relay JEEP CHEROKEE 1994 Service Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 456 of 1784

POWER DOOR LOCKS

CONTENTS

page page

KEYLESS ENTRY........................ 8POWER LOCKS......................... 1

POWER LOCKS

INDEX

page page

Actuator Motor Stall Test.................... 6

Description.............................. 1

Diagnosing Power Door Locks............... 1

General................................. 1Liftgate Lock Cylinder Replacement............ 7

Solenoid and Latch Assembly Replacement..... 6

Switch Replacement....................... 6

GENERAL

The door lock actuators, including liftgate, are con-

trolled by two-way switches. To lock the doors, push

down on either switch. To unlock doors from inside

the vehicle push upward on either switch.

The power door locks do not lock or unlock the

doors from outside the vehicle. Insert the key into

the lock cylinder to lock or unlock each individual

door.

DESCRIPTION

The door locks are operated by reversible motors

that receive voltage from fuse #13 in the fuse panel.

Voltage is applied to the driver's side door lock

switch and the passenger's side door lock switch

through the #9 fuse. With the driver's side door lock

switch in LOCK, voltage is applied through the

switch to the door lock relay coil. The relay coil is

energized which closes the circuit from the circuit

breaker to the lock motor. The motor is grounded by

the unlock relay.

The passenger's side door lock window switch oper-

ates the same as the driver's door switch. The volt-

age and ground paths are reversed to unlock the

doors.

The power door lock operates with battery power

and, therefore, is independent of the ignition switch.

DIAGNOSING POWER DOOR LOCKS

If vehicle has Keyless Entry and the door locks op-

erate properly using door switches but do not work

with transmitter, refer to Keyless Entry in this

group.

NO DOOR LOCKS OPERATE USING DOOR

LOCK SWITCHES

(1) Inspect fuse #13. Replace if necessary. If OK,

measure voltage at battery side of fuse. There should

be 12 volts. If not, repair open from Power Distribu-

tion Center.

(2) Remove door switch and measure voltage at

terminal 1. Meter should read battery voltage. If not,

repair open to #9 fuse.

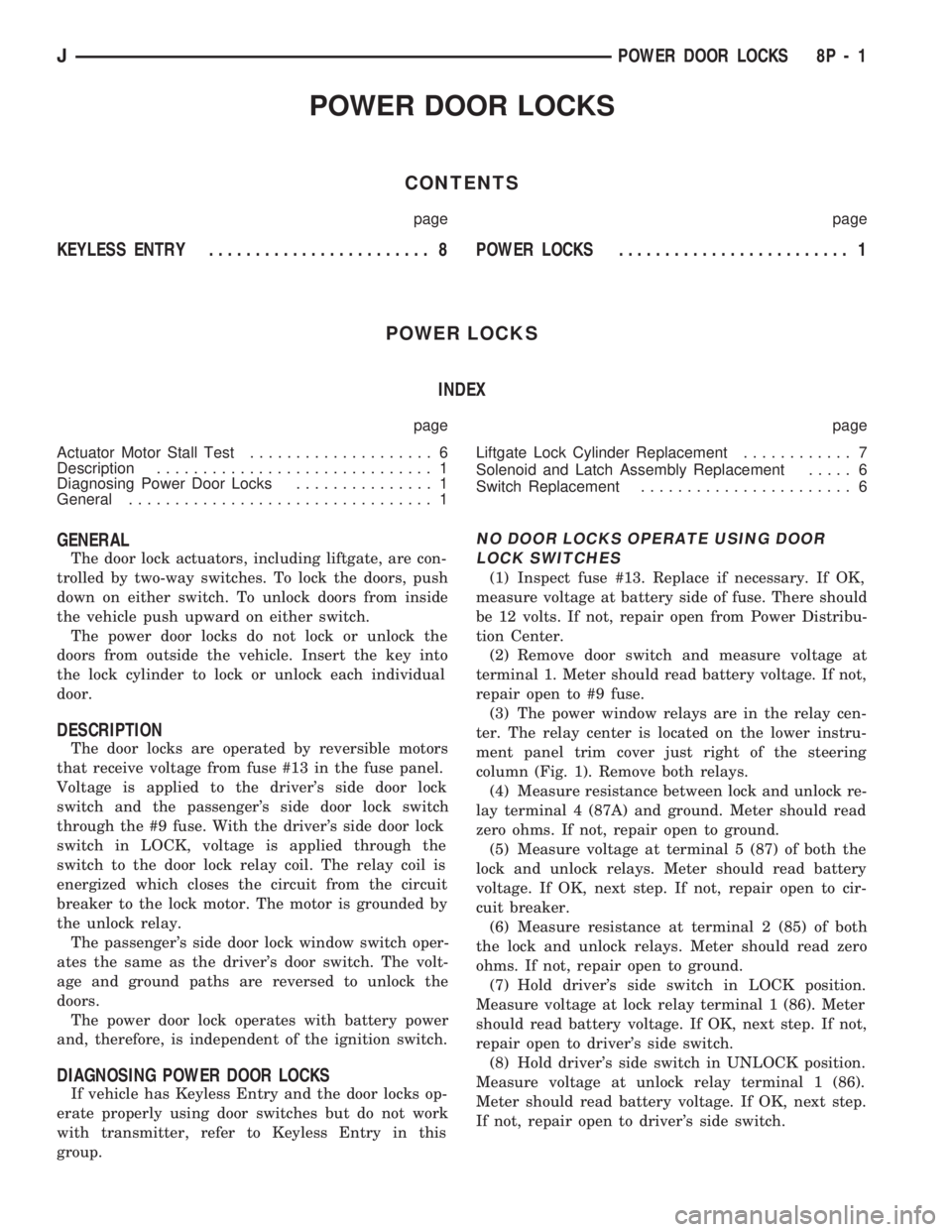

(3) The power window relays are in the relay cen-

ter. The relay center is located on the lower instru-

ment panel trim cover just right of the steering

column (Fig. 1). Remove both relays.

