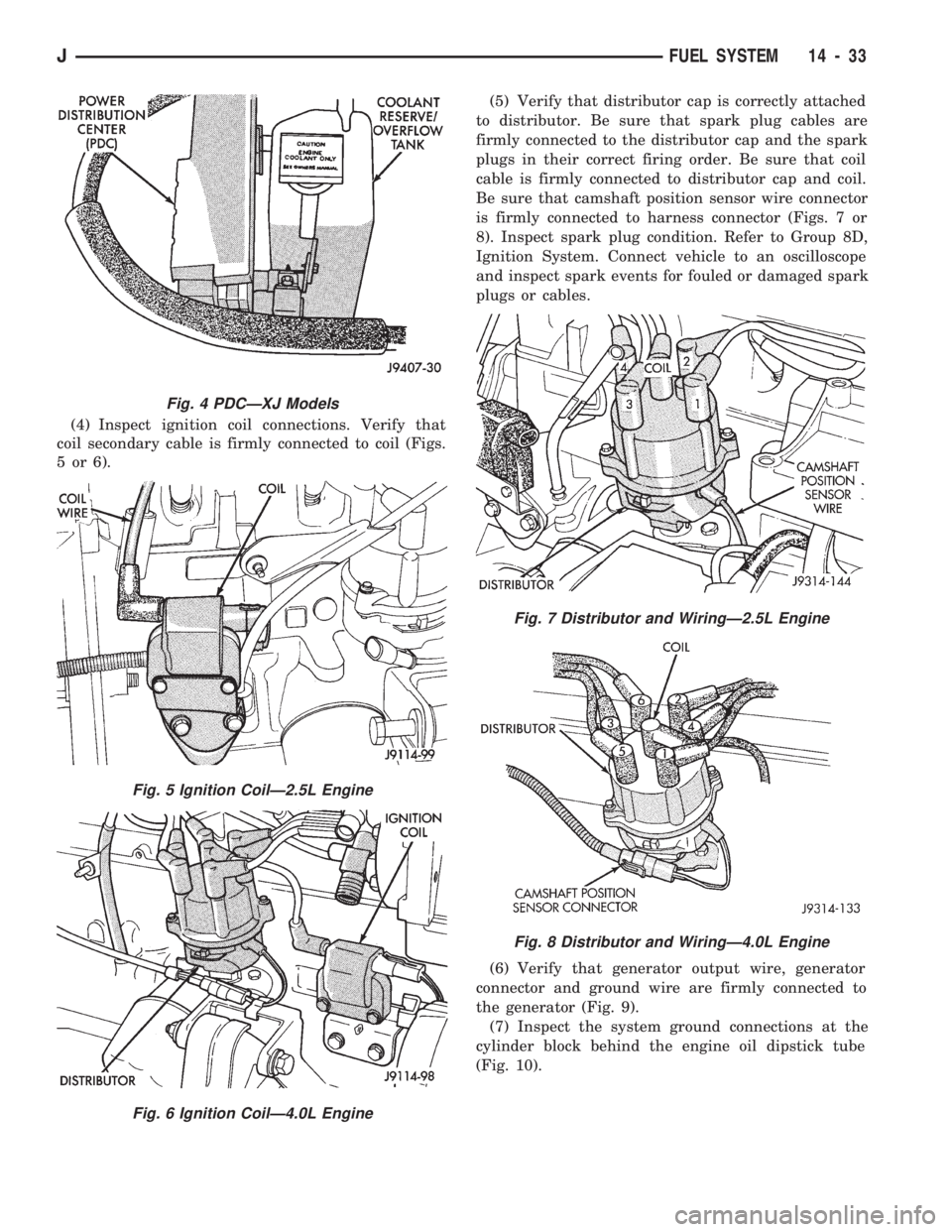

(4) Inspect ignition coil connections. Verify that

coil secondary cable is firmly connected to coil (Figs.

5or6).(5) Verify that distributor cap is correctly attached

to distributor. Be sure that spark plug cables are

firmly connected to the distributor cap and the spark

plugs in their correct firing order. Be sure that coil

cable is firmly connected to distributor cap and coil.

Be sure that camshaft position sensor wire connector

is firmly connected to harness connector (Figs. 7 or

8). Inspect spark plug condition. Refer to Group 8D,

Ignition System. Connect vehicle to an oscilloscope

and inspect spark events for fouled or damaged spark

plugs or cables.

(6) Verify that generator output wire, generator

connector and ground wire are firmly connected to

the generator (Fig. 9).

(7) Inspect the system ground connections at the

cylinder block behind the engine oil dipstick tube

(Fig. 10).

