JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1421 of 2198

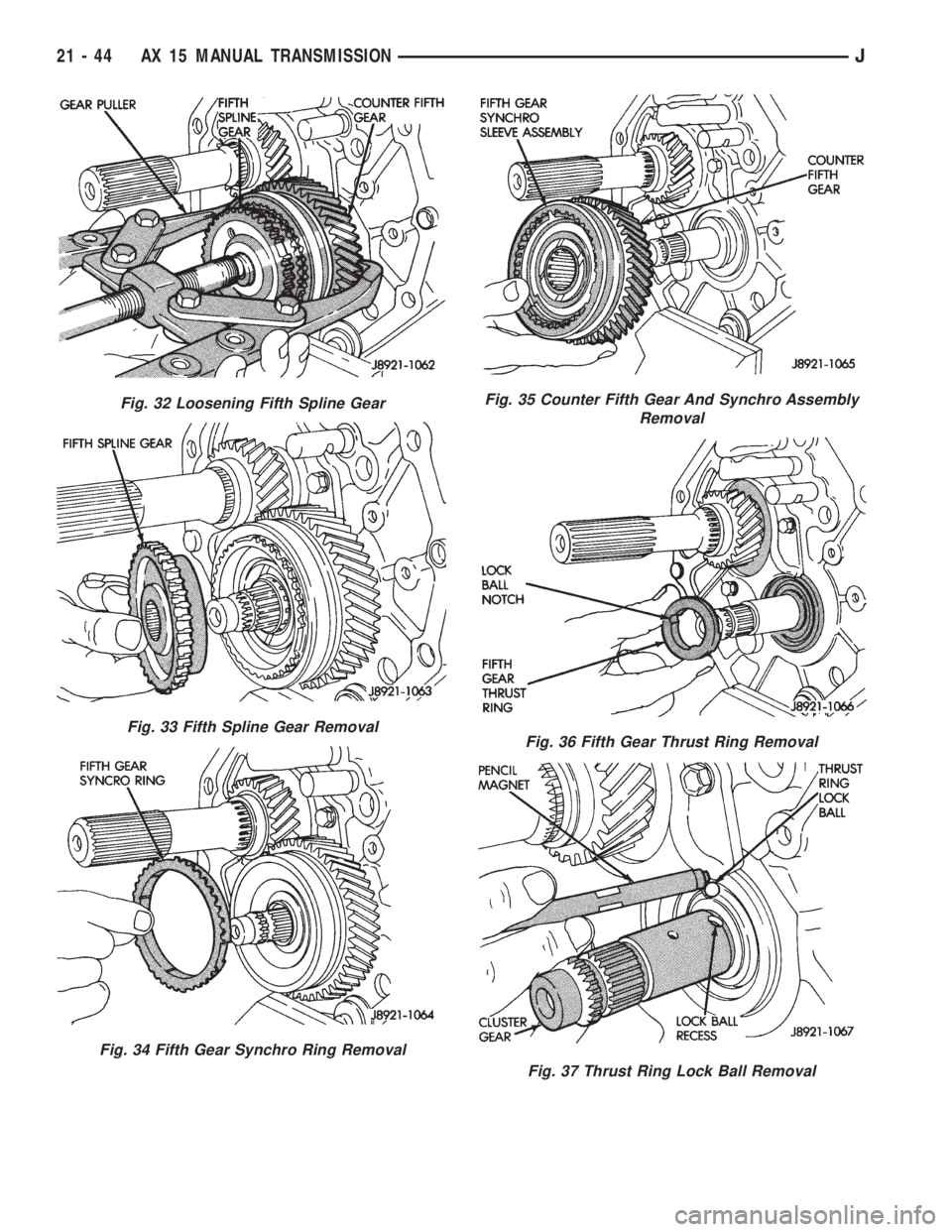

Fig. 32 Loosening Fifth Spline Gear

Fig. 33 Fifth Spline Gear Removal

Fig. 34 Fifth Gear Synchro Ring Removal

Fig. 35 Counter Fifth Gear And Synchro Assembly

Removal

Fig. 36 Fifth Gear Thrust Ring Removal

Fig. 37 Thrust Ring Lock Ball Removal

21 - 44 AX 15 MANUAL TRANSMISSIONJ

Page 1422 of 2198

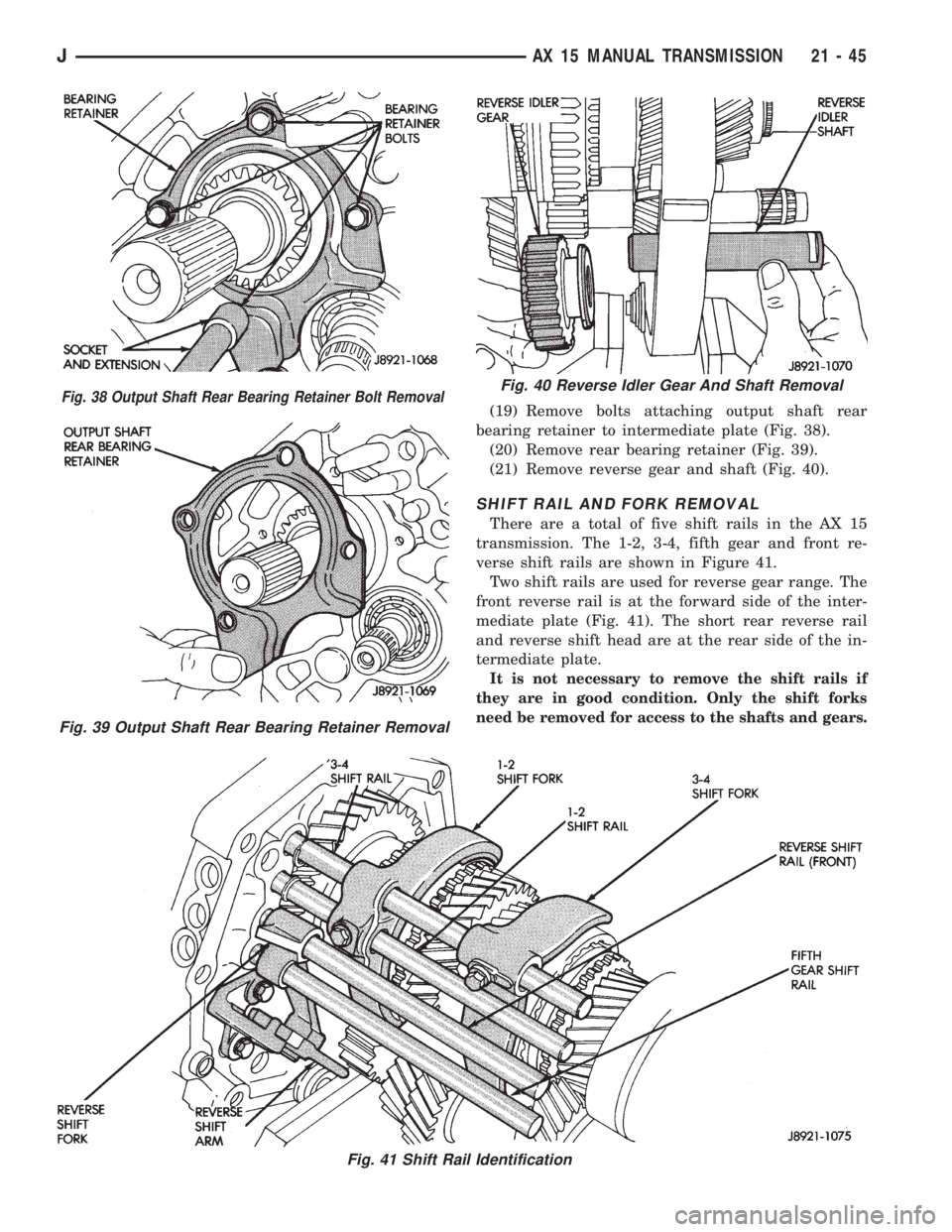

(19) Remove bolts attaching output shaft rear

bearing retainer to intermediate plate (Fig. 38).

(20) Remove rear bearing retainer (Fig. 39).

(21) Remove reverse gear and shaft (Fig. 40).

SHIFT RAIL AND FORK REMOVAL

There are a total of five shift rails in the AX 15

transmission. The 1-2, 3-4, fifth gear and front re-

verse shift rails are shown in Figure 41.

