JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1381 of 2198

(7) Disconnect transfer case shift linkage at trans-

fer case.

(8) Disconnect vehicle speed sensor wires and

transfer case vent hose.

(9) Remove slave cylinder from clutch housing.

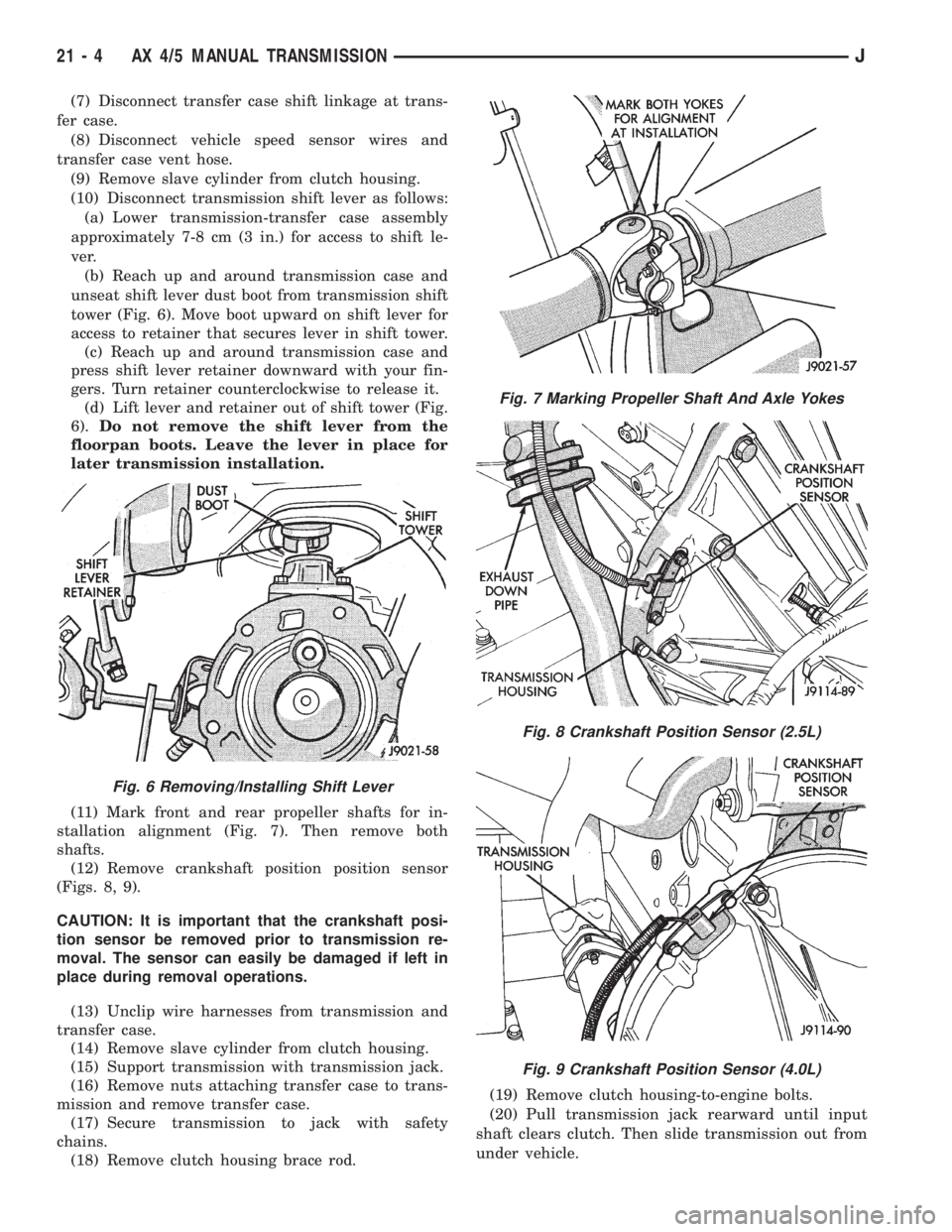

(10) Disconnect transmission shift lever as follows:

(a) Lower transmission-transfer case assembly

approximately 7-8 cm (3 in.) for access to shift le-

ver.

(b) Reach up and around transmission case and

unseat shift lever dust boot from transmission shift

tower (Fig. 6). Move boot upward on shift lever for

access to retainer that secures lever in shift tower.

(c) Reach up and around transmission case and

press shift lever retainer downward with your fin-

gers. Turn retainer counterclockwise to release it.

(d) Lift lever and retainer out of shift tower (Fig.

6).Do not remove the shift lever from the

floorpan boots. Leave the lever in place for

later transmission installation.

