key JEEP CHEROKEE 1995 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 310 of 2198

SUNGLASSES STORAGE BIN REMOVE/INSTALL

(1) Open sunglasses storage bin door.

(2) Remove cover plate (Fig. 9).(3) Unhook torque spring from wall and put in

down position as shown by arrow in Fig. 10.

(4) Remove sunglasses storage bin door by flexing

the center panel. Then remove the side of the door

with the gear first (Fig. 11). The gear side of the door

has a short pivot rod. Slide door out of the compart-

ment.

(5) Remove and discard latch spring (Fig. 9).

(6) Install new latch spring as shown. This may re-

quire flexing the housing in that area for clearance.

(7) Install new sunglasses storage bin door in the

open position as follows:

(a) Make sure the torque spring lines up with

the slot in the longer pivot rod, then insert the

longer pivot rod (Fig. 11).

(b) Flex the center panel and snap in the short

pivot rod.

(c) Hook torque spring back over the wall (Fig.

10).

(d) Cycle door several times to ensure that the

door functions properly.

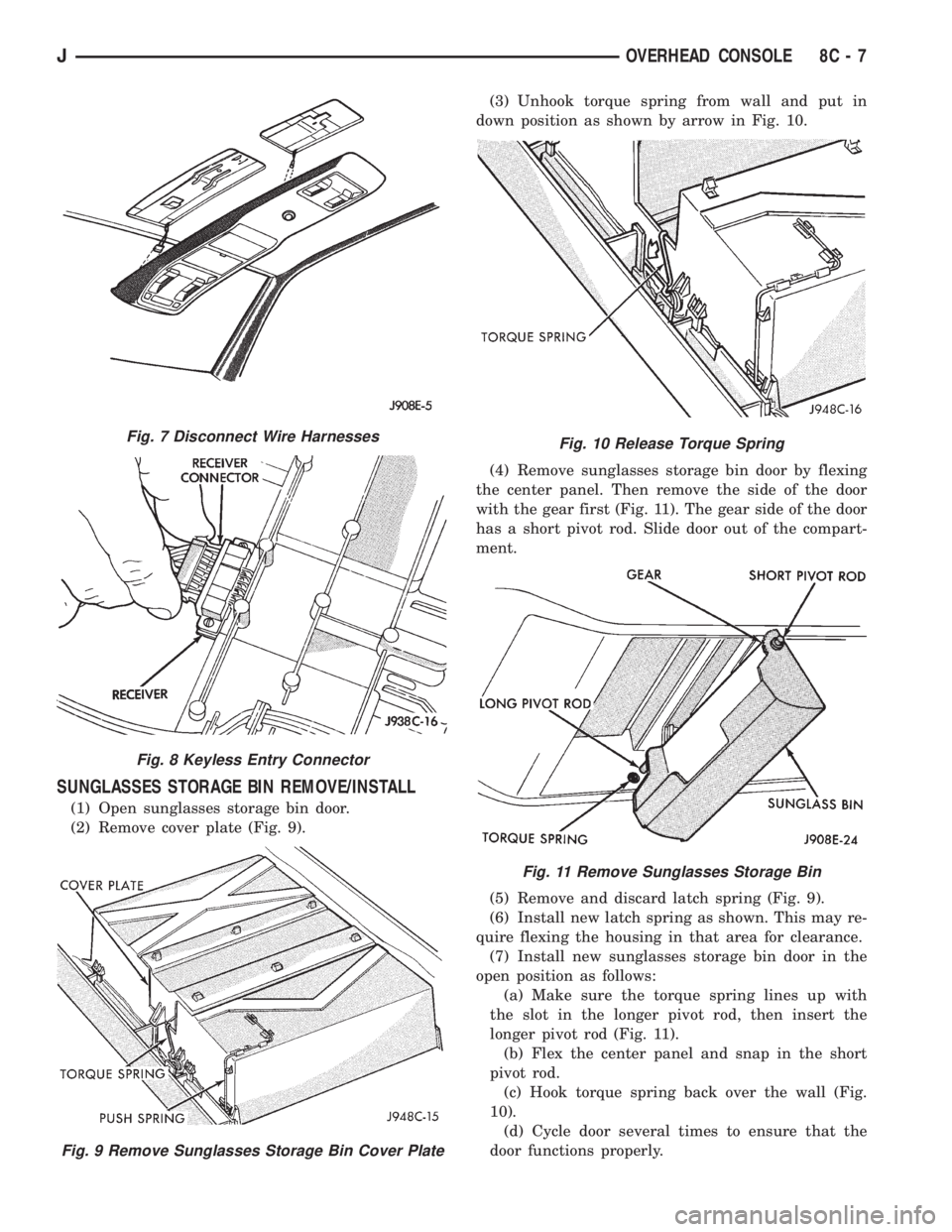

Fig. 7 Disconnect Wire Harnesses

Fig. 8 Keyless Entry Connector

Fig. 9 Remove Sunglasses Storage Bin Cover Plate

Fig. 10 Release Torque Spring

Fig. 11 Remove Sunglasses Storage Bin

JOVERHEAD CONSOLE 8C - 7

Page 317 of 2198

DIAGNOSTICS/SERVICE PROCEDURES

INDEX

page page

Automatic Shutdown (ASD) Relay Test.......... 6

Camshaft Position Sensor Test................ 6

Crankshaft Position Sensor Test............... 7

Distributor Cap............................ 7

Distributor Rotor........................... 8

DRB Scan Tool............................ 8

Engine Coolant Temperature Sensor Test........ 9

General Information........................ 6

Ignition Coil.............................. 9

Ignition Secondary Circuit Diagnosis........... 10Ignition Timing............................ 11

Intake Manifold Air Temperature Sensor Test..... 11

Manifold Absolute Pressure (MAP) Sensor Test . . . 11

On-Board Diagnostics...................... 15

Oxygen (O2S) Sensor Tests................. 15

Powertrain Control Module (PCM)............. 11

Spark Plug Secondary Cables................ 14

Spark Plugs............................. 12

Throttle Position Sensor Test................. 15

GENERAL INFORMATION

This section of the group, Diagnostics/Service Pro-

cedures, will discuss basic ignition system diagnostics

and service adjustments.

For system operation and component identification,

refer to the Component Identification/System Opera-

tion section of this group.

For removal or installation of ignition system com-

ponents, refer to the Component Removal/Installa-

tion section of this group.

For other useful information, refer to the On-Board

Diagnostics section.

For operation of the DRB Scan Tool, refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice manual.

AUTOMATIC SHUTDOWN (ASD) RELAY TEST

To perform a complete test of this relay and its cir-

cuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the relay only, refer to RelaysÐOpera-

tion/Testing in the Group 14, Fuel Systems section.