(4) Measure resistance between lock and unlock re-

lay terminal 4 (87A) and ground. Meter should read

zero ohms. If not, repair open to ground.

(5) Measure voltage at terminal 5 (87) of both the

lock and unlock relays. Meter should read battery

voltage. If OK, next step. If not, repair open to cir-

cuit breaker.

(6) Measure resistance at terminal 2 (85) of both

the lock and unlock relays. Meter should read zero

ohms. If not, repair open to ground.

(7) Hold driver's side switch in LOCK position.

Measure voltage at lock relay terminal 1 (86). Meter

should read battery voltage. If OK, next step. If not,

repair open to driver's side switch.

(8) Hold driver's side switch in UNLOCK position.

Measure voltage at unlock relay terminal 1 (86).

Meter should read battery voltage. If OK, next step.

If not, repair open to driver's side switch.

JPOWER DOOR LOCKS 8P - 1

Page 457 of 1784

(9) Hold driver's side switch in LOCK position.

Measure voltage at lock relay terminal 3 (30). Meter

should read battery voltage. If OK, next step. If not,

replace lock relay.

(10) Hold driver's side switch in UNLOCK posi-

tion. Measure voltage at unlock relay terminal 3

(30). Meter should read battery voltage. If OK, check

connections and door motor. If not, replace unlock re-

lay.

(11) Repeat procedures for passenger's side switch.

