JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1331 of 2198

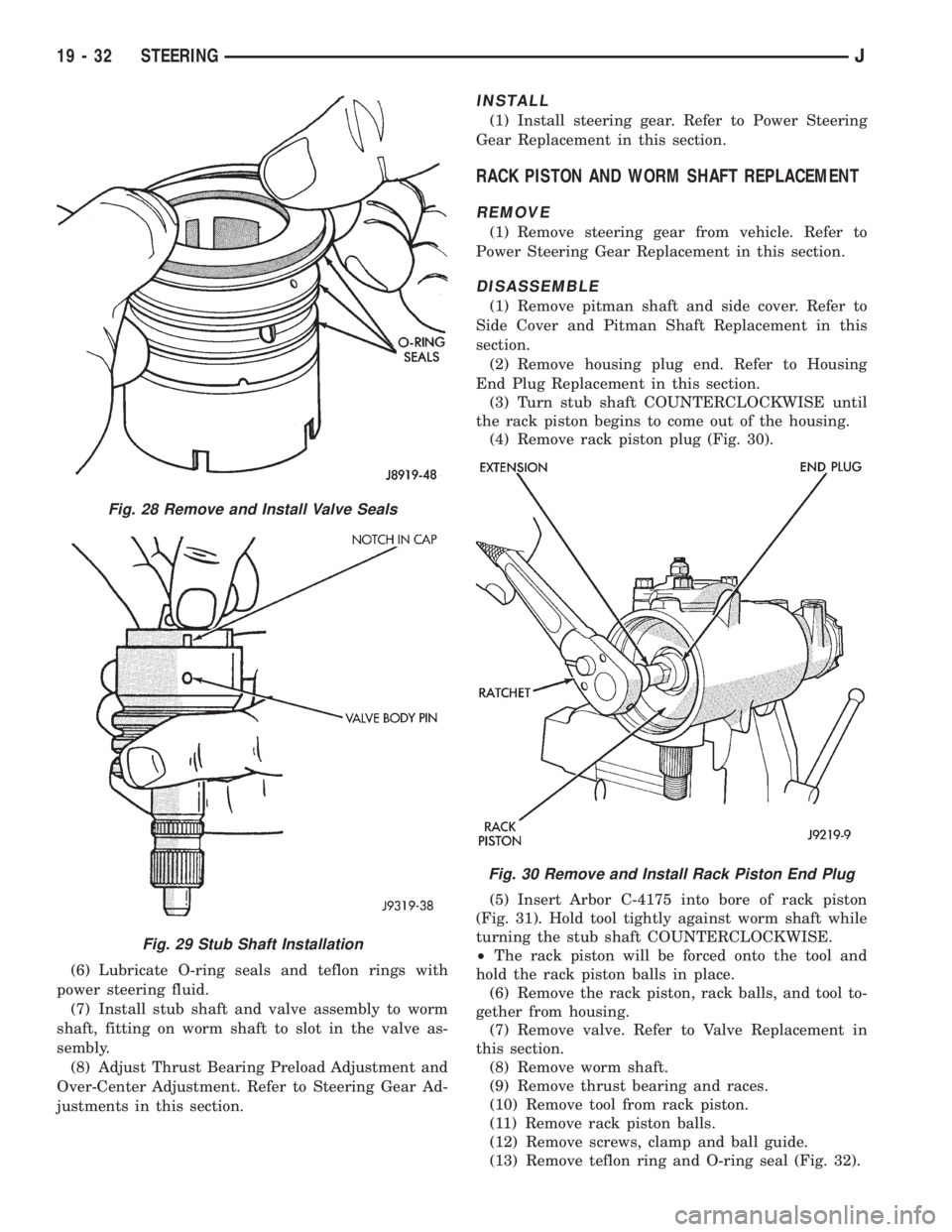

(6) Lubricate O-ring seals and teflon rings with

power steering fluid.

(7) Install stub shaft and valve assembly to worm

shaft, fitting on worm shaft to slot in the valve as-

sembly.

(8) Adjust Thrust Bearing Preload Adjustment and

Over-Center Adjustment. Refer to Steering Gear Ad-

justments in this section.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

RACK PISTON AND WORM SHAFT REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

DISASSEMBLE

(1) Remove pitman shaft and side cover. Refer to

Side Cover and Pitman Shaft Replacement in this

section.

(2) Remove housing plug end. Refer to Housing

End Plug Replacement in this section.

(3) Turn stub shaft COUNTERCLOCKWISE until

the rack piston begins to come out of the housing.

(4) Remove rack piston plug (Fig. 30).

(5) Insert Arbor C-4175 into bore of rack piston

(Fig. 31). Hold tool tightly against worm shaft while

turning the stub shaft COUNTERCLOCKWISE.

²The rack piston will be forced onto the tool and

hold the rack piston balls in place.

(6) Remove the rack piston, rack balls, and tool to-

gether from housing.

(7) Remove valve. Refer to Valve Replacement in

this section.

(8) Remove worm shaft.

(9) Remove thrust bearing and races.

(10) Remove tool from rack piston.

(11) Remove rack piston balls.

(12) Remove screws, clamp and ball guide.

(13) Remove teflon ring and O-ring seal (Fig. 32).

Fig. 28 Remove and Install Valve Seals

Fig. 29 Stub Shaft Installation

Fig. 30 Remove and Install Rack Piston End Plug

19 - 32 STEERINGJ

Page 1332 of 2198

CLEAN AND INSPECTION

(1) Wash all components in clean solvent and dry

with compressed air.

(2) Check for scores, nicks or burrs on the rack pis-

ton finished surface. Slight wear is normal on the

worm gear surfaces.

