ECO mode JEEP CHEROKEE 1994 Service Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1665 of 1784

WARNING: LARGE AMOUNTS OF REFRIGERANT

RELEASED IN A CLOSED WORK AREA WILL DIS-

PLACE THE OXYGEN AND CAUSE SUFFOCATION.

ALWAYS MAINTAIN GOOD VENTILATION SUR-

ROUNDING THE WORK AREA.

R-12 gas, under normal conditions, is non-poison-

ous.

WARNING: THE DISCHARGE OF R-12 GAS NEAR

AN OPEN FLAME CAN PRODUCE A VERY POISON-

OUS GAS CALLED PHOSGENE. PHOSGENE IS

GENERATED WHEN A FLAME-TYPE LEAK DETEC-

TOR IS USED.

CAUTION: When charging an A/C system always

keep the tank in an upright position. If the tank is

on its side or upside down, liquid refrigerant will

enter the system and may damage the compressor.

In most instances when charging or adding refrig-

erant, moderate heat is required to bring the pres-

sure of the refrigerant above the pressure of the

system. A bucket or large pan of hot water, not over

52ÉC (125ÉF), is all the heat required for this pur-

pose. DO NOT heat the refrigerant container with a

blow torch or any other means that would raise the

temperature and pressure above this temperature.

CAUTION: DO NOT allow liquid refrigerant to touch

bright metal. Refrigerant will tarnish bright metal

and chrome surfaces. Refrigerant in combination

with moisture is very corrosive and can cause ex-

tensive damage to all metal surfaces.

Avoid splashing the refrigerant on any surface.

RECYCLING

(R-12) refrigerant is a chloroflorocarbon (CFC) that

can contribute to the depletion of the ozone layer in

the upper atmosphere. Ozone filters out harmful ra-

diation from the sun. To assist in protecting the

ozone layer, Chrysler Corporation requires that an

(R-12) refrigerant recovery device that meets SAE

standard J1991 be used. Contact an automotive ser-

vice equipment supplier for refrigerant recycling

equipment that is available in your area. Refer to

the operating instructions provided with the recy-

cling equipment for proper operation.

SERVICE PRECAUTIONS

Never open or loosen a connection before discharg-

ing the system refrigerant.

A system which has been opened to replace a com-

ponent or one which has discharged through leakage

must be evacuated before charging.

Immediately after disconnecting a component from

the system, seal the open fittings with a cap or plug.Before disconnecting a component from the system,

clean the outside of the fittings thoroughly.

DO NOT remove the sealing caps from a replace-

ment component until ready to install.

Refrigerant oil will absorb moisture from the atmo-

sphere if left uncapped. DO NOT open an oil con-

tainer until ready to use and install the cap

immediately after using. Store the oil only in a clean

moisture-free container.

Before connecting an open fitting always install a

new seal ring. Coat the fitting and seal with clean

refrigerant oil before connecting.

When installing a refrigerant line avoid sharp

bends. Position the line away from the exhaust or

any sharp edges which may chafe the line.

Tighten fittings only to the specified torque. The

copper and aluminum fittings used in the A/C system

will not tolerate over tightening.

When disconnecting a fitting use a wrench on both

halves of the fitting to prevent twisting of the refrig-

erant lines or tubes.

DO NOT open a refrigerant system or uncap a re-

placement component unless it is as close as possible

to room temperature. This will prevent condensation

from forming inside of a component which is cooler

than the surrounding air.

Keep service tools and the work area clean. Con-

tamination of A/C system through careless work hab-

its must be avoided.

PRESSURE GAUGE AND MANIFOLD ASSEMBLY

Pressure Gauge and Manifold Assembly Tool

C-3740-B (Fig. 1) is the most important tool used to

service the air conditioning system. The gauge as-

sembly is used to determine:

²System high side gauge pressures

²System low side gauge pressures

²The correct refrigerant charge

²System diagnosis

It is designed to provide simultaneous high and low

side pressure indications, because these pressures

must be compared to determine the correct system

operation.

LOW SIDE GAUGE

The low side gauge is a compound gauge, which

means that it will register both pressure and vacuum

(Fig. 1). The compound gauge is calibrated 0-1034

kPa (0-150 psi) pressure and 0-760 mm (0-30 in.) of

mercury vacuum. It is connected to the suction ser-

vice valve to check the low side pressure or vacuum.

HIGH SIDE GAUGE

The high side gauge is used to check the pressure

in the discharge side of the air conditioning system

(Fig. 1).

24 - 2 HEATING AND AIR CONDITIONINGJ

Page 1677 of 1784

SERVICE DIAGNOSISÐELECTRICAL

BLOWER CONTROLSÐXJ VEHICLES

DESCRIPTION

The blower motor delivers air to the inside of the

vehicle. Its speed is controlled by the blower switch

and the blower resistors. With the switch in LO, part

of the battery voltage is supplied to the motor

through all of the resistors. The motor runs slowly.

As the blower switch is moved to a higher speed, the

switch allows more voltage to be applied to the

blower motor, which will increase its speed. When

the switch is in HI, the blower resistors are bypassed

and battery voltage is applied directly to the blower

motor. The motor runs at the fastest speed in this

mode.

DIAGNOSIS

Refer to the Group 8W, Wiring Diagrams for com-

plete system schematic.

1. BLOWER MOTOR INOPERATIVE

²Remove and inspect fuse. If the fuse is blown, re-

place fuse.

2. BLOWER MOTOR INOPERATIVE (HI Posi-

tion)

Put the ignition switch in RUN, the select switch

in HEAT and the blower switch on HI.

²Blower motor connector (Terminal A) should be

battery voltage. If not go to next step.

²Blower motor connector (Terminal B) should be 0

ohms. If not, repair wire to ground.

²Blower switch connector (Terminal C) should be

battery voltage. If battery voltage replace blower

switch. If not, replace select switch.

3. BLOWER MOTOR INOPERATIVE (LO, M1

& M2 Positions)

Ignition switch in RUN, select switch in HEAT.

²Blower resistors connector (Terminal D) should be

battery voltage. If not, replace select switch.

²Blower resistors connector (Terminal C) should be

battery voltage. If not, replace blower switch.

²Blower resistors connector (Terminal A) should be

battery voltage. If not, replace blower switch.

²Blower resistors connector (Terminal B) should be

battery voltage. If not, replace blower resistor.

AIR CONDITIONING SYSTEMÐXJ VEHICLES

DESCRIPTION

The A/C Compressor Clutch is belt-driven by the

engine. A clutch, operated by a solenoid, automati-

cally turns the compressor on and off to control evap-

orator icing.

The A/C Compressor Clutch operation is controlled

by several components: the A/C Low-Pressure

Switch, Thermostat Switch, Fuel Pump Relay, A/C

Clutch Relay and the Engine Controller.The A/C low pressure switch opens when there is

not enough refrigerant in the system. When this hap-

pens, voltage is no longer present at the Engine Con-

troller. The Engine Controller will turn off the A/C

clutch relay. With the proper refrigerant level in the

system, the low pressure switch remains closed.

When the evaporator temperature is low enough to

ice the cooling coils, the thermostat switch opens.

The Engine Controller will turn off the A/C clutch.

The thermostat switch closes when the temperature

rises. The Engine Controller will then turn the A/C

clutch relay on again.

DIAGNOSIS

Refer to the Group 8W, Wiring Diagrams for com-

plete system schematic.

With engine running, Engine Controller may delay

A/C clutch up to 30 seconds.

1. A/C COMPRESSOR CLUTCH INOPERA-

TIVE

Clutch connector disconnected.

²Jumper fused test lead, battery to clutch connec-

tor, clutch should operate. If not, replace compressor

clutch assembly.

2. A/C LOW PRESSURE SWITCH

Ignition in RUN, A/C controls in MAX or NORM.

²Low pressure switch connector (Terminal A)

should be battery voltage. If not, repair open to select

switch.

²Low pressure switch connector (Terminal C)

should be battery voltage. If not, check switch resis-

tance and check freon pressure.

3. A/C CLUTCH RELAY

Engine RUNNING, A/C controls in MAX or

NORM.

²Relay connector Pin 4 to ground should be battery

voltage. If not, check fuse F6 in Power Distribution

Center.

²Ground A/C clutch relay (Terminal 5) should have

A/C compressor clutch engagement. If not, check En-

gine Controller Terminals 27, 28 and 34.

HEATING SYSTEMÐYJ VEHICLES

DESCRIPTION

The blower motor circuit begins at a 25 amp fuse

that receives its battery feed from the ignition

switch. From the fuse the circuit extends to a micro-

switch mounted on the heater control.

The micro-switch is normally closed is operated by

a cam on the heater control lever. In all heater con-

trol lever positions, except OFF and VENT, the

blower motor electrical circuit is complete. In the

OFF and VENT positions the cam depresses the mi-

cro-switch lever opening the electrical circuit to the

blower motor.

24 - 14 HEATING AND AIR CONDITIONINGJ

Page 1717 of 1784

REFRIGERANT LEAK TESTING, DISCHARGING, EVACUATING AND CHARGING

LEAK TESTING REFRIGERANT

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE LEAK TESTING.

If A/C system is not cooling properly, determine if

system is fully charged. Refer to Refrigerant System

Diagnosis Chart. If the system is empty evacuate the

A/C system and charge system with 0.283 kPa (0.6

lbs. or 10 oz.) R-134a refrigerant. Refer to Charging

Refrigerant System for instructions. To detect a leak

in the system, perform the following procedures.

(1) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(2) Bring A/C system up to operating temperature

and pressure. This is done by allowing the engine to

run with the A/C on for 5 to 7 minutes.

(3) Open hood 5 minutes prior to leak test. This

will dissipate any accumulated refrigerant in the en-

gine compartment.

(4) With the engine not running, use an R-134a

Electronic Leak Detector and search for leaks. Move

probe slowly along the bottom side of lines and fit-

tings, because R-134a is heavier than air. Fittings,

lines, or components that appear to be oily usually

indicates a refrigerant leak.

(5) To inspect the evaporator core for leaks. Set the

blower at low speed and the selector in PANEL and

RECIRC mode check for leaks at CENTER panel ou-

lets.

DISCHARGING REFRIGERANT SYSTEM

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE DISCHARGING SYSTEM.

R-134a refrigrant is a hydrofluorocarbon (HFC)

that does not contain chlorine. R-134a refrigerant Re-

covery/Recycling Station that meets SAE standard

J2210 must be used to discharge the refrigerant sys-

tem. Refer to the operating instructions provided

with the equipment for proper operation.

EVACUATING REFRIGERANT SYSTEM

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE EVACUATING SYSTEM.If the A/C system has been open to the atmosphere,

it must be evacuated before the system can be

charged. Moisture and air mixed with refrigerant will

raise the compressor head pressure above acceptable

operating levels. This will reduce the performance of

the air conditioner and damage the compressor. Mois-

ture will boil at near room temperature when ex-

posed to vacuum. To evacuate the refrigerant system

use following procedure:

(1) Connect a suitable charging station and mani-

fold gauge set to the vehicle.

(2) Open the low and high side valves and start

vacuum pump. When suction gauge reads 88 kPag

(26 in. Hg) vacuum or greater, close all valves and

turn off vacuum pump. If system fails to reach spec-

ified vacuum, the system has a leak that must be

corrected. If system maintains the specified vacuum

for 30 minutes, start the vacuum pump. Then open

the suction and discharge valves and evacuate an ad-

ditional 10 minutes.

