Rpm JEEP CHEROKEE 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1242 of 2198

DATA LINK CONNECTORÐPCM OUTPUT

Refer to the previous paragraphs on Data Link

ConnectorÐPCM Input for information.

EMR LAMPÐPCM OUTPUT

The EMR (SRI) lamp is not used for the 1995

model year.

FUEL PUMP RELAYÐPCM OUTPUT

The PCM energizes the fuel pump and the oxygen

sensor (O2S) heating element through the fuel pump

relay. Battery voltage is applied to the relay from the

ignition switch. The relay is energized when a

ground is provided by the PCM. Refer to Automatic

Shutdown Relay for additional information.

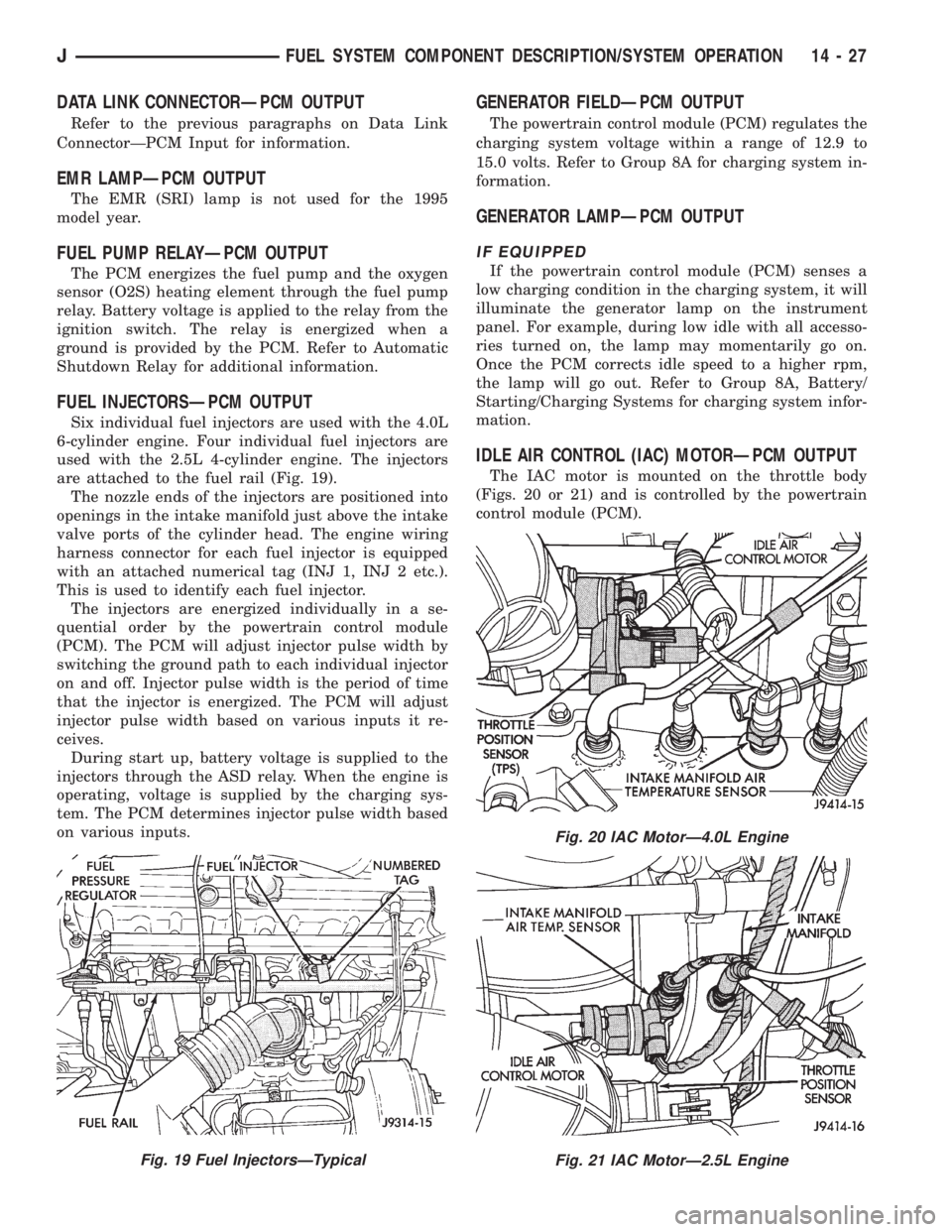

FUEL INJECTORSÐPCM OUTPUT

Six individual fuel injectors are used with the 4.0L

6-cylinder engine. Four individual fuel injectors are

used with the 2.5L 4-cylinder engine. The injectors

are attached to the fuel rail (Fig. 19).

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector.

The injectors are energized individually in a se-

quential order by the powertrain control module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it re-

ceives.

During start up, battery voltage is supplied to the

injectors through the ASD relay. When the engine is

operating, voltage is supplied by the charging sys-

tem. The PCM determines injector pulse width based

on various inputs.

GENERATOR FIELDÐPCM OUTPUT

The powertrain control module (PCM) regulates the

charging system voltage within a range of 12.9 to

15.0 volts. Refer to Group 8A for charging system in-

formation.

GENERATOR LAMPÐPCM OUTPUT

IF EQUIPPED

If the powertrain control module (PCM) senses a

low charging condition in the charging system, it will

illuminate the generator lamp on the instrument

panel. For example, during low idle with all accesso-

ries turned on, the lamp may momentarily go on.

Once the PCM corrects idle speed to a higher rpm,

the lamp will go out. Refer to Group 8A, Battery/

Starting/Charging Systems for charging system infor-

mation.

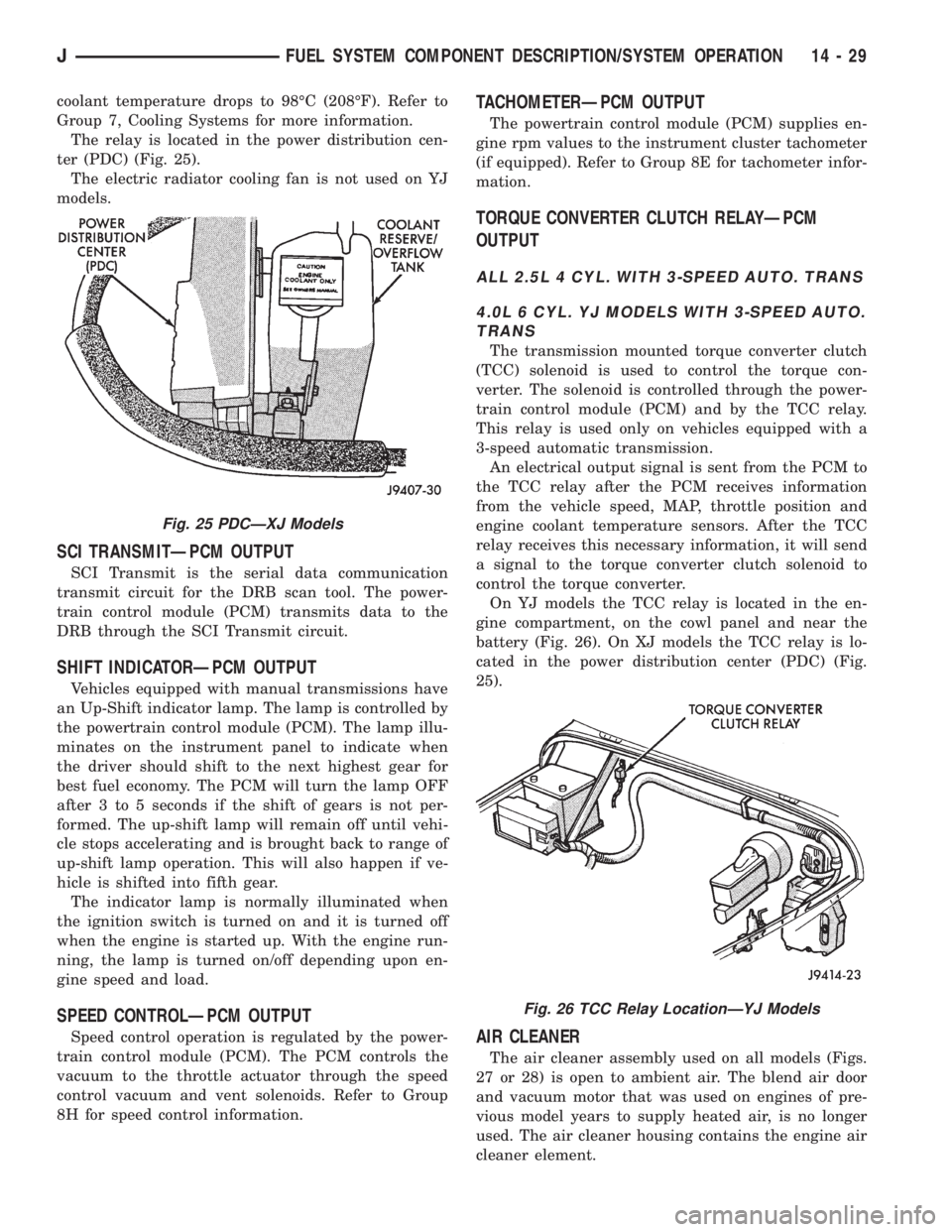

IDLE AIR CONTROL (IAC) MOTORÐPCM OUTPUT

The IAC motor is mounted on the throttle body

(Figs. 20 or 21) and is controlled by the powertrain

control module (PCM).