Fig. 4 PDCÐXJ Models

Fig. 5 Ignition CoilÐ2.5L Engine

Fig. 6 Ignition CoilÐ4.0L Engine

Fig. 7 Distributor and WiringÐ2.5L Engine

Fig. 8 Distributor and WiringÐ4.0L Engine

JFUEL SYSTEM 14 - 33

Page 1009 of 1784

87 and 30. Continuity should not be present between

terminals number 87A and 30.

(8) Disconnect jumper wires from relay and 12

Volt power source.

If continuity or resistance tests did not pass, re-

place relay. If tests passed, refer to Group 8W, Wir-

ing Diagrams for additional circuit information. Also

refer to the appropriate Powertrain Diagnostic Proce-

dures manual for operation of the DRB scan tool.

STARTER MOTOR RELAY TEST

Refer to Group 8A, Battery/Starting/Charging/Sys-

tem Diagnostics, for starter motor relay testing.

INJECTOR TEST

Disconnect the injector wire connector from the in-

jector. Place an ohmmeter on the injector terminals.

Resistance reading should be approximately 14.5

ohms61.2 ohms at 20ÉC (68ÉF). Proceed to following

Injector Diagnosis chart.

FUEL SYSTEM PRESSURE TEST

Refer to the Fuel Delivery System section of this

group. See Fuel System Pressure Test.

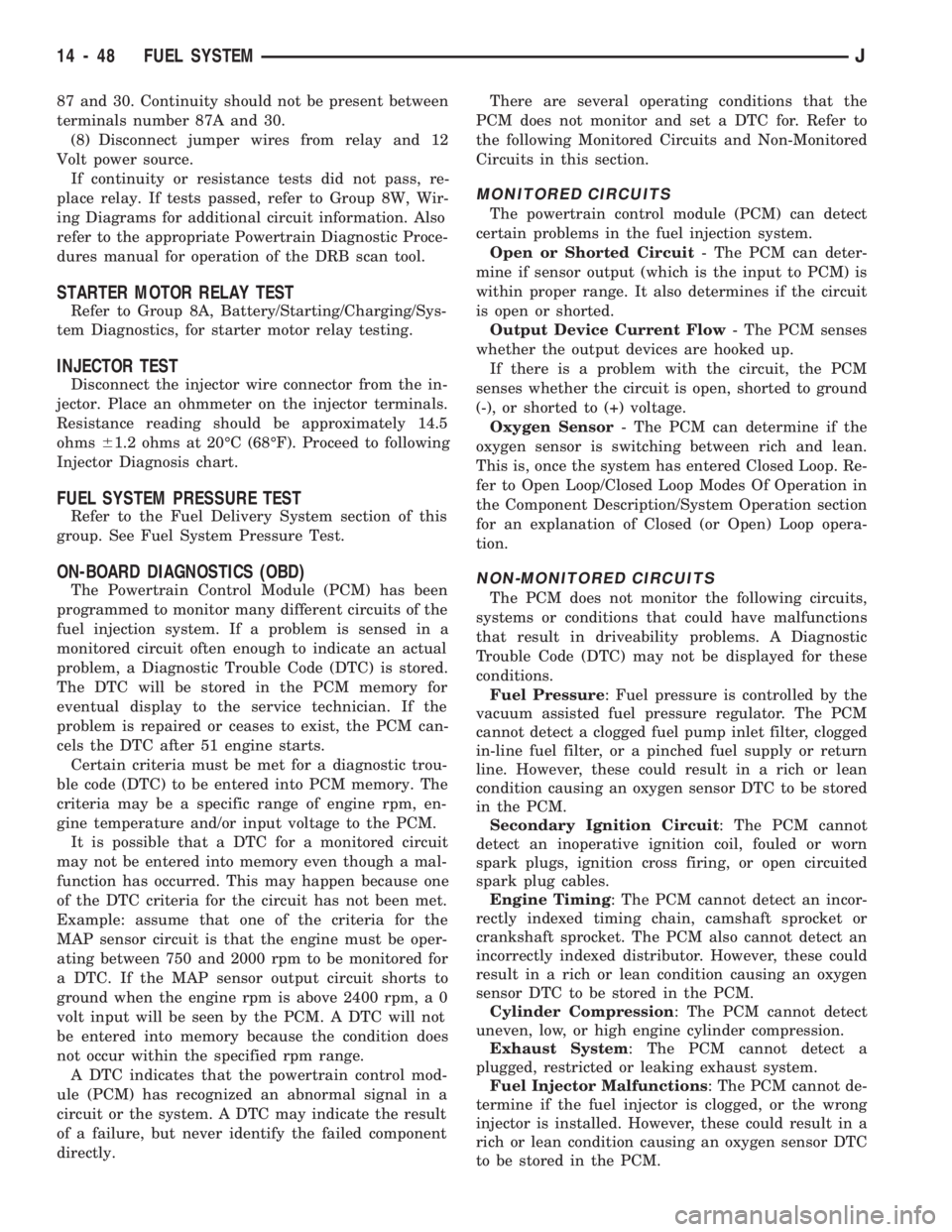

ON-BOARD DIAGNOSTICS (OBD)

The Powertrain Control Module (PCM) has been

programmed to monitor many different circuits of the

fuel injection system. If a problem is sensed in a

monitored circuit often enough to indicate an actual

problem, a Diagnostic Trouble Code (DTC) is stored.