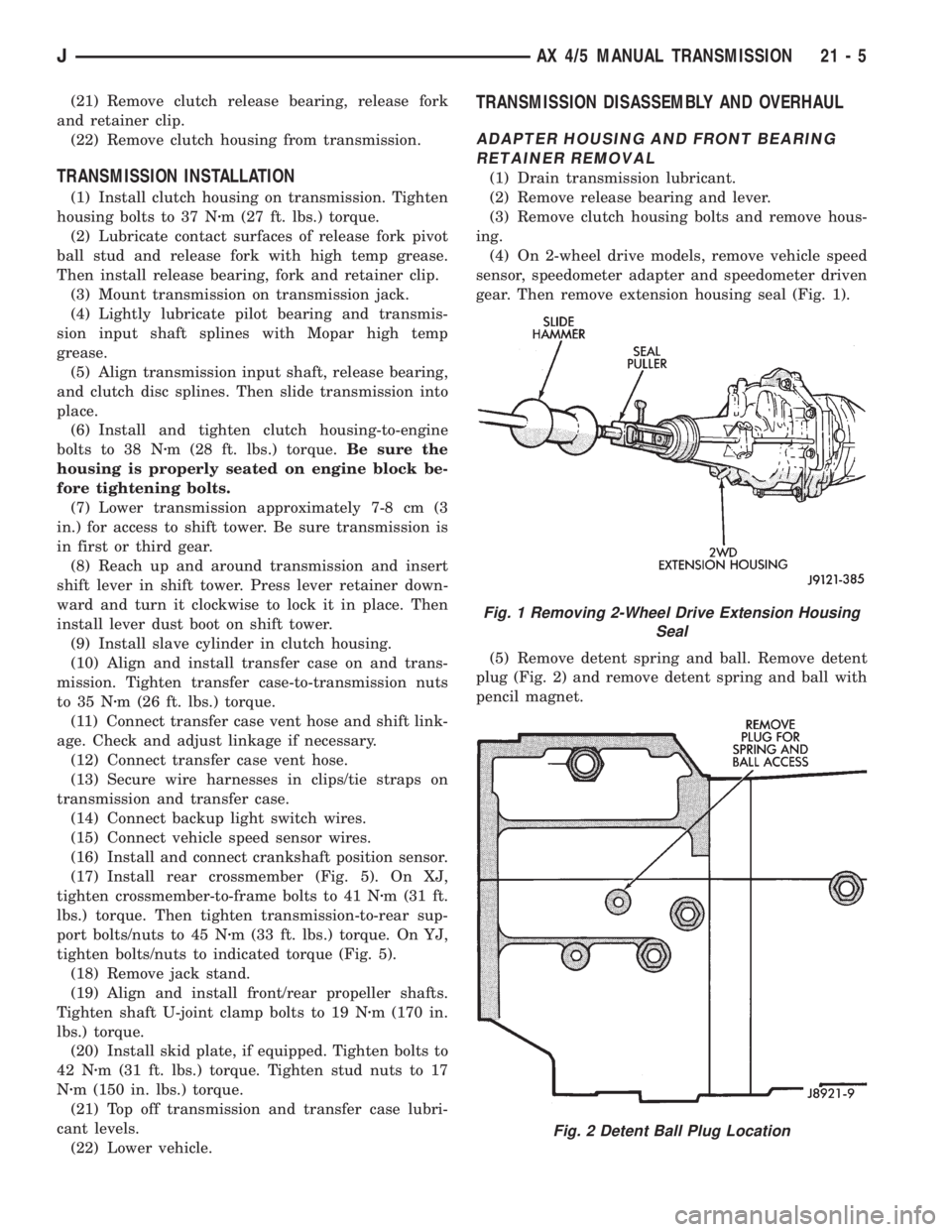

(11) Mark front and rear propeller shafts for in-

stallation alignment (Fig. 7). Then remove both

shafts.

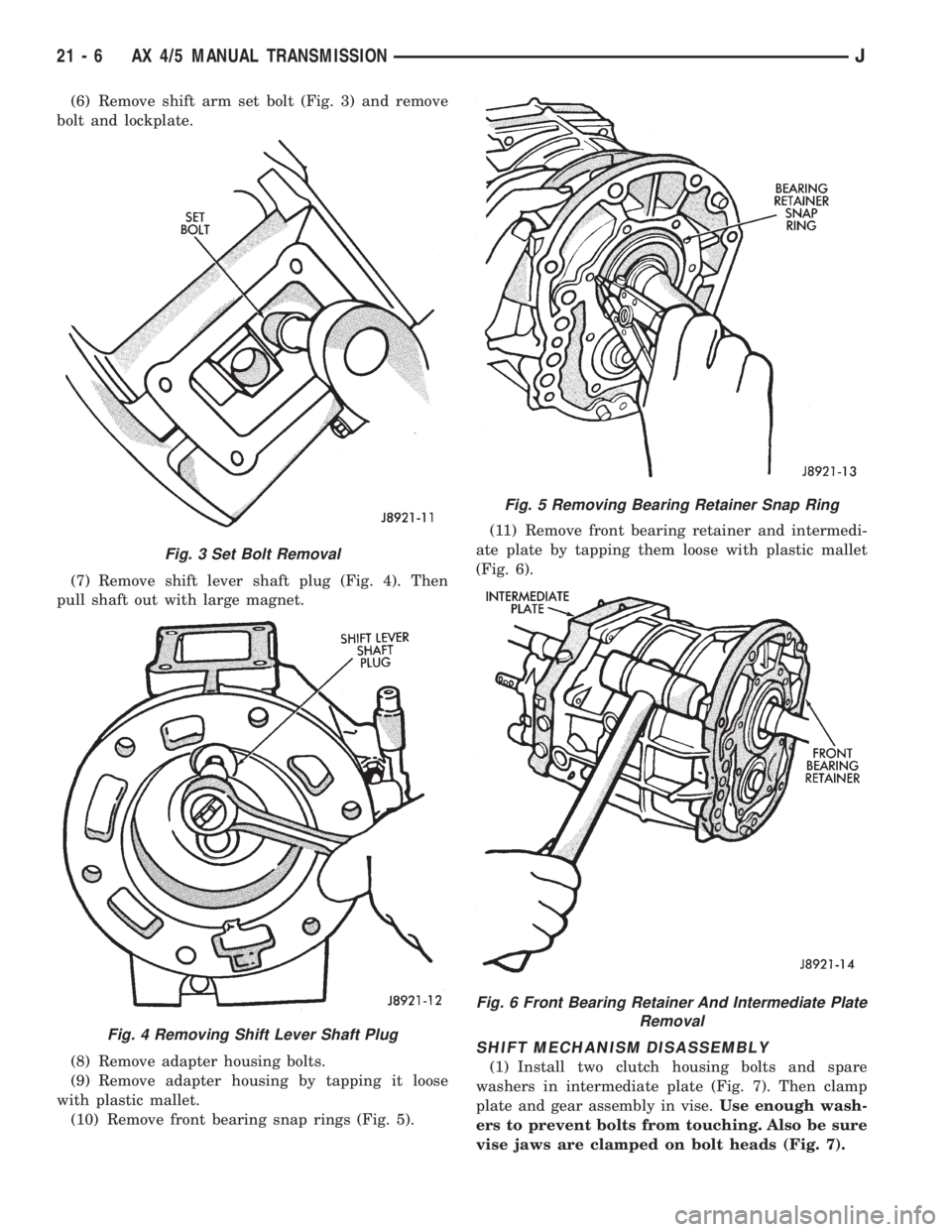

(12) Remove crankshaft position position sensor

(Figs. 8, 9).

CAUTION: It is important that the crankshaft posi-

tion sensor be removed prior to transmission re-

moval. The sensor can easily be damaged if left in

place during removal operations.

(13) Unclip wire harnesses from transmission and

transfer case.

(14) Remove slave cylinder from clutch housing.

(15) Support transmission with transmission jack.

(16) Remove nuts attaching transfer case to trans-

mission and remove transfer case.