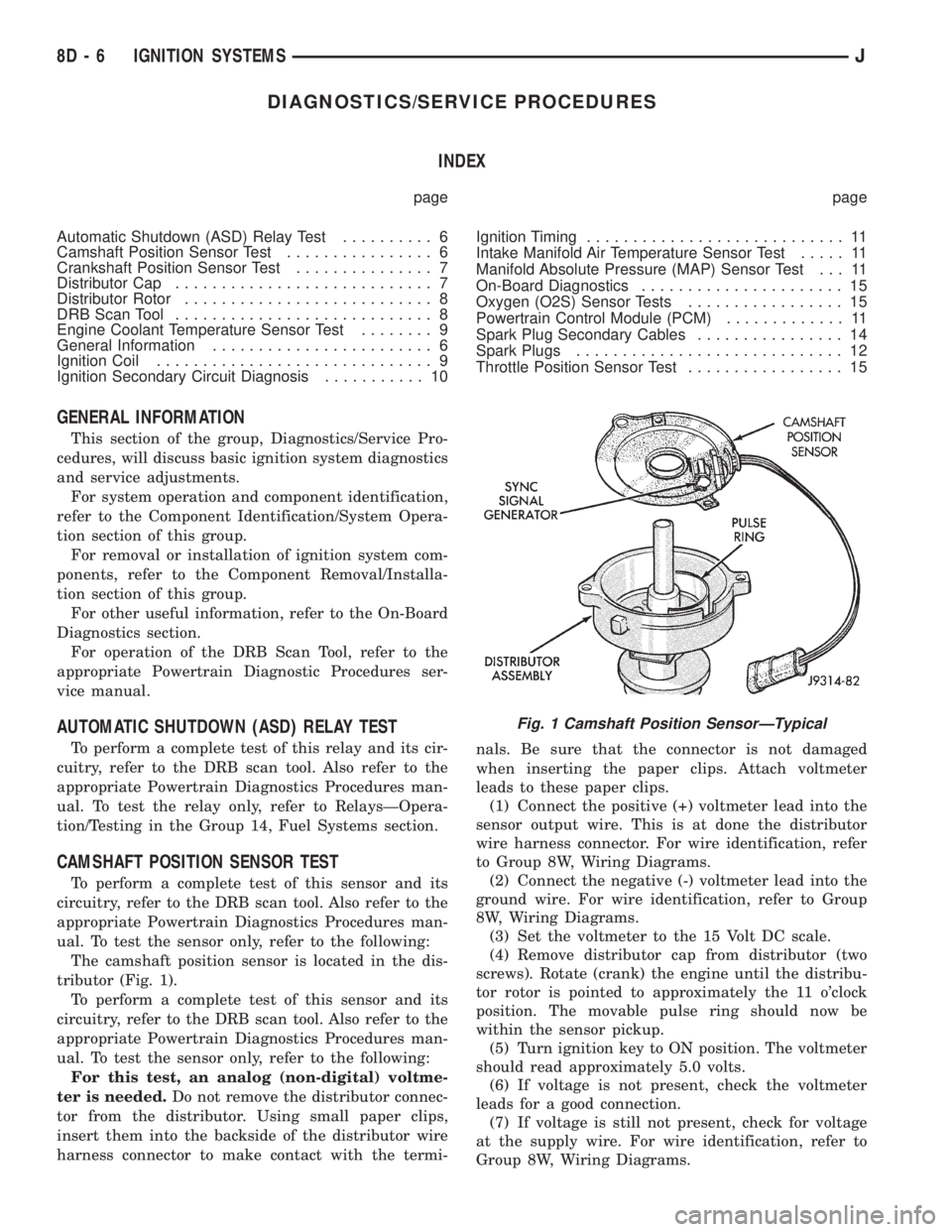

CAMSHAFT POSITION SENSOR TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

The camshaft position sensor is located in the dis-

tributor (Fig. 1).

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

For this test, an analog (non-digital) voltme-

ter is needed.Do not remove the distributor connec-

tor from the distributor. Using small paper clips,

insert them into the backside of the distributor wire

harness connector to make contact with the termi-nals. Be sure that the connector is not damaged

when inserting the paper clips. Attach voltmeter

leads to these paper clips.

(1) Connect the positive (+) voltmeter lead into the

sensor output wire. This is at done the distributor

wire harness connector. For wire identification, refer

to Group 8W, Wiring Diagrams.

(2) Connect the negative (-) voltmeter lead into the

ground wire. For wire identification, refer to Group

8W, Wiring Diagrams.

(3) Set the voltmeter to the 15 Volt DC scale.

(4) Remove distributor cap from distributor (two

screws). Rotate (crank) the engine until the distribu-

tor rotor is pointed to approximately the 11 o'clock

position. The movable pulse ring should now be

within the sensor pickup.

(5) Turn ignition key to ON position. The voltmeter

should read approximately 5.0 volts.

(6) If voltage is not present, check the voltmeter

leads for a good connection.

(7) If voltage is still not present, check for voltage

at the supply wire. For wire identification, refer to

Group 8W, Wiring Diagrams.

