JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1341 of 2198

(6) Lubricate the wormshaft threads with chassis

lubricant. Rotate the shaft to move it in and out of

the ball nut and distribute the lubricant.

(7) Lubricate the wormshaft upper bearing with

chassis lubricant and install it on the wormshaft.

WORMSHAFT BEARING ADJUSTMENT CAP

DISASSEMBLY

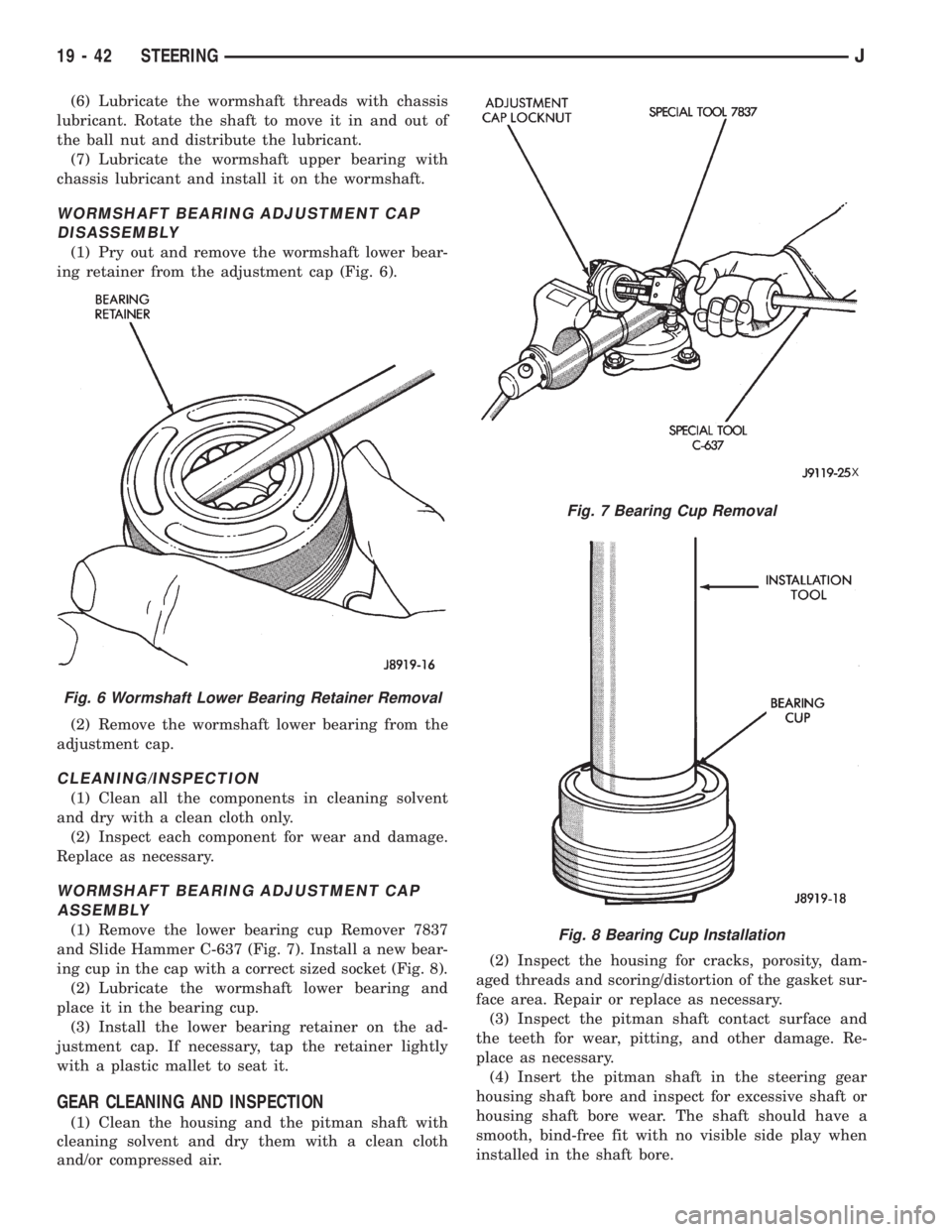

(1) Pry out and remove the wormshaft lower bear-

ing retainer from the adjustment cap (Fig. 6).

(2) Remove the wormshaft lower bearing from the

adjustment cap.

CLEANING/INSPECTION

(1) Clean all the components in cleaning solvent

and dry with a clean cloth only.

(2) Inspect each component for wear and damage.

Replace as necessary.

