lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1439 of 2198

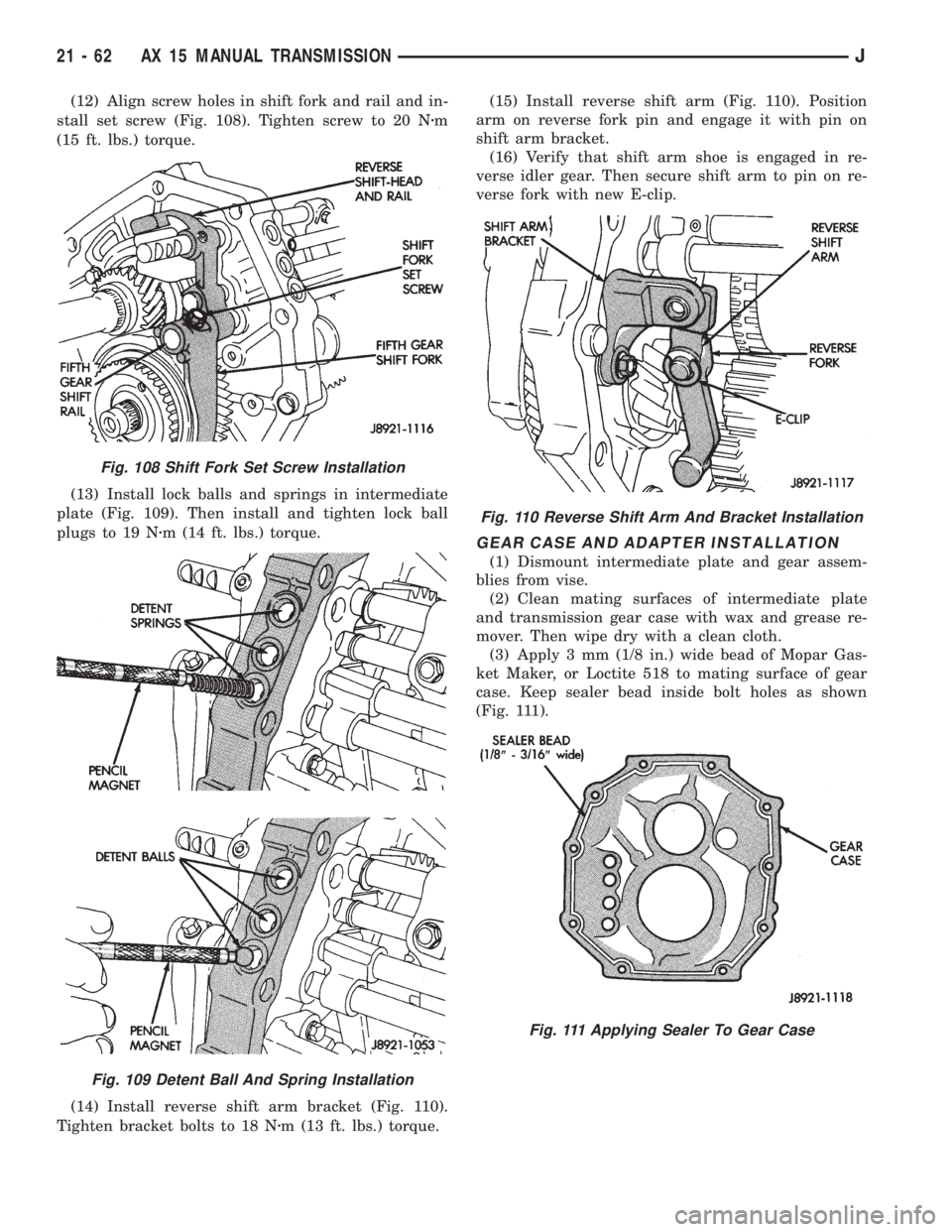

(12) Align screw holes in shift fork and rail and in-

stall set screw (Fig. 108). Tighten screw to 20 Nzm

(15 ft. lbs.) torque.

(13) Install lock balls and springs in intermediate

plate (Fig. 109). Then install and tighten lock ball

plugs to 19 Nzm (14 ft. lbs.) torque.