(3) Close all valves. Turn off and disconnect the

vacuum pump.

The system is now ready to be charged with refrig-

erant.

CHARGING REFRIGERANT SYSTEM

WARNING: REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE CHARGING SYSTEM.

After the system has been tested for leaks and

evacuated, a refrigerant charge can be injected into

the system. Refer to refrigerant capacities for proper

amount of refrigerant charge.

The most accurate method of charging is to com-

pletely evacuate the system. Then charge the system

using a Recovery/Recycling Station approved for

R-134a refrigerant. Refer to the operating instruc-

tions provided with the equipment for proper opera-

tion.

CAUTION: Do not over charge refrigerant system.

This will cause excessive compressor head pres-

sure and can cause noise and system failure.

REFRIGERANT CHARGE CAPACITY

The R-134a system charge capacity is 0.9 kPag (32

oz.) for XJ and YJ vehicles.

8 AIR CONDITIONINGJ

Page 1722 of 1784

EVAPORATIVE EMISSION CONTROLS

INDEX

page page

Crankcase Ventilation System................ 5

EVAP (Evaporation) Control System........... 4

EVAP Canister........................... 4Fuel Tank Filler Tube Cap.................. 4

Pressure Relief/Rollover Valve................ 5

EVAP (EVAPORATION) CONTROL SYSTEM

GENERAL INFORMATION

The function of the EVAP control system is to pre-

vent the emissions of gasoline vapors from the fuel

tank into the atmosphere. When fuel evaporates in

the fuel tank, the vapors pass through vent hoses or

tubes to a carbon filled EVAP canister. They are

temporarily held in the canister until they can be

drawn into the intake manifold when the engine is

running.

The EVAP canister is a feature on all models for

the storage of fuel vapors from the fuel tank.

The hoses used in this system are specially

manufactured. If replacement becomes neces-

sary, it is important to use only fuel resistant

hose.

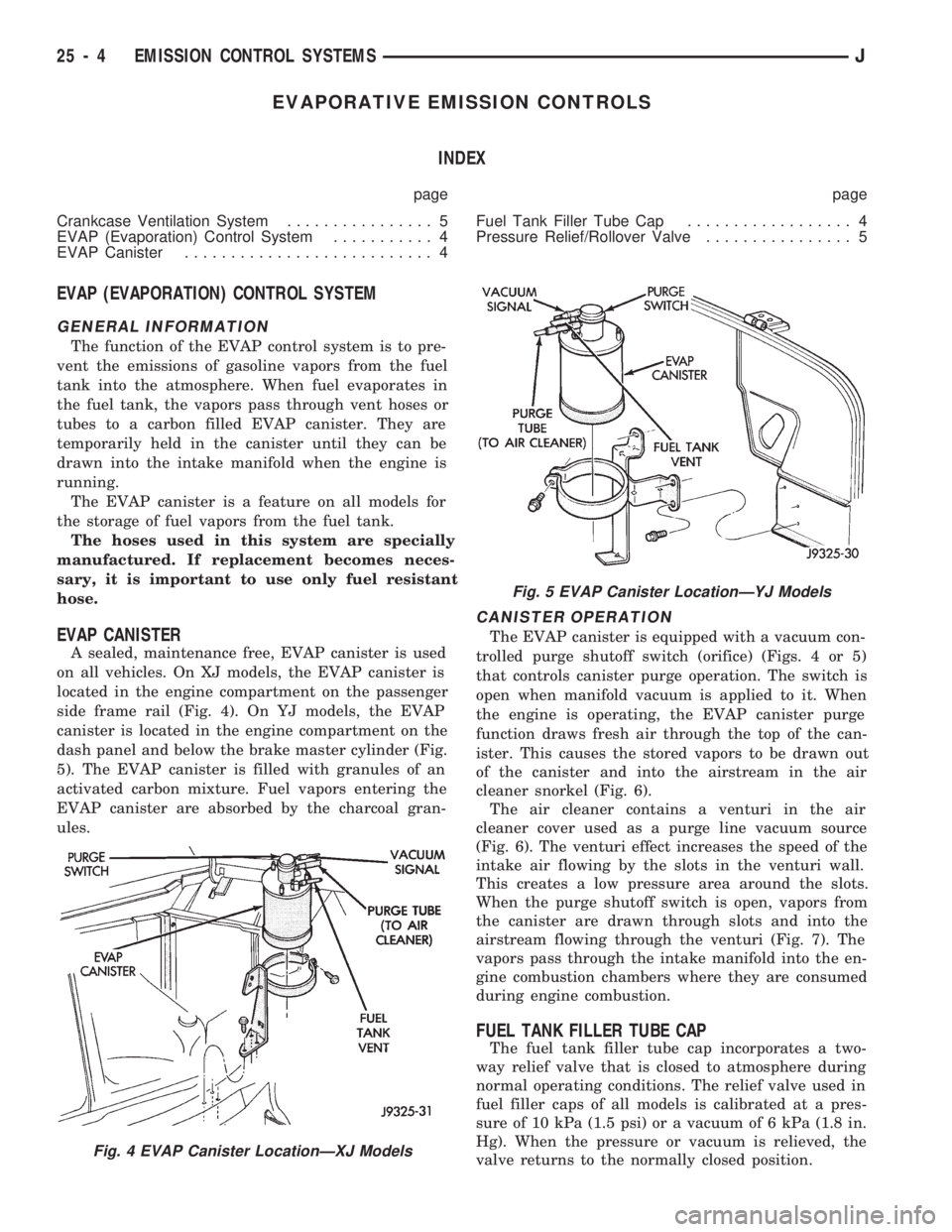

EVAP CANISTER

A sealed, maintenance free, EVAP canister is used

on all vehicles. On XJ models, the EVAP canister is

located in the engine compartment on the passenger

side frame rail (Fig. 4). On YJ models, the EVAP

canister is located in the engine compartment on the

dash panel and below the brake master cylinder (Fig.

5). The EVAP canister is filled with granules of an

activated carbon mixture. Fuel vapors entering the

EVAP canister are absorbed by the charcoal gran-

ules.

CANISTER OPERATION

The EVAP canister is equipped with a vacuum con-

trolled purge shutoff switch (orifice) (Figs. 4 or 5)

that controls canister purge operation. The switch is

open when manifold vacuum is applied to it. When

the engine is operating, the EVAP canister purge

function draws fresh air through the top of the can-

ister. This causes the stored vapors to be drawn out

of the canister and into the airstream in the air

cleaner snorkel (Fig. 6).

The air cleaner contains a venturi in the air

cleaner cover used as a purge line vacuum source

(Fig. 6). The venturi effect increases the speed of the

intake air flowing by the slots in the venturi wall.

This creates a low pressure area around the slots.

When the purge shutoff switch is open, vapors from

the canister are drawn through slots and into the

airstream flowing through the venturi (Fig. 7). The

vapors pass through the intake manifold into the en-

gine combustion chambers where they are consumed

during engine combustion.

FUEL TANK FILLER TUBE CAP

The fuel tank filler tube cap incorporates a two-

way relief valve that is closed to atmosphere during

normal operating conditions. The relief valve used in

fuel filler caps of all models is calibrated at a pres-

sure of 10 kPa (1.5 psi) or a vacuum of 6 kPa (1.8 in.

Hg). When the pressure or vacuum is relieved, the

valve returns to the normally closed position.

Fig. 4 EVAP Canister LocationÐXJ Models

Fig. 5 EVAP Canister LocationÐYJ Models

25 - 4 EMISSION CONTROL SYSTEMSJ

Page 1746 of 1784

ASSEMBLY REPLACEMENTÐYJ VEHICLES,

DRIVE AXLE; FRONT SUSPENSION AND

AXLE...............................2-21

ASSEMBLY REPLACEMENTÐYJ VEHICLES,

DRIVE AXLE; REAR SUSPENSION AND

AXLES..............................3-12

ASSEMBLY (SHORT BLOCK), SERVICE

ENGINE..............................9-4

ASSEMBLY TIPS, TRANSMISSION........21-146

ASSEMBLY, TRANSFER CASE......21-282,21-306

ASSEMBLYÐXJ VEHICLES, ENGINE....9-14,9-54

ASSEMBLYÐYJ VEHICLES, ENGINE....9-16,9-57

ASSEMBLY/INSTALLATION, PINION

GEAR; FRONT SUSPENSION AND AXLE....2-40

ASSEMBLY/INSTALLATION, PINION

GEAR; REAR SUSPENSION AND AXLES....3-22

ASSIST HANDLE, FULL-METAL DOOR.....23-175

ASSIST HANDLEÐXJ VEHICLES.........23-118

AUTO SHUT DOWN (ASD) RELAYÐPCM

OUTPUT............................14-24

AUTOMATIC BELT TENSIONERÐXJ

MODELS............................7-36

AUTOMATIC, PARK-LOCK CABLEÐ

CONSOLE SHIFT.....................19-45

AUTOMATIC SHUT DOWN (ASD) RELAY;

FUEL SYSTEM.......................14-54

AUTOMATIC SHUT DOWN (ASD) RELAY;

IGNITION SYSTEMS..........8D-1,8D-8,8D-20

AUTOMATIC SHUT DOWN (ASD) RELAY

TESTING...........................14-43

AUTOMATIC SHUT DOWN (ASD)

SENSEÐPCM INPUT..................14-19

AUTOMATIC TRANSMISSION..............0-23

AUTOMATIC TRANSMISSION, 30RH/

32RH..............................21-66

AUTOMATIC TRANSMISSION, AW-4.......21-156

AW-4 AUTOMATIC TRANSMISSION.......21-156

AW-4 BUSHING AND PISTON CLEARANCE . . 21-326

AW-4 CLUTCH AND BRAKE PACK

REQUIREMENTS....................21-328

AW-4 CLUTCH DISC AND PLATE

THICKNESS........................21-325

AW-4 GENERAL SPECIFICATIONS........21-324

AW-4 IN-VEHICLE SERVICE.............21-173

AW-4 OIL PUMP WEAR LIMITS..........21-325

AW-4 RETAINER AND PISTON

SPECIFICATIONS....................21-327

AW-4 TORQUE SPECIFICATIONS.........21-331

AW-4 TRANSMISSION DIAGNOSIS.......21-167

AW-4 TRANSMISSION OVERHAUL........21-192

AW-4 TRANSMISSION REMOVAL AND

INSTALLATION......................21-189

AW-4 VALVE AND SPRING

IDENTIFICATION....................21-330

AW-4 VALVE BODY CHECK BALL

DIMENSIONS.......................21-328

AX 15 MANUAL TRANSMISSION..........21-32

AX 15 MANUAL TRANSMISSION,

TORQUE SPECIFICATIONS.............21-320

AX 4/5 MANUAL TRANSMISSION..........21-1

AXLE (2WD), MODEL 30 AXLE AND TUBE . . . 2-20

AXLE 8 1/4 INCH, REAR.........3-29,3-44,3-50

AXLE ALIGNMENT, REAR..................3-8

AXLE AND TUBE AXLE (2WD), MODEL 30 . . . 2-20

AXLE ASSEMBLY REPLACEMENTÐXJ

VEHICLES, DRIVE; FRONT SUSPENSION

AND AXLE...........................2-21

AXLE ASSEMBLY REPLACEMENTÐ

XJ VEHICLES, DRIVE; REAR SUSPENSION

AND AXLES......................3-11,3-30

AXLE ASSEMBLY REPLACEMENTÐ

YJ VEHICLES, DRIVE; FRONT SUSPENSION

AND AXLE...........................2-21

AXLE ASSEMBLY REPLACEMENTÐ

YJ VEHICLES, DRIVE; REAR SUSPENSION

AND AXLES..........................3-12

AXLE BUSHING REPLACEMENT........2-11,2-32

AXLE, FRONT DRIVE.....................2-3

AXLE, MODEL 30 FRONT.............2-46,2-47

AXLE MODEL 35, REAR........3-11, 3-28, 3-50

AXLE NOISE/VIBRATION DIAGNOSIS;