(17) Secure transmission to jack with safety

chains.

(18) Remove clutch housing brace rod.(19) Remove clutch housing-to-engine bolts.

(20) Pull transmission jack rearward until input

shaft clears clutch. Then slide transmission out from

under vehicle.

Fig. 6 Removing/Installing Shift Lever

Fig. 7 Marking Propeller Shaft And Axle Yokes

Fig. 8 Crankshaft Position Sensor (2.5L)

Fig. 9 Crankshaft Position Sensor (4.0L)

21 - 4 AX 4/5 MANUAL TRANSMISSIONJ

Page 1382 of 2198

(21) Remove clutch release bearing, release fork

and retainer clip.

(22) Remove clutch housing from transmission.

TRANSMISSION INSTALLATION

(1) Install clutch housing on transmission. Tighten

housing bolts to 37 Nzm (27 ft. lbs.) torque.

(2) Lubricate contact surfaces of release fork pivot

ball stud and release fork with high temp grease.

Then install release bearing, fork and retainer clip.

(3) Mount transmission on transmission jack.

(4) Lightly lubricate pilot bearing and transmis-

sion input shaft splines with Mopar high temp

grease.

(5) Align transmission input shaft, release bearing,

and clutch disc splines. Then slide transmission into

place.

(6) Install and tighten clutch housing-to-engine

bolts to 38 Nzm (28 ft. lbs.) torque.Be sure the

housing is properly seated on engine block be-

fore tightening bolts.

(7) Lower transmission approximately 7-8 cm (3

in.) for access to shift tower. Be sure transmission is

in first or third gear.

(8) Reach up and around transmission and insert

shift lever in shift tower. Press lever retainer down-

ward and turn it clockwise to lock it in place. Then

install lever dust boot on shift tower.

(9) Install slave cylinder in clutch housing.

(10) Align and install transfer case on and trans-

mission. Tighten transfer case-to-transmission nuts

to 35 Nzm (26 ft. lbs.) torque.

(11) Connect transfer case vent hose and shift link-

age. Check and adjust linkage if necessary.

(12) Connect transfer case vent hose.

(13) Secure wire harnesses in clips/tie straps on

transmission and transfer case.

(14) Connect backup light switch wires.

(15) Connect vehicle speed sensor wires.

(16) Install and connect crankshaft position sensor.

(17) Install rear crossmember (Fig. 5). On XJ,

tighten crossmember-to-frame bolts to 41 Nzm (31 ft.

lbs.) torque. Then tighten transmission-to-rear sup-

port bolts/nuts to 45 Nzm (33 ft. lbs.) torque. On YJ,

tighten bolts/nuts to indicated torque (Fig. 5).

(18) Remove jack stand.

(19) Align and install front/rear propeller shafts.

Tighten shaft U-joint clamp bolts to 19 Nzm (170 in.

lbs.) torque.

(20) Install skid plate, if equipped. Tighten bolts to

42 Nzm (31 ft. lbs.) torque. Tighten stud nuts to 17

Nzm (150 in. lbs.) torque.

(21) Top off transmission and transfer case lubri-

cant levels.

(22) Lower vehicle.

TRANSMISSION DISASSEMBLY AND OVERHAUL

ADAPTER HOUSING AND FRONT BEARING

RETAINER REMOVAL

(1) Drain transmission lubricant.

(2) Remove release bearing and lever.

(3) Remove clutch housing bolts and remove hous-

ing.

(4) On 2-wheel drive models, remove vehicle speed

sensor, speedometer adapter and speedometer driven

gear. Then remove extension housing seal (Fig. 1).

(5) Remove detent spring and ball. Remove detent

plug (Fig. 2) and remove detent spring and ball with

pencil magnet.