Fig. 19 Fuel InjectorsÐTypical

Fig. 20 IAC MotorÐ4.0L Engine

Fig. 21 IAC MotorÐ2.5L Engine

JFUEL SYSTEM COMPONENT DESCRIPTION/SYSTEM OPERATION 14 - 27

Page 1244 of 2198

coolant temperature drops to 98ÉC (208ÉF). Refer to

Group 7, Cooling Systems for more information.

The relay is located in the power distribution cen-

ter (PDC) (Fig. 25).

The electric radiator cooling fan is not used on YJ

models.

SCI TRANSMITÐPCM OUTPUT

SCI Transmit is the serial data communication

transmit circuit for the DRB scan tool. The power-

train control module (PCM) transmits data to the

DRB through the SCI Transmit circuit.

SHIFT INDICATORÐPCM OUTPUT

Vehicles equipped with manual transmissions have

an Up-Shift indicator lamp. The lamp is controlled by

the powertrain control module (PCM). The lamp illu-

minates on the instrument panel to indicate when

the driver should shift to the next highest gear for

best fuel economy. The PCM will turn the lamp OFF

after 3 to 5 seconds if the shift of gears is not per-

formed. The up-shift lamp will remain off until vehi-

cle stops accelerating and is brought back to range of

up-shift lamp operation. This will also happen if ve-

hicle is shifted into fifth gear.

The indicator lamp is normally illuminated when

the ignition switch is turned on and it is turned off

when the engine is started up. With the engine run-

ning, the lamp is turned on/off depending upon en-

gine speed and load.

SPEED CONTROLÐPCM OUTPUT

Speed control operation is regulated by the power-

train control module (PCM). The PCM controls the

vacuum to the throttle actuator through the speed

control vacuum and vent solenoids. Refer to Group

8H for speed control information.

TACHOMETERÐPCM OUTPUT

The powertrain control module (PCM) supplies en-

gine rpm values to the instrument cluster tachometer

(if equipped). Refer to Group 8E for tachometer infor-

mation.

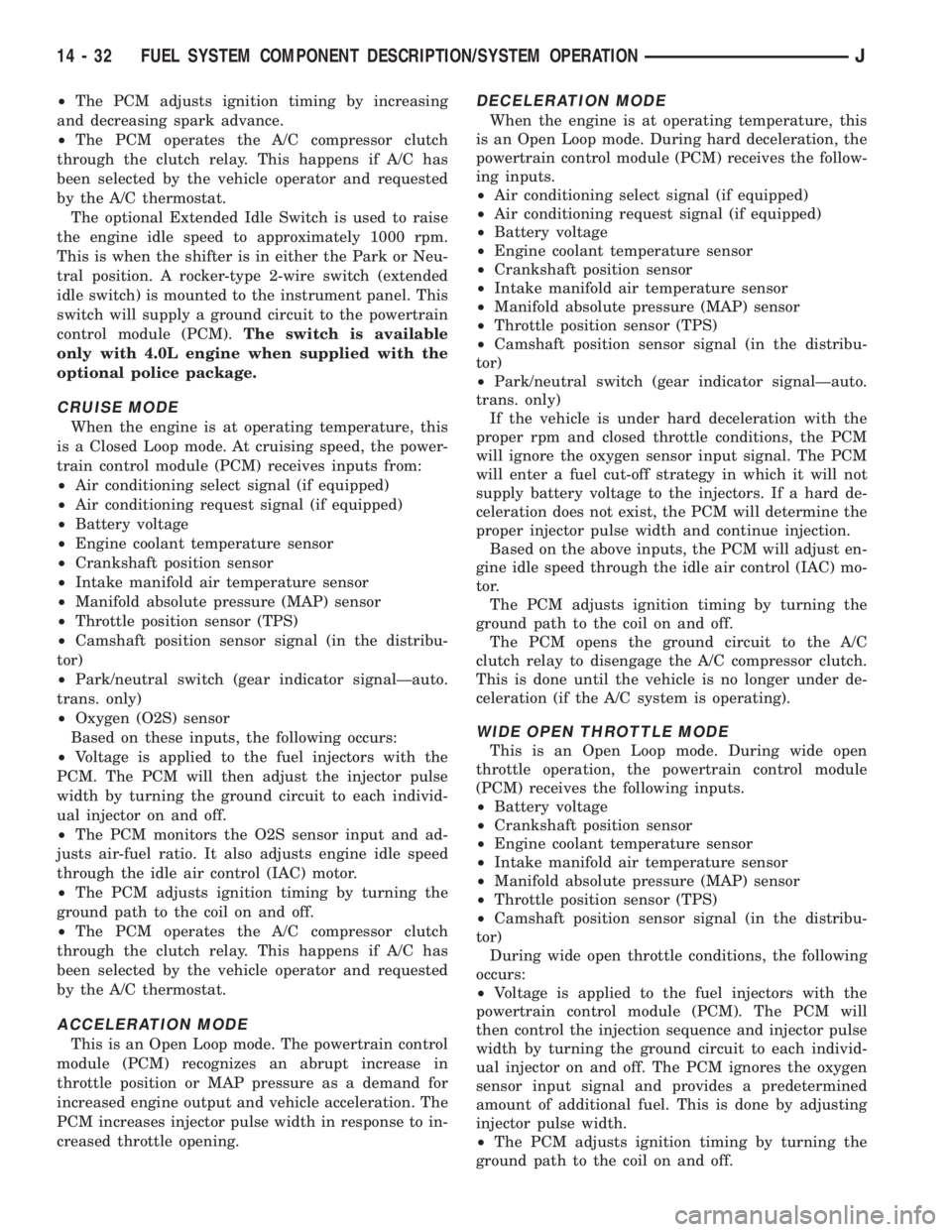

TORQUE CONVERTER CLUTCH RELAYÐPCM

OUTPUT

ALL 2.5L 4 CYL. WITH 3-SPEED AUTO. TRANS

4.0L 6 CYL. YJ MODELS WITH 3-SPEED AUTO.

TRANS

The transmission mounted torque converter clutch

(TCC) solenoid is used to control the torque con-

verter. The solenoid is controlled through the power-

train control module (PCM) and by the TCC relay.

This relay is used only on vehicles equipped with a

3-speed automatic transmission.

An electrical output signal is sent from the PCM to

the TCC relay after the PCM receives information

from the vehicle speed, MAP, throttle position and

engine coolant temperature sensors. After the TCC

relay receives this necessary information, it will send

a signal to the torque converter clutch solenoid to

control the torque converter.

On YJ models the TCC relay is located in the en-

gine compartment, on the cowl panel and near the

battery (Fig. 26). On XJ models the TCC relay is lo-

cated in the power distribution center (PDC) (Fig.

25).

AIR CLEANER

The air cleaner assembly used on all models (Figs.

27 or 28) is open to ambient air. The blend air door

and vacuum motor that was used on engines of pre-

vious model years to supply heated air, is no longer

used. The air cleaner housing contains the engine air

cleaner element.

Fig. 25 PDCÐXJ Models

Fig. 26 TCC Relay LocationÐYJ Models

JFUEL SYSTEM COMPONENT DESCRIPTION/SYSTEM OPERATION 14 - 29

Page 1247 of 2198

²The PCM adjusts ignition timing by increasing

and decreasing spark advance.

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

The optional Extended Idle Switch is used to raise

the engine idle speed to approximately 1000 rpm.

This is when the shifter is in either the Park or Neu-

tral position. A rocker-type 2-wire switch (extended

idle switch) is mounted to the instrument panel. This

switch will supply a ground circuit to the powertrain

control module (PCM).The switch is available

only with 4.0L engine when supplied with the

optional police package.

