JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1291 of 2198

SERVICE PROCEDURES

PRECAUTIONS

Use exact replacement hardware for attaching the

propeller shafts. Exact replacement will ensure safe

operation. The specified torque must always be ap-

plied when tightening the fasteners.

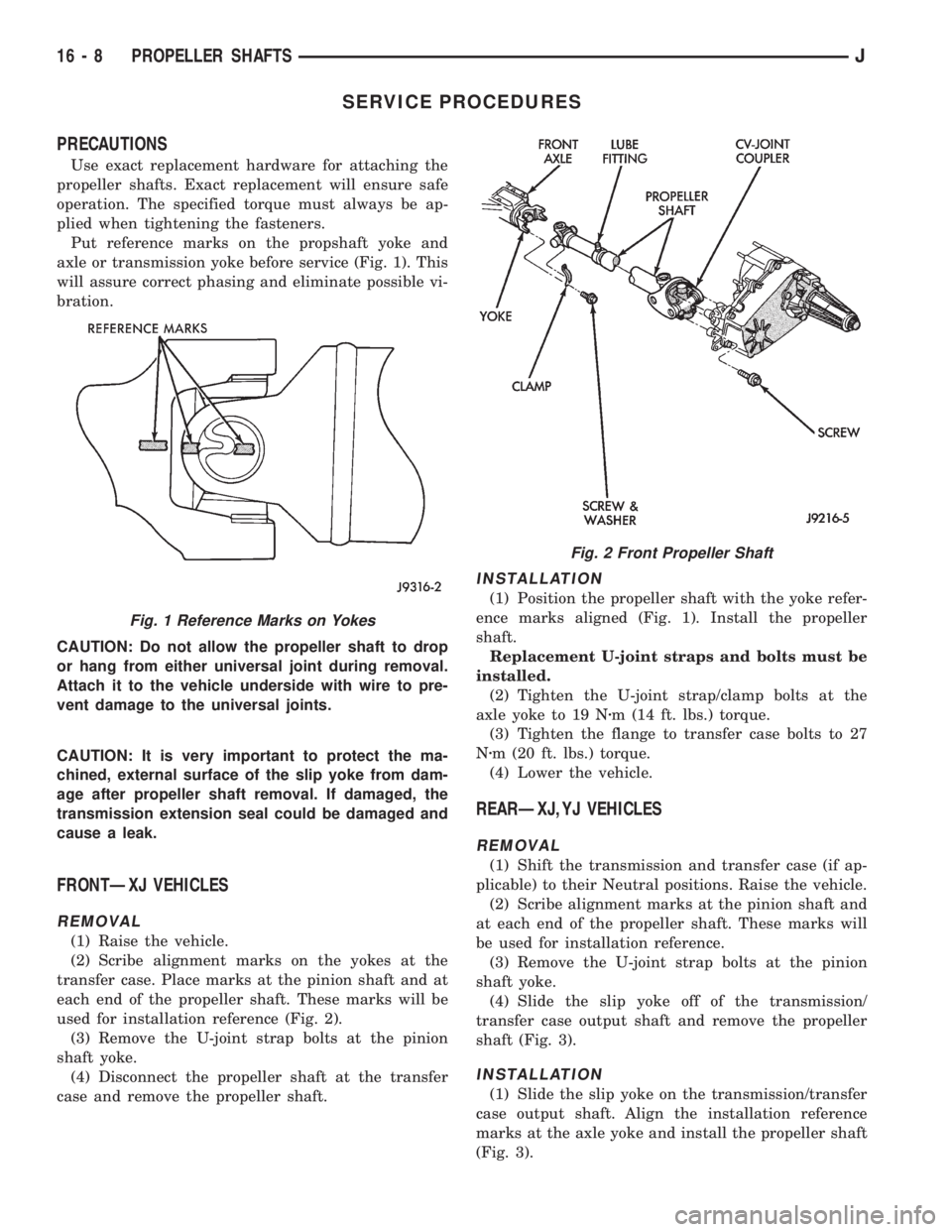

Put reference marks on the propshaft yoke and

axle or transmission yoke before service (Fig. 1). This

will assure correct phasing and eliminate possible vi-

bration.

CAUTION: Do not allow the propeller shaft to drop

or hang from either universal joint during removal.

Attach it to the vehicle underside with wire to pre-

vent damage to the universal joints.

CAUTION: It is very important to protect the ma-

chined, external surface of the slip yoke from dam-

age after propeller shaft removal. If damaged, the

transmission extension seal could be damaged and

cause a leak.

FRONTÐXJ VEHICLES

REMOVAL

(1) Raise the vehicle.

