ECO mode JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 133 of 1784

87 and 30. Continuity should not be present between

terminals number 87A and 30.

(8) Disconnect jumper wires from relay and 12

Volt power source.

If continuity or resistance tests did not pass, re-

place relay. If tests passed, refer to Group 8W, Wir-

ing Diagrams for additional circuit information. Also

refer to the appropriate Powertrain Diagnostic Proce-

dures manual for operation of the DRB scan tool.

STARTER MOTOR RELAY TEST

Refer to Group 8A, Battery/Starting/Charging/Sys-

tem Diagnostics, for starter motor relay testing.

INJECTOR TEST

Disconnect the injector wire connector from the in-

jector. Place an ohmmeter on the injector terminals.

Resistance reading should be approximately 14.5

ohms61.2 ohms at 20ÉC (68ÉF). Proceed to following

Injector Diagnosis chart.

FUEL SYSTEM PRESSURE TEST

Refer to the Fuel Delivery System section of this

group. See Fuel System Pressure Test.

ON-BOARD DIAGNOSTICS (OBD)

The Powertrain Control Module (PCM) has been

programmed to monitor many different circuits of the

fuel injection system. If a problem is sensed in a

monitored circuit often enough to indicate an actual

problem, a Diagnostic Trouble Code (DTC) is stored.

The DTC will be stored in the PCM memory for

eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a diagnostic trou-

ble code (DTC) to be entered into PCM memory. The

criteria may be a specific range of engine rpm, en-

gine temperature and/or input voltage to the PCM.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. This may happen because one

of the DTC criteria for the circuit has not been met.

Example: assume that one of the criteria for the

MAP sensor circuit is that the engine must be oper-

ating between 750 and 2000 rpm to be monitored for

a DTC. If the MAP sensor output circuit shorts to

ground when the engine rpm is above 2400 rpm, a 0

volt input will be seen by the PCM. A DTC will not

be entered into memory because the condition does

not occur within the specified rpm range.

A DTC indicates that the powertrain control mod-

ule (PCM) has recognized an abnormal signal in a

circuit or the system. A DTC may indicate the result

of a failure, but never identify the failed component

directly.There are several operating conditions that the

PCM does not monitor and set a DTC for. Refer to

the following Monitored Circuits and Non-Monitored

Circuits in this section.

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain problems in the fuel injection system.

Open or Shorted Circuit- The PCM can deter-

mine if sensor output (which is the input to PCM) is

within proper range. It also determines if the circuit

is open or shorted.

Output Device Current Flow- The PCM senses

whether the output devices are hooked up.

If there is a problem with the circuit, the PCM

senses whether the circuit is open, shorted to ground

(-), or shorted to (+) voltage.

Oxygen Sensor- The PCM can determine if the

oxygen sensor is switching between rich and lean.

This is, once the system has entered Closed Loop. Re-

fer to Open Loop/Closed Loop Modes Of Operation in

the Component Description/System Operation section

for an explanation of Closed (or Open) Loop opera-

tion.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems or conditions that could have malfunctions

that result in driveability problems. A Diagnostic

Trouble Code (DTC) may not be displayed for these

conditions.

Fuel Pressure: Fuel pressure is controlled by the

vacuum assisted fuel pressure regulator. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, or a pinched fuel supply or return

line. However, these could result in a rich or lean

condition causing an oxygen sensor DTC to be stored

in the PCM.

Secondary Ignition Circuit: The PCM cannot

detect an inoperative ignition coil, fouled or worn

spark plugs, ignition cross firing, or open circuited

spark plug cables.

Engine Timing: The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket or

crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor DTC to be stored in the PCM.

Cylinder Compression: The PCM cannot detect

uneven, low, or high engine cylinder compression.

Exhaust System: The PCM cannot detect a

plugged, restricted or leaking exhaust system.

Fuel Injector Malfunctions: The PCM cannot de-

termine if the fuel injector is clogged, or the wrong

injector is installed. However, these could result in a

rich or lean condition causing an oxygen sensor DTC

to be stored in the PCM.

14 - 48 FUEL SYSTEMJ

Page 135 of 1784

Excessive Oil Consumption: Although the PCM

monitors exhaust stream oxygen content through ox-

ygen sensor (closed loop), it cannot determine exces-

sive oil consumption.

Throttle Body Air Flow: The PCM cannot detect

a clogged or restricted air cleaner inlet or air filter

element.

Evaporative System: The PCM will not detect a

restricted, plugged or loaded EVAP canister.

Vacuum Assist: Leaks or restrictions in the vac-

uum circuits of vacuum assisted engine control sys-

tem devices are not monitored by the PCM. However,

a vacuum leak at the MAP sensor will be monitored

and a diagnostic trouble code (DTC) will be gener-

ated by the PCM.

Powertrain Control Module (PCM) System

Ground: The PCM cannot determine a poor system

ground. However, a DTC may be generated as a re-

sult of this condition.

Powertrain Control Module (PCM) Connector

Engagement: The PCM cannot determine spread or

damaged connector pins. However, a DTC may be

generated as a result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device. It will es-

tablish high and low limits that are programmed into

it for that device. If the input voltage is not within

specifications and other Diagnostic Trouble Code

(DTC) criteria are met, a DTC will be stored in mem-

ory. Other DTC criteria might include engine rpm

limits or input voltages from other sensors or

switches. The other inputs might have to be sensed

by the PCM when it senses a high or low input volt-

age from the control system device in question.

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored Diagnostic Trouble Code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the Malfunction

Indicator Lamp. This lamp was formerly referred to

as the Check Engine Lamp. The lamp is located on

the instrument panel.