CRUISE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the power-

train control module (PCM) receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distribu-

tor)

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen (O2S) sensor

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

PCM. The PCM will then adjust the injector pulse

width by turning the ground circuit to each individ-

ual injector on and off.

²The PCM monitors the O2S sensor input and ad-

justs air-fuel ratio. It also adjusts engine idle speed

through the idle air control (IAC) motor.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

ACCELERATION MODE

This is an Open Loop mode. The powertrain control

module (PCM) recognizes an abrupt increase in

throttle position or MAP pressure as a demand for

increased engine output and vehicle acceleration. The

PCM increases injector pulse width in response to in-

creased throttle opening.

DECELERATION MODE

When the engine is at operating temperature, this

is an Open Loop mode. During hard deceleration, the

powertrain control module (PCM) receives the follow-

ing inputs.

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distribu-

tor)

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

If the vehicle is under hard deceleration with the

proper rpm and closed throttle conditions, the PCM

will ignore the oxygen sensor input signal. The PCM

will enter a fuel cut-off strategy in which it will not

supply battery voltage to the injectors. If a hard de-

celeration does not exist, the PCM will determine the

proper injector pulse width and continue injection.

Based on the above inputs, the PCM will adjust en-

gine idle speed through the idle air control (IAC) mo-

tor.

The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

The PCM opens the ground circuit to the A/C

clutch relay to disengage the A/C compressor clutch.

This is done until the vehicle is no longer under de-

celeration (if the A/C system is operating).

WIDE OPEN THROTTLE MODE

This is an Open Loop mode. During wide open

throttle operation, the powertrain control module

(PCM) receives the following inputs.

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distribu-

tor)

During wide open throttle conditions, the following

occurs:

²Voltage is applied to the fuel injectors with the

powertrain control module (PCM). The PCM will

then control the injection sequence and injector pulse

width by turning the ground circuit to each individ-

ual injector on and off. The PCM ignores the oxygen

sensor input signal and provides a predetermined

amount of additional fuel. This is done by adjusting

injector pulse width.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

14 - 32 FUEL SYSTEM COMPONENT DESCRIPTION/SYSTEM OPERATIONJ

Page 1263 of 2198

EXTENDED IDLE SWITCH TEST

OPTIONAL POLICE PACKAGE ONLY

OPERATION

The extended idle switch is used to raise the en-

gine idle speed to approximately 1000 rpm when the

shifter is in either the Park or Neutral position. A

rocker-type 2-wire switch (extended idle switch) is

mounted to the instrument panel.This switch is

available only with 4.0L engine when supplied

with the optional police package.

TESTING

The extended idle switch will control a ground cir-

cuit going to the powertrain control module (PCM).

When a ground signal (through this switch) has been

received at pin number 10 in the PCM, engine idle

speed will increase.

Bring the engine to normal operating temperature

and turn the extended idle switch to the ON position.

Engine speed should now increase to approximately

1000 rpm when the shifter is in either the Park or

Neutral position. If engine speed does not increase,

apply a good ground to pin number 10 at the PCM

using a small paper clip. Be careful not to damage

the wiring with the paper clip. If the engine speed

now increases, it can be assumed that the PCM is

functioning correctly. Check the instrument panel

mounted switch for a closed ground circuit when in

the ON position. If the engine speed will not increase

after applying a ground to pin number 10, replace

the PCM. Refer to Group 8W, Wiring Diagrams for

circuit and wiring information.

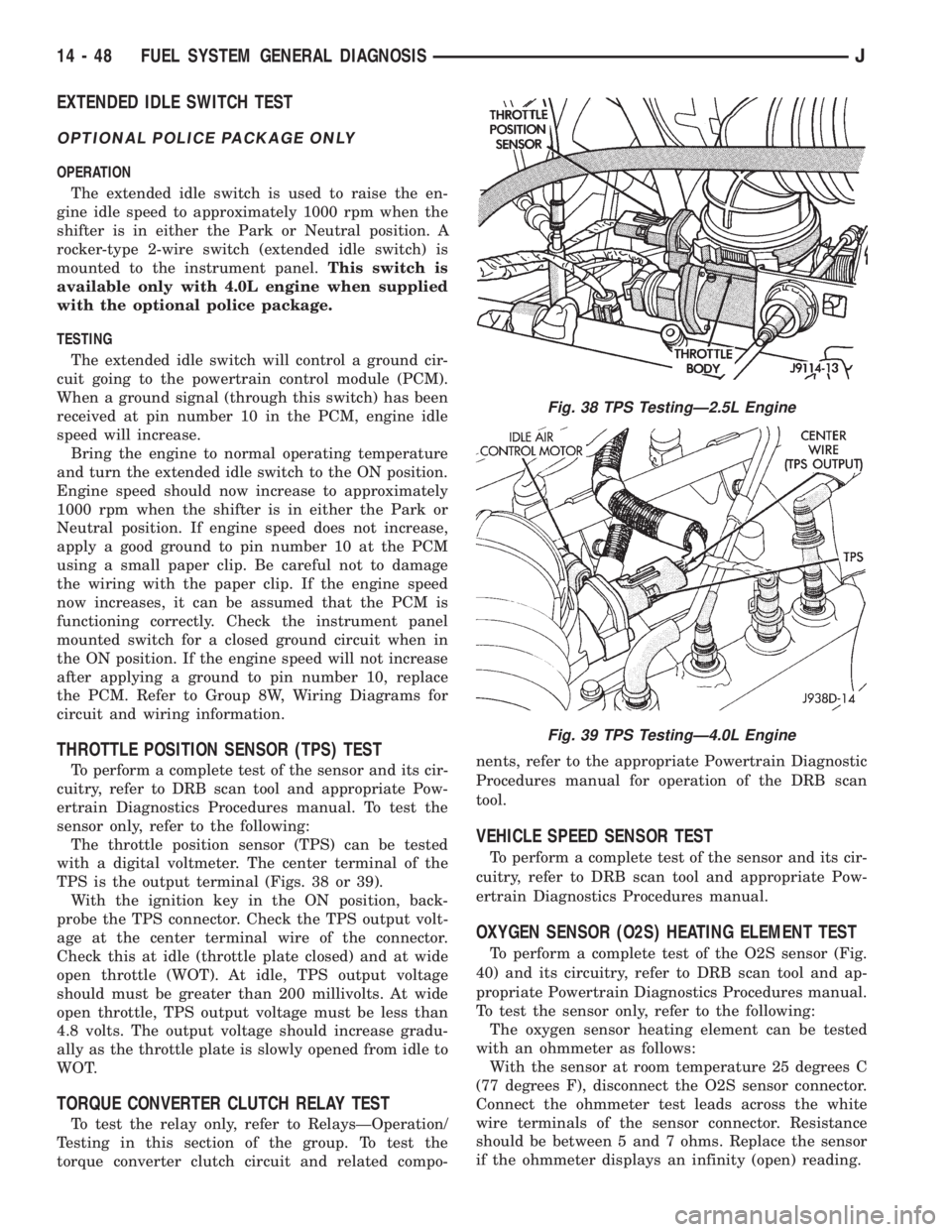

THROTTLE POSITION SENSOR (TPS) TEST

To perform a complete test of the sensor and its cir-

cuitry, refer to DRB scan tool and appropriate Pow-

ertrain Diagnostics Procedures manual. To test the

sensor only, refer to the following:

The throttle position sensor (TPS) can be tested

with a digital voltmeter. The center terminal of the

TPS is the output terminal (Figs. 38 or 39).

With the ignition key in the ON position, back-

probe the TPS connector. Check the TPS output volt-

age at the center terminal wire of the connector.

Check this at idle (throttle plate closed) and at wide

open throttle (WOT). At idle, TPS output voltage

should must be greater than 200 millivolts. At wide

open throttle, TPS output voltage must be less than

4.8 volts. The output voltage should increase gradu-

ally as the throttle plate is slowly opened from idle to

WOT.

TORQUE CONVERTER CLUTCH RELAY TEST

To test the relay only, refer to RelaysÐOperation/

Testing in this section of the group. To test the

torque converter clutch circuit and related compo-nents, refer to the appropriate Powertrain Diagnostic

Procedures manual for operation of the DRB scan

tool.

VEHICLE SPEED SENSOR TEST

To perform a complete test of the sensor and its cir-

cuitry, refer to DRB scan tool and appropriate Pow-

ertrain Diagnostics Procedures manual.