ASSEMBLE

(1) Install O-ring seal and teflon ring and lubricate

with power steering fluid.

(2) Install worm shaft to rack piston outside of

housing. Fully seat worm shaft to rack piston and

align worm shaft spiral groove with rack piston ball

guide hole (Fig. 33).

WARNING: MAKE SURE ALL RACK PISTON BALLS

ARE REINSTALLED IN THE RACK PISTON. IM-

PROPER INSTALLATION MAY RESULT IN PER-

SONAL INJURY.There are 24 balls in the rack piston circuit,

12 are black and 12 are silver (Chrome). The

black rack piston balls are smaller than the sil-

ver balls. THE BLACK AND SILVER BALLS

MUST BE INSTALLED ALTERNATELY INTO

THE RACK PISTON AND BALL GUIDE. This

procedure will maintain worm shaft preload.

(3) Lubricate and install rack piston balls through

return guide hole while turning wormshaft COUN-

TERCLOCKWISE.

(4) Install remaining balls to guide using grease or

petroleum jelly at each end to hold in place (Fig. 34).

(5) Install guide onto rack piston and return with

clamp and screws. Tighten screws to 58 Nzm (43 in.

lbs.) torque.

(6) Insert Arbor C-4175 into bore of rack piston.

Hold tool tightly against worm shaft while turning

Fig. 31 Remove and Install Rack Piston

Fig. 32 Remove and Install Seal on Rack Piston

Fig. 33 Installing Balls in Rack Piston

Fig. 34 Balls in the Return Guide

JSTEERING 19 - 33

Page 1333 of 2198

the stub shaft COUNTERCLOCKWISE.

²The rack piston will be forced onto the tool and

hold the rack piston balls in place.

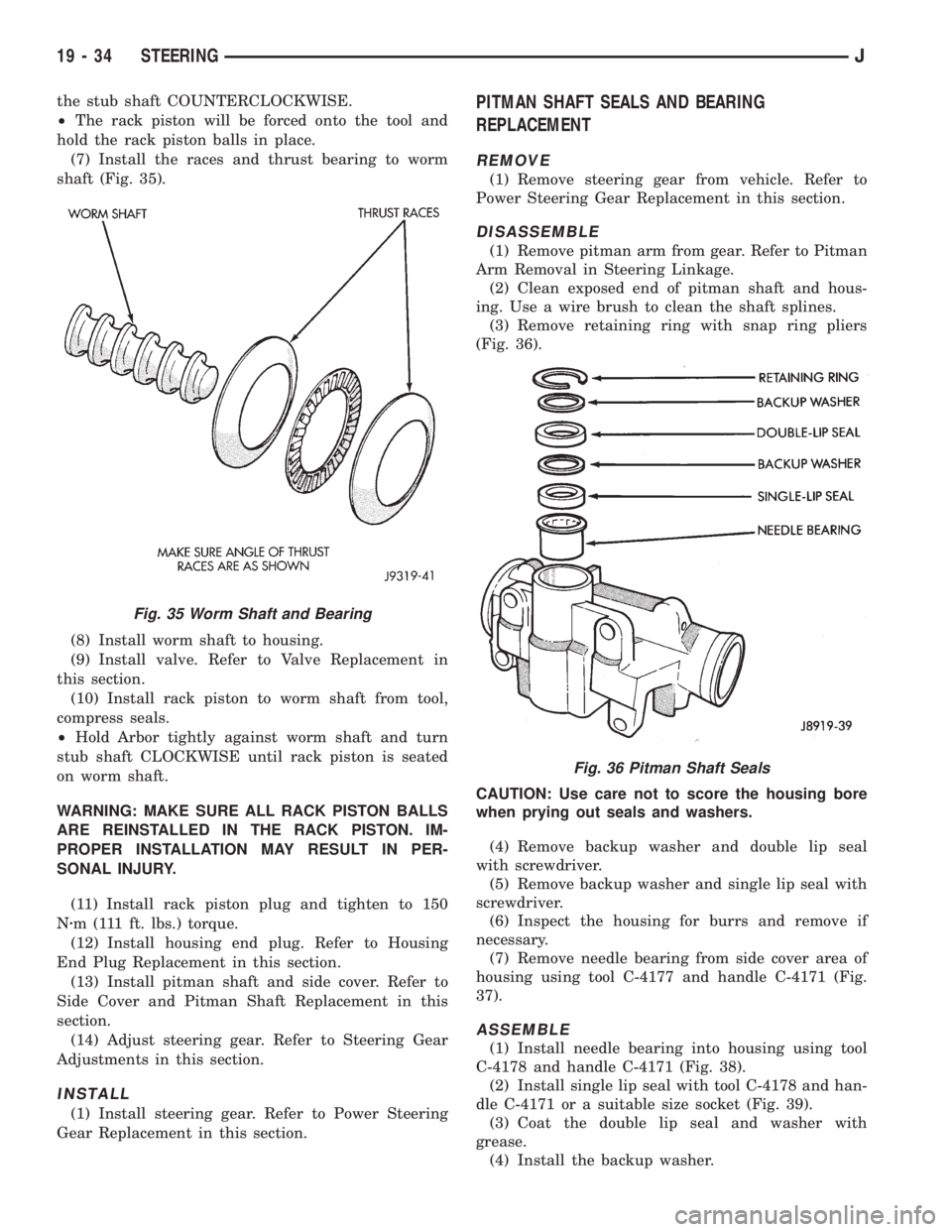

(7) Install the races and thrust bearing to worm

shaft (Fig. 35).

