key JEEP CHEROKEE 1995 Service Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 694 of 2198

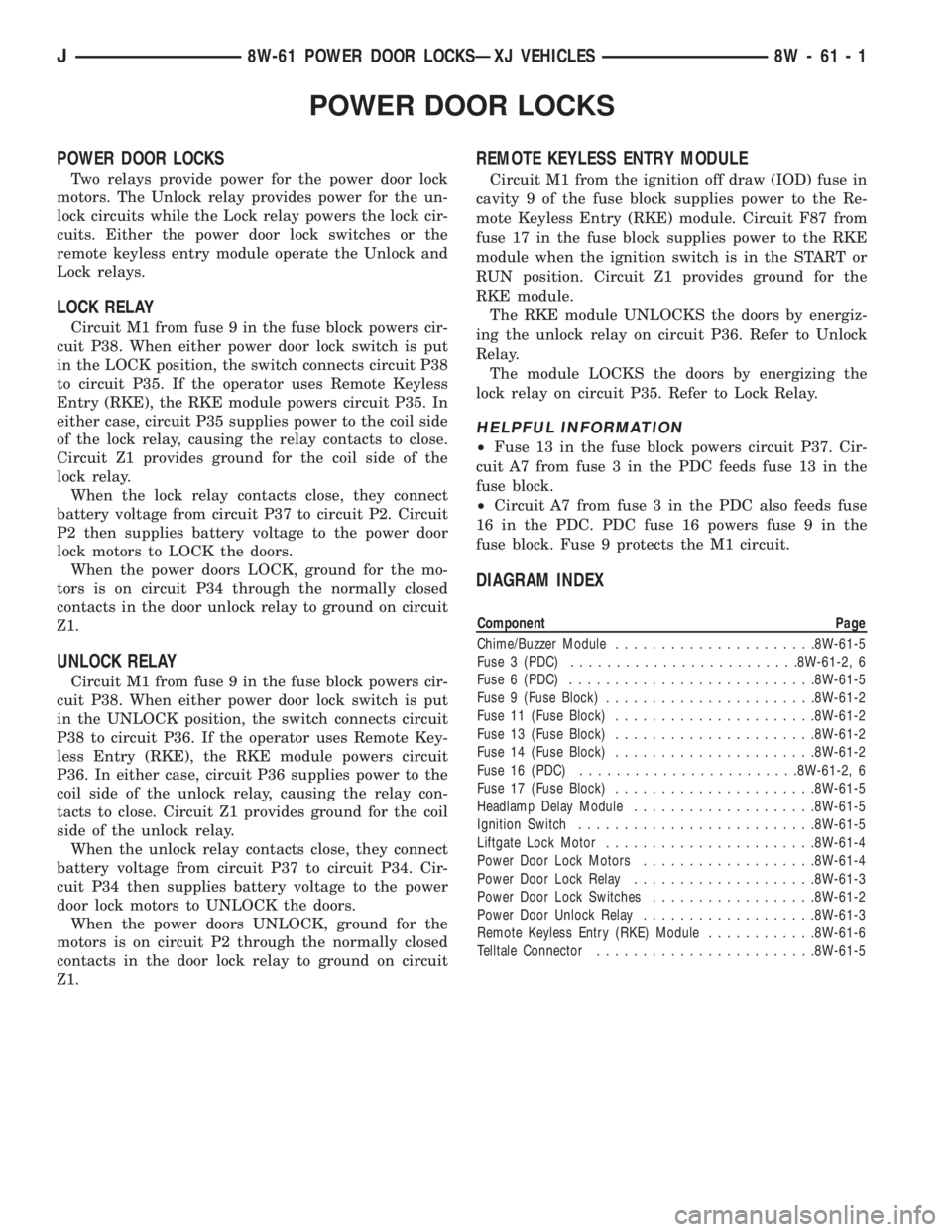

POWER DOOR LOCKS

POWER DOOR LOCKS

Two relays provide power for the power door lock

motors. The Unlock relay provides power for the un-

lock circuits while the Lock relay powers the lock cir-

cuits. Either the power door lock switches or the

remote keyless entry module operate the Unlock and

Lock relays.

LOCK RELAY

Circuit M1 from fuse 9 in the fuse block powers cir-

cuit P38. When either power door lock switch is put

in the LOCK position, the switch connects circuit P38

to circuit P35. If the operator uses Remote Keyless

Entry (RKE), the RKE module powers circuit P35. In

either case, circuit P35 supplies power to the coil side

of the lock relay, causing the relay contacts to close.

Circuit Z1 provides ground for the coil side of the

lock relay.

When the lock relay contacts close, they connect

battery voltage from circuit P37 to circuit P2. Circuit

P2 then supplies battery voltage to the power door

lock motors to LOCK the doors.

When the power doors LOCK, ground for the mo-

tors is on circuit P34 through the normally closed

contacts in the door unlock relay to ground on circuit

Z1.

UNLOCK RELAY

Circuit M1 from fuse 9 in the fuse block powers cir-

cuit P38. When either power door lock switch is put

in the UNLOCK position, the switch connects circuit

P38 to circuit P36. If the operator uses Remote Key-

less Entry (RKE), the RKE module powers circuit

P36. In either case, circuit P36 supplies power to the

coil side of the unlock relay, causing the relay con-

tacts to close. Circuit Z1 provides ground for the coil

side of the unlock relay.

When the unlock relay contacts close, they connect

battery voltage from circuit P37 to circuit P34. Cir-

cuit P34 then supplies battery voltage to the power

door lock motors to UNLOCK the doors.

When the power doors UNLOCK, ground for the

motors is on circuit P2 through the normally closed

contacts in the door lock relay to ground on circuit

Z1.

REMOTE KEYLESS ENTRY MODULE

Circuit M1 from the ignition off draw (IOD) fuse in

cavity 9 of the fuse block supplies power to the Re-

mote Keyless Entry (RKE) module. Circuit F87 from

fuse 17 in the fuse block supplies power to the RKE

module when the ignition switch is in the START or

RUN position. Circuit Z1 provides ground for the

RKE module.

The RKE module UNLOCKS the doors by energiz-

ing the unlock relay on circuit P36. Refer to Unlock

Relay.

The module LOCKS the doors by energizing the

lock relay on circuit P35. Refer to Lock Relay.

HELPFUL INFORMATION

²Fuse 13 in the fuse block powers circuit P37. Cir-

cuit A7 from fuse 3 in the PDC feeds fuse 13 in the

fuse block.

²Circuit A7 from fuse 3 in the PDC also feeds fuse

16 in the PDC. PDC fuse 16 powers fuse 9 in the

fuse block. Fuse 9 protects the M1 circuit.