The DTC will be stored in the PCM memory for

eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a diagnostic trou-

ble code (DTC) to be entered into PCM memory. The

criteria may be a specific range of engine rpm, en-

gine temperature and/or input voltage to the PCM.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. This may happen because one

of the DTC criteria for the circuit has not been met.

Example: assume that one of the criteria for the

MAP sensor circuit is that the engine must be oper-

ating between 750 and 2000 rpm to be monitored for

a DTC. If the MAP sensor output circuit shorts to

ground when the engine rpm is above 2400 rpm, a 0

volt input will be seen by the PCM. A DTC will not

be entered into memory because the condition does

not occur within the specified rpm range.

A DTC indicates that the powertrain control mod-

ule (PCM) has recognized an abnormal signal in a

circuit or the system. A DTC may indicate the result

of a failure, but never identify the failed component

directly.There are several operating conditions that the

PCM does not monitor and set a DTC for. Refer to

the following Monitored Circuits and Non-Monitored

Circuits in this section.

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain problems in the fuel injection system.

Open or Shorted Circuit- The PCM can deter-

mine if sensor output (which is the input to PCM) is

within proper range. It also determines if the circuit

is open or shorted.

Output Device Current Flow- The PCM senses

whether the output devices are hooked up.

If there is a problem with the circuit, the PCM

senses whether the circuit is open, shorted to ground

(-), or shorted to (+) voltage.

Oxygen Sensor- The PCM can determine if the

oxygen sensor is switching between rich and lean.

This is, once the system has entered Closed Loop. Re-

fer to Open Loop/Closed Loop Modes Of Operation in

the Component Description/System Operation section

for an explanation of Closed (or Open) Loop opera-

tion.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems or conditions that could have malfunctions

that result in driveability problems. A Diagnostic

Trouble Code (DTC) may not be displayed for these

conditions.

Fuel Pressure: Fuel pressure is controlled by the

vacuum assisted fuel pressure regulator. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, or a pinched fuel supply or return

line. However, these could result in a rich or lean

condition causing an oxygen sensor DTC to be stored

in the PCM.

Secondary Ignition Circuit: The PCM cannot

detect an inoperative ignition coil, fouled or worn

spark plugs, ignition cross firing, or open circuited

spark plug cables.

Engine Timing: The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket or

crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor DTC to be stored in the PCM.

Cylinder Compression: The PCM cannot detect

uneven, low, or high engine cylinder compression.

Exhaust System: The PCM cannot detect a

plugged, restricted or leaking exhaust system.

Fuel Injector Malfunctions: The PCM cannot de-

termine if the fuel injector is clogged, or the wrong

injector is installed. However, these could result in a

rich or lean condition causing an oxygen sensor DTC

to be stored in the PCM.

14 - 48 FUEL SYSTEMJ

Page 1011 of 1784

Excessive Oil Consumption: Although the PCM

monitors exhaust stream oxygen content through ox-

ygen sensor (closed loop), it cannot determine exces-

sive oil consumption.

Throttle Body Air Flow: The PCM cannot detect

a clogged or restricted air cleaner inlet or air filter

element.

Evaporative System: The PCM will not detect a

restricted, plugged or loaded EVAP canister.

Vacuum Assist: Leaks or restrictions in the vac-

uum circuits of vacuum assisted engine control sys-

tem devices are not monitored by the PCM. However,

a vacuum leak at the MAP sensor will be monitored

and a diagnostic trouble code (DTC) will be gener-

ated by the PCM.

Powertrain Control Module (PCM) System

Ground: The PCM cannot determine a poor system

ground. However, a DTC may be generated as a re-

sult of this condition.

Powertrain Control Module (PCM) Connector

Engagement: The PCM cannot determine spread or

damaged connector pins. However, a DTC may be

generated as a result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device. It will es-

tablish high and low limits that are programmed into

it for that device. If the input voltage is not within

specifications and other Diagnostic Trouble Code

(DTC) criteria are met, a DTC will be stored in mem-

ory. Other DTC criteria might include engine rpm

limits or input voltages from other sensors or

switches. The other inputs might have to be sensed

by the PCM when it senses a high or low input volt-

age from the control system device in question.