OXYGEN SENSOR (O2S) HEATING ELEMENT TEST

To perform a complete test of the O2S sensor (Fig.

40) and its circuitry, refer to DRB scan tool and ap-

propriate Powertrain Diagnostics Procedures manual.

To test the sensor only, refer to the following:

The oxygen sensor heating element can be tested

with an ohmmeter as follows:

With the sensor at room temperature 25 degrees C

(77 degrees F), disconnect the O2S sensor connector.

Connect the ohmmeter test leads across the white

wire terminals of the sensor connector. Resistance

should be between 5 and 7 ohms. Replace the sensor

if the ohmmeter displays an infinity (open) reading.

Fig. 38 TPS TestingÐ2.5L Engine

Fig. 39 TPS TestingÐ4.0L Engine

14 - 48 FUEL SYSTEM GENERAL DIAGNOSISJ

Page 1266 of 2198

(8) Disconnect jumper wires from relay and 12 Volt

power source.

If continuity or resistance tests did not pass, re-

place relay. If tests passed, refer to Group 8W, Wiring

Diagrams for additional circuit information. Also re-

fer to the appropriate Powertrain Diagnostic Proce-

dures manual for operation of the DRB scan tool.

STARTER MOTOR RELAY TEST

Refer to Group 8A, Battery/Starting/Charging/Sys-

tem Diagnostics, for starter motor relay testing.

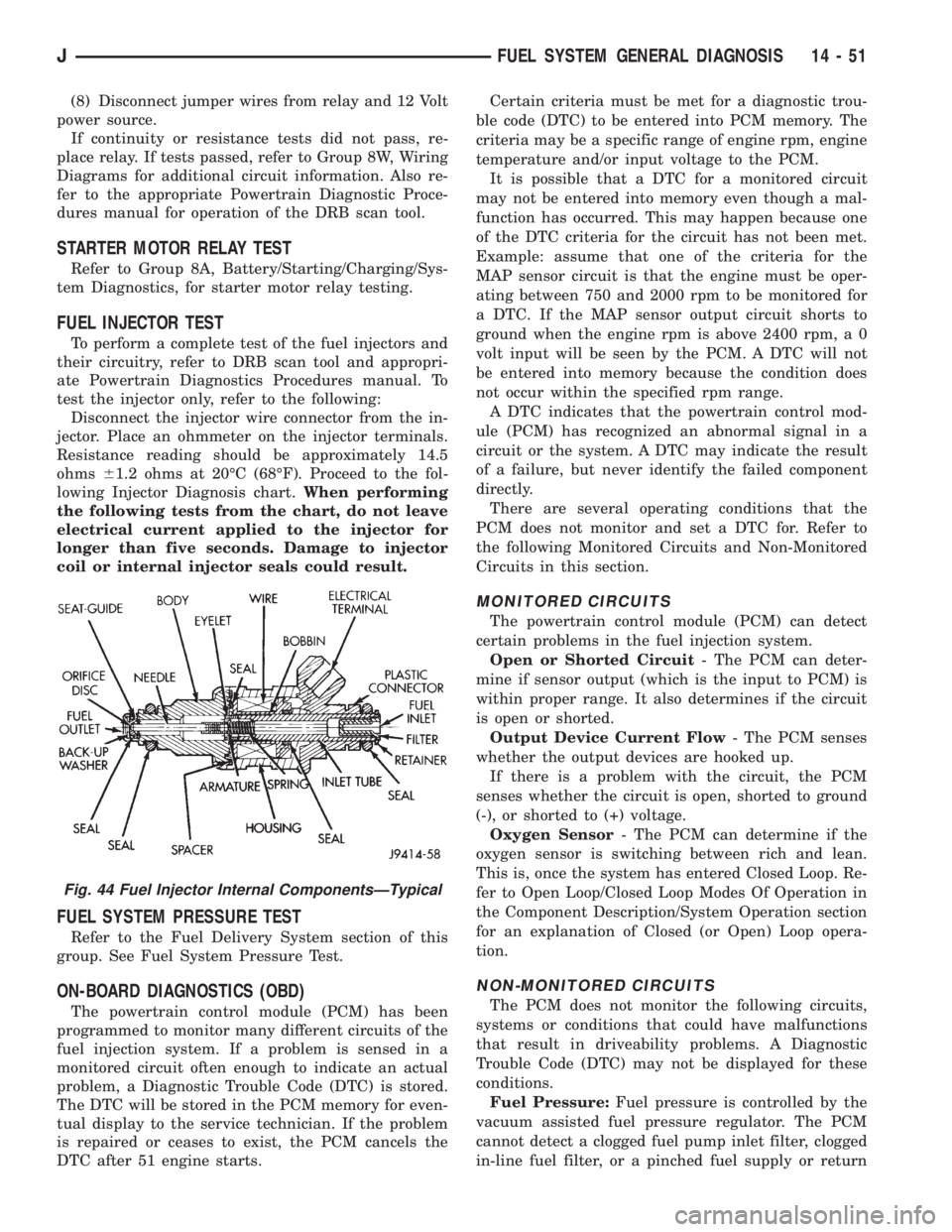

FUEL INJECTOR TEST

To perform a complete test of the fuel injectors and

their circuitry, refer to DRB scan tool and appropri-

ate Powertrain Diagnostics Procedures manual. To

test the injector only, refer to the following:

Disconnect the injector wire connector from the in-

jector. Place an ohmmeter on the injector terminals.

Resistance reading should be approximately 14.5

ohms61.2 ohms at 20ÉC (68ÉF). Proceed to the fol-

lowing Injector Diagnosis chart.When performing

the following tests from the chart, do not leave

electrical current applied to the injector for

longer than five seconds. Damage to injector

coil or internal injector seals could result.

FUEL SYSTEM PRESSURE TEST

Refer to the Fuel Delivery System section of this

group. See Fuel System Pressure Test.

ON-BOARD DIAGNOSTICS (OBD)

The powertrain control module (PCM) has been

programmed to monitor many different circuits of the

fuel injection system. If a problem is sensed in a

monitored circuit often enough to indicate an actual

problem, a Diagnostic Trouble Code (DTC) is stored.

The DTC will be stored in the PCM memory for even-

tual display to the service technician. If the problem

is repaired or ceases to exist, the PCM cancels the

DTC after 51 engine starts.Certain criteria must be met for a diagnostic trou-

ble code (DTC) to be entered into PCM memory. The

criteria may be a specific range of engine rpm, engine

temperature and/or input voltage to the PCM.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. This may happen because one

of the DTC criteria for the circuit has not been met.

Example: assume that one of the criteria for the

MAP sensor circuit is that the engine must be oper-

ating between 750 and 2000 rpm to be monitored for

a DTC. If the MAP sensor output circuit shorts to

ground when the engine rpm is above 2400 rpm, a 0

volt input will be seen by the PCM. A DTC will not

be entered into memory because the condition does

not occur within the specified rpm range.

A DTC indicates that the powertrain control mod-

ule (PCM) has recognized an abnormal signal in a

circuit or the system. A DTC may indicate the result

of a failure, but never identify the failed component

directly.

There are several operating conditions that the

PCM does not monitor and set a DTC for. Refer to

the following Monitored Circuits and Non-Monitored

Circuits in this section.

MONITORED CIRCUITS

The powertrain control module (PCM) can detect

certain problems in the fuel injection system.

Open or Shorted Circuit- The PCM can deter-

mine if sensor output (which is the input to PCM) is

within proper range. It also determines if the circuit

is open or shorted.

Output Device Current Flow- The PCM senses

whether the output devices are hooked up.

If there is a problem with the circuit, the PCM

senses whether the circuit is open, shorted to ground

(-), or shorted to (+) voltage.

Oxygen Sensor- The PCM can determine if the

oxygen sensor is switching between rich and lean.

This is, once the system has entered Closed Loop. Re-

fer to Open Loop/Closed Loop Modes Of Operation in

the Component Description/System Operation section

for an explanation of Closed (or Open) Loop opera-

tion.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems or conditions that could have malfunctions

that result in driveability problems. A Diagnostic

Trouble Code (DTC) may not be displayed for these

conditions.

Fuel Pressure:Fuel pressure is controlled by the

vacuum assisted fuel pressure regulator. The PCM

cannot detect a clogged fuel pump inlet filter, clogged

in-line fuel filter, or a pinched fuel supply or return

Fig. 44 Fuel Injector Internal ComponentsÐTypical

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 51

Page 1268 of 2198

line. However, these could result in a rich or lean

condition causing an oxygen sensor DTC to be stored

in the PCM.