(14) Install reverse shift arm bracket (Fig. 110).

Tighten bracket bolts to 18 Nzm (13 ft. lbs.) torque.(15) Install reverse shift arm (Fig. 110). Position

arm on reverse fork pin and engage it with pin on

shift arm bracket.

(16) Verify that shift arm shoe is engaged in re-

verse idler gear. Then secure shift arm to pin on re-

verse fork with new E-clip.

GEAR CASE AND ADAPTER INSTALLATION

(1) Dismount intermediate plate and gear assem-

blies from vise.

(2) Clean mating surfaces of intermediate plate

and transmission gear case with wax and grease re-

mover. Then wipe dry with a clean cloth.

(3) Apply 3 mm (1/8 in.) wide bead of Mopar Gas-

ket Maker, or Loctite 518 to mating surface of gear

case. Keep sealer bead inside bolt holes as shown

(Fig. 111).

Fig. 108 Shift Fork Set Screw Installation

Fig. 109 Detent Ball And Spring Installation

Fig. 110 Reverse Shift Arm And Bracket Installation

Fig. 111 Applying Sealer To Gear Case

21 - 62 AX 15 MANUAL TRANSMISSIONJ

Page 1440 of 2198

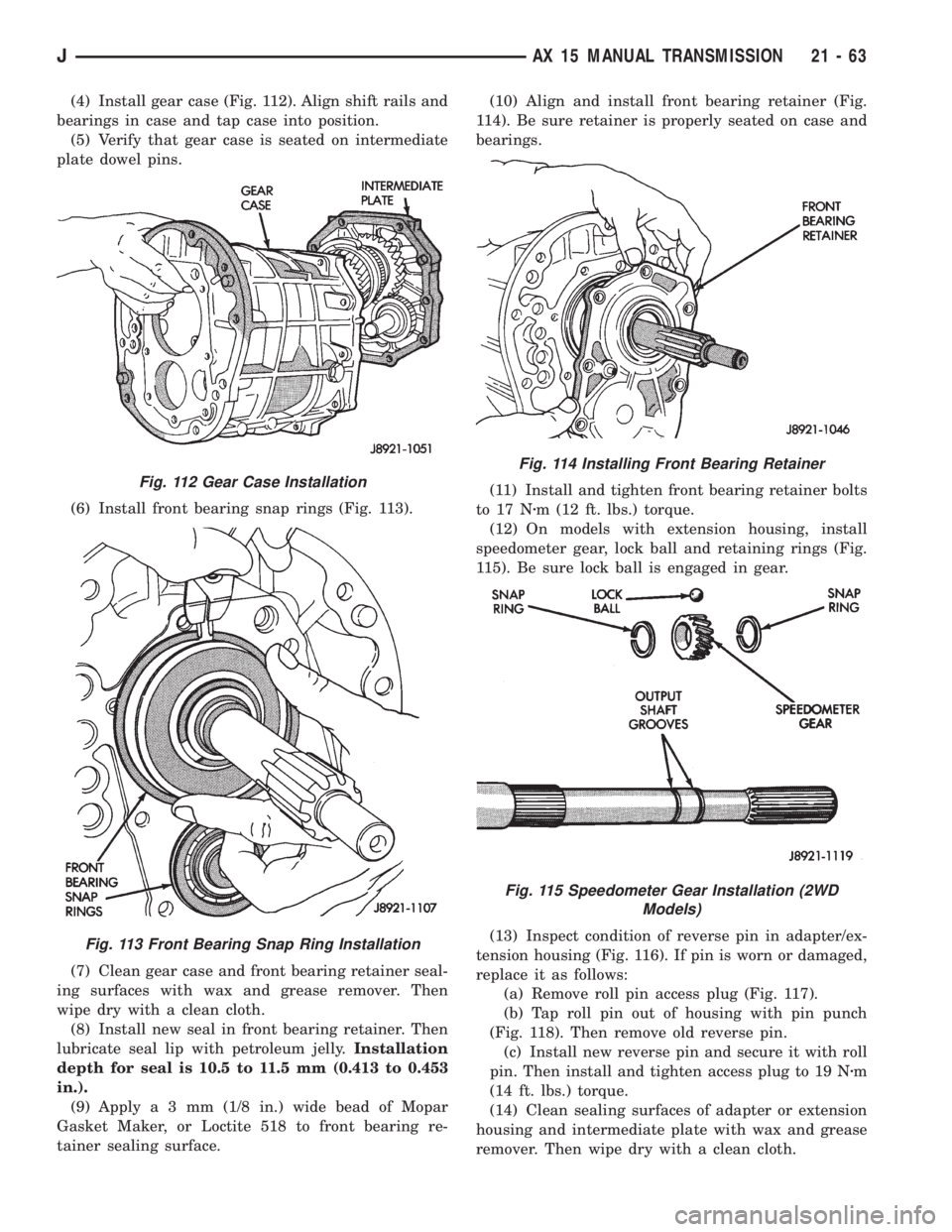

(4) Install gear case (Fig. 112). Align shift rails and

bearings in case and tap case into position.

(5) Verify that gear case is seated on intermediate

plate dowel pins.

(6) Install front bearing snap rings (Fig. 113).

(7) Clean gear case and front bearing retainer seal-

ing surfaces with wax and grease remover. Then

wipe dry with a clean cloth.

(8) Install new seal in front bearing retainer. Then

lubricate seal lip with petroleum jelly.Installation

depth for seal is 10.5 to 11.5 mm (0.413 to 0.453

in.).

(9) Applya3mm(1/8 in.) wide bead of Mopar

Gasket Maker, or Loctite 518 to front bearing re-

tainer sealing surface.(10) Align and install front bearing retainer (Fig.

114). Be sure retainer is properly seated on case and

bearings.

(11) Install and tighten front bearing retainer bolts

to 17 Nzm (12 ft. lbs.) torque.

(12) On models with extension housing, install

speedometer gear, lock ball and retaining rings (Fig.