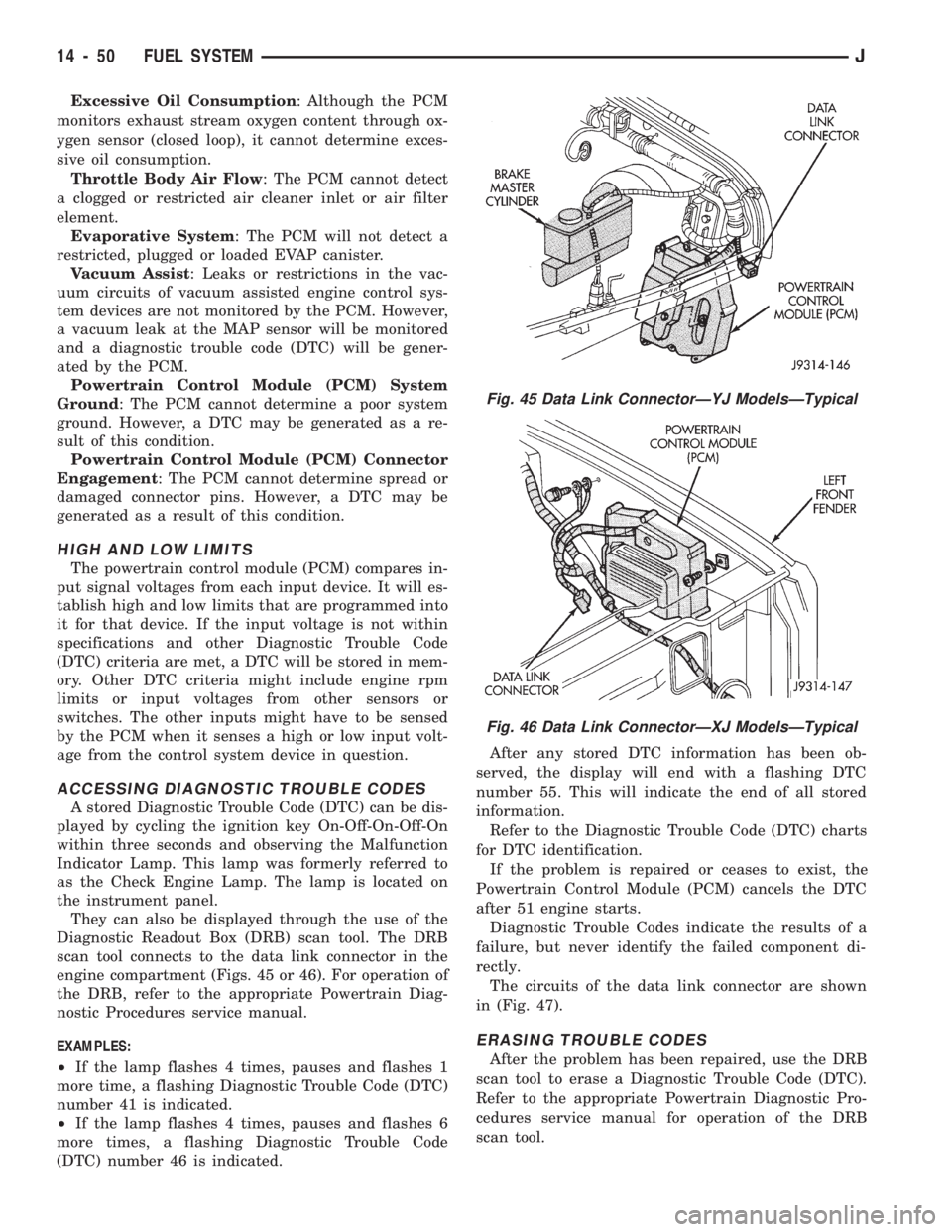

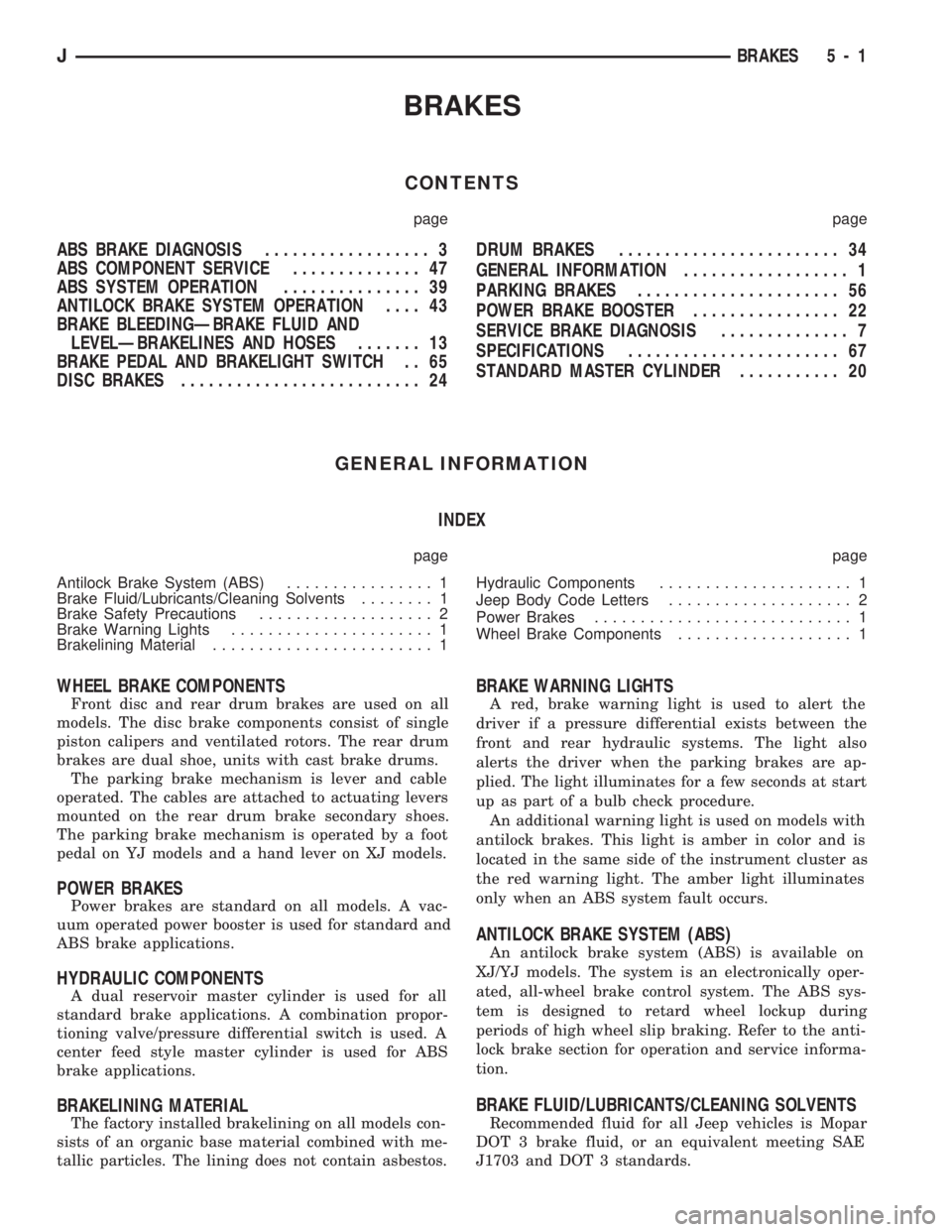

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

scan tool connects to the data link connector in the

engine compartment (Figs. 45 or 46). For operation of

the DRB, refer to the appropriate Powertrain Diag-

nostic Procedures service manual.

EXAMPLES:

²If the lamp flashes 4 times, pauses and flashes 1

more time, a flashing Diagnostic Trouble Code (DTC)

number 41 is indicated.

²If the lamp flashes 4 times, pauses and flashes 6

more times, a flashing Diagnostic Trouble Code

(DTC) number 46 is indicated.After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored

information.

Refer to the Diagnostic Trouble Code (DTC) charts

for DTC identification.

If the problem is repaired or ceases to exist, the

Powertrain Control Module (PCM) cancels the DTC

after 51 engine starts.

Diagnostic Trouble Codes indicate the results of a

failure, but never identify the failed component di-

rectly.

The circuits of the data link connector are shown

in (Fig. 47).

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a Diagnostic Trouble Code (DTC).

Refer to the appropriate Powertrain Diagnostic Pro-

cedures service manual for operation of the DRB

scan tool.

Fig. 45 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 46 Data Link ConnectorÐXJ ModelsÐTypical

14 - 50 FUEL SYSTEMJ

Page 148 of 1784

BRAKES

CONTENTS

page page

ABS BRAKE DIAGNOSIS.................. 3

ABS COMPONENT SERVICE.............. 47

ABS SYSTEM OPERATION............... 39

ANTILOCK BRAKE SYSTEM OPERATION.... 43

BRAKE BLEEDINGÐBRAKE FLUID AND

LEVELÐBRAKELINES AND HOSES....... 13

BRAKE PEDAL AND BRAKELIGHT SWITCH . . 65

DISC BRAKES.......................... 24DRUM BRAKES........................ 34

GENERAL INFORMATION.................. 1

PARKING BRAKES...................... 56

POWER BRAKE BOOSTER................ 22

SERVICE BRAKE DIAGNOSIS.............. 7

SPECIFICATIONS....................... 67

STANDARD MASTER CYLINDER........... 20

GENERAL INFORMATION

INDEX

page page

Antilock Brake System (ABS)................ 1

Brake Fluid/Lubricants/Cleaning Solvents........ 1

Brake Safety Precautions................... 2

Brake Warning Lights...................... 1

Brakelining Material........................ 1Hydraulic Components..................... 1

