lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1423 of 2198

(1) Remove fifth gear shift rail (Fig. 41). Catch lock

ball in your hand as rail comes out of intermediate plate.

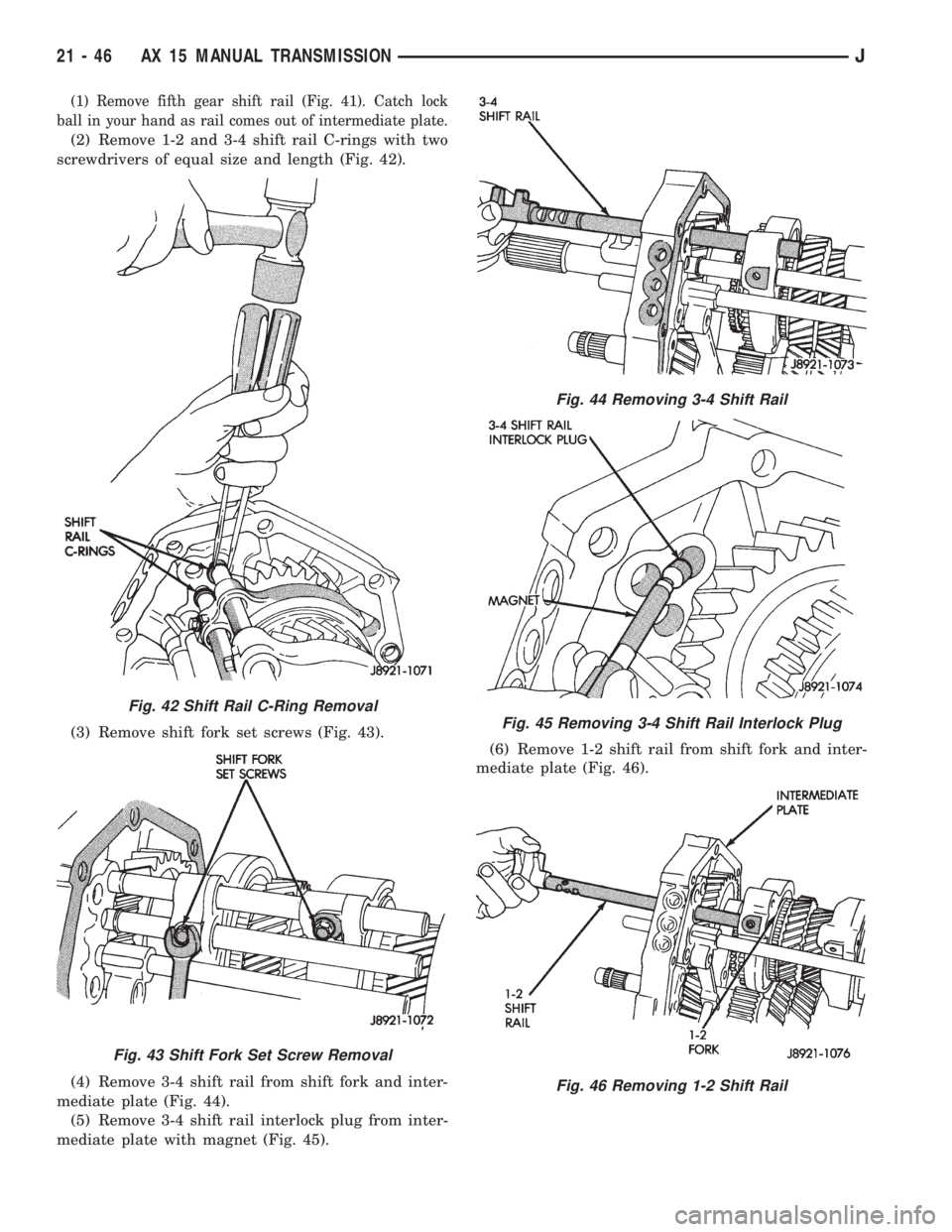

(2) Remove 1-2 and 3-4 shift rail C-rings with two

screwdrivers of equal size and length (Fig. 42).

(3) Remove shift fork set screws (Fig. 43).

(4) Remove 3-4 shift rail from shift fork and inter-

mediate plate (Fig. 44).

(5) Remove 3-4 shift rail interlock plug from inter-

mediate plate with magnet (Fig. 45).(6) Remove 1-2 shift rail from shift fork and inter-

mediate plate (Fig. 46).

