JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1371 of 2198

(9) Install the shift tube thrust washer and the re-

tainer plate snap ring.

(10) Install the lower bearing in the steering col-

umn.

(11) Position the shift gate in the steering column

support. Install the attaching screws.

(12) Position the support in the steering column.

(13) Install all support attaching screws finger-

tight. Next, tighten the screws alternately and evenly

to7Nzm (60 in. lbs.) torque.

(14) Install the remote rod in the support. Route

the rod through the upper end of the shroud and in-

sert it into the rod slot located in the support.

(15) Install the dimmer switch and ignition switch.

(16) Install the steering shaft in the steering col-

umn.

(17) Install replacement races and bearings in the

key/lock cylinder, if removed.Ensure that the bear-

ings are lubricated with chassis lubricant be-

fore installation.

(18) Install the lock shoes, the lock shoe springs

and the lock shoe pin the key/lock cylinder housing.

Use a 4.5-mm (0.18-in) diameter rod to align the

shoes and the pin during installation.

(19) Install the tilt-release lever, the lever spring

and the lever pin in the key/lock cylinder housing.

Insert a wedge between the housing and the lever to

relieve the spring tension. This will allow easier re-

lease lever pin installation.

(20) Install the lock bolt in the key/lock cylinder

housing and engage it in the lock sector cam surface.

(21) Install the lock rack, the rack preload spring

and a replacement shim in the key/lock cylinder

housing. Align and mate the square block tooth on

the lock rack and the lock sector.

(22) Install the lock spring and the spring retain-

ing screw. Tighten the screw to 4 Nzm (35 in. lbs.)

torque.

(23) Align and install the assembled key/lock cylin-

der housing on the support. Retain the lock shoes in

the disengaged position for easier housing installa-

tion.

(24) Align the pivot pin holes in the housing with

those in the support. Insert the pivot pins.Press the

housing firmly downward when inserting the

pivot pins. This prevents damaging the holes in

the support.When the pivot pins are within both

the housing and the support holes, seat them fully

with a punch and a hammer.

(25) Insert tilt-release lever in key/lock cylinder

housing and place housing in the full-upward tilt po-

sition.

(26) Lubricate the tilt spring guide and the tilt

spring liberally with chassis lubricant and position

the spring on the guide.

(27) Insert the tilt spring guide and the spring into

the key/lock cylinder housing. Install the guide re-tainer over the spring. Engage the retainer lock tabs

with the housing lugs by pressing the retainer down-

ward and turning clockwise with a screwdriver.

(28) Place the cover on the key/lock cylinder hous-

ing. Align and install the cover retaining screws.

Tighten the screws to 7 Nzm (60 in. lbs.) torque.

(29) Install the gear selector indicator lamp mount-

ing bracket screw.

(30) Install the gear selector indicator cover and

retaining screws.

(31) Route the dimmer switch wire harness and

gear selector indicator down through the steering col-

umn.

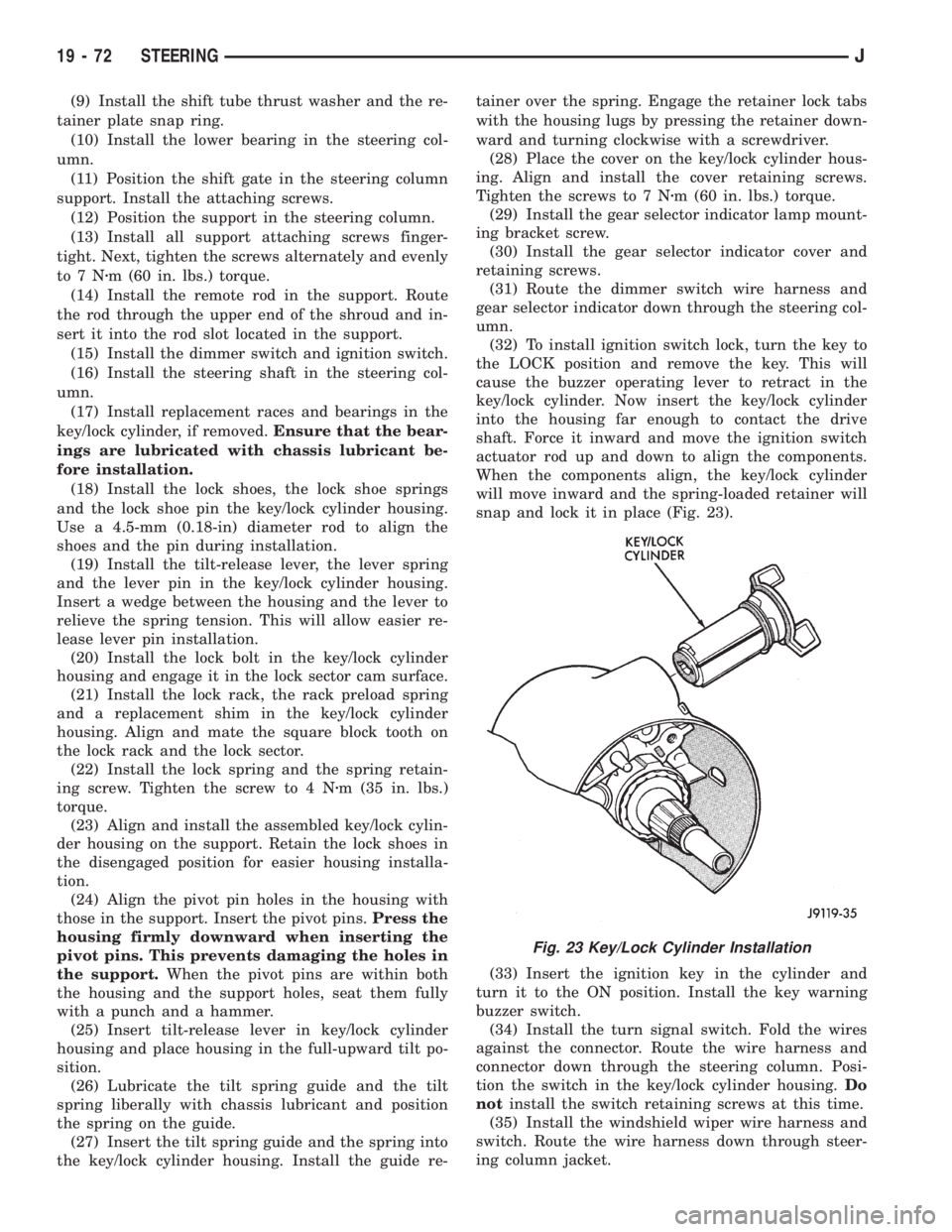

(32) To install ignition switch lock, turn the key to

the LOCK position and remove the key. This will

cause the buzzer operating lever to retract in the

key/lock cylinder. Now insert the key/lock cylinder

into the housing far enough to contact the drive

shaft. Force it inward and move the ignition switch

actuator rod up and down to align the components.