DIAGRAM INDEX

Component Page

Chime/Buzzer Module......................8W-61-5

Fuse 3 (PDC).........................8W-61-2, 6

Fuse 6 (PDC)...........................8W-61-5

Fuse 9 (Fuse Block).......................8W-61-2

Fuse 11 (Fuse Block)......................8W-61-2

Fuse 13 (Fuse Block)......................8W-61-2

Fuse 14 (Fuse Block)......................8W-61-2

Fuse 16 (PDC)........................8W-61-2, 6

Fuse 17 (Fuse Block)......................8W-61-5

Headlamp Delay Module....................8W-61-5

Ignition Switch..........................8W-61-5

Liftgate Lock Motor.......................8W-61-4

Power Door Lock Motors...................8W-61-4

Power Door Lock Relay....................8W-61-3

Power Door Lock Switches..................8W-61-2

Power Door Unlock Relay...................8W-61-3

Remote Keyless Entry (RKE) Module............8W-61-6

Telltale Connector........................8W-61-5

J8W-61 POWER DOOR LOCKSÐXJ VEHICLES 8W - 61 - 1

Page 814 of 2198

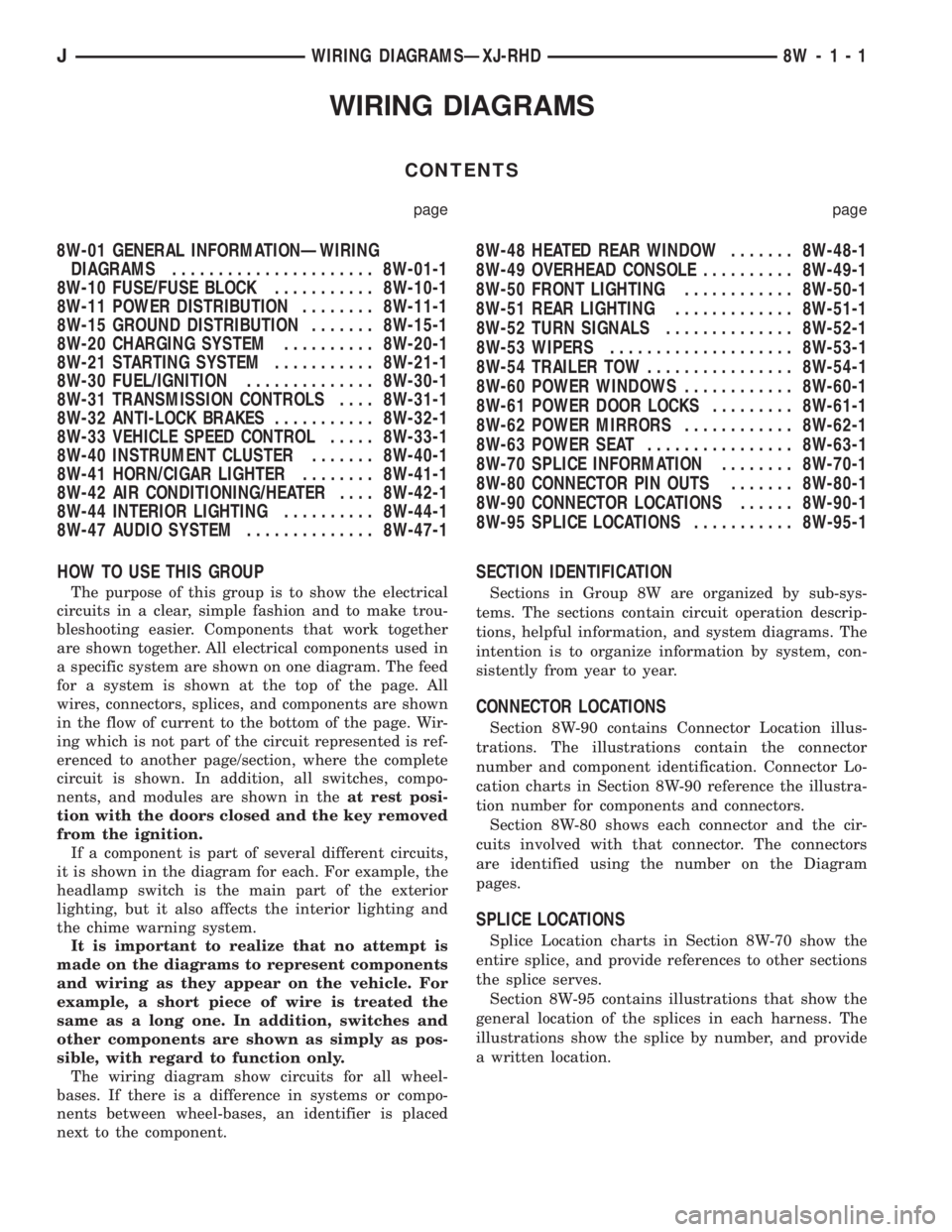

WIRING DIAGRAMS

CONTENTS

page page

8W-01 GENERAL INFORMATIONÐWIRING

DIAGRAMS...................... 8W-01-1

8W-10 FUSE/FUSE BLOCK........... 8W-10-1

8W-11 POWER DISTRIBUTION........ 8W-11-1

8W-15 GROUND DISTRIBUTION....... 8W-15-1

8W-20 CHARGING SYSTEM.......... 8W-20-1

8W-21 STARTING SYSTEM........... 8W-21-1

8W-30 FUEL/IGNITION.............. 8W-30-1

8W-31 TRANSMISSION CONTROLS.... 8W-31-1

8W-32 ANTI-LOCK BRAKES........... 8W-32-1

8W-33 VEHICLE SPEED CONTROL..... 8W-33-1

8W-40 INSTRUMENT CLUSTER....... 8W-40-1

8W-41 HORN/CIGAR LIGHTER........ 8W-41-1

8W-42 AIR CONDITIONING/HEATER.... 8W-42-1

8W-44 INTERIOR LIGHTING.......... 8W-44-1

8W-47 AUDIO SYSTEM.............. 8W-47-18W-48 HEATED REAR WINDOW....... 8W-48-1

8W-49 OVERHEAD CONSOLE.......... 8W-49-1

8W-50 FRONT LIGHTING............ 8W-50-1

8W-51 REAR LIGHTING............. 8W-51-1

8W-52 TURN SIGNALS.............. 8W-52-1

8W-53 WIPERS.................... 8W-53-1

8W-54 TRAILER TOW................ 8W-54-1

8W-60 POWER WINDOWS............ 8W-60-1

8W-61 POWER DOOR LOCKS......... 8W-61-1

8W-62 POWER MIRRORS............ 8W-62-1

8W-63 POWER SEAT................ 8W-63-1

8W-70 SPLICE INFORMATION........ 8W-70-1

8W-80 CONNECTOR PIN OUTS....... 8W-80-1

8W-90 CONNECTOR LOCATIONS...... 8W-90-1

8W-95 SPLICE LOCATIONS........... 8W-95-1

HOW TO USE THIS GROUP

The purpose of this group is to show the electrical

circuits in a clear, simple fashion and to make trou-

bleshooting easier. Components that work together

are shown together. All electrical components used in

a specific system are shown on one diagram. The feed

for a system is shown at the top of the page. All

wires, connectors, splices, and components are shown

in the flow of current to the bottom of the page. Wir-

ing which is not part of the circuit represented is ref-

erenced to another page/section, where the complete

circuit is shown. In addition, all switches, compo-

nents, and modules are shown in theat rest posi-

tion with the doors closed and the key removed

from the ignition.

If a component is part of several different circuits,

it is shown in the diagram for each. For example, the

headlamp switch is the main part of the exterior

lighting, but it also affects the interior lighting and

the chime warning system.

It is important to realize that no attempt is

made on the diagrams to represent components

and wiring as they appear on the vehicle. For

example, a short piece of wire is treated the

same as a long one. In addition, switches and

other components are shown as simply as pos-

sible, with regard to function only.

The wiring diagram show circuits for all wheel-

bases. If there is a difference in systems or compo-

nents between wheel-bases, an identifier is placed

next to the component.

SECTION IDENTIFICATION

Sections in Group 8W are organized by sub-sys-

tems. The sections contain circuit operation descrip-

tions, helpful information, and system diagrams. The

intention is to organize information by system, con-

sistently from year to year.

CONNECTOR LOCATIONS

Section 8W-90 contains Connector Location illus-

trations. The illustrations contain the connector

number and component identification. Connector Lo-

cation charts in Section 8W-90 reference the illustra-

tion number for components and connectors.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the number on the Diagram

pages.

SPLICE LOCATIONS

Splice Location charts in Section 8W-70 show the

entire splice, and provide references to other sections

the splice serves.

Section 8W-95 contains illustrations that show the

general location of the splices in each harness. The

illustrations show the splice by number, and provide

a written location.