Two shift rails are used for reverse gear range. The

front reverse rail is at the forward side of the inter-

mediate plate (Fig. 41). The short rear reverse rail

and reverse shift head are at the rear side of the in-

termediate plate.

It is not necessary to remove the shift rails if

they are in good condition. Only the shift forks

need be removed for access to the shafts and gears.

Fig. 38 Output Shaft Rear Bearing Retainer Bolt Removal

Fig. 39 Output Shaft Rear Bearing Retainer Removal

Fig. 40 Reverse Idler Gear And Shaft Removal

Fig. 41 Shift Rail Identification

JAX 15 MANUAL TRANSMISSION 21 - 45

Page 1423 of 2198

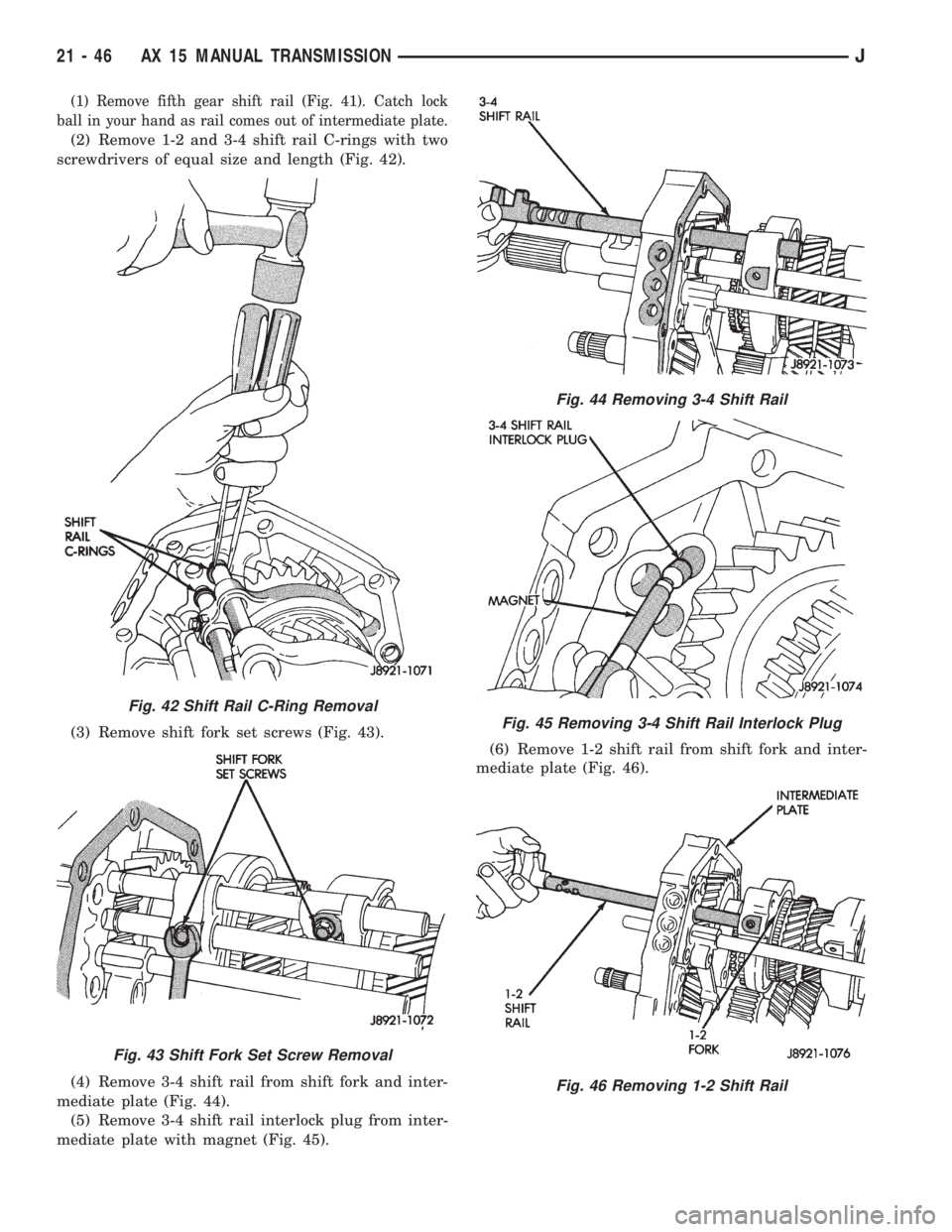

(1) Remove fifth gear shift rail (Fig. 41). Catch lock

ball in your hand as rail comes out of intermediate plate.