Fig. 1 Removing 2-Wheel Drive Extension Housing

Seal

Fig. 2 Detent Ball Plug Location

JAX 4/5 MANUAL TRANSMISSION 21 - 5

Page 1383 of 2198

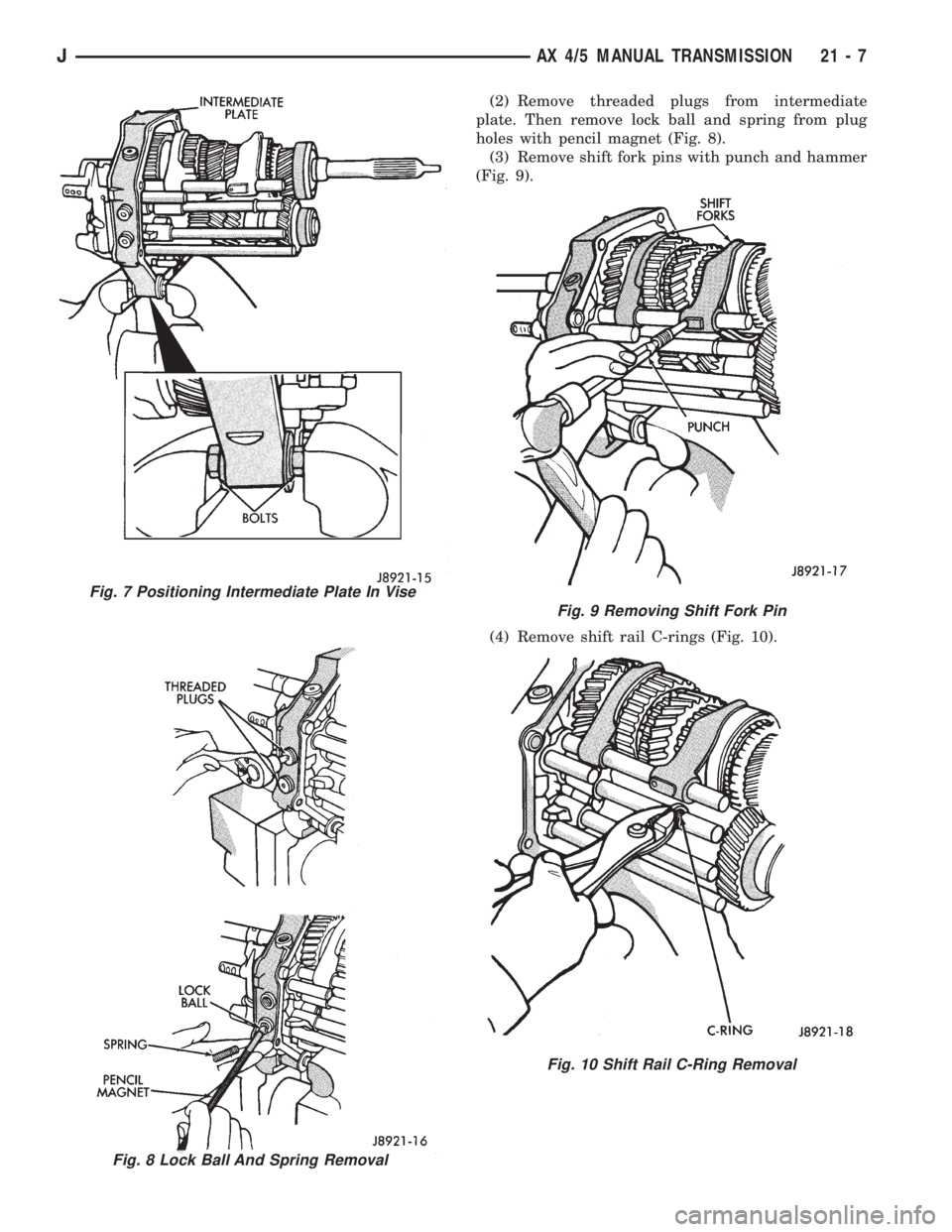

(6) Remove shift arm set bolt (Fig. 3) and remove

bolt and lockplate.

(7) Remove shift lever shaft plug (Fig. 4). Then

pull shaft out with large magnet.

(8) Remove adapter housing bolts.

(9) Remove adapter housing by tapping it loose

with plastic mallet.

(10) Remove front bearing snap rings (Fig. 5).(11) Remove front bearing retainer and intermedi-

ate plate by tapping them loose with plastic mallet

(Fig. 6).

SHIFT MECHANISM DISASSEMBLY

(1) Install two clutch housing bolts and spare

washers in intermediate plate (Fig. 7). Then clamp

plate and gear assembly in vise.Use enough wash-

ers to prevent bolts from touching. Also be sure

vise jaws are clamped on bolt heads (Fig. 7).

Fig. 3 Set Bolt Removal

Fig. 4 Removing Shift Lever Shaft Plug

Fig. 5 Removing Bearing Retainer Snap Ring

Fig. 6 Front Bearing Retainer And Intermediate Plate

Removal

21 - 6 AX 4/5 MANUAL TRANSMISSIONJ

Page 1384 of 2198

(2) Remove threaded plugs from intermediate

plate. Then remove lock ball and spring from plug

holes with pencil magnet (Fig. 8).

(3) Remove shift fork pins with punch and hammer

(Fig. 9).

(4) Remove shift rail C-rings (Fig. 10).

Fig. 7 Positioning Intermediate Plate In Vise

Fig. 8 Lock Ball And Spring Removal

Fig. 9 Removing Shift Fork Pin

Fig. 10 Shift Rail C-Ring Removal

JAX 4/5 MANUAL TRANSMISSION 21 - 7

Page 1385 of 2198

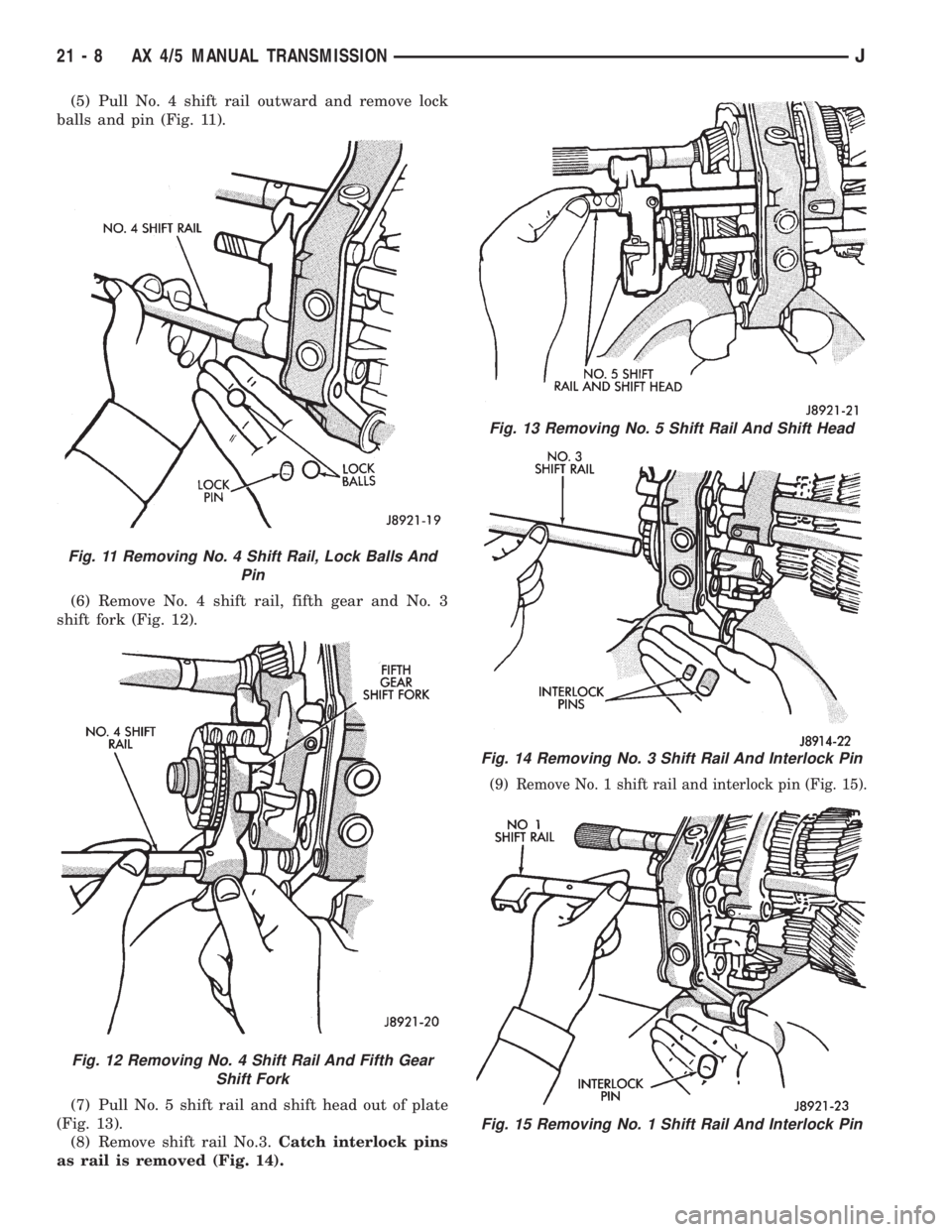

(5) Pull No. 4 shift rail outward and remove lock

balls and pin (Fig. 11).