Fig. 1 Door Lock/Unlock Relays

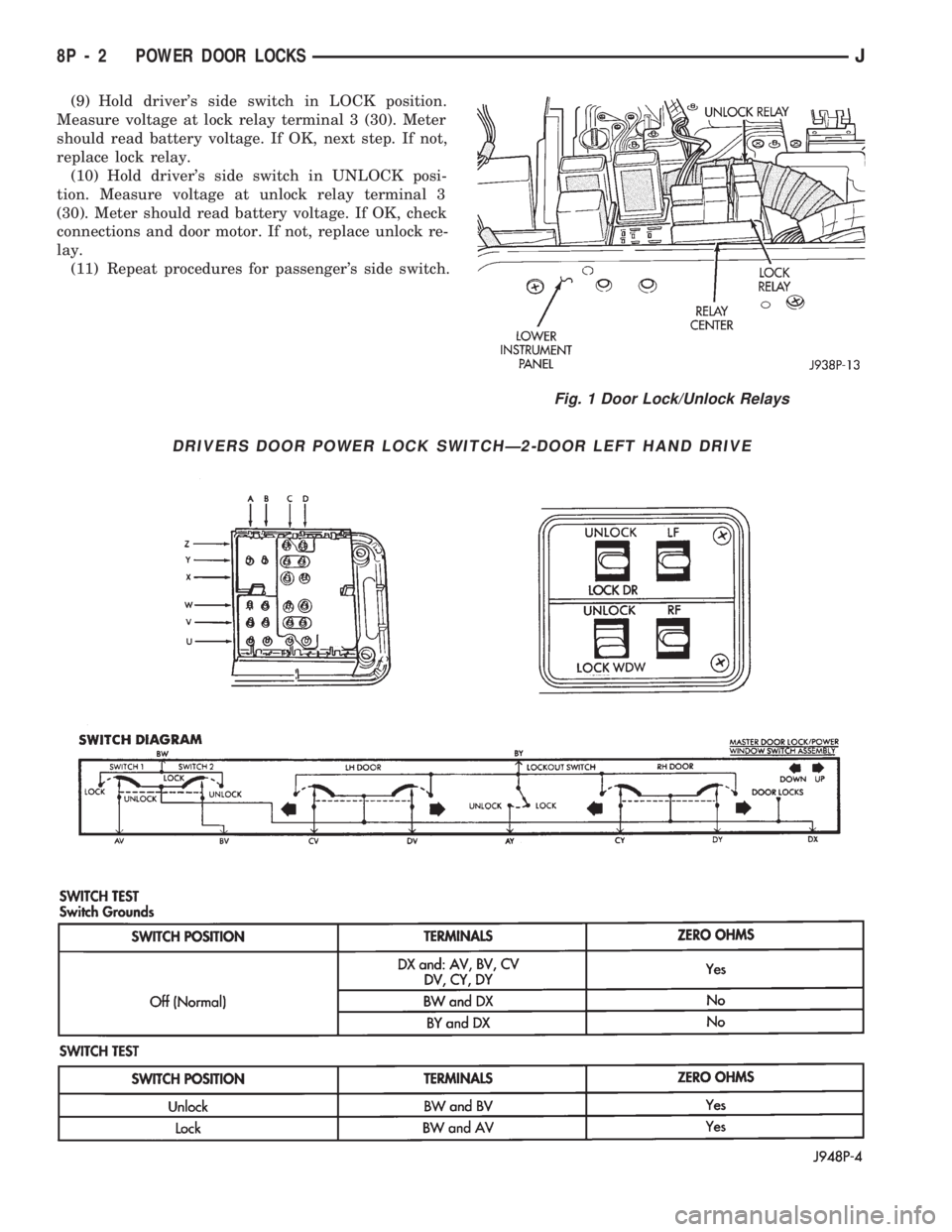

DRIVERS DOOR POWER LOCK SWITCHÐ2-DOOR LEFT HAND DRIVE

8P - 2 POWER DOOR LOCKSJ

Page 463 of 1784

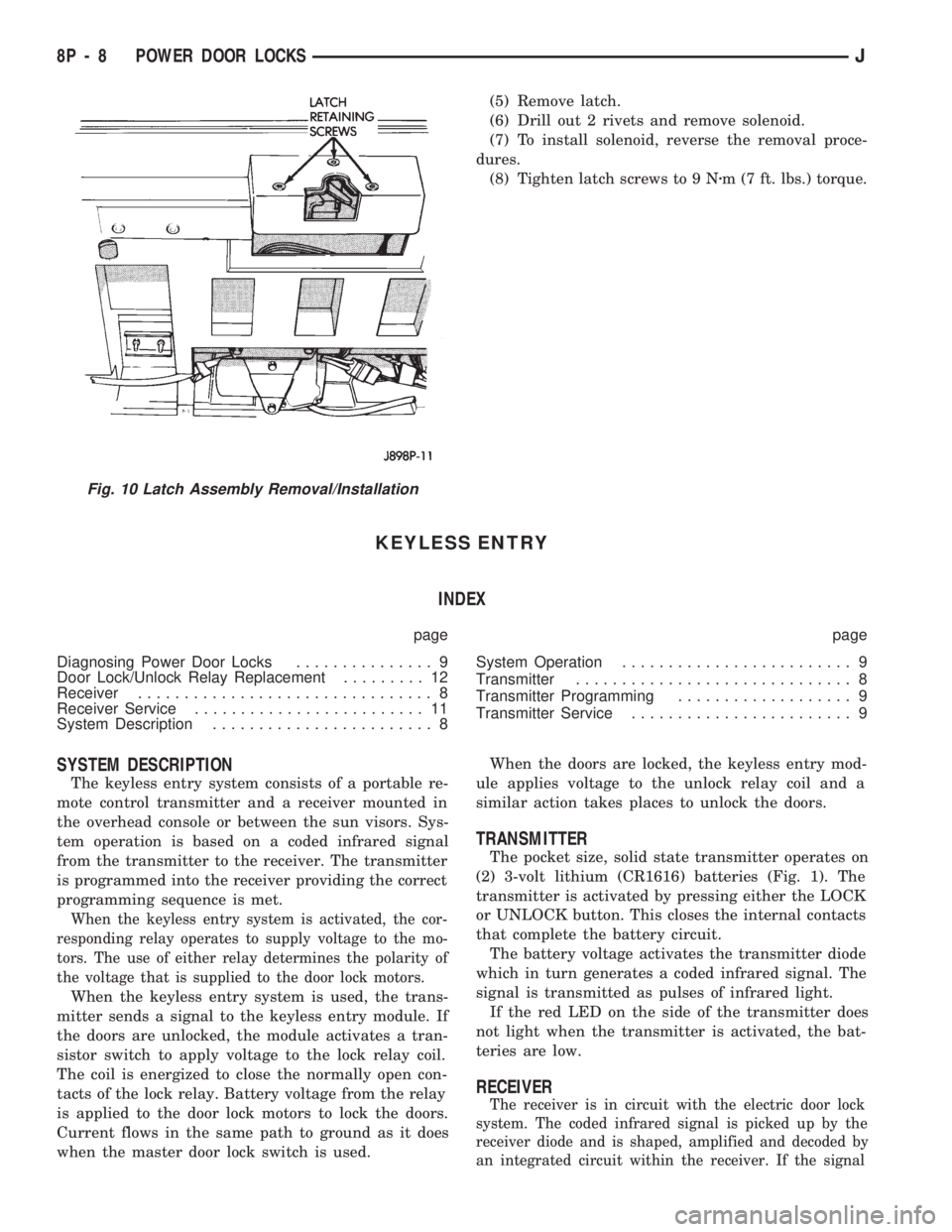

(5) Remove latch.

(6) Drill out 2 rivets and remove solenoid.

(7) To install solenoid, reverse the removal proce-

dures.

(8) Tighten latch screws to 9 Nzm (7 ft. lbs.) torque.

KEYLESS ENTRY

INDEX

page page

Diagnosing Power Door Locks............... 9

Door Lock/Unlock Relay Replacement......... 12

Receiver................................ 8

Receiver Service......................... 11

System Description........................ 8System Operation......................... 9

Transmitter.............................. 8

Transmitter Programming................... 9

Transmitter Service........................ 9

SYSTEM DESCRIPTION

The keyless entry system consists of a portable re-

mote control transmitter and a receiver mounted in

the overhead console or between the sun visors. Sys-

tem operation is based on a coded infrared signal

from the transmitter to the receiver. The transmitter

is programmed into the receiver providing the correct

programming sequence is met.

When the keyless entry system is activated, the cor-

responding relay operates to supply voltage to the mo-

tors. The use of either relay determines the polarity of

the voltage that is supplied to the door lock motors.

When the keyless entry system is used, the trans-

mitter sends a signal to the keyless entry module. If

the doors are unlocked, the module activates a tran-

sistor switch to apply voltage to the lock relay coil.

The coil is energized to close the normally open con-

tacts of the lock relay. Battery voltage from the relay

is applied to the door lock motors to lock the doors.

Current flows in the same path to ground as it does

when the master door lock switch is used.When the doors are locked, the keyless entry mod-

ule applies voltage to the unlock relay coil and a

similar action takes places to unlock the doors.