(2) Remove 1-2 and 3-4 shift rail C-rings with two

screwdrivers of equal size and length (Fig. 42).

(3) Remove shift fork set screws (Fig. 43).

(4) Remove 3-4 shift rail from shift fork and inter-

mediate plate (Fig. 44).

(5) Remove 3-4 shift rail interlock plug from inter-

mediate plate with magnet (Fig. 45).(6) Remove 1-2 shift rail from shift fork and inter-

mediate plate (Fig. 46).

Fig. 42 Shift Rail C-Ring Removal

Fig. 43 Shift Fork Set Screw Removal

Fig. 44 Removing 3-4 Shift Rail

Fig. 45 Removing 3-4 Shift Rail Interlock Plug

Fig. 46 Removing 1-2 Shift Rail

21 - 46 AX 15 MANUAL TRANSMISSIONJ

Page 1424 of 2198

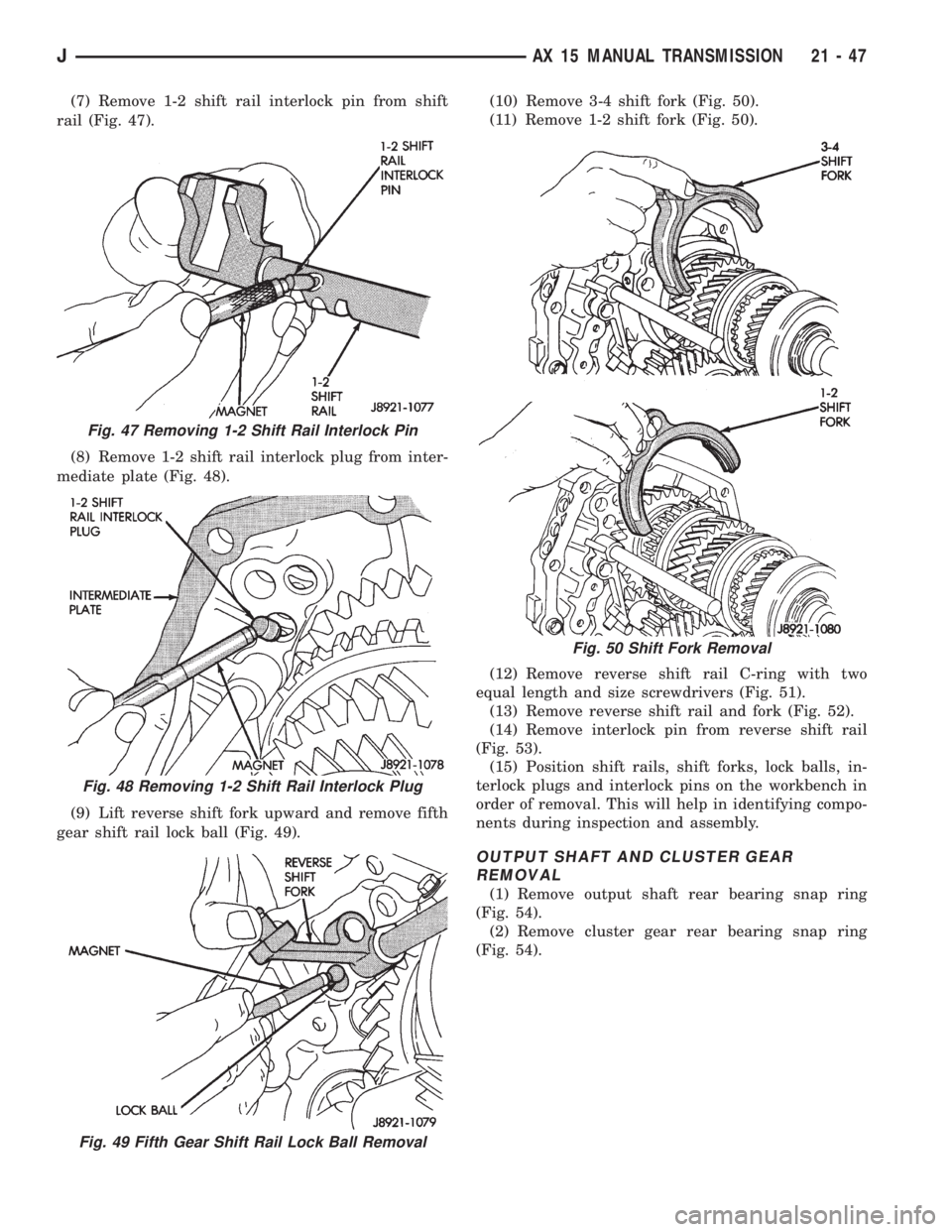

(7) Remove 1-2 shift rail interlock pin from shift

rail (Fig. 47).

(8) Remove 1-2 shift rail interlock plug from inter-

mediate plate (Fig. 48).

(9) Lift reverse shift fork upward and remove fifth

gear shift rail lock ball (Fig. 49).(10) Remove 3-4 shift fork (Fig. 50).

(11) Remove 1-2 shift fork (Fig. 50).