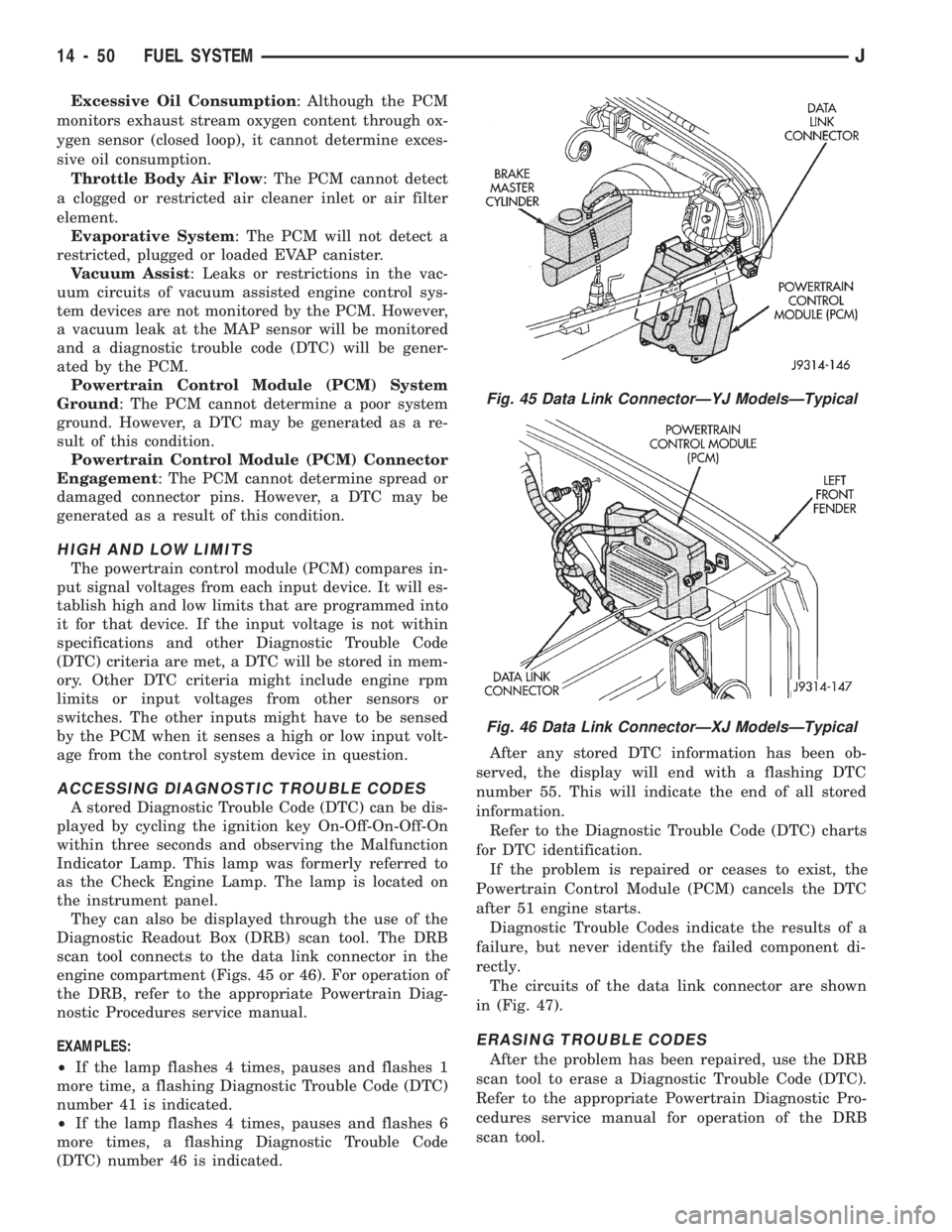

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored Diagnostic Trouble Code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the Malfunction

Indicator Lamp. This lamp was formerly referred to

as the Check Engine Lamp. The lamp is located on

the instrument panel.

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

scan tool connects to the data link connector in the

engine compartment (Figs. 45 or 46). For operation of

the DRB, refer to the appropriate Powertrain Diag-

nostic Procedures service manual.

EXAMPLES:

²If the lamp flashes 4 times, pauses and flashes 1

more time, a flashing Diagnostic Trouble Code (DTC)

number 41 is indicated.

²If the lamp flashes 4 times, pauses and flashes 6

more times, a flashing Diagnostic Trouble Code

(DTC) number 46 is indicated.After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored

information.

Refer to the Diagnostic Trouble Code (DTC) charts

for DTC identification.

If the problem is repaired or ceases to exist, the

Powertrain Control Module (PCM) cancels the DTC

after 51 engine starts.

Diagnostic Trouble Codes indicate the results of a

failure, but never identify the failed component di-

rectly.

The circuits of the data link connector are shown

in (Fig. 47).

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a Diagnostic Trouble Code (DTC).

Refer to the appropriate Powertrain Diagnostic Pro-

cedures service manual for operation of the DRB

scan tool.