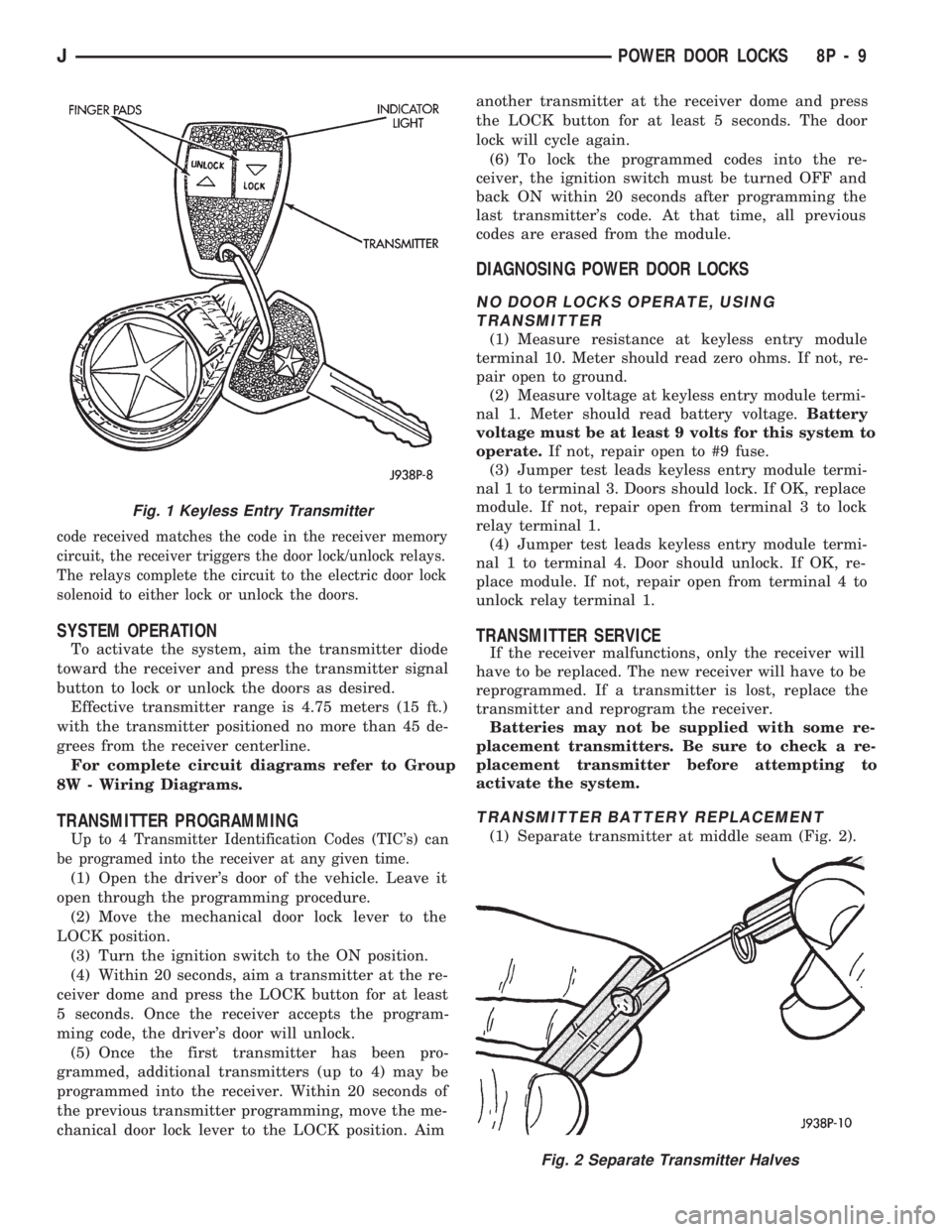

TRANSMITTER

The pocket size, solid state transmitter operates on

(2) 3-volt lithium (CR1616) batteries (Fig. 1). The

transmitter is activated by pressing either the LOCK

or UNLOCK button. This closes the internal contacts

that complete the battery circuit.

The battery voltage activates the transmitter diode

which in turn generates a coded infrared signal. The

signal is transmitted as pulses of infrared light.

If the red LED on the side of the transmitter does

not light when the transmitter is activated, the bat-

teries are low.

RECEIVER

The receiver is in circuit with the electric door lock

system. The coded infrared signal is picked up by the

receiver diode and is shaped, amplified and decoded by

an integrated circuit within the receiver. If the signal

Fig. 10 Latch Assembly Removal/Installation

8P - 8 POWER DOOR LOCKSJ

Page 464 of 1784

code received matches the code in the receiver memory

circuit, the receiver triggers the door lock/unlock relays.

The relays complete the circuit to the electric door lock

solenoid to either lock or unlock the doors.

SYSTEM OPERATION

To activate the system, aim the transmitter diode

toward the receiver and press the transmitter signal

button to lock or unlock the doors as desired.

Effective transmitter range is 4.75 meters (15 ft.)

with the transmitter positioned no more than 45 de-

grees from the receiver centerline.

For complete circuit diagrams refer to Group

8W - Wiring Diagrams.

TRANSMITTER PROGRAMMING

Up to 4 Transmitter Identification Codes (TIC's) can

be programed into the receiver at any given time.

(1) Open the driver's door of the vehicle. Leave it

open through the programming procedure.

(2) Move the mechanical door lock lever to the

LOCK position.

(3) Turn the ignition switch to the ON position.