WORMSHAFT BEARING ADJUSTMENT CAP

ASSEMBLY

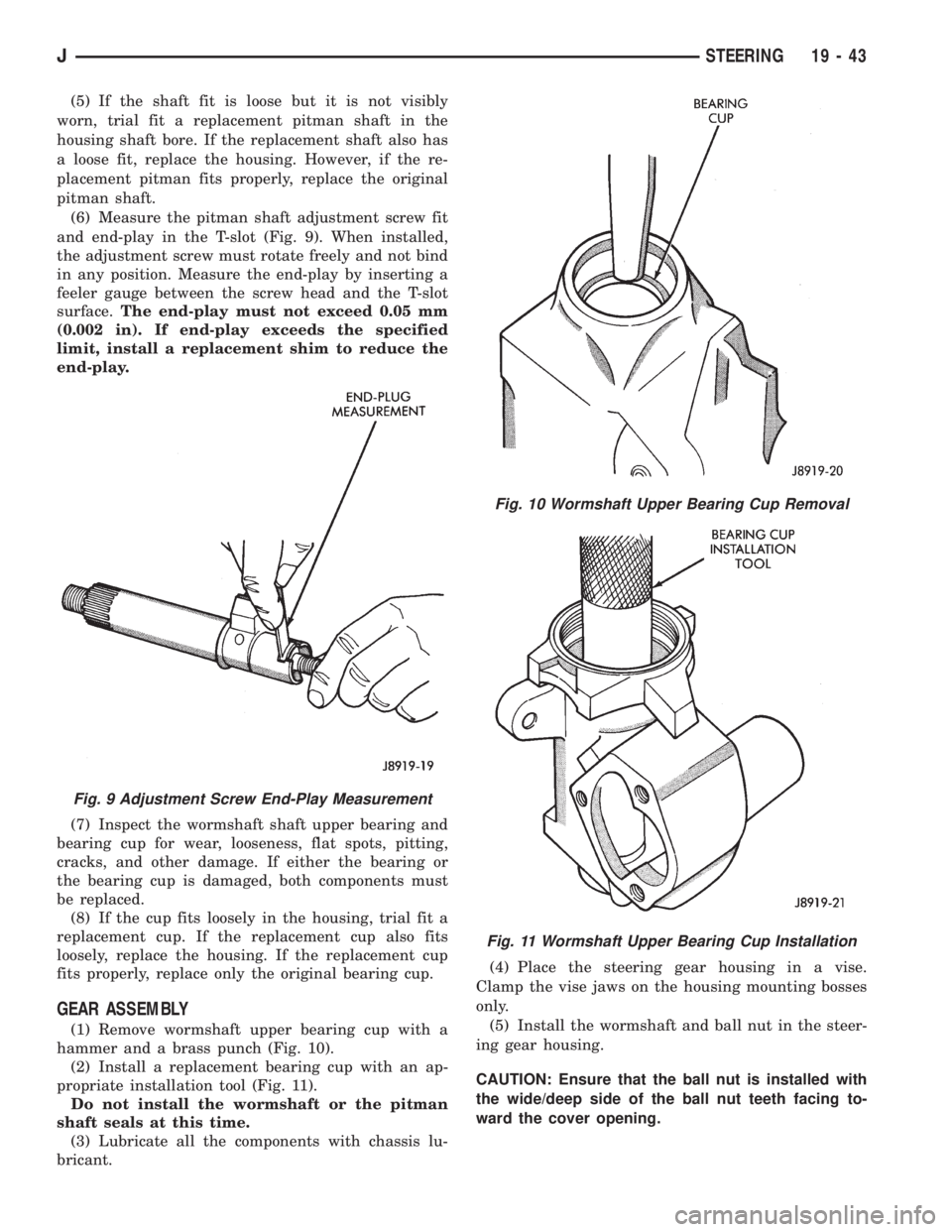

(1) Remove the lower bearing cup Remover 7837

and Slide Hammer C-637 (Fig. 7). Install a new bear-

ing cup in the cap with a correct sized socket (Fig. 8).

(2) Lubricate the wormshaft lower bearing and

place it in the bearing cup.

(3) Install the lower bearing retainer on the ad-

justment cap. If necessary, tap the retainer lightly

with a plastic mallet to seat it.

GEAR CLEANING AND INSPECTION

(1) Clean the housing and the pitman shaft with

cleaning solvent and dry them with a clean cloth

and/or compressed air.(2) Inspect the housing for cracks, porosity, dam-

aged threads and scoring/distortion of the gasket sur-

face area. Repair or replace as necessary.

(3) Inspect the pitman shaft contact surface and

the teeth for wear, pitting, and other damage. Re-

place as necessary.

(4) Insert the pitman shaft in the steering gear

housing shaft bore and inspect for excessive shaft or

housing shaft bore wear. The shaft should have a

smooth, bind-free fit with no visible side play when

installed in the shaft bore.

Fig. 6 Wormshaft Lower Bearing Retainer Removal

Fig. 7 Bearing Cup Removal

X

Fig. 8 Bearing Cup Installation

19 - 42 STEERINGJ

Page 1342 of 2198

(5) If the shaft fit is loose but it is not visibly

worn, trial fit a replacement pitman shaft in the

housing shaft bore. If the replacement shaft also has

a loose fit, replace the housing. However, if the re-

placement pitman fits properly, replace the original

pitman shaft.

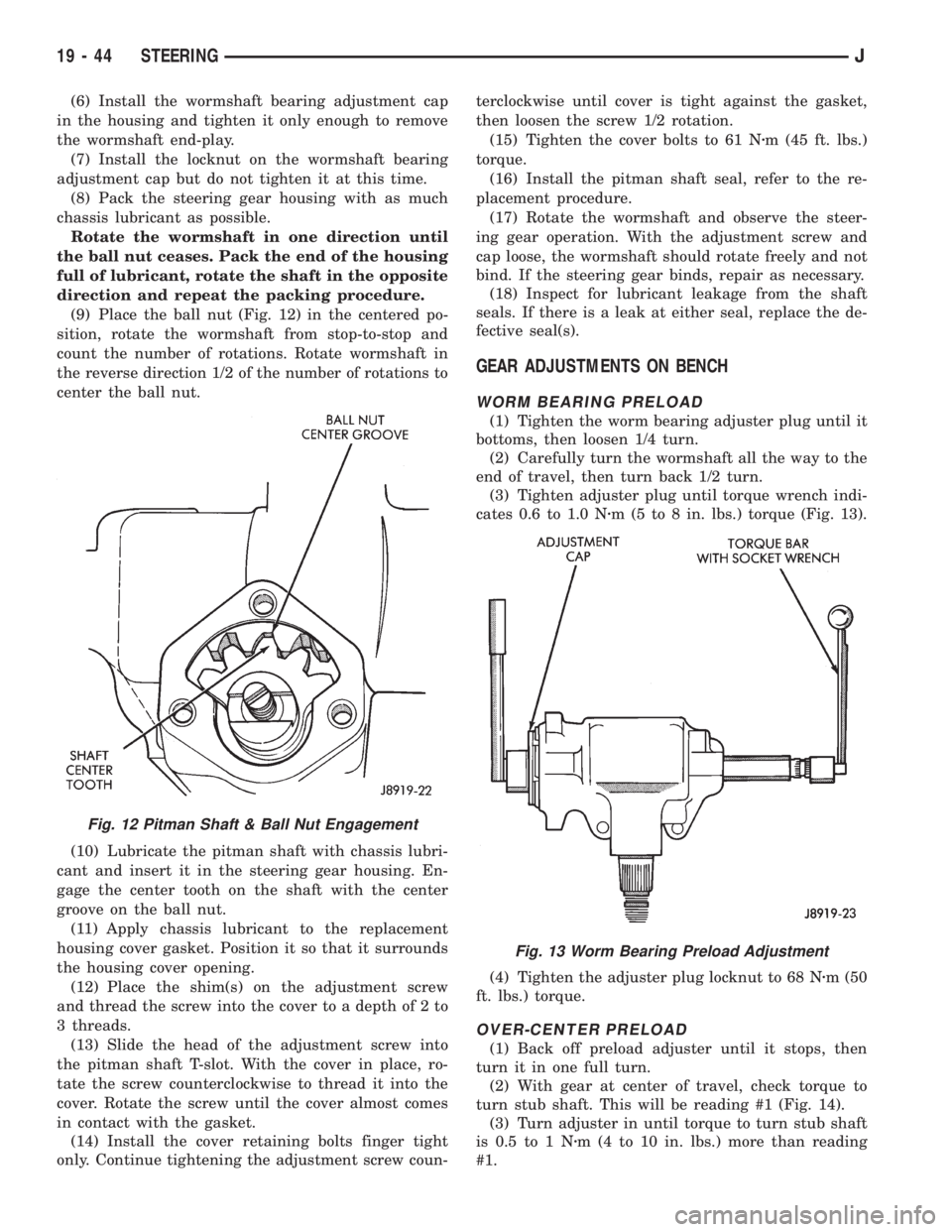

(6) Measure the pitman shaft adjustment screw fit

and end-play in the T-slot (Fig. 9). When installed,

the adjustment screw must rotate freely and not bind

in any position. Measure the end-play by inserting a

feeler gauge between the screw head and the T-slot

surface.The end-play must not exceed 0.05 mm

(0.002 in). If end-play exceeds the specified

limit, install a replacement shim to reduce the

end-play.

(7) Inspect the wormshaft shaft upper bearing and

bearing cup for wear, looseness, flat spots, pitting,

cracks, and other damage. If either the bearing or

the bearing cup is damaged, both components must

be replaced.

(8) If the cup fits loosely in the housing, trial fit a

replacement cup. If the replacement cup also fits

loosely, replace the housing. If the replacement cup

fits properly, replace only the original bearing cup.

GEAR ASSEMBLY

(1) Remove wormshaft upper bearing cup with a

hammer and a brass punch (Fig. 10).

(2) Install a replacement bearing cup with an ap-

propriate installation tool (Fig. 11).

Do not install the wormshaft or the pitman

shaft seals at this time.