JWIRING DIAGRAMSÐXJ-RHD 8W - 1 - 1

Page 854 of 2198

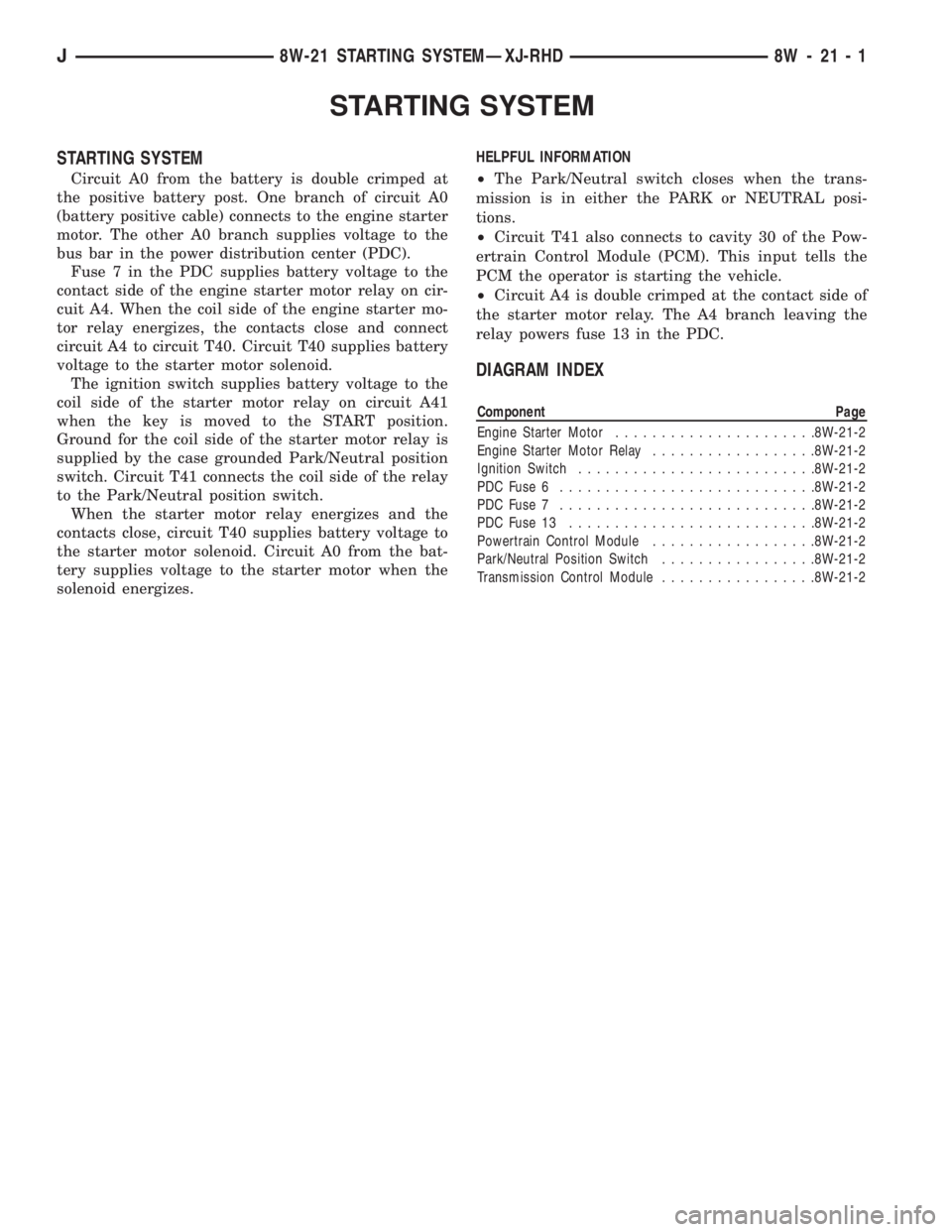

STARTING SYSTEM

STARTING SYSTEM

Circuit A0 from the battery is double crimped at

the positive battery post. One branch of circuit A0

(battery positive cable) connects to the engine starter

motor. The other A0 branch supplies voltage to the

bus bar in the power distribution center (PDC).

Fuse 7 in the PDC supplies battery voltage to the

contact side of the engine starter motor relay on cir-

cuit A4. When the coil side of the engine starter mo-

tor relay energizes, the contacts close and connect

circuit A4 to circuit T40. Circuit T40 supplies battery

voltage to the starter motor solenoid.

The ignition switch supplies battery voltage to the

coil side of the starter motor relay on circuit A41

when the key is moved to the START position.

Ground for the coil side of the starter motor relay is

supplied by the case grounded Park/Neutral position

switch. Circuit T41 connects the coil side of the relay

to the Park/Neutral position switch.

When the starter motor relay energizes and the

contacts close, circuit T40 supplies battery voltage to

the starter motor solenoid. Circuit A0 from the bat-

tery supplies voltage to the starter motor when the

solenoid energizes.HELPFUL INFORMATION

²The Park/Neutral switch closes when the trans-

mission is in either the PARK or NEUTRAL posi-

tions.

²Circuit T41 also connects to cavity 30 of the Pow-

ertrain Control Module (PCM). This input tells the

PCM the operator is starting the vehicle.

²Circuit A4 is double crimped at the contact side of

the starter motor relay. The A4 branch leaving the

relay powers fuse 13 in the PDC.

DIAGRAM INDEX

Component Page

Engine Starter Motor......................8W-21-2

Engine Starter Motor Relay..................8W-21-2

Ignition Switch..........................8W-21-2

PDC Fuse 6............................8W-21-2

PDC Fuse 7............................8W-21-2

PDC Fuse 13...........................8W-21-2

Powertrain Control Module..................8W-21-2

Park/Neutral Position Switch.................8W-21-2

Transmission Control Module.................8W-21-2

J8W-21 STARTING SYSTEMÐXJ-RHD 8W - 21 - 1

Page 909 of 2198

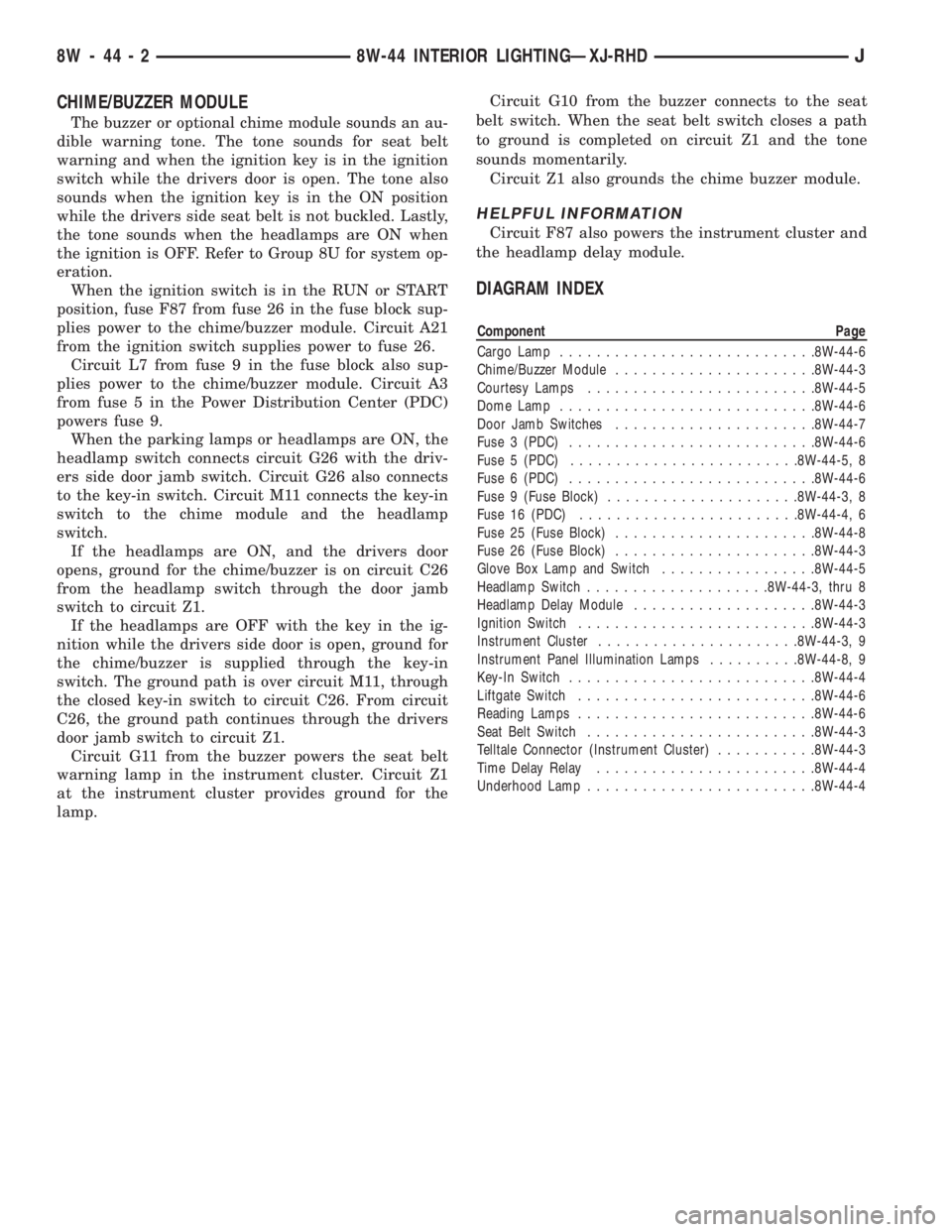

CHIME/BUZZER MODULE

The buzzer or optional chime module sounds an au-

dible warning tone. The tone sounds for seat belt

warning and when the ignition key is in the ignition

switch while the drivers door is open. The tone also

sounds when the ignition key is in the ON position

while the drivers side seat belt is not buckled. Lastly,

the tone sounds when the headlamps are ON when

the ignition is OFF. Refer to Group 8U for system op-

eration.