Jeep Body Code Letters.................... 2

Power Brakes............................ 1

Wheel Brake Components................... 1

WHEEL BRAKE COMPONENTS

Front disc and rear drum brakes are used on all

models. The disc brake components consist of single

piston calipers and ventilated rotors. The rear drum

brakes are dual shoe, units with cast brake drums.

The parking brake mechanism is lever and cable

operated. The cables are attached to actuating levers

mounted on the rear drum brake secondary shoes.

The parking brake mechanism is operated by a foot

pedal on YJ models and a hand lever on XJ models.

POWER BRAKES

Power brakes are standard on all models. A vac-

uum operated power booster is used for standard and

ABS brake applications.

HYDRAULIC COMPONENTS

A dual reservoir master cylinder is used for all

standard brake applications. A combination propor-

tioning valve/pressure differential switch is used. A

center feed style master cylinder is used for ABS

brake applications.

BRAKELINING MATERIAL

The factory installed brakelining on all models con-

sists of an organic base material combined with me-

tallic particles. The lining does not contain asbestos.

BRAKE WARNING LIGHTS

A red, brake warning light is used to alert the

driver if a pressure differential exists between the

front and rear hydraulic systems. The light also

alerts the driver when the parking brakes are ap-

plied. The light illuminates for a few seconds at start

up as part of a bulb check procedure.

An additional warning light is used on models with

antilock brakes. This light is amber in color and is

located in the same side of the instrument cluster as

the red warning light. The amber light illuminates

only when an ABS system fault occurs.

ANTILOCK BRAKE SYSTEM (ABS)

An antilock brake system (ABS) is available on

XJ/YJ models. The system is an electronically oper-

ated, all-wheel brake control system. The ABS sys-

tem is designed to retard wheel lockup during

periods of high wheel slip braking. Refer to the anti-

lock brake section for operation and service informa-

tion.

BRAKE FLUID/LUBRICANTS/CLEANING SOLVENTS

Recommended fluid for all Jeep vehicles is Mopar

DOT 3 brake fluid, or an equivalent meeting SAE

J1703 and DOT 3 standards.