(8) Install worm shaft to housing.

(9) Install valve. Refer to Valve Replacement in

this section.

(10) Install rack piston to worm shaft from tool,

compress seals.

²Hold Arbor tightly against worm shaft and turn

stub shaft CLOCKWISE until rack piston is seated

on worm shaft.

WARNING: MAKE SURE ALL RACK PISTON BALLS

ARE REINSTALLED IN THE RACK PISTON. IM-

PROPER INSTALLATION MAY RESULT IN PER-

SONAL INJURY.

(11) Install rack piston plug and tighten to 150

Nzm (111 ft. lbs.) torque.

(12) Install housing end plug. Refer to Housing

End Plug Replacement in this section.

(13) Install pitman shaft and side cover. Refer to

Side Cover and Pitman Shaft Replacement in this

section.

(14) Adjust steering gear. Refer to Steering Gear

Adjustments in this section.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

PITMAN SHAFT SEALS AND BEARING

REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

DISASSEMBLE

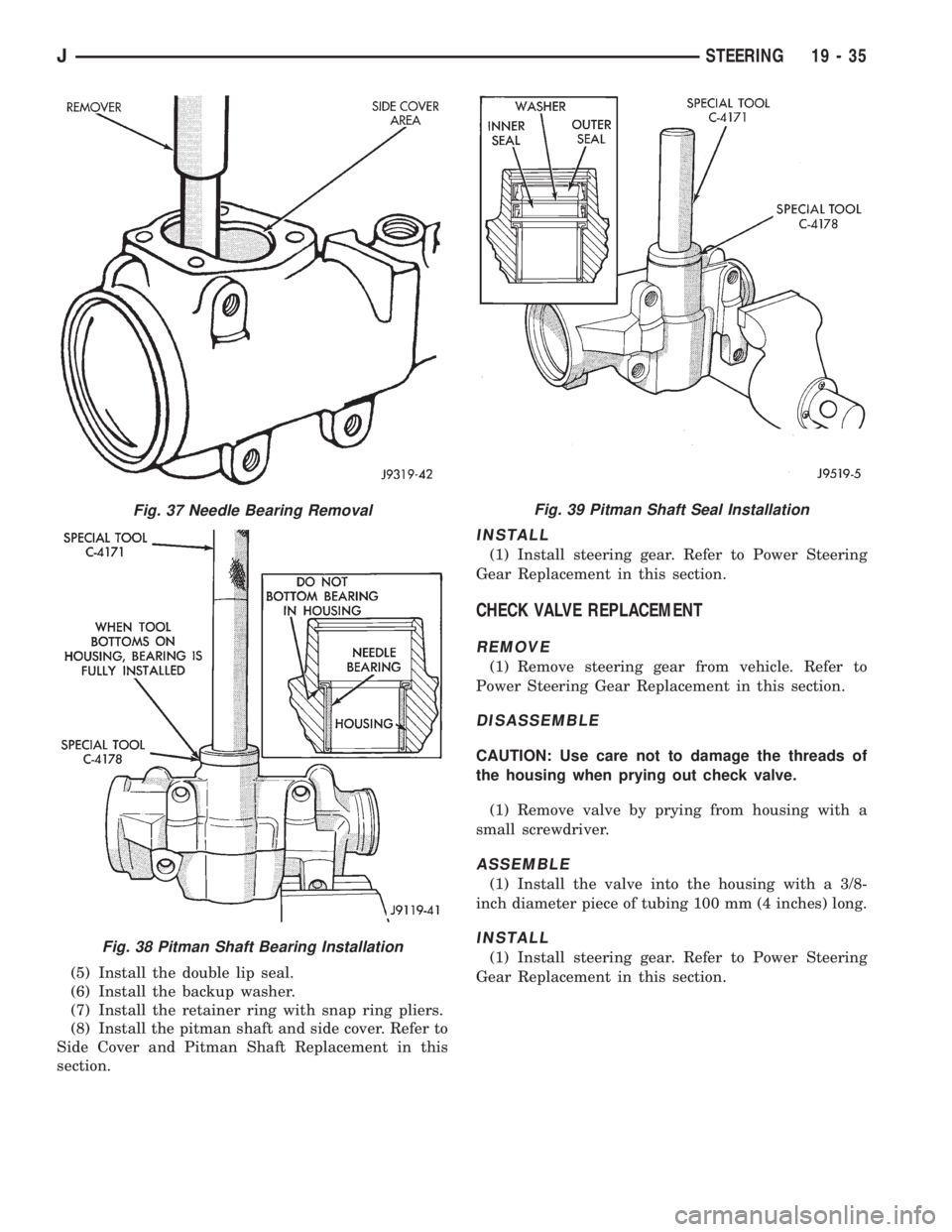

(1) Remove pitman arm from gear. Refer to Pitman

Arm Removal in Steering Linkage.

(2) Clean exposed end of pitman shaft and hous-

ing. Use a wire brush to clean the shaft splines.

(3) Remove retaining ring with snap ring pliers

(Fig. 36).

CAUTION: Use care not to score the housing bore

when prying out seals and washers.

(4) Remove backup washer and double lip seal

with screwdriver.

(5) Remove backup washer and single lip seal with

screwdriver.

(6) Inspect the housing for burrs and remove if

necessary.

(7) Remove needle bearing from side cover area of

housing using tool C-4177 and handle C-4171 (Fig.

37).

ASSEMBLE

(1) Install needle bearing into housing using tool

C-4178 and handle C-4171 (Fig. 38).

(2) Install single lip seal with tool C-4178 and han-

dle C-4171 or a suitable size socket (Fig. 39).