When the ignition switch is in the RUN or START

position, fuse F87 from fuse 26 in the fuse block sup-

plies power to the chime/buzzer module. Circuit A21

from the ignition switch supplies power to fuse 26.

Circuit L7 from fuse 9 in the fuse block also sup-

plies power to the chime/buzzer module. Circuit A3

from fuse 5 in the Power Distribution Center (PDC)

powers fuse 9.

When the parking lamps or headlamps are ON, the

headlamp switch connects circuit G26 with the driv-

ers side door jamb switch. Circuit G26 also connects

to the key-in switch. Circuit M11 connects the key-in

switch to the chime module and the headlamp

switch.

If the headlamps are ON, and the drivers door

opens, ground for the chime/buzzer is on circuit C26

from the headlamp switch through the door jamb

switch to circuit Z1.

If the headlamps are OFF with the key in the ig-

nition while the drivers side door is open, ground for

the chime/buzzer is supplied through the key-in

switch. The ground path is over circuit M11, through

the closed key-in switch to circuit C26. From circuit

C26, the ground path continues through the drivers

door jamb switch to circuit Z1.

Circuit G11 from the buzzer powers the seat belt

warning lamp in the instrument cluster. Circuit Z1

at the instrument cluster provides ground for the

lamp.Circuit G10 from the buzzer connects to the seat

belt switch. When the seat belt switch closes a path

to ground is completed on circuit Z1 and the tone

sounds momentarily.

Circuit Z1 also grounds the chime buzzer module.

HELPFUL INFORMATION

Circuit F87 also powers the instrument cluster and

the headlamp delay module.

DIAGRAM INDEX

Component Page

Cargo Lamp............................8W-44-6

Chime/Buzzer Module......................8W-44-3

Courtesy Lamps.........................8W-44-5

Dome Lamp............................8W-44-6

Door Jamb Switches......................8W-44-7

Fuse 3 (PDC)...........................8W-44-6

Fuse 5 (PDC).........................8W-44-5, 8

Fuse 6 (PDC)...........................8W-44-6

Fuse 9 (Fuse Block).....................8W-44-3, 8

Fuse 16 (PDC)........................8W-44-4, 6

Fuse 25 (Fuse Block)......................8W-44-8

Fuse 26 (Fuse Block)......................8W-44-3

Glove Box Lamp and Switch.................8W-44-5

Headlamp Switch....................8W-44-3, thru 8

Headlamp Delay Module....................8W-44-3

Ignition Switch..........................8W-44-3

Instrument Cluster......................8W-44-3, 9

Instrument Panel Illumination Lamps..........8W-44-8, 9

Key-In Switch...........................8W-44-4

Liftgate Switch..........................8W-44-6

Reading Lamps..........................8W-44-6

Seat Belt Switch.........................8W-44-3

Telltale Connector (Instrument Cluster)...........8W-44-3

Time Delay Relay........................8W-44-4

Underhood Lamp.........................8W-44-4

8W - 44 - 2 8W-44 INTERIOR LIGHTINGÐXJ-RHDJ

Page 1121 of 2198

at the engine cylinder head. Also tap the top of the

retainer to seat the valve locks.

(8) Install the engine cylinder head.

VALVE TIMING

Disconnect the spark plug wires and remove the

spark plugs.

Remove the engine cylinder head cover.

Remove the capscrews, bridge and pivot assembly,

and rocker arms from above the No.1 cylinder.

Alternately loosen each capscrew, one turn at a

time, to avoid damaging the bridge.

Rotate the crankshaft until the No.4 piston is at

top dead center (TDC) on the compression stroke.

Rotate the crankshaft counterclockwise (viewed

from the front of the engine) 90É.

Install a dial indicator on the end of the No.1 cyl-

inder intake valve push rod. Use rubber tubing to se-

cure the indicator stem on the push rod.

Set the dial indicator pointer at zero.

Rotate the crankshaft clockwise (viewed from the

front of the engine) until the dial indicator pointer

indicates 0.305 mm (0.012 inch) travel distance (lift).

The timing notch index on the vibration damper

should be aligned with the TDC mark on the timing

degree scale.

If the timing notch is more than 13 mm (1/2 inch)

away from the TDC mark in either direction, the

valve timing is incorrect.

If the valve timing is incorrect, the cause may be a

broken camshaft pin. It is not necessary to replace

the camshaft because of pin failure. A spring pin is

available for service replacement.

VIBRATION DAMPER

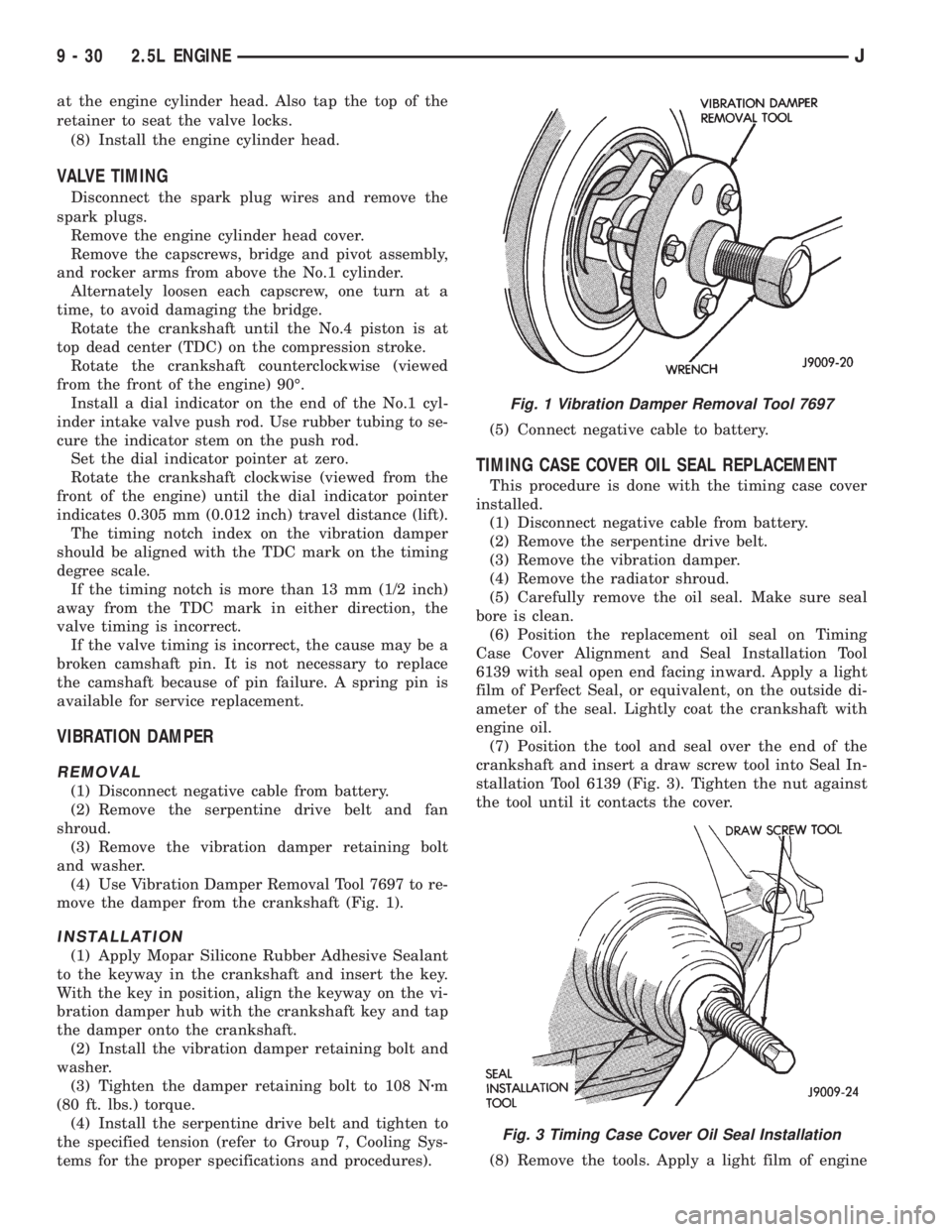

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt and fan

shroud.

(3) Remove the vibration damper retaining bolt

and washer.

(4) Use Vibration Damper Removal Tool 7697 to re-

move the damper from the crankshaft (Fig. 1).