115). Be sure lock ball is engaged in gear.

(13) Inspect condition of reverse pin in adapter/ex-

tension housing (Fig. 116). If pin is worn or damaged,

replace it as follows:

(a) Remove roll pin access plug (Fig. 117).

(b) Tap roll pin out of housing with pin punch

(Fig. 118). Then remove old reverse pin.

(c) Install new reverse pin and secure it with roll

pin. Then install and tighten access plug to 19 Nzm

(14 ft. lbs.) torque.

(14) Clean sealing surfaces of adapter or extension

housing and intermediate plate with wax and grease

remover. Then wipe dry with a clean cloth.

Fig. 112 Gear Case Installation

Fig. 113 Front Bearing Snap Ring Installation

Fig. 114 Installing Front Bearing Retainer

Fig. 115 Speedometer Gear Installation (2WD

Models)

JAX 15 MANUAL TRANSMISSION 21 - 63

Page 1446 of 2198

driven by the torque converter. The converter is con-

nected to the engine crankshaft through the drive-

plate.

The pressure regulator valve maintains line pres-

sure. The regulator valve is located in the valve body.

The amount of line pressure developed is controlled

by throttle pressure, which is dependent on the de-

gree of throttle opening.

The governor valve is operated by the transmission

output shaft. Governor pressure increases approxi-

mately in proportion to vehicle speed.

The throttle valve determines line pressure and

shift speed. The throttle valve also controls upshift

and downshift speeds by regulating pressure in con-

junction with throttle position.

Shift Valves

The manual valve is operated by the gearshift link-

age and provides the operating range selected by the

driver.

The 1-2 shift valve provides automatic 1-2 or 2-1

shifts and the 2-3 shift valve provides automatic 2-3

or 3-2 shifts. The kickdown valve provides forced 3-2

or 3-1 downshifts depending on vehicle speed. Down-

shifts occur when the throttle is opened beyond

downshift detent position which is just before wide

open throttle.