(3) Coat the double lip seal and washer with

grease.

(4) Install the backup washer.

Fig. 35 Worm Shaft and Bearing

Fig. 36 Pitman Shaft Seals

19 - 34 STEERINGJ

Page 1334 of 2198

(5) Install the double lip seal.

(6) Install the backup washer.

(7) Install the retainer ring with snap ring pliers.

(8) Install the pitman shaft and side cover. Refer to

Side Cover and Pitman Shaft Replacement in this

section.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

CHECK VALVE REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

DISASSEMBLE

CAUTION: Use care not to damage the threads of

the housing when prying out check valve.

(1) Remove valve by prying from housing with a

small screwdriver.

ASSEMBLE

(1) Install the valve into the housing with a 3/8-

inch diameter piece of tubing 100 mm (4 inches) long.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

Fig. 37 Needle Bearing Removal

Fig. 38 Pitman Shaft Bearing Installation

Fig. 39 Pitman Shaft Seal Installation

JSTEERING 19 - 35

Page 1335 of 2198

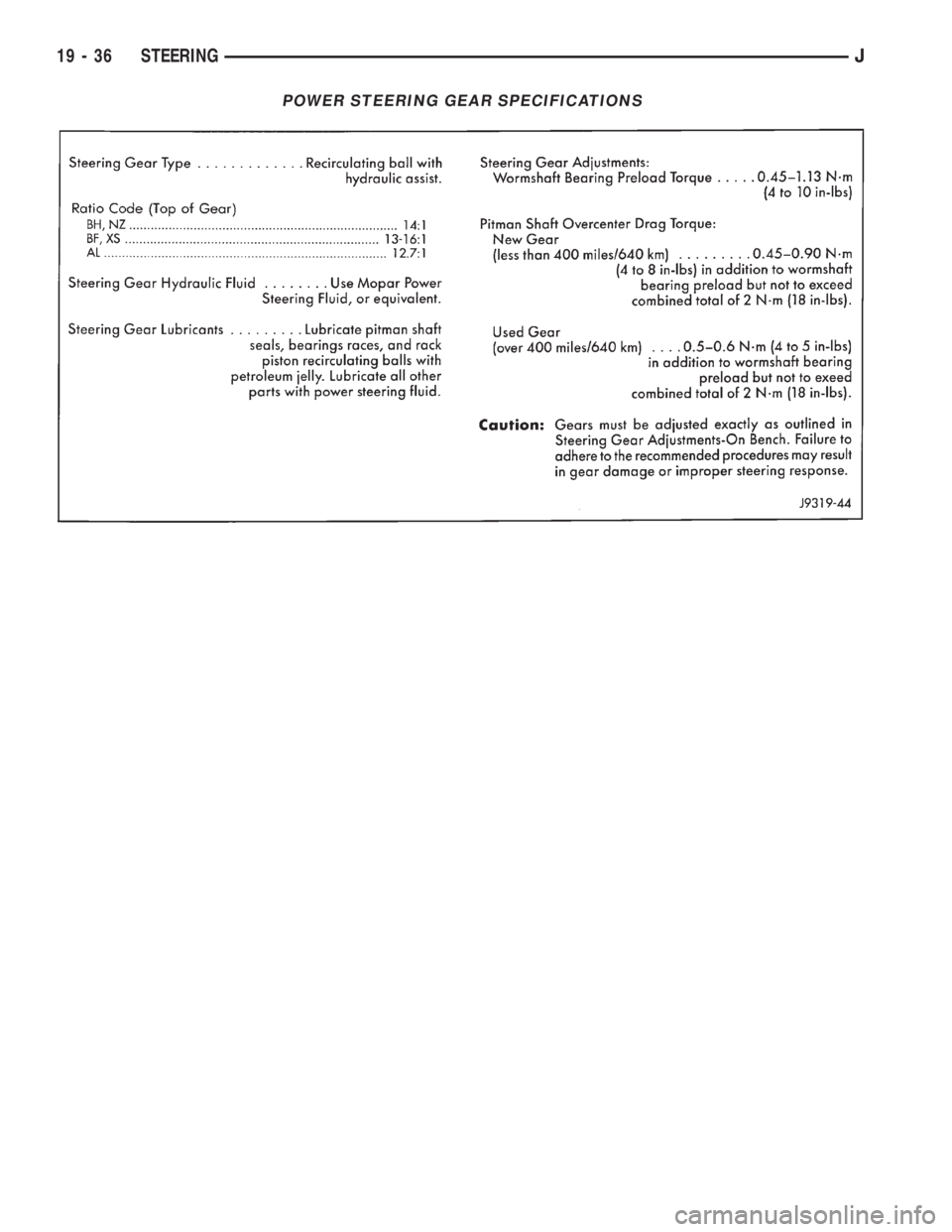

POWER STEERING GEAR SPECIFICATIONS

19 - 36 STEERINGJ

Page 1336 of 2198

MANUAL STEERING GEAR

INDEX

page page

Diagnosis............................... 37

Gear Adjustments in Vehicle................. 39

Gear Adjustments on Bench................. 44

Gear Assembly........................... 43

Gear Cleaning and Inspection................ 42Gear Disassembly......................... 39