INSTALLATION

(1) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key in position, align the keyway on the vi-

bration damper hub with the crankshaft key and tap

the damper onto the crankshaft.

(2) Install the vibration damper retaining bolt and

washer.

(3) Tighten the damper retaining bolt to 108 Nzm

(80 ft. lbs.) torque.

(4) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tems for the proper specifications and procedures).(5) Connect negative cable to battery.

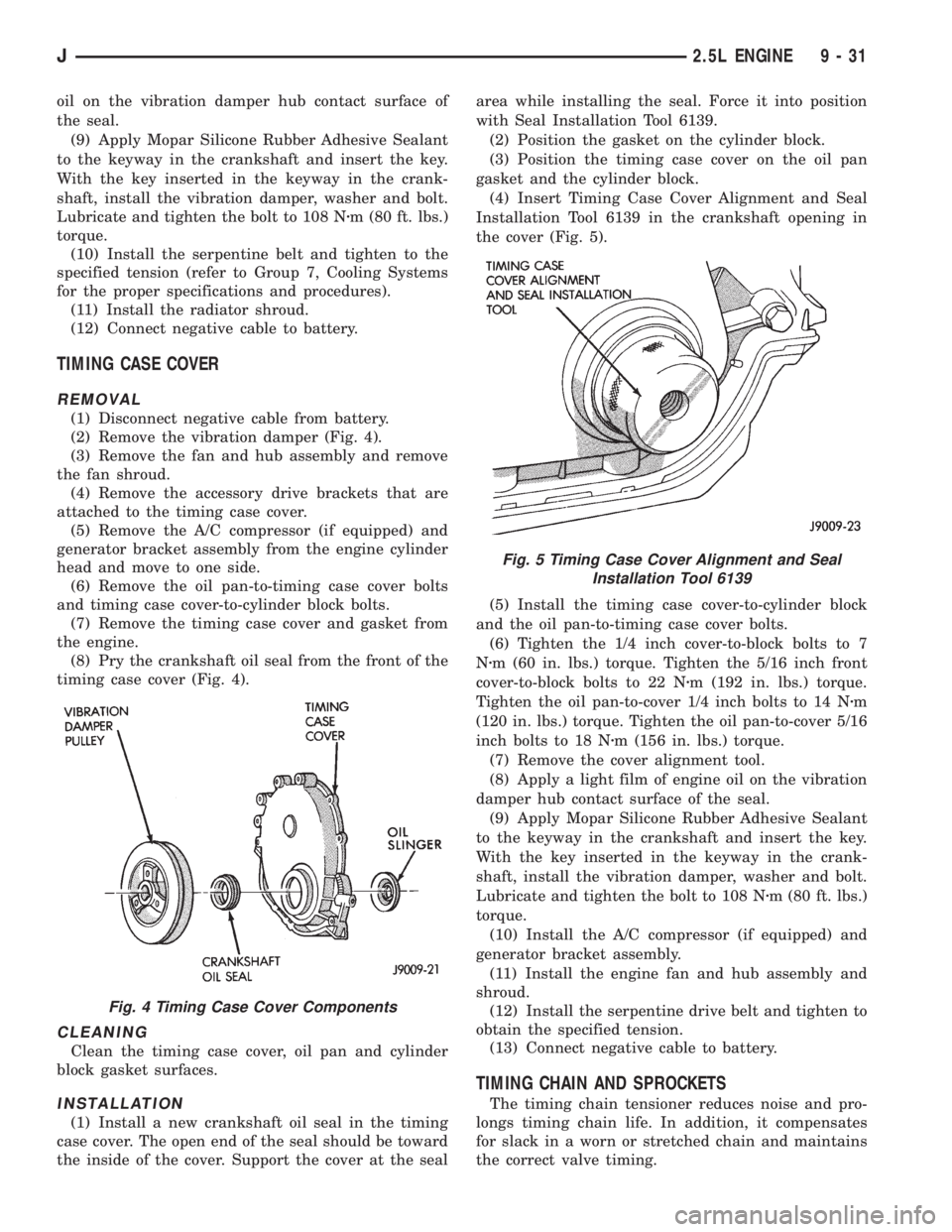

TIMING CASE COVER OIL SEAL REPLACEMENT

This procedure is done with the timing case cover

installed.

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt.

(3) Remove the vibration damper.

(4) Remove the radiator shroud.

(5) Carefully remove the oil seal. Make sure seal

bore is clean.

(6) Position the replacement oil seal on Timing

Case Cover Alignment and Seal Installation Tool

6139 with seal open end facing inward. Apply a light

film of Perfect Seal, or equivalent, on the outside di-

ameter of the seal. Lightly coat the crankshaft with

engine oil.

(7) Position the tool and seal over the end of the

crankshaft and insert a draw screw tool into Seal In-

stallation Tool 6139 (Fig. 3). Tighten the nut against

the tool until it contacts the cover.

(8) Remove the tools. Apply a light film of engine

Fig. 1 Vibration Damper Removal Tool 7697

Fig. 3 Timing Case Cover Oil Seal Installation

9 - 30 2.5L ENGINEJ

Page 1122 of 2198

oil on the vibration damper hub contact surface of

the seal.

(9) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key inserted in the keyway in the crank-

shaft, install the vibration damper, washer and bolt.

Lubricate and tighten the bolt to 108 Nzm (80 ft. lbs.)

torque.

(10) Install the serpentine belt and tighten to the

specified tension (refer to Group 7, Cooling Systems

for the proper specifications and procedures).

(11) Install the radiator shroud.

(12) Connect negative cable to battery.

TIMING CASE COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the vibration damper (Fig. 4).

(3) Remove the fan and hub assembly and remove

the fan shroud.

(4) Remove the accessory drive brackets that are

attached to the timing case cover.

(5) Remove the A/C compressor (if equipped) and

generator bracket assembly from the engine cylinder

head and move to one side.

(6) Remove the oil pan-to-timing case cover bolts

and timing case cover-to-cylinder block bolts.

(7) Remove the timing case cover and gasket from

the engine.

(8) Pry the crankshaft oil seal from the front of the

timing case cover (Fig. 4).

CLEANING

Clean the timing case cover, oil pan and cylinder

block gasket surfaces.

INSTALLATION

(1) Install a new crankshaft oil seal in the timing

case cover. The open end of the seal should be toward

the inside of the cover. Support the cover at the sealarea while installing the seal. Force it into position

with Seal Installation Tool 6139.

(2) Position the gasket on the cylinder block.

(3) Position the timing case cover on the oil pan

gasket and the cylinder block.

(4) Insert Timing Case Cover Alignment and Seal

Installation Tool 6139 in the crankshaft opening in

the cover (Fig. 5).

(5) Install the timing case cover-to-cylinder block

and the oil pan-to-timing case cover bolts.

(6) Tighten the 1/4 inch cover-to-block bolts to 7

Nzm (60 in. lbs.) torque. Tighten the 5/16 inch front

cover-to-block bolts to 22 Nzm (192 in. lbs.) torque.

Tighten the oil pan-to-cover 1/4 inch bolts to 14 Nzm

(120 in. lbs.) torque. Tighten the oil pan-to-cover 5/16

inch bolts to 18 Nzm (156 in. lbs.) torque.

(7) Remove the cover alignment tool.

(8) Apply a light film of engine oil on the vibration

damper hub contact surface of the seal.

(9) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key inserted in the keyway in the crank-

shaft, install the vibration damper, washer and bolt.

Lubricate and tighten the bolt to 108 Nzm (80 ft. lbs.)

torque.

(10) Install the A/C compressor (if equipped) and

generator bracket assembly.

(11) Install the engine fan and hub assembly and

shroud.

(12) Install the serpentine drive belt and tighten to

obtain the specified tension.

(13) Connect negative cable to battery.

TIMING CHAIN AND SPROCKETS

The timing chain tensioner reduces noise and pro-

longs timing chain life. In addition, it compensates

for slack in a worn or stretched chain and maintains

the correct valve timing.

Fig. 4 Timing Case Cover Components

Fig. 5 Timing Case Cover Alignment and Seal

Installation Tool 6139

J2.5L ENGINE 9 - 31

Page 1123 of 2198

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the fan and shroud.

(3) Remove the serpentine drive belt.

(4) Remove the crankshaft vibration damper.

(5) Remove the timing case cover.