(3) Lubricate all the components with chassis lu-

bricant.(4) Place the steering gear housing in a vise.

Clamp the vise jaws on the housing mounting bosses

only.

(5) Install the wormshaft and ball nut in the steer-

ing gear housing.

CAUTION: Ensure that the ball nut is installed with

the wide/deep side of the ball nut teeth facing to-

ward the cover opening.

Fig. 9 Adjustment Screw End-Play Measurement

Fig. 10 Wormshaft Upper Bearing Cup Removal

Fig. 11 Wormshaft Upper Bearing Cup Installation

JSTEERING 19 - 43

Page 1343 of 2198

(6) Install the wormshaft bearing adjustment cap

in the housing and tighten it only enough to remove

the wormshaft end-play.

(7) Install the locknut on the wormshaft bearing

adjustment cap but do not tighten it at this time.

(8) Pack the steering gear housing with as much

chassis lubricant as possible.

Rotate the wormshaft in one direction until

the ball nut ceases. Pack the end of the housing

full of lubricant, rotate the shaft in the opposite

direction and repeat the packing procedure.

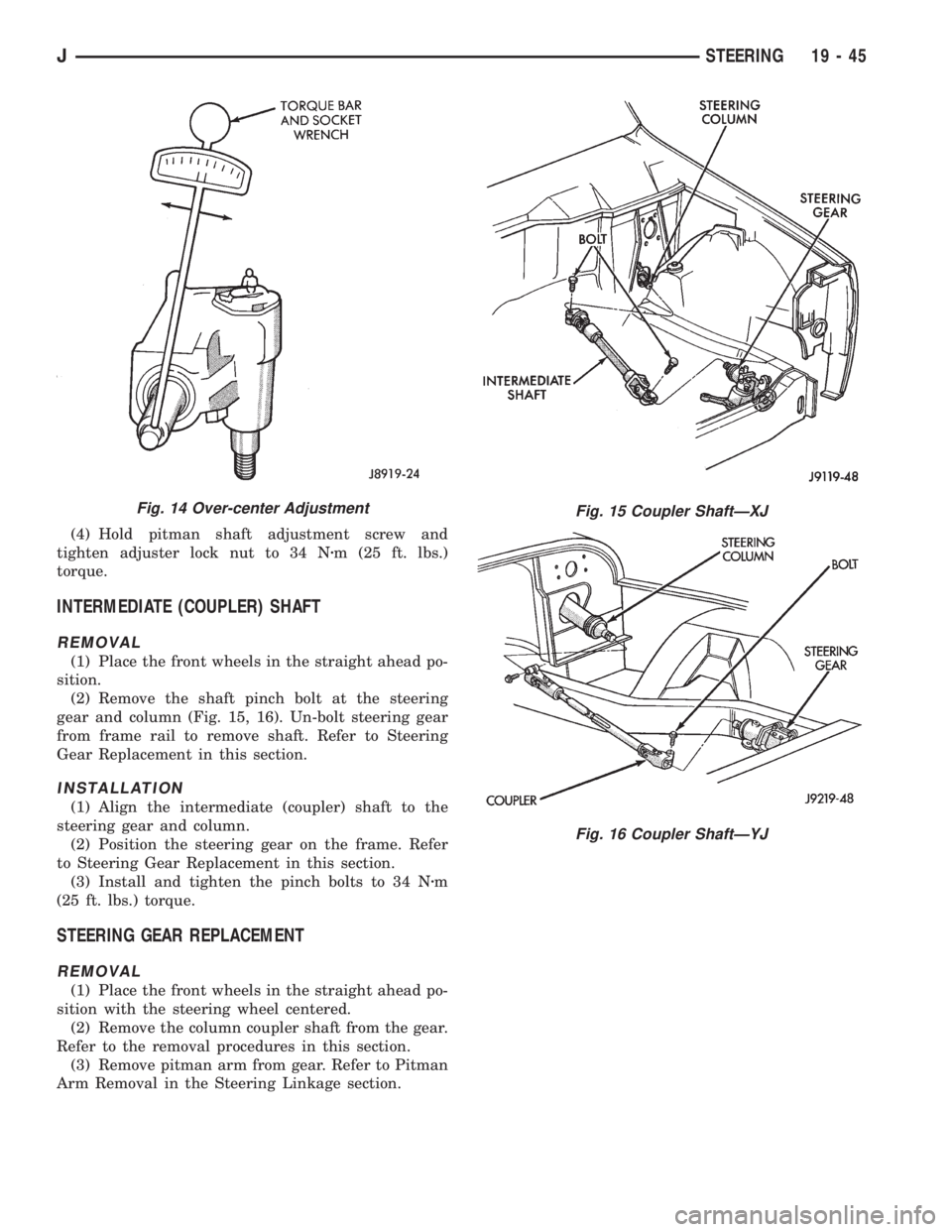

(9) Place the ball nut (Fig. 12) in the centered po-

sition, rotate the wormshaft from stop-to-stop and

count the number of rotations. Rotate wormshaft in

the reverse direction 1/2 of the number of rotations to

center the ball nut.

(10) Lubricate the pitman shaft with chassis lubri-

cant and insert it in the steering gear housing. En-

gage the center tooth on the shaft with the center

groove on the ball nut.

(11) Apply chassis lubricant to the replacement

housing cover gasket. Position it so that it surrounds

the housing cover opening.

(12) Place the shim(s) on the adjustment screw

and thread the screw into the cover to a depth of 2 to

3 threads.

(13) Slide the head of the adjustment screw into

the pitman shaft T-slot. With the cover in place, ro-

tate the screw counterclockwise to thread it into the

cover. Rotate the screw until the cover almost comes

in contact with the gasket.

(14) Install the cover retaining bolts finger tight

only. Continue tightening the adjustment screw coun-terclockwise until cover is tight against the gasket,

then loosen the screw 1/2 rotation.

(15) Tighten the cover bolts to 61 Nzm (45 ft. lbs.)

torque.

(16) Install the pitman shaft seal, refer to the re-

placement procedure.

(17) Rotate the wormshaft and observe the steer-

ing gear operation. With the adjustment screw and

cap loose, the wormshaft should rotate freely and not

bind. If the steering gear binds, repair as necessary.

(18) Inspect for lubricant leakage from the shaft

seals. If there is a leak at either seal, replace the de-

fective seal(s).

GEAR ADJUSTMENTS ON BENCH

WORM BEARING PRELOAD

(1) Tighten the worm bearing adjuster plug until it

bottoms, then loosen 1/4 turn.

(2) Carefully turn the wormshaft all the way to the

end of travel, then turn back 1/2 turn.

(3) Tighten adjuster plug until torque wrench indi-

cates 0.6 to 1.0 Nzm (5 to 8 in. lbs.) torque (Fig. 13).

(4) Tighten the adjuster plug locknut to 68 Nzm (50

ft. lbs.) torque.

OVER-CENTER PRELOAD

(1) Back off preload adjuster until it stops, then

turn it in one full turn.

(2) With gear at center of travel, check torque to

turn stub shaft. This will be reading #1 (Fig. 14).

(3) Turn adjuster in until torque to turn stub shaft

is 0.5 to 1 Nzm (4 to 10 in. lbs.) more than reading

#1.