Information.............................. 37

Intermediate (Coupler) Shaft................. 45

Pitman Shaft Seal Replacement.............. 37

Steering Gear Replacement................. 45

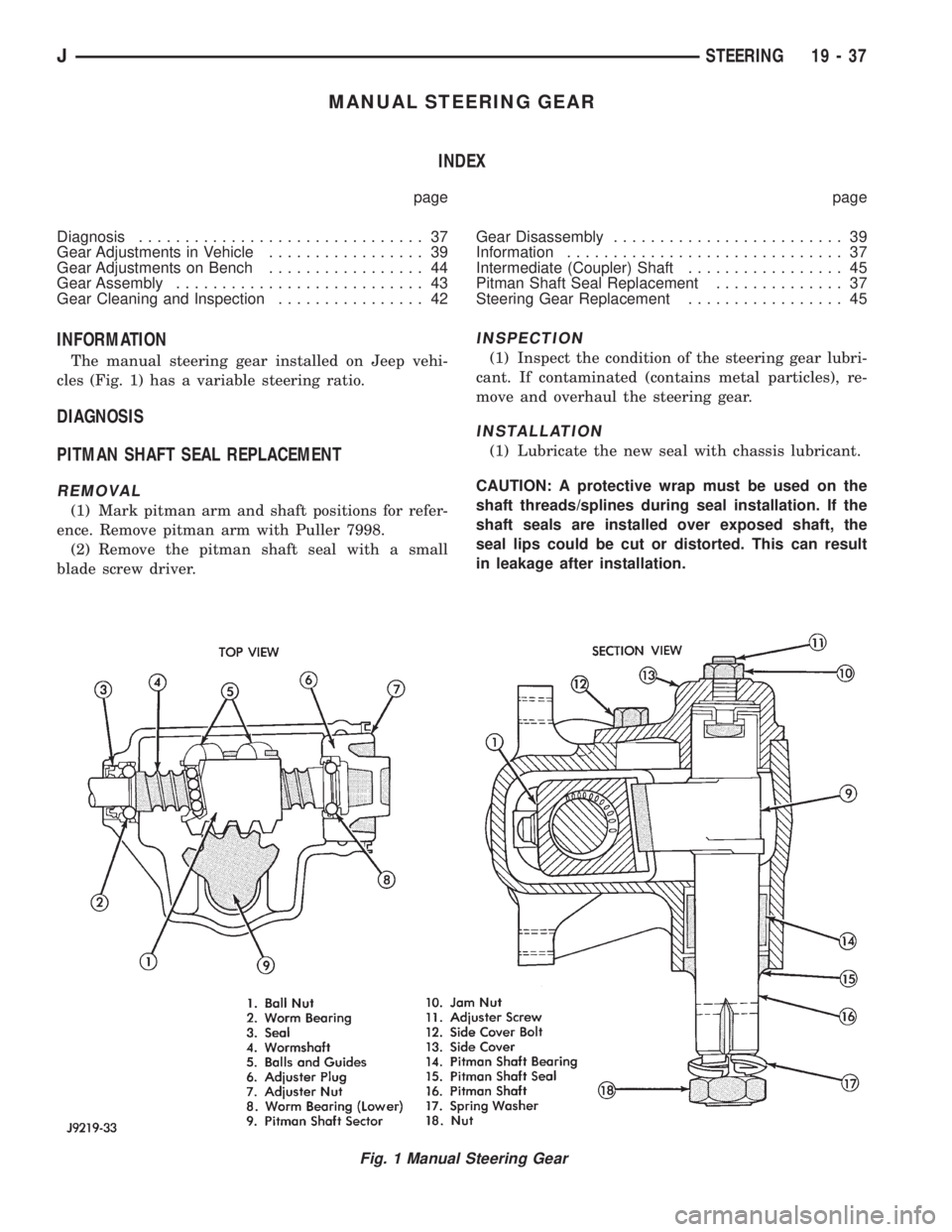

INFORMATION

The manual steering gear installed on Jeep vehi-

cles (Fig. 1) has a variable steering ratio.

DIAGNOSIS

PITMAN SHAFT SEAL REPLACEMENT

REMOVAL

(1) Mark pitman arm and shaft positions for refer-

ence. Remove pitman arm with Puller 7998.

(2) Remove the pitman shaft seal with a small

blade screw driver.

INSPECTION

(1) Inspect the condition of the steering gear lubri-

cant. If contaminated (contains metal particles), re-

move and overhaul the steering gear.

INSTALLATION

(1) Lubricate the new seal with chassis lubricant.

CAUTION: A protective wrap must be used on the

shaft threads/splines during seal installation. If the

shaft seals are installed over exposed shaft, the

seal lips could be cut or distorted. This can result

in leakage after installation.