Fig. 42 Shift Rail C-Ring Removal

Fig. 43 Shift Fork Set Screw Removal

Fig. 44 Removing 3-4 Shift Rail

Fig. 45 Removing 3-4 Shift Rail Interlock Plug

Fig. 46 Removing 1-2 Shift Rail

21 - 46 AX 15 MANUAL TRANSMISSIONJ

Page 1424 of 2198

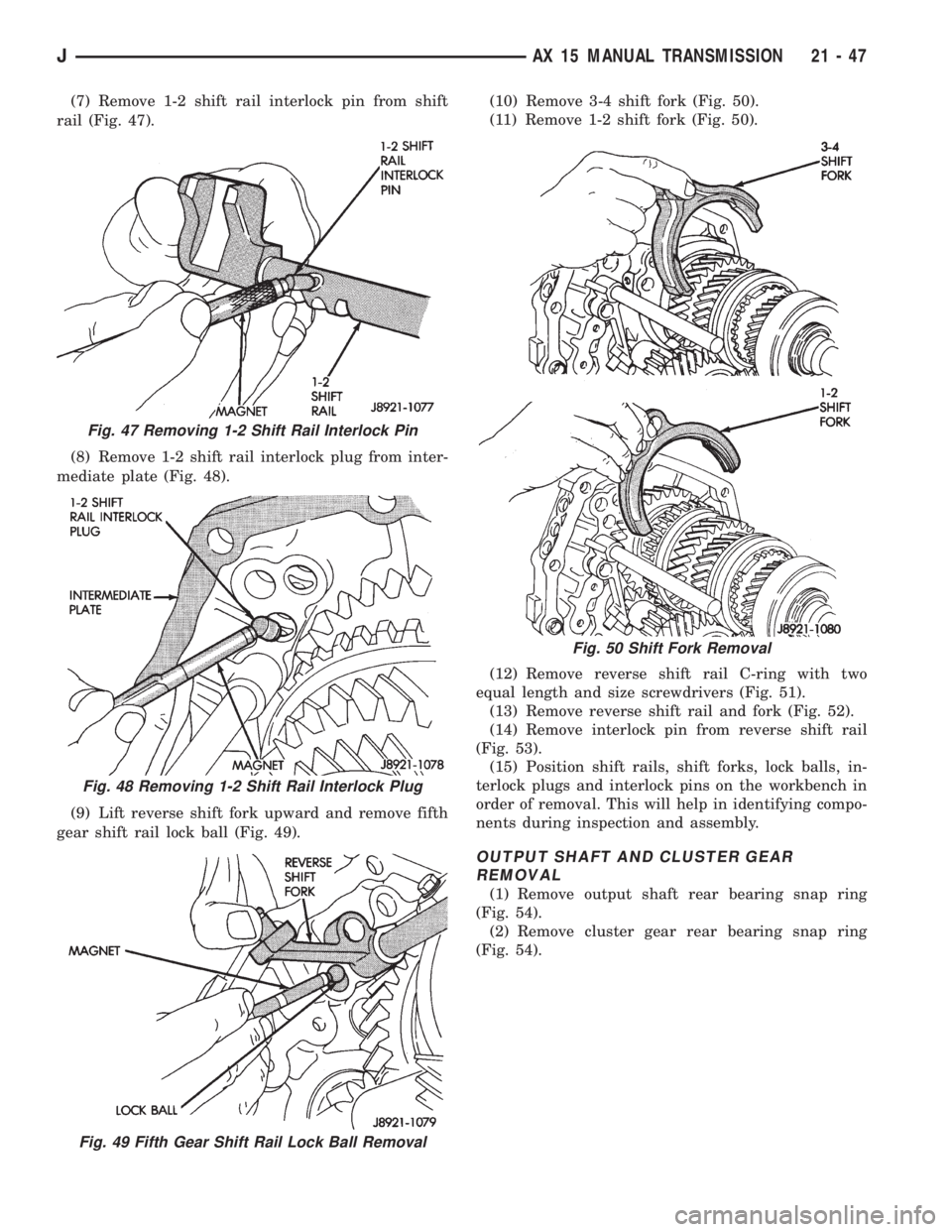

(7) Remove 1-2 shift rail interlock pin from shift

rail (Fig. 47).

(8) Remove 1-2 shift rail interlock plug from inter-

mediate plate (Fig. 48).

(9) Lift reverse shift fork upward and remove fifth

gear shift rail lock ball (Fig. 49).(10) Remove 3-4 shift fork (Fig. 50).

(11) Remove 1-2 shift fork (Fig. 50).

(12) Remove reverse shift rail C-ring with two

equal length and size screwdrivers (Fig. 51).

(13) Remove reverse shift rail and fork (Fig. 52).

(14) Remove interlock pin from reverse shift rail

(Fig. 53).

(15) Position shift rails, shift forks, lock balls, in-

terlock plugs and interlock pins on the workbench in

order of removal. This will help in identifying compo-

nents during inspection and assembly.

OUTPUT SHAFT AND CLUSTER GEAR

REMOVAL

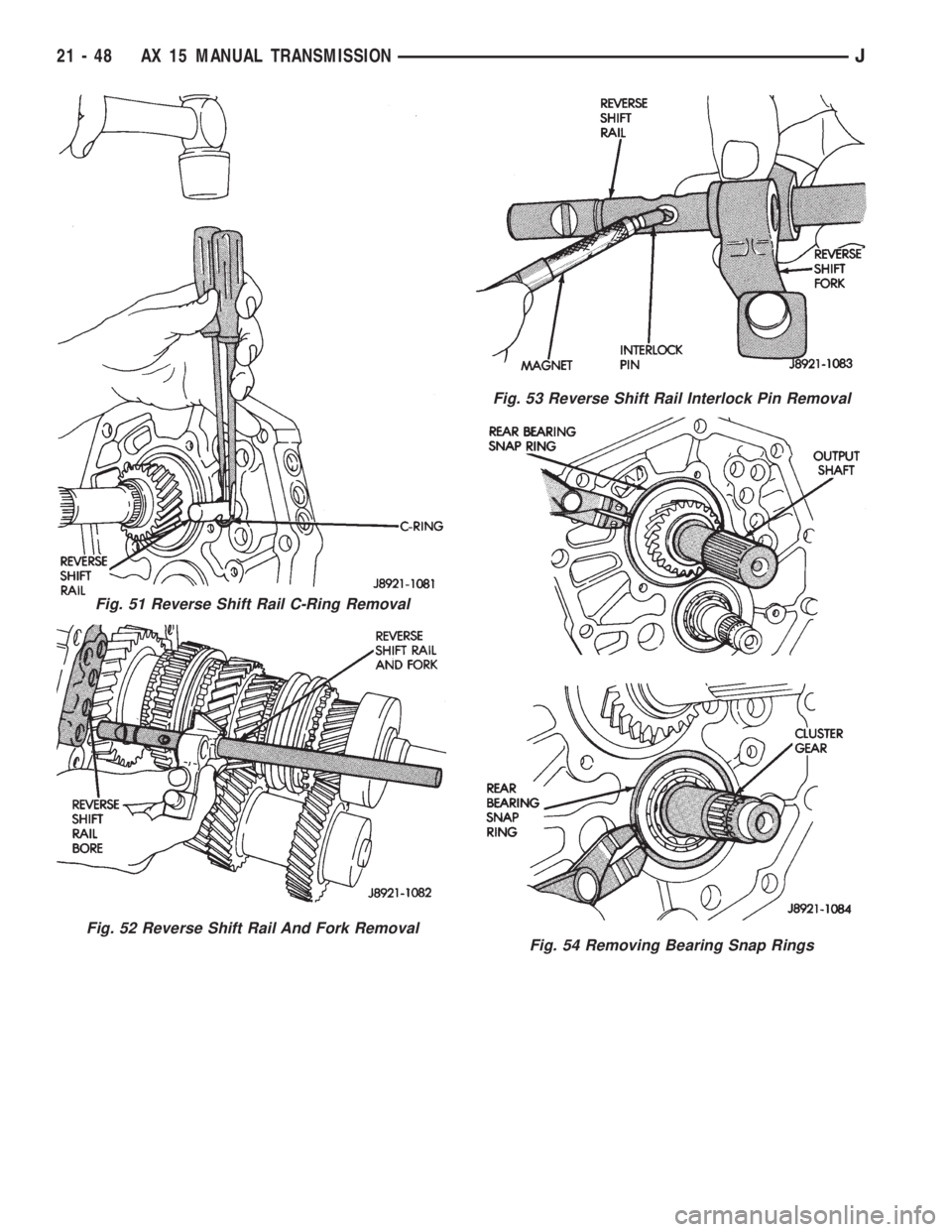

(1) Remove output shaft rear bearing snap ring

(Fig. 54).