The 2-3 valve throttle pressure plug provides 3-2

downshifts with varying throttle openings and de-

pending on vehicle speed. The 1-2 shift control valve

transmits 1-2 shift pressure to the accumulator pis-

ton to control kickdown band capacity on 1-2 upshifts

and 3-2 downshifts.The shuttle valve has two functions. First is fast

front band release and smooth engagement during

lift-foot 2-3 upshifts. The second is to regulate front

clutch and band application during 3-2 downshifts.

Clutches-Bands-Servos-Accumulator

The front/rear clutch pistons and servo pistons are

actuated by line pressure. When line pressure is re-

moved, the pistons are released by spring tension.

On 2-3 upshifts, the front servo piston is released

by spring tension and hydraulic pressure. The accu-

mulator controls hydraulic pressure on the apply side

of the front servo during 1-2 upshifts and at all

throttle openings.

Converter Clutch Controls

Converter clutch operation is controlled by the

power train control module, and by the solenoid and

clutch module on the valve body. The solenoid is op-

erated by a relay on the engine compartment side of

the dash panel.

Activating the solenoid opens a vent allowing fluid

to flow into the clutch module. When line pressure

exceeds tension of the module valve springs, the

module valves open. This allows fluid to be chan-

neled to the converter clutch through the reaction

shaft support and transmission shaft.

Gearshift And Park Lock Controls

The gearshift lever provides six operating positions:

Park (P), Reverse (R), Neutral (N), and the D, 2 and

1 forward drive ranges.

Manual 1 position provides first gear only. Overrun

braking occurs in 1 range when the throttle is re-

leased. Upshifts are not provided in 1 range.

Manual 2 range provides first and second gear. A

1-2 upshift will take place but a 2-3 upshift will not

occur.

D position provides 1-2, 2-3 upshifts and 3-2 and

3-1 downshifts.

Park position allows the park rod to move the park

pawl into engagement with the park gear. This pre-

vents rotation of the transmission output shaft. The

park lock mechanism is only engaged when the shift

lever is in the Park detent.

A park/neutral position switch controls engine

starting. The switch is designed to allow engine

starts only in park or neutral positions.