(4) Within 20 seconds, aim a transmitter at the re-

ceiver dome and press the LOCK button for at least

5 seconds. Once the receiver accepts the program-

ming code, the driver's door will unlock.

(5) Once the first transmitter has been pro-

grammed, additional transmitters (up to 4) may be

programmed into the receiver. Within 20 seconds of

the previous transmitter programming, move the me-

chanical door lock lever to the LOCK position. Aimanother transmitter at the receiver dome and press

the LOCK button for at least 5 seconds. The door

lock will cycle again.

(6) To lock the programmed codes into the re-

ceiver, the ignition switch must be turned OFF and

back ON within 20 seconds after programming the

last transmitter's code. At that time, all previous

codes are erased from the module.

DIAGNOSING POWER DOOR LOCKS

NO DOOR LOCKS OPERATE, USING

TRANSMITTER

(1) Measure resistance at keyless entry module

terminal 10. Meter should read zero ohms. If not, re-

pair open to ground.

(2) Measure voltage at keyless entry module termi-

nal 1. Meter should read battery voltage.Battery

voltage must be at least 9 volts for this system to

operate.If not, repair open to #9 fuse.

(3) Jumper test leads keyless entry module termi-

nal 1 to terminal 3. Doors should lock. If OK, replace

module. If not, repair open from terminal 3 to lock

relay terminal 1.

(4) Jumper test leads keyless entry module termi-

nal 1 to terminal 4. Door should unlock. If OK, re-

place module. If not, repair open from terminal 4 to

unlock relay terminal 1.

TRANSMITTER SERVICE

If the receiver malfunctions, only the receiver will

have to be replaced. The new receiver will have to be

reprogrammed. If a transmitter is lost, replace the

transmitter and reprogram the receiver.

Batteries may not be supplied with some re-

placement transmitters. Be sure to check a re-

placement transmitter before attempting to

activate the system.

TRANSMITTER BATTERY REPLACEMENT

(1) Separate transmitter at middle seam (Fig. 2).

Fig. 2 Separate Transmitter Halves

Fig. 1 Keyless Entry Transmitter

JPOWER DOOR LOCKS 8P - 9

Page 467 of 1784

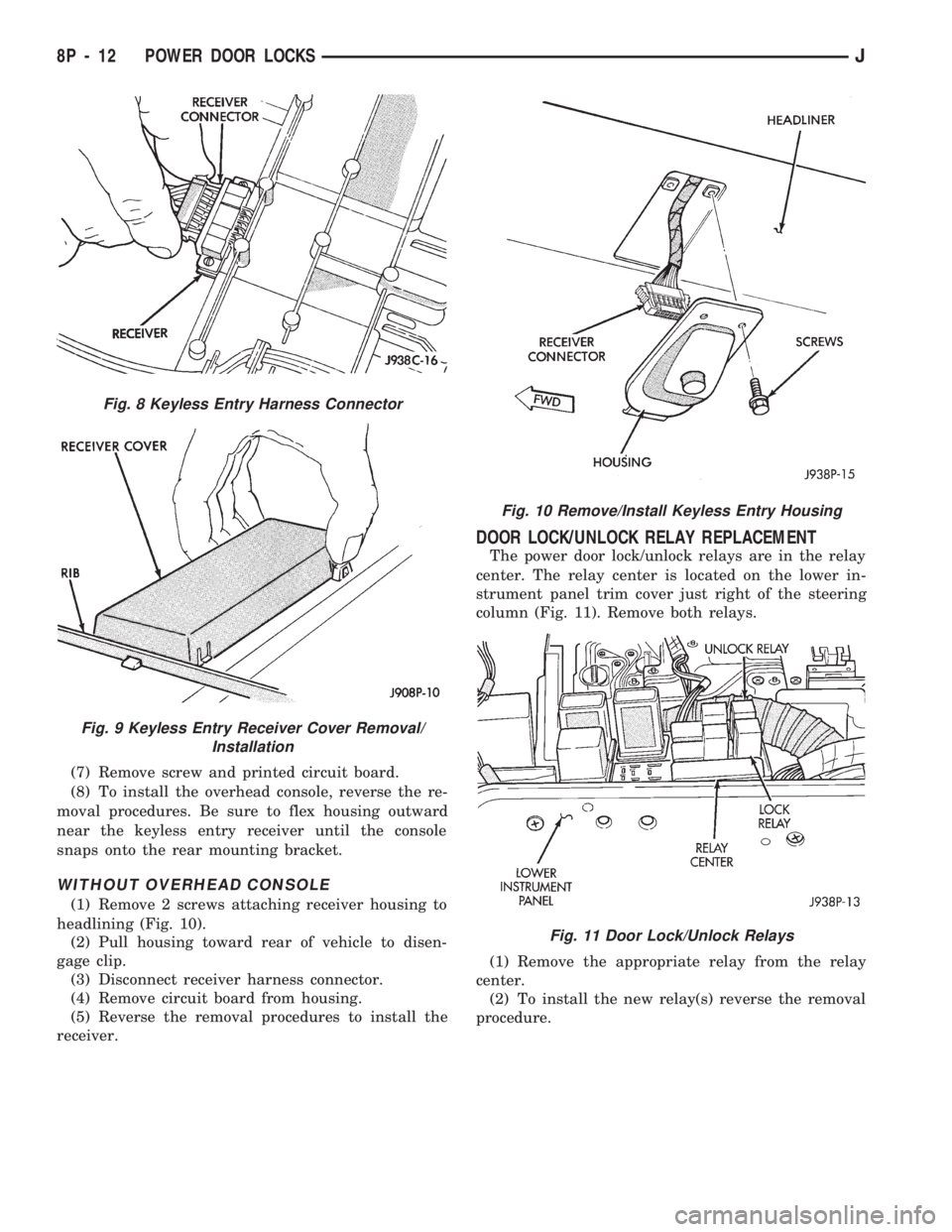

(7) Remove screw and printed circuit board.