Secondary Ignition Circuit:The PCM cannot

detect an inoperative ignition coil, fouled or worn

spark plugs, ignition cross firing, or open circuited

spark plug cables.

Engine Timing:The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket or

crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor DTC to be stored in the PCM.

Cylinder Compression:The PCM cannot detect

uneven, low, or high engine cylinder compression.

Exhaust System:The PCM cannot detect a

plugged, restricted or leaking exhaust system.

Fuel Injector Malfunctions:The PCM cannot de-

termine if the fuel injector is clogged, or the wrong

injector is installed. However, these could result in a

rich or lean condition causing an oxygen sensor DTC

to be stored in the PCM.

Excessive Oil Consumption:Although the PCM

monitors exhaust stream oxygen content through ox-

ygen sensor (closed loop), it cannot determine exces-

sive oil consumption.

Throttle Body Air Flow:The PCM cannot detect

a clogged or restricted air cleaner inlet or air cleaner

element.

Evaporative System:The PCM will not detect a

restricted, plugged or loaded EVAP canister.

Vacuum Assist:Leaks or restrictions in the vac-

uum circuits of vacuum assisted engine control sys-

tem devices are not monitored by the PCM. However,

a vacuum leak at the MAP sensor will be monitored

and a diagnostic trouble code (DTC) will be gener-

ated by the PCM.

Powertrain Control Module (PCM) System

Ground:The PCM cannot determine a poor system

ground. However, a DTC may be generated as a re-

sult of this condition.

Powertrain Control Module (PCM) Connector

Engagement:The PCM cannot determine spread or

damaged connector pins. However, a DTC may be

generated as a result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device. It will es-

tablish high and low limits that are programmed into

it for that device. If the input voltage is not within

specifications and other Diagnostic Trouble Code

(DTC) criteria are met, a DTC will be stored in mem-

ory. Other DTC criteria might include engine rpm

limits or input voltages from other sensors or

switches. The other inputs might have to be sensed

by the PCM when it senses a high or low input volt-

age from the control system device in question.

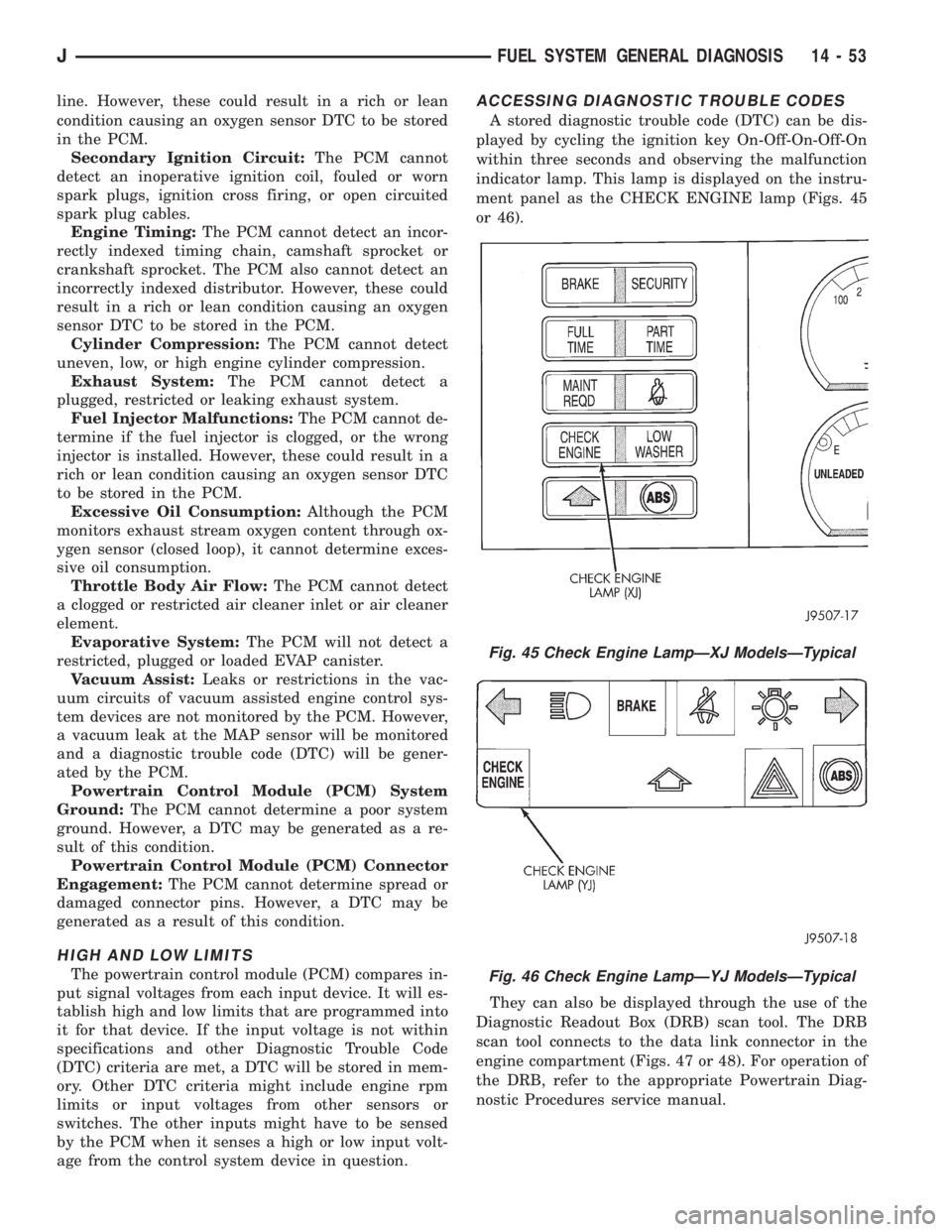

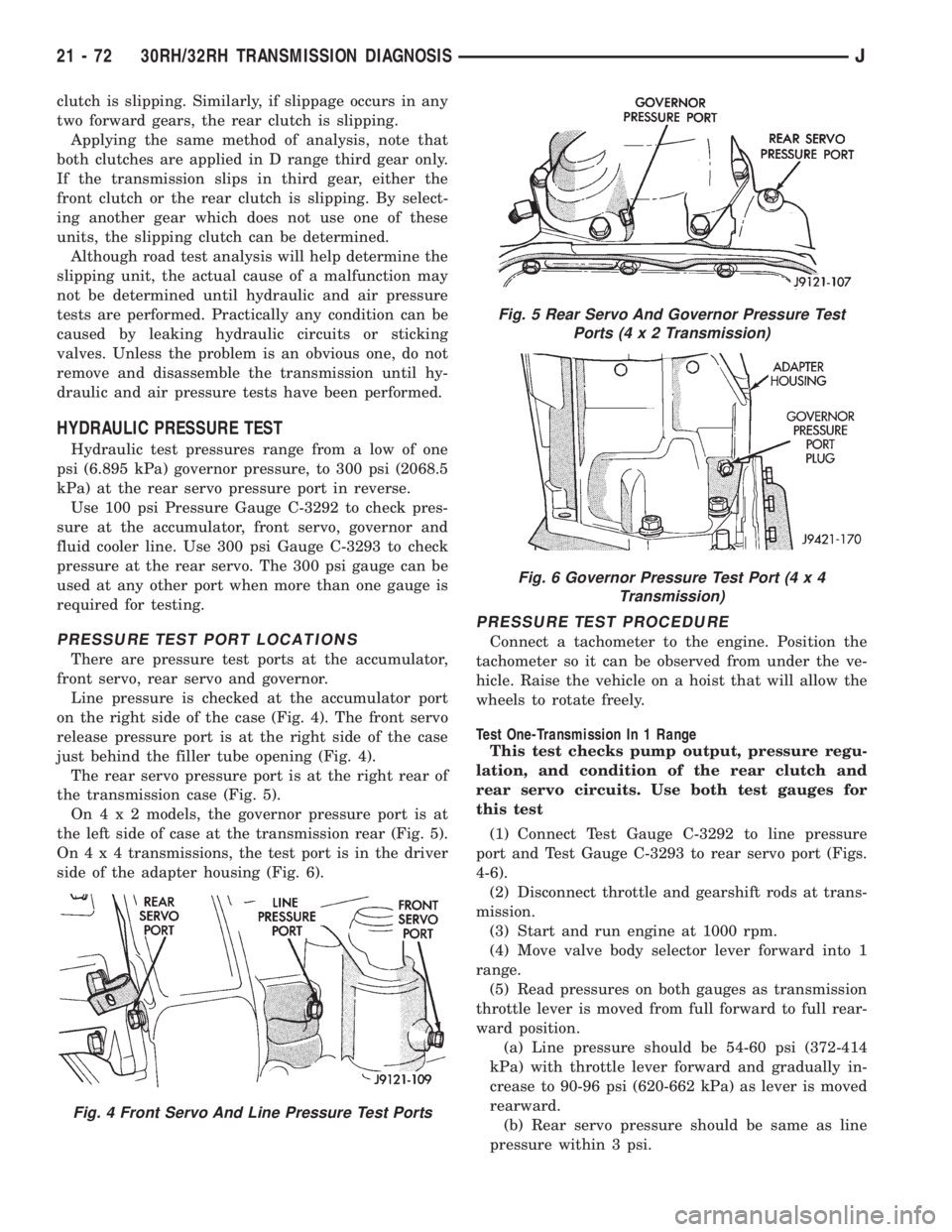

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored diagnostic trouble code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the malfunction

indicator lamp. This lamp is displayed on the instru-

ment panel as the CHECK ENGINE lamp (Figs. 45

or 46).