(6) Remove No. 4 shift rail, fifth gear and No. 3

shift fork (Fig. 12).

(7) Pull No. 5 shift rail and shift head out of plate

(Fig. 13).

(8) Remove shift rail No.3.Catch interlock pins

as rail is removed (Fig. 14).

(9) Remove No. 1 shift rail and interlock pin (Fig. 15).

Fig. 11 Removing No. 4 Shift Rail, Lock Balls And

Pin

Fig. 12 Removing No. 4 Shift Rail And Fifth Gear

Shift Fork

Fig. 13 Removing No. 5 Shift Rail And Shift Head

Fig. 14 Removing No. 3 Shift Rail And Interlock Pin

Fig. 15 Removing No. 1 Shift Rail And Interlock Pin

21 - 8 AX 4/5 MANUAL TRANSMISSIONJ

Page 1386 of 2198

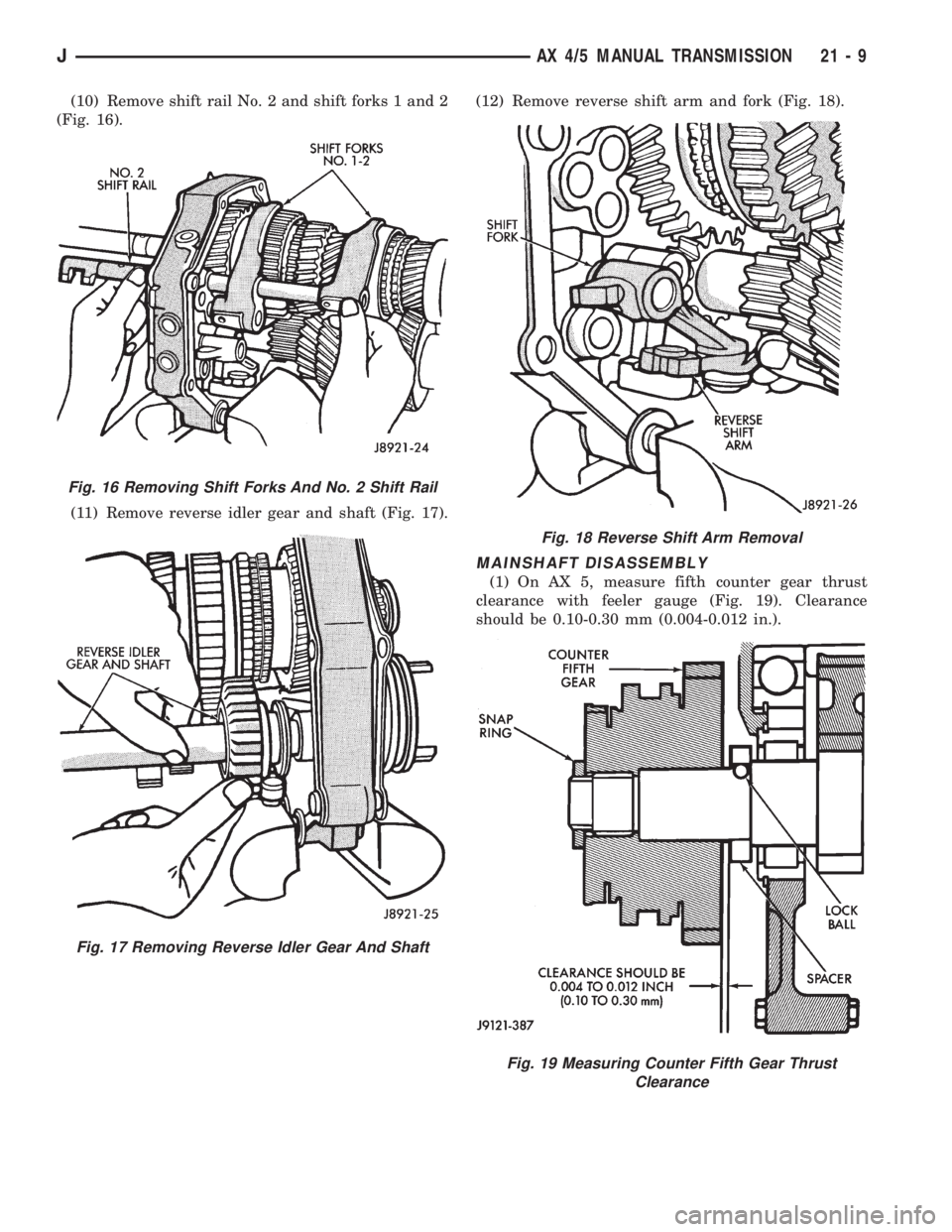

(10) Remove shift rail No. 2 and shift forks 1 and 2

(Fig. 16).

(11) Remove reverse idler gear and shaft (Fig. 17).(12) Remove reverse shift arm and fork (Fig. 18).

MAINSHAFT DISASSEMBLY

(1) On AX 5, measure fifth counter gear thrust

clearance with feeler gauge (Fig. 19). Clearance

should be 0.10-0.30 mm (0.004-0.012 in.).