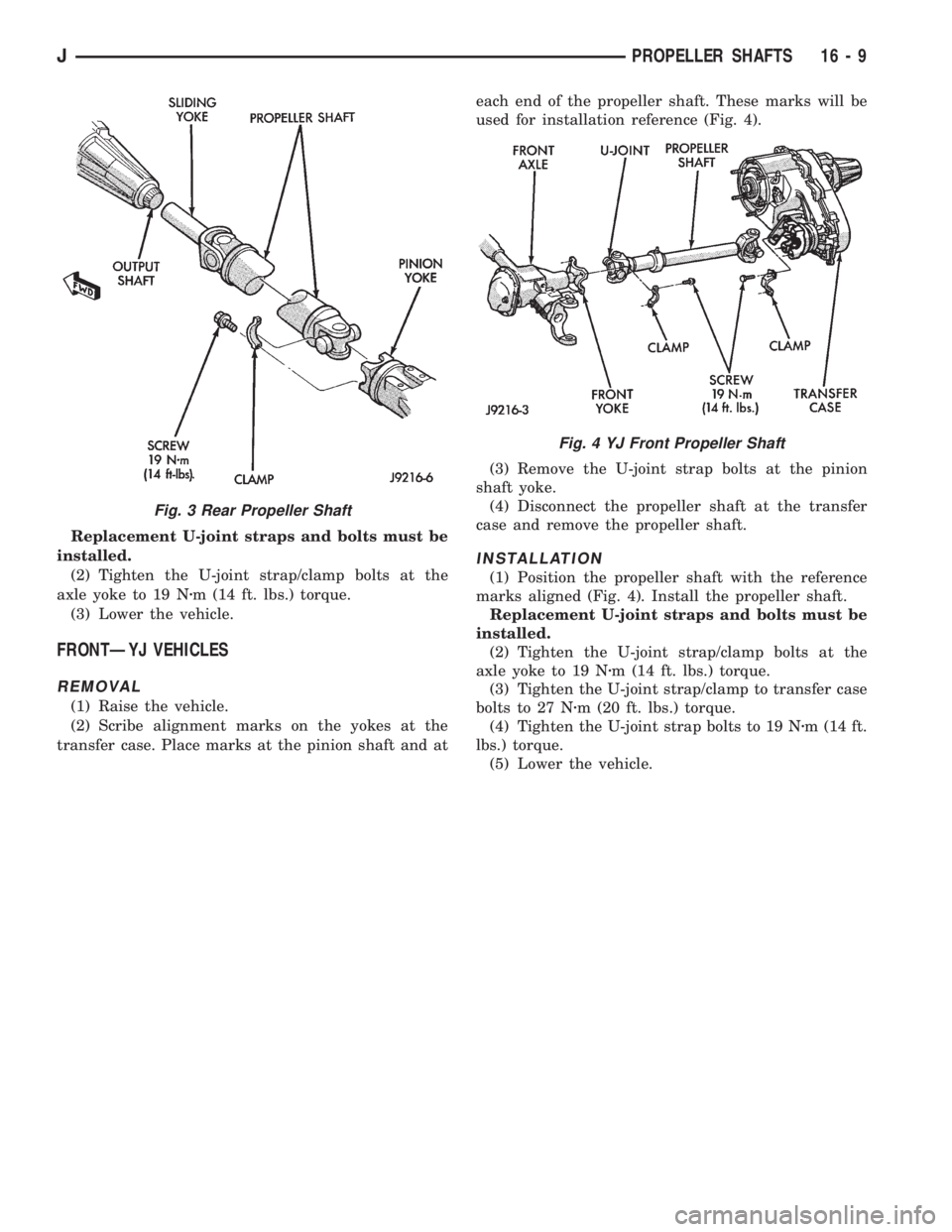

(2) Scribe alignment marks on the yokes at the

transfer case. Place marks at the pinion shaft and at

each end of the propeller shaft. These marks will be

used for installation reference (Fig. 2).

(3) Remove the U-joint strap bolts at the pinion

shaft yoke.

(4) Disconnect the propeller shaft at the transfer

case and remove the propeller shaft.

INSTALLATION

(1) Position the propeller shaft with the yoke refer-

ence marks aligned (Fig. 1). Install the propeller

shaft.

Replacement U-joint straps and bolts must be

installed.

(2) Tighten the U-joint strap/clamp bolts at the

axle yoke to 19 Nzm (14 ft. lbs.) torque.

(3) Tighten the flange to transfer case bolts to 27

Nzm (20 ft. lbs.) torque.

(4) Lower the vehicle.

REARÐXJ,YJ VEHICLES

REMOVAL

(1) Shift the transmission and transfer case (if ap-

plicable) to their Neutral positions. Raise the vehicle.

(2) Scribe alignment marks at the pinion shaft and

at each end of the propeller shaft. These marks will

be used for installation reference.

(3) Remove the U-joint strap bolts at the pinion

shaft yoke.