Fig. 12 Pitman Shaft & Ball Nut Engagement

Fig. 13 Worm Bearing Preload Adjustment

19 - 44 STEERINGJ

Page 1344 of 2198

(4) Hold pitman shaft adjustment screw and

tighten adjuster lock nut to 34 Nzm (25 ft. lbs.)

torque.

INTERMEDIATE (COUPLER) SHAFT

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition.

(2) Remove the shaft pinch bolt at the steering

gear and column (Fig. 15, 16). Un-bolt steering gear

from frame rail to remove shaft. Refer to Steering

Gear Replacement in this section.

INSTALLATION

(1) Align the intermediate (coupler) shaft to the

steering gear and column.

(2) Position the steering gear on the frame. Refer

to Steering Gear Replacement in this section.

(3) Install and tighten the pinch bolts to 34 Nzm

(25 ft. lbs.) torque.

STEERING GEAR REPLACEMENT

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition with the steering wheel centered.

(2) Remove the column coupler shaft from the gear.

Refer to the removal procedures in this section.

(3) Remove pitman arm from gear. Refer to Pitman

Arm Removal in the Steering Linkage section.

Fig. 14 Over-center AdjustmentFig. 15 Coupler ShaftÐXJ

Fig. 16 Coupler ShaftÐYJ

JSTEERING 19 - 45

Page 1345 of 2198

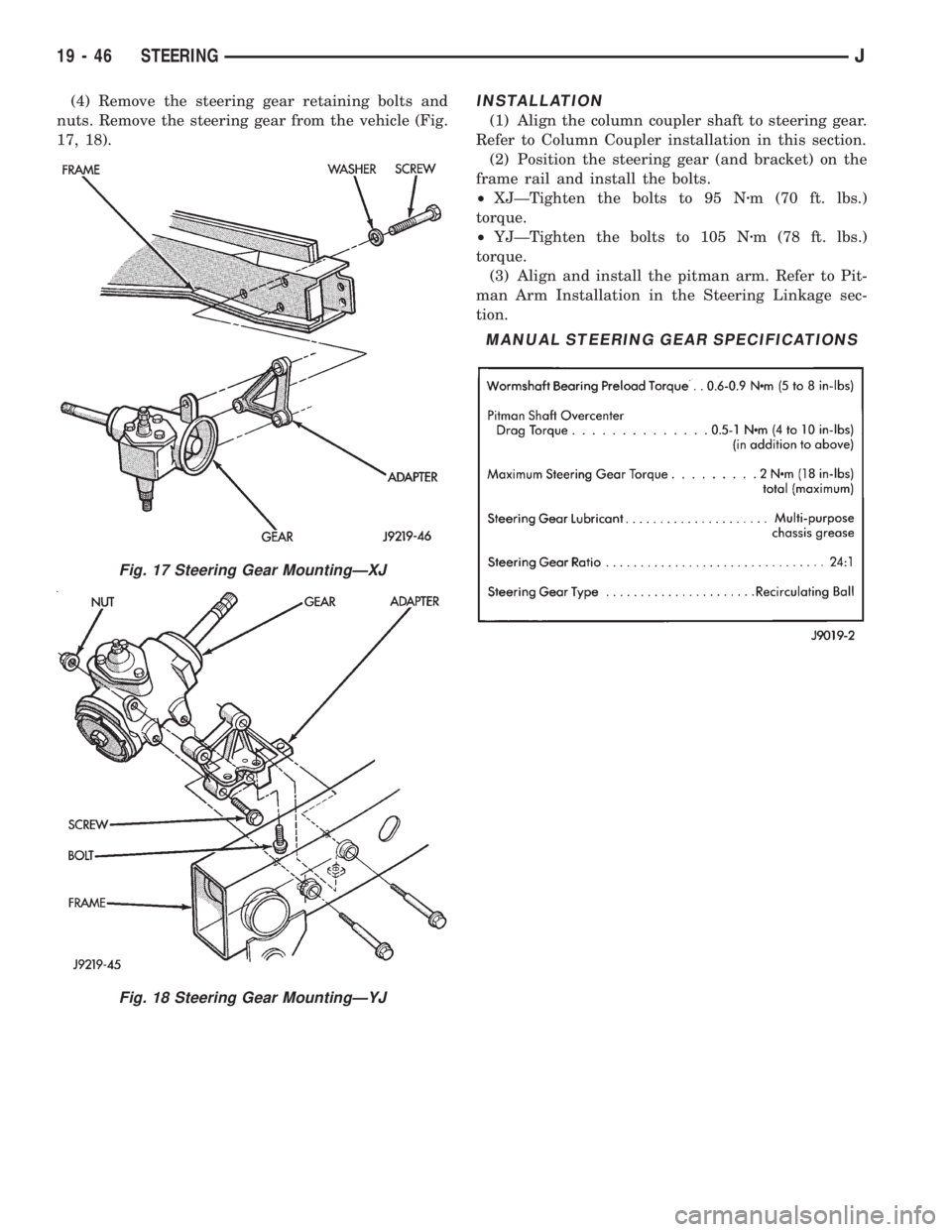

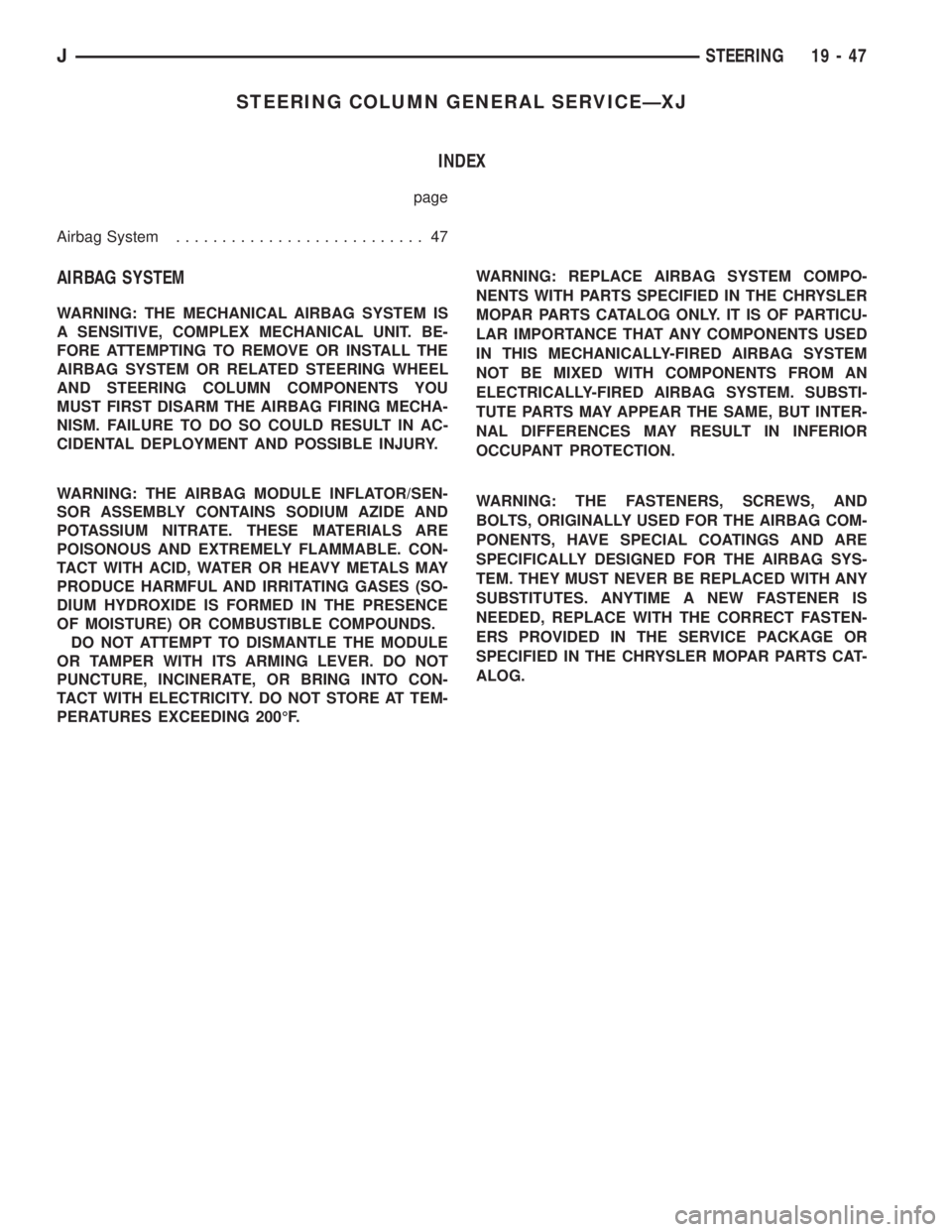

(4) Remove the steering gear retaining bolts and

nuts. Remove the steering gear from the vehicle (Fig.

17, 18).INSTALLATION

(1) Align the column coupler shaft to steering gear.

Refer to Column Coupler installation in this section.

(2) Position the steering gear (and bracket) on the

frame rail and install the bolts.

²XJÐTighten the bolts to 95 Nzm (70 ft. lbs.)

torque.

²YJÐTighten the bolts to 105 Nzm (78 ft. lbs.)

torque.

(3) Align and install the pitman arm. Refer to Pit-

man Arm Installation in the Steering Linkage sec-

tion.

Fig. 17 Steering Gear MountingÐXJ

Fig. 18 Steering Gear MountingÐYJ

MANUAL STEERING GEAR SPECIFICATIONS

19 - 46 STEERINGJ

Page 1346 of 2198

STEERING COLUMN GENERAL SERVICEÐXJ

INDEX

page

Airbag System........................... 47

AIRBAG SYSTEM

WARNING: THE MECHANICAL AIRBAG SYSTEM IS

A SENSITIVE, COMPLEX MECHANICAL UNIT. BE-

FORE ATTEMPTING TO REMOVE OR INSTALL THE

AIRBAG SYSTEM OR RELATED STEERING WHEEL

AND STEERING COLUMN COMPONENTS YOU

MUST FIRST DISARM THE AIRBAG FIRING MECHA-

NISM. FAILURE TO DO SO COULD RESULT IN AC-

CIDENTAL DEPLOYMENT AND POSSIBLE INJURY.

WARNING: THE AIRBAG MODULE INFLATOR/SEN-

SOR ASSEMBLY CONTAINS SODIUM AZIDE AND

POTASSIUM NITRATE. THESE MATERIALS ARE

POISONOUS AND EXTREMELY FLAMMABLE. CON-

TACT WITH ACID, WATER OR HEAVY METALS MAY

PRODUCE HARMFUL AND IRRITATING GASES (SO-

DIUM HYDROXIDE IS FORMED IN THE PRESENCE