JBRAKES 5 - 1

Page 149 of 1784

Use Mopar Multi Mileage grease to lubricate drum

brake pivot pins and rear brakeshoe contact points

on the support plates. Use GE 661, or Dow 111 sili-

cone grease on caliper bushings and mounting bolts.

Use fresh brake fluid or Mopar brake cleaner to

clean or flush brake system components. These are

the only cleaning materials recommended.

CAUTION: Never use gasoline, kerosene, methyl or

isopropyl alcohol, paint thinner, or any fluid con-

taining mineral oil to clean the system components.

These fluids damage rubber cups and seals. If sys-

tem contamination is suspected, check the fluid for

dirt, discoloration, or separation into distinct layers.

Drain and flush the system with new brake fluid if

contamination is suspected.

JEEP BODY CODE LETTERS

The body/model identification code letters for Jeep

vehicles are as follows:

²Code letters XJ: Cherokee

²Code letters YJ: Wrangler/YJ

The code letters are used throughout this group to

simplify model identification and component applica-

tion.

BRAKE SAFETY PRECAUTIONS

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKELINING ON JEEP VEHICLES IS MADE FROM

ASBESTOS FREE MATERIALS, SOME AFTER MARKET

BRAKELINING MAY CONTAIN ASBESTOS. THIS

SHOULD BE TAKEN INTO ACCOUNT WHEN REPAIR-

ING A VEHICLE WITH PRIOR BRAKE SERVICE. WEAR

A RESPIRATOR WHEN CLEANING BRAKE COMPO-

NENTS AS ASBESTOS FIBERS CAN BE A HEALTH

HAZARD. NEVER CLEAN WHEEL BRAKE COMPO-

NENTS WITH COMPRESSED AIR. USE A VACUUM

CLEANER SPECIFICALLY DESIGNED FOR REMOVING

BRAKE DUST. IF A VACUUM CLEANER IS NOT AVAIL-

ABLE, CLEAN THE PARTS WITH WATER DAMPENED

SHOP RAGS. DO NOT CREATE DUST BY SANDING

BRAKELINING. DISPOSE OF ALL DUST AND DIRT

SUSPECTED OF CONTAINING ASBESTOS FIBERS IN

SEALED BAGS OR CONTAINERS. FOLLOW ALL REC-

OMMENDED SAFETY PRACTICES PRESCRIBED BY

THE OCCUPATIONAL SAFETY AND HEALTH ADMINIS-

TRATION (OSHA) AND THE ENVIRONMENTAL PRO-

TECTION AGENCY (EPA), FOR HANDLING AND

DISPOSAL OF PRODUCTS CONTAINING ASBESTOS.

5 - 2 BRAKESJ

Page 150 of 1784

ABS BRAKE DIAGNOSIS

INDEX

page page

ABS Fault Diagnosis....................... 4

ABS System Wiring and Electrical Circuits...... 4

ABS Warning Light Display.................. 3

Brake Warning Light Display................. 4

Diagnosis Procedures...................... 3

ECU Diagnosis........................... 4

HCU Diagnosis........................... 4Loss of Sensor Input....................... 3

Operating Sound Levels.................... 3

Rear Speed Sensor Air Gap................. 3

Steering Response........................ 3

Vehicle Response in Antilock Mode............ 3

Wheel/Tire Size and Input Signals............. 3

DIAGNOSIS PROCEDURES

ABS diagnosis involves three basic steps. First is

observation of the warning light display. Second is a

visual examination for low fluid level, leaks, parking

brakes applied, or obvious damage to system compo-

nents or wires. The third step involves using the

DRB II scan tool to identify a faulty component.

The visual examination requires a check of reser-

voir fluid level and all system components. Things to

look for are leaks, loose connections, or obvious com-

ponent damage.

The final diagnosis step involves using the DRB II

scan tool to determine the specific circuit or compo-

nent at fault. The tester is connected to the ABS di-

agnostic connector in the passenger compartment.

The connector is at the driver side of the center con-

sole under the instrument panel. Refer to the DRB II

scan tool Manual for tester procedures. Also refer to

the ABS Fault Diagnosis charts at the end of this

section for additional diagnosis information.

Initial faults should be cleared and the vehicle road

tested to reset any faults that remain in the system.

Faults can be cleared with the DRB II scan tool.

REAR SPEED SENSOR AIR GAP

The front wheel sensors are fixed and cannot be ad-

justed. Only the rear sensor air gap is adjustable. Air

gap must be set with a brass feeler gauge.

Correct air gap is important to proper signal gen-

eration. An air gap that is too large may cause com-

plete loss of sensor input. Or, a gap that is too small

could produce a false input signal, or damaging con-

tact between the sensor and tone ring.

WHEEL/TIRE SIZE AND INPUT SIGNALS

Antilock system operation is dependant on accurate

signals from the wheel speed sensors. Ideally, the ve-

hicle wheels and tires should all be the same size

and type. However, the Jeep ABS system is designed

to function with a compact spare tire installed.

OPERATING SOUND LEVELS

The ABS pump and solenoid valves may produce

some sound as they cycle on and off. This is a normal

condition and should not be mistaken for faulty oper-

ation.

VEHICLE RESPONSE IN ANTILOCK MODE

During antilock braking, the HCU solenoid valves

cycle rapidly in response to ECU inputs.

The driver will experience a pulsing sensation

within the vehicle as the solenoids decrease, hold, or

increase pressure as needed. A pulsing brake pedal

will also be noted.

The pulsing sensation occurs as the solenoids cycle

during antilock mode braking. A slight pulse in the

brake pedal may also be noted during the dynamic

self check part of system initialization.

STEERING RESPONSE

A modest amount of steering input is required dur-

ing extremely high deceleration braking, or when

braking on differing traction surfaces. An example of

differing traction surfaces would be when the left

side wheels are on ice and the right side wheels are

on dry pavement.