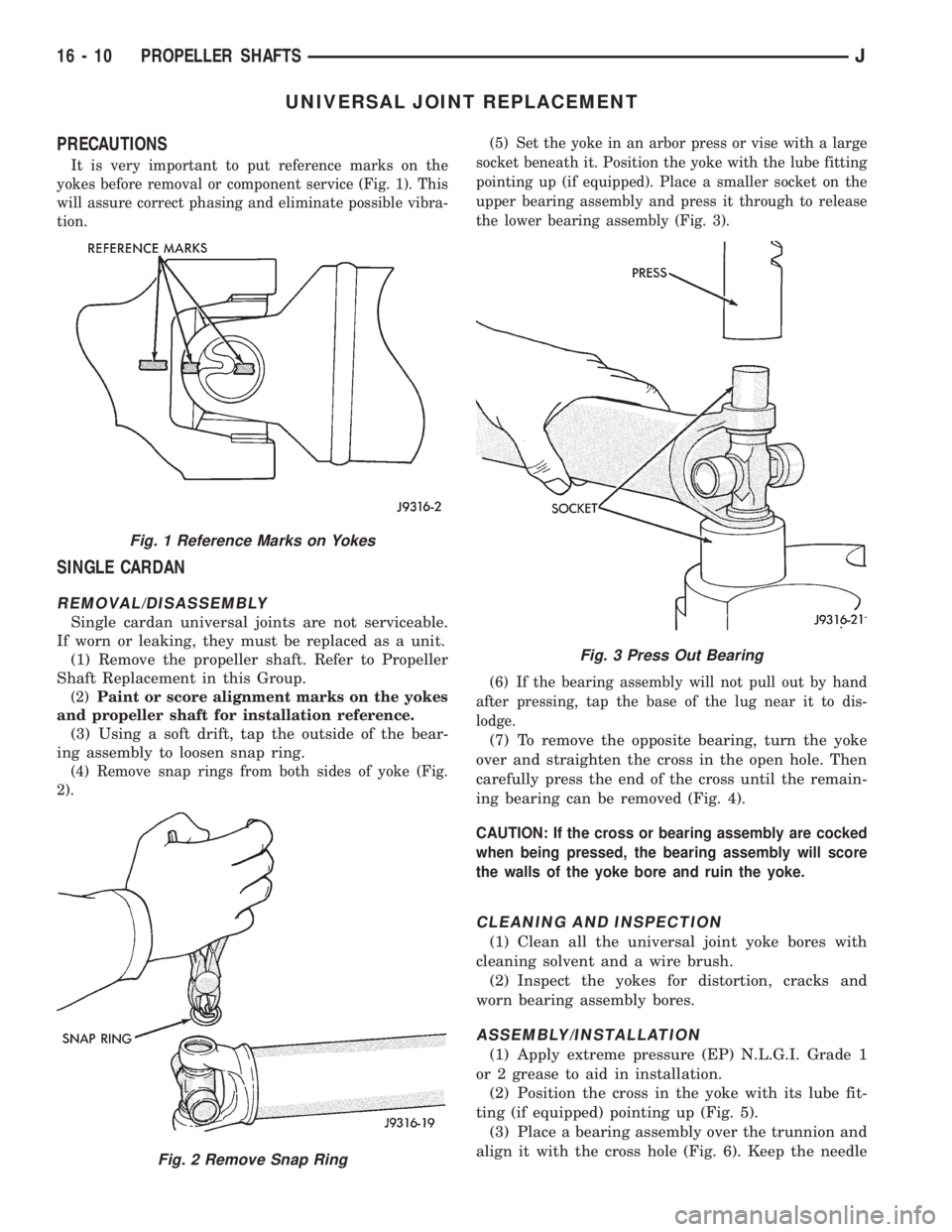

(4) Slide the slip yoke off of the transmission/

transfer case output shaft and remove the propeller

shaft (Fig. 3).

INSTALLATION

(1) Slide the slip yoke on the transmission/transfer

case output shaft. Align the installation reference

marks at the axle yoke and install the propeller shaft

(Fig. 3).

Fig. 1 Reference Marks on Yokes

Fig. 2 Front Propeller Shaft

16 - 8 PROPELLER SHAFTSJ

Page 1292 of 2198

Replacement U-joint straps and bolts must be

installed.

(2) Tighten the U-joint strap/clamp bolts at the

axle yoke to 19 Nzm (14 ft. lbs.) torque.

(3) Lower the vehicle.

FRONTÐYJ VEHICLES

REMOVAL

(1) Raise the vehicle.

(2) Scribe alignment marks on the yokes at the

transfer case. Place marks at the pinion shaft and ateach end of the propeller shaft. These marks will be

used for installation reference (Fig. 4).

(3) Remove the U-joint strap bolts at the pinion

shaft yoke.

(4) Disconnect the propeller shaft at the transfer

case and remove the propeller shaft.

INSTALLATION

(1) Position the propeller shaft with the reference

marks aligned (Fig. 4). Install the propeller shaft.

Replacement U-joint straps and bolts must be

installed.

(2) Tighten the U-joint strap/clamp bolts at the

axle yoke to 19 Nzm (14 ft. lbs.) torque.

(3) Tighten the U-joint strap/clamp to transfer case

bolts to 27 Nzm (20 ft. lbs.) torque.

(4) Tighten the U-joint strap bolts to 19 Nzm (14 ft.

lbs.) torque.

(5) Lower the vehicle.