Fig. 45 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 46 Data Link ConnectorÐXJ ModelsÐTypical

14 - 50 FUEL SYSTEMJ

Page 1112 of 1784

TRANSMISSION AND TRANSFER CASE

CONTENTS

page page

30RH/32RH AUTOMATIC TRANSMISSION . . . 66

AW-4 AUTOMATIC TRANSMISSION........ 156AX 15 MANUAL TRANSMISSION.......... 32

AX 4/5 MANUAL TRANSMISSION........... 1

AX 4/5 MANUAL TRANSMISSION

INDEX

page page

Cleaning and Inspection................... 13

Gear Ratios............................. 2

General Information........................ 1

Recommended Lubricant.................... 2

Service Diagnosis......................... 2

Shift Pattern............................. 2Transmission Assembly and Adjustment....... 15

Transmission Disassembly and Overhaul........ 5

Transmission Identification................... 1

Transmission Installation.................... 4

Transmission Removal..................... 3

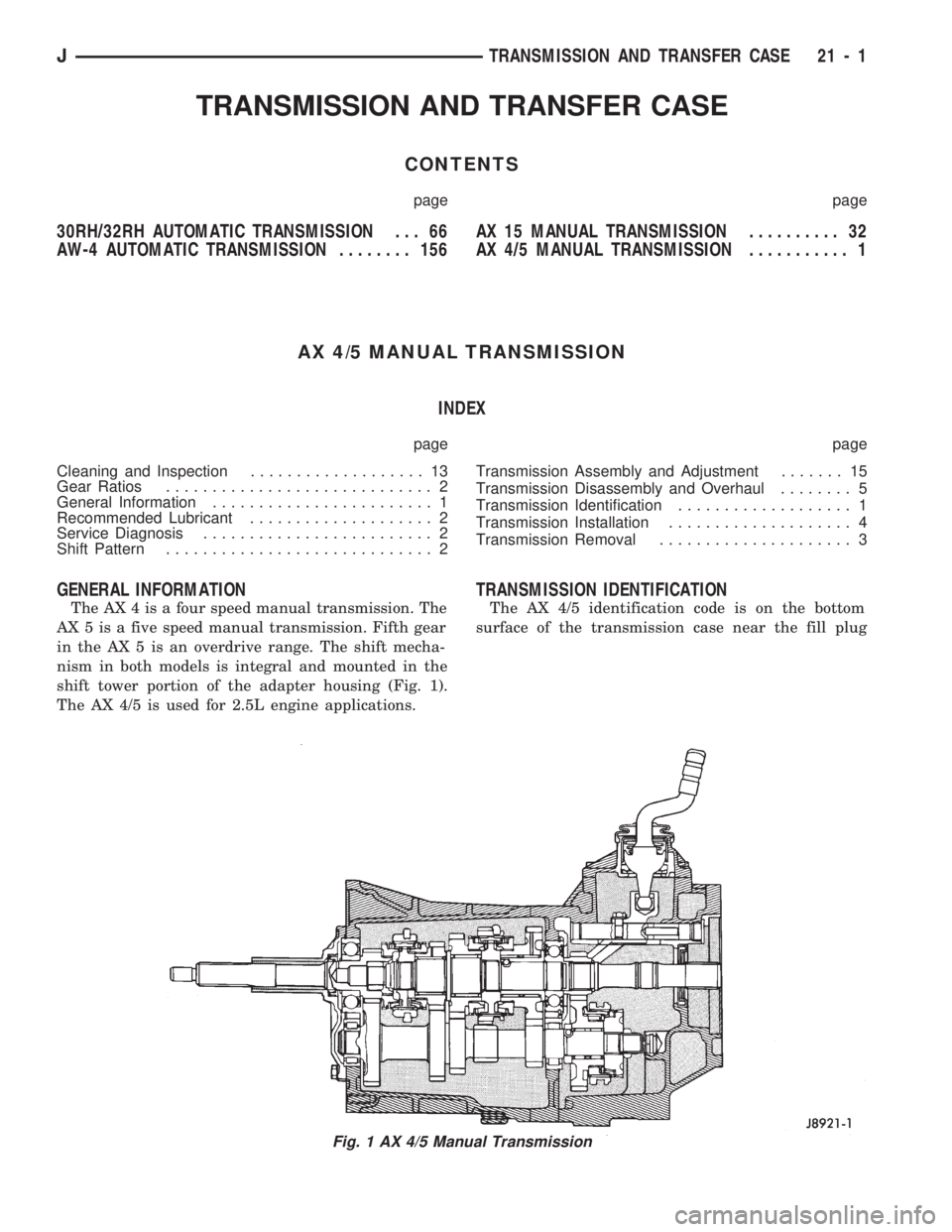

GENERAL INFORMATION

The AX 4 is a four speed manual transmission. The

AX 5 is a five speed manual transmission. Fifth gear

in the AX 5 is an overdrive range. The shift mecha-

nism in both models is integral and mounted in the

shift tower portion of the adapter housing (Fig. 1).