Fig. 1 Camshaft Position SensorÐTypical

8D - 6 IGNITION SYSTEMSJ

Page 322 of 2198

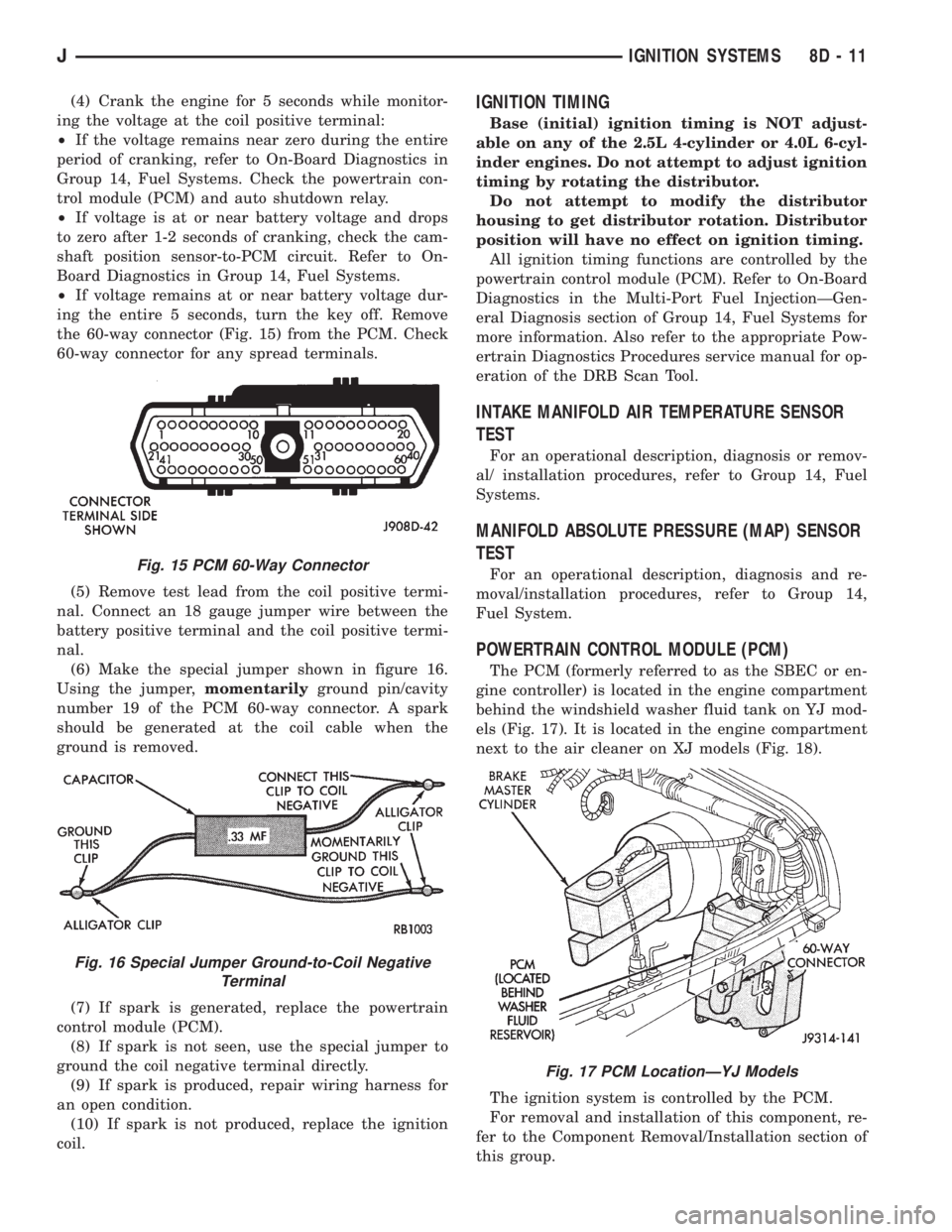

(4) Crank the engine for 5 seconds while monitor-

ing the voltage at the coil positive terminal:

²If the voltage remains near zero during the entire

period of cranking, refer to On-Board Diagnostics in

Group 14, Fuel Systems. Check the powertrain con-

trol module (PCM) and auto shutdown relay.

²If voltage is at or near battery voltage and drops

to zero after 1-2 seconds of cranking, check the cam-

shaft position sensor-to-PCM circuit. Refer to On-

Board Diagnostics in Group 14, Fuel Systems.

²If voltage remains at or near battery voltage dur-

ing the entire 5 seconds, turn the key off. Remove

the 60-way connector (Fig. 15) from the PCM. Check

60-way connector for any spread terminals.

(5) Remove test lead from the coil positive termi-

nal. Connect an 18 gauge jumper wire between the

battery positive terminal and the coil positive termi-

nal.

(6) Make the special jumper shown in figure 16.

Using the jumper,momentarilyground pin/cavity

number 19 of the PCM 60-way connector. A spark

should be generated at the coil cable when the

ground is removed.

(7) If spark is generated, replace the powertrain

control module (PCM).

(8) If spark is not seen, use the special jumper to

ground the coil negative terminal directly.

(9) If spark is produced, repair wiring harness for

an open condition.

(10) If spark is not produced, replace the ignition

coil.IGNITION TIMING

Base (initial) ignition timing is NOT adjust-

able on any of the 2.5L 4-cylinder or 4.0L 6-cyl-

inder engines. Do not attempt to adjust ignition

timing by rotating the distributor.

Do not attempt to modify the distributor

housing to get distributor rotation. Distributor

position will have no effect on ignition timing.

All ignition timing functions are controlled by the

powertrain control module (PCM). Refer to On-Board

Diagnostics in the Multi-Port Fuel InjectionÐGen-

eral Diagnosis section of Group 14, Fuel Systems for

more information. Also refer to the appropriate Pow-

ertrain Diagnostics Procedures service manual for op-

eration of the DRB Scan Tool.

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

TEST

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

TEST

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

POWERTRAIN CONTROL MODULE (PCM)

The PCM (formerly referred to as the SBEC or en-

gine controller) is located in the engine compartment

behind the windshield washer fluid tank on YJ mod-

els (Fig. 17). It is located in the engine compartment

next to the air cleaner on XJ models (Fig. 18).

The ignition system is controlled by the PCM.

For removal and installation of this component, re-

fer to the Component Removal/Installation section of

this group.

Fig. 15 PCM 60-Way Connector

Fig. 16 Special Jumper Ground-to-Coil Negative

Terminal

Fig. 17 PCM LocationÐYJ Models

JIGNITION SYSTEMS 8D - 11

Page 326 of 2198

To test ignition coil-to-distributor cap cable, do not

remove the cable from the cap. Connect ohmmeter to

rotor button (center contact) of distributor cap and

terminal at ignition coil end of cable. If resistance is

not within specifications as found in the Spark Plug

Cable Resistance chart, remove the cable from the

distributor cap. Connect the ohmmeter to the termi-

nal ends of the cable. If resistance is not within spec-

ifications as found in the Spark Plug Cable

Resistance chart, replace the cable. Inspect the igni-

tion coil tower for cracks, burns or corrosion.

For removal and installation of spark plug cables,

refer to Spark Plug Secondary Cables in the Compo-

nent Removal/Installation section.