When the components align, the key/lock cylinder

will move inward and the spring-loaded retainer will

snap and lock it in place (Fig. 23).

(33) Insert the ignition key in the cylinder and

turn it to the ON position. Install the key warning

buzzer switch.

(34) Install the turn signal switch. Fold the wires

against the connector. Route the wire harness and

connector down through the steering column. Posi-

tion the switch in the key/lock cylinder housing.Do

notinstall the switch retaining screws at this time.

(35) Install the windshield wiper wire harness and

switch. Route the wire harness down through steer-

ing column jacket.

Fig. 23 Key/Lock Cylinder Installation

19 - 72 STEERINGJ

Page 1372 of 2198

(36) If equipped, install the cruise control wire har-

ness. Install the turn signal stalk by pushing it

straight into the column.

(37) Insert the hazard warning knob in the hazard

warning switch and press it inward. Align and install

the turn signal switch retaining screws. Ensure that

the turn signal switch is properly seated before tight-

ening the screws. Tighten the screws to 4 Nzm (33 in.

lbs.) torque. Thread the hazard warning switch knob

into the switch and pull the knob outward.

(38) Install and seat the upper bearing race in the

key/lock cylinder housing.

(39) Install the upper bearing preload spring, the

canceling cam and the lockplate.

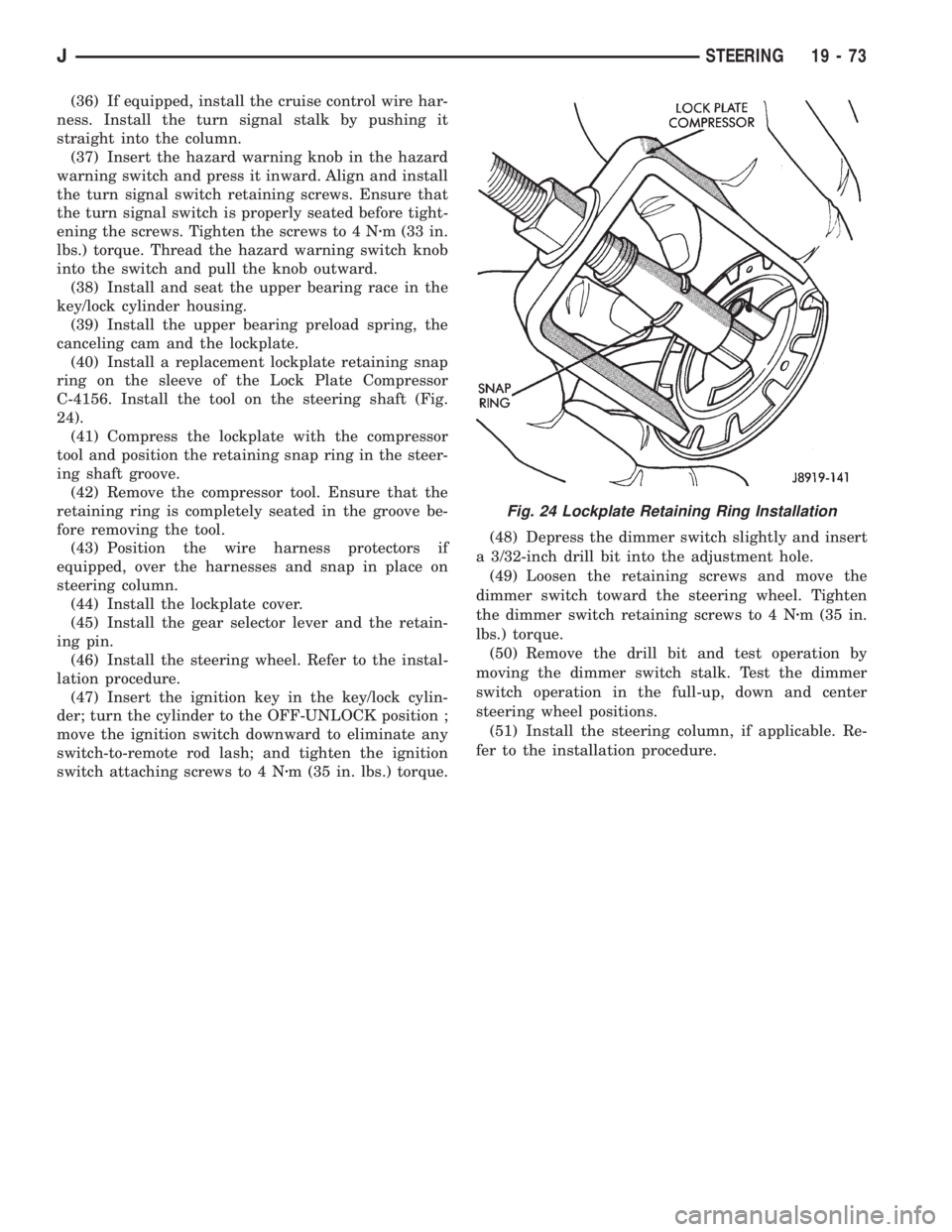

(40) Install a replacement lockplate retaining snap

ring on the sleeve of the Lock Plate Compressor

C-4156. Install the tool on the steering shaft (Fig.

24).

(41) Compress the lockplate with the compressor

tool and position the retaining snap ring in the steer-

ing shaft groove.

(42) Remove the compressor tool. Ensure that the

retaining ring is completely seated in the groove be-

fore removing the tool.

(43) Position the wire harness protectors if

equipped, over the harnesses and snap in place on

steering column.

(44) Install the lockplate cover.

(45) Install the gear selector lever and the retain-

ing pin.

(46) Install the steering wheel. Refer to the instal-

lation procedure.

(47) Insert the ignition key in the key/lock cylin-

der; turn the cylinder to the OFF-UNLOCK position ;

move the ignition switch downward to eliminate any

switch-to-remote rod lash; and tighten the ignition

switch attaching screws to 4 Nzm (35 in. lbs.) torque.(48) Depress the dimmer switch slightly and insert

a 3/32-inch drill bit into the adjustment hole.