(2) Remove cluster gear rear bearing snap ring

(Fig. 54).

Fig. 47 Removing 1-2 Shift Rail Interlock Pin

Fig. 48 Removing 1-2 Shift Rail Interlock Plug

Fig. 49 Fifth Gear Shift Rail Lock Ball Removal

Fig. 50 Shift Fork Removal

JAX 15 MANUAL TRANSMISSION 21 - 47

Page 1425 of 2198

Fig. 51 Reverse Shift Rail C-Ring Removal

Fig. 52 Reverse Shift Rail And Fork Removal

Fig. 53 Reverse Shift Rail Interlock Pin Removal

Fig. 54 Removing Bearing Snap Rings

21 - 48 AX 15 MANUAL TRANSMISSIONJ

Page 1428 of 2198

(5) Remove first/reverse hub snap ring (Fig. 63).

(6) Remove synchro ring.

(7) Press reverse gear and first/reverse hub off

shaft as assembly.

(8) Remove remaining synchro ring and second

gear and bearing (Fig. 63).

(9) Remove snap ring at front of output shaft (Fig.

63).

(10) Press 3-4 hub and sleeve off output shaft as

assembly (Fig. 63).

(11) Remove synchro ring.

(12) Remove third gear and needle bearing (Fig.

63).

TRANSMISSION CLEANING AND INSPECTION

Clean the transmission components in solvent.

Then dry the cases, gears, shift mechanism and

shafts with compressed air.Dry the bearings with

clean, dry shop towels only. Never use com-

pressed air on the bearings. This could damage

the bearing rollers.

Replace components that are obviously worn,

cracked, chipped or damaged.

Inspect the transmission case. Replace the case if

cracked or porous or if any of the bearing and gear

bores are damaged.

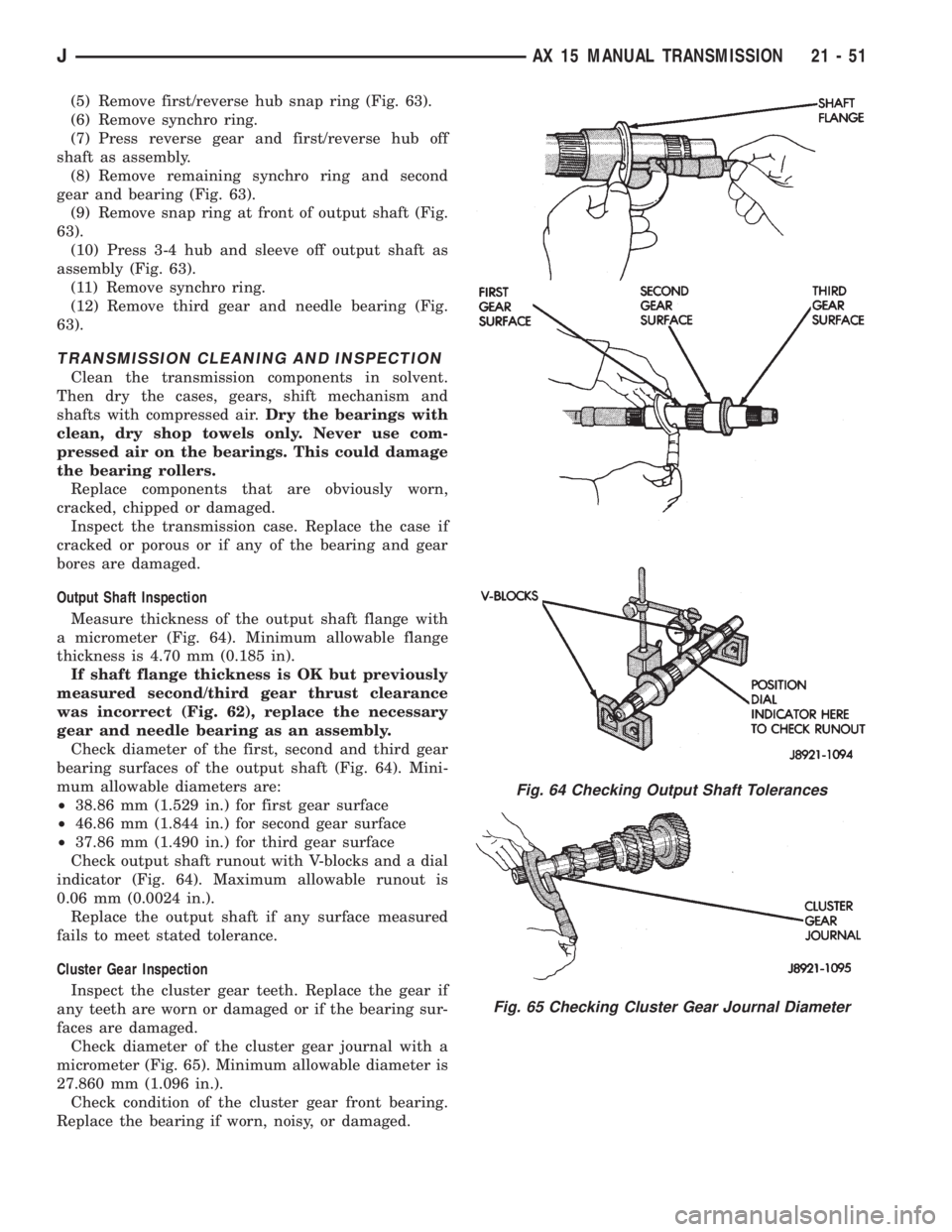

Output Shaft Inspection

Measure thickness of the output shaft flange with

a micrometer (Fig. 64). Minimum allowable flange

thickness is 4.70 mm (0.185 in).