(8) To install the overhead console, reverse the re-

moval procedures. Be sure to flex housing outward

near the keyless entry receiver until the console

snaps onto the rear mounting bracket.

WITHOUT OVERHEAD CONSOLE

(1) Remove 2 screws attaching receiver housing to

headlining (Fig. 10).

(2) Pull housing toward rear of vehicle to disen-

gage clip.

(3) Disconnect receiver harness connector.

(4) Remove circuit board from housing.

(5) Reverse the removal procedures to install the

receiver.

DOOR LOCK/UNLOCK RELAY REPLACEMENT

The power door lock/unlock relays are in the relay

center. The relay center is located on the lower in-

strument panel trim cover just right of the steering

column (Fig. 11). Remove both relays.

(1) Remove the appropriate relay from the relay

center.

(2) To install the new relay(s) reverse the removal

procedure.

Fig. 8 Keyless Entry Harness Connector

Fig. 9 Keyless Entry Receiver Cover Removal/

Installation

Fig. 10 Remove/Install Keyless Entry Housing

Fig. 11 Door Lock/Unlock Relays

8P - 12 POWER DOOR LOCKSJ

Page 488 of 1784

CHIME/BUZZER WARNING SYSTEMS

CONTENTS

page page

GENERAL.............................. 1

IGNITION KEY WARNING SWITCH REPLACEMENT.4OPERATION/DIAGNOSIS.................. 1

GENERAL

The buzzer or optional chime module is mounted on

the left side of the fuse block (above and to the left of

the brake/clutch pedal). The buzzer or chime sounds

an audible warning tone in any of the following con-

ditions:

²Vehicle lights are ON when the ignition has been

switched OFF and the key is removed and then the

driver's door is opened (except YJ).²The key is in the ignition and the driver's door is

open (On some vehicles, the buzzer will not sound if

the ignition switch is in the ON position).

²The ignition is switched ON and the driver's seat

belt is not buckled. Buzzer will quit after 4 to 8 sec-

onds. Besides the buzzer, a seat belt indicator lamp

turns on as a reminder to fasten seat belt.

OPERATION/DIAGNOSIS

OPERATION

Battery voltage for module operation is supplied to

two pins. Voltage is always present at pin 7. Pin 1

receives voltage when the ignition switch is in the

ON or START position.

SEAT BELT WARNING

The seat belt warning system uses both visual and

audible signals. These consist of a buzzer that is part

of a combined seat belt and key warning buzzer and

a red light on the instrument panel.

The system will always illuminate the seat belt

warning lamp for four to eight seconds when the ig-

nition switch is turned to the ON position. Also, only

if the driver does not fasten his seat belt, the buzzer

will sound during the same time interval. Passenger

belts are not connected to the system.

A timed buzzer-relay is used to operate the system

for the time period. It has a time delay mechanism

and buzzer assembly. Only the driver's seat belt

buckle has a switch that is connected to the system.

KEY-IN-IGNITION WARNING

To sound the key-in-ignition warning, the following

must occur:

²the ignition key warning switch must be closed

²the driver's door jamb switch must be closed.

These conditions ground pin 6 of the module. These

switches are closed when the key is in the ignition

and the driver's door is open.On some vehicles the chime/buzzer will not

sound if the door is open and the key is in the

ON position.

LIGHTS-ON WARNING (EXCEPT YJ)

To sound the lights-on warning, the following must

occur:

²the headlamp switch must be closed

²the driver's door jamb switch must be closed.

These conditions ground pin 6 of the module. These

switches are closed when the headlamp switch is ON

and the driver's door is open.

DIAGNOSIS

If the buzzer/chime unit does not operate as de-

scribed, check the two fuses for pins 1 and 7 (Figs. 1

and 2) and replace as required. If the fuses are not

defective, perform the following tests to determine if

the problem is in the module or in the wiring. Using

a flat head screwdriver, release the locking plastic

clip while carefully pulling out the module. Plug in a

known good module and check its operation. If the

problem is not corrected by replacing the module, re-

move the module and continue as follows:

VOLTAGE TESTS

Ignition in ON position, measure between the

following pins and vehicle ground.

²Measure voltage at buzzer/chime module connector

pin 1. Meter should read battery voltage. If not, re-

pair open to ignition switch.

Turn ignition OFF and remove the key from the ig-

nition.

JCHIME/BUZZER WARNING SYSTEMS 8U - 1

Page 494 of 1784

WIRING DIAGRAMS

CONTENTS

page page

FUSE CHARTS AND RELAY BANKS......... 8

GENERAL INFORMATION.................. 1

SPLICE LOCATIONS..................... 53

WIRING AND COMPONENT IDENTIFICATION . 13WIRING DIAGRAMS XJ.................. 149

WIRING DIAGRAMS XJ RHD............. 271

WIRING DIAGRAMS YJ.................. 73

GENERAL INFORMATION

INDEX

page page

Circuit Identification........................ 2

Component Identification.................... 2

Connector and Terminal Assembly Replacement . . 5

Connector Replacement.................... 4

Connectors.............................. 3

Fusible Link Replacement................... 4

Fusible Links............................. 3

Locating A System........................ 2Secondary Ignition Wiring................... 1

Splice Locations.......................... 2

Symbols, Fuses and Abbreviations............ 6

Terminal Replacement...................... 5

Troubleshooting Wiring Problems.............. 3

Wire Code Identification.................... 2

Wiring Diagram Sheets and Indexes........... 1

Wiring Repair............................ 4

The wiring diagrams contain the latest information

at the time of publication.