(49) Loosen the retaining screws and move the

dimmer switch toward the steering wheel. Tighten

the dimmer switch retaining screws to 4 Nzm (35 in.

lbs.) torque.

(50) Remove the drill bit and test operation by

moving the dimmer switch stalk. Test the dimmer

switch operation in the full-up, down and center

steering wheel positions.

(51) Install the steering column, if applicable. Re-

fer to the installation procedure.

Fig. 24 Lockplate Retaining Ring Installation

JSTEERING 19 - 73

Page 1373 of 2198

STEERING RHD

GENERAL SERVICE PROCEDURE INFORMATION

Right hand drive service procedures and torque

specifications involving steering; linkage, gear and

column are the same as left hand drive vehicles ex-

cept where shown. Refer to appropriate service pro-

cedures regarding each component in the system.

The steering linkage consists of a pitman arm, drag

link, and tie rod. Adjustment sleeves are used on the

tie rod and drag link for toe and steering wheel

alignment (Fig. 1).

RECIRCULATING-BALL POWER STEERING GEARS

The steering gears can be adjusted and internally

serviced. The components CANNOT be interchanged

with those of a left hand drive vehicle.

The steering gear has a 17.5:1 ratio.

POWER STEERING PUMP

PRESSURE AND RETURN LINE

REPLACEMENT

Cap hose open ends and pump/steering gear fit-

tings to prevent entry of foreign material.

WARNING: POWER STEERING FLUID (AND PUMP

COMPONENTS) AND THE EXHAUST SYSTEM CAN

BE EXTREMELY HOT IF THE ENGINE HAS BEEN

RECENTLY OPERATING. DO NOT START THE EN-

GINE WITH ANY LOOSE OR DISCONNECTED

HOSES. DO NOT ALLOW THE LINES TO TOUCH A

HOT EXHAUST MANIFOLD.REMOVAL

(1) Place a drain pan under the pump and gear.

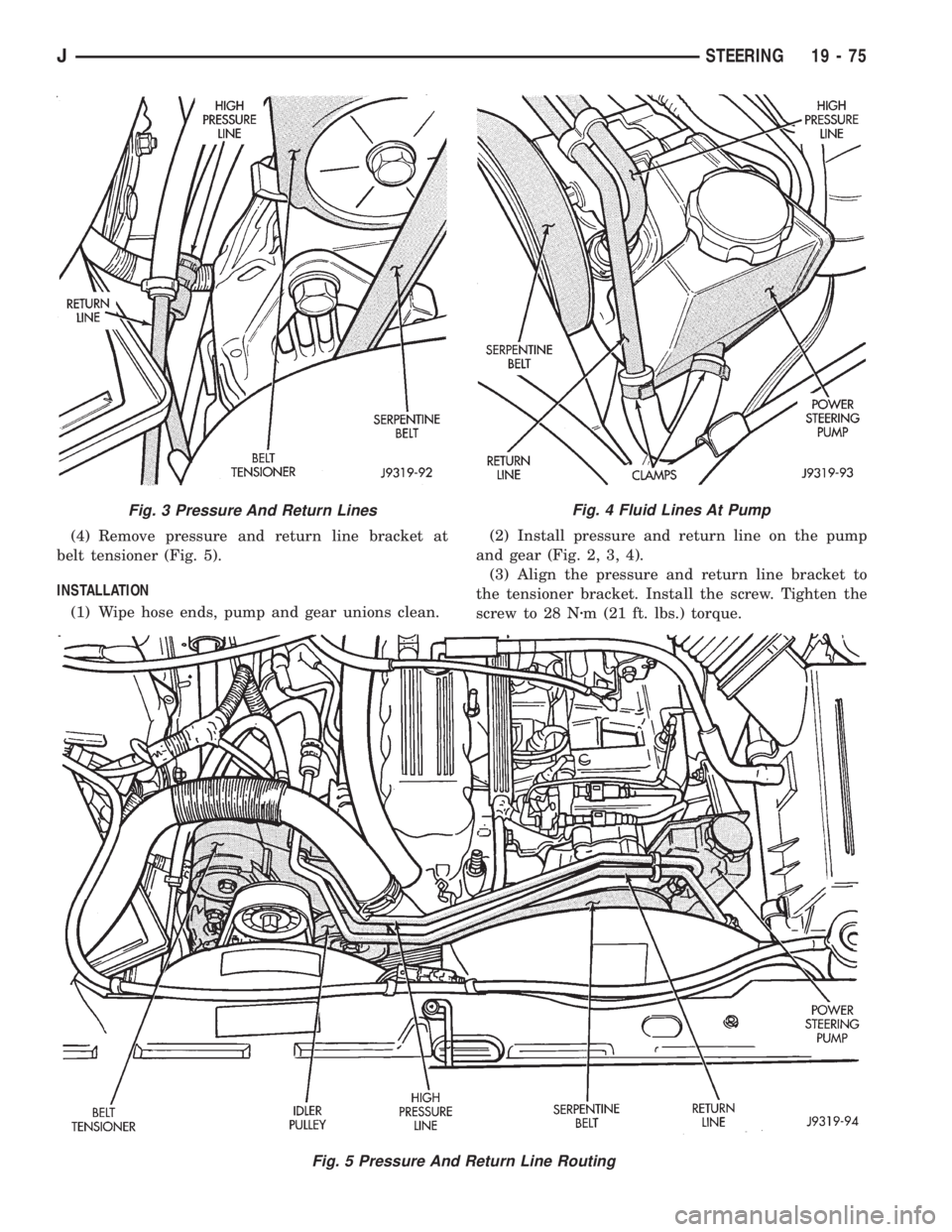

(2) Disconnect the pressure and return line from

the steering gear (Fig. 2, 3).

(3) Disconnect the pressure and return line from

the pump (Fig. 4). Drain the fluid from pump and

reservoir.

Fig. 1 RHD Steering Linkage

Fig. 2 Fluid Lines On Steering Gear

19 - 74 STEERINGJ

Page 1374 of 2198

(4) Remove pressure and return line bracket at

belt tensioner (Fig. 5).

INSTALLATION

(1) Wipe hose ends, pump and gear unions clean.(2) Install pressure and return line on the pump

and gear (Fig. 2, 3, 4).