Fig. 1 Manual Steering Gear

JSTEERING 19 - 37

Page 1337 of 2198

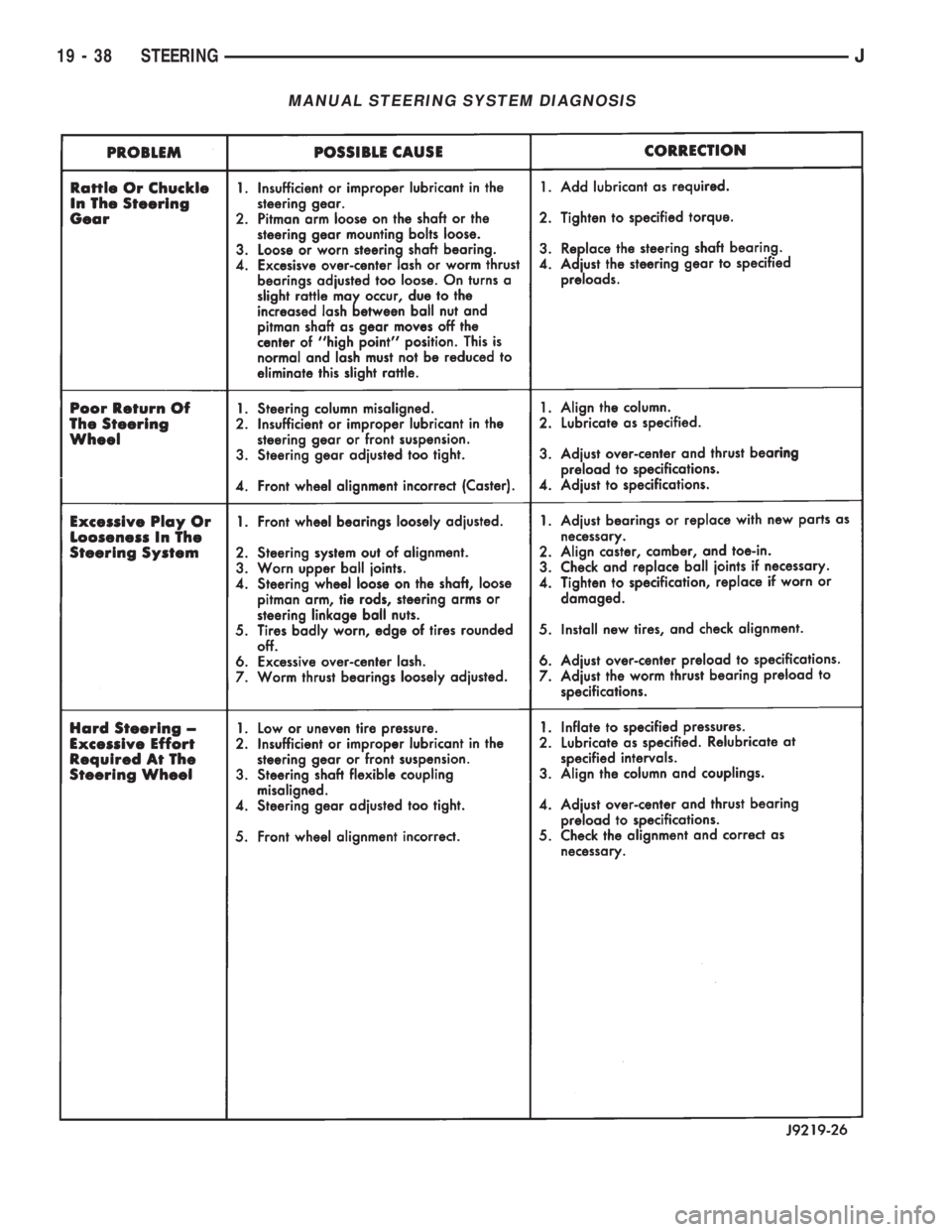

MANUAL STEERING SYSTEM DIAGNOSIS

19 - 38 STEERINGJ

Page 1338 of 2198

(2) Wrap a single layer of plastic tape around the

pitman shaft threads and splines. This will protect

the replacement seals during installation.

(3) Install the seal with a suitable size socket.

(4) Remove the tape from the shaft.

(5) Center the steering gear.

(6) Align and install the pitman arm.

(7) Install the washer and retaining nut on the pit-

man shaft. Tighten the nut to 251 Nzm (185 ft. lbs.)

torque.

GEAR ADJUSTMENTS IN VEHICLE

REMOVE

(1) Raise and support the vehicle.

(2) Mark the pitman shaft and pitman arm for in-

stallation reference. Remove the pitman arm from

the shaft.

(3) Loosen the adjuster lock nut then back the ad-

juster plug off 1/4 turn.

(4) Remove the steering wheel horn pad.

(5) Turn the steering wheel in one direction until

stopped by the gear. Then turn back 1/2 turn.

CAUTION: Do not turn the steering wheel hard

against the internal stops when the linkage is re-

moved. This could result in damage to the recircu-

lating ball guides.

MEASURE

Place a low calibration (50 in. lbs.) torque wrench

and socket on the steering wheel nut. Rotate the

wrench and nut through a 90 degree arc (1/4 turn).

This will measure the worm shaft bearing preload.

ADJUST WORMSHAFT BEARING PRELOAD

TORQUE

(1) Adjust the preload by tightening the adjuster

plug. The preload should be 0.6 to 1 Nzm(5to8in.

lbs.) torque.

Steering column/shaft misalignment or damage will

increase the amount of torque required to rotate the

steering wheel. If the rotating torque is exceptionally

high, inspect the steering column/shaft alignment. If

the alignment is correct, remove the steering gear,

determine the cause of the high preload torque, and

repair as necessary.

(2) Tighten the adjuster locknut to 68 Nzm (50 ft.

lbs.) torque. Measure the preload torque. If neces-

sary, adjust the preload torque again.

ADJUST OVERCENTER DRAG TORQUE

(1) Turn the steering wheel from one stop to the

other and count the total numbers of turns. Turn the

wheel back in reverse direction 1/2 the total number

of turns to center the steering gear.(2) Turn the over center adjusting screw in to re-

move all lash between the ball nut and pitman shaft

sector teeth. Hold the adjustment screw and tighten

the lock nut to 34 Nzm (25 ft. lbs.) torque.

(3) Check the torque at the steering wheel by tak-

ing the highest reading as the wheel is turned

through the center position.

(4) The overcenter drag torque should be 0.5 to 1

Nzm (4 to 10 in. lbs.).

(5) If necessary, loosen the lock nut and adjust the

over center adjuster screw to obtain the proper

torque. Re-tighten the lock nut to the lock nut.

(6) After tightening the locknut, measure the over-

center drag torque again and readjust the torque, if

necessary.

INSTALL

(1) Align the installation reference marks and in-

stall the pitman arm.