Throughout this group references may be made to

a particular vehicle by letter or number designation.

A chart showing the breakdown of these designations

is included in the Introduction Section at the front of

this service manual.

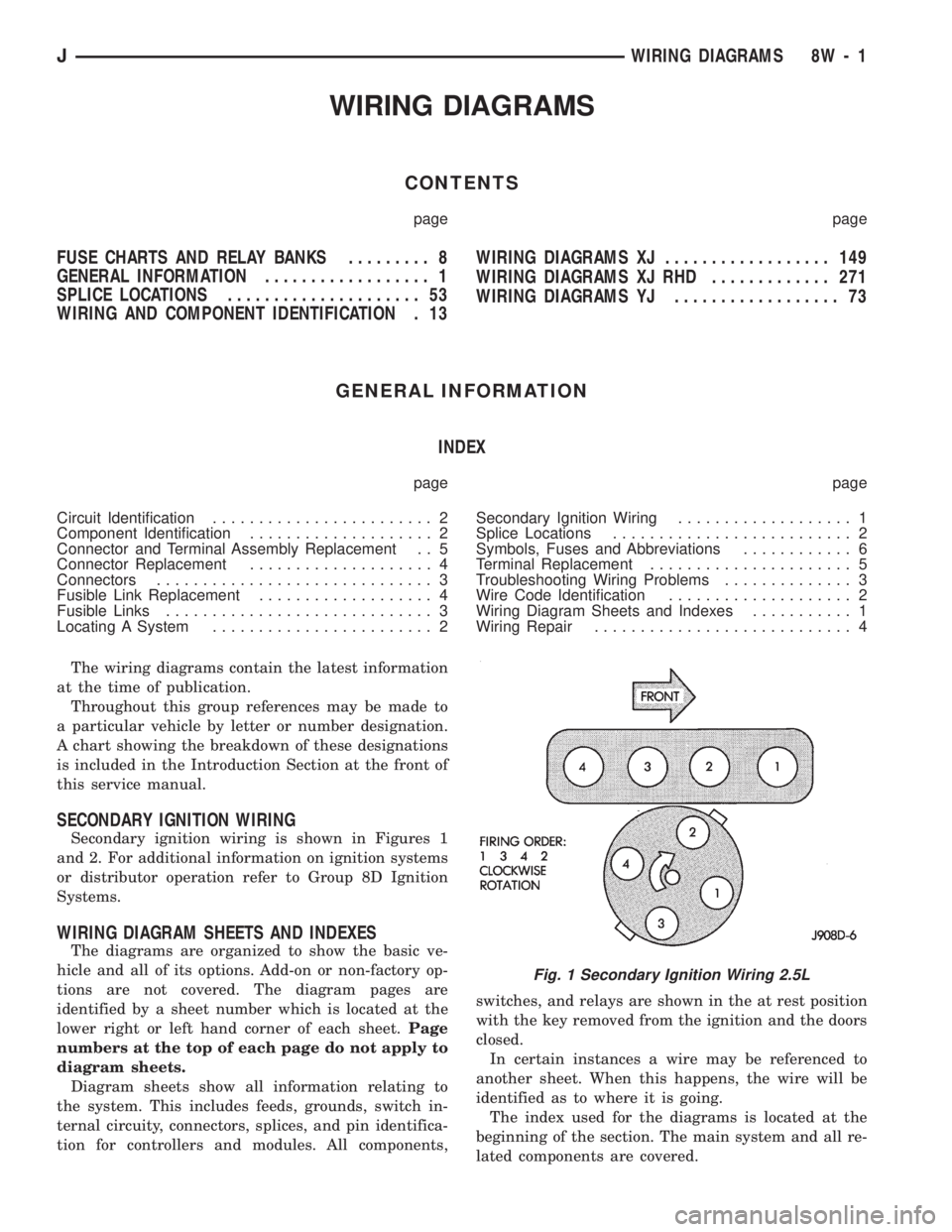

SECONDARY IGNITION WIRING

Secondary ignition wiring is shown in Figures 1

and 2. For additional information on ignition systems

or distributor operation refer to Group 8D Ignition

Systems.

WIRING DIAGRAM SHEETS AND INDEXES

The diagrams are organized to show the basic ve-

hicle and all of its options. Add-on or non-factory op-

tions are not covered. The diagram pages are

identified by a sheet number which is located at the

lower right or left hand corner of each sheet.Page

numbers at the top of each page do not apply to

diagram sheets.

Diagram sheets show all information relating to

the system. This includes feeds, grounds, switch in-

ternal circuity, connectors, splices, and pin identifica-

tion for controllers and modules. All components,switches, and relays are shown in the at rest position

with the key removed from the ignition and the doors

closed.

In certain instances a wire may be referenced to

another sheet. When this happens, the wire will be

identified as to where it is going.

The index used for the diagrams is located at the

beginning of the section. The main system and all re-

lated components are covered.

Fig. 1 Secondary Ignition Wiring 2.5L

JWIRING DIAGRAMS 8W - 1

Page 499 of 1784

(10) Spread the strands of the wire apart on each

of the exposed wires (Fig. 7 example 1).