(3) Align the pressure and return line bracket to

the tensioner bracket. Install the screw. Tighten the

screw to 28 Nzm (21 ft. lbs.) torque.

Fig. 4 Fluid Lines At Pump

Fig. 5 Pressure And Return Line Routing

Fig. 3 Pressure And Return Lines

JSTEERING 19 - 75

Page 1375 of 2198

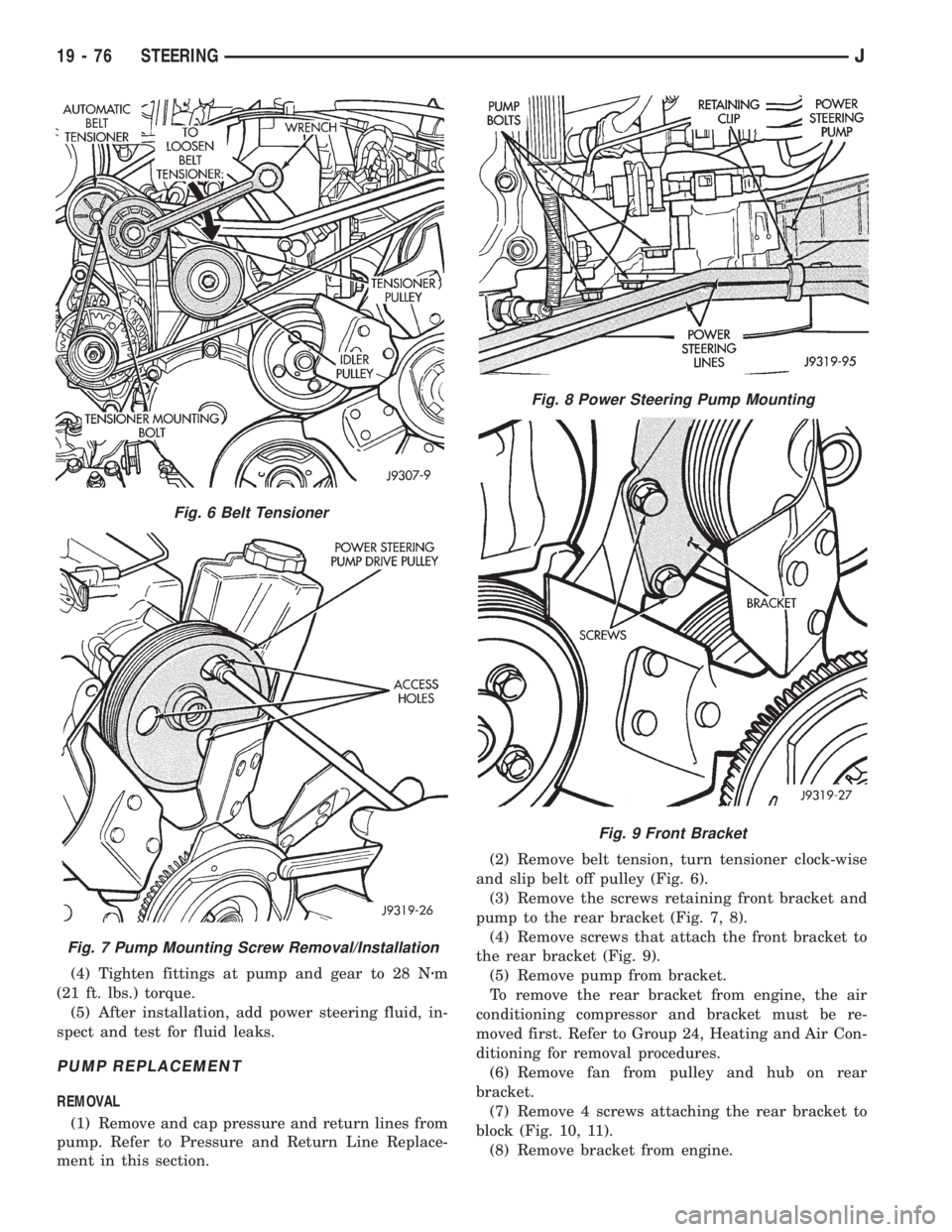

(4) Tighten fittings at pump and gear to 28 Nzm

(21 ft. lbs.) torque.

(5) After installation, add power steering fluid, in-

spect and test for fluid leaks.

PUMP REPLACEMENT

REMOVAL

(1) Remove and cap pressure and return lines from

pump. Refer to Pressure and Return Line Replace-

ment in this section.(2) Remove belt tension, turn tensioner clock-wise

and slip belt off pulley (Fig. 6).

(3) Remove the screws retaining front bracket and

pump to the rear bracket (Fig. 7, 8).

(4) Remove screws that attach the front bracket to

the rear bracket (Fig. 9).

(5) Remove pump from bracket.

To remove the rear bracket from engine, the air

conditioning compressor and bracket must be re-

moved first. Refer to Group 24, Heating and Air Con-

ditioning for removal procedures.

(6) Remove fan from pulley and hub on rear

bracket.