LOSS OF SENSOR INPUT

Sensor malfunctions will most likely be due to

loose connections, damaged sensor wires, incorrect

rear sensor air gap, or a malfunctioning sensor. Ad-

ditional causes of sensor faults would be sensor and

tone ring misalignment or damage.

ABS WARNING LIGHT DISPLAY

ABS Light Illuminates At Startup

The amber ABS light illuminates at startup as

part of the system self check feature. The light illu-

minates for 2-3 seconds then goes off as part of the

normal self check routine.

ABS Light Remains On After Startup

An ABS system fault is indicated when the light

remains on after startup. Diagnosis with the DRB II

JBRAKES 5 - 3

Page 155 of 1784

(2) If red warning light is illuminated, or if neither

warning light is illuminated, make several stops and

note pedal action and brake response.

(3) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under steady foot pressure. If pedal falls away,

problem is either in vacuum booster or master cylin-

der.

(4) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as pull, grab, drag, noise, fade, pedal pul-

sation, etc.

(5) Inspect suspect brake components and refer to

problem diagnosis information for causes of various

brake conditions.

COMPONENT INSPECTION

Fluid leak points and dragging brake units can

usually be located without removing any compo-

nents. The area around a leak point will be wet with

fluid. The components at a dragging brake unit

(wheel, tire, rotor) will be quite warm or hot to the

touch.

Other brake problem conditions will require compo-

nent removal for proper inspection. Raise the vehicle

and remove the necessary wheels for better visual ac-

cess.

During component inspection, pay particular atten-

tion to heavily rusted/corroded brake components

(e.g. rotors, caliper pistons, brake return/holddown

springs, support plates, etc.).

Heavy accumulations of rust may be covering se-

vere damage to a brake component. It is wise to re-

move surface rust in order to accurately determine

the depth of rust penetration and damage. Light sur-

face rust is fairly normal and not a major concern (as

long as it is removed). However, heavy rust buildup,

especially on high mileage vehicles may cover struc-

tural damage to such important components as

brakelines, rotors, support plates, and brake boosters.

Refer to the wheel brake service procedures in this

group for more information.

DIAGNOSING SERVICE BRAKE PROBLEMS

BRAKE WARNING LIGHT OPERATION

The red brake warning light will illuminate under

the following conditions:

²for 2-3 seconds at startup as part of normal bulb

check

²parking brakes applied

²low pedal caused by malfunction in front/rear

brake hydraulic circuit (differential switch valve ac-

tuated)

If the red light remains on after startup, first ver-

ify that the parking brakes are fully released. Then

check pedal action and fluid level. A red light indi-

cates that the valve in the differential pressureswitch has been actuated. If a problem is confirmed,

inspect the hydraulic system and wheel brake compo-

nents.

On models with ABS brakes, the amber warning

light only illuminates when an ABS component has

malfunctioned. The ABS light operates indepen-

dently of the red warning light. Refer to the antilock

brake section for more detailed diagnosis informa-

tion.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brakeline, fitting, hose,

wheel cylinder, or caliper. Internal leakage in the

master cylinder caused by worn or damaged piston

cups, may also be the problem cause.

If leakage is severe, fluid will be evident at or

around the leaking component. However internal

leakage in the master cylinder will not be physically

evident. Refer to the cylinder test procedure in this

section.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, worn lining

and worn rotors or drums are the most likely causes.

However, if the pedal remains low and/or the warn-

ing light illuminates, the problem is in the master

cylinder, wheel cylinders, or calipers.

A decrease in master cylinder fluid level may only

be the result of normal lining wear. Fluid level will

decrease as lining wear occurs. It is a result of the

outward movement of caliper and wheel cylinder pis-

tons to compensate for normal wear.

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However, thin drums or substandard brake

lines and hoses will also cause a condition similar to

a spongy pedal. The proper course of action is to

bleed the system, or replace thin drums and suspect

quality brake lines and hoses.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could

also be faulty. Test the booster and valve as de-

scribed in this section.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at

one wheel, all wheels, fronts only, or rears only. It is

a product of incomplete brakeshoe release. Drag can

be minor or severe enough to overheat the linings,

rotors and drums.

5 - 8 BRAKESJ

Page 157 of 1784

when the cover is off. The second involves adding to,

or filling the cylinder reservoirs with a non-recom-

mended fluid.

Brake fluid contaminated with only dirt, or debris

usually retains a normal appearance. In some cases,

the foreign material will remain suspended in the

fluid and be visible. The fluid and foreign material

can be removed from the reservoir with a suction

gun but only if the brakes have not been applied. If

the brakes are applied after contamination, system

flushing will be required. The master cylinder may

also have to be disassembled, cleaned and the piston

seals replaced. Foreign material lodged in the reser-

voir compensator/return ports can cause brake drag

by restricting fluid return after brake application.

Brake fluid contaminated by a non-recommended

fluid will usually be discolored, milky, oily looking,

or foamy. In some cases, it may even appear as if the

fluid contains sludge.However, remember that

brake fluid will darken in time and occasionally

be cloudy in appearance. These are normal con-

ditions and should not be mistaken for contami-

nation.

If some type of oil has been added to the system,

the fluid will separate into distinct layers. To verify

this, drain off a sample with a clean suction gun.

Then pour the sample into a glass container and ob-

serve fluid action. If the fluid separates into distinct

layers, it is definitely contaminated.

The only real correction for contamination by non-

recommended fluid is to flush the entire hydraulic

system and replace all the seals.

BRAKE NOISE

Squeak/Squeal

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or

oil. Glazed linings and rotors with hard spots can

also contribute to squeak. Dirt and foreign material

embedded in the brake lining will also cause squeak/

squeal.

A very loud squeak or squeal is frequently a sign

of severely worn brake lining. If the lining has worn

through to the brakeshoes in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors can become so scored that replacement is nec-

essary.