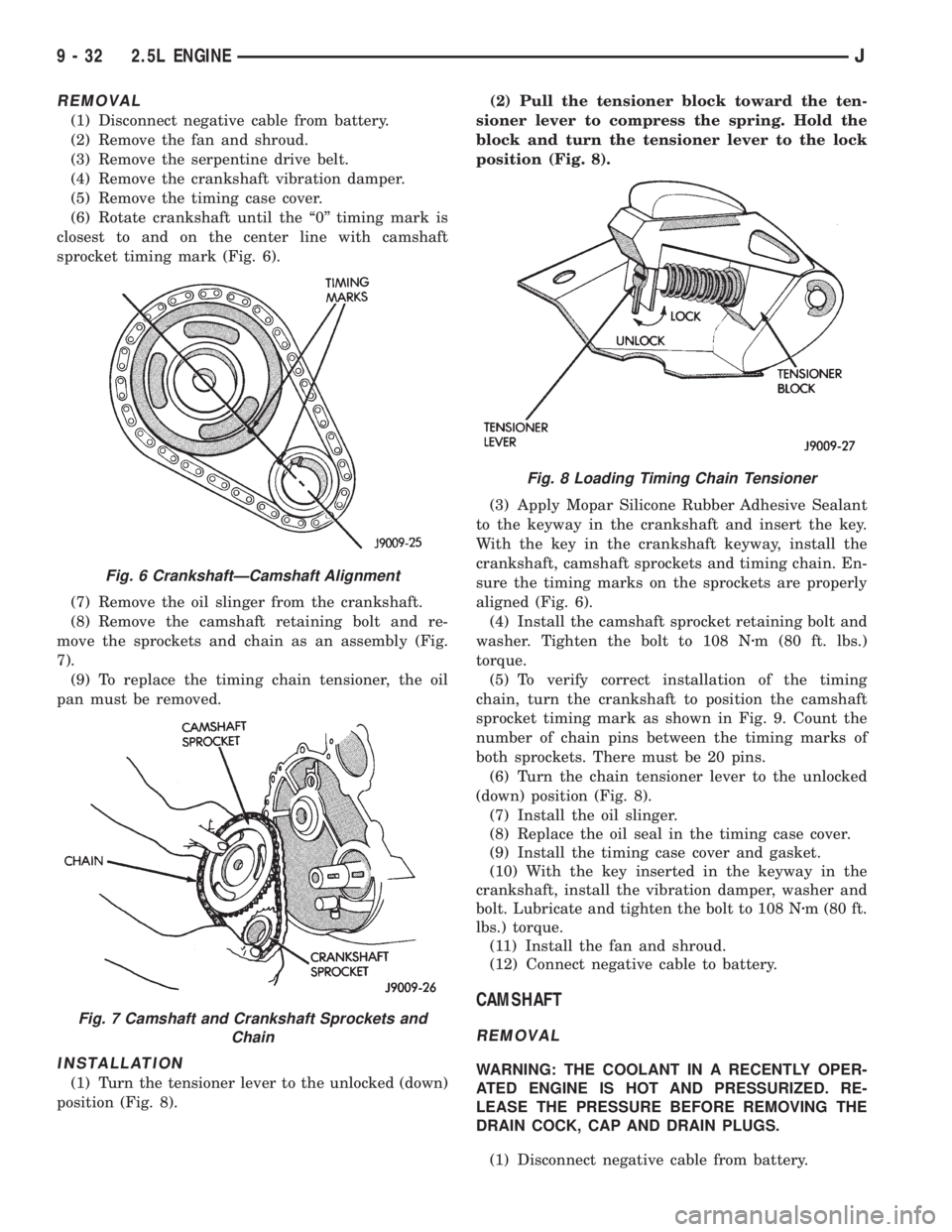

(6) Rotate crankshaft until the ``0'' timing mark is

closest to and on the center line with camshaft

sprocket timing mark (Fig. 6).

(7) Remove the oil slinger from the crankshaft.

(8) Remove the camshaft retaining bolt and re-

move the sprockets and chain as an assembly (Fig.

7).

(9) To replace the timing chain tensioner, the oil

pan must be removed.

INSTALLATION

(1) Turn the tensioner lever to the unlocked (down)

position (Fig. 8).(2) Pull the tensioner block toward the ten-

sioner lever to compress the spring. Hold the

block and turn the tensioner lever to the lock

position (Fig. 8).

(3) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key in the crankshaft keyway, install the

crankshaft, camshaft sprockets and timing chain. En-

sure the timing marks on the sprockets are properly

aligned (Fig. 6).

(4) Install the camshaft sprocket retaining bolt and

washer. Tighten the bolt to 108 Nzm (80 ft. lbs.)

torque.

(5) To verify correct installation of the timing

chain, turn the crankshaft to position the camshaft

sprocket timing mark as shown in Fig. 9. Count the

number of chain pins between the timing marks of

both sprockets. There must be 20 pins.

(6) Turn the chain tensioner lever to the unlocked

(down) position (Fig. 8).

(7) Install the oil slinger.

(8) Replace the oil seal in the timing case cover.

(9) Install the timing case cover and gasket.

(10) With the key inserted in the keyway in the

crankshaft, install the vibration damper, washer and

bolt. Lubricate and tighten the bolt to 108 Nzm (80 ft.

lbs.) torque.

(11) Install the fan and shroud.

(12) Connect negative cable to battery.

CAMSHAFT

REMOVAL

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED. RE-

LEASE THE PRESSURE BEFORE REMOVING THE

DRAIN COCK, CAP AND DRAIN PLUGS.

(1) Disconnect negative cable from battery.

Fig. 6 CrankshaftÐCamshaft Alignment

Fig. 7 Camshaft and Crankshaft Sprockets and

Chain

Fig. 8 Loading Timing Chain Tensioner

9 - 32 2.5L ENGINEJ

Page 1163 of 2198

VIBRATION DAMPER

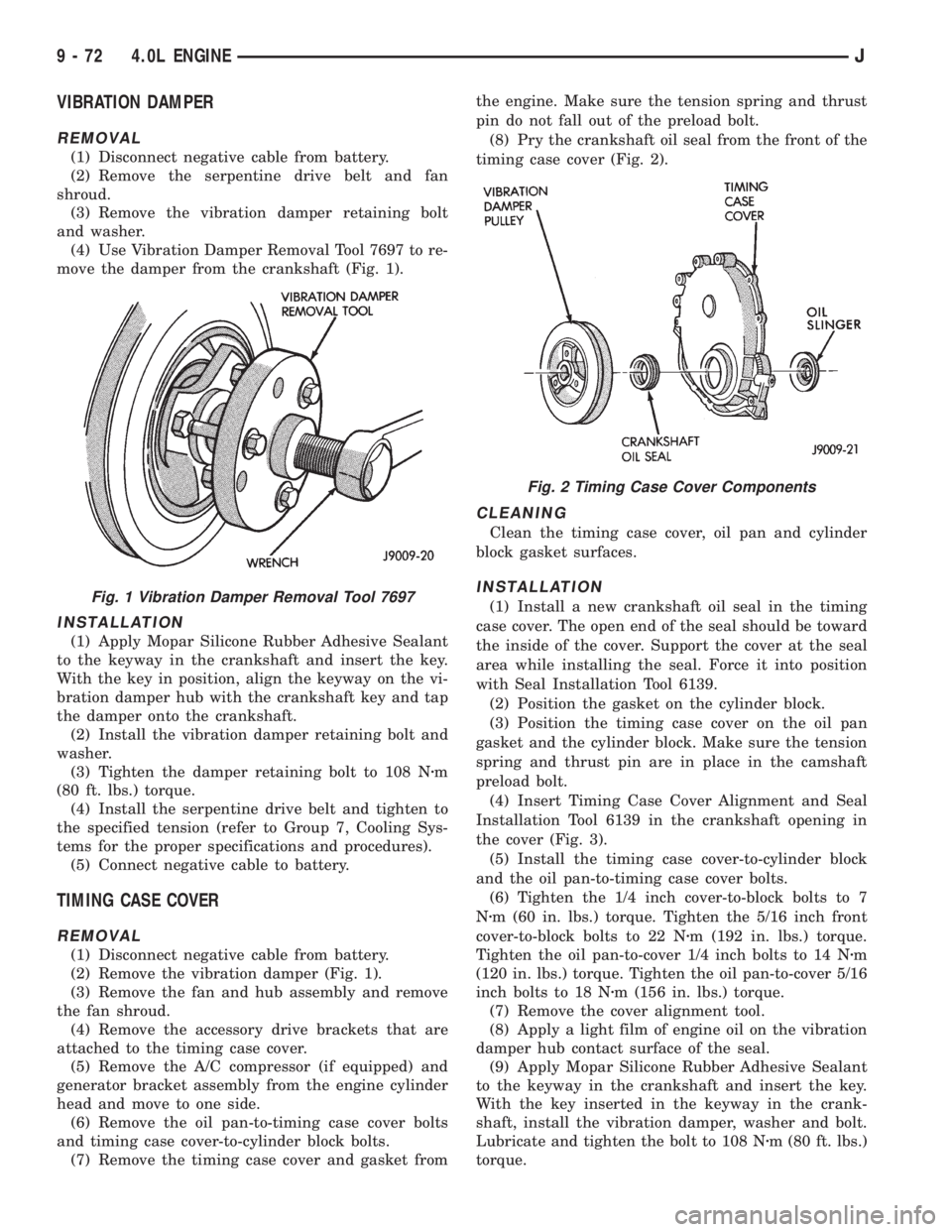

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt and fan

shroud.