(7) Remove 4 screws attaching the rear bracket to

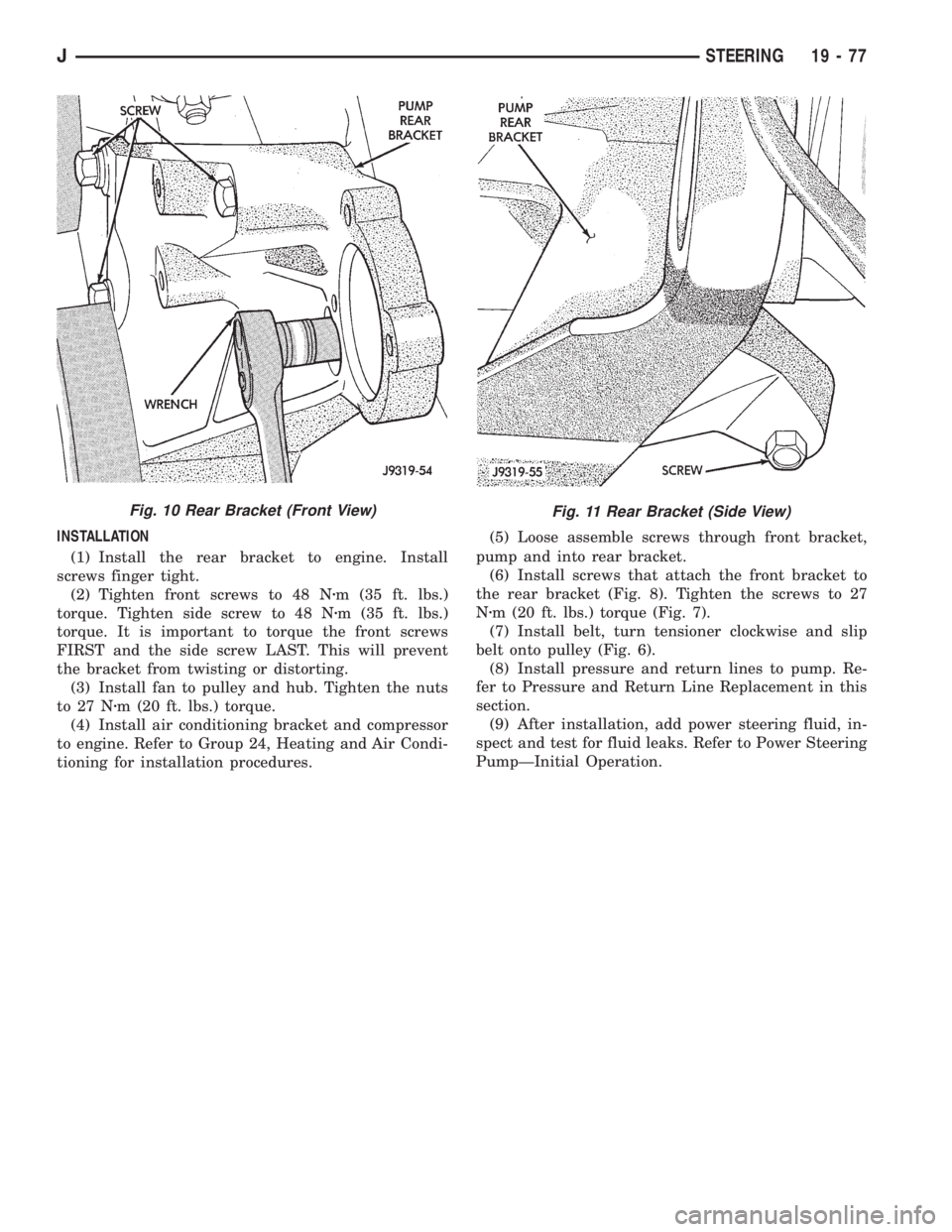

block (Fig. 10, 11).

(8) Remove bracket from engine.

Fig. 6 Belt Tensioner

Fig. 7 Pump Mounting Screw Removal/Installation

Fig. 8 Power Steering Pump Mounting

Fig. 9 Front Bracket

19 - 76 STEERINGJ

Page 1376 of 2198

INSTALLATION

(1) Install the rear bracket to engine. Install

screws finger tight.

(2) Tighten front screws to 48 Nzm (35 ft. lbs.)

torque. Tighten side screw to 48 Nzm (35 ft. lbs.)

torque. It is important to torque the front screws

FIRST and the side screw LAST. This will prevent

the bracket from twisting or distorting.

(3) Install fan to pulley and hub. Tighten the nuts

to 27 Nzm (20 ft. lbs.) torque.

(4) Install air conditioning bracket and compressor

to engine. Refer to Group 24, Heating and Air Condi-

tioning for installation procedures.(5) Loose assemble screws through front bracket,

pump and into rear bracket.

(6) Install screws that attach the front bracket to

the rear bracket (Fig. 8). Tighten the screws to 27

Nzm (20 ft. lbs.) torque (Fig. 7).

(7) Install belt, turn tensioner clockwise and slip

belt onto pulley (Fig. 6).

(8) Install pressure and return lines to pump. Re-

fer to Pressure and Return Line Replacement in this

section.

(9) After installation, add power steering fluid, in-

spect and test for fluid leaks. Refer to Power Steering

PumpÐInitial Operation.

Fig. 11 Rear Bracket (Side View)Fig. 10 Rear Bracket (Front View)