OF MOISTURE) OR COMBUSTIBLE COMPOUNDS.

DO NOT ATTEMPT TO DISMANTLE THE MODULE

OR TAMPER WITH ITS ARMING LEVER. DO NOT

PUNCTURE, INCINERATE, OR BRING INTO CON-

TACT WITH ELECTRICITY. DO NOT STORE AT TEM-

PERATURES EXCEEDING 200ÉF.WARNING: REPLACE AIRBAG SYSTEM COMPO-

NENTS WITH PARTS SPECIFIED IN THE CHRYSLER

MOPAR PARTS CATALOG ONLY. IT IS OF PARTICU-

LAR IMPORTANCE THAT ANY COMPONENTS USED

IN THIS MECHANICALLY-FIRED AIRBAG SYSTEM

NOT BE MIXED WITH COMPONENTS FROM AN

ELECTRICALLY-FIRED AIRBAG SYSTEM. SUBSTI-

TUTE PARTS MAY APPEAR THE SAME, BUT INTER-

NAL DIFFERENCES MAY RESULT IN INFERIOR

OCCUPANT PROTECTION.

WARNING: THE FASTENERS, SCREWS, AND

BOLTS, ORIGINALLY USED FOR THE AIRBAG COM-

PONENTS, HAVE SPECIAL COATINGS AND ARE

SPECIFICALLY DESIGNED FOR THE AIRBAG SYS-

TEM. THEY MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANYTIME A NEW FASTENER IS

NEEDED, REPLACE WITH THE CORRECT FASTEN-

ERS PROVIDED IN THE SERVICE PACKAGE OR

SPECIFIED IN THE CHRYSLER MOPAR PARTS CAT-

ALOG.

JSTEERING 19 - 47

Page 1347 of 2198

GENERAL INFORMATION

The airbag system is a standard equipment safety

device on XJ (Cherokee) models. It is designed to pro-

tect the driver from serious injury, caused by a fron-

tal impact of the vehicle. If the airbag module

assembly is defective and non-deployed, refer to

Chrysler Corporation current return list for proper

handling procedures.

ARMING/DISARMING MECHANISM

BEFORE SERVICING A COLUMN EQUIPPED

WITH AIR BAG, REFER TO GROUP 8M, ELEC-

TRICAL FOR PROPER AND SAFE PROCE-

DURES.

The steering wheel hub incorporates an airbag

Arming/Disarming mechanism and a specially de-

signed nut-blocker. The nut-blocker serves as a safety

to prevent removal of the airbag module until the

unit has been disarmed. A removable plastic cover

plug on the top, outer hub of the steering wheel al-

lows access to the arming screw.

When the airbag module is disarmed, the arming

screw extends upward from the steering wheel hub.

This will prevent installation of the plastic cover

plug. Also, the nut-blocker is retracted to allow ac-

cess to the two upper airbag module mounting nuts.

When the airbag module is armed, the plastic cover

plug will install flush with the outer surface of the

steering wheel hub. In addition, the nut-blocker will

prevent access to the two upper airbag module

mounting nuts.THE FASTENERS, SCREWS, AND BOLTS, ORIG-

INALLY USED FOR THE AIR BAG COMPONENTS,

HAVE SPECIAL COATINGS. THIS HARDWARE IS

SPECIFICALLY DESIGNED FOR THE AIR BAG

SYSTEM. THEY MUST NEVER BE REPLACED

WITH ANY SUBSTITUTES. REPLACE WITH THE

CORRECT FASTENERS PROVIDED IN THE SER-

VICE PACKAGE OR FASTENERS IN THE PARTS

BOOK.