Fig. 3 Rear Propeller Shaft

Fig. 4 YJ Front Propeller Shaft

JPROPELLER SHAFTS 16 - 9

Page 1293 of 2198

UNIVERSAL JOINT REPLACEMENT

PRECAUTIONS

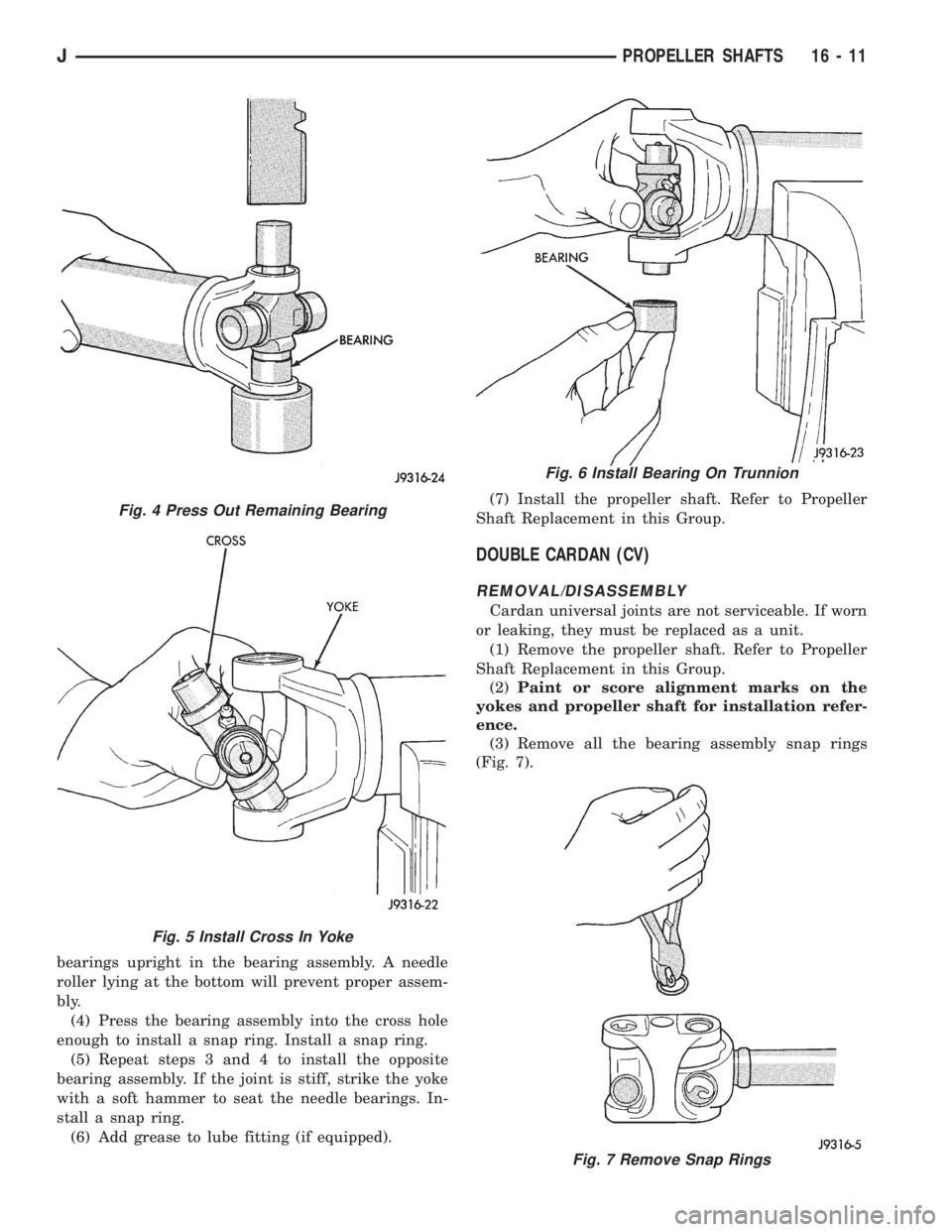

It is very important to put reference marks on the

yokes before removal or component service (Fig. 1). This

will assure correct phasing and eliminate possible vibra-

tion.

SINGLE CARDAN

REMOVAL/DISASSEMBLY

Single cardan universal joints are not serviceable.

If worn or leaking, they must be replaced as a unit.

(1) Remove the propeller shaft. Refer to Propeller

Shaft Replacement in this Group.

(2)Paint or score alignment marks on the yokes

and propeller shaft for installation reference.

(3) Using a soft drift, tap the outside of the bear-

ing assembly to loosen snap ring.

(4) Remove snap rings from both sides of yoke (Fig.

2).(5) Set the yoke in an arbor press or vise with a large

socket beneath it. Position the yoke with the lube fitting

pointing up (if equipped). Place a smaller socket on the

upper bearing assembly and press it through to release

the lower bearing assembly (Fig. 3).

(6) If the bearing assembly will not pull out by hand

after pressing, tap the base of the lug near it to dis-

lodge.

(7) To remove the opposite bearing, turn the yoke

over and straighten the cross in the open hole. Then

carefully press the end of the cross until the remain-

ing bearing can be removed (Fig. 4).

CAUTION: If the cross or bearing assembly are cocked

when being pressed, the bearing assembly will score

the walls of the yoke bore and ruin the yoke.

CLEANING AND INSPECTION

(1) Clean all the universal joint yoke bores with

cleaning solvent and a wire brush.

(2) Inspect the yokes for distortion, cracks and

worn bearing assembly bores.

ASSEMBLY/INSTALLATION

(1) Apply extreme pressure (EP) N.L.G.I. Grade 1

or 2 grease to aid in installation.

(2) Position the cross in the yoke with its lube fit-

ting (if equipped) pointing up (Fig. 5).

(3) Place a bearing assembly over the trunnion and

align it with the cross hole (Fig. 6). Keep the needle

Fig. 1 Reference Marks on Yokes

Fig. 2 Remove Snap Ring

Fig. 3 Press Out Bearing

16 - 10 PROPELLER SHAFTSJ

Page 1294 of 2198

bearings upright in the bearing assembly. A needle

roller lying at the bottom will prevent proper assem-

bly.

(4) Press the bearing assembly into the cross hole

enough to install a snap ring. Install a snap ring.

(5) Repeat steps 3 and 4 to install the opposite

bearing assembly. If the joint is stiff, strike the yoke

with a soft hammer to seat the needle bearings. In-

stall a snap ring.

(6) Add grease to lube fitting (if equipped).(7) Install the propeller shaft. Refer to Propeller

Shaft Replacement in this Group.

DOUBLE CARDAN (CV)

REMOVAL/DISASSEMBLY

Cardan universal joints are not serviceable. If worn

or leaking, they must be replaced as a unit.

(1) Remove the propeller shaft. Refer to Propeller

Shaft Replacement in this Group.

(2)Paint or score alignment marks on the

yokes and propeller shaft for installation refer-

ence.

(3) Remove all the bearing assembly snap rings

(Fig. 7).