If shaft flange thickness is OK but previously

measured second/third gear thrust clearance

was incorrect (Fig. 62), replace the necessary

gear and needle bearing as an assembly.

Check diameter of the first, second and third gear

bearing surfaces of the output shaft (Fig. 64). Mini-

mum allowable diameters are:

²38.86 mm (1.529 in.) for first gear surface

²46.86 mm (1.844 in.) for second gear surface

²37.86 mm (1.490 in.) for third gear surface

Check output shaft runout with V-blocks and a dial

indicator (Fig. 64). Maximum allowable runout is

0.06 mm (0.0024 in.).

Replace the output shaft if any surface measured

fails to meet stated tolerance.

Cluster Gear Inspection

Inspect the cluster gear teeth. Replace the gear if

any teeth are worn or damaged or if the bearing sur-

faces are damaged.

Check diameter of the cluster gear journal with a

micrometer (Fig. 65). Minimum allowable diameter is

27.860 mm (1.096 in.).

Check condition of the cluster gear front bearing.

Replace the bearing if worn, noisy, or damaged.

Fig. 64 Checking Output Shaft Tolerances

Fig. 65 Checking Cluster Gear Journal Diameter

JAX 15 MANUAL TRANSMISSION 21 - 51

Page 1433 of 2198

(23) Install input shaft on output shaft (Fig. 59).

Be sure output shaft hub is fully seated in pilot bear-

ing.

OUTPUT SHAFT AND CLUSTER GEAR

INSTALLATION

(1) Mount intermediate plate in vise (Fig. 24).

(2) Lubricate cluster gear journal and rear bearing

with petroleum jelly or gear lubricant.

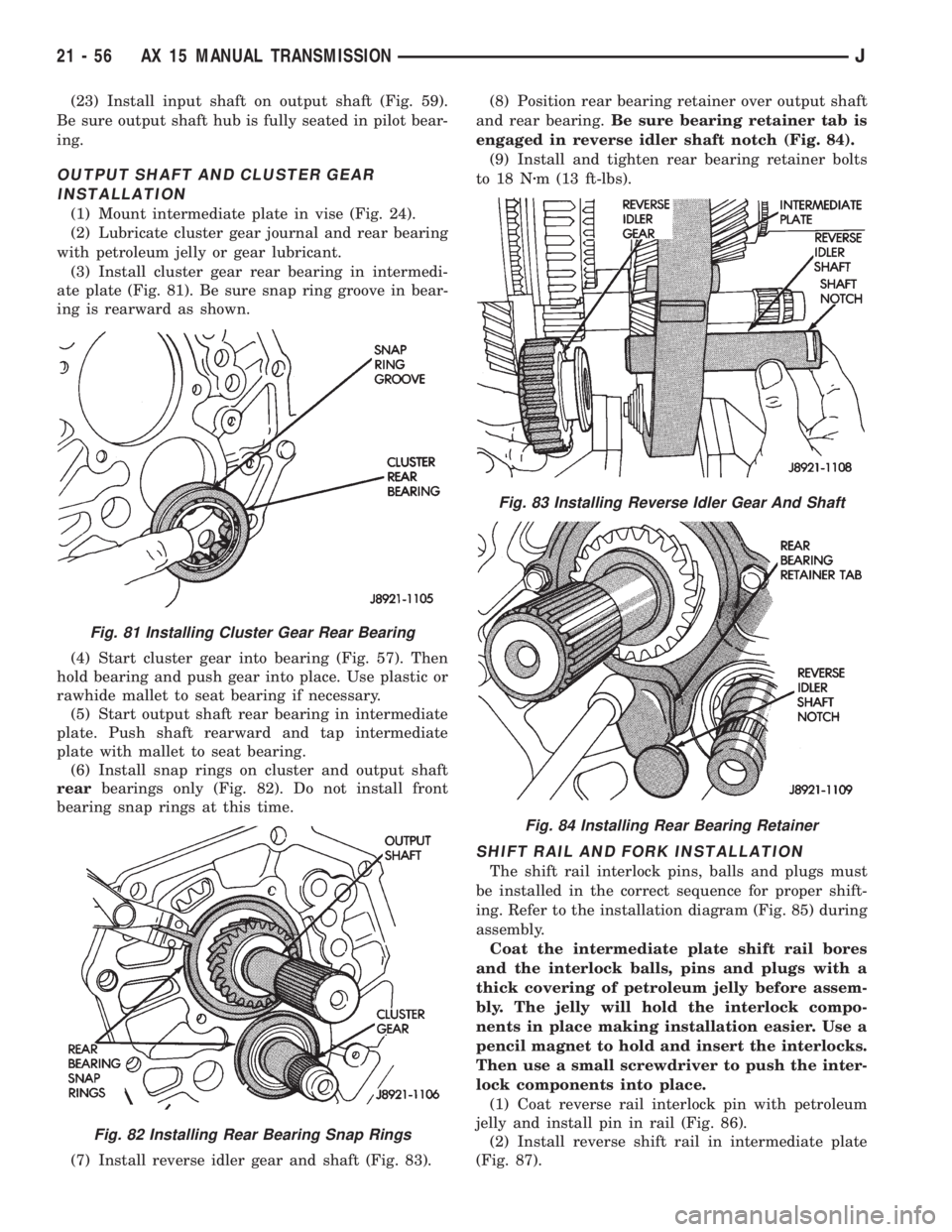

(3) Install cluster gear rear bearing in intermedi-

ate plate (Fig. 81). Be sure snap ring groove in bear-

ing is rearward as shown.

(4) Start cluster gear into bearing (Fig. 57). Then

hold bearing and push gear into place. Use plastic or

rawhide mallet to seat bearing if necessary.

(5) Start output shaft rear bearing in intermediate

plate. Push shaft rearward and tap intermediate

plate with mallet to seat bearing.