(11) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 7 ex-

ample 2).

(12) Twist the wires together (Fig. 7 example 3).

(13) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(14) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(15) Insert the repaired wire into the connector.

(16) Install the connector locking wedge and recon-

nect the connector to its mating half.

(17) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.(18) Connect battery and test affected systems.

SYMBOLS, FUSES AND ABBREVIATIONS

Various symbols are used throughout the wiring di-

agrams. These symbols can be identified by referring

to the symbol identification chart (Fig. 11).

Certain abbreviations are also used in the dia-

grams. These have been developed in such a way

that there meaning should be clear. For fuse block,

relay bank, and power distribution center informa-

tion refer to the fuse charts and relay bank index.

CAUTION: When replacing a blown fuse it is impor-

tant to replace it with a fuse having the correct am-

perage rating. The use of a fuse with a rating other

than indicated may result in an electrical overload.

If a proper rated fuse continues to blow, it indicates

a problem that should be corrected.

8W - 6 WIRING DIAGRAMSJ

Page 501 of 1784

FUSE CHARTS AND RELAY BANKS

INDEX

Fig. Fig.

Fuse Panel XJ........................... 2

Fuse Panel YJ........................... 1Power Distribution Center YJ................. 3

Power Distribution Center XJ................. 4

8W - 8 WIRING DIAGRAMSJ

Page 566 of 1784

WIRING DIAGRAMS YJ

ALPHABETICAL INDEX

Wiring Diagram Name Sheet Number

ABS Accelerator Sensor........................59

ABS Control Module.....................57, 58, 59

ABS Control Module Connector...................60

ABS Motor Pump Relay........................57

ABS Power Relay............................57

A/C Blower Switch............................50

A/C Compressor.............................49

A/C Low Pressure Switch.......................49

A/C Relay.................................49

A/C Thermostat..............................50

Accessory Illumination.........................32

Air Conditioning System (4.0L).................49, 50

A/C Blower Switch..........................50

A/C Compressor............................49

A/C Low Pressure Switch.....................49

A/C Relay................................49

A/C Thermostat............................50

Field Jumper..............................50

Powertrain Control Module.....................49

Anti-Lock Brake System (TEVES).............57, 58, 59

ABS Accelerator Sensor.......................59

ABS Control Module....................57, 58, 59

ABS Motor Pump Relay.......................57

ABS Power Relay...........................57

Brake Pedal Travel Sensor.....................57

Data Link Connector.........................57

Diode..................................58

Hydraulic Actuation Unit......................58

Left Front Wheel Sensor......................59

Left Rear Wheel Sensor.......................59

Power Distribution Center.....................57

Pump Motor..............................57

Pump Motor Sensor.........................57

Right Front Wheel Sensor.....................59

Right Rear Wheel Sensor......................59

Automatic Shut-Down Relay...................11, 17

Back-Up Lamps...........................51, 52

Back-Up Lamp Switch..........................7

Battery................................1,3,5

Blower Motor...............................47

Blower Resistor.............................47

Blower Switch..............................47

Body Harness Connector........................36

Brake Pedal Travel Sensor.......................57

Brake Warning Switch..........................9

Bulkhead Connector........................65, 66

Buzzer Module..............................36

Camshaft Position Sensor....................12, 18

Center High Mounted Stop Lamp..................52

Charging System 2.5L Engine...................3,4

Battery..................................3

Generator.................................3

Power Distribution Center......................4Wiring Diagram Name Sheet Number

Charging System 4.0L Engine...................5,6

Battery..................................5

Generator.................................5

Power Distribution Center......................6

Cigar Lighter...............................24

Circuit Breakers

Headlamp Switch.........................1,29

#11 (W/Wiper).....................2,10,38,39

Clock....................................45

Cluster Connector............................41

Crankshaft Position Sensor...................12, 18

Data Link Connector.....................13, 19, 57

Daytime Running Lamp Module...................28

Dimmer Switch............................1,29

Dome and Courtesy Lamps......................35

Dome Lamp..............................35

Left Courtesy Lamp.........................35

Left Front Door Jamb Switch...................35

Right Courtesy Lamp........................35

Right Front Door Jamb Switch..................35

Dome Lamp................................35

Electrically Tuned Radio with Clock.................45

Electrical Schematic of Cluster....................42

Electrical Schematic of Gauge Package..............44

Electronic Speedometer.........................42

Electronic Tachometer..........................42

Engine Coolant Temp Gauge.....................44

Engine Coolant Temperature Sensor..............15, 21

Engine Oil Pressure and Temperature System..........23

Engine Coolant Temperature Sending Unit...........23

Engine Oil Pressure Sending Unit................23

Engine Oil Pressure Gauge......................44

Engine Starter System........................2,7

Back-Up Lamp Switch........................7

Engine Starter Motor.........................7

Engine Starter Relay..........................7

Park/Neutral Position Switch....................7

Engine Wiring Connector (16 Way).................69

4-WD Command Trac Switch......................8

Field Jumper...............................50

Fog Lamp Relays............................30

Fog Lamp Switch............................30

Front End Lighting.........................25, 26

Left Fog Lamp.............................25

Left Headlamp.............................25

Left Park and Turn Signal Lamp.................25

Left Side Marker Lamp.......................25

Right Fog Lamp............................26

Right Headlamp............................26

Right Park and Turn Signal Lamp................26

Right Side Marker Lamp......................26

Front End Lighting (Canada)...................27, 28

Daytime Running Lamp Module.................28

JWIRING DIAGRAMS 8W - 73