Fig. 16 Removing Shift Forks And No. 2 Shift Rail

Fig. 17 Removing Reverse Idler Gear And Shaft

Fig. 18 Reverse Shift Arm Removal

Fig. 19 Measuring Counter Fifth Gear Thrust

Clearance

JAX 4/5 MANUAL TRANSMISSION 21 - 9

Page 1387 of 2198

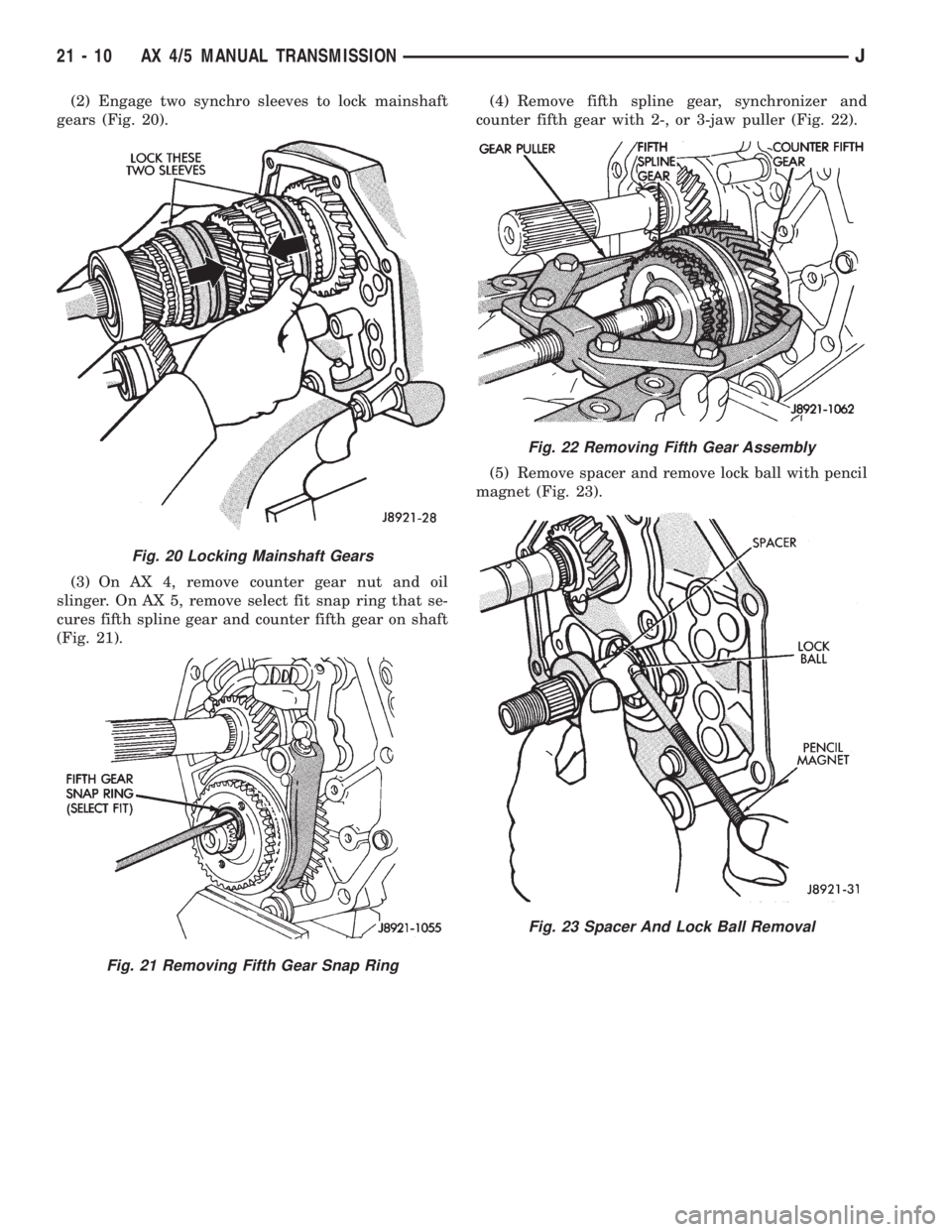

(2) Engage two synchro sleeves to lock mainshaft

gears (Fig. 20).

(3) On AX 4, remove counter gear nut and oil

slinger. On AX 5, remove select fit snap ring that se-

cures fifth spline gear and counter fifth gear on shaft

(Fig. 21).(4) Remove fifth spline gear, synchronizer and

counter fifth gear with 2-, or 3-jaw puller (Fig. 22).

(5) Remove spacer and remove lock ball with pencil

magnet (Fig. 23).