FRONT SUSPENSION AND AXLE

..........2-16

AXLE NOISE/VIBRATION DIAGNOSIS;

REAR SUSPENSION AND AXLES

..........3-7

AXLE SHAFT

...........................3-14

AXLE SHAFTÐCARDAN U-JOINT

...........2-25AXLE SHAFT, HUB BEARING..............2-24

AXLE SHAFT OIL SEAL REPLACEMENT,

INNER..............................2-33

AXLE SHAFT SEAL AND BEARING..........3-15

AXLE SHAFT, SEAL AND BEARING

SERVICE............................3-31

AXLE SPECIFICATIONS; FRONT

SUSPENSION AND AXLE................2-46

AXLE SPECIFICATIONS; REAR

SUSPENSION AND AXLES...........3-28,3-44

AXLEÐYJ VEHICLES, VACUUM

DISCONNECT.........................2-26

AXLES................................3-1

AXLES, FRONT AND REAR................0-26

AXLE/SHIFT MOTOR DIAGNOSIS

DISCONNECT.....................2-28,2-27

BACKLASH AND CONTACT PATTERN

ANALYSIS; FRONT SUSPENSION AND AXLE . 2-44

BACKLASH AND CONTACT PATTERN

ANALYSIS; REAR SUSPENSION AND

AXLES..............................3-25

BACK-UP/REAR TURN SIGNAL/TAIL

LAMP BULB REPLACEMENT.............8L-9

BALANCE, TIRE AND WHEEL..............22-6

BALL DIMENSIONS, AW-4 VALVE BODY

CHECK............................21-328

BALL POWER STEERING GEAR,

RECIRCULATING.....................19-19

BALL STUD REPLACEMENT, LIFTGATE

SUPPORT ROD......................23-70

BALL STUDS, STEERING KNUCKLE.........2-30

BALL STUDS, STEERING LINKAGE.........0-30

BAND ADJUSTMENT, FRONT.............21-99

BAND ADJUSTMENT, REAR..............21-99

BAND ADJUSTMENTS, SPECIFICATIONS....21-66

BAND OVERHAUL, FRONT SERVO........21-136

BAND OVERHAUL, REAR SERVO.........21-136

BANKS, FUSE CHARTS AND RELAY........8W-8

BAR REPLACEMENT, SOUND..............8F-7

BAR, SPORT.........................23-171

BAR, STABILIZER...................2-10,2-14

BAR, TRACK; FRONT SUSPENSION AND

AXLE...........................2-10,2-13

BAR, TRACK; REAR SUSPENSION AND

AXLES...............................3-6

BARÐXJ VEHICLES, STABILIZER...........3-4

BASECOAT/CLEARCOAT................23-202

BASE/COLOR COAT...................23-201

BATTERY.............................0-18

BATTERY CHARGING....................8A-5

BATTERY CHARGING TIME TABLE..........8A-5

BATTERY CLASSIFICATIONS AND

RATINGS............................8A-8

BATTERY CLASSIFICATIONS AND

RATINGSÐLEFT HAND DRIVE..........8B-10

BATTERY CLASSIFICATIONS AND

RATINGSÐRIGHT HAND DRIVE.........8B-10

BATTERY DIAGNOSTICS CHART...........8A-7

BATTERY INDICATOR (BASE CLUSTER

ONLY), OPERATIONAL CHECK...........8A-14

BATTERY LOAD TEST....................8A-4

BATTERY MAINTENANCE.................8B-1

BATTERY OPEN CIRCUIT VOLTAGE.........8A-4

BATTERY OPEN CIRCUIT VOLTAGE TEST....8A-3

BATTERY REPLACEMENTÐLEFT HAND

DRIVE..............................8B-1

BATTERY REPLACEMENTÐRIGHT HAND

DRIVE..............................8B-2

BATTERY SERVICE PROCEDURES..........8B-1

BATTERY TEST PROCEDURES.............8A-2

BATTERY TESTING GENERAL

INFORMATION........................8A-3

BATTERY TORQUE SPECIFICATIONS.......8B-10

BATTERY TRAY..................23-13,23-140

BATTERY VOLTAGEÐPCM INPUT.........14-19

BATTERY/STARTING/CHARGING

SYSTEMS DIAGNOSTICS...............8A-1

BEAM ADJUSTMENT, FOG LAMP..........8L-12

BEAM ADJUSTMENT, HEADLAMP..........8L-3

BEARING AND AXLE SHAFT, HUB..........2-24

BEARING, AXLE SHAFT SEAL

..............3-15

BEARING FITTING CHART, CONNECTING

ROD

............................9-36,9-76

BEARING FITTING CHART, MAIN

.......9-43,9-83

BEARING LUBRICANTS, CHASSIS

COMPONENT AND WHEEL

..............0-30BEARING NOISE, GEAR AND; FRONT

SUSPENSION AND AXLE................2-16

BEARING NOISE, GEAR AND; REAR

SUSPENSION AND AXLES................3-7

BEARING REPLACEMENT, PILOT...........6-11

BEARING REPLACEMENT, PITMAN

SHAFT SEALS.......................19-32

BEARING REPLACEMENT, RELEASE.........6-11

BEARING SERVICE, AXLE SHAFT, SEAL......3-31

BEARINGS, CRANKSHAFT MAIN.......9-40,9-80

BEARINGS, FRONT WHEEL...............0-31

BELT, ACCESSORY DRIVE................0-20

BELT DIAGNOSIS.......................7-31

BELT DIAGNOSIS, SERPENTINE DRIVE......7-32

BELT INDICATOR, SEAT..................8E-4

BELT REMINDER LAMP, SEAT............8E-16

BELT SCHEMATICS......................7-34

BELT SERVICEÐEXCEPT RIGHT HAND

DRIVE..............................7-34

BELT SERVICEÐWITH RIGHT HAND

DRIVE..............................7-35

BELT TENSION........................8B-10

BELT TENSION, DRIVE...................7-38

BELT TENSIONÐEXCEPT RIGHT HAND

DRIVE (RHD).........................7-33

BELT TENSIONÐRIGHT HAND DRIVE (RHD) . . 7-34

BELT TENSION SPECIFICATIONS...........7-34

BELT TENSIONERÐXJ MODELS,

AUTOMATIC..........................7-36

BELT/BUCKLEÐXJ VEHICLES, FRONT

SHOULDER........................23-119

BELT/BUCKLEÐXJ VEHICLES,

REAR SHOULDER/LAP...............23-120

BELTS, ENGINE ACCESSORY DRIVE........7-31

BELTS, FRONT SHOULDER..............23-196

BELTS, REAR SHOULDER...............23-196

BENCH, GEAR ADJUSTMENTS............19-42

BEZEL, INSTRUMENT CLUSTER.....23-91,23-191

BEZEL REPLACEMENT, INDICATOR........8E-17

BLADE REPLACEMENT, FRONT WIPER......8K-8

BLEEDINGÐBRAKE FLUID AND LEVELÐ

BRAKELINES AND HOSES, BRAKE........5-13

BLEEDINGÐWITH ABS BRAKES, BRAKE.....5-14

BLEEDINGÐWITH STANDARD BRAKES,

BRAKE..............................5-13

BLOCK, CYLINDER..................9-45,9-85

BLOCK HEATER, ENGINE.................7-37

BLOCKSÐTWO-DOOR VEHICLES, FRONT

DOOR SPACER......................23-60

BLOWER CONTROLSÐXJ VEHICLES.......24-14

BLOWER MOTOR, A/C..................24-43

BLOWER MOTOR (HEATING).............24-40

BLOWER MOTOR RESISTORS

REPLACEMENT......................24-35

BLOWER MOTOR/AIR DOOR MOTOR

SWITCH REPLACEMENT...............24-39

BLOWER MOTOR/FAN REPLACEMENT......24-26

BODY...............................13-18

BODY ASSEMBLY AND ADJUSTMENT,

VALVE ............................21-144

BODY CHECK BALL DIMENSIONS, AW-4

VALVE ............................21-328

BODY CODE LETTERS, JEEP...............5-2

BODY COLORS, EXTERIOR..............23-204

BODY COMPONENTS....................0-34

BODY COMPONENTS, CHASSIS............0-30

BODY COMPONENTSÐREFINISHING......23-200

BODY COMPONENTSÐYJ VEHICLES......23-132

BODY DISASSEMBLY AND INSPECTION,

VALVE

............................21-138

BODY EXTENSION PANELS AND

FASCIASÐYJ RENEGADE VEHICLES

.....23-147

BODY INSTALLATION, TRANSMISSION

VALVE

............................21-177

BODY INSTALLATION, VALVE

............21-101

BODY LUBRICANT SPECIFICATIONS

........0-35

BODY OVERHAUL, TRANSMISSION

VALVE

............................21-240

BODY REMOVAL, TRANSMISSION

VALVE

............................21-176

BODY REMOVAL, VALVE

...............21-100

BODY SERVICE INFORMATION, GENERAL

....23-1

BODY SERVICE, VALVE

................21-100

BODY SIDE MOULDING/CLADDING

........23-19

BODY SIDE STEP MOULDING

...........23-145

2 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 1747 of 1784

BODY SOLENOIDS, TRANSMISSION

VALVE ............................21-175

BODY STRIPES/DECALS...........23-25,23-153

BODY, THROTTLE.................14-29,14-59

BODY UNDERCOAT....................23-203

BOOSTER CHECK VALVE TEST, POWER......5-11

BOOSTER INSTALLATION, POWER

BRAKE..........................5-23,5-51

BOOSTER OPERATION, POWER BRAKE......5-22

BOOSTER, POWER BRAKE............5-22,5-40

BOOSTER REMOVAL, POWER BRAKE . . . 5-22,5-51

BOOSTER TEST, MASTER CYLINDER/

POWER.............................5-11

BOOSTER VACUUM TEST, POWER..........5-12

BORES, HONING CYLINDER................9-2

BOX, GLOVE.........................23-194

BRACKET, FUEL FILTER.................23-86

BRACKET, FUEL FILTER SHIELD...........13-17

BRACKET, I/P TWEETER SPEAKER/

COURTESY LAMP SUPPORT............23-95

BRACKET, MUFFLER/TAILPIPE HANGER.....13-16

BRACKET, REARVIEW MIRROR

RETAINING........................23-183

BRACKET REPLACEMENT, INTERIOR

REARVIEW MIRROR SUPPORT..........23-75

BRACKETS, CATALYTIC CONVERTER/

MUFFLER/TAILPIPE SUPPORT...........23-85

BRACKETSÐXJ VEHICLES, SPARE TIRE/

WHEEL HOLDDOWN AND FLOOR.......23-128