(3) Remove the vibration damper retaining bolt

and washer.

(4) Use Vibration Damper Removal Tool 7697 to re-

move the damper from the crankshaft (Fig. 1).

INSTALLATION

(1) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key in position, align the keyway on the vi-

bration damper hub with the crankshaft key and tap

the damper onto the crankshaft.

(2) Install the vibration damper retaining bolt and

washer.

(3) Tighten the damper retaining bolt to 108 Nzm

(80 ft. lbs.) torque.

(4) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tems for the proper specifications and procedures).

(5) Connect negative cable to battery.

TIMING CASE COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the vibration damper (Fig. 1).

(3) Remove the fan and hub assembly and remove

the fan shroud.

(4) Remove the accessory drive brackets that are

attached to the timing case cover.

(5) Remove the A/C compressor (if equipped) and

generator bracket assembly from the engine cylinder

head and move to one side.

(6) Remove the oil pan-to-timing case cover bolts

and timing case cover-to-cylinder block bolts.

(7) Remove the timing case cover and gasket fromthe engine. Make sure the tension spring and thrust

pin do not fall out of the preload bolt.

(8) Pry the crankshaft oil seal from the front of the

timing case cover (Fig. 2).

CLEANING

Clean the timing case cover, oil pan and cylinder

block gasket surfaces.

INSTALLATION

(1) Install a new crankshaft oil seal in the timing

case cover. The open end of the seal should be toward

the inside of the cover. Support the cover at the seal

area while installing the seal. Force it into position

with Seal Installation Tool 6139.

(2) Position the gasket on the cylinder block.

(3) Position the timing case cover on the oil pan

gasket and the cylinder block. Make sure the tension

spring and thrust pin are in place in the camshaft

preload bolt.

(4) Insert Timing Case Cover Alignment and Seal

Installation Tool 6139 in the crankshaft opening in

the cover (Fig. 3).

(5) Install the timing case cover-to-cylinder block

and the oil pan-to-timing case cover bolts.

(6) Tighten the 1/4 inch cover-to-block bolts to 7

Nzm (60 in. lbs.) torque. Tighten the 5/16 inch front

cover-to-block bolts to 22 Nzm (192 in. lbs.) torque.

Tighten the oil pan-to-cover 1/4 inch bolts to 14 Nzm

(120 in. lbs.) torque. Tighten the oil pan-to-cover 5/16

inch bolts to 18 Nzm (156 in. lbs.) torque.

(7) Remove the cover alignment tool.

(8) Apply a light film of engine oil on the vibration

damper hub contact surface of the seal.

(9) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key inserted in the keyway in the crank-

shaft, install the vibration damper, washer and bolt.

Lubricate and tighten the bolt to 108 Nzm (80 ft. lbs.)

torque.Fig. 1 Vibration Damper Removal Tool 7697

Fig. 2 Timing Case Cover Components

9 - 72 4.0L ENGINEJ

Page 1164 of 2198

(10) Install the A/C compressor (if equipped) and

generator bracket assembly.

(11) Install the engine fan and hub assembly and

shroud.

(12) Install the serpentine drive belt and tighten to

obtain the specified tension.

(13) Connect negative cable to battery.

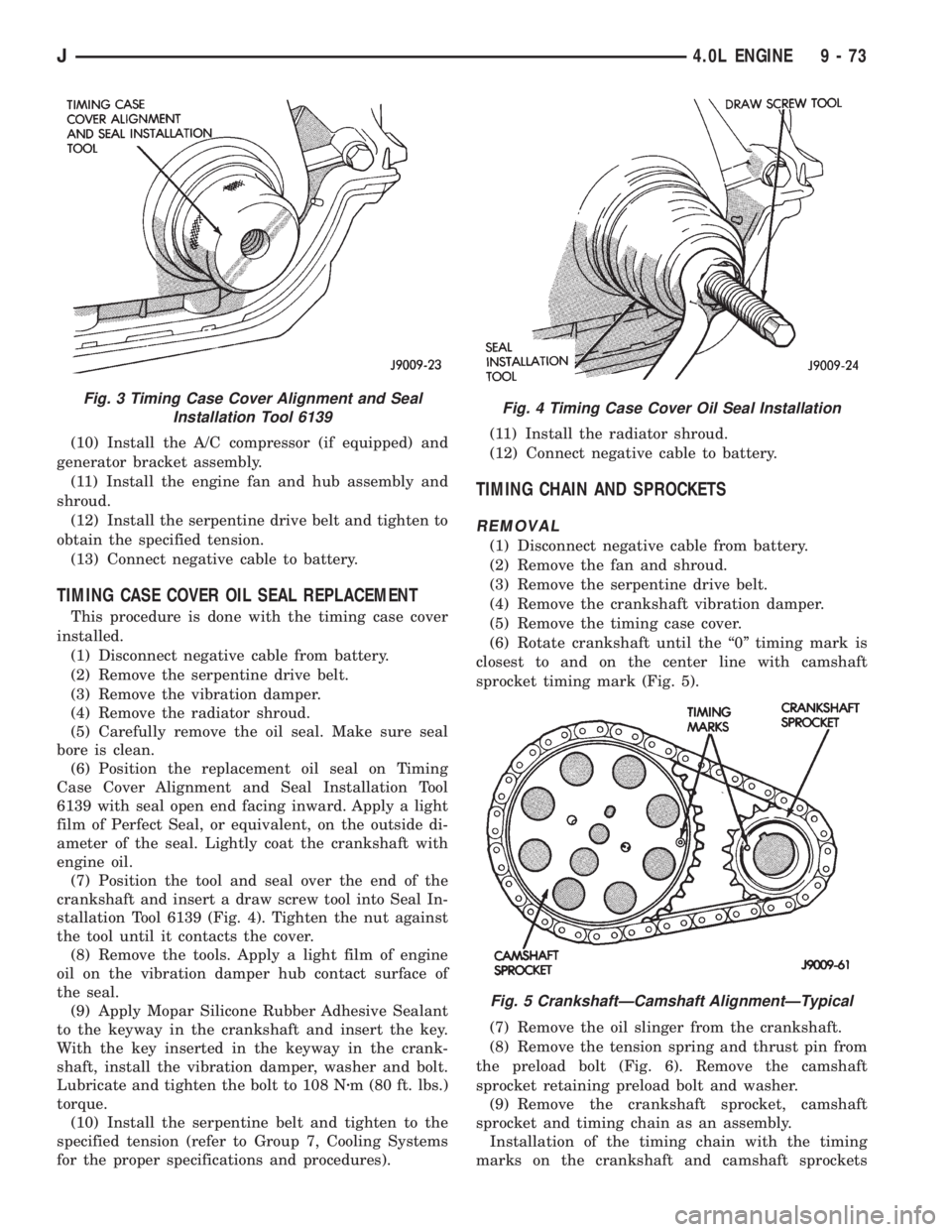

TIMING CASE COVER OIL SEAL REPLACEMENT

This procedure is done with the timing case cover

installed.

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt.

(3) Remove the vibration damper.

(4) Remove the radiator shroud.

(5) Carefully remove the oil seal. Make sure seal

bore is clean.

(6) Position the replacement oil seal on Timing

Case Cover Alignment and Seal Installation Tool

6139 with seal open end facing inward. Apply a light

film of Perfect Seal, or equivalent, on the outside di-

ameter of the seal. Lightly coat the crankshaft with

engine oil.