JSTEERING 19 - 77

Page 1377 of 2198

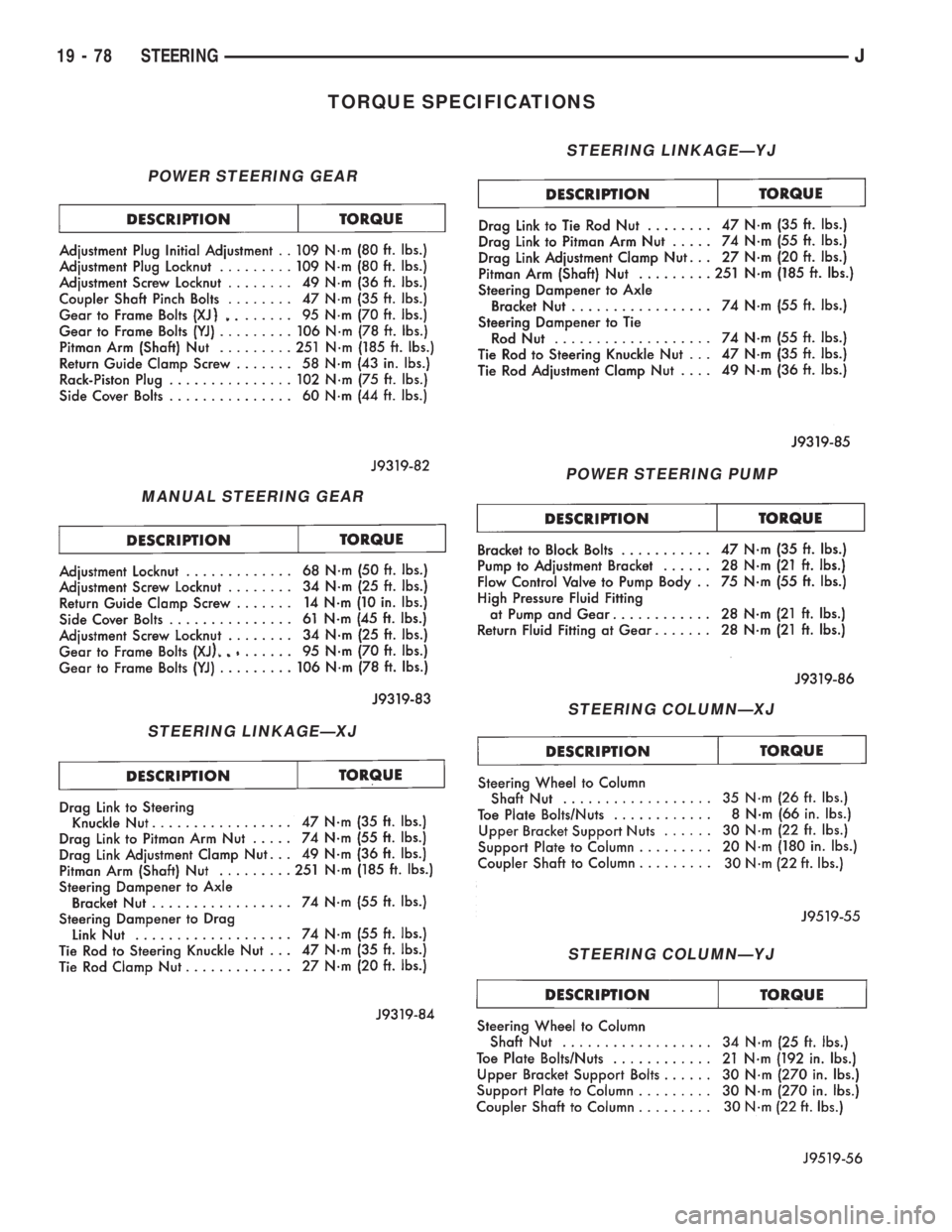

TORQUE SPECIFICATIONS

POWER STEERING GEAR

MANUAL STEERING GEAR

STEERING LINKAGEÐXJ

STEERING LINKAGEÐYJ

POWER STEERING PUMP

STEERING COLUMNÐXJ

STEERING COLUMNÐYJ

19 - 78 STEERINGJ

Page 1378 of 2198

TRANSMISSION AND TRANSFER CASE

CONTENTS

page page

30RH/32RH AUTOMATIC TRANSMISSION.... 67

AW 4 AUTOMATIC TRANSMISSION........ 165

AX 15 MANUAL TRANSMISSION........... 33

AX 4/5 MANUAL TRANSMISSION............ 1NP231 TRANSFER CASE................. 283

NP242 TRANSFER CASE................. 306

TRANSMISSION/TRANSFER CASE

SPECIFICATIONS..................... 333

AX 4/5 MANUAL TRANSMISSION

INDEX

page page

Cleaning and Inspection.................... 13

Gear Ratios.............................. 2

General Information........................ 1

Recommended Lubricant.................... 2

Service Diagnosis.......................... 2

Shift Pattern.............................. 2Transmission Assembly and Adjustment......... 16

Transmission Disassembly and Overhaul......... 5

Transmission Identification................... 2

Transmission Installation..................... 5

Transmission Removal...................... 3

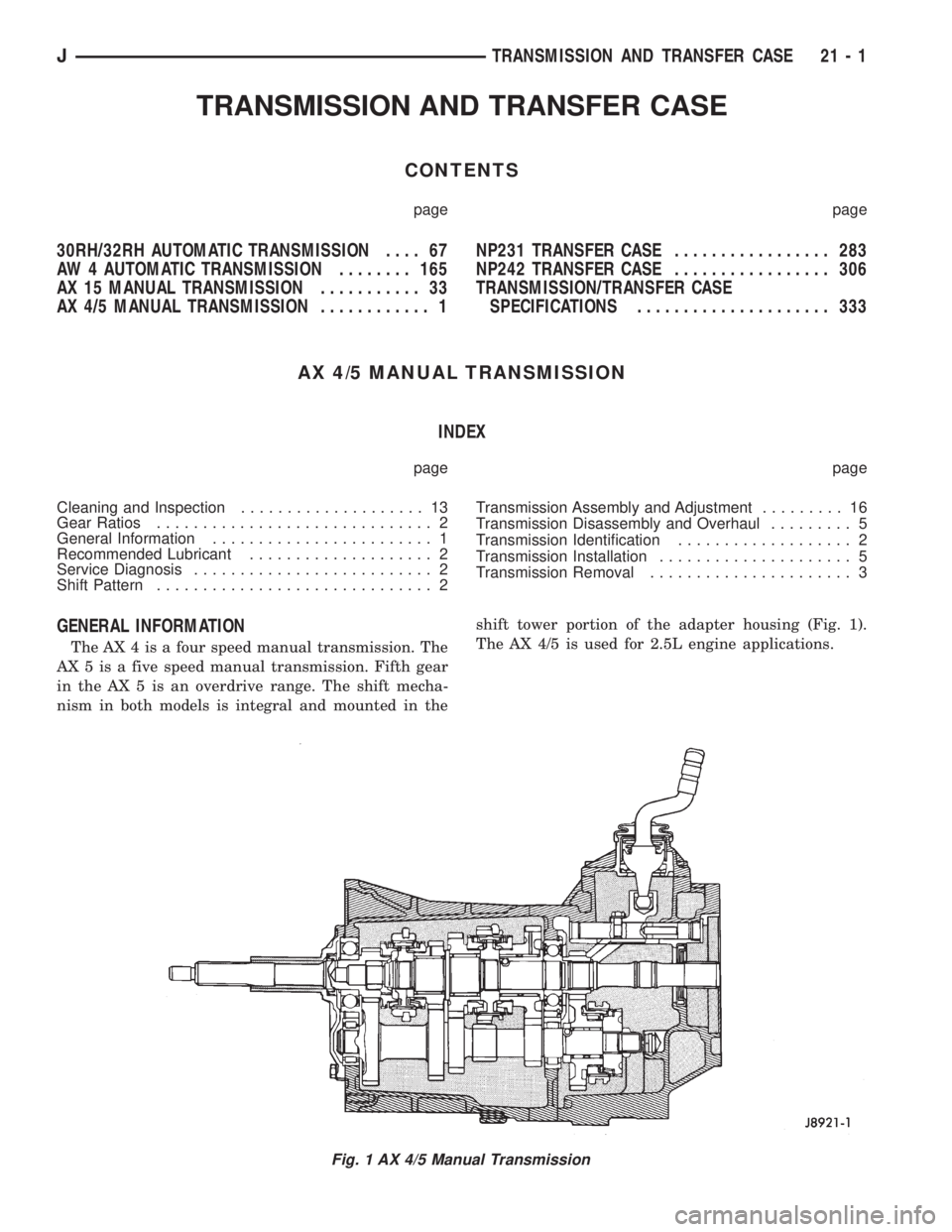

GENERAL INFORMATION

The AX 4 is a four speed manual transmission. The

AX 5 is a five speed manual transmission. Fifth gear

in the AX 5 is an overdrive range. The shift mecha-

nism in both models is integral and mounted in theshift tower portion of the adapter housing (Fig. 1).