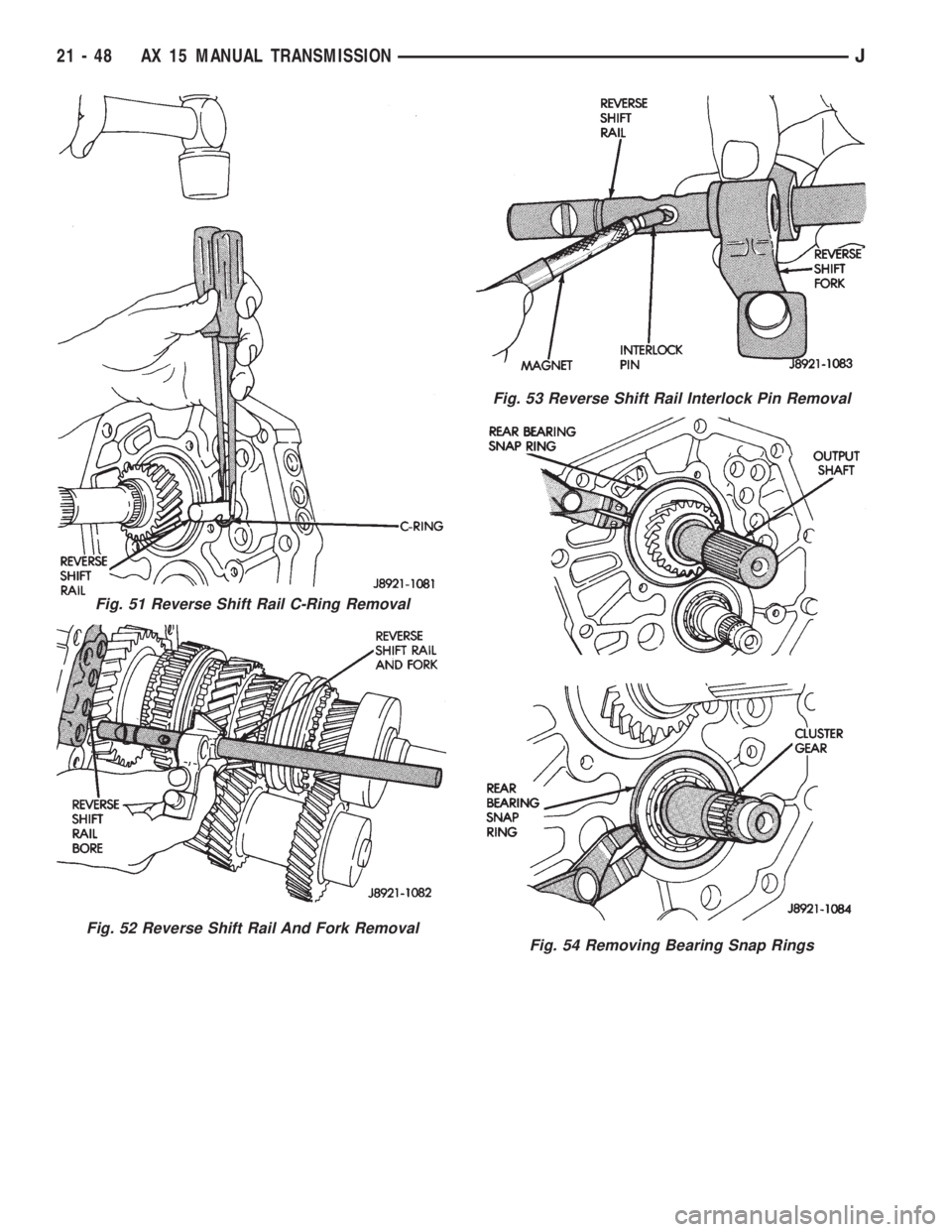

(12) Remove reverse shift rail C-ring with two

equal length and size screwdrivers (Fig. 51).

(13) Remove reverse shift rail and fork (Fig. 52).

(14) Remove interlock pin from reverse shift rail

(Fig. 53).

(15) Position shift rails, shift forks, lock balls, in-

terlock plugs and interlock pins on the workbench in

order of removal. This will help in identifying compo-

nents during inspection and assembly.

OUTPUT SHAFT AND CLUSTER GEAR

REMOVAL

(1) Remove output shaft rear bearing snap ring

(Fig. 54).

(2) Remove cluster gear rear bearing snap ring

(Fig. 54).