(6) Install snap rings on cluster and output shaft

rearbearings only (Fig. 82). Do not install front

bearing snap rings at this time.

(7) Install reverse idler gear and shaft (Fig. 83).(8) Position rear bearing retainer over output shaft

and rear bearing.Be sure bearing retainer tab is

engaged in reverse idler shaft notch (Fig. 84).

(9) Install and tighten rear bearing retainer bolts

to 18 Nzm (13 ft-lbs).

SHIFT RAIL AND FORK INSTALLATION

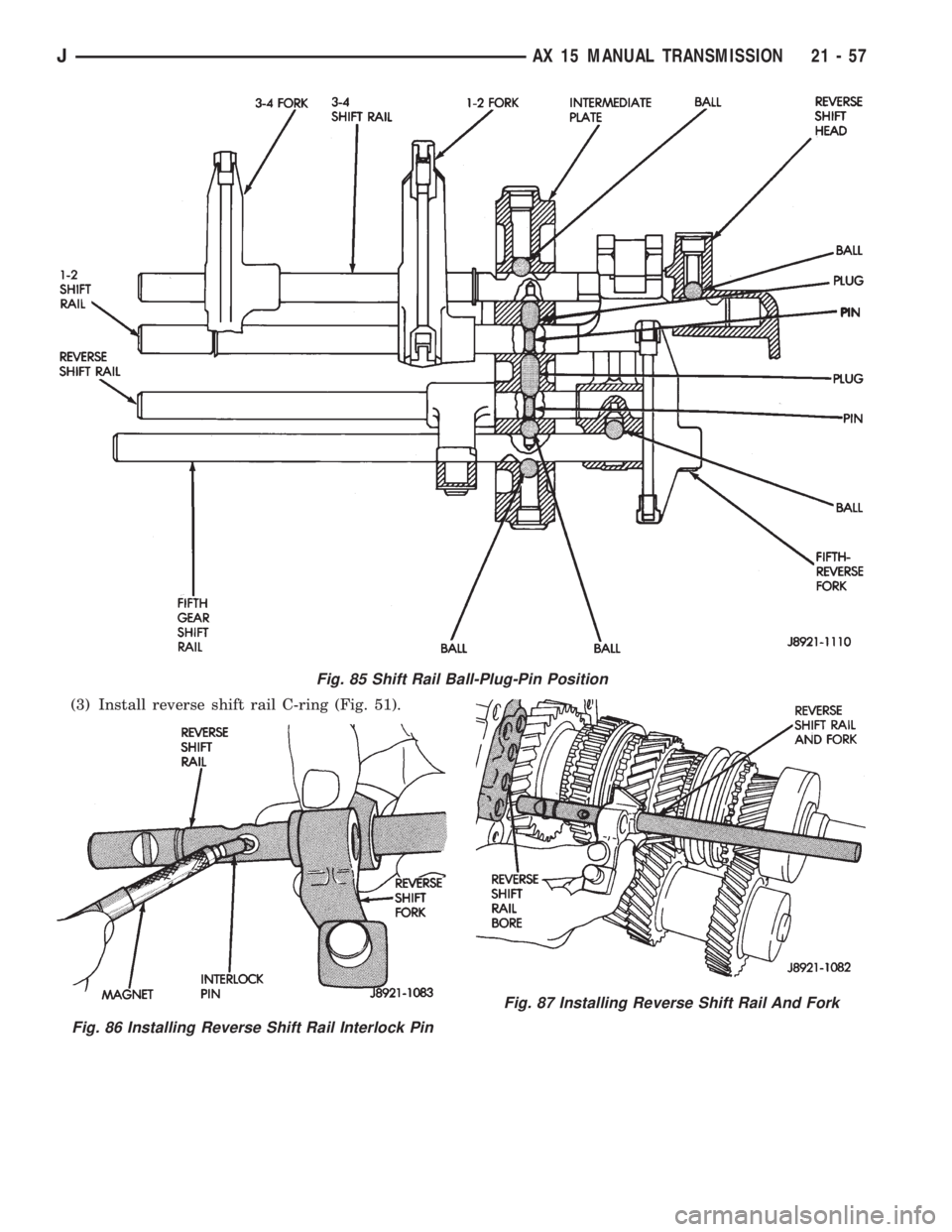

The shift rail interlock pins, balls and plugs must

be installed in the correct sequence for proper shift-

ing. Refer to the installation diagram (Fig. 85) during

assembly.

Coat the intermediate plate shift rail bores

and the interlock balls, pins and plugs with a

thick covering of petroleum jelly before assem-

bly. The jelly will hold the interlock compo-

nents in place making installation easier. Use a

pencil magnet to hold and insert the interlocks.

Then use a small screwdriver to push the inter-

lock components into place.

(1) Coat reverse rail interlock pin with petroleum

jelly and install pin in rail (Fig. 86).

(2) Install reverse shift rail in intermediate plate

(Fig. 87).

Fig. 81 Installing Cluster Gear Rear Bearing

Fig. 82 Installing Rear Bearing Snap Rings

Fig. 83 Installing Reverse Idler Gear And Shaft

Fig. 84 Installing Rear Bearing Retainer

21 - 56 AX 15 MANUAL TRANSMISSIONJ

Page 1434 of 2198

(3) Install reverse shift rail C-ring (Fig. 51).