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

scan tool connects to the data link connector in the

engine compartment (Figs. 47 or 48). For operation of

the DRB, refer to the appropriate Powertrain Diag-

nostic Procedures service manual.

Fig. 45 Check Engine LampÐXJ ModelsÐTypical

Fig. 46 Check Engine LampÐYJ ModelsÐTypical

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 53

Page 1449 of 2198

clutch is slipping. Similarly, if slippage occurs in any

two forward gears, the rear clutch is slipping.

Applying the same method of analysis, note that

both clutches are applied in D range third gear only.

If the transmission slips in third gear, either the

front clutch or the rear clutch is slipping. By select-

ing another gear which does not use one of these

units, the slipping clutch can be determined.

Although road test analysis will help determine the

slipping unit, the actual cause of a malfunction may

not be determined until hydraulic and air pressure

tests are performed. Practically any condition can be

caused by leaking hydraulic circuits or sticking

valves. Unless the problem is an obvious one, do not

remove and disassemble the transmission until hy-

draulic and air pressure tests have been performed.

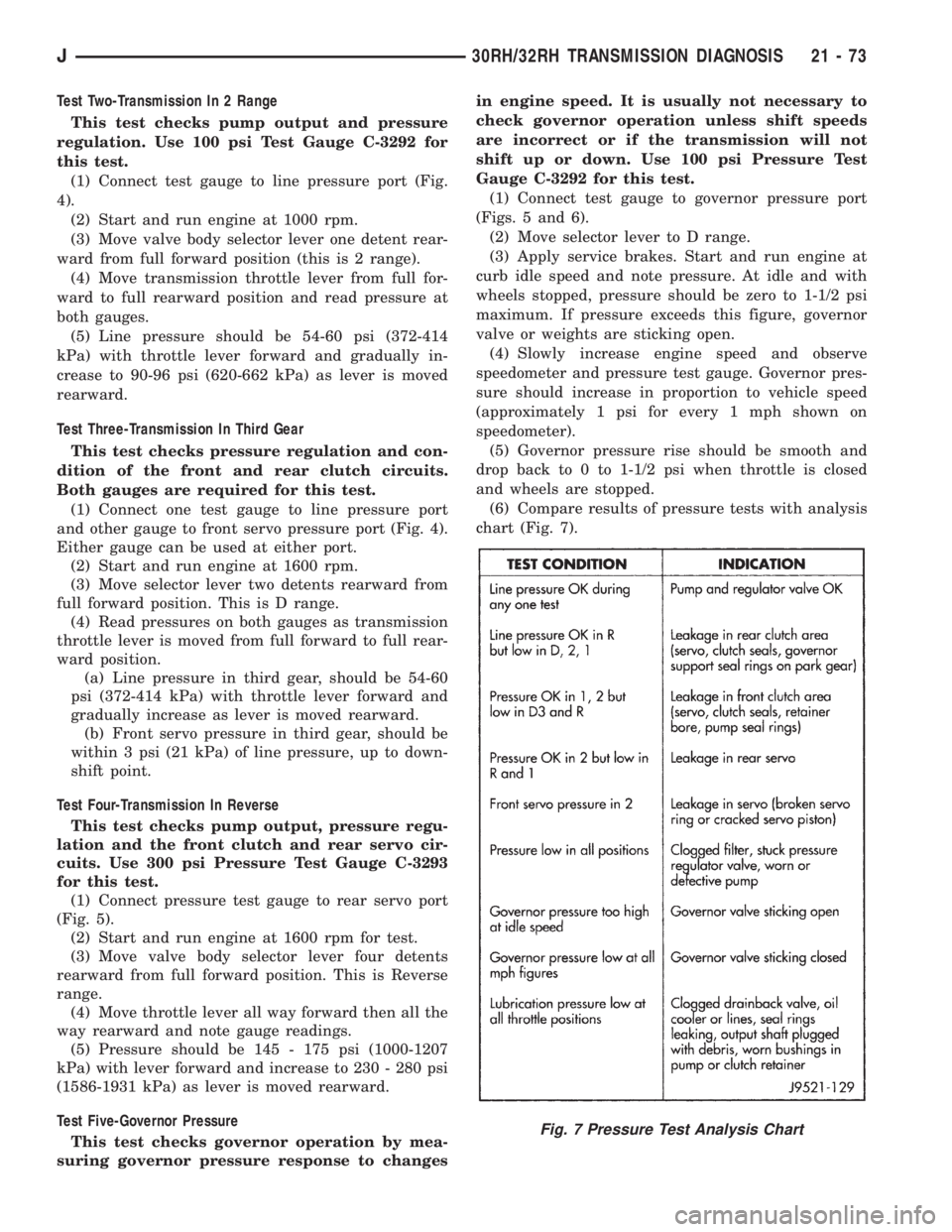

HYDRAULIC PRESSURE TEST

Hydraulic test pressures range from a low of one

psi (6.895 kPa) governor pressure, to 300 psi (2068.5

kPa) at the rear servo pressure port in reverse.

Use 100 psi Pressure Gauge C-3292 to check pres-

sure at the accumulator, front servo, governor and

fluid cooler line. Use 300 psi Gauge C-3293 to check

pressure at the rear servo. The 300 psi gauge can be

used at any other port when more than one gauge is

required for testing.

PRESSURE TEST PORT LOCATIONS

There are pressure test ports at the accumulator,

front servo, rear servo and governor.

Line pressure is checked at the accumulator port

on the right side of the case (Fig. 4). The front servo

release pressure port is at the right side of the case

just behind the filler tube opening (Fig. 4).

The rear servo pressure port is at the right rear of

the transmission case (Fig. 5).

On4x2models, the governor pressure port is at

the left side of case at the transmission rear (Fig. 5).

On4x4transmissions, the test port is in the driver

side of the adapter housing (Fig. 6).

PRESSURE TEST PROCEDURE

Connect a tachometer to the engine. Position the

tachometer so it can be observed from under the ve-

hicle. Raise the vehicle on a hoist that will allow the

wheels to rotate freely.

Test One-Transmission In 1 Range

This test checks pump output, pressure regu-

lation, and condition of the rear clutch and

rear servo circuits. Use both test gauges for

this test

(1) Connect Test Gauge C-3292 to line pressure

port and Test Gauge C-3293 to rear servo port (Figs.

4-6).

(2) Disconnect throttle and gearshift rods at trans-

mission.

(3) Start and run engine at 1000 rpm.

(4) Move valve body selector lever forward into 1

range.

(5) Read pressures on both gauges as transmission

throttle lever is moved from full forward to full rear-

ward position.

(a) Line pressure should be 54-60 psi (372-414

kPa) with throttle lever forward and gradually in-

crease to 90-96 psi (620-662 kPa) as lever is moved

rearward.

(b) Rear servo pressure should be same as line

pressure within 3 psi.

Fig. 4 Front Servo And Line Pressure Test Ports

Fig. 5 Rear Servo And Governor Pressure Test

Ports (4x2Transmission)

Fig. 6 Governor Pressure Test Port (4 x 4

Transmission)

21 - 72 30RH/32RH TRANSMISSION DIAGNOSISJ

Page 1450 of 2198

Test Two-Transmission In 2 Range

This test checks pump output and pressure

regulation. Use 100 psi Test Gauge C-3292 for

this test.

(1) Connect test gauge to line pressure port (Fig.

4).

(2) Start and run engine at 1000 rpm.

(3) Move valve body selector lever one detent rear-

ward from full forward position (this is 2 range).