(7) Position the tool and seal over the end of the

crankshaft and insert a draw screw tool into Seal In-

stallation Tool 6139 (Fig. 4). Tighten the nut against

the tool until it contacts the cover.

(8) Remove the tools. Apply a light film of engine

oil on the vibration damper hub contact surface of

the seal.

(9) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key inserted in the keyway in the crank-

shaft, install the vibration damper, washer and bolt.

Lubricate and tighten the bolt to 108 Nzm (80 ft. lbs.)

torque.

(10) Install the serpentine belt and tighten to the

specified tension (refer to Group 7, Cooling Systems

for the proper specifications and procedures).(11) Install the radiator shroud.

(12) Connect negative cable to battery.

TIMING CHAIN AND SPROCKETS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the fan and shroud.

(3) Remove the serpentine drive belt.

(4) Remove the crankshaft vibration damper.

(5) Remove the timing case cover.

(6) Rotate crankshaft until the ``0'' timing mark is

closest to and on the center line with camshaft

sprocket timing mark (Fig. 5).

(7) Remove the oil slinger from the crankshaft.

(8) Remove the tension spring and thrust pin from

the preload bolt (Fig. 6). Remove the camshaft

sprocket retaining preload bolt and washer.

(9) Remove the crankshaft sprocket, camshaft

sprocket and timing chain as an assembly.

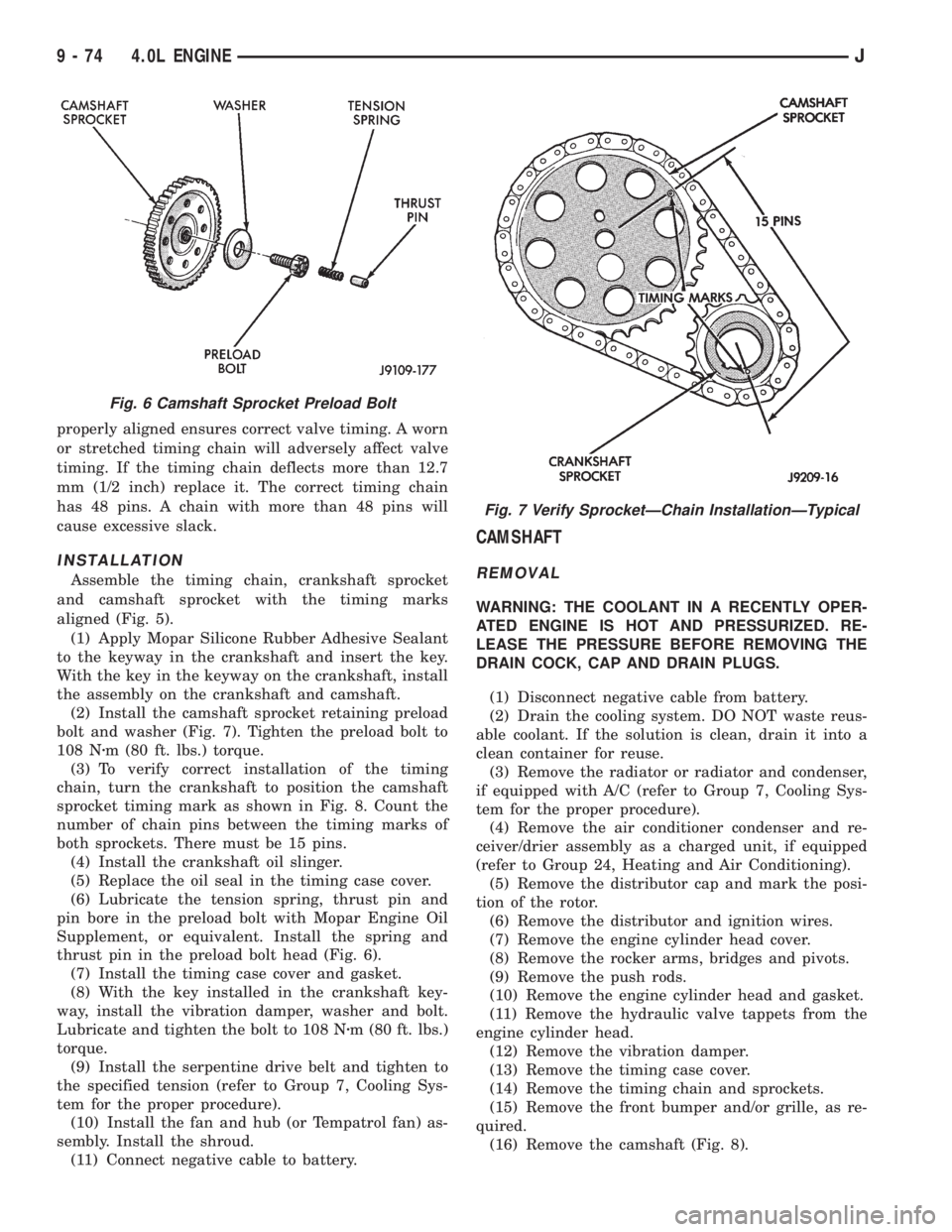

Installation of the timing chain with the timing

marks on the crankshaft and camshaft sprockets

Fig. 3 Timing Case Cover Alignment and Seal

Installation Tool 6139Fig. 4 Timing Case Cover Oil Seal Installation

Fig. 5 CrankshaftÐCamshaft AlignmentÐTypical

J4.0L ENGINE 9 - 73

Page 1165 of 2198

properly aligned ensures correct valve timing. A worn

or stretched timing chain will adversely affect valve

timing. If the timing chain deflects more than 12.7

mm (1/2 inch) replace it. The correct timing chain

has 48 pins. A chain with more than 48 pins will

cause excessive slack.

INSTALLATION

Assemble the timing chain, crankshaft sprocket

and camshaft sprocket with the timing marks

aligned (Fig. 5).

(1) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key in the keyway on the crankshaft, install

the assembly on the crankshaft and camshaft.

(2) Install the camshaft sprocket retaining preload

bolt and washer (Fig. 7). Tighten the preload bolt to

108 Nzm (80 ft. lbs.) torque.

(3) To verify correct installation of the timing

chain, turn the crankshaft to position the camshaft

sprocket timing mark as shown in Fig. 8. Count the

number of chain pins between the timing marks of

both sprockets. There must be 15 pins.

(4) Install the crankshaft oil slinger.

(5) Replace the oil seal in the timing case cover.

(6) Lubricate the tension spring, thrust pin and

pin bore in the preload bolt with Mopar Engine Oil

Supplement, or equivalent. Install the spring and

thrust pin in the preload bolt head (Fig. 6).

(7) Install the timing case cover and gasket.

(8) With the key installed in the crankshaft key-

way, install the vibration damper, washer and bolt.

Lubricate and tighten the bolt to 108 Nzm (80 ft. lbs.)

torque.

(9) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tem for the proper procedure).

(10) Install the fan and hub (or Tempatrol fan) as-

sembly. Install the shroud.

(11) Connect negative cable to battery.

CAMSHAFT

REMOVAL

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED. RE-

LEASE THE PRESSURE BEFORE REMOVING THE

DRAIN COCK, CAP AND DRAIN PLUGS.

(1) Disconnect negative cable from battery.

(2) Drain the cooling system. DO NOT waste reus-

able coolant. If the solution is clean, drain it into a

clean container for reuse.

(3) Remove the radiator or radiator and condenser,

if equipped with A/C (refer to Group 7, Cooling Sys-

tem for the proper procedure).

(4) Remove the air conditioner condenser and re-

ceiver/drier assembly as a charged unit, if equipped

(refer to Group 24, Heating and Air Conditioning).

(5) Remove the distributor cap and mark the posi-

tion of the rotor.

(6) Remove the distributor and ignition wires.

(7) Remove the engine cylinder head cover.

(8) Remove the rocker arms, bridges and pivots.

(9) Remove the push rods.

(10) Remove the engine cylinder head and gasket.

(11) Remove the hydraulic valve tappets from the

engine cylinder head.

(12) Remove the vibration damper.

(13) Remove the timing case cover.

(14) Remove the timing chain and sprockets.

(15) Remove the front bumper and/or grille, as re-

quired.

(16) Remove the camshaft (Fig. 8).

Fig. 6 Camshaft Sprocket Preload Bolt

Fig. 7 Verify SprocketÐChain InstallationÐTypical

9 - 74 4.0L ENGINEJ