The AX 4/5 is used for 2.5L engine applications.

Fig. 1 AX 4/5 Manual Transmission

JTRANSMISSION AND TRANSFER CASE 21 - 1

Page 1379 of 2198

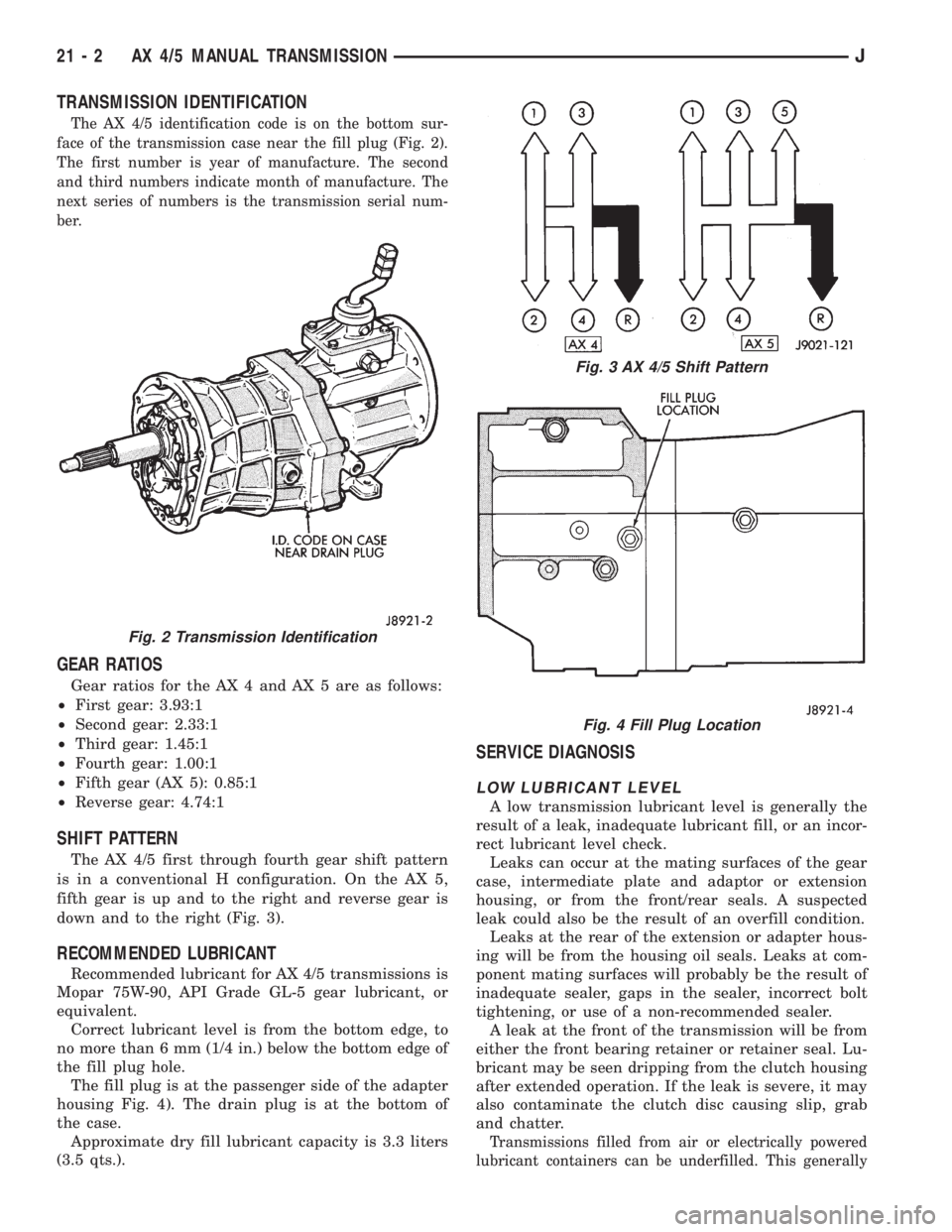

TRANSMISSION IDENTIFICATION

The AX 4/5 identification code is on the bottom sur-

face of the transmission case near the fill plug (Fig. 2).

The first number is year of manufacture. The second

and third numbers indicate month of manufacture. The

next series of numbers is the transmission serial num-

ber.

GEAR RATIOS

Gear ratios for the AX 4 and AX 5 are as follows:

²First gear: 3.93:1

²Second gear: 2.33:1

²Third gear: 1.45:1

²Fourth gear: 1.00:1

²Fifth gear (AX 5): 0.85:1

²Reverse gear: 4.74:1

SHIFT PATTERN

The AX 4/5 first through fourth gear shift pattern

is in a conventional H configuration. On the AX 5,

fifth gear is up and to the right and reverse gear is

down and to the right (Fig. 3).

RECOMMENDED LUBRICANT

Recommended lubricant for AX 4/5 transmissions is

Mopar 75W-90, API Grade GL-5 gear lubricant, or

equivalent.

Correct lubricant level is from the bottom edge, to

no more than 6 mm (1/4 in.) below the bottom edge of

the fill plug hole.

The fill plug is at the passenger side of the adapter

housing Fig. 4). The drain plug is at the bottom of

the case.

Approximate dry fill lubricant capacity is 3.3 liters

(3.5 qts.).

SERVICE DIAGNOSIS

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the

result of a leak, inadequate lubricant fill, or an incor-

rect lubricant level check.

Leaks can occur at the mating surfaces of the gear

case, intermediate plate and adaptor or extension

housing, or from the front/rear seals. A suspected

leak could also be the result of an overfill condition.

Leaks at the rear of the extension or adapter hous-

ing will be from the housing oil seals. Leaks at com-

ponent mating surfaces will probably be the result of

inadequate sealer, gaps in the sealer, incorrect bolt

tightening, or use of a non-recommended sealer.

A leak at the front of the transmission will be from

either the front bearing retainer or retainer seal. Lu-

bricant may be seen dripping from the clutch housing

after extended operation. If the leak is severe, it may

also contaminate the clutch disc causing slip, grab

and chatter.