Fig. 47 Removing 1-2 Shift Rail Interlock Pin

Fig. 48 Removing 1-2 Shift Rail Interlock Plug

Fig. 49 Fifth Gear Shift Rail Lock Ball Removal

Fig. 50 Shift Fork Removal

JAX 15 MANUAL TRANSMISSION 21 - 47

Page 1425 of 2198

Fig. 51 Reverse Shift Rail C-Ring Removal

Fig. 52 Reverse Shift Rail And Fork Removal

Fig. 53 Reverse Shift Rail Interlock Pin Removal

Fig. 54 Removing Bearing Snap Rings

21 - 48 AX 15 MANUAL TRANSMISSIONJ

Page 1426 of 2198

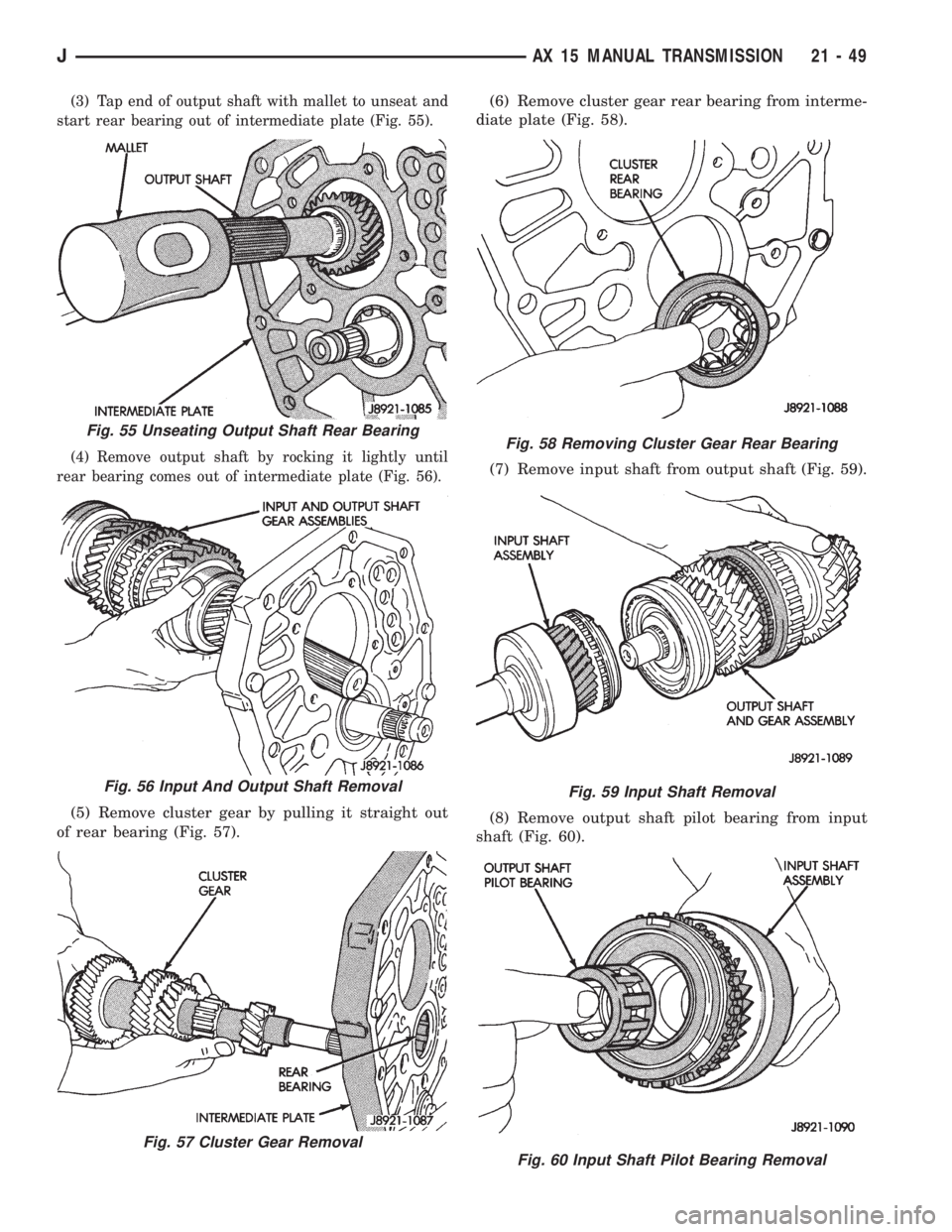

(3) Tap end of output shaft with mallet to unseat and

start rear bearing out of intermediate plate (Fig. 55).

(4) Remove output shaft by rocking it lightly until

rear bearing comes out of intermediate plate (Fig. 56).

(5) Remove cluster gear by pulling it straight out

of rear bearing (Fig. 57).(6) Remove cluster gear rear bearing from interme-

diate plate (Fig. 58).

(7) Remove input shaft from output shaft (Fig. 59).

(8) Remove output shaft pilot bearing from input

shaft (Fig. 60).

Fig. 55 Unseating Output Shaft Rear Bearing

Fig. 56 Input And Output Shaft Removal

Fig. 57 Cluster Gear Removal

Fig. 58 Removing Cluster Gear Rear Bearing

Fig. 59 Input Shaft Removal

Fig. 60 Input Shaft Pilot Bearing Removal

JAX 15 MANUAL TRANSMISSION 21 - 49

Page 1427 of 2198

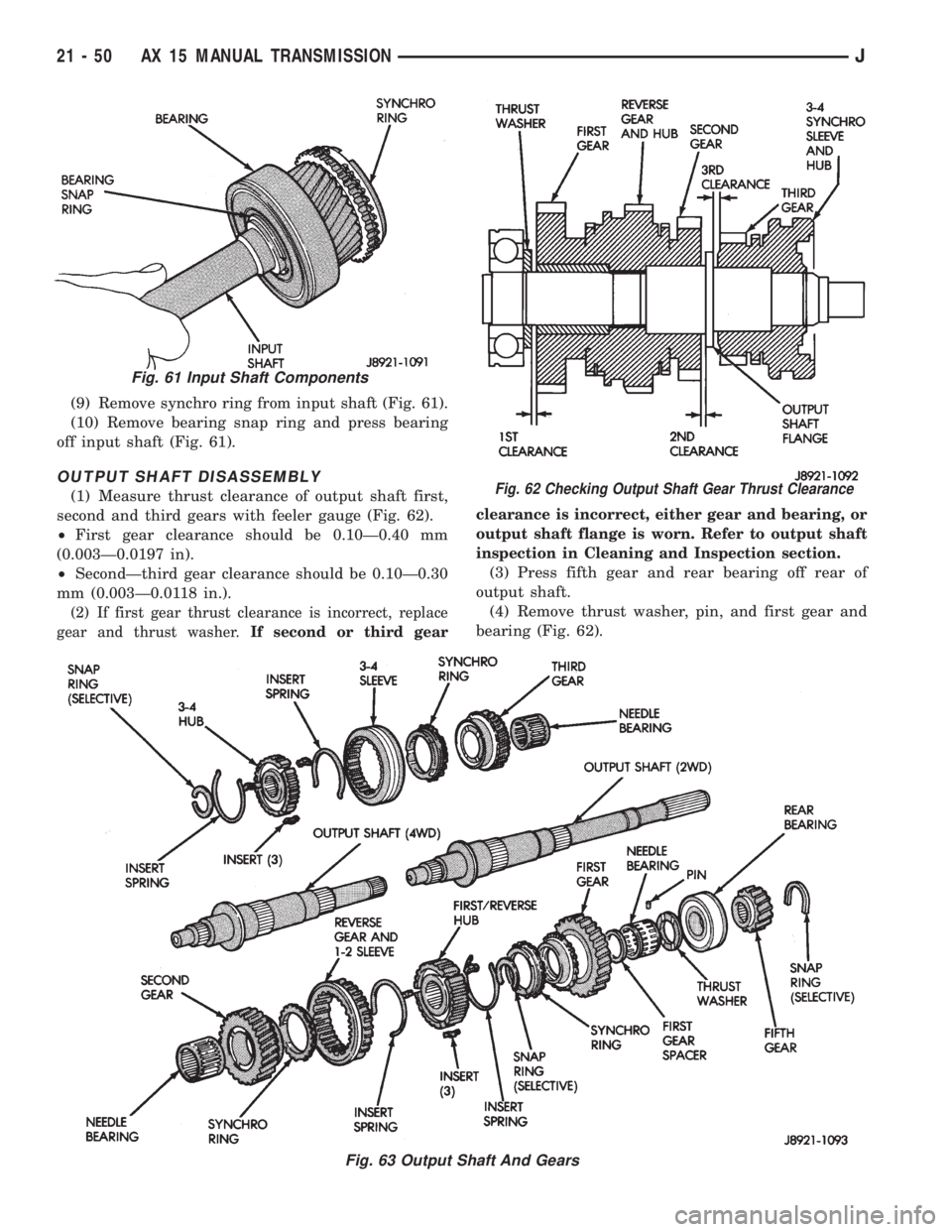

(9) Remove synchro ring from input shaft (Fig. 61).