THROTTLE POSITION SENSOR TEST

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

OXYGEN (O2S) SENSOR TESTS

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

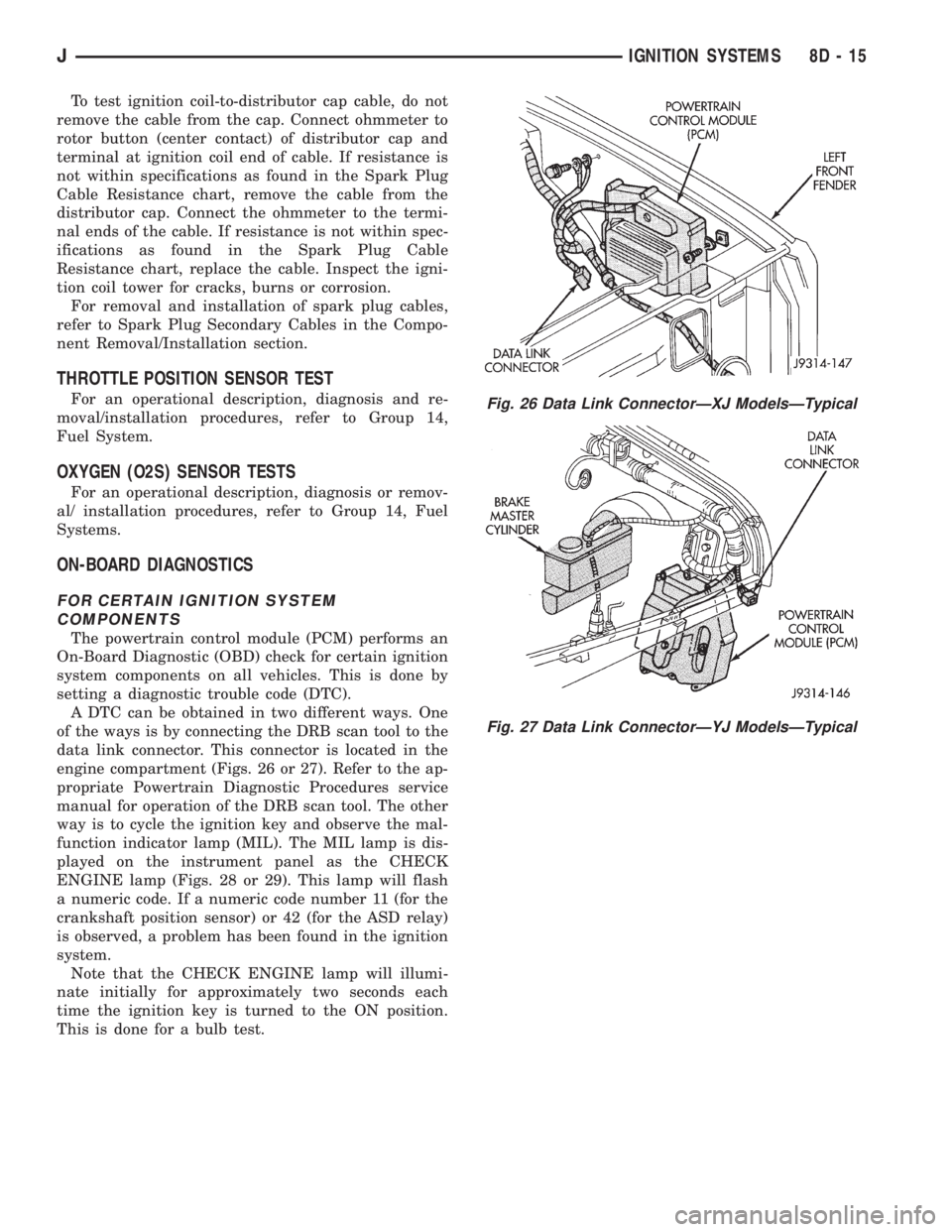

ON-BOARD DIAGNOSTICS

FOR CERTAIN IGNITION SYSTEM

COMPONENTS

The powertrain control module (PCM) performs an

On-Board Diagnostic (OBD) check for certain ignition

system components on all vehicles. This is done by

setting a diagnostic trouble code (DTC).

A DTC can be obtained in two different ways. One

of the ways is by connecting the DRB scan tool to the

data link connector. This connector is located in the

engine compartment (Figs. 26 or 27). Refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual for operation of the DRB scan tool. The other

way is to cycle the ignition key and observe the mal-

function indicator lamp (MIL). The MIL lamp is dis-

played on the instrument panel as the CHECK

ENGINE lamp (Figs. 28 or 29). This lamp will flash

a numeric code. If a numeric code number 11 (for the

crankshaft position sensor) or 42 (for the ASD relay)

is observed, a problem has been found in the ignition

system.

Note that the CHECK ENGINE lamp will illumi-

nate initially for approximately two seconds each

time the ignition key is turned to the ON position.

This is done for a bulb test.

Fig. 26 Data Link ConnectorÐXJ ModelsÐTypical

Fig. 27 Data Link ConnectorÐYJ ModelsÐTypical

JIGNITION SYSTEMS 8D - 15

Page 337 of 2198

IGNITION SWITCHÐXJ MODELS

IGNITION SWITCH AND KEY CYLINDER SERVICE

The ignition switch is located on the steering col-

umn. The Key-In-Switch and Halo Light are integral

with the ignition switch. Refer to Group 8U for Key-

In-Switch and Halo Light diagnosis for XJ models.

Refer to Group 8W, Wiring for ignition switch wir-

ing circuits.

REMOVAL

(1) Disconnect negative battery cable from battery.

(2) If vehicle has a tilt column, remove tilt lever by

turning it counterclockwise.

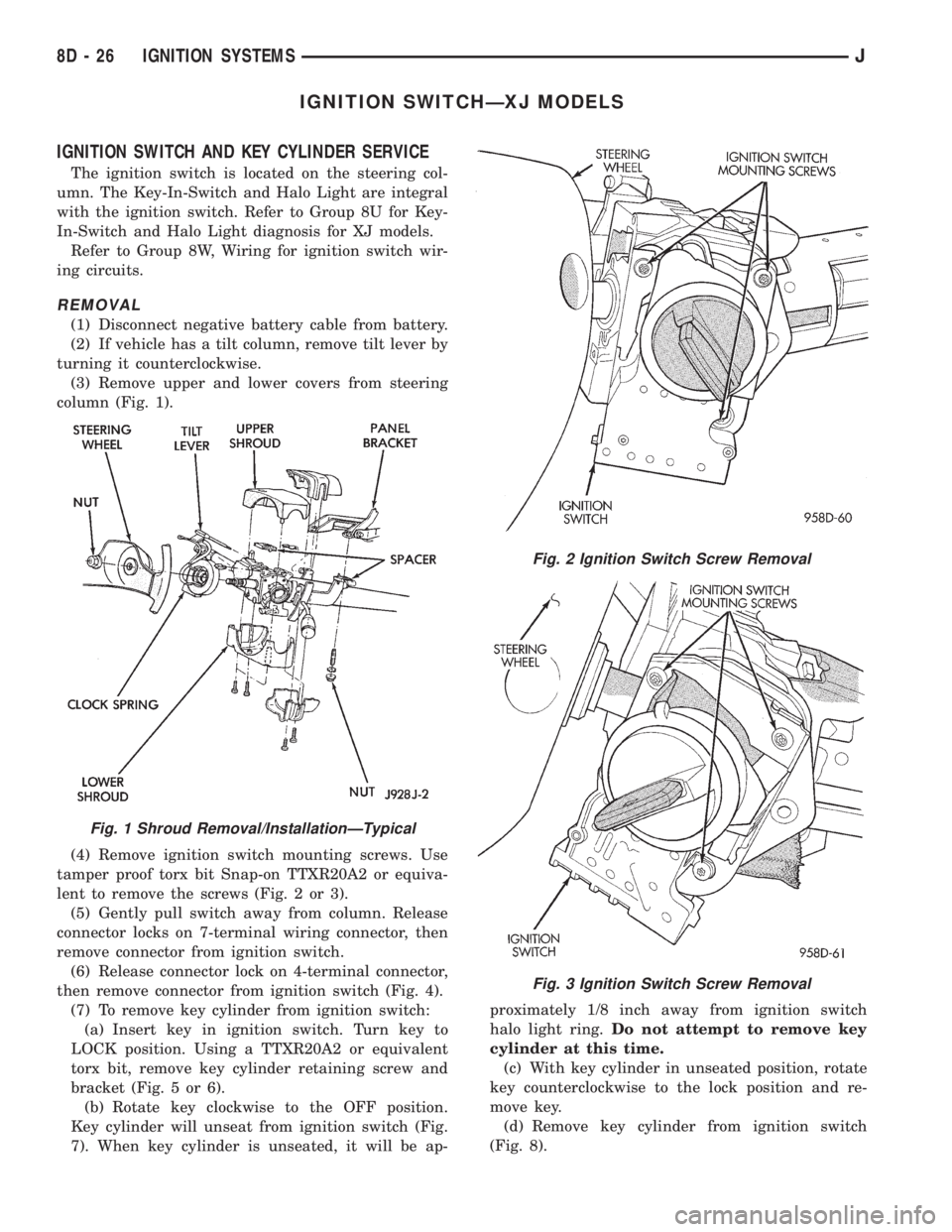

(3) Remove upper and lower covers from steering

column (Fig. 1).