(4) Move transmission throttle lever from full for-

ward to full rearward position and read pressure at

both gauges.

(5) Line pressure should be 54-60 psi (372-414

kPa) with throttle lever forward and gradually in-

crease to 90-96 psi (620-662 kPa) as lever is moved

rearward.

Test Three-Transmission In Third Gear

This test checks pressure regulation and con-

dition of the front and rear clutch circuits.

Both gauges are required for this test.

(1) Connect one test gauge to line pressure port

and other gauge to front servo pressure port (Fig. 4).

Either gauge can be used at either port.

(2) Start and run engine at 1600 rpm.

(3) Move selector lever two detents rearward from

full forward position. This is D range.

(4) Read pressures on both gauges as transmission

throttle lever is moved from full forward to full rear-

ward position.

(a) Line pressure in third gear, should be 54-60

psi (372-414 kPa) with throttle lever forward and

gradually increase as lever is moved rearward.

(b) Front servo pressure in third gear, should be

within 3 psi (21 kPa) of line pressure, up to down-

shift point.

Test Four-Transmission In Reverse

This test checks pump output, pressure regu-

lation and the front clutch and rear servo cir-

cuits. Use 300 psi Pressure Test Gauge C-3293

for this test.

(1) Connect pressure test gauge to rear servo port

(Fig. 5).

(2) Start and run engine at 1600 rpm for test.

(3) Move valve body selector lever four detents

rearward from full forward position. This is Reverse

range.

(4) Move throttle lever all way forward then all the

way rearward and note gauge readings.

(5) Pressure should be 145 - 175 psi (1000-1207

kPa) with lever forward and increase to 230 - 280 psi

(1586-1931 kPa) as lever is moved rearward.

Test Five-Governor Pressure

This test checks governor operation by mea-

suring governor pressure response to changesin engine speed. It is usually not necessary to

check governor operation unless shift speeds

are incorrect or if the transmission will not

shift up or down. Use 100 psi Pressure Test

Gauge C-3292 for this test.

(1) Connect test gauge to governor pressure port

(Figs. 5 and 6).

(2) Move selector lever to D range.

(3) Apply service brakes. Start and run engine at

curb idle speed and note pressure. At idle and with

wheels stopped, pressure should be zero to 1-1/2 psi

maximum. If pressure exceeds this figure, governor

valve or weights are sticking open.

(4) Slowly increase engine speed and observe

speedometer and pressure test gauge. Governor pres-

sure should increase in proportion to vehicle speed

(approximately 1 psi for every 1 mph shown on

speedometer).

(5) Governor pressure rise should be smooth and

drop back to 0 to 1-1/2 psi when throttle is closed

and wheels are stopped.

(6) Compare results of pressure tests with analysis

chart (Fig. 7).

Fig. 7 Pressure Test Analysis Chart

J30RH/32RH TRANSMISSION DIAGNOSIS 21 - 73

Page 1451 of 2198

CONVERTER STALL TEST

Stall testing involves determining maximum engine

rpm obtainable at full throttle with the rear wheels

locked and the transmission in D range. This test

checks the holding ability of the converter overrun-

ning clutch and both of the transmission clutches.

When stall testing is completed, refer to the Stall

Speed Specifications chart and Stall Speed Diagnosis

guides.

WARNING: NEVER ALLOW ANYONE TO STAND IN

FRONT OF THE VEHICLE DURING A STALL TEST.

ALWAYS BLOCK THE FRONT WHEELS AND APPLY

THE SERVICE AND PARKING BRAKES DURING

THE TEST.

STALL TEST PROCEDURE

(1) Connect tachometer to engine.

(2) Check and adjust transmission fluid level.

(3) Start and run engine until transmission fluid

reaches normal operating temperature.

(4) Block front wheels.

(5) Fully apply service and parking brakes.

(6) Open throttle completely and record maximum

engine rpm registered on tachometer. It will take

from 3 to 10 seconds to reach maximum rpm. How-

ever, once maximum rpm has been achieved,do not

hold wide open throttle for more than 5 sec-

onds.

CAUTION: Stalling the converter causes a rapid in-

crease in fluid temperature. To avoid fluid overheat-

ing, hold wide open throttle for no more than 5

seconds after reaching peak rpm. In addition, if

more than one stall test is required, run the engine

at 1000 rpm with the transmission in Neutral for at

least 20 seconds to cool the fluid.

(7) Stall speeds should be in 1700-2150 rpm range.

CAUTION: If engine exceeds 2150 rpm, release ac-

celerator pedal immediately as transmission clutch

slippage is occurring.

(8) Shift transmission into Neutral. Run engine for

20-30 seconds at 1000 rpm to cool fluid. Then stop

engine, shift transmission into Park and release

brakes.

(9) Refer to Stall Test Diagnosis.

STALL TEST DIAGNOSIS

Stall Speed Too Low

Low stall speeds with a properly tuned engine in-

dicate a torque converter overrunning clutch prob-

lem. The condition should be confirmed by road

testing prior to converter replacement.The converter overrunning clutch is slipping when

stall speeds are 250 to 350 rpm below specified min-

imum.

A converter overrunning clutch failure will result

in sluggish acceleration in all speed ranges. It will

also require greater than normal throttle opening to

maintain cruising speeds.

Stall Speed Too High

If stall speed exceeds 2150 rpm, transmission

clutch slippage is occurring.

Stall Speed Normal But Acceleration Is Sluggish

If stall speeds are within specified range but abnor-

mal throttle opening is required for acceleration, or

to maintain cruise speeds, the converter overrunning

clutch is seized. The torque converter will have to be

replaced.

Converter Noise During Test

A whining noise caused by fluid flow is normal dur-

ing a stall test. However, loud metallic noises indi-

cate a damaged converter. To confirm that noise is

originating from the converter, operate the vehicle at

light throttle in Drive and Neutral on a hoist and lis-

ten for noise from the converter housing.

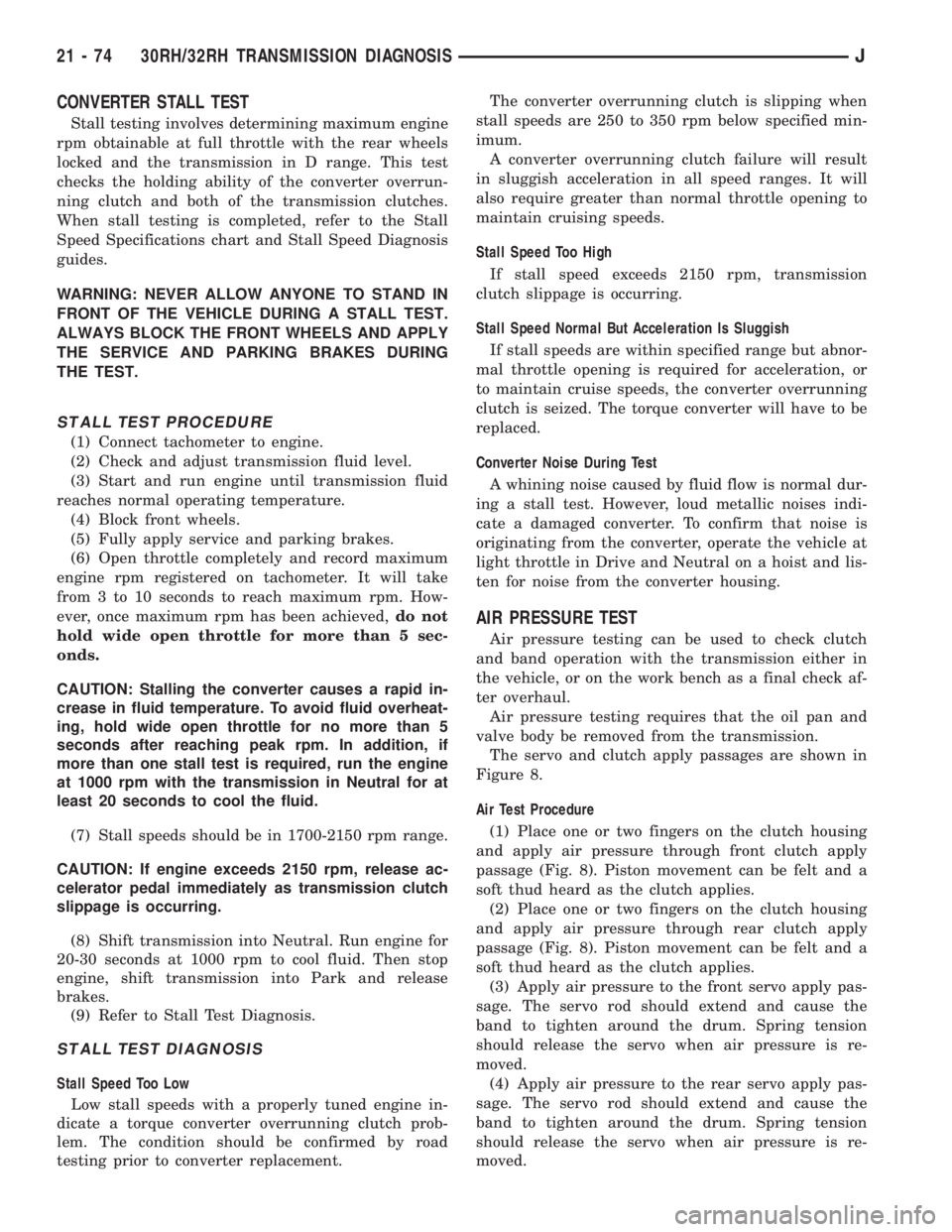

AIR PRESSURE TEST

Air pressure testing can be used to check clutch

and band operation with the transmission either in

the vehicle, or on the work bench as a final check af-

ter overhaul.