(10) Remove bearing snap ring and press bearing

off input shaft (Fig. 61).

OUTPUT SHAFT DISASSEMBLY

(1) Measure thrust clearance of output shaft first,

second and third gears with feeler gauge (Fig. 62).

²First gear clearance should be 0.10Ð0.40 mm

(0.003Ð0.0197 in).

²SecondÐthird gear clearance should be 0.10Ð0.30

mm (0.003Ð0.0118 in.).

(2) If first gear thrust clearance is incorrect, replace

gear and thrust washer.If second or third gearclearance is incorrect, either gear and bearing, or

output shaft flange is worn. Refer to output shaft

inspection in Cleaning and Inspection section.

(3) Press fifth gear and rear bearing off rear of

output shaft.

(4) Remove thrust washer, pin, and first gear and

bearing (Fig. 62).

Fig. 61 Input Shaft Components

Fig. 62 Checking Output Shaft Gear Thrust Clearance

Fig. 63 Output Shaft And Gears

21 - 50 AX 15 MANUAL TRANSMISSIONJ

Page 1428 of 2198

(5) Remove first/reverse hub snap ring (Fig. 63).

(6) Remove synchro ring.

(7) Press reverse gear and first/reverse hub off

shaft as assembly.

(8) Remove remaining synchro ring and second

gear and bearing (Fig. 63).

(9) Remove snap ring at front of output shaft (Fig.

63).

(10) Press 3-4 hub and sleeve off output shaft as

assembly (Fig. 63).

(11) Remove synchro ring.

(12) Remove third gear and needle bearing (Fig.

63).

TRANSMISSION CLEANING AND INSPECTION

Clean the transmission components in solvent.

Then dry the cases, gears, shift mechanism and

shafts with compressed air.Dry the bearings with

clean, dry shop towels only. Never use com-

pressed air on the bearings. This could damage

the bearing rollers.

Replace components that are obviously worn,

cracked, chipped or damaged.

Inspect the transmission case. Replace the case if

cracked or porous or if any of the bearing and gear

bores are damaged.

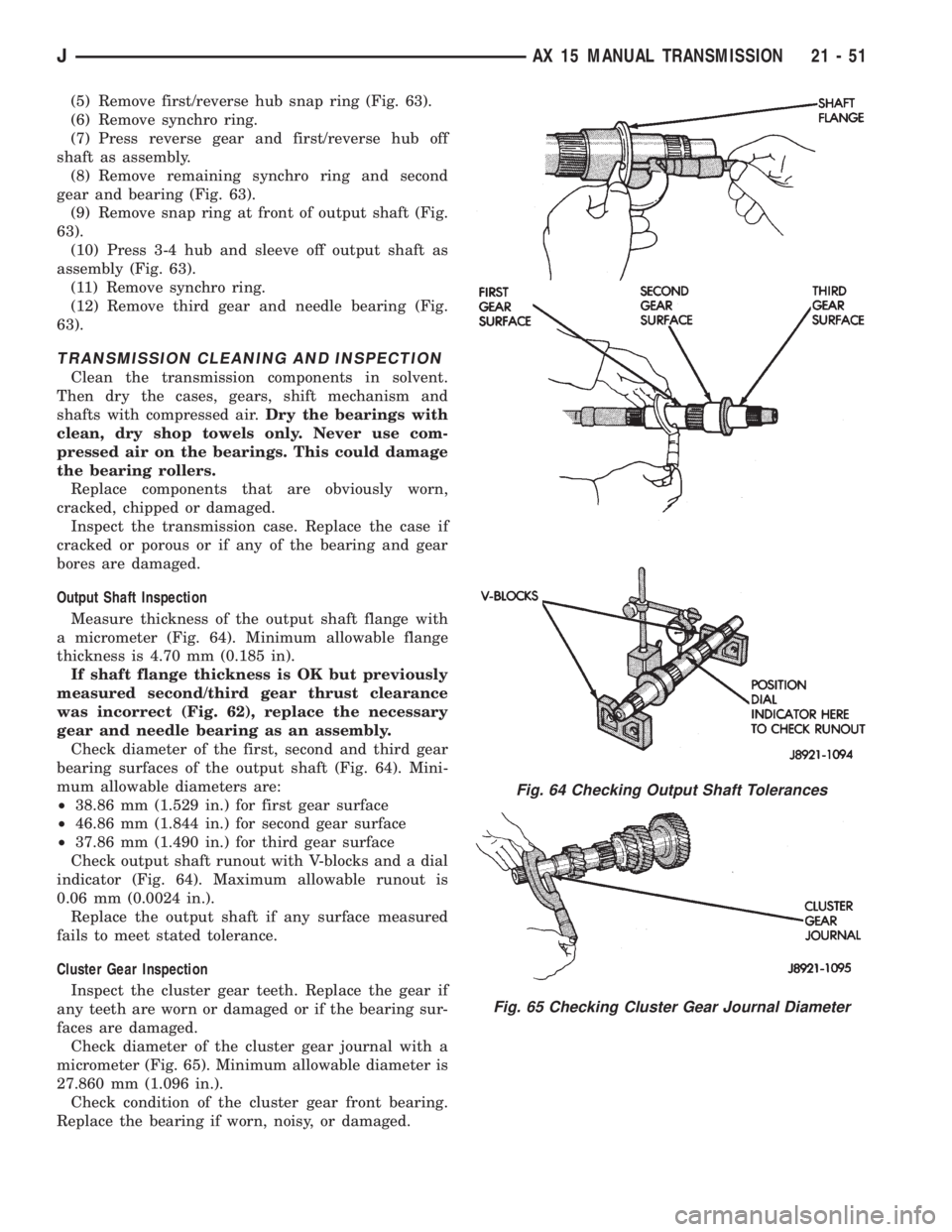

Output Shaft Inspection

Measure thickness of the output shaft flange with

a micrometer (Fig. 64). Minimum allowable flange

thickness is 4.70 mm (0.185 in).