BRAKE ADJUSTMENT, DRUM..............5-35

BRAKE ADJUSTMENT PARKING............5-63

BRAKE BLEEDINGÐBRAKE FLUID AND

LEVELÐBRAKELINES AND HOSES........5-13

BRAKE BLEEDINGÐWITH ABS BRAKES.....5-14

BRAKE BLEEDINGÐWITH STANDARD

BRAKES.............................5-13

BRAKE BOOSTER INSTALLATION,

POWER.........................5-23,5-51

BRAKE BOOSTER OPERATION, POWER......5-22

BRAKE BOOSTER, POWER............5-22,5-40

BRAKE BOOSTER REMOVAL, POWER . . . 5-22,5-51

BRAKE CABLE TENSIONER REPLACEMENT

(XJ), PARKING........................5-61

BRAKE CHECK, PRELIMINARY..............5-7

BRAKE COMPONENTS, WHEEL.............5-1

BRAKE DIAGNOSIS, ABS..................5-3

BRAKE DIAGNOSIS, SERVICE..............5-7

BRAKE DRUM REFINISHING..............5-37

BRAKE FLUID CONTAMINATION............5-13

BRAKE FLUID, IMPORTANCE OF CLEAN.....5-48

BRAKE FLUID LEVEL....................5-13

BRAKE FLUID, RECOMMENDED........5-13,5-48

BRAKE FLUID TUBE RETAINER CLIP,

FUEL AND; BODY COMPONENTSÐXJ

VEHICLES..........................23-86

BRAKE FLUID TUBE RETAINER CLIP,

FUEL AND; FRAME AND BUMPERS......13-16

BRAKE FLUID/LUBRICANTS/CLEANING

SOLVENTS............................5-1

BRAKE FRONT CABLE REPLACEMENT

(YJ), PARKING........................5-62

BRAKE INDICATOR INOPERATIVE..........8E-4

BRAKE INDICATOR LAMP; INSTRUMENT

PANEL AND GAUGESÐXJ...............8E-2

BRAKE INDICATOR LAMP; INSTRUMENT

PANEL AND GAUGESÐYJ

..............8E-16

BRAKE LEVER INSTALLATION (XJ WITH

FULLCONSOLE), PARKING

..............5-60

BRAKE LEVER INSTALLATION (XJ WITH

MINICONSOLE), PARKING

...............5-58

BRAKE LEVER INSTALLATION (XJ

WITHOUT CONSOLE), PARKING

..........5-60

BRAKE LEVER REMOVAL (XJ WITH FULL

CONSOLE), PARKING

..................5-59

BRAKE LEVER REMOVAL (XJ WITH MINI

CONSOLE), PARKING

..................5-58

BRAKE LEVER REMOVAL (XJ WITHOUT

CONSOLE), PARKING

..................5-60

BRAKE OPERATION, PARKING

.............5-56

BRAKE OVERHAUL, SECOND

............21-232

BRAKE PACK REQUIREMENTS, AW-4

CLUTCH

...........................21-328

BRAKE PEDAL AND BRAKELIGHT

SWITCH

.............................5-65

BRAKE PEDAL INSTALLATION

.............5-66BRAKE PEDAL INSTALLATION (YJ),

PARKING............................5-61

BRAKE PEDAL REMOVAL.................5-65

BRAKE PEDAL REMOVAL (YJ), PARKING....5-61

BRAKE PEDAL SERVICE..................5-65

BRAKE PISTON AND TRANSMISSION

CASE OVERHAUL, FIRST-REVERSE......21-237

BRAKE PROBLEMS, DIAGNOSING

PARKING............................5-10

BRAKE PROBLEMS, DIAGNOSING

SERVICE.............................5-8

BRAKE REAR CABLE REPLACEMENT

(XJ), PARKING........................5-62

BRAKE REAR CABLE REPLACEMENT (YJ),

PARKING............................5-63

BRAKE ROTOR REFINISHING, DISC.........5-32

BRAKE ROTOR RUNOUT, DISC............5-31

BRAKE ROTOR THICKNESS, DISC..........5-31

BRAKE ROTOR THICKNESS VARIATION,

DISC...............................5-31

BRAKE SAFETY PRECAUTIONS.............5-2

BRAKE SERVO, SECOND COAST.........21-181

BRAKE SWITCH.......................14-54

BRAKE SWITCHÐPCM INPUT............14-20

BRAKE SYSTEM (ABS), ANTILOCK..........5-1

BRAKE SYSTEM (ABS) INDICATOR

LAMP, ANTI-LOCK.....................8E-2

BRAKE SYSTEM OPERATION, ANTILOCK.....5-43

BRAKE SYSTEM, POWER.................0-32

BRAKE TORQUE SPECIFICATIONS..........5-67

BRAKE WARNING LIGHT DISPLAY...........5-4

BRAKE WARNING LIGHTS.................5-1

BRAKELIGHT SWITCH ADJUSTMENT........5-66

BRAKELIGHT SWITCH, BRAKE PEDAL.......5-65

BRAKELIGHT SWITCH INSTALLATION.......5-66

BRAKELIGHT SWITCH REMOVAL...........5-66

BRAKELINE CHARTS....................5-15

BRAKELINES AND HOSES................5-15

BRAKELINING MATERIAL..................5-1

BRAKES, BRAKE BLEEDINGÐWITH ABS.....5-14

BRAKES, BRAKE BLEEDINGÐWITH

STANDARD..........................5-13

BRAKES, DISC.........................5-24

BRAKES, DRUM........................5-34

BRAKES, PARKING......................5-56

BRAKES, POWER........................5-1

BRAKESHOE INSTALLATION, DISC..........5-26

BRAKESHOE INSTALLATION, DRUM........5-34

BRAKESHOE REMOVAL, DISC.............5-25

BRAKESHOE REMOVAL, DRUM............5-34

BRAKING MODE, ABS OPERATION IN

ANTILOCK...........................5-43

BRAKING MODE, ABS OPERATION

IN NORMAL..........................5-43

BREAK-IN, ENGINE......................0-13

BRUSH GUARD........................23-3

BUCKET SEAT COMPONENTS, POWER....23-106

BUCKET SEAT CUSHION AND COVER......23-98

BUCKET SEAT PLATFORM AND TRACKS . . . 23-105

BUCKET SEATBACK COVER AND FRAME . . . 23-100

BUCKET SEATBACK RECONDITIONING.....23-102

BUCKET SEATS, FRONT.................23-97

BUFFING AND POLISHING..............23-203

BULB REPLACEMENT, BACK-UP/REAR

TURN SIGNAL/TAIL LAMP...............8L-9

BULB REPLACEMENT, FRONT PARK/

TURN SIGNAL LAMP

...................8L-8

BULB REPLACEMENT, HEADLAMP

..........8L-3

BULB REPLACEMENT, INSTRUMENT

CLUSTER

...........................8E-19

BULB REPLACEMENT, SIDE MARKER

LAMP

...............................8L-7

BULB REPLACEMENT, UNDERHOOD

LAMP

..............................8L-18

BULB REPLACEMENTÐYJ VEHICLES,

HARDTOP DOME/CARGO LAMP

.........8L-20

BULB/ELEMENT REPLACEMENT, FOG

LAMP

..............................8L-13

BUMPER, FRONT

..................13-3,13-14

BUMPER, LIFTGATE LICENSE PLATE

SCREW ANCHOR

.....................23-72

BUMPER, REAR

...................13-6,13-18

BUMPER, REAR JOUNCE

................13-18

BUMPERÐXJ VEHICLES, REAR

SEATBACK LATCH STRIKER

...........23-111BUMPERS AND FRAME ATTACHED

COMPONENTS, YJ....................13-14

BUMPERS, FUEL FILLER DOOR...........23-31

BUMPERS, XJ.........................13-3

BUSHING AND PISTON CLEARANCE, AW-

4 ................................21-326

BUSHING REPLACEMENT, AXLE.......2-11,2-32

BUSHING REPLACEMENT, LEAF SPRING

EYE; FRONT SUSPENSION AND AXLE.....2-15

BUSHING REPLACEMENT, LEAF SPRING

EYE; REAR SUSPENSION AND AXLES . . . 3-4,3-6

BUZZER SYSTEM, CHIME/WARNING........8A-1

CABLE, ACCELERATOR PEDAL AND

THROTTLE.....................14-16,14-54

CABLE ADJUSTMENT, PARK INTERLOCK . . . 21-186

CABLE ADJUSTMENT, SHIFT............21-186

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE....................21-98,21-185

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE VALVE....................21-70

CABLE ADJUSTMENT (XJ), PARK

INTERLOCK.........................21-97

CABLE ADJUSTMENT (XJ), SHIFT.........21-97

CABLE REPLACEMENT, HEATER

CONTROL..........................24-30

CABLE REPLACEMENT, LATCH

RELEASE...........................23-10

CABLE REPLACEMENT, SERVO............8H-9

CABLE REPLACEMENT, TRANSMISSION

THROTTLE.........................21-184

CABLE REPLACEMENT (XJ),

PARKING BRAKE REAR.................5-62

CABLE REPLACEMENT (YJ), PARKING

BRAKE FRONT........................5-62

CABLE REPLACEMENT (YJ), PARKING

BRAKE REAR.........................5-63

CABLE RESISTANCE, SPARK PLUG........8D-18

CABLE TENSIONER REPLACEMENT (XJ),

PARKING BRAKE......................5-61

CABLE, THROTTLE.....................14-16

CABLEÐCONSOLE SHIFT AUTOMATIC,

PARK-LOCK.........................19-45

CABLES, DISTRIBUTOR CAP AND ROTOR,

IGNITION............................0-18

CABLES, SPARK PLUG SECONDARY . . 8D-17,8D-29

CABLES, VENT DOOR CONTROL..........24-39

CALIBRATION VALUES, GAUGE...........8E-22

CALIPER ASSEMBLY....................5-29

CALIPER CLEANING AND INSPECTION......5-28

CALIPER DISASSEMBLY..................5-27

CALIPER INSTALLATION..................5-30

CALIPER OPERATION AND WEAR

COMPENSATION......................5-24

CALIPER REMOVAL.....................5-27

CAMSHAFT........................9-29,9-69

CAMSHAFT PIN REPLACEMENT........9-31,9-71

CAMSHAFT POSITION SENSOR; FUEL

SYSTEM............................14-54

CAMSHAFT POSITION SENSOR;

IGNITION SYSTEMS..............8D-1,8D-20

CAMSHAFT POSITION SENSORÐPCM

INPUT.............................14-20

CAMSHAFT POSITION SENSOR TEST;

FUEL SYSTEM.......................14-43

CAMSHAFT POSITION SENSOR TEST;