Thump/Clunk

Thumping or clunk noises during braking are fre-

quentlynotcaused by brake components. In many

cases, such noises are caused by loose or damaged

steering, suspension, or engine components. How-

ever, calipers that bind on the slide surfaces can gen-

erate a thump or clunk noise. In addition, worn out,

improperly adjusted, or improperly assembled rear

brakeshoes can also produce a thump noise.Chatter/Shudder

Brake chatter, or shudder is usually caused by

loose or worn components, or glazed/burnt lining. Ro-

tors with hard spots can also contribute to chatter.

Additional causes of chatter are out of tolerance ro-

tors, brake lining not securely attached to the shoes,

loose wheel bearings and contaminated brake lining.

BRAKELINING CONTAMINATION

Brakelining contamination is usually a product of

leaking calipers or wheel cylinders, driving through

deep water puddles, or lining that has become cov-

ered with grease and grit during repair.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a condition similar to grab as the tire loses

and recovers traction.

Flat-spotted tires can cause vibration and wheel

tramp and generate shudder during brake operation.

A tire with internal damage such as a severe

bruise or ply separation can cause pull and vibration.

DIAGNOSING PARKING BRAKE PROBLEMS

Adjustment Mechanism

Parking brake adjustment is controlled by a

cable tensioner mechanism. This applies to 1991

through 1994 YJ models and 1992 and later XJ

models. The cable tensioner, once adjusted at

the factory, will not need further adjustment un-

der normal circumstances. There are only two

instances when adjustment is required. The first

is when a new tensioner, or cables have been in-

stalled. And the second, is when the tensioner

and cables are disconnected for access to other

brake components.

Parking Brake problem Causes

In most cases, the actual cause of an improperly

functioning parking brake (too loose/too tight/wont

hold), can be traced to a drum brake component.

The leading cause of improper parking brake

operation, is excessive clearance between the

brakeshoes and the drum surface. Excessive

clearance is a result of: lining and/or drum wear;

oversize drums; or inoperative shoe adjuster

components.

Excessive parking brake lever travel (sometimes

described as a loose lever or too loose condition), is

the result of worn brakeshoes/drums, improper

brakeshoe adjustment, or mis-assembled brake parts.

A ``too loose'' condition can also be caused by inop-

erative brakeshoe adjusters. If the adjusters are mis-

5 - 10 BRAKESJ

Page 160 of 1784

BRAKE BLEEDINGÐBRAKE FLUID AND LEVELÐBRAKELINES AND HOSES

INDEX

page page

Brake BleedingÐXJ/YJ with ABS Brakes....... 14

Brake BleedingÐXJ/YJ with Standard Brakes . . . 13

Brake Fluid Contamination.................. 13

Brake Fluid Level........................ 13Brakeline Charts......................... 15

Brakelines and Hoses..................... 15

Combination Valve....................... 15

Recommended Brake Fluid................. 13

RECOMMENDED BRAKE FLUID

The only brake fluid recommended for Jeep vehi-

cles with standard or antilock brakes, is Mopar brake

fluid, or an equivalent fluid meeting SAE J1703 and

DOT 3 standards.

Use new brake fluid only to top off the master

cylinder or refill the system. Never use re-

claimed fluid, fluid not meeting the SAE/DOT

standards or fluid from an unsealed container.

Do not use fluid from any container that has

been left open for any length of time. Fluid in

open containers can absorb moisture.

BRAKE FLUID LEVEL

Always clean the master cylinder and cover before

checking fluid level. If not cleaned, dirt from the

cover could enter the fluid. Also check the cover seal

and replace it if torn or distorted.

Correct fluid level is to within 6 mm (1/4 in.) of the

reservoir rim, or to the fill mark on models with a

plastic reservoir. Refer to the Antilock Brake section

for fluid levels on models equipped with ABS brakes.

BRAKE FLUID CONTAMINATION

Oil in the fluid will cause brake system rubber

seals to soften and swell. The seals may also become

porous and begin to deteriorate.

If fluid contamination is suspected, drain off a sam-

ple from the master cylinder. A suction gun or simi-

lar device can be used for this purpose.

Empty the drained fluid into a glass container.

Contaminants in the fluid will cause the fluid to sep-

arate into distinct layers. If contamination has oc-

curred, the system rubber seals, hoses and cups must

be replaced and the system thoroughly flushed with

clean brake fluid.

BRAKE BLEEDINGÐXJ/YJ WITH STANDARD

BRAKES

Use Mopar DOT 3 brake fluid, or an equivalent

meeting SAE/DOT standards J1703-F and DOT 3, to

fill and bleed the system.

On standard brake models, bleeding can be per-

formed either manually or with pressure equipment.

However, if pressure equipment is used, it will be

necessary to hold the front brake metering valveopen in order to bleed the front brakes. The valve

can be held open with a tension clip tool or by hand.

It will also be necessary that a suitable size pressure

tank hose adapter be available for use on the master

cylinder.

MANUAL BLEEDING PROCEDURE

(1) If master cylinder has been overhauled or a

new cylinder will be installed, bleed cylinder on

bench before installation. This shortens time needed

to bleed system and ensures proper cylinder opera-

tion.

(2) Wipe master cylinder reservoir and cap clean

with shop towels.

(3) Remove cover and fill master cylinder reservoir

with Mopar, or equivalent DOT 3 brake fluid.

(4) Open all caliper and wheel cylinder bleed

screws.

(5) Close bleed screws after fluid begins flowing

from each bleed screw.

(6) Top off master cylinder reservoir again.

(7) Use following bleed sequence:

²master cylinder

²right rear

²left rear

²right front

²left front

(8) Observe following brake bleeding precautions:

²Do not pump brake pedal at any time while bleed-

ing. Air in system will be compressed into small bub-

bles that are distributed throughout hydraulic

system. This will make a second and third bleeding

operation necessary.