If shaft flange thickness is OK but previously

measured second/third gear thrust clearance

was incorrect (Fig. 62), replace the necessary

gear and needle bearing as an assembly.

Check diameter of the first, second and third gear

bearing surfaces of the output shaft (Fig. 64). Mini-

mum allowable diameters are:

²38.86 mm (1.529 in.) for first gear surface

²46.86 mm (1.844 in.) for second gear surface

²37.86 mm (1.490 in.) for third gear surface

Check output shaft runout with V-blocks and a dial

indicator (Fig. 64). Maximum allowable runout is

0.06 mm (0.0024 in.).

Replace the output shaft if any surface measured

fails to meet stated tolerance.

Cluster Gear Inspection

Inspect the cluster gear teeth. Replace the gear if

any teeth are worn or damaged or if the bearing sur-

faces are damaged.

Check diameter of the cluster gear journal with a

micrometer (Fig. 65). Minimum allowable diameter is

27.860 mm (1.096 in.).

Check condition of the cluster gear front bearing.

Replace the bearing if worn, noisy, or damaged.

Fig. 64 Checking Output Shaft Tolerances

Fig. 65 Checking Cluster Gear Journal Diameter

JAX 15 MANUAL TRANSMISSION 21 - 51

Page 1429 of 2198

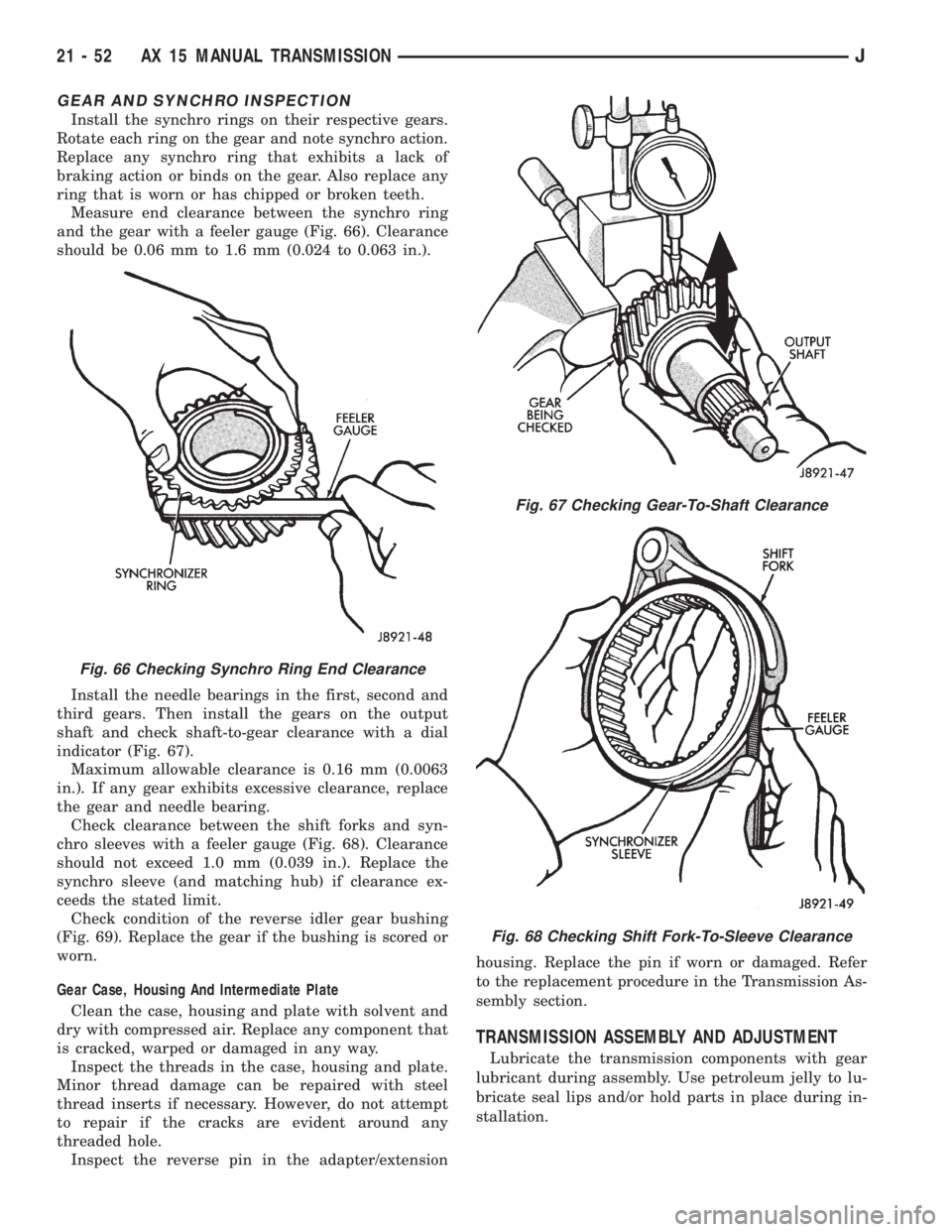

GEAR AND SYNCHRO INSPECTION

Install the synchro rings on their respective gears.

Rotate each ring on the gear and note synchro action.

Replace any synchro ring that exhibits a lack of

braking action or binds on the gear. Also replace any

ring that is worn or has chipped or broken teeth.

Measure end clearance between the synchro ring

and the gear with a feeler gauge (Fig. 66). Clearance

should be 0.06 mm to 1.6 mm (0.024 to 0.063 in.).

Install the needle bearings in the first, second and

third gears. Then install the gears on the output

shaft and check shaft-to-gear clearance with a dial

indicator (Fig. 67).

Maximum allowable clearance is 0.16 mm (0.0063

in.). If any gear exhibits excessive clearance, replace

the gear and needle bearing.