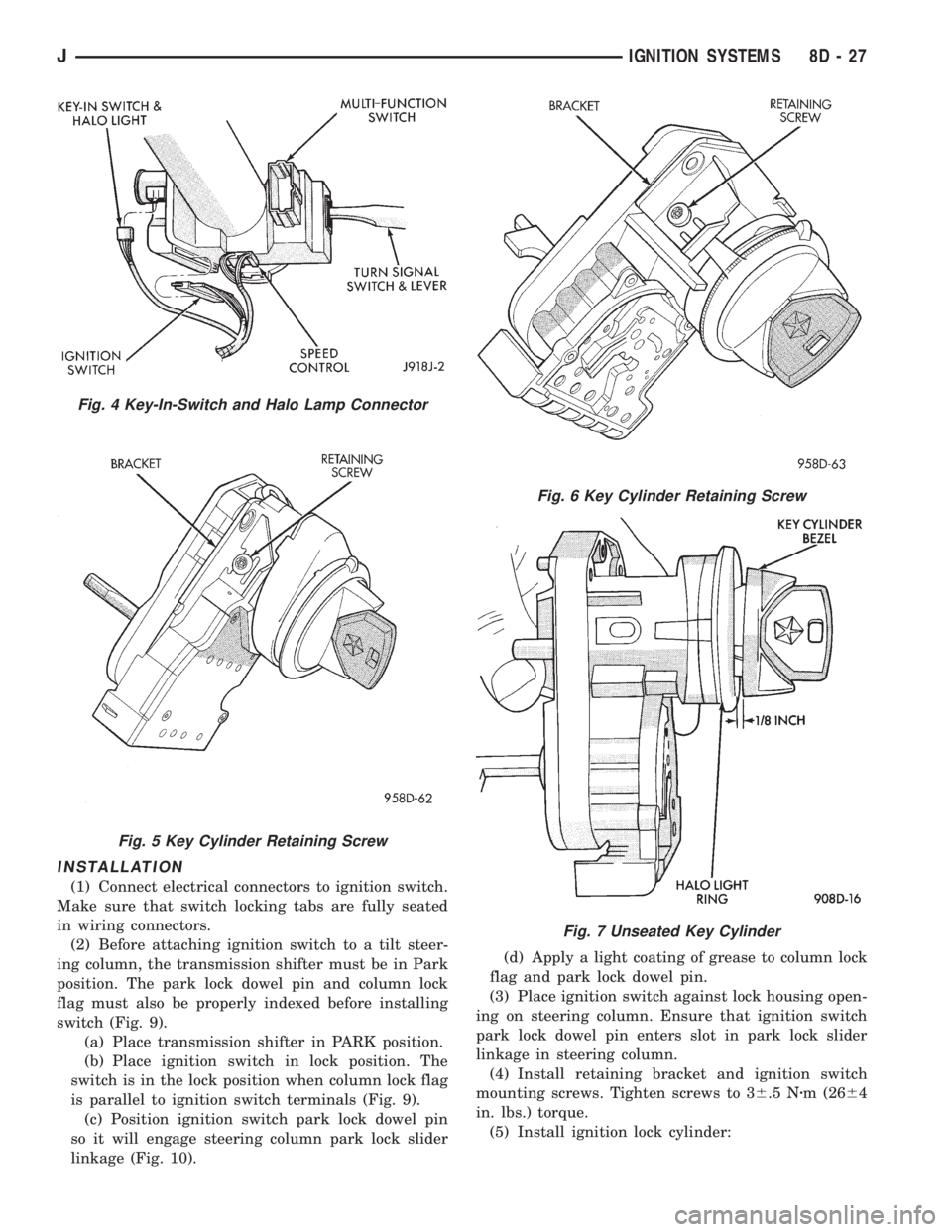

(4) Remove ignition switch mounting screws. Use

tamper proof torx bit Snap-on TTXR20A2 or equiva-

lent to remove the screws (Fig. 2 or 3).

(5) Gently pull switch away from column. Release

connector locks on 7-terminal wiring connector, then

remove connector from ignition switch.

(6) Release connector lock on 4-terminal connector,

then remove connector from ignition switch (Fig. 4).

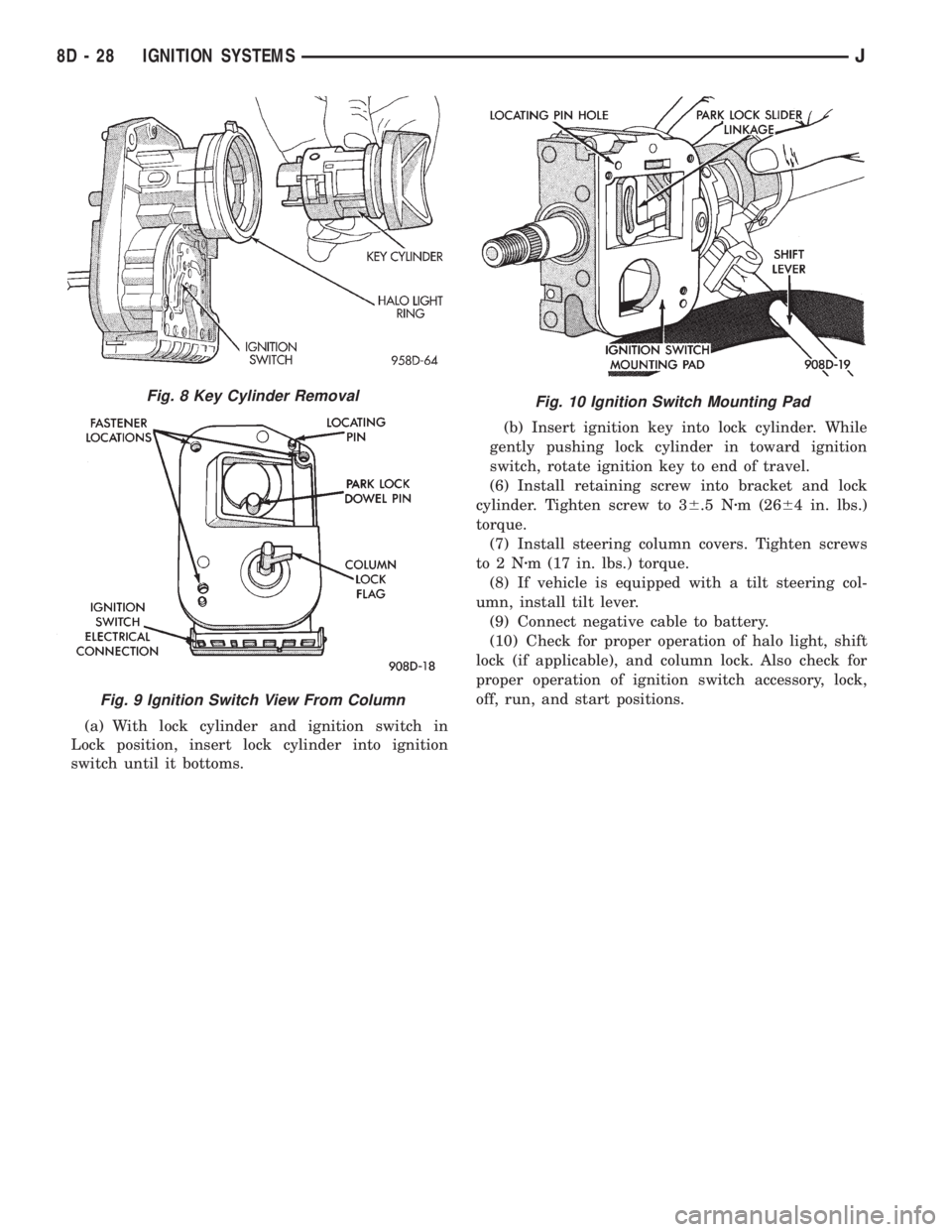

(7) To remove key cylinder from ignition switch:

(a) Insert key in ignition switch. Turn key to

LOCK position. Using a TTXR20A2 or equivalent

torx bit, remove key cylinder retaining screw and

bracket (Fig. 5 or 6).

(b) Rotate key clockwise to the OFF position.

Key cylinder will unseat from ignition switch (Fig.

7). When key cylinder is unseated, it will be ap-proximately 1/8 inch away from ignition switch

halo light ring.Do not attempt to remove key

cylinder at this time.

(c) With key cylinder in unseated position, rotate

key counterclockwise to the lock position and re-

move key.

(d) Remove key cylinder from ignition switch

(Fig. 8).

Fig. 1 Shroud Removal/InstallationÐTypical

Fig. 2 Ignition Switch Screw Removal

Fig. 3 Ignition Switch Screw Removal

8D - 26 IGNITION SYSTEMSJ

Page 338 of 2198

INSTALLATION

(1) Connect electrical connectors to ignition switch.

Make sure that switch locking tabs are fully seated

in wiring connectors.

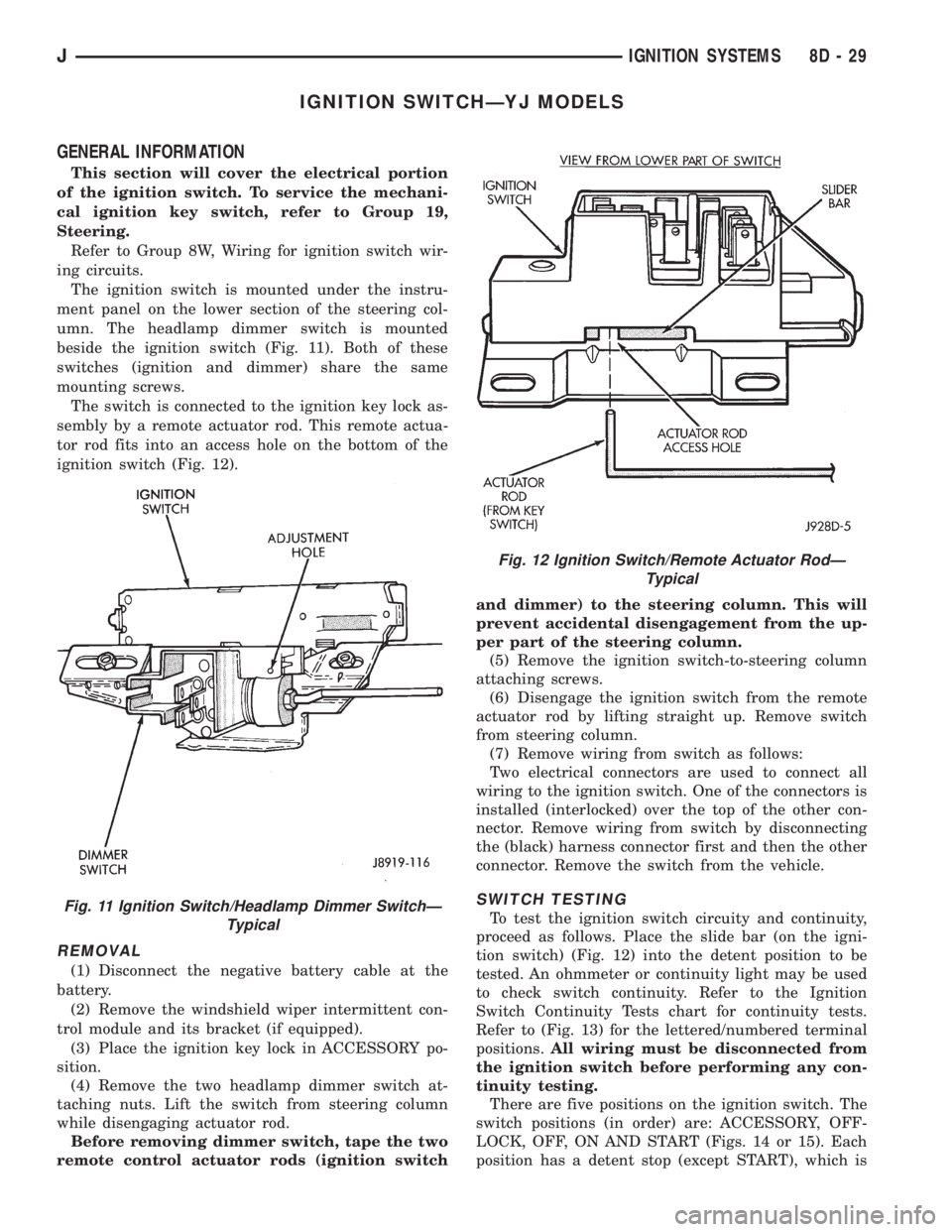

(2) Before attaching ignition switch to a tilt steer-

ing column, the transmission shifter must be in Park

position. The park lock dowel pin and column lock

flag must also be properly indexed before installing

switch (Fig. 9).

(a) Place transmission shifter in PARK position.

(b) Place ignition switch in lock position. The

switch is in the lock position when column lock flag

is parallel to ignition switch terminals (Fig. 9).

(c) Position ignition switch park lock dowel pin

so it will engage steering column park lock slider

linkage (Fig. 10).(d) Apply a light coating of grease to column lock

flag and park lock dowel pin.

(3) Place ignition switch against lock housing open-

ing on steering column. Ensure that ignition switch

park lock dowel pin enters slot in park lock slider

linkage in steering column.

(4) Install retaining bracket and ignition switch

mounting screws. Tighten screws to 36.5 Nzm (2664

in. lbs.) torque.

(5) Install ignition lock cylinder:

Fig. 4 Key-In-Switch and Halo Lamp Connector

Fig. 5 Key Cylinder Retaining Screw

Fig. 6 Key Cylinder Retaining Screw

Fig. 7 Unseated Key Cylinder

JIGNITION SYSTEMS 8D - 27

Page 339 of 2198

(a) With lock cylinder and ignition switch in

Lock position, insert lock cylinder into ignition

switch until it bottoms.(b) Insert ignition key into lock cylinder. While

gently pushing lock cylinder in toward ignition

switch, rotate ignition key to end of travel.