Fig. 4 Press Out Remaining Bearing

Fig. 5 Install Cross In Yoke

Fig. 6 Install Bearing On Trunnion

Fig. 7 Remove Snap Rings

JPROPELLER SHAFTS 16 - 11

Page 1295 of 2198

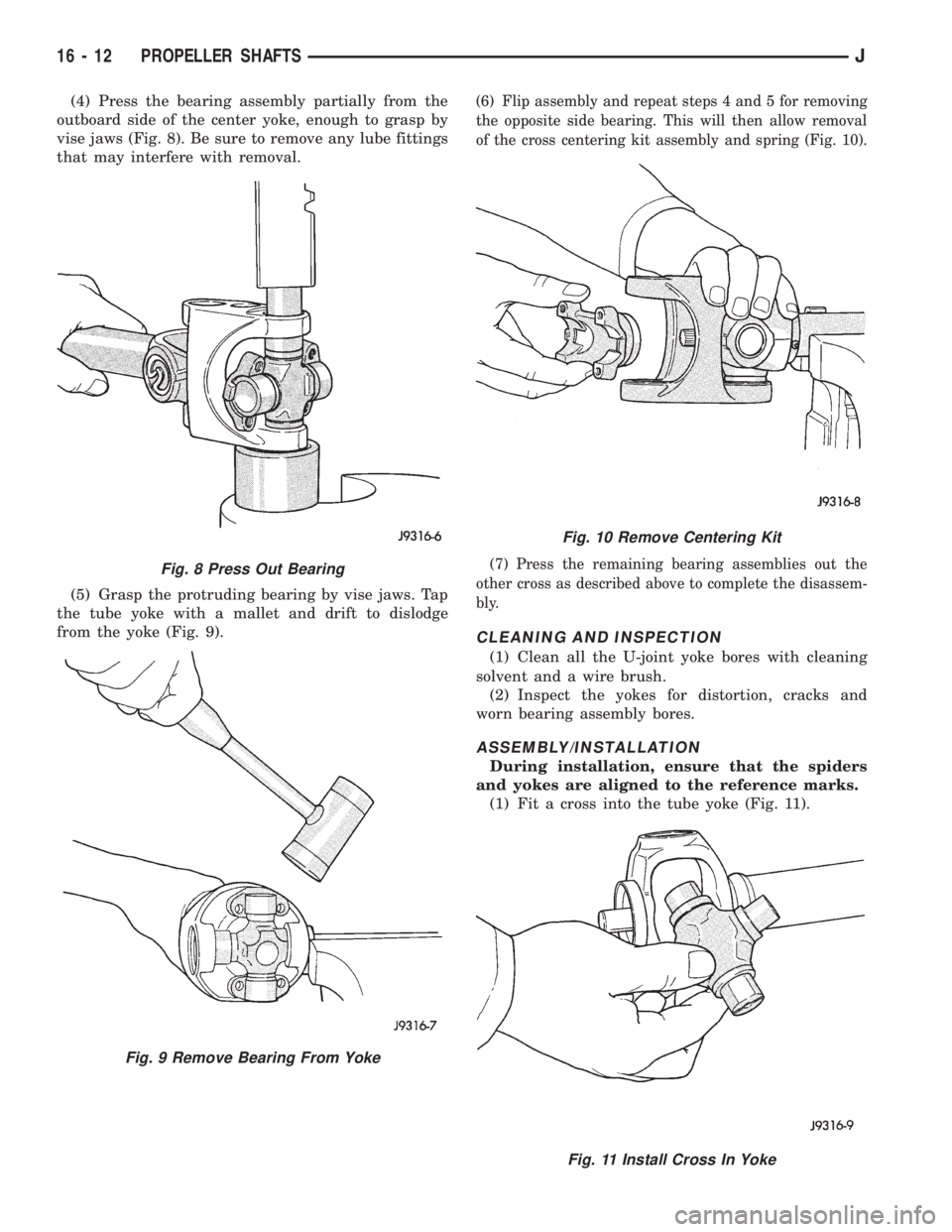

(4) Press the bearing assembly partially from the

outboard side of the center yoke, enough to grasp by

vise jaws (Fig. 8). Be sure to remove any lube fittings

that may interfere with removal.

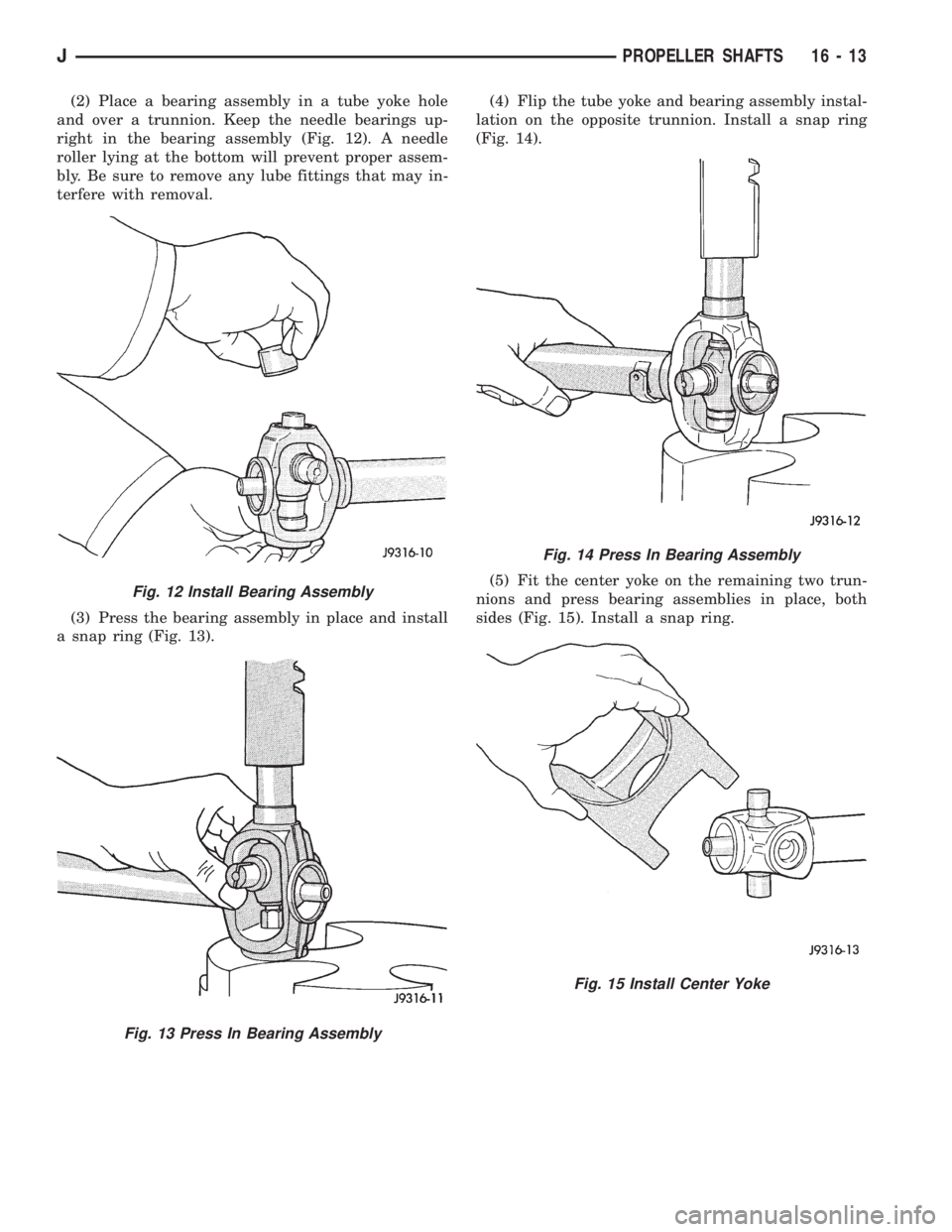

(5) Grasp the protruding bearing by vise jaws. Tap

the tube yoke with a mallet and drift to dislodge

from the yoke (Fig. 9).(6) Flip assembly and repeat steps 4 and 5 for removing

the opposite side bearing. This will then allow removal

of the cross centering kit assembly and spring (Fig. 10).