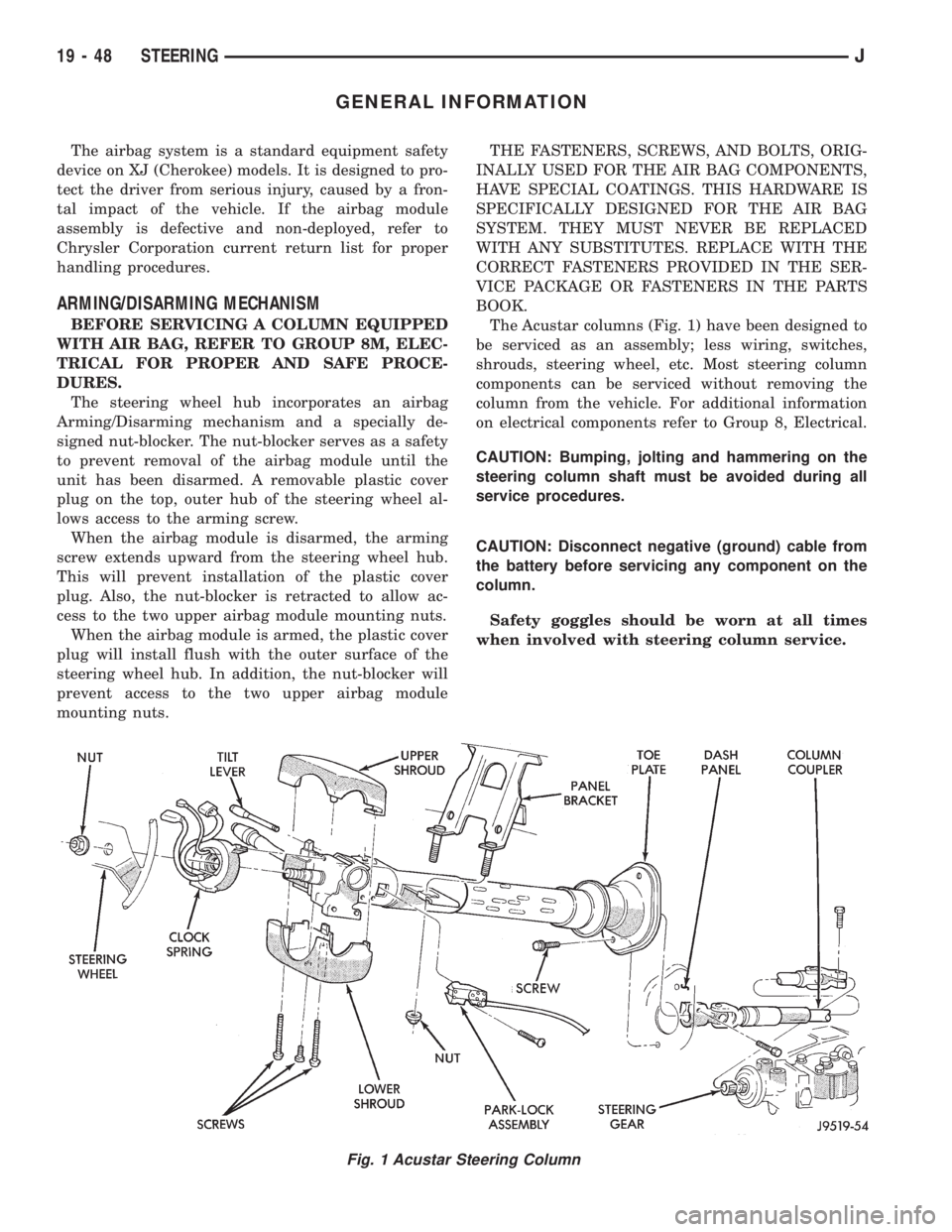

The Acustar columns (Fig. 1) have been designed to

be serviced as an assembly; less wiring, switches,

shrouds, steering wheel, etc. Most steering column

components can be serviced without removing the

column from the vehicle. For additional information

on electrical components refer to Group 8, Electrical.

CAUTION: Bumping, jolting and hammering on the

steering column shaft must be avoided during all

service procedures.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any component on the

column.

Safety goggles should be worn at all times

when involved with steering column service.

Fig. 1 Acustar Steering Column

19 - 48 STEERINGJ

Page 1348 of 2198

AIRBAG MODULE REMOVEÐINSTALL

WARNING: THIS AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX MECHANICAL UNIT. BEFORE ATTEMPT-

ING TO REMOVE OR INSTALL THE AIRBAG SYS-

TEM OR RELATED STEERING WHEEL AND

STEERING COLUMN COMPONENTS YOU MUST

FIRST DISARM THE AIRBAG FIRING MECHANISM.

FAILURE TO DO SO COULD RESULT IN ACCIDEN-

TAL DEPLOYMENT AND POSSIBLE PERSONAL IN-

JURY.

When removing a deployed airbag module,

rubber gloves, eye protection and long-sleeved

shirt should be worn. There may be deposits on

the airbag module and other interior surfaces,

which can cause irritation to the skin and eyes

in large doses.