(6) Install retaining screw into bracket and lock

cylinder. Tighten screw to 36.5 Nzm (2664 in. lbs.)

torque.

(7) Install steering column covers. Tighten screws

to2Nzm (17 in. lbs.) torque.

(8) If vehicle is equipped with a tilt steering col-

umn, install tilt lever.

(9) Connect negative cable to battery.

(10) Check for proper operation of halo light, shift

lock (if applicable), and column lock. Also check for

proper operation of ignition switch accessory, lock,

off, run, and start positions.

Fig. 10 Ignition Switch Mounting PadFig. 8 Key Cylinder Removal

Fig. 9 Ignition Switch View From Column

8D - 28 IGNITION SYSTEMSJ

Page 340 of 2198

IGNITION SWITCHÐYJ MODELS

GENERAL INFORMATION

This section will cover the electrical portion

of the ignition switch. To service the mechani-

cal ignition key switch, refer to Group 19,

Steering.

Refer to Group 8W, Wiring for ignition switch wir-

ing circuits.

The ignition switch is mounted under the instru-

ment panel on the lower section of the steering col-

umn. The headlamp dimmer switch is mounted

beside the ignition switch (Fig. 11). Both of these

switches (ignition and dimmer) share the same

mounting screws.

The switch is connected to the ignition key lock as-

sembly by a remote actuator rod. This remote actua-

tor rod fits into an access hole on the bottom of the

ignition switch (Fig. 12).

REMOVAL

(1) Disconnect the negative battery cable at the

battery.

(2) Remove the windshield wiper intermittent con-

trol module and its bracket (if equipped).

(3) Place the ignition key lock in ACCESSORY po-

sition.

(4) Remove the two headlamp dimmer switch at-

taching nuts. Lift the switch from steering column

while disengaging actuator rod.

Before removing dimmer switch, tape the two

remote control actuator rods (ignition switchand dimmer) to the steering column. This will

prevent accidental disengagement from the up-

per part of the steering column.

(5) Remove the ignition switch-to-steering column

attaching screws.

(6) Disengage the ignition switch from the remote

actuator rod by lifting straight up. Remove switch

from steering column.

(7) Remove wiring from switch as follows:

Two electrical connectors are used to connect all

wiring to the ignition switch. One of the connectors is

installed (interlocked) over the top of the other con-

nector. Remove wiring from switch by disconnecting

the (black) harness connector first and then the other

connector. Remove the switch from the vehicle.

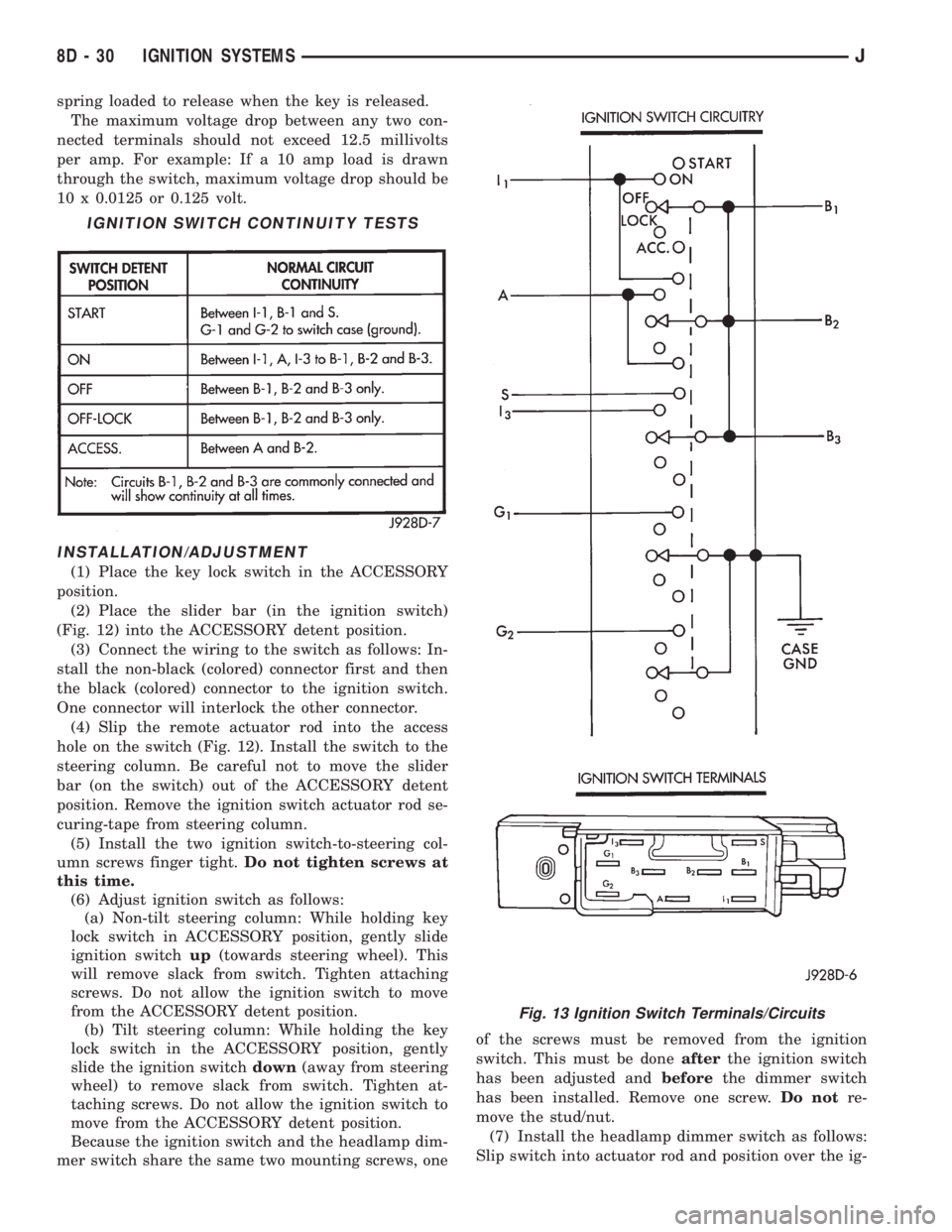

SWITCH TESTING

To test the ignition switch circuity and continuity,

proceed as follows. Place the slide bar (on the igni-

tion switch) (Fig. 12) into the detent position to be

tested. An ohmmeter or continuity light may be used

to check switch continuity. Refer to the Ignition

Switch Continuity Tests chart for continuity tests.

Refer to (Fig. 13) for the lettered/numbered terminal

positions.All wiring must be disconnected from

the ignition switch before performing any con-

tinuity testing.

There are five positions on the ignition switch. The

switch positions (in order) are: ACCESSORY, OFF-

LOCK, OFF, ON AND START (Figs. 14 or 15). Each

position has a detent stop (except START), which isFig. 11 Ignition Switch/Headlamp Dimmer SwitchÐ

Typical

Fig. 12 Ignition Switch/Remote Actuator RodÐ

Typical

JIGNITION SYSTEMS 8D - 29

Page 341 of 2198

spring loaded to release when the key is released.