Air pressure testing requires that the oil pan and

valve body be removed from the transmission.

The servo and clutch apply passages are shown in

Figure 8.

Air Test Procedure

(1) Place one or two fingers on the clutch housing

and apply air pressure through front clutch apply

passage (Fig. 8). Piston movement can be felt and a

soft thud heard as the clutch applies.

(2) Place one or two fingers on the clutch housing

and apply air pressure through rear clutch apply

passage (Fig. 8). Piston movement can be felt and a

soft thud heard as the clutch applies.

(3) Apply air pressure to the front servo apply pas-

sage. The servo rod should extend and cause the

band to tighten around the drum. Spring tension

should release the servo when air pressure is re-

moved.

(4) Apply air pressure to the rear servo apply pas-

sage. The servo rod should extend and cause the

band to tighten around the drum. Spring tension

should release the servo when air pressure is re-

moved.

21 - 74 30RH/32RH TRANSMISSION DIAGNOSISJ

Page 1452 of 2198

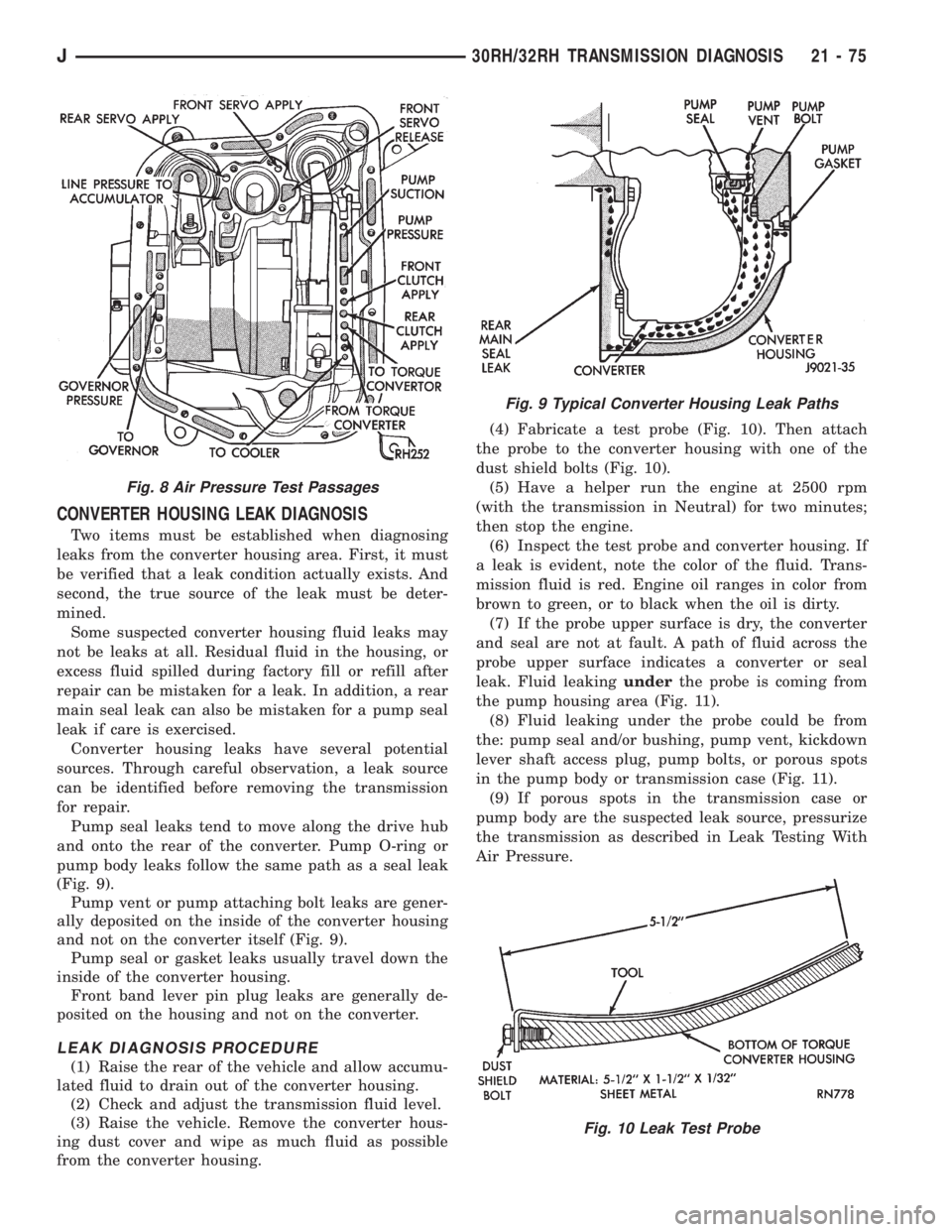

CONVERTER HOUSING LEAK DIAGNOSIS

Two items must be established when diagnosing

leaks from the converter housing area. First, it must

be verified that a leak condition actually exists. And

second, the true source of the leak must be deter-

mined.

Some suspected converter housing fluid leaks may

not be leaks at all. Residual fluid in the housing, or

excess fluid spilled during factory fill or refill after

repair can be mistaken for a leak. In addition, a rear

main seal leak can also be mistaken for a pump seal

leak if care is exercised.

Converter housing leaks have several potential

sources. Through careful observation, a leak source

can be identified before removing the transmission

for repair.

Pump seal leaks tend to move along the drive hub

and onto the rear of the converter. Pump O-ring or

pump body leaks follow the same path as a seal leak

(Fig. 9).

Pump vent or pump attaching bolt leaks are gener-

ally deposited on the inside of the converter housing

and not on the converter itself (Fig. 9).

Pump seal or gasket leaks usually travel down the

inside of the converter housing.

Front band lever pin plug leaks are generally de-

posited on the housing and not on the converter.

LEAK DIAGNOSIS PROCEDURE

(1) Raise the rear of the vehicle and allow accumu-

lated fluid to drain out of the converter housing.

(2) Check and adjust the transmission fluid level.

(3) Raise the vehicle. Remove the converter hous-

ing dust cover and wipe as much fluid as possible

from the converter housing.(4) Fabricate a test probe (Fig. 10). Then attach

the probe to the converter housing with one of the

dust shield bolts (Fig. 10).

(5) Have a helper run the engine at 2500 rpm

(with the transmission in Neutral) for two minutes;

then stop the engine.

(6) Inspect the test probe and converter housing. If

a leak is evident, note the color of the fluid. Trans-

mission fluid is red. Engine oil ranges in color from

brown to green, or to black when the oil is dirty.

(7) If the probe upper surface is dry, the converter

and seal are not at fault. A path of fluid across the

probe upper surface indicates a converter or seal

leak. Fluid leakingunderthe probe is coming from

the pump housing area (Fig. 11).

(8) Fluid leaking under the probe could be from

the: pump seal and/or bushing, pump vent, kickdown

lever shaft access plug, pump bolts, or porous spots

in the pump body or transmission case (Fig. 11).

(9) If porous spots in the transmission case or

pump body are the suspected leak source, pressurize

the transmission as described in Leak Testing With

Air Pressure.

Fig. 8 Air Pressure Test Passages

Fig. 9 Typical Converter Housing Leak Paths

Fig. 10 Leak Test Probe

J30RH/32RH TRANSMISSION DIAGNOSIS 21 - 75