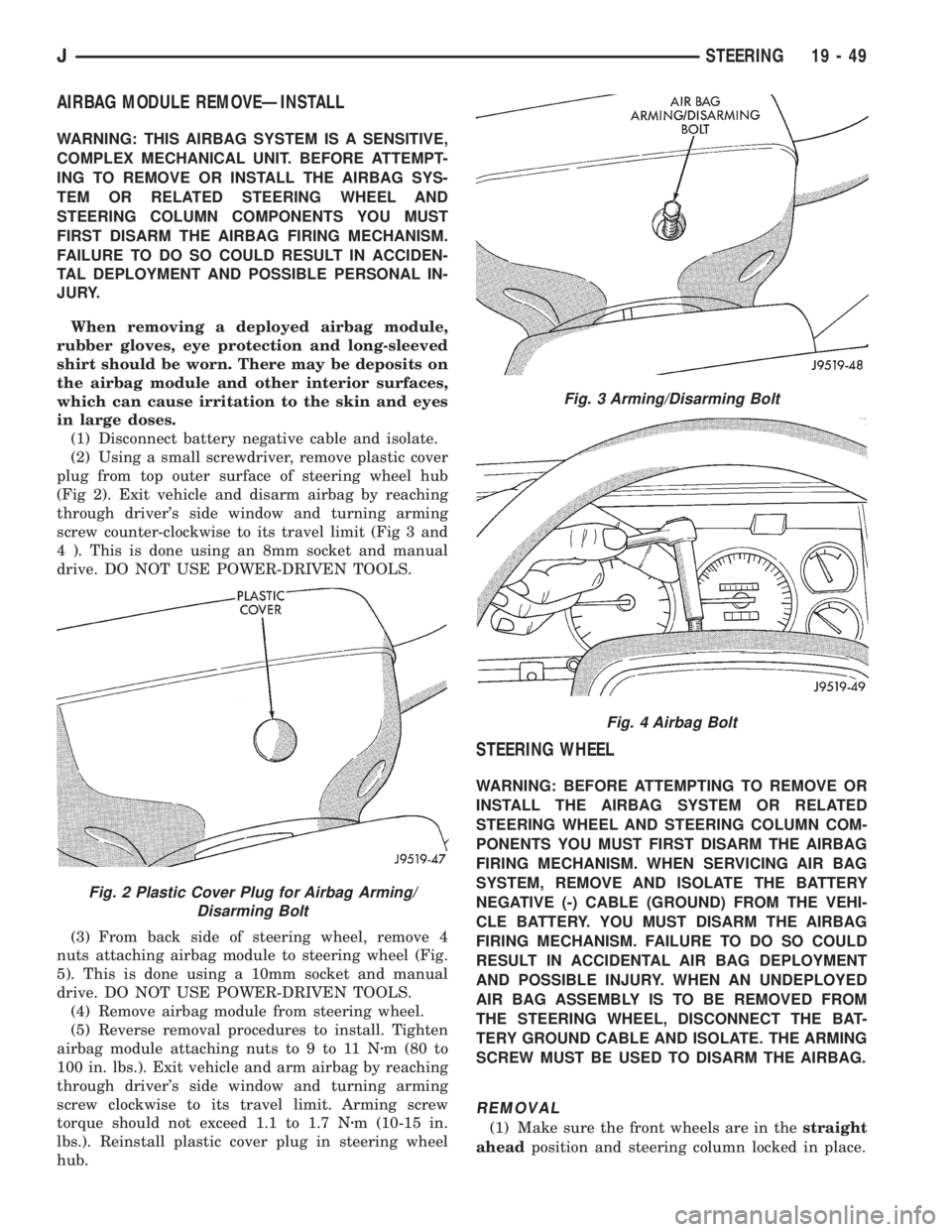

(1) Disconnect battery negative cable and isolate.

(2) Using a small screwdriver, remove plastic cover

plug from top outer surface of steering wheel hub

(Fig 2). Exit vehicle and disarm airbag by reaching

through driver's side window and turning arming

screw counter-clockwise to its travel limit (Fig 3 and

4 ). This is done using an 8mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

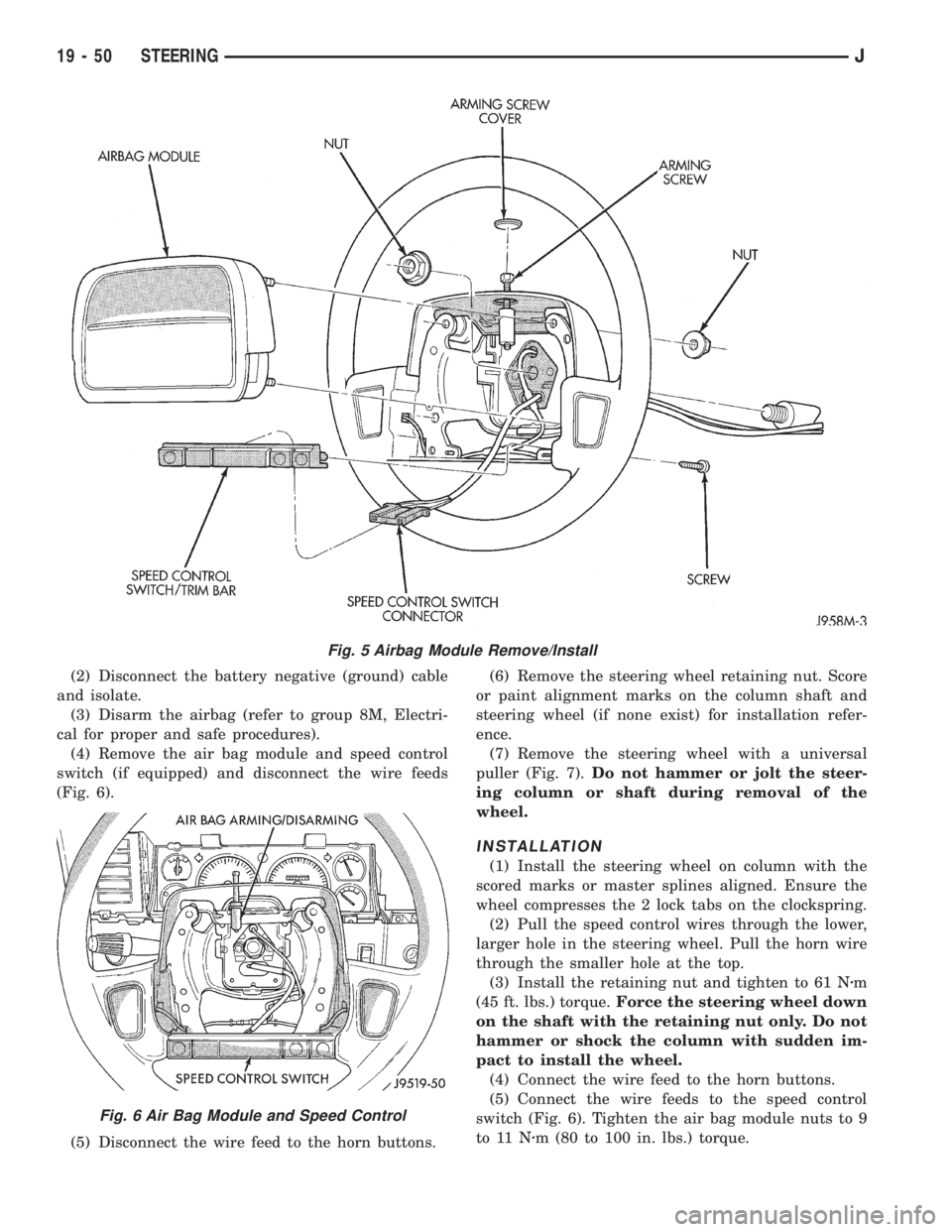

(3) From back side of steering wheel, remove 4

nuts attaching airbag module to steering wheel (Fig.

5). This is done using a 10mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

(4) Remove airbag module from steering wheel.

(5) Reverse removal procedures to install. Tighten

airbag module attaching nuts to 9 to 11 Nzm (80 to

100 in. lbs.). Exit vehicle and arm airbag by reaching

through driver's side window and turning arming

screw clockwise to its travel limit. Arming screw

torque should not exceed 1.1 to 1.7 Nzm (10-15 in.

lbs.). Reinstall plastic cover plug in steering wheel

hub.

STEERING WHEEL

WARNING: BEFORE ATTEMPTING TO REMOVE OR

INSTALL THE AIRBAG SYSTEM OR RELATED

STEERING WHEEL AND STEERING COLUMN COM-

PONENTS YOU MUST FIRST DISARM THE AIRBAG

FIRING MECHANISM. WHEN SERVICING AIR BAG

SYSTEM, REMOVE AND ISOLATE THE BATTERY

NEGATIVE (-) CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. YOU MUST DISARM THE AIRBAG

FIRING MECHANISM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIR BAG DEPLOYMENT

AND POSSIBLE INJURY. WHEN AN UNDEPLOYED

AIR BAG ASSEMBLY IS TO BE REMOVED FROM

THE STEERING WHEEL, DISCONNECT THE BAT-

TERY GROUND CABLE AND ISOLATE. THE ARMING

SCREW MUST BE USED TO DISARM THE AIRBAG.

REMOVAL

(1) Make sure the front wheels are in thestraight

aheadposition and steering column locked in place.

Fig. 2 Plastic Cover Plug for Airbag Arming/

Disarming Bolt

Fig. 3 Arming/Disarming Bolt

Fig. 4 Airbag Bolt

JSTEERING 19 - 49

Page 1349 of 2198

(2) Disconnect the battery negative (ground) cable

and isolate.

(3) Disarm the airbag (refer to group 8M, Electri-

cal for proper and safe procedures).