Fig. 20 Locking Mainshaft Gears

Fig. 21 Removing Fifth Gear Snap Ring

Fig. 22 Removing Fifth Gear Assembly

Fig. 23 Spacer And Lock Ball Removal

21 - 10 AX 4/5 MANUAL TRANSMISSIONJ

Page 1388 of 2198

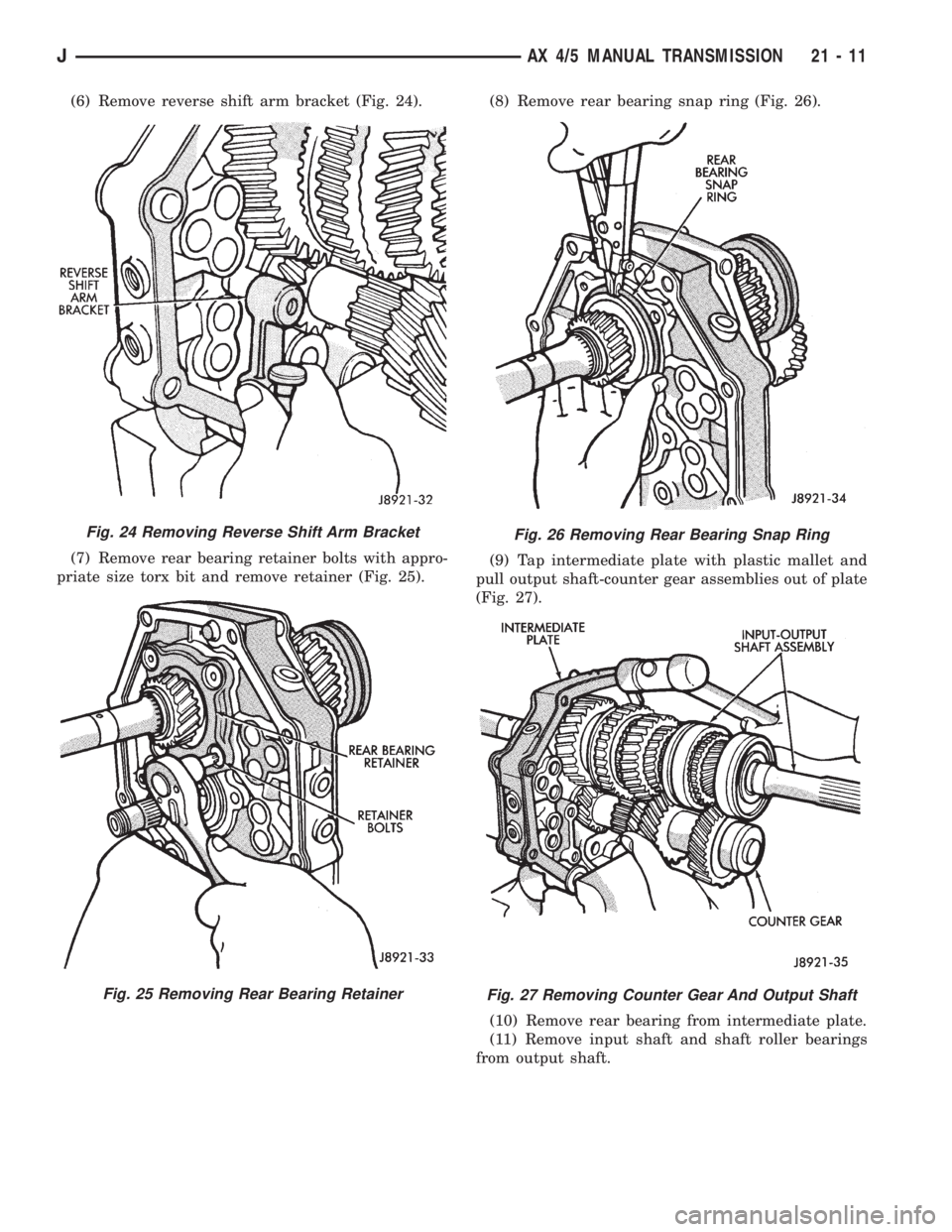

(6) Remove reverse shift arm bracket (Fig. 24).

(7) Remove rear bearing retainer bolts with appro-

priate size torx bit and remove retainer (Fig. 25).(8) Remove rear bearing snap ring (Fig. 26).

(9) Tap intermediate plate with plastic mallet and

pull output shaft-counter gear assemblies out of plate

(Fig. 27).

(10) Remove rear bearing from intermediate plate.

(11) Remove input shaft and shaft roller bearings

from output shaft.

Fig. 24 Removing Reverse Shift Arm Bracket

Fig. 25 Removing Rear Bearing Retainer

Fig. 26 Removing Rear Bearing Snap Ring

Fig. 27 Removing Counter Gear And Output Shaft

JAX 4/5 MANUAL TRANSMISSION 21 - 11

Page 1389 of 2198

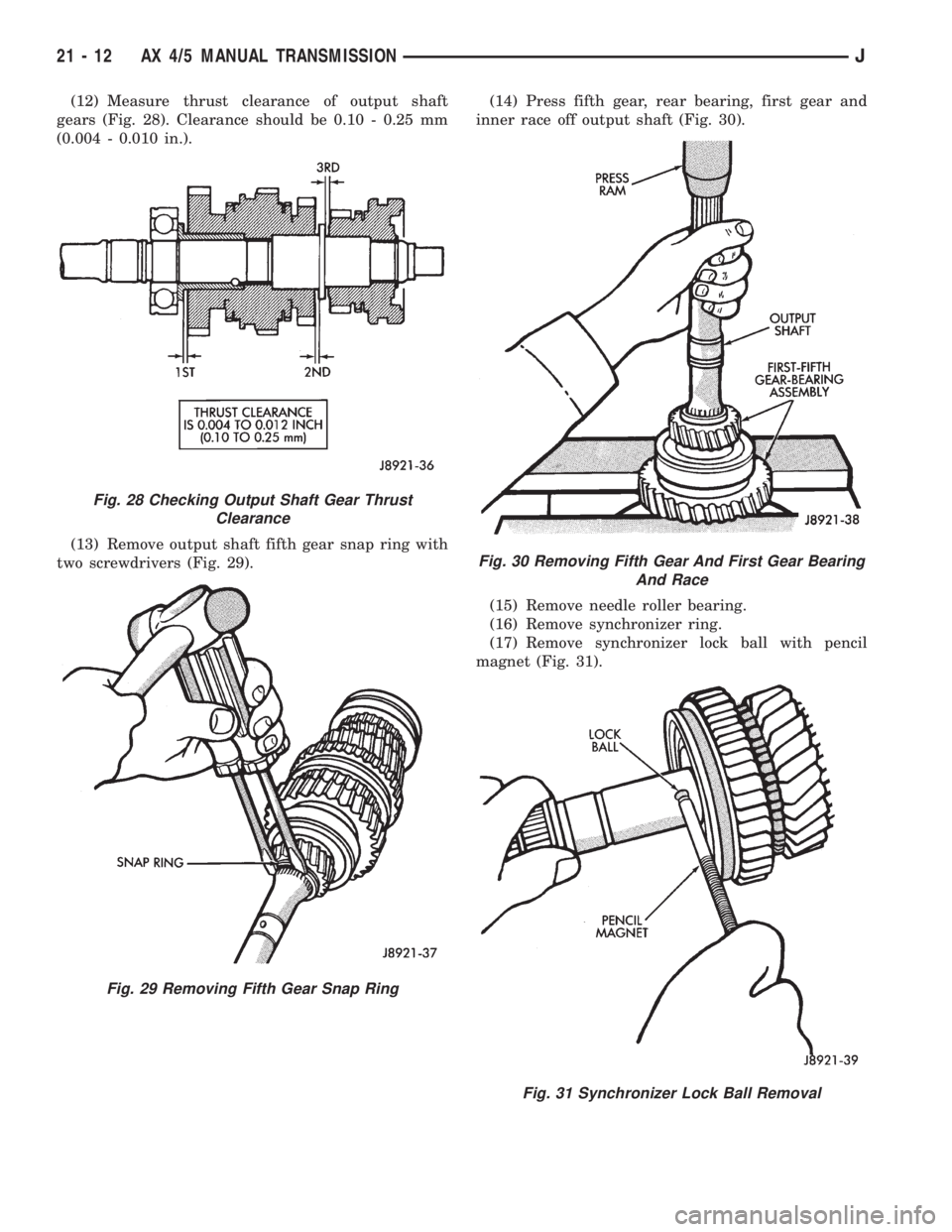

(12) Measure thrust clearance of output shaft

gears (Fig. 28). Clearance should be 0.10 - 0.25 mm

(0.004 - 0.010 in.).