Transmissions filled from air or electrically powered

lubricant containers can be underfilled. This generally

Fig. 2 Transmission Identification

Fig. 3 AX 4/5 Shift Pattern

Fig. 4 Fill Plug Location

21 - 2 AX 4/5 MANUAL TRANSMISSIONJ

Page 1380 of 2198

happens when the container delivery mechanism is im-

properly calibrated. Always check the lubricant level af-

ter filling to avoid an under fill condition.

A correct lubricant level check can only be made

when the vehicle is level; use a drive-on hoist to en-

sure this. Also allow the lubricant to settle for a

minute or so before checking. These recommenda-

tions will ensure an accurate check and avoid an un-

der-or-overfill condition.

HARD SHIFTING

Hard shifting is usually caused by a low lubricant

level, improper or contaminated lubricants, compo-

nent damage, incorrect clutch adjustment, or by a

damaged clutch pressure plate or disc.

Substantial lubricant leaks can result in gear, shift

rail, synchro and bearing damage. If a leak goes un-

detected for an extended period, the first indications

of a problem are usually hard shifting and noise.

Incorrect or contaminated lubricants can also con-

tribute to hard shifting. The consequence of using

non-recommended lubricants is noise, excessive wear,

internal bind and hard shifting.

Improper clutch release is a frequent cause of hard

shifting. Incorrect adjustment or a worn, damaged

pressure plate or disc can cause incorrect release. If

the clutch problem is advanced, gear clash during

shifts can result.

Worn or damaged synchro rings can cause gear clash

when shifting into any forward gear. In some new or re-

built transmissions, new synchro rings may tend to

stick slightly causing hard or noisy shifts. In most

cases, this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise dur-

ing normal operation. Rotating gears generate a mild

whine that is audible but only at extreme speeds.

Severe, highly audible transmission noise is gener-

ally the result of a lubricant problem. Insufficient,

improper, or contaminated lubricant will promote

rapid wear of gears, synchros, shift rails, forks and

bearings. The overheating caused by a lubricant

problem, can also lead to gear breakage.

TRANSMISSION REMOVAL

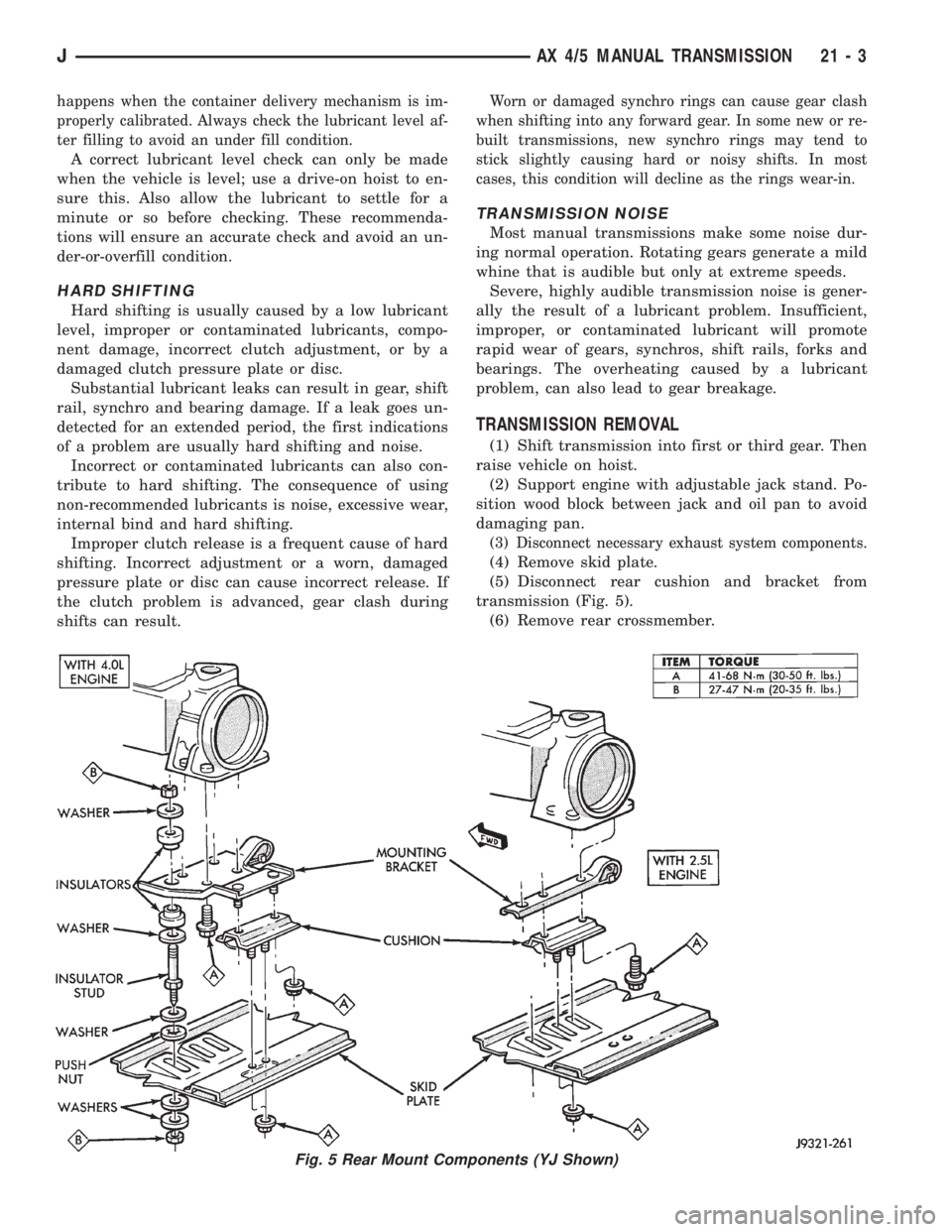

(1) Shift transmission into first or third gear. Then

raise vehicle on hoist.

(2) Support engine with adjustable jack stand. Po-

sition wood block between jack and oil pan to avoid

damaging pan.

(3) Disconnect necessary exhaust system components.

(4) Remove skid plate.

(5) Disconnect rear cushion and bracket from

transmission (Fig. 5).

(6) Remove rear crossmember.

Fig. 5 Rear Mount Components (YJ Shown)

JAX 4/5 MANUAL TRANSMISSION 21 - 3