The AX 4/5 is used for 2.5L engine applications.

TRANSMISSION IDENTIFICATION

The AX 4/5 identification code is on the bottom

surface of the transmission case near the fill plug

Fig. 1 AX 4/5 Manual Transmission

JTRANSMISSION AND TRANSFER CASE 21 - 1

Page 1144 of 1784

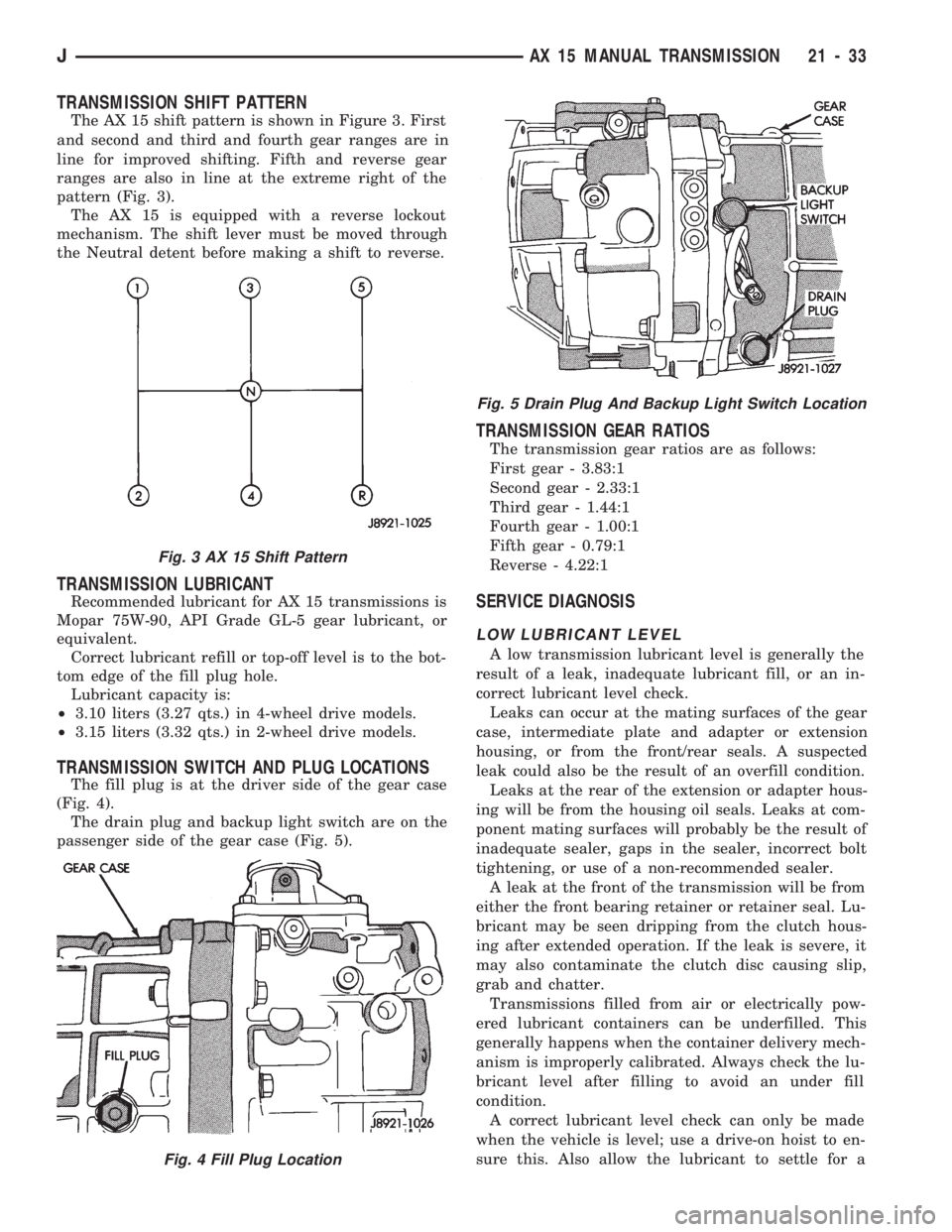

TRANSMISSION SHIFT PATTERN

The AX 15 shift pattern is shown in Figure 3. First

and second and third and fourth gear ranges are in

line for improved shifting. Fifth and reverse gear

ranges are also in line at the extreme right of the

pattern (Fig. 3).

The AX 15 is equipped with a reverse lockout

mechanism. The shift lever must be moved through

the Neutral detent before making a shift to reverse.