(4) Remove the air bag module and speed control

switch (if equipped) and disconnect the wire feeds

(Fig. 6).

(5) Disconnect the wire feed to the horn buttons.(6) Remove the steering wheel retaining nut. Score

or paint alignment marks on the column shaft and

steering wheel (if none exist) for installation refer-

ence.

(7) Remove the steering wheel with a universal

puller (Fig. 7).Do not hammer or jolt the steer-

ing column or shaft during removal of the

wheel.

INSTALLATION

(1) Install the steering wheel on column with the

scored marks or master splines aligned. Ensure the

wheel compresses the 2 lock tabs on the clockspring.

(2) Pull the speed control wires through the lower,

larger hole in the steering wheel. Pull the horn wire

through the smaller hole at the top.

(3) Install the retaining nut and tighten to 61 Nzm

(45 ft. lbs.) torque.Force the steering wheel down

on the shaft with the retaining nut only. Do not

hammer or shock the column with sudden im-

pact to install the wheel.

(4) Connect the wire feed to the horn buttons.

(5) Connect the wire feeds to the speed control

switch (Fig. 6). Tighten the air bag module nuts to 9

to 11 Nzm (80 to 100 in. lbs.) torque.

Fig. 5 Airbag Module Remove/Install

Fig. 6 Air Bag Module and Speed Control

19 - 50 STEERINGJ

Page 1350 of 2198

CLOCKSPRING

WARNING: BEFORE SERVICING AIR BAG SYSTEM,

REMOVE AND ISOLATE BATTERY NEGATIVE (-) CA-

BLE (GROUND) FROM VEHICLE BATTERY. WHEN

AN UNDEPLOYED AIR BAG ASSEMBLY IS TO BE

REMOVED FROM THE STEERING WHEEL, DISCON-

NECT THE BATTERY GROUND CABLE AND ISO-

LATE.

REMOVAL

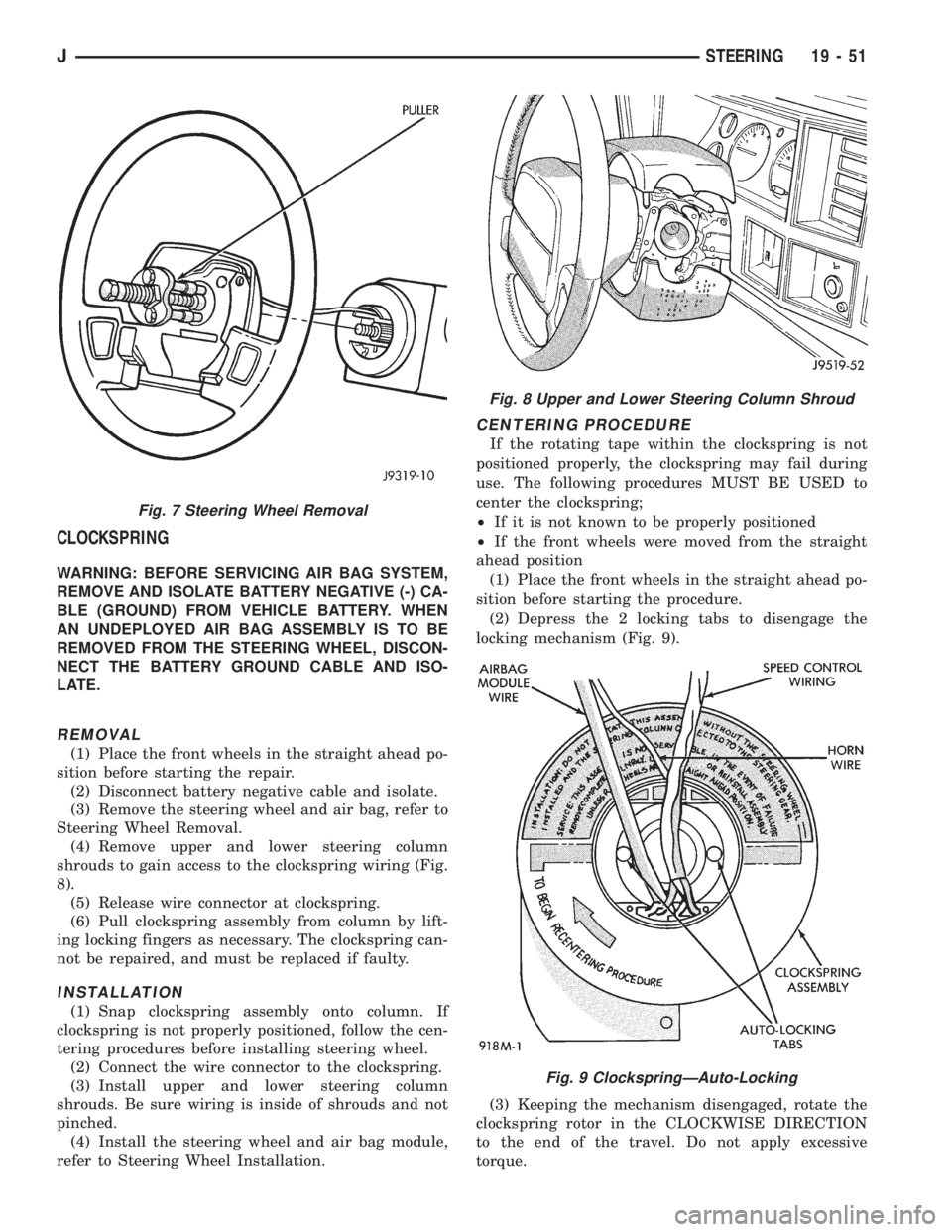

(1) Place the front wheels in the straight ahead po-

sition before starting the repair.

(2) Disconnect battery negative cable and isolate.

(3) Remove the steering wheel and air bag, refer to

Steering Wheel Removal.

(4) Remove upper and lower steering column

shrouds to gain access to the clockspring wiring (Fig.

8).

(5) Release wire connector at clockspring.

(6) Pull clockspring assembly from column by lift-

ing locking fingers as necessary. The clockspring can-

not be repaired, and must be replaced if faulty.

INSTALLATION

(1) Snap clockspring assembly onto column. If

clockspring is not properly positioned, follow the cen-

tering procedures before installing steering wheel.

(2) Connect the wire connector to the clockspring.

(3) Install upper and lower steering column

shrouds. Be sure wiring is inside of shrouds and not

pinched.

(4) Install the steering wheel and air bag module,

refer to Steering Wheel Installation.

CENTERING PROCEDURE

If the rotating tape within the clockspring is not

positioned properly, the clockspring may fail during

use. The following procedures MUST BE USED to

center the clockspring;

²If it is not known to be properly positioned

²If the front wheels were moved from the straight

ahead position

(1) Place the front wheels in the straight ahead po-

sition before starting the procedure.

(2) Depress the 2 locking tabs to disengage the

locking mechanism (Fig. 9).

(3) Keeping the mechanism disengaged, rotate the

clockspring rotor in the CLOCKWISE DIRECTION

to the end of the travel. Do not apply excessive

torque.

Fig. 7 Steering Wheel Removal

Fig. 8 Upper and Lower Steering Column Shroud

Fig. 9 ClockspringÐAuto-Locking

JSTEERING 19 - 51