²Bleed only one wheel brake unit at a time and use

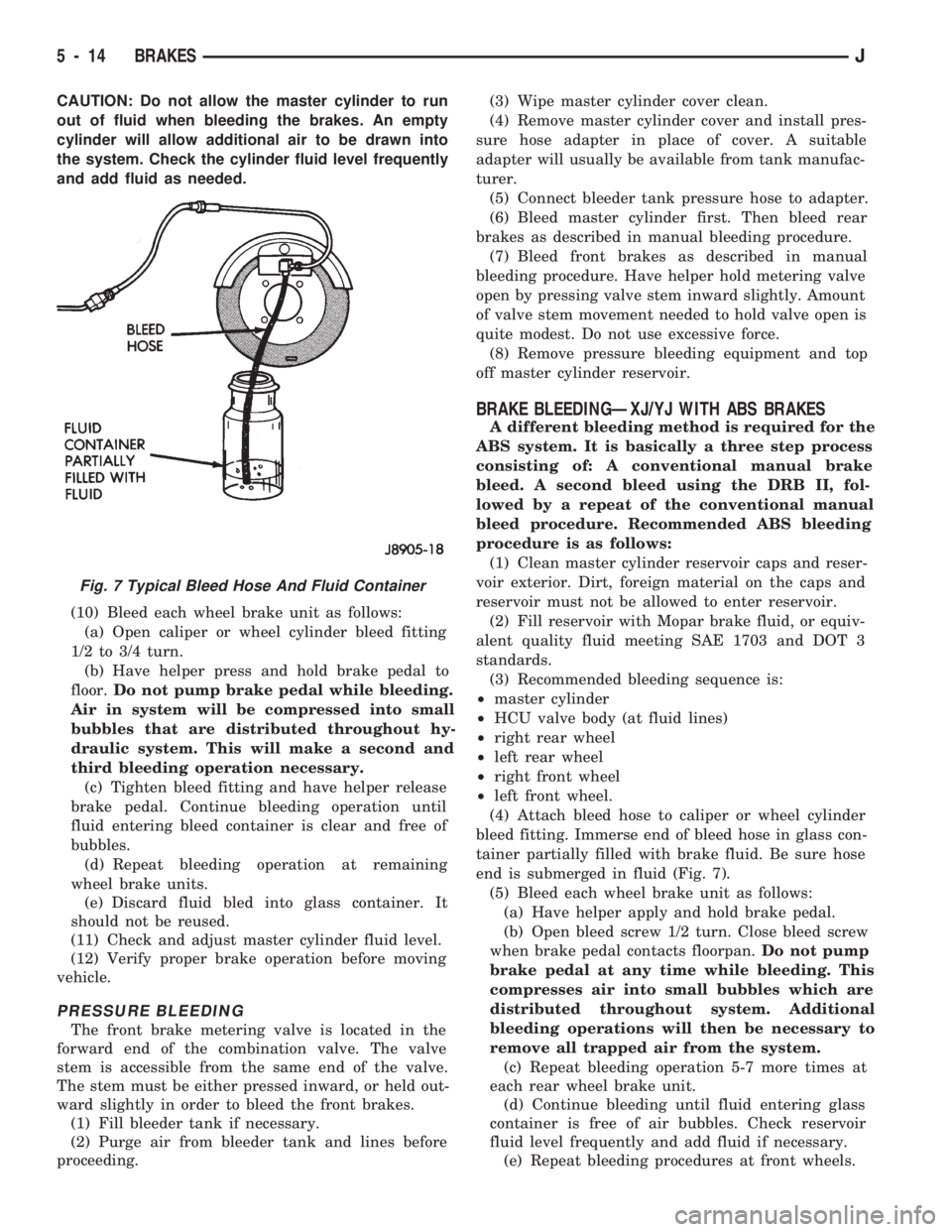

a bleed hose to bleed each wheel brake unit (Fig. 7).

²Attach one end of bleed hose to bleed screw and in-

sert opposite end in glass container partially filled

with brake fluid (Fig. 7). Glass container makes it

easier to see air bubbles as they exit the bleed hose.

²Be sure end of bleed hose is immersed in fluid. Im-

mersing hose end in fluid prevents air from being

drawn back into cylinder and brakeline.

(9) Bleed master cylinder first. Have helper oper-

ate brake pedal while bleeding each master cylinder

fluid outlet line.

JBRAKES 5 - 13

Page 161 of 1784

CAUTION: Do not allow the master cylinder to run

out of fluid when bleeding the brakes. An empty

cylinder will allow additional air to be drawn into

the system. Check the cylinder fluid level frequently

and add fluid as needed.

(10) Bleed each wheel brake unit as follows:

(a) Open caliper or wheel cylinder bleed fitting

1/2 to 3/4 turn.

(b) Have helper press and hold brake pedal to

floor.Do not pump brake pedal while bleeding.

Air in system will be compressed into small

bubbles that are distributed throughout hy-

draulic system. This will make a second and

third bleeding operation necessary.

(c) Tighten bleed fitting and have helper release

brake pedal. Continue bleeding operation until

fluid entering bleed container is clear and free of

bubbles.

(d) Repeat bleeding operation at remaining

wheel brake units.

(e) Discard fluid bled into glass container. It

should not be reused.

(11) Check and adjust master cylinder fluid level.

(12) Verify proper brake operation before moving

vehicle.

PRESSURE BLEEDING

The front brake metering valve is located in the

forward end of the combination valve. The valve

stem is accessible from the same end of the valve.

The stem must be either pressed inward, or held out-

ward slightly in order to bleed the front brakes.

(1) Fill bleeder tank if necessary.

(2) Purge air from bleeder tank and lines before

proceeding.(3) Wipe master cylinder cover clean.

(4) Remove master cylinder cover and install pres-

sure hose adapter in place of cover. A suitable

adapter will usually be available from tank manufac-

turer.