IGNITION SYSTEMS...................8D-8

CANADA ONLY, DAYTIME RUNNING

LIGHTS............................8L-16

CANISTER, EVAP...................25-4,25-9

CAP AND ROTOR, IGNITION CABLES,

DISTRIBUTOR........................0-18

CAP, DISTRIBUTOR.....................8D-9

CAP, FUEL TANK FILLER TUBE; EMISSION

CONTROL SYSTEMS...............25-4,25-9

CAP, FUEL TANK FILLER TUBE; FUEL

SYSTEM............................14-12

CAP, RADIATOR PRESSURE...............7-20

CAPACITIES, COOLING SYSTEM...........7-38

CAPACITIES, FLUID......................0-4

CAPACITIES, FUEL TANK...........14-12,14-62

CAPACITY TEST, FUEL PUMP..............14-7

CAR REPLACEMENT, PITMAN SHAFT

SEALSÐIN

.........................19-21

CARDAN (CV), DOUBLE

.................16-10

CARDAN, SINGLE

.......................16-9

CARDAN U-JOINT, AXLE SHAFT

............2-25

JINDEX3

Description Group-Page Description Group-Page Description Group-Page

Page 1753 of 1784

FILTER REPLACEMENT, OIL.............21-100

FILTER SHIELD AND BRACKET, FUEL.......13-17

FINAL ASSEMBLY; FRONT SUSPENSION

AND AXLE...........................2-44

FINAL ASSEMBLY; REAR SUSPENSION

AND AXLES..........................3-26

FIRING ORDERÐ2.5L ENGINE, ENGINE....8D-33

FIRING ORDERÐ4.0L ENGINE, ENGINE....8D-33

FIRST GEAR (1) POSITION, HYDRAULIC

FLOW IN MANUAL...................21-94

FIRST GEAR, HYDRAULIC FLOW IN D

RANGE.............................21-87

FIRST-REVERSE BRAKE PISTON AND

TRANSMISSION CASE OVERHAUL......21-237

FIRST, SYMPTOM AND ACTIONÐSEE

PRELIMINARY CHECKS..................7-6

FIRSTÐTHIRDÐREVERSE GEAR

COMPONENTS......................21-159

FITTING CHART, CONNECTING ROD

BEARING........................9-36,9-76

FITTING CHART, MAIN BEARING.......9-43,9-83

FITTING O-RING SEAL, FLOW CONTROL

VALVE .............................19-12

FITTINGS, QUICK-CONNECT..........14-9,14-59

FITTINGS, SERVICING TRANSMISSION

COOLER LINES.....................21-106

FITTINGS, TRANSMISSION COOLER LINE . . 21-187

FIXED GLASS WATER LEAK DETECTION

AND REPAIR ..................23-83,23-189

FIXED WINDOW GLASS...........23-73,23-183

FIXED WINDOW GLASS, REAR DOOR......23-53

FLARE, FENDER......................23-144

FLARES AND LINERS, REAR

WHEELHOUSE.......................23-18

FLASHER, TURN SIGNALS AND HAZARD

WARNING...........................8A-1

FLOOR BRACKETSÐXJ VEHICLES,

SPARE TIRE/WHEEL HOLDDOWN.......23-128

FLOOR CONSOLEÐXJ VEHICLES, FULL . . . 23-125

FLOOR CONSOLES....................23-197

FLOOR MATS, CARPETS................23-129

FLOW CONTROL VALVE FITTING O-RING

SEAL..............................19-12

FLOW DURING FULL THROTTLE 3-2

DOWNSHIFT, HYDRAULIC..............21-92

FLOW DURING PART THROTTLE 3-2

DOWNSHIFT, HYDRAULIC..............21-91

FLOW IN D RANGE FIRST GEAR,

HYDRAULIC.........................21-87

FLOW IN D RANGE SECOND GEAR,

HYDRAULIC.........................21-88

FLOW IN D RANGE THIRD GEAR,

HYDRAULIC.........................21-89

FLOW IN MANUAL FIRST GEAR

(1) POSITION, HYDRAULIC.............21-94

FLOW IN MANUAL SECOND (2) RANGE,

HYDRAULIC.........................21-93

FLOW IN PARK AND NEUTRAL,

HYDRAULIC.........................21-86

FLOW IN REVERSE, HYDRAULIC..........21-95

FLOW IN THIRD GEAR (CONVERTER

CLUTCH ENGAGED), HYDRAULIC........21-90

FLOW TESTING, TRANSMISSION

COOLER...........................21-106

FLUID AND LEVELÐBRAKELINES

AND HOSES, BRAKE BLEEDINGÐ

BRAKE..............................5-13

FLUID CAPACITIES.......................0-4

FLUID, CLUTCH LINKAGE

..................6-1

FLUID CONTAMINATION, BRAKE

...........5-13

FLUID, IMPORTANCE OF CLEAN BRAKE

.....5-48

FLUID LEVEL AND CONDITION

...........21-69

FLUID LEVEL AND CONDITION,

CHECKING

....................21-96,21-173

FLUID LEVEL, BRAKE

....................5-13

FLUID LEVEL, CLUTCH

...................6-14

FLUID LEVEL, CORRECT

.................5-48

FLUID, RECOMMENDED

............21-66,21-96

FLUID, RECOMMENDED BRAKE; BRAKES

....5-13,

5-48

FLUID TUBE RETAINER CLIP, FUEL AND

BRAKE; BODY COMPONENTSÐXJ

VEHICLES

..........................23-86

FLUID TUBE RETAINER CLIP, FUEL

AND BRAKE; FRAME AND BUMPERS

.....13-16FLUID/LUBRICANTS/CLEANING

SOLVENTS, BRAKE.....................5-1

FLUSHING, COOLING SYSTEM CLEANING/

REVERSE............................7-17

FLUSHING, TRANSMISSION COOLER

REVERSE..........................21-105

FLYWHEEL SERVICE.....................6-15

FOG LAMP BEAM ADJUSTMENT..........8L-12

FOG LAMP BULB/ELEMENT

REPLACEMENT......................8L-13

FOG LAMP REPLACEMENT..............8L-15

FOG LAMP SERVICE INFORMATION........8L-12

FOG LAMP SWITCH REPLACEMENT.......8L-14

FOG LAMP TROUBLE DIAGNOSIS.........8L-12

FOG LAMPÐYJ RENEGADE VEHICLES....23-150

FORM-IN-PLACE GASKETS.................9-1

FORMULAS AND EQUIVALENT VALUES,

CONVERSION.....................INTRO.-8

FORWARD CLUTCH OVERHAUL..........21-223

FOURTH GEAR OVERDRIVE COMPONENTS . . 21-158

FRAME ALIGNMENT....................13-10

FRAME, BUCKET SEATBACK COVER......23-100

FRAME CROSSMEMBER COVER..........13-14

FRAME INSPECTION/MEASUREMENTS.....13-10

FRAME REPAIR SERVICE................13-13

FRAME WEATHERSTRIP SEAL,

WINDSHIELD.......................23-185

FRAME, WINDSHIELD.................23-184

FRAME, YJ............................13-8

FRESH AIR DOOR VACUUM MOTOR.......24-41

FRESH AIR INTAKE DUCT...............24-41

FRESH AIR VENTILATION................24-39

FRONT AND REAR AXLES................0-26

FRONT AXLE, MODEL 30.................2-46

FRONT BAND ADJUSTMENT.............21-99

FRONT BUCKET SEATS..................23-97

FRONT BUMPER...................13-3,13-14

FRONT CABLE REPLACEMENT (YJ),

PARKING BRAKE......................5-62

FRONT CARPET/MATÐXJ VEHICLES......23-129

FRONT CLUTCH OVERHAUL.............21-125

FRONT DOOR SPACER BLOCKSÐTWO-

DOOR VEHICLES.....................23-60

FRONT DOOR VENT WINDOW............23-50

FRONT DOOR WINDOW GLASS...........23-49

FRONT DOOR WINDOW GLASS

REGULATOR........................23-48

FRONT DRIVE AXLE......................2-3

FRONT FASCIA AND SKID PLATEÐYJ

RENEGADE VEHICLES................23-148

FRONT FENDER.......................23-14

FRONT FENDER EXTENSION PANELÐYJ

RENEGADE VEHICLES................23-149

FRONT INNER SCUFF PLATE/COWL SIDE

TRIM PANELÐXJ VEHICLES...........23-114

FRONT PARK/TURN SIGNAL LAMP BULB

REPLACEMENT.......................8L-8

FRONT PLANETARY GEAR OVERHAUL.....21-228

FRONT SERVO AND BAND OVERHAUL....21-136

FRONT SHOULDER BELT/BUCKLEÐXJ

VEHICLES.........................23-119

FRONT SHOULDER BELTS..............23-196

FRONT SKID PLATE....................23-84

FRONT SUPPORT CUSHION, ENGINE.......13-15

FRONT SUSPENSION.....................2-1

FRONT SUSPENSION COMPONENTS, XJ.....2-47

FRONT SUSPENSION COMPONENTS, YJ.....2-47

FRONT SUSPENSION, XJ.................2-10

FRONT SUSPENSION, YJ.................2-13

FRONT TOW HOOKS

....................13-5

FRONT WHEEL ALIGNMENT

................2-5

FRONT WHEEL BEARINGS

................0-31

FRONT WHEEL SENSOR INSTALLATION

.....5-49

FRONT WHEEL SENSOR REMOVAL

.........5-49

FRONT WIPER ARM AND PIVOT

ASSEMBLY REPLACEMENT

..............8K-9

FRONT WIPER ARM REPLACEMENT

........8K-8

FRONT WIPER BLADE REPLACEMENT

......8K-8

FRONT WIPER MOTOR

.................8K-10

FRONT WIPERS/WASHERS

...............8K-1

FRONT WIPERS/WASHERS GENERAL

INFORMATION

........................8K-8

FUEL AND BRAKE FLUID TUBE RETAINER

CLIP; BODY COMPONENTSÐXJ

VEHICLES

..........................23-86FUEL AND BRAKE FLUID TUBE

RETAINER CLIP; FRAME AND BUMPERS . . . 13-16

FUEL DELIVERY SYSTEM.................14-2

FUEL FILLER DOOR BUMPERS...........23-31

FUEL FILLER HOSE SPLASH SHIELDÐXJ

VEHICLES..........................23-86

FUEL FILLER NOZZLE/TUBE..............23-30

FUEL FILLER PROTECTOR/NOZZLE.......23-158

FUEL FILTER......................14-8,14-55

FUEL FILTER BRACKET..................23-86

FUEL FILTER SHIELD AND BRACKET.......13-17

FUEL GAUGE..........................8E-2

FUEL GAUGE INOPERATIVE...............8E-3

FUEL GAUGE SENDING UNIT.............14-15

FUEL INJECTION (MFI)ÐCOMPONENT

DESCRIPTION/SYSTEM OPERATION,

MULTI-PORT........................14-17

FUEL INJECTION (MFI)ÐCOMPONENT

REMOVAL/INSTALLATION, MULTI-PORT . . . 14-54

FUEL INJECTION (MFI)ÐGENERAL

DIAGNOSIS, MULTI-PORT..............14-32

FUEL INJECTOR.......................14-55

FUEL INJECTORSÐPCM OUTPUT.........14-25

FUEL PRESSURE LEAK DOWN TEST........14-7

FUEL PRESSURE REGULATOR............14-30

FUEL PRESSURE RELEASE PROCEDURE.....14-5

FUEL PUMP CAPACITY TEST..............14-7

FUEL PUMP ELECTRICAL CONTROL........14-5

FUEL PUMP MODULE..............14-2,14-56

FUEL PUMP RELAY....................14-56

FUEL PUMP RELAYÐPCM OUTPUT.......14-25

FUEL PUMP RELAY TESTING.............14-44

FUEL RAIL...........................14-30

FUEL RAIL ASSEMBLY..................14-56

FUEL REQUIREMENTS....................0-2

FUEL SYSTEM........................14-62

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE........................14-56