(7) Press the remaining bearing assemblies out the

other cross as described above to complete the disassem-

bly.

CLEANING AND INSPECTION

(1) Clean all the U-joint yoke bores with cleaning

solvent and a wire brush.

(2) Inspect the yokes for distortion, cracks and

worn bearing assembly bores.

ASSEMBLY/INSTALLATION

During installation, ensure that the spiders

and yokes are aligned to the reference marks.

(1) Fit a cross into the tube yoke (Fig. 11).

Fig. 8 Press Out Bearing

Fig. 9 Remove Bearing From Yoke

Fig. 10 Remove Centering Kit

Fig. 11 Install Cross In Yoke

16 - 12 PROPELLER SHAFTSJ

Page 1296 of 2198

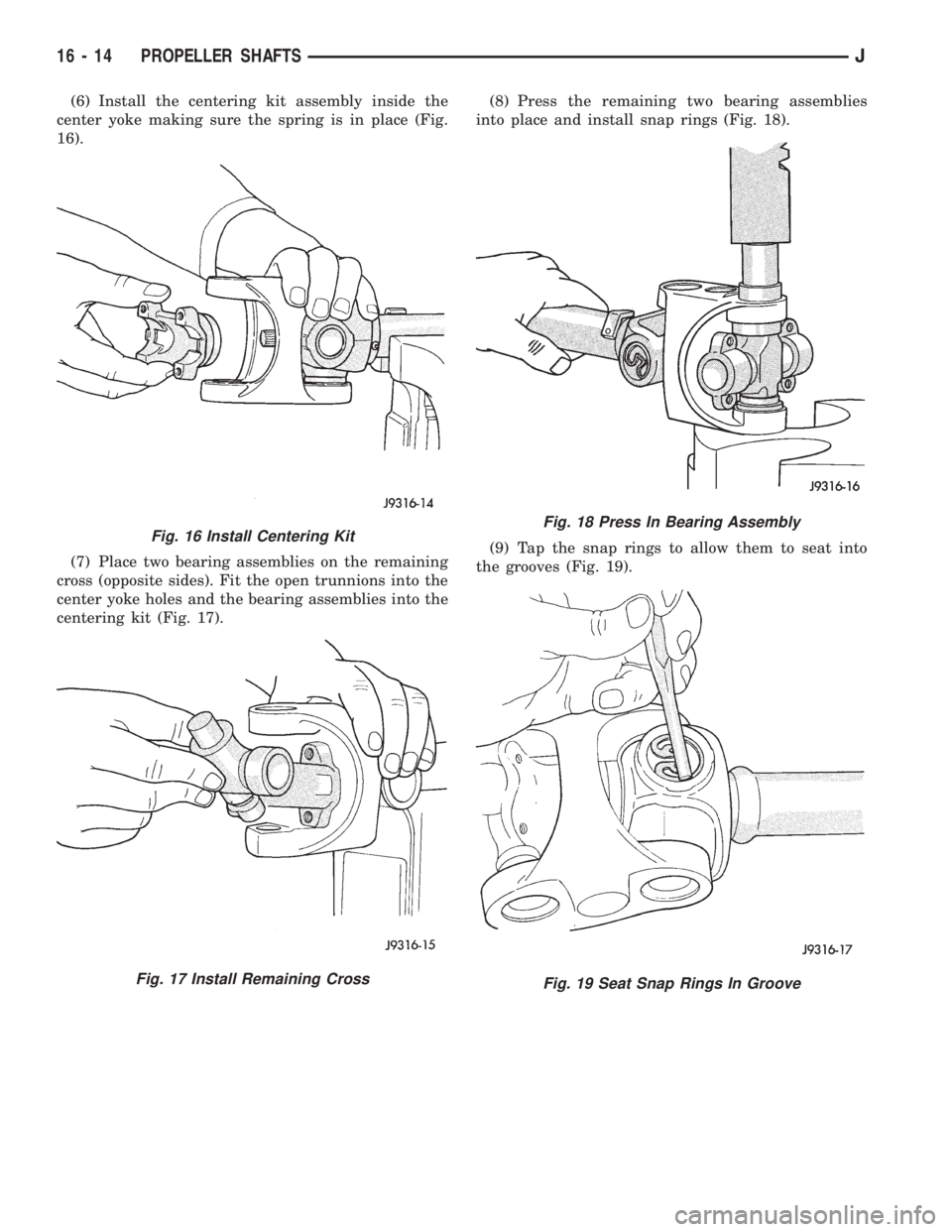

(2) Place a bearing assembly in a tube yoke hole

and over a trunnion. Keep the needle bearings up-

right in the bearing assembly (Fig. 12). A needle

roller lying at the bottom will prevent proper assem-

bly. Be sure to remove any lube fittings that may in-

terfere with removal.

(3) Press the bearing assembly in place and install

a snap ring (Fig. 13).(4) Flip the tube yoke and bearing assembly instal-

lation on the opposite trunnion. Install a snap ring

(Fig. 14).