Fig. 85 Shift Rail Ball-Plug-Pin Position

Fig. 86 Installing Reverse Shift Rail Interlock Pin

Fig. 87 Installing Reverse Shift Rail And Fork

JAX 15 MANUAL TRANSMISSION 21 - 57

Page 1435 of 2198

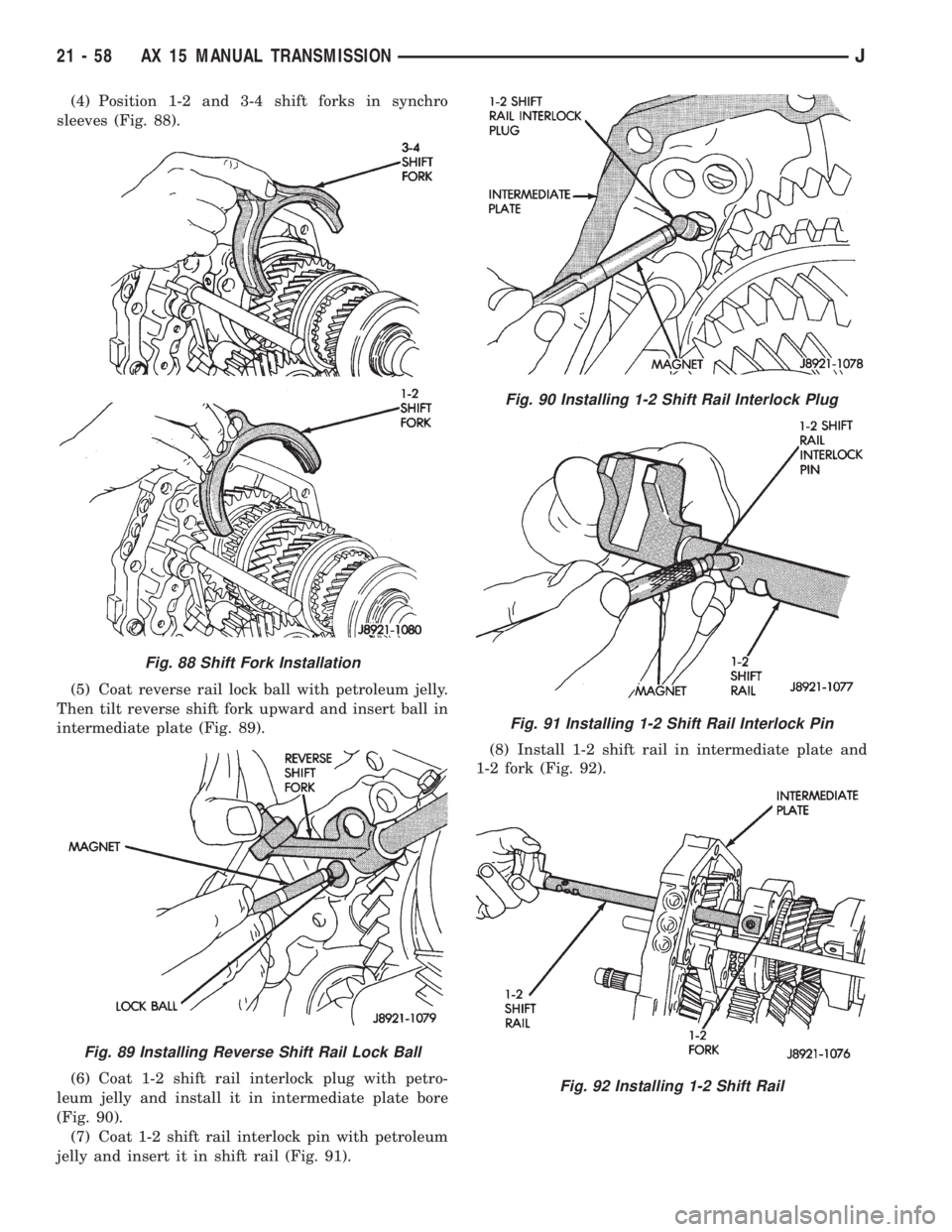

(4) Position 1-2 and 3-4 shift forks in synchro

sleeves (Fig. 88).

(5) Coat reverse rail lock ball with petroleum jelly.

Then tilt reverse shift fork upward and insert ball in

intermediate plate (Fig. 89).

(6) Coat 1-2 shift rail interlock plug with petro-

leum jelly and install it in intermediate plate bore

(Fig. 90).

(7) Coat 1-2 shift rail interlock pin with petroleum

jelly and insert it in shift rail (Fig. 91).(8) Install 1-2 shift rail in intermediate plate and

1-2 fork (Fig. 92).