FUEL SYSTEM PRESSURE TEST......14-5,14-48

FUEL TANK...........................14-12

FUEL TANK CAPACITIES............14-12,14-62

FUEL TANK FILLER TUBE CAP;

EMISSION CONTROL SYSTEMS......25-4,25-9

FUEL TANK FILLER TUBE CAP; FUEL

SYSTEM............................14-12

FUEL TANK FILLER TUBE, NO-LEAD.......14-12

FUEL TANK PRESSURE RELIEF/

ROLLOVER VALVE...............14-15,14-56

FUEL TANK SKID PLATE; BODY

COMPONENTSÐXJ VEHICLES..........23-84

FUEL TANK SKID PLATE; FRAME AND

BUMPERS..........................13-16

FUEL TANK SUPPORT STRAP............23-86

FUEL TANKS.....................14-12,14-56

FUEL TUBES/LINES/HOSES AND CLAMPS . . . 14-9,

14-56

FUEL USAGE STATEMENT................14-1

FUEL USAGE STATEMENTÐGAS

ENGINES............................0-17

FUEL WARNING INOPERATIVE, LOW........8E-4

FUEL WARNING LAMP, LOW..............8E-2

FULL FLOOR CONSOLEÐXJ VEHICLES....23-125

FULL-METAL DOOR ASSIST HANDLE.....23-175

FULL-METAL DOOR HINGES............23-179

FULL-METAL DOOR KEY LOCK

CYLINDER.........................23-178

FULL-METAL DOOR LATCH.............23-179

FULL-METAL DOOR LATCH EXTERNAL

RELEASE HANDLE...................23-178

FULL-METAL DOOR LATCH INSIDE

RELEASE AND LOCK HANDLE..........23-175

FULL-METAL DOOR SERVICE............23-181

FULL-METAL DOOR TRIM PANEL........23-175

FULL-METAL DOOR VENT WINDOW

GLASS............................23-177

FULL-METAL DOOR WATERDAM.........23-176

FULL-METAL DOOR WEATHERSTRIP

SEALS............................23-180

FULL-METAL DOOR WINDOW GLASS.....23-178

FULL-METAL DOOR WINDOW GLASS

REGULATOR

.......................23-177

FULL-METAL DOOR WINDOW GLASS

REGULATOR HANDLE

................23-175

FUNCTION TROUBLE DIAGNOSISÐXJ

VEHICLES, HEADLAMP DELAY

..........8L-16

FUSE CHARTS AND RELAY BANKS

.........8W-8

JINDEX9

Description Group-Page Description Group-Page Description Group-Page

Page 1758 of 1784

LIFTGATE LOCK CYLINDER

REPLACEMENT.......................8P-7

LIFTGATE OPENING WEATHERSTRIP SEAL . . . 23-70

LIFTGATE PILLAR TRIM COVERSÐXJ

VEHICLES.........................23-116

LIFTGATE REMOVAL/INSTALLATION........23-65

LIFTGATE SERVICE INFORMATIONÐXJ

VEHICLES..........................23-65

LIFTGATE SUPPORT ROD BALL

STUD REPLACEMENT.................23-70

LIFTGATE SUPPORT ROD CYLINDER.......23-69

LIFTGATE SUPPORT ROD CYLINDER

DISPOSAL..........................23-70

LIFTGATE TRIM PANEL.................23-66

LIFTGATE WINDOW GLASSÐXJ

VEHICLES..........................23-81

LIFTGATE WIPER.......................8K-5

LIFTGATE WIPER SWITCH REPLACEMENT....8K-6

LIGHT DISPLAY, ABS WARNING............5-3

LIGHT DISPLAY, BRAKE WARNING..........5-4

LIGHTED VANITY MIRROR...............8L-19

LIGHTED VANITY MIRROR TROUBLE

DIAGNOSIS.........................8L-19

LIGHTS, BRAKE WARNING.................5-1

LIGHTS (CANADA ONLY), DAYTIME

RUNNING...........................8L-16

LIGHTS, SYSTEM WARNING..............5-42

LIMITED SLIP DIFFERENTIAL...............3-8

LIMITS, AW-4 OIL PUMP WEAR.........21-325

LINE CLUSTER, HIGH...................8E-12

LINE CLUSTER, LOW...................8E-11

LINE FITTINGS, TRANSMISSION COOLER . . 21-187

LINERS, REAR WHEELHOUSE FLARES.....23-18

LINERS, WHEELHOUSE SPLASH.........23-146

LINES AND FITTINGS, SERVICING

TRANSMISSION COOLER.............21-106

LINK CONNECTORÐPCM INPUT, DATA.....14-20

LINK CONNECTORÐPCM OUTPUT, DATA . . . 14-24

LINK, DRAG.....................19-14,19-17

LINK REPLACEMENT, FUSIBLE............8W-4

LINKAGE ADJUSTMENT, SHIFT....21-275,21-296

LINKAGE ADJUSTMENT (YJ), GEARSHIFT . . . 21-96

LINKAGE AND BALL STUDS, STEERING.....0-30

LINKAGE FLUID, CLUTCH..................6-1

LINKAGE, GEARSHIFT..................21-70

LINKAGE INSTALLATION, CLUTCH

HYDRAULIC..........................6-12

LINKAGE REMOVAL, CLUTCH HYDRAULIC....6-11

LINKAGEÐXJ, STEERING..........19-14,19-73

LINKAGEÐYJ, STEERING..........19-17,19-73

LINKS, FUSIBLE.......................8W-3

LOAD DATA, VEHICLE................INTRO.-3

LOAD DATA, XJ VEHICLE.............INTRO.-5

LOAD DATA, YJ-VEHICLE.............INTRO.-6

LOAD TEST, BATTERY...................8A-4

LOCATING A SYSTEM...................8W-2

LOCATIONS, SPLICE..............8W-2,8W-53

LOCATIONS, TRANSMISSION SWITCH

AND PLUG..........................21-33

LOCATIONS, XJ RHD SPLICE............8W-67

LOCATIONS, XJ SPLICE................8W-59

LOCATIONS, YJ SPLICE................8W-53

LOCK COMPONENT OVERHAUL,

ADAPTER HOUSING AND PARK........21-120

LOCK COMPONENT REPLACEMENT,

PARK .............................21-102

LOCK CYLINDER, DOOR KEY.............23-54

LOCK CYLINDER, FULL-METAL DOOR

KEY ..............................23-178

LOCK CYLINDER REPLACEMENT,

LIFTGATE............................8P-7

LOCK CYLINDER, TAILGATE.............23-160

LOCK CYLINDER/STRIKER, LIFTGATE

LATCH/KEY.........................23-68

LOCK CYLINDERS, KEY............23-2,23-132

LOCK HANDLE, FULL-METAL DOOR.......23-175

LOCK, HYDROSTATIC.....................9-4

LOCK RODS, DOOR INSIDE LATCH

RELEASE...........................23-57

LOCK SWITCH, PASSENGER DOOR

.........8P-5

LOCK SWITCHÐ2-DOOR LEFT HAND

DRIVE, DRIVERS DOOR POWER

..........8P-2

LOCK SWITCHÐ2-DOOR RIGHT HAND

DRIVE,DRIVERS DOOR POWER

..........8P-3

LOCK SWITCHÐ4-DOOR, DRIVERS

DOOR POWER

........................8P-4LOCKS, DIAGNOSING POWER DOOR . . . 8P-1,8P-9

LOCKS, POWER; ELECTRICAL.............8A-1

LOCKS, POWER; POWER DOOR LOCKS.....8P-1

LOCKS, POWER DOOR..................8P-10

LOCK/UNLOCK RELAY REPLACEMENT,

DOOR.............................8P-12

LOOP MODES OF OPERATION, OPEN

LOOP/CLOSED.......................14-27

LOOP/CLOSED LOOP MODES OF

OPERATION, OPEN...................14-27

LOSS OF SENSOR INPUT..................5-3

LOW FUEL WARNING INOPERATIVE........8E-4

LOW FUEL WARNING LAMP..............8E-2

LOW LINE CLUSTER...................8E-11

LOW SPEED KNOCK; FRONT SUSPENSION

AND AXLE...........................2-17

LOW SPEED KNOCK; REAR SUSPENSION

AND AXLES...........................3-8

LOW WASHER INDICATOR INOPERATIVE....8E-4

LOWER SUSPENSION ARM...............2-11

LUBRICANT AND REPLACEMENT PARTS,

RECOMMENDED.......................0-3

LUBRICANT CHANGE; FRONT

SUSPENSION AND AXLE................2-22

LUBRICANT CHANGE; REAR SUSPENSION

AND AXLES......................3-13,3-30

LUBRICANT, RECOMMENDED.............21-2

LUBRICANT SPECIFICATIONS, BODY........0-35

LUBRICANT SPECIFICATIONS; FRONT

SUSPENSION AND AXLE................2-20

LUBRICANT SPECIFICATIONS; REAR

SUSPENSION AND AXLES...........3-11,3-30

LUBRICANT, TRANSFER CASE.....21-273,21-294

LUBRICANT, TRANSMISSION.............21-33

LUBRICANTS, CHASSIS COMPONENT

AND WHEEL BEARING.................0-30

LUBRICANTS, CLASSIFICATION OF..........0-2

LUBRICATION, CLUTCH COMPONENT........6-1

LUBRICATION, COMPONENTS

REQUIRING NO........................0-3

LUG NUT, WHEEL......................22-11

LUGGAGE RACKÐXJ VEHICLES..........23-32

MAGNETIC CLUTCH....................24-18

MAIN BEARING FITTING CHART.......9-43,9-83

MAIN BEARINGS, CRANKSHAFT.......9-40,9-80

MAIN OIL SEALS, REAR..............9-44,9-84

MAINTENANCE, BATTERY................8B-1

MAINTENANCE, ENGINE..................0-13

MAINTENANCE SCHEDULES...............0-5

MAINTENANCE, SEVERE SERVICE...........0-5

MAJOR COMPONENT IDENTIFICATION . . . INTRO.-3

MALFUNCTION INDICATOR LAMP

(CHECK ENGINE); INSTRUMENT PANEL

AND GAUGESÐXJ................8E-2,8E-4

MALFUNCTION INDICATOR LAMP

(CHECK ENGINE); INSTRUMENT PANEL

AND GAUGESÐYJ...................8E-16

MALFUNCTION INDICATOR LAMPÐPCM

OUTPUT............................14-26

MANIFOLDÐ2.5L ENGINE, ENGINE

EXHAUST............................11-7

MANIFOLDÐ2.5L ENGINE, INTAKE.........11-8

MANIFOLDÐ4.0L ENGINE, ENGINE

EXHAUST............................11-7

MANIFOLDÐ4.0L ENGINE, INTAKE

.........11-9

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR; FUEL SYSTEM