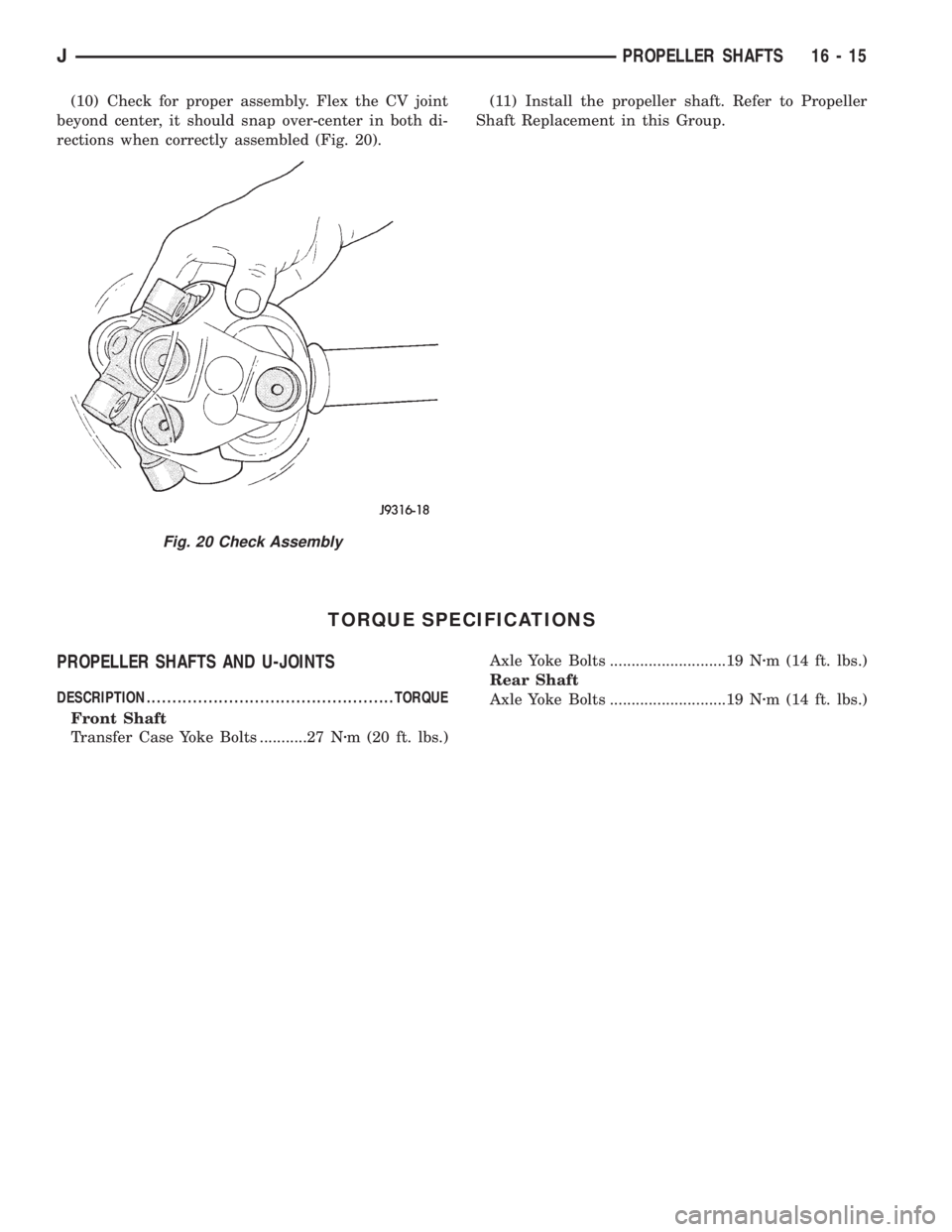

(5) Fit the center yoke on the remaining two trun-

nions and press bearing assemblies in place, both

sides (Fig. 15). Install a snap ring.

Fig. 12 Install Bearing Assembly

Fig. 13 Press In Bearing Assembly

Fig. 14 Press In Bearing Assembly

Fig. 15 Install Center Yoke

JPROPELLER SHAFTS 16 - 13

Page 1297 of 2198

(6) Install the centering kit assembly inside the

center yoke making sure the spring is in place (Fig.

16).

(7) Place two bearing assemblies on the remaining

cross (opposite sides). Fit the open trunnions into the

center yoke holes and the bearing assemblies into the

centering kit (Fig. 17).(8) Press the remaining two bearing assemblies

into place and install snap rings (Fig. 18).

(9) Tap the snap rings to allow them to seat into

the grooves (Fig. 19).

Fig. 16 Install Centering Kit

Fig. 17 Install Remaining Cross

Fig. 18 Press In Bearing Assembly

Fig. 19 Seat Snap Rings In Groove

16 - 14 PROPELLER SHAFTSJ

Page 1298 of 2198

(10) Check for proper assembly. Flex the CV joint

beyond center, it should snap over-center in both di-

rections when correctly assembled (Fig. 20).(11) Install the propeller shaft. Refer to Propeller

Shaft Replacement in this Group.

TORQUE SPECIFICATIONS

PROPELLER SHAFTS AND U-JOINTS

DESCRIPTION ................................................TORQUE

Front Shaft

Transfer Case Yoke Bolts ...........27 Nzm (20 ft. lbs.)Axle Yoke Bolts ...........................19 Nzm (14 ft. lbs.)

Rear Shaft

Axle Yoke Bolts ...........................19 Nzm (14 ft. lbs.)