TRANSMISSION LUBRICANT

Recommended lubricant for AX 15 transmissions is

Mopar 75W-90, API Grade GL-5 gear lubricant, or

equivalent.

Correct lubricant refill or top-off level is to the bot-

tom edge of the fill plug hole.

Lubricant capacity is:

²3.10 liters (3.27 qts.) in 4-wheel drive models.

²3.15 liters (3.32 qts.) in 2-wheel drive models.

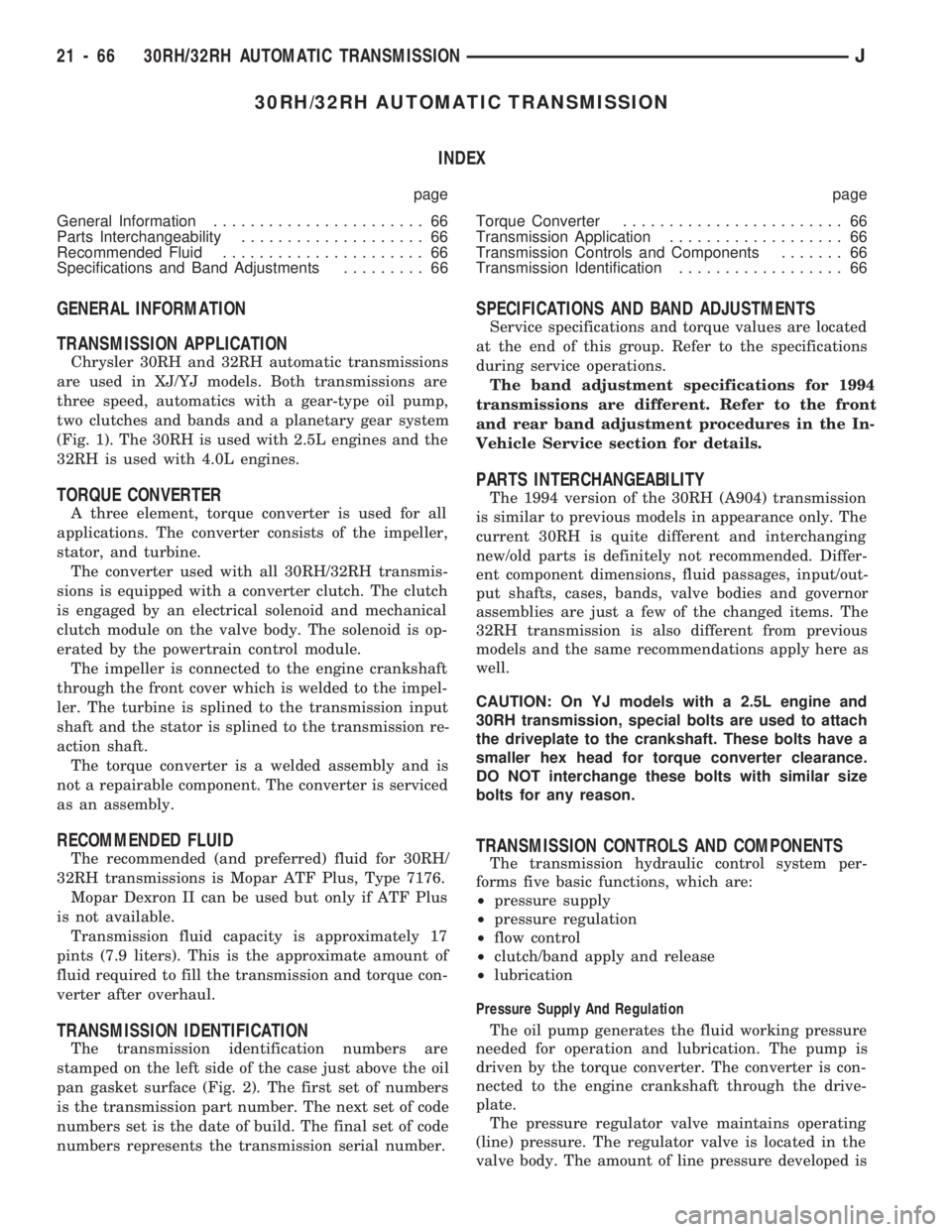

TRANSMISSION SWITCH AND PLUG LOCATIONS

The fill plug is at the driver side of the gear case

(Fig. 4).

The drain plug and backup light switch are on the

passenger side of the gear case (Fig. 5).

TRANSMISSION GEAR RATIOS

The transmission gear ratios are as follows:

First gear - 3.83:1

Second gear - 2.33:1

Third gear - 1.44:1

Fourth gear - 1.00:1

Fifth gear - 0.79:1

Reverse - 4.22:1

SERVICE DIAGNOSIS

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the

result of a leak, inadequate lubricant fill, or an in-

correct lubricant level check.