Fig. 88 Shift Fork Installation

Fig. 89 Installing Reverse Shift Rail Lock Ball

Fig. 90 Installing 1-2 Shift Rail Interlock Plug

Fig. 91 Installing 1-2 Shift Rail Interlock Pin

Fig. 92 Installing 1-2 Shift Rail

21 - 58 AX 15 MANUAL TRANSMISSIONJ

Page 1436 of 2198

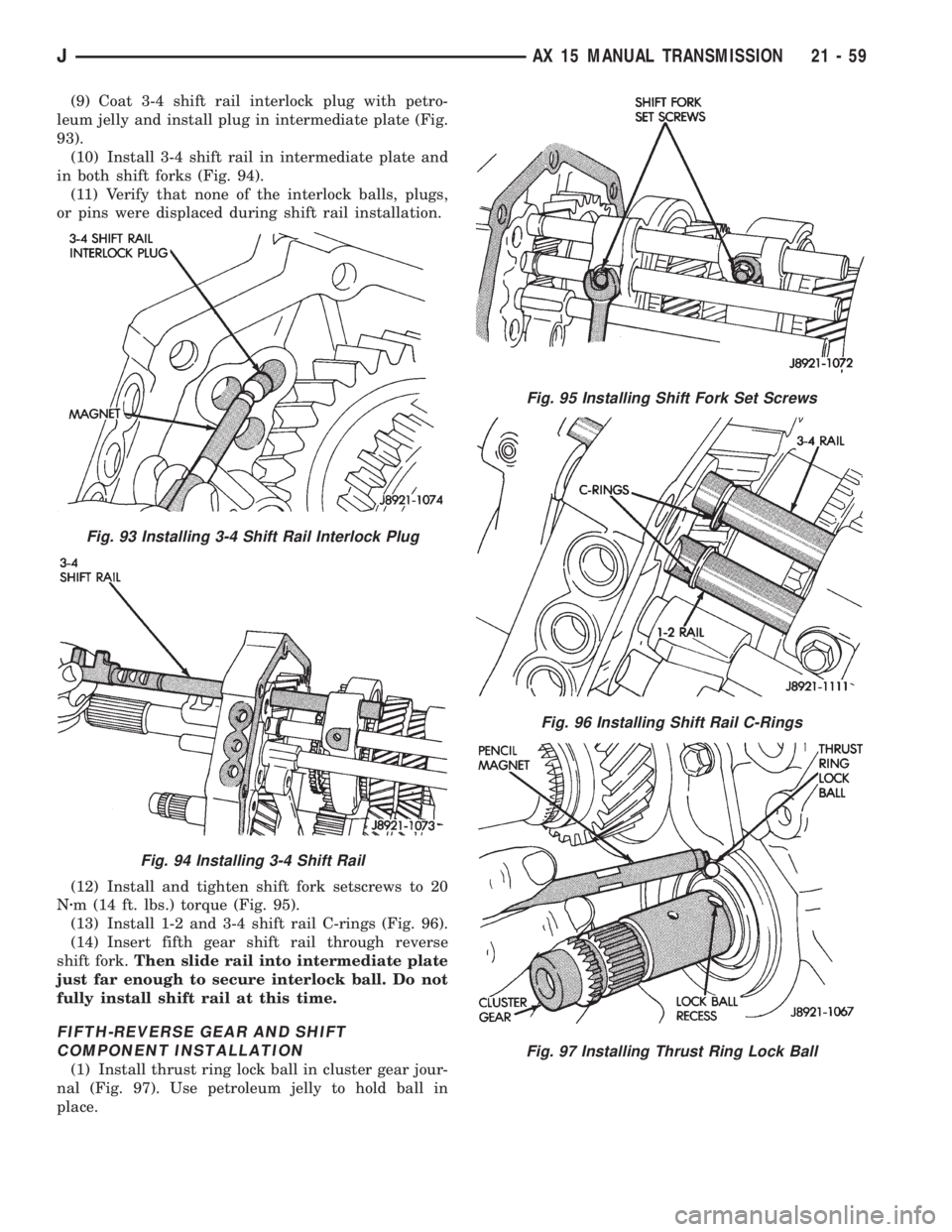

(9) Coat 3-4 shift rail interlock plug with petro-

leum jelly and install plug in intermediate plate (Fig.

93).

(10) Install 3-4 shift rail in intermediate plate and

in both shift forks (Fig. 94).

(11) Verify that none of the interlock balls, plugs,

or pins were displaced during shift rail installation.

(12) Install and tighten shift fork setscrews to 20

Nzm (14 ft. lbs.) torque (Fig. 95).

(13) Install 1-2 and 3-4 shift rail C-rings (Fig. 96).

(14) Insert fifth gear shift rail through reverse

shift fork.Then slide rail into intermediate plate

just far enough to secure interlock ball. Do not

fully install shift rail at this time.

FIFTH-REVERSE GEAR AND SHIFT

COMPONENT INSTALLATION

(1) Install thrust ring lock ball in cluster gear jour-

nal (Fig. 97). Use petroleum jelly to hold ball in

place.

Fig. 93 Installing 3-4 Shift Rail Interlock Plug

Fig. 94 Installing 3-4 Shift Rail

Fig. 95 Installing Shift Fork Set Screws

Fig. 96 Installing Shift Rail C-Rings

Fig. 97 Installing Thrust Ring Lock Ball

JAX 15 MANUAL TRANSMISSION 21 - 59

Page 1437 of 2198

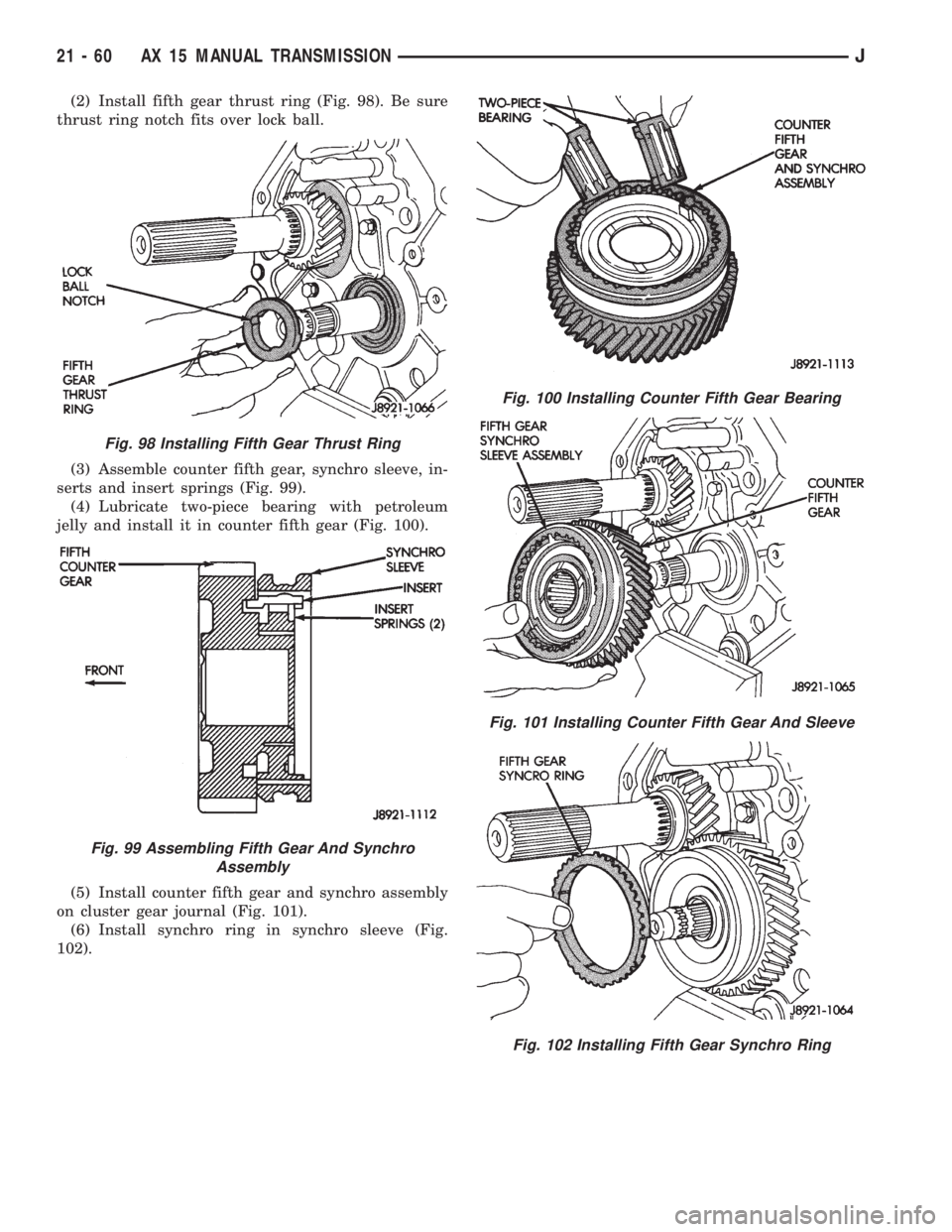

(2) Install fifth gear thrust ring (Fig. 98). Be sure

thrust ring notch fits over lock ball.