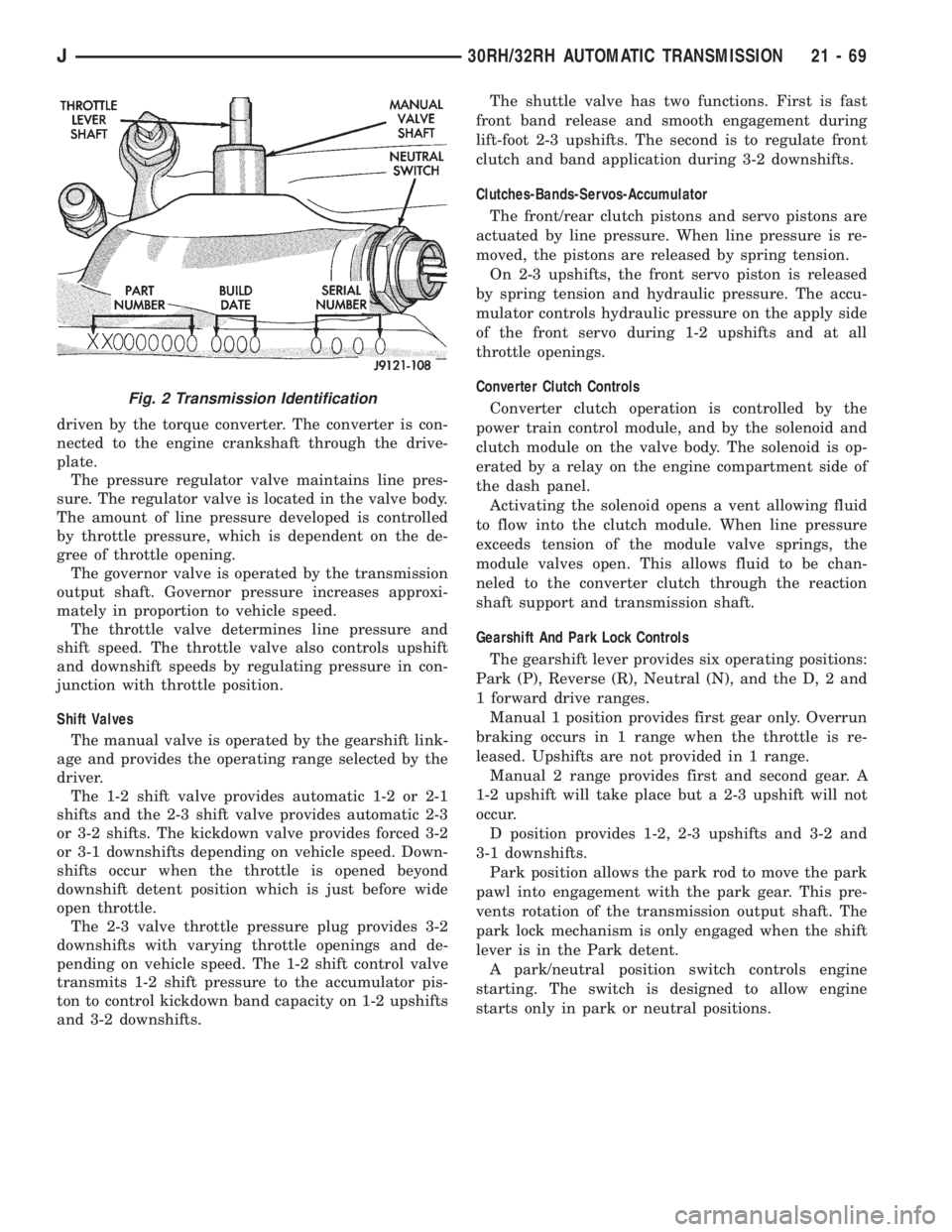

Fig. 2 Transmission Identification

J30RH/32RH AUTOMATIC TRANSMISSION 21 - 69

Page 1451 of 2198

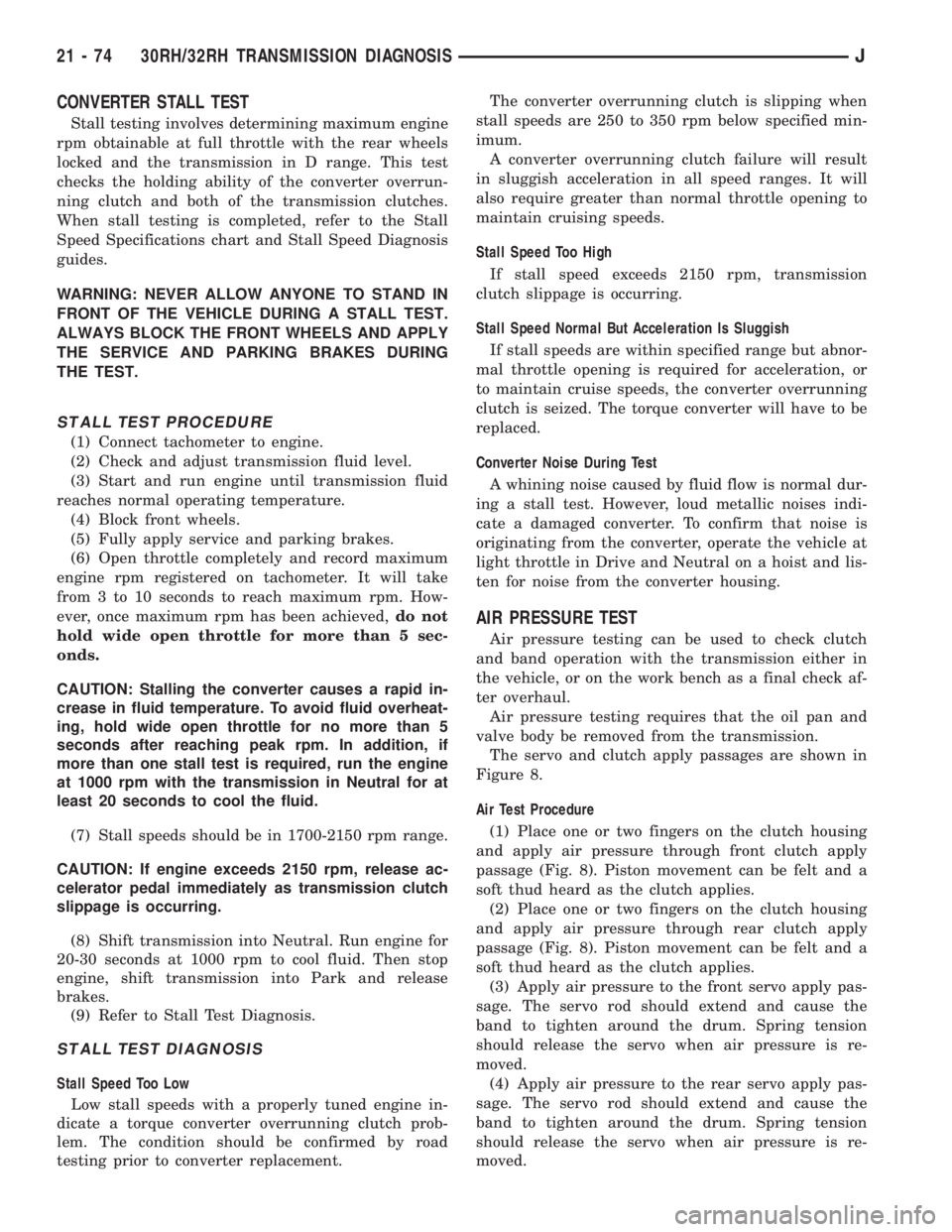

CONVERTER STALL TEST

Stall testing involves determining maximum engine

rpm obtainable at full throttle with the rear wheels

locked and the transmission in D range. This test

checks the holding ability of the converter overrun-

ning clutch and both of the transmission clutches.

When stall testing is completed, refer to the Stall

Speed Specifications chart and Stall Speed Diagnosis

guides.

WARNING: NEVER ALLOW ANYONE TO STAND IN

FRONT OF THE VEHICLE DURING A STALL TEST.

ALWAYS BLOCK THE FRONT WHEELS AND APPLY

THE SERVICE AND PARKING BRAKES DURING

THE TEST.

STALL TEST PROCEDURE

(1) Connect tachometer to engine.

(2) Check and adjust transmission fluid level.

(3) Start and run engine until transmission fluid

reaches normal operating temperature.

(4) Block front wheels.

(5) Fully apply service and parking brakes.

(6) Open throttle completely and record maximum

engine rpm registered on tachometer. It will take

from 3 to 10 seconds to reach maximum rpm. How-

ever, once maximum rpm has been achieved,do not

hold wide open throttle for more than 5 sec-

onds.

CAUTION: Stalling the converter causes a rapid in-

crease in fluid temperature. To avoid fluid overheat-

ing, hold wide open throttle for no more than 5

seconds after reaching peak rpm. In addition, if

more than one stall test is required, run the engine

at 1000 rpm with the transmission in Neutral for at

least 20 seconds to cool the fluid.

(7) Stall speeds should be in 1700-2150 rpm range.

CAUTION: If engine exceeds 2150 rpm, release ac-

celerator pedal immediately as transmission clutch

slippage is occurring.

(8) Shift transmission into Neutral. Run engine for

20-30 seconds at 1000 rpm to cool fluid. Then stop

engine, shift transmission into Park and release

brakes.

(9) Refer to Stall Test Diagnosis.

STALL TEST DIAGNOSIS

Stall Speed Too Low

Low stall speeds with a properly tuned engine in-

dicate a torque converter overrunning clutch prob-

lem. The condition should be confirmed by road

testing prior to converter replacement.The converter overrunning clutch is slipping when

stall speeds are 250 to 350 rpm below specified min-

imum.

A converter overrunning clutch failure will result

in sluggish acceleration in all speed ranges. It will

also require greater than normal throttle opening to

maintain cruising speeds.