(2) Install and tighten the pitman shaft nut and

washer to 251 Nzm (185 ft. lbs.) torque.

(3) Install the horn button.

GEAR DISASSEMBLY

(1) Rotate the wormshaft from stop-to-stop and

count the number of rotations. Rotate the wormshaft

in the reverse direction 1/2 of the total number of ro-

tations to center it and the ball nut.

(2) Remove the pitman shaft adjustment screw

locknut. Remove the cover retaining bolts, cover, and

gasket (Fig. 3).

(3) Slide the adjustment screw head (Fig. 3) out of

the pitman shaft T-slot and remove it and the

shim(s).

(4) Retain the shim(s) for end-play measurement

during assembly.

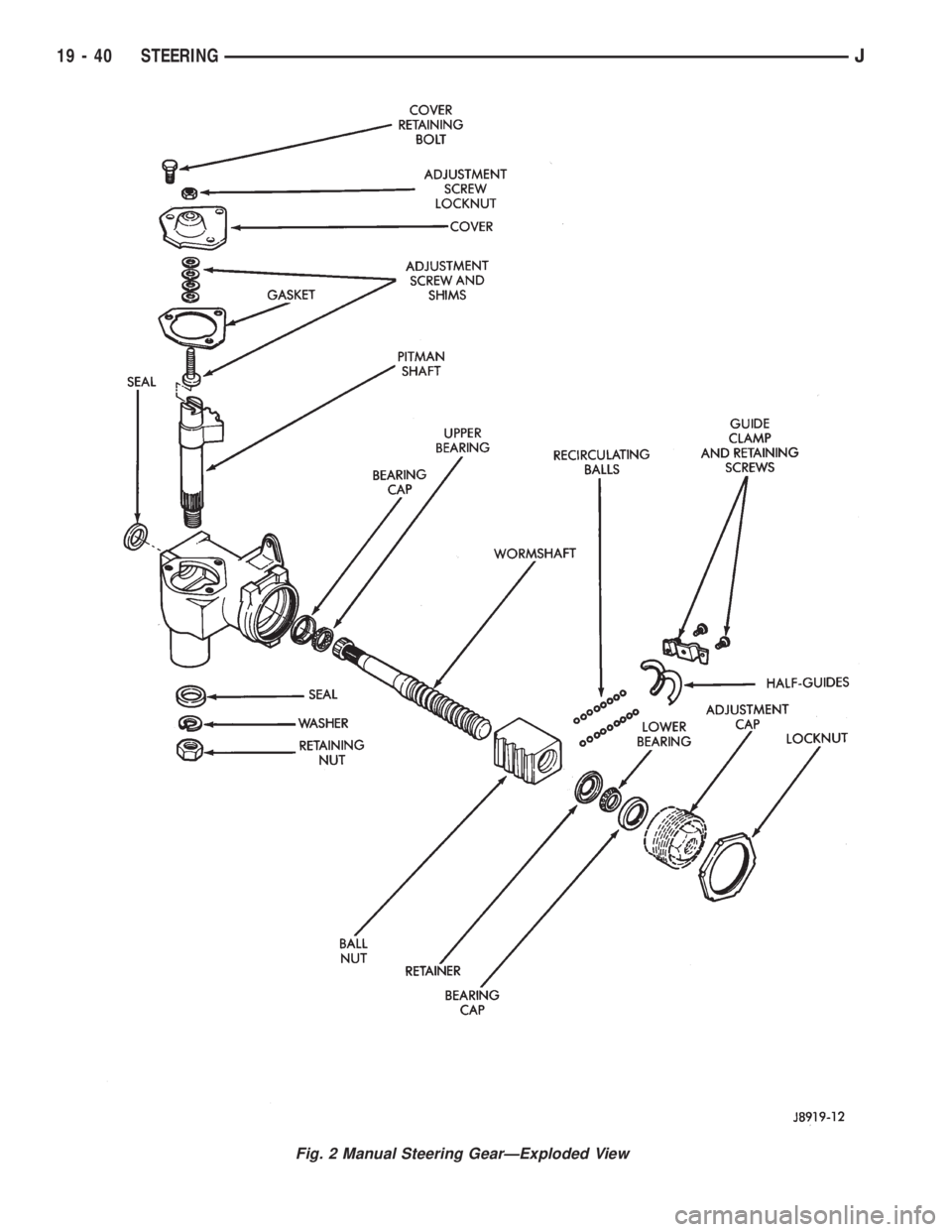

(5) Remove the pitman shaft, the wormshaft bear-

ing preload torque adjustment cap locknut, and the

adjustment cap (Fig. 2).

(6) Remove the wormshaft and the ball nut (Fig.

2).

(7) Remove (pry) the pitman shaft and the worm-

shaft seals from the steering gear housing (Fig. 3).

WORMSHAFT AND BALL NUT DISASSEMBLY

(1) Remove the upper bearing from the wormshaft

(Fig. 2).

CAUTION: Do not allow the ball nut to rotate freely

and travel to either extreme end of the wormshaft.

This could damage the tangs at the ends of the re-

circulating ball guides (Fig. 3).

(2) Remove the recirculating ball guide clamp re-

taining screws, the clamp and the guides (Fig. 2).

Separate the half-guides and place the recirculating

balls aside in a container.

JSTEERING 19 - 39

Page 1339 of 2198

Fig. 2 Manual Steering GearÐExploded View

19 - 40 STEERINGJ

Page 1340 of 2198

(3) Hold the ball nut over a cloth. Remove the re-

maining recirculating balls by rotating the worm-

shaft back and forth.