The maximum voltage drop between any two con-

nected terminals should not exceed 12.5 millivolts

per amp. For example: If a 10 amp load is drawn

through the switch, maximum voltage drop should be

10 x 0.0125 or 0.125 volt.

INSTALLATION/ADJUSTMENT

(1) Place the key lock switch in the ACCESSORY

position.

(2) Place the slider bar (in the ignition switch)

(Fig. 12) into the ACCESSORY detent position.

(3) Connect the wiring to the switch as follows: In-

stall the non-black (colored) connector first and then

the black (colored) connector to the ignition switch.

One connector will interlock the other connector.

(4) Slip the remote actuator rod into the access

hole on the switch (Fig. 12). Install the switch to the

steering column. Be careful not to move the slider

bar (on the switch) out of the ACCESSORY detent

position. Remove the ignition switch actuator rod se-

curing-tape from steering column.

(5) Install the two ignition switch-to-steering col-

umn screws finger tight.Do not tighten screws at

this time.

(6) Adjust ignition switch as follows:

(a) Non-tilt steering column: While holding key

lock switch in ACCESSORY position, gently slide

ignition switchup(towards steering wheel). This

will remove slack from switch. Tighten attaching

screws. Do not allow the ignition switch to move

from the ACCESSORY detent position.

(b) Tilt steering column: While holding the key

lock switch in the ACCESSORY position, gently

slide the ignition switchdown(away from steering

wheel) to remove slack from switch. Tighten at-

taching screws. Do not allow the ignition switch to

move from the ACCESSORY detent position.

Because the ignition switch and the headlamp dim-

mer switch share the same two mounting screws, oneof the screws must be removed from the ignition

switch. This must be doneafterthe ignition switch

has been adjusted andbeforethe dimmer switch

has been installed. Remove one screw.Do notre-

move the stud/nut.

(7) Install the headlamp dimmer switch as follows:

Slip switch into actuator rod and position over the ig-

IGNITION SWITCH CONTINUITY TESTS

Fig. 13 Ignition Switch Terminals/Circuits

8D - 30 IGNITION SYSTEMSJ

Page 443 of 2198

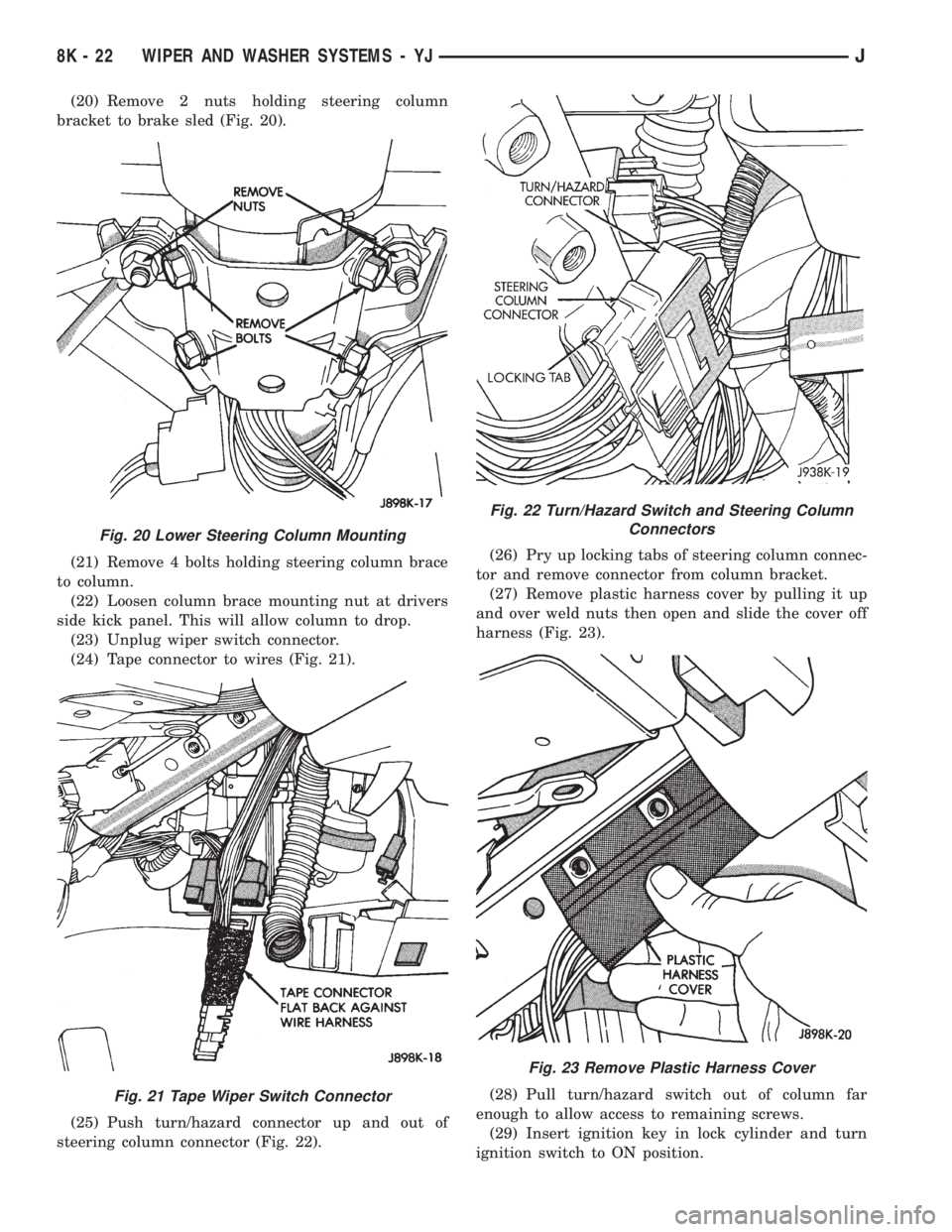

(20) Remove 2 nuts holding steering column

bracket to brake sled (Fig. 20).

(21) Remove 4 bolts holding steering column brace

to column.

(22) Loosen column brace mounting nut at drivers

side kick panel. This will allow column to drop.

(23) Unplug wiper switch connector.

(24) Tape connector to wires (Fig. 21).

(25) Push turn/hazard connector up and out of

steering column connector (Fig. 22).(26) Pry up locking tabs of steering column connec-

tor and remove connector from column bracket.

(27) Remove plastic harness cover by pulling it up

and over weld nuts then open and slide the cover off

harness (Fig. 23).

(28) Pull turn/hazard switch out of column far

enough to allow access to remaining screws.

(29) Insert ignition key in lock cylinder and turn

ignition switch to ON position.

Fig. 20 Lower Steering Column Mounting

Fig. 21 Tape Wiper Switch Connector

Fig. 22 Turn/Hazard Switch and Steering Column

Connectors

Fig. 23 Remove Plastic Harness Cover

8K - 22 WIPER AND WASHER SYSTEMS - YJJ