...............14-57

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR; IGNITION SYSTEMS

......8D-5,8D-27

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT

................14-21

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR TEST; FUEL SYSTEM

..........14-44

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR TEST; IGNITION SYSTEMS

......8D-14

MANIFOLD AIR TEMPERATURE SENSOR,

INTAKE

........................8D-5,8D-27

MANIFOLD AIR TEMPERATURE

SENSOR TEST, INTAKE

................8D-14

MANIFOLD ASSEMBLY, PRESSURE

GAUGE

..............................24-2

MANIFOLD, INTAKE

....................14-57

MANIFOLD LEAKAGE DIAGNOSIS, INTAKE

.....9-5

MANUAL FIRST GEAR (1) POSITION,

HYDRAULIC FLOW IN

.................21-94MANUAL SECOND (2) RANGE,

HYDRAULIC FLOW IN.................21-93

MANUAL SHIFTING TEST...............21-168

MANUAL STEERING GEAR..........19-35,19-73

MANUAL STEERING GEAR

SPECIFICATIONS.....................19-44

MANUAL STEERING GEARÐYJ VEHICLES....0-32

MANUAL STEERING SYSTEM DIAGNOSIS . . . 19-36

MANUAL TRANSMISSION................0-22

MANUAL TRANSMISSION, AX 15.........21-32

MANUAL TRANSMISSION, AX 4/5..........21-1

MANUAL TRANSMISSION, SELECTIVE

SNAP RING CHARTÐAX 15...........21-321

MANUAL TRANSMISSION, TORQUE

SPECIFICATIONSÐ AX 15.............21-320

MANUAL VALVE SHAFT OVERHAUL.......21-205

MANUAL VALVE SHAFT SEAL

REPLACEMENT.....................21-178

MARKER LAMP BULB REPLACEMENT,

SIDE...............................8L-7

MASTER CYLINDER.....................5-40

MASTER CYLINDER INSTALLATION.....5-20,5-50

MASTER CYLINDER OVERHAUL...........5-20

MASTER CYLINDER REMOVAL........5-20,5-50

MASTER CYLINDER, STANDARD...........5-20

MASTER CYLINDER/POWER BOOSTER

TEST...............................5-11

MATCH MOUNTING TIRES................22-7

MATERIAL, BRAKELINING.................5-1

MATS, CARPET/FLOOR.................23-198

MATS, CARPETS AND FLOOR...........23-129

MEASUREMENT AND ADJUSTMENT,

DIFFERENTIAL SHIM PACK..............2-42

MEASUREMENT, DIFFERENTIAL AND

PINION; FRONT SUSPENSION AND AXLE....2-38

MEASUREMENT, DIFFERENTIAL AND

PINION; REAR SUSPENSION AND AXLES....3-20

MEASUREMENT, UNIVERSAL JOINT

ANGLE..............................16-4

MEASUREMENTS AND ADJUSTMENTS,

ALIGNMENT...........................2-6

MEASURING WITH PLASTIGAGE............9-3

METALS, PAINT REPAIR ON GALVANIZED . . 23-202

METRIC SYSTEM NOTATION...........INTRO.-8

METRIC, THREAD NOTATIONÐSAE.....INTRO.-9

(MFI)ÐCOMPONENT DESCRIPTION/

SYSTEM OPERATION, MULTI-

PORT FUEL INJECTION................14-17

(MFI)ÐCOMPONENT REMOVAL/

INSTALLATION, MULTI-PORT FUEL

INJECTION..........................14-54

(MFI)ÐGENERAL DIAGNOSIS,

MULTI-PORT FUEL INJECTION..........14-32

MINI-FLOOR CONSOLEÐXJ VEHICLES....23-124

MIRROR (EXTERNAL), HALF METAL

DOOR

............................23-158

MIRROR, INTERIOR REARVIEW

...........23-74

MIRROR, LIGHTED VANITY

..............8L-19

MIRROR, REARVIEW

..................23-183

MIRROR REPLACEMENT, POWER

..........8T-4

MIRROR RETAINING BRACKET,

REARVIEW

.........................23-183

MIRROR SUPPORT BRACKET

REPLACEMENT, INTERIOR REARVIEW

....23-75

MIRROR SWITCH, POWER

................8T-2

MIRROR SWITCH REPLACEMENT,

POWER

.............................8T-4

MIRROR SWITCH TESTING, POWER

........8T-2

MIRROR TROUBLE DIAGNOSIS, LIGHTED

VANITY

............................8L-19

MIRRORS, EXTERNAL

..................23-31

MIRRORS, POWER

.....................8A-1

MISS, INJECTOR DIAGNOSISÐVEHICLE

RUNS ROUGH AND/OR HAS A

..........14-49

MODE, ABS OPERATION IN ANTILOCK

BRAKING

............................5-43

MODE, ABS OPERATION IN NORMAL

BRAKING

............................5-43

MODE, VEHICLE RESPONSE IN

ANTILOCK

............................5-3

MODEL 30 AXLE AND TUBE AXLE

(2WD)

..............................2-20

MODEL 30 FRONT AXLE

.............2-46,2-47

MODEL 35, REAR AXLE

..........3-11,3-28,3-50

14 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 1759 of 1784

MODES OF OPERATION, OPEN LOOP/

CLOSED LOOP.......................14-27

MODULE, ELECTRICAL TESTS

AT POWERTRAIN CONTROL.............8H-6

MODULE, FUEL PUMP..............14-2,14-56

MODULE, INTERMITTENT WIPER..........8K-5

MODULE (PCM) 60-WAY CONNECTOR,

POWERTRAIN CONTROL...............14-38

MODULE (PCM), POWERTRAIN

CONTROL; EMISSION CONTROL

SYSTEMS...........................25-9

MODULE (PCM), POWERTRAIN CONTROL;

FUEL SYSTEM..................14-18,14-58

MODULE (PCM), POWERTRAIN CONTROL;

IGNITION SYSTEMS.........8D-6,8D-15,8D-28

MODULE REPLACEMENT, DRL............8L-16

MODULE REPLACEMENTÐXJ VEHICLES,

HEADLAMP DELAY...................8L-16

MODULE (TCM) SERVICE, TRANSMISSION

CONTROL.........................21-173

MODULEÐXJ VEHICLES, SENTINEL

HEADLAMP DELAY...................8L-15

MOTOR, A/C BLOWER..................24-43

MOTOR DIAGNOSIS, DISCONNECT AXLE/

SHIFT...............................2-27

MOTOR, FRESH AIR DOOR VACUUM.......24-41

MOTOR, FRONT WIPER.................8K-10

MOTOR (HEATING), BLOWER............24-40

MOTOR, IDLE AIR CONTROL (IAC)........14-56

MOTOR NOISE DIAGNOSIS, 2.5L

STARTER...........................8A-13

MOTORÐPCM OUTPUT, IDLE AIR

CONTROL (IAC)......................14-25

MOTOR RELAY TEST, STARTER...........14-48

MOTOR REMOVAL/INSTALLATION, 2.5L

STARTER............................8B-5

MOTOR REMOVAL/INSTALLATION,

4.0L STARTER........................8B-6

MOTOR REPLACEMENT, A/C

RECIRCULATING AIR DOOR VACUUM.....24-31

MOTOR REPLACEMENT, HEATER/

DEFROSTER/INSTRUMENT PANEL

OUTLET DOOR VACUUM...............24-30

MOTOR REPLACEMENT, POWER SEAT......8R-2

MOTOR REPLACEMENT, REAR WIPER.....8K-13

MOTOR RESISTORS REPLACEMENT,

BLOWER...........................24-35

MOTOR SERVICE PROCEDURES,

ENGINE STARTER.....................8B-4

MOTOR SPECIFICATIONS, 2.5L STARTER . . . 8B-11

MOTOR STALL TEST, ACTUATOR...........8P-6

MOTOR SWITCH REPLACEMENT,

BLOWER MOTOR/AIR DOOR............24-39

MOTOR TEST, IDLE AIR CONTROL........14-46

MOTOR TEST PROCEDURES ON

VEHICLE, ENGINE STARTER.............8A-9

MOTOR TORQUE SPECIFICATIONS,

STARTER...........................8B-11

MOTOR, WINDSHIELD WIPER.............8K-2

MOTOR/AIR DOOR MOTOR SWITCH

REPLACEMENT, BLOWER..............24-39

MOTOR/FAN REPLACEMENT, BLOWER.....24-26

MOULDING, BODY SIDE STEP...........23-145

MOULDING, WINDSHIELD REVEAL . . 23-73,23-183

MOULDING, WOODGRAIN...............23-19

MOULDINGÐXJ VEHICLES, DRIP RAIL.....23-29

MOULDINGÐXJ VEHICLES, WINDSHIELD

SIDE.............................23-114

MOULDING/CLADDING, BODY SIDE........23-19

MOULDINGS, DOOR WINDOW EXTERIOR . . . 23-61

MOUNTING, MATCH TIRES...............22-7

MOUNTÐREAR, ENGINE.............9-12,9-52

MOUNTSÐFRONT, ENGINE...........9-10,9-51

MUFFLER AND EXHAUST TAILPIPEÐXJ

VEHICLES...........................11-5

MUFFLER AND EXHAUST TAILPIPEÐ

YJ VEHICLES.........................11-6

MUFFLER AND TAILPIPE HEAT SHIELDS....13-17

MUFFLER/TAILPIPE HANGER BRACKET

.....13-16

MULTI-PORT FUEL INJECTION (MFI)Ð

COMPONENT DESCRIPTION/

SYSTEM OPERATION

..................14-17

MULTI-PORT FUEL INJECTION (MFI)Ð

COMPONENT REMOVAL/INSTALLATION

. . . 14-54

MULTI-PORT FUEL INJECTION (MFI)Ð

GENERAL DIAGNOSIS

.................14-32NAMEPLATES (ADHESIVE-BACKED),

EXTERIOR.........................23-158

NAMEPLATES, EXTERIOR................23-30

NEUTRAL, HYDRAULIC FLOW IN PARK.....21-86

NEUTRAL SWITCH, PARK...............14-58

NOISE DIAGNOSIS......................3-45

NOISE DIAGNOSIS, 2.5L STARTER MOTOR . . . 8A-13

NOISE DIAGNOSIS, RADIO................8F-2

NOISE, GEAR AND BEARING; FRONT

SUSPENSION AND AXLE................2-16

NOISE, GEAR AND BEARING; REAR

SUSPENSION AND AXLES................3-7

NOISE OR VIBRATION, TIRE..............22-4

NOISE/VIBRATION DIAGNOSIS, AXLE;

FRONT SUSPENSION AND AXLE..........2-16

NOISE/VIBRATION DIAGNOSIS, AXLE;