(3) Assemble counter fifth gear, synchro sleeve, in-

serts and insert springs (Fig. 99).

(4) Lubricate two-piece bearing with petroleum

jelly and install it in counter fifth gear (Fig. 100).

(5) Install counter fifth gear and synchro assembly

on cluster gear journal (Fig. 101).

(6) Install synchro ring in synchro sleeve (Fig.

102).

Fig. 98 Installing Fifth Gear Thrust Ring

Fig. 99 Assembling Fifth Gear And Synchro

Assembly

Fig. 100 Installing Counter Fifth Gear Bearing

Fig. 101 Installing Counter Fifth Gear And Sleeve

Fig. 102 Installing Fifth Gear Synchro Ring

21 - 60 AX 15 MANUAL TRANSMISSIONJ

Page 1438 of 2198

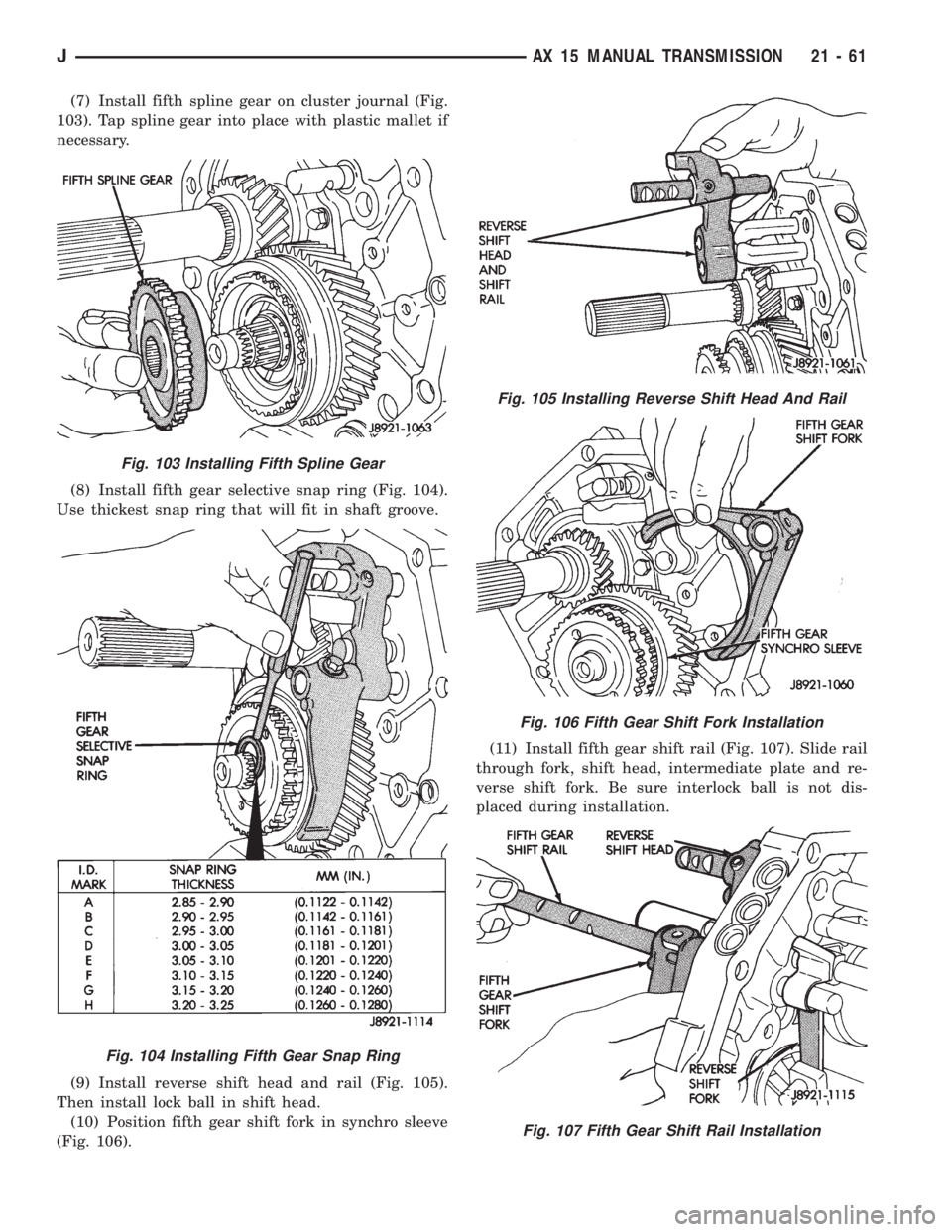

(7) Install fifth spline gear on cluster journal (Fig.

103). Tap spline gear into place with plastic mallet if

necessary.

(8) Install fifth gear selective snap ring (Fig. 104).

Use thickest snap ring that will fit in shaft groove.

(9) Install reverse shift head and rail (Fig. 105).

Then install lock ball in shift head.

(10) Position fifth gear shift fork in synchro sleeve

(Fig. 106).(11) Install fifth gear shift rail (Fig. 107). Slide rail

through fork, shift head, intermediate plate and re-

verse shift fork. Be sure interlock ball is not dis-

placed during installation.

Fig. 103 Installing Fifth Spline Gear

Fig. 104 Installing Fifth Gear Snap Ring

Fig. 105 Installing Reverse Shift Head And Rail

Fig. 106 Fifth Gear Shift Fork Installation

Fig. 107 Fifth Gear Shift Rail Installation

JAX 15 MANUAL TRANSMISSION 21 - 61