There are a total of 50 recirculating balls

within the ball nut and the guides (25 in each

circuit).

(4) Remove the wormshaft from the ball nut (Fig.

2).

CLEANING AND INSPECTION

(1) Clean all the components in a cleaning solvent

and dry them with a clean cloth and/or compressed

air.

(2) Inspect each component for wear, scoring,

cracks, nicks and surface pitting. Replace as neces-

sary.

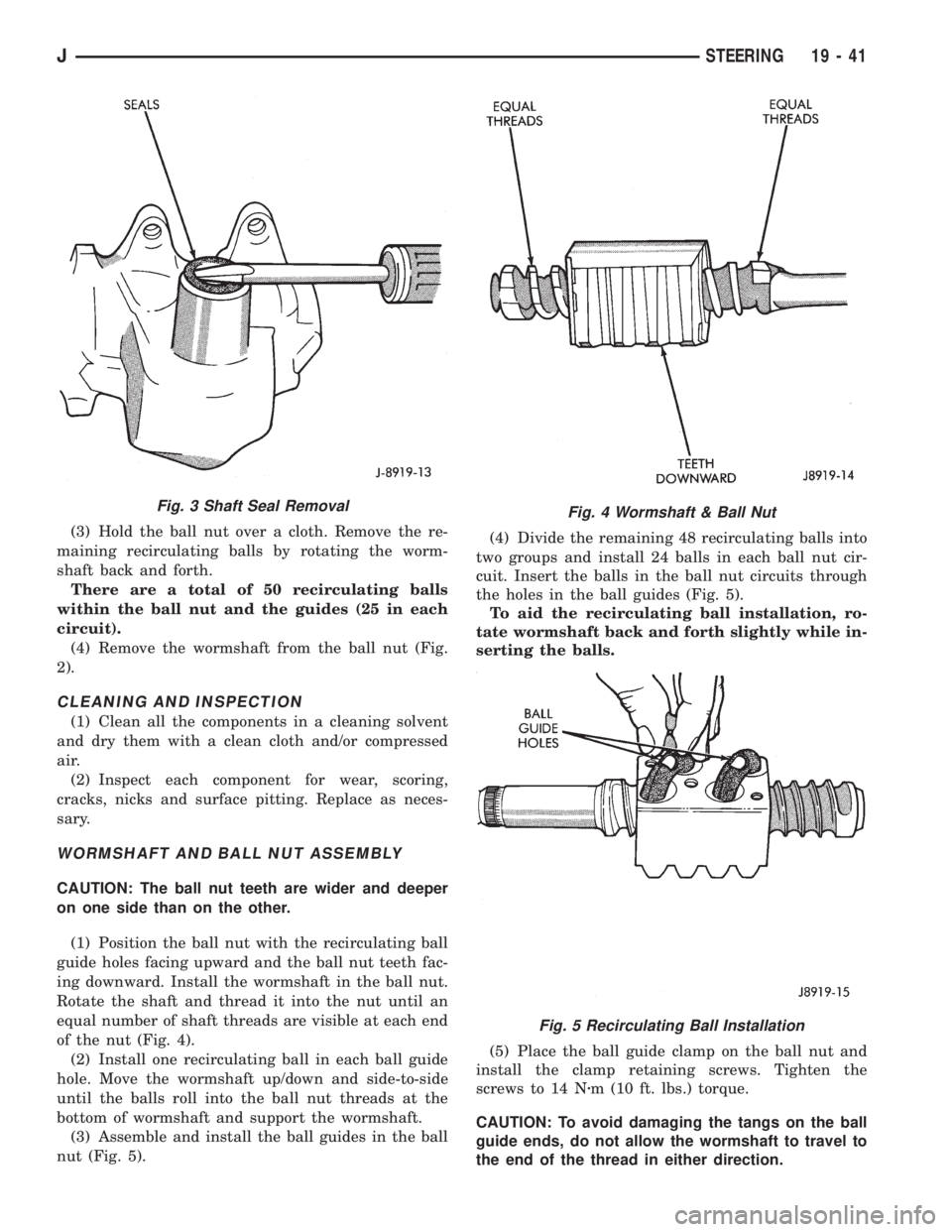

WORMSHAFT AND BALL NUT ASSEMBLY

CAUTION: The ball nut teeth are wider and deeper

on one side than on the other.

(1) Position the ball nut with the recirculating ball

guide holes facing upward and the ball nut teeth fac-

ing downward. Install the wormshaft in the ball nut.

Rotate the shaft and thread it into the nut until an

equal number of shaft threads are visible at each end

of the nut (Fig. 4).

(2) Install one recirculating ball in each ball guide

hole. Move the wormshaft up/down and side-to-side

until the balls roll into the ball nut threads at the

bottom of wormshaft and support the wormshaft.

(3) Assemble and install the ball guides in the ball

nut (Fig. 5).(4) Divide the remaining 48 recirculating balls into

two groups and install 24 balls in each ball nut cir-

cuit. Insert the balls in the ball nut circuits through

the holes in the ball guides (Fig. 5).

To aid the recirculating ball installation, ro-

tate wormshaft back and forth slightly while in-

serting the balls.

(5) Place the ball guide clamp on the ball nut and

install the clamp retaining screws. Tighten the

screws to 14 Nzm (10 ft. lbs.) torque.

CAUTION: To avoid damaging the tangs on the ball

guide ends, do not allow the wormshaft to travel to

the end of the thread in either direction.

Fig. 3 Shaft Seal RemovalFig. 4 Wormshaft & Ball Nut

Fig. 5 Recirculating Ball Installation

JSTEERING 19 - 41