Check clearance between the shift forks and syn-

chro sleeves with a feeler gauge (Fig. 68). Clearance

should not exceed 1.0 mm (0.039 in.). Replace the

synchro sleeve (and matching hub) if clearance ex-

ceeds the stated limit.

Check condition of the reverse idler gear bushing

(Fig. 69). Replace the gear if the bushing is scored or

worn.

Gear Case, Housing And Intermediate Plate

Clean the case, housing and plate with solvent and

dry with compressed air. Replace any component that

is cracked, warped or damaged in any way.

Inspect the threads in the case, housing and plate.

Minor thread damage can be repaired with steel

thread inserts if necessary. However, do not attempt

to repair if the cracks are evident around any

threaded hole.

Inspect the reverse pin in the adapter/extensionhousing. Replace the pin if worn or damaged. Refer

to the replacement procedure in the Transmission As-

sembly section.

TRANSMISSION ASSEMBLY AND ADJUSTMENT

Lubricate the transmission components with gear

lubricant during assembly. Use petroleum jelly to lu-

bricate seal lips and/or hold parts in place during in-

stallation.

Fig. 66 Checking Synchro Ring End Clearance

Fig. 67 Checking Gear-To-Shaft Clearance

Fig. 68 Checking Shift Fork-To-Sleeve Clearance

21 - 52 AX 15 MANUAL TRANSMISSIONJ

Page 1430 of 2198

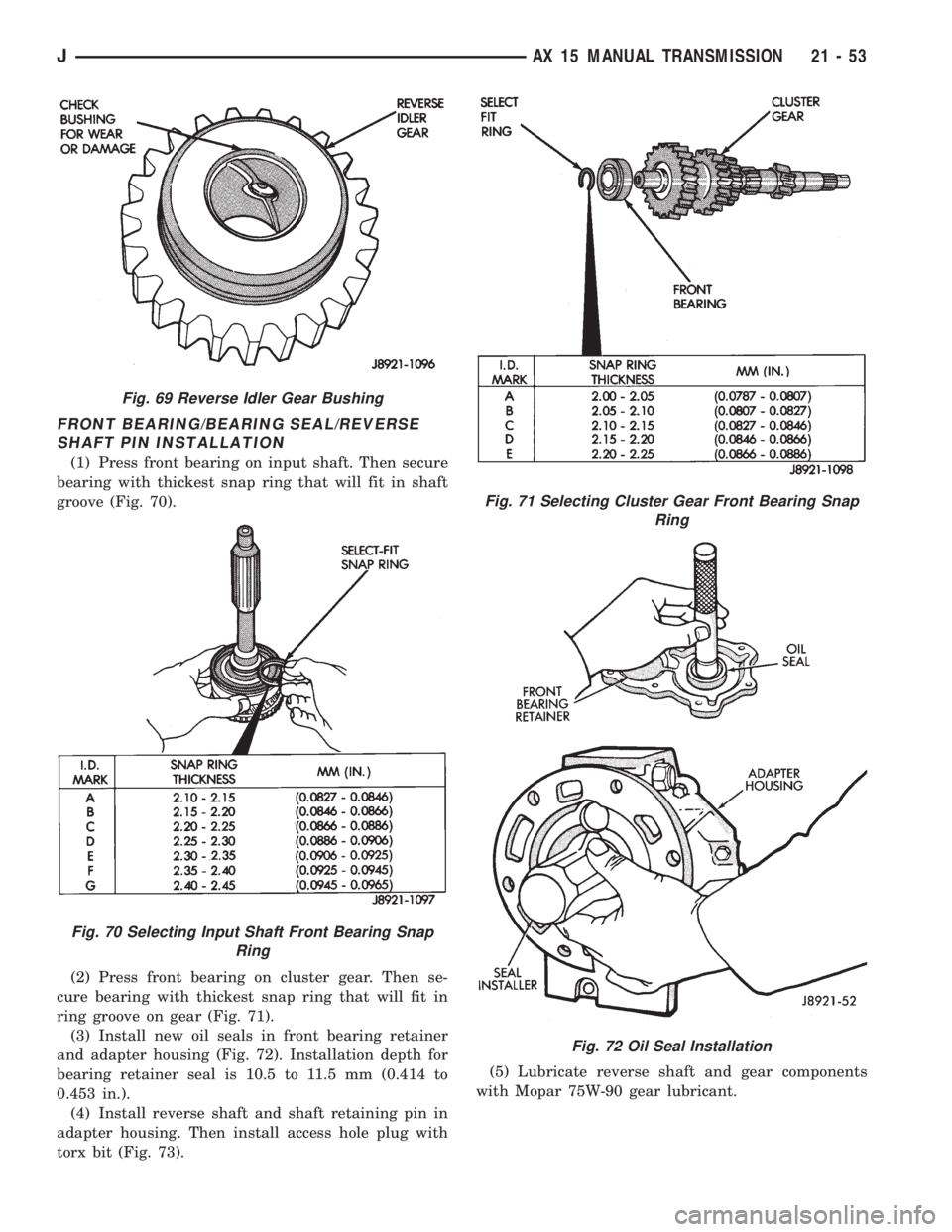

FRONT BEARING/BEARING SEAL/REVERSE

SHAFT PIN INSTALLATION

(1) Press front bearing on input shaft. Then secure

bearing with thickest snap ring that will fit in shaft

groove (Fig. 70).

(2) Press front bearing on cluster gear. Then se-

cure bearing with thickest snap ring that will fit in

ring groove on gear (Fig. 71).

(3) Install new oil seals in front bearing retainer

and adapter housing (Fig. 72). Installation depth for

bearing retainer seal is 10.5 to 11.5 mm (0.414 to

0.453 in.).

(4) Install reverse shaft and shaft retaining pin in

adapter housing. Then install access hole plug with

torx bit (Fig. 73).(5) Lubricate reverse shaft and gear components

with Mopar 75W-90 gear lubricant.

Fig. 69 Reverse Idler Gear Bushing

Fig. 70 Selecting Input Shaft Front Bearing Snap

Ring

Fig. 71 Selecting Cluster Gear Front Bearing Snap

Ring

Fig. 72 Oil Seal Installation

JAX 15 MANUAL TRANSMISSION 21 - 53