Leaks can occur at the mating surfaces of the gear

case, intermediate plate and adapter or extension

housing, or from the front/rear seals. A suspected

leak could also be the result of an overfill condition.

Leaks at the rear of the extension or adapter hous-

ing will be from the housing oil seals. Leaks at com-

ponent mating surfaces will probably be the result of

inadequate sealer, gaps in the sealer, incorrect bolt

tightening, or use of a non-recommended sealer.

A leak at the front of the transmission will be from

either the front bearing retainer or retainer seal. Lu-

bricant may be seen dripping from the clutch hous-

ing after extended operation. If the leak is severe, it

may also contaminate the clutch disc causing slip,

grab and chatter.

Transmissions filled from air or electrically pow-

ered lubricant containers can be underfilled. This

generally happens when the container delivery mech-

anism is improperly calibrated. Always check the lu-

bricant level after filling to avoid an under fill

condition.

A correct lubricant level check can only be made

when the vehicle is level; use a drive-on hoist to en-

sure this. Also allow the lubricant to settle for a

Fig. 3 AX 15 Shift Pattern

Fig. 4 Fill Plug Location

Fig. 5 Drain Plug And Backup Light Switch Location

JAX 15 MANUAL TRANSMISSION 21 - 33

Page 1177 of 1784

30RH/32RH AUTOMATIC TRANSMISSION

INDEX

page page

General Information....................... 66

Parts Interchangeability.................... 66

Recommended Fluid...................... 66

Specifications and Band Adjustments......... 66Torque Converter........................ 66

Transmission Application................... 66

Transmission Controls and Components....... 66

Transmission Identification.................. 66

GENERAL INFORMATION

TRANSMISSION APPLICATION

Chrysler 30RH and 32RH automatic transmissions

are used in XJ/YJ models. Both transmissions are

three speed, automatics with a gear-type oil pump,

two clutches and bands and a planetary gear system

(Fig. 1). The 30RH is used with 2.5L engines and the

32RH is used with 4.0L engines.

TORQUE CONVERTER

A three element, torque converter is used for all

applications. The converter consists of the impeller,

stator, and turbine.

The converter used with all 30RH/32RH transmis-

sions is equipped with a converter clutch. The clutch

is engaged by an electrical solenoid and mechanical

clutch module on the valve body. The solenoid is op-

erated by the powertrain control module.

The impeller is connected to the engine crankshaft

through the front cover which is welded to the impel-

ler. The turbine is splined to the transmission input

shaft and the stator is splined to the transmission re-

action shaft.

The torque converter is a welded assembly and is

not a repairable component. The converter is serviced

as an assembly.

RECOMMENDED FLUID

The recommended (and preferred) fluid for 30RH/

32RH transmissions is Mopar ATF Plus, Type 7176.

Mopar Dexron II can be used but only if ATF Plus

is not available.

Transmission fluid capacity is approximately 17

pints (7.9 liters). This is the approximate amount of

fluid required to fill the transmission and torque con-

verter after overhaul.

TRANSMISSION IDENTIFICATION

The transmission identification numbers are

stamped on the left side of the case just above the oil

pan gasket surface (Fig. 2). The first set of numbers

is the transmission part number. The next set of code

numbers set is the date of build. The final set of code

numbers represents the transmission serial number.

SPECIFICATIONS AND BAND ADJUSTMENTS

Service specifications and torque values are located

at the end of this group. Refer to the specifications

during service operations.

The band adjustment specifications for 1994

transmissions are different. Refer to the front

and rear band adjustment procedures in the In-

Vehicle Service section for details.

PARTS INTERCHANGEABILITY

The 1994 version of the 30RH (A904) transmission

is similar to previous models in appearance only. The

current 30RH is quite different and interchanging

new/old parts is definitely not recommended. Differ-

ent component dimensions, fluid passages, input/out-

put shafts, cases, bands, valve bodies and governor

assemblies are just a few of the changed items. The

32RH transmission is also different from previous

models and the same recommendations apply here as

well.

CAUTION: On YJ models with a 2.5L engine and

30RH transmission, special bolts are used to attach

the driveplate to the crankshaft. These bolts have a

smaller hex head for torque converter clearance.

DO NOT interchange these bolts with similar size

bolts for any reason.

TRANSMISSION CONTROLS AND COMPONENTS

The transmission hydraulic control system per-

forms five basic functions, which are:

²pressure supply

²pressure regulation

²flow control

²clutch/band apply and release

²lubrication

Pressure Supply And Regulation

The oil pump generates the fluid working pressure

needed for operation and lubrication. The pump is

driven by the torque converter. The converter is con-

nected to the engine crankshaft through the drive-

plate.

The pressure regulator valve maintains operating

(line) pressure. The regulator valve is located in the

valve body. The amount of line pressure developed is

21 - 66 30RH/32RH AUTOMATIC TRANSMISSIONJ