Fig. 20 Check Assembly

JPROPELLER SHAFTS 16 - 15

Page 1299 of 2198

Page 1300 of 2198

STEERING

CONTENTS

page page

GENERAL INFORMATION.................. 1

GENERAL INFORMATION................. 48

MANUAL STEERING GEAR................ 37

POWER STEERING PUMP................. 11

POWER STEERING SYSTEM DIAGNOSIS...... 3

RECIRCULATING BALL POWER STEERING

GEAR............................... 21STEERING COLUMN GENERAL SERVICEÐXJ . 47

STEERING COLUMNÐYJ................. 58

STEERING LINKAGEÐXJ................. 16

STEERING LINKAGEÐYJ................. 19

STEERING RHD......................... 74

TORQUE SPECIFICATIONS................ 78

GENERAL INFORMATION

STEERING SYSTEM COMPONENTS

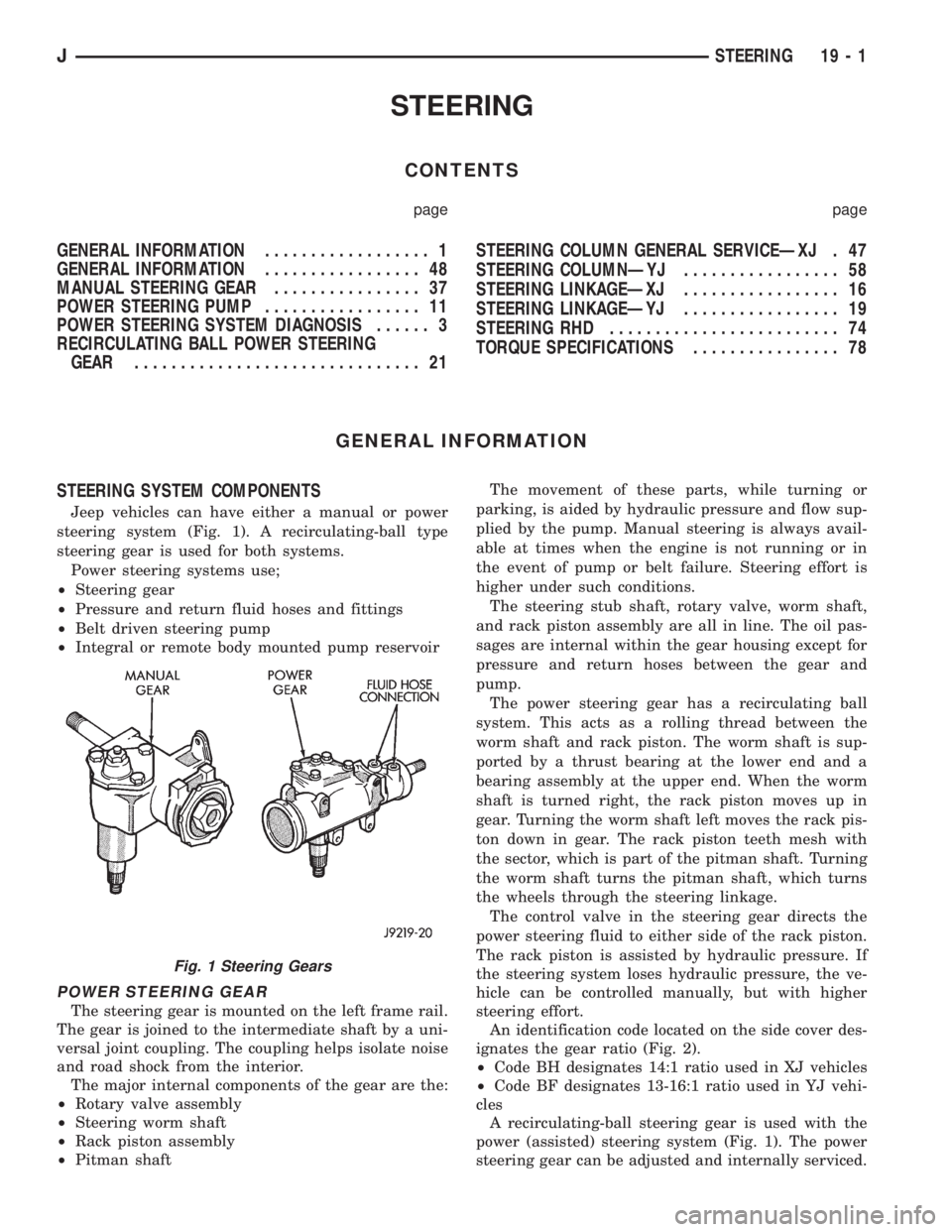

Jeep vehicles can have either a manual or power

steering system (Fig. 1). A recirculating-ball type

steering gear is used for both systems.

Power steering systems use;

²Steering gear

²Pressure and return fluid hoses and fittings

²Belt driven steering pump

²Integral or remote body mounted pump reservoir

POWER STEERING GEAR

The steering gear is mounted on the left frame rail.

The gear is joined to the intermediate shaft by a uni-

versal joint coupling. The coupling helps isolate noise

and road shock from the interior.

The major internal components of the gear are the:

²Rotary valve assembly

²Steering worm shaft

²Rack piston assembly

²Pitman shaftThe movement of these parts, while turning or

parking, is aided by hydraulic pressure and flow sup-

plied by the pump. Manual steering is always avail-

able at times when the engine is not running or in

the event of pump or belt failure. Steering effort is

higher under such conditions.

The steering stub shaft, rotary valve, worm shaft,

and rack piston assembly are all in line. The oil pas-

sages are internal within the gear housing except for

pressure and return hoses between the gear and

pump.

The power steering gear has a recirculating ball

system. This acts as a rolling thread between the

worm shaft and rack piston. The worm shaft is sup-

ported by a thrust bearing at the lower end and a

bearing assembly at the upper end. When the worm

shaft is turned right, the rack piston moves up in

gear. Turning the worm shaft left moves the rack pis-

ton down in gear. The rack piston teeth mesh with

the sector, which is part of the pitman shaft. Turning

the worm shaft turns the pitman shaft, which turns

the wheels through the steering linkage.

The control valve in the steering gear directs the

power steering fluid to either side of the rack piston.

The rack piston is assisted by hydraulic pressure. If

the steering system loses hydraulic pressure, the ve-

hicle can be controlled manually, but with higher

steering effort.

An identification code located on the side cover des-

ignates the gear ratio (Fig. 2).

²Code BH designates 14:1 ratio used in XJ vehicles

²Code BF designates 13-16:1 ratio used in YJ vehi-

cles

A recirculating-ball steering gear is used with the

power (assisted) steering system (Fig. 1). The power

steering gear can be adjusted and internally serviced.

Fig. 1 Steering Gears

JSTEERING 19 - 1