REAR SUSPENSION AND AXLES..........3-7

NO-LEAD FUEL TANK FILLER TUBE........14-12

NON-INTERMITTENT WINDSHIELD

WASHER, DIAGNOSING...............8K-12

NON-TILT STEERING COLUMN............19-50

NORMAL BRAKING MODE, ABS

OPERATION IN.......................5-43

NOTATION, METRIC SYSTEM..........INTRO.-8

NOTATIONÐSAE AND METRIC, THREAD . INTRO.-9

NOTATIONS, SPECIFICATION...........INTRO.-8

NOZZLE AND DUCT, DEFROSTER..........24-40

NOZZLE REPLACEMENT, WASHER.........8K-13

NOZZLE/TUBE, FUEL FILLER.............23-30

NP231 SERVICE DIAGNOSIS............21-274

NP231 TRANSFER CASE.........21-272,21-291

NP231 TRANSFER CASE, LEGEND FOR....21-292

NP231/NP242 TORQUE SPECIFICATIONS . . . 21-331

NP242 SERVICE DIAGNOSIS............21-295

NP242 TRANSFER CASE...............21-293

NP242 TRANSFER CASE, LEGEND FOR....21-319

NUMBER (VIN) DECODING, VEHICLE

IDENTIFICATION...................INTRO.-2

NUMBER (VIN) PLATE, VEHICLE

IDENTIFICATION...................INTRO.-1

NUT TIGHTENING, WHEEL............5-32,5-37

NUT, WHEEL LUG......................22-11

OFF DRAW (IOD) DIAGNOSIS, IGNITION.....8A-8

OIL CHANGE AND FILTER REPLACEMENT,

ENGINE.............................0-15

OIL COOLERS, TRANSMISSION............7-29

OIL, ENGINE...........................0-13

OIL FILTER, ENGINE.....................0-14

OIL FILTER REPLACEMENT.............21-100

OIL LEVEL, COMPRESSOR................24-6

OIL PAN ..........................9-32,9-72

OIL PRESSURE GAUGE..................8E-1

OIL PRESSURE GAUGE INOPERATIVE.......8E-3

OIL PRESSURE INDICATOR...............8E-1

OIL PRESSURE INDICATOR INOPERATIVE....8E-3

OIL PUMP........................9-33,9-73

OIL PUMP OVERHAUL...........21-122,21-206

OIL PUMP SEAL REPLACEMENT.........21-189

OIL PUMP WEAR LIMITS, AW-4.........21-325

OIL SEAL REPLACEMENT, INNER AXLE

SHAFT..............................2-33

OIL SEAL REPLACEMENT, TIMING CASE

COVER..........................9-26,9-67

OIL SEALS, REAR MAIN..............9-44,9-84

OIL SEALS, VALVE SPRINGS..........9-21,9-62

ON-BOARD DIAGNOSTIC SYSTEM,

USING.............................8A-19

ON-BOARD DIAGNOSTICS (OBD);

COOLING SYSTEM.....................7-4

ON-BOARD DIAGNOSTICS (OBD); FUEL

SYSTEM............................14-48

ON-BOARD DIAGNOSTICS (OBD);

IGNITION SYSTEMS..................8D-19

ONE GAUGE INOPERATIVE...............8E-22

ONE-WAY CLUTCH OVERHAUL, NO. 2.....21-234

ONE-WAY CLUTCH OVERHAUL, NO. 1.....21-229

OPEN CIRCUIT VOLTAGE, BATTERY.........8A-4

OPEN CIRCUIT VOLTAGE TEST, BATTERY....8A-3

OPEN LOOP/CLOSED LOOP MODES OF

OPERATION

.........................14-27

OPENING PANEL (GOP), GRILLE AND

GRILLE

.............................23-3

OPENING WEATHERSTRIP SEAL,

LIFTGATE

...........................23-70

OPENING WEATHERSTRIP SEALS,

DOOR WINDOW GLASS AND DOOR

......23-62OPERATING SOUND LEVELS...............5-3

OPERATING SPECIFICATIONS, PUMP.......19-3

OPERATION, ABS SYSTEM................5-39

OPERATION, A/C........................24-1

OPERATION, ACCELERATION SWITCH.......5-45

OPERATION AND APPLICATION CHARTS,

GEARTRAIN........................21-159

OPERATION AND WEAR COMPENSATION,

CALIPER............................5-24

OPERATION, ANTILOCK BRAKE

SYSTEM............................5-43

OPERATION; CHIME/BUZZER

WARNING SYSTEMS...................8U-1

OPERATION, CLUTCH.....................6-2

OPERATION, COMPONENT

IDENTIFICATION/SYSTEM...............8D-1

OPERATION, COMPONENTS.............21-157

OPERATION, ECU

.......................5-46

OPERATION, HCU PUMP AND PEDAL

TRAVEL SENSOR

......................5-44

OPERATION, HCU SOLENOID VALVE

........5-43

OPERATION, HEATER/DEFROSTER

.........24-37

OPERATION IN ANTILOCK BRAKING

MODE, ABS

..........................5-43

OPERATION IN NORMAL BRAKING MODE,

ABS

................................5-43

OPERATION, MULTI-PORT FUEL

INJECTION (MFI)ÐCOMPONENT

DESCRIPTION/SYSTEM

................14-17

OPERATION, OPEN LOOP/CLOSED LOOP

MODES OF

..........................14-27

OPERATION, PARKING BRAKE

.............5-56

OPERATION, POWER BRAKE BOOSTER

......5-22

OPERATION, POWER STEERING PUMPÐ

INITIAL

............................19-13

OPERATION; REAR SUSPENSION AND

AXLES

..............................3-44

OPERATION, SYSTEM

...................8P-9

OPERATION, WHEEL SPEED SENSOR

.......5-45

OPERATION/DIAGNOSIS

..................8U-1

OPERATIONAL CHECK (ROAD TEST)

........8H-7

OPERATIONAL CHECK WITH BATTERY

INDICATOR (BASE CLUSTER ONLY)

......8A-14

OPERATIONAL CHECK WITH VOLTMETER

. . . 8A-15

O-RING SEAL, FLOW CONTROL VALVE

FITTING

............................19-12

ORNAMENTATION, WHEEL

................22-6

OUTER SCUFF PLATESÐXJ VEHICLES

....23-118

OUTLET DOOR VACUUM MOTOR

REPLACEMENT, HEATER/DEFROSTER/

INSTRUMENT PANEL

..................24-30

OUTPUT, AIR CONDITIONING CLUTCH

RELAYÐPCM

.......................14-24

OUTPUT, AUTO SHUT DOWN (ASD)

RELAYÐPCM

.......................14-24

OUTPUT, DATA LINK CONNECTORÐPCM

. . . 14-24

OUTPUT, EMR LAMPÐPCM

..............14-24

OUTPUT, FUEL INJECTORSÐPCM

.........14-25

OUTPUT, FUEL PUMP RELAYÐPCM

.......14-25

OUTPUT, GENERATOR FIELDÐPCM

.......14-25

OUTPUT, GENERATOR LAMPÐPCM

.......14-25

OUTPUT, IDLE AIR CONTROL (IAC)

MOTORÐPCM

.......................14-25

OUTPUT, IGNITION COILÐPCM

...........14-26

OUTPUT, MALFUNCTION INDICATOR

LAMPÐPCM

........................14-26

OUTPUT, RADIATOR FAN RELAYÐPCM

.....14-26

OUTPUT, SCI TRANSMITÐPCM

...........14-26

OUTPUT SHAFT OVERHAUL, NO. 2 ONE-

WAY CLUTCH

......................21-234

OUTPUT, SHIFT INDICATORÐPCM

........14-26

OUTPUT, SPEED CONTROLÐPCM

.........14-27

OUTPUT, TACHOMETERÐPCM

...........14-27

OUTPUT, TORQUE CONVERTER CLUTCH

RELAYÐPCM

.......................14-27

OUTPUT VOLTAGE SPECIFICATIONS

.......8B-12

OVERDRIVE COMPONENTS, FOURTH

GEAR

.............................21-158

OVERDRIVE PLANETARY GEAR AND

CLUTCH OVERHAUL

.................21-209

OVERDRIVE SUPPORT OVERHAUL

.......21-216

JINDEX15

Description Group-Page Description Group-Page Description Group-Page

Page 1762 of 1784

PUMP REPLACEMENTÐLEFT HAND

DRIVE, WASHER......................8K-2

PUMP REPLACEMENT, REAR WASHER.....8K-13

PUMP REPLACEMENTÐRIGHT HAND

DRIVE, WASHER......................8K-3

PUMP REPLACEMENT, WASHER......8K-6,8K-11

PUMP SEAL REPLACEMENT, OIL.........21-189

PUMP TESTS, WATER....................7-9

PUMP WEAR LIMITS, AW-4 OIL.........21-325

PUMPSÐGENERAL INFORMATION, WATER . . . 7-9

PUMPSÐREMOVAL/INSTALLATION, WATER . . 7-10

PURGING COMPRESSOR OF AIR..........24-17

QUARTER AND WHEELHOUSE TRIM

PANELSÐXJ VEHICLES..............23-115

QUARTER EXTENSION PANELÐYJ

RENEGADE VEHICLES, REAR..........23-151

QUARTER PLASTIC INSERT ÐXJ

VEHICLES, QUARTER WINDOW GLASS/

REAR..............................23-80

QUARTER TRIM PANEL EXTENSIONÐXJ

VEHICLES.........................23-115

QUARTER VENT WINDOW GLASSÐ

XJ VEHICLES, REAR..................23-80

QUARTER WINDOW APPLIQUEÐXJ

VEHICLES..........................23-29

QUARTER WINDOW GLASS, HARD TOP . . . 23-188

QUARTER WINDOW GLASS/REAR QUARTER

PLASTIC INSERT ÐXJ VEHICLES, REAR . . 23-80

QUICK-CONNECT FITTINGS..........14-9,14-59

RACK PISTON AND WORM SHAFT

REPLACEMENT......................19-30

RACKÐXJ VEHICLES, LUGGAGE..........23-32

RADIATOR FAN RELAYÐPCM OUTPUT.....14-26

RADIATOR GRILLE APPLIQUE...........23-134

RADIATOR PRESSURE CAP...............7-20

RADIATOR SUPPORT CROSSMEMBER......23-5

RADIATORS...........................7-22

RADIO ANTENNA.......................8F-8

RADIO CONNECTOR PINS................8F-3

RADIO ILLUMINATION RELAY.............8F-3

RADIO NOISE DIAGNOSIS................8F-2

RADIO REPLACEMENT...............8F-4,8F-6

RADIO SPEAKERS..................8F-4,8F-6

RADIO/CLOCK ILLUMINATION.............8E-4

RAIL ASSEMBLY, FUEL..................14-56

RAIL, FUEL...........................14-30

RAIL MOULDINGÐXJ VEHICLES, DRIP.....23-29

RANGE FIRST GEAR, HYDRAULIC FLOW

IN D...............................21-87

RANGE, HYDRAULIC FLOW IN MANUAL

SECOND (2).........................21-93

RANGE SECOND GEAR, HYDRAULIC FLOW

IN D...............................21-88

RANGE THIRD GEAR, HYDRAULIC FLOW

IN D...............................21-89

RANGES AND SHIFT LEVER POSITIONS,

TRANSMISSION.....................21-157

RATE, CHARGE.........................8A-6

RATINGS, BATTERY CLASSIFICATIONS......8A-8

RATINGSÐLEFT HAND DRIVE, BATTERY

CLASSIFICATIONS....................8B-10

RATINGSÐRIGHT HAND DRIVE, BATTERY

CLASSIFICATIONS....................8B-10

RATIOS, GEAR.........................21-2

RATIOS, TRANSMISSION GEAR...........21-33

REAR AXLE 8 1/4 INCH..................3-50

REAR AXLE ALIGNMENT..................3-8

REAR AXLE MODEL 35..................3-50

REAR AXLES, FRONT....................0-26

REAR BAND ADJUSTMENT..............21-99

REAR BUMPER....................13-6,13-18

REAR CABLE REPLACEMENT (XJ),

PARKING BRAKE......................5-62

REAR CABLE REPLACEMENT (YJ),

PARKING BRAKE......................5-63

REAR CARPET/MATÐXJ VEHICLES.......23-130

REAR CLUTCH OVERHAUL..............21-128

REAR DEFOGGER RELAY.................8N-4

REAR DEFOGGER/FOG LAMP/REAR

WIPER SWITCHES....................8E-21

REAR DOOR FIXED WINDOW GLASS

......23-53

REAR DOOR WINDOW GLASS

............23-52