(13) Remove output shaft fifth gear snap ring with

two screwdrivers (Fig. 29).(14) Press fifth gear, rear bearing, first gear and

inner race off output shaft (Fig. 30).

(15) Remove needle roller bearing.

(16) Remove synchronizer ring.

(17) Remove synchronizer lock ball with pencil

magnet (Fig. 31).

Fig. 28 Checking Output Shaft Gear Thrust

Clearance

Fig. 29 Removing Fifth Gear Snap Ring

Fig. 30 Removing Fifth Gear And First Gear Bearing

And Race

Fig. 31 Synchronizer Lock Ball Removal

21 - 12 AX 4/5 MANUAL TRANSMISSIONJ

Page 1390 of 2198

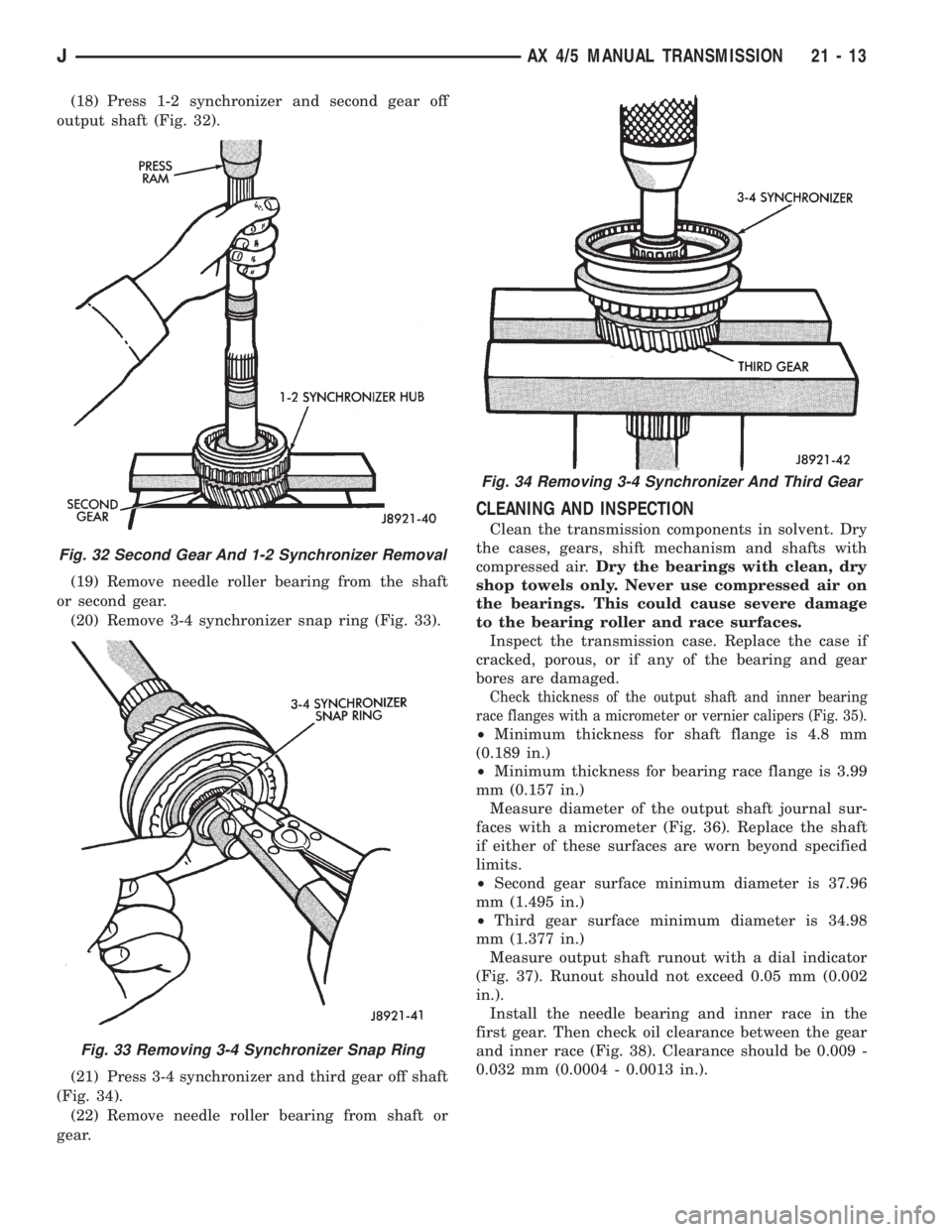

(18) Press 1-2 synchronizer and second gear off

output shaft (Fig. 32).

(19) Remove needle roller bearing from the shaft

or second gear.

(20) Remove 3-4 synchronizer snap ring (Fig. 33).

(21) Press 3-4 synchronizer and third gear off shaft

(Fig. 34).

(22) Remove needle roller bearing from shaft or

gear.

CLEANING AND INSPECTION

Clean the transmission components in solvent. Dry

the cases, gears, shift mechanism and shafts with

compressed air.Dry the bearings with clean, dry

shop towels only. Never use compressed air on

the bearings. This could cause severe damage

to the bearing roller and race surfaces.

Inspect the transmission case. Replace the case if

cracked, porous, or if any of the bearing and gear

bores are damaged.

Check thickness of the output shaft and inner bearing

race flanges with a micrometer or vernier calipers (Fig. 35).

²Minimum thickness for shaft flange is 4.8 mm

(0.189 in.)

²Minimum thickness for bearing race flange is 3.99

mm (0.157 in.)

Measure diameter of the output shaft journal sur-

faces with a micrometer (Fig. 36). Replace the shaft

if either of these surfaces are worn beyond specified

limits.

²Second gear surface minimum diameter is 37.96

mm (1.495 in.)

²Third gear surface minimum diameter is 34.98

mm (1.377 in.)

Measure output shaft runout with a dial indicator

(Fig. 37). Runout should not exceed 0.05 mm (0.002

in.).

Install the needle bearing and inner race in the

first gear. Then check oil clearance between the gear

and inner race (Fig. 38). Clearance should be 0.009 -

0.032 mm (0.0004 - 0.0013 in.).

Fig. 32 Second Gear And 1-2 Synchronizer Removal

Fig. 33 Removing 3-4 Synchronizer Snap Ring

Fig. 34 Removing 3-4 Synchronizer And Third Gear

JAX 4/5 MANUAL TRANSMISSION 21 - 13