(5) Connect bleeder tank pressure hose to adapter.

(6) Bleed master cylinder first. Then bleed rear

brakes as described in manual bleeding procedure.

(7) Bleed front brakes as described in manual

bleeding procedure. Have helper hold metering valve

open by pressing valve stem inward slightly. Amount

of valve stem movement needed to hold valve open is

quite modest. Do not use excessive force.

(8) Remove pressure bleeding equipment and top

off master cylinder reservoir.

BRAKE BLEEDINGÐXJ/YJ WITH ABS BRAKES

A different bleeding method is required for the

ABS system. It is basically a three step process

consisting of: A conventional manual brake

bleed. A second bleed using the DRB II, fol-

lowed by a repeat of the conventional manual

bleed procedure. Recommended ABS bleeding

procedure is as follows:

(1) Clean master cylinder reservoir caps and reser-

voir exterior. Dirt, foreign material on the caps and

reservoir must not be allowed to enter reservoir.

(2) Fill reservoir with Mopar brake fluid, or equiv-

alent quality fluid meeting SAE 1703 and DOT 3

standards.

(3) Recommended bleeding sequence is:

²master cylinder

²HCU valve body (at fluid lines)

²right rear wheel

²left rear wheel

²right front wheel

²left front wheel.

(4) Attach bleed hose to caliper or wheel cylinder

bleed fitting. Immerse end of bleed hose in glass con-

tainer partially filled with brake fluid. Be sure hose

end is submerged in fluid (Fig. 7).

(5) Bleed each wheel brake unit as follows:

(a) Have helper apply and hold brake pedal.

(b) Open bleed screw 1/2 turn. Close bleed screw

when brake pedal contacts floorpan.Do not pump

brake pedal at any time while bleeding. This

compresses air into small bubbles which are

distributed throughout system. Additional

bleeding operations will then be necessary to

remove all trapped air from the system.

(c) Repeat bleeding operation 5-7 more times at

each rear wheel brake unit.

(d) Continue bleeding until fluid entering glass

container is free of air bubbles. Check reservoir

fluid level frequently and add fluid if necessary.

(e) Repeat bleeding procedures at front wheels.

Fig. 7 Typical Bleed Hose And Fluid Container

5 - 14 BRAKESJ

Page 190 of 1784

ANTILOCK BRAKE SYSTEM OPERATION

INDEX

page page

ABS Operation in Antilock Braking Mode....... 43

ABS Operation in Normal Braking Mode....... 43

Acceleration Switch Operation............... 45

ECY Operation.......................... 46HCU Pump and Pedal Travel Sensor Operation . 44

HCU Solenoid Valve Operation.............. 43

System Power-Up and Initialization........... 43

Wheel Speed Sensor Operation............. 45

SYSTEM POWER-UP AND INITIALIZATION

The antilock system is in standby mode with the

ignition switch in Off or Accessory position. The an-

tilock electrical components are not operational.

Turning the ignition switch to On or Run position

allows battery voltage to flow through the switch to

the ECU ignition terminal.

The ABS system is activated when battery voltage

is supplied to the ECU. The ECU performs a system

initialization procedure at this point. Initialization

consists of a static and dynamic self check of system

electrical components.

The static check occurs immediately after the igni-

tion switch is turned to the On position. The dynamic

check occurs when vehicle road speed reaches ap-

proximately 10 kph (6 mph). During the dynamic

check, the ECU briefly cycles the pump to verify op-

eration. The HCU solenoids are checked continu-

ously.

If an ABS component exhibits a fault during ini-

tialization, the ECU illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

ABS OPERATION IN NORMAL BRAKING MODE

The ECU monitors wheel speed sensor inputs con-

tinuously while the vehicle is in motion. However,

the ECU will not activate any ABS components as

long as sensor inputs and the acceleration switch in-

dicate normal braking.

During normal braking, the master cylinder, power

booster and wheel brake units all function as they

would in a vehicle without ABS. The HCU compo-

nents are not activated.

ABS OPERATION IN ANTILOCK BRAKING MODE

The purpose of the antilock system is to prevent

wheel lockup during periods of high wheel slip. Pre-

venting lockup helps maintain vehicle braking action

and steering control.

The antilock ECU activates the system whenever

sensor signals indicate periods of high wheel slip.

High wheel slip can be described as the point where

wheel rotation begins approaching zero (or lockup)

during braking. Periods of high wheel slip occur

when brake stops involve high pedal pressure and

rate of vehicle deceleration.The antilock system retards lockup during high

slip conditions by modulating fluid apply pressure to

the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. A sensor at each wheel converts wheel speed

into electrical signals. These signals are transmitted

to the ECU for processing and determination of

wheel slip and deceleration rate.

The Jeep ABS system has three fluid pressure con-

trol channels. The front brakes are controlled sepa-

rately and the rear brakes in tandem (Fig. 10). A

speed sensor input signal indicating high slip condi-

tions activates the ECU antilock program.

Two solenoid valves are used in each antilock con-

trol channel (Fig. 11). The valves are all located

within the HCU valve body and work in pairs to ei-

ther increase, hold, or decrease apply pressure as

needed in the individual control channels.

The solenoid valves are not static during antilock

braking. They are cycled continuously to modulate

pressure. Solenoid cycle time in antilock mode can be

measured in milliseconds.

HCU SOLENOID VALVE OPERATION

Normal Braking

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

Antilock Pressure Modulation

Solenoid valve pressure modulation occurs in three

stages which are: pressure increase, pressure hold,

and pressure decrease. The valves are all contained

in the valve body portion of the HCU.

Pressure Decrease

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle (Fig. 11).

A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the ECU opens the outlet

valve. Opening the outlet valve also opens the hy-

draulic return circuit to the master cylinder reser-

JANTILOCK BRAKE SYSTEM OPERATION 5 - 43