Stall Speed Too High

If stall speed exceeds 2150 rpm, transmission

clutch slippage is occurring.

Stall Speed Normal But Acceleration Is Sluggish

If stall speeds are within specified range but abnor-

mal throttle opening is required for acceleration, or

to maintain cruise speeds, the converter overrunning

clutch is seized. The torque converter will have to be

replaced.

Converter Noise During Test

A whining noise caused by fluid flow is normal dur-

ing a stall test. However, loud metallic noises indi-

cate a damaged converter. To confirm that noise is

originating from the converter, operate the vehicle at

light throttle in Drive and Neutral on a hoist and lis-

ten for noise from the converter housing.

AIR PRESSURE TEST

Air pressure testing can be used to check clutch

and band operation with the transmission either in

the vehicle, or on the work bench as a final check af-

ter overhaul.

Air pressure testing requires that the oil pan and

valve body be removed from the transmission.

The servo and clutch apply passages are shown in

Figure 8.

Air Test Procedure

(1) Place one or two fingers on the clutch housing

and apply air pressure through front clutch apply

passage (Fig. 8). Piston movement can be felt and a

soft thud heard as the clutch applies.

(2) Place one or two fingers on the clutch housing

and apply air pressure through rear clutch apply

passage (Fig. 8). Piston movement can be felt and a

soft thud heard as the clutch applies.

(3) Apply air pressure to the front servo apply pas-

sage. The servo rod should extend and cause the

band to tighten around the drum. Spring tension

should release the servo when air pressure is re-

moved.

(4) Apply air pressure to the rear servo apply pas-

sage. The servo rod should extend and cause the

band to tighten around the drum. Spring tension

should release the servo when air pressure is re-

moved.

21 - 74 30RH/32RH TRANSMISSION DIAGNOSISJ

Page 1476 of 2198

30RH/32RH IN-VEHICLE SERVICE

INDEX

page page

Converter Drainback Check Valve Service...... 113

Fluid and Filter Replacement................. 99

Fluid Level Check......................... 99

Front Band Adjustment.................... 102

Governor and Park Gear Service............. 105

Oil Filter Replacement..................... 103

Park Interlock Cable Adjustment (XJ).......... 101

Park Lock Component Replacement.......... 108

Park/Neutral Position Switch Service.......... 109

Rear Band Adjustment.................... 103

Recommended Fluid....................... 99Refilling After Overhaul or Fluid/Filter Change . . . 100

Shift Cable Adjustment (XJ)................. 100

Shift Linkage Adjustment (YJ)............... 100

Speedometer Service..................... 109

Throttle Valve Cable Adjustment (XJ/YJ)....... 101

Transmission Cooler Flow Testing............ 113

Transmission Cooler Line and Fitting Service.... 111

Transmission Cooler Reverse Flushing......... 114

Valve Body Installation.................... 104

Valve Body Removal...................... 104

Valve Body Service....................... 104

RECOMMENDED FLUID

Recommended (and preferred) fluid for 30RH/32RH

transmissions is Mopar ATF Plus, type 7176.

Dexron II is not really recommended and should

only be used when ATF Plus is not available.

FLUID LEVEL CHECK

Transmission fluid level should be checked monthly

under normal operation. If the vehicle is used for

trailer towing or similar heavy load hauling, check

fluid level and condition weekly.

Fluid level is checked with the engine running at

curb idle speed, the transmission in Neutral and the

transmission fluid at normal operating temperature.

FLUID LEVEL CHECK PROCEDURE

(1) Transmission fluid must be at normal operating

temperature for accurate fluid level check. Drive ve-

hicle if necessary to bring fluid temperature up to

normal hot operating temperature of 82ÉC (180ÉF).

(2) Position vehicle on level surface. This is ex-

tremely important for accurate fluid level check.

(3) Start and run engine at curb idle speed.

(4) Apply parking brakes.

(5) Shift transmission momentarily into all gear

ranges. Then shift transmission back to Neutral.

(6) Clean top of filler tube and dipstick to keep dirt

from entering tube.

(7) Remove dipstick and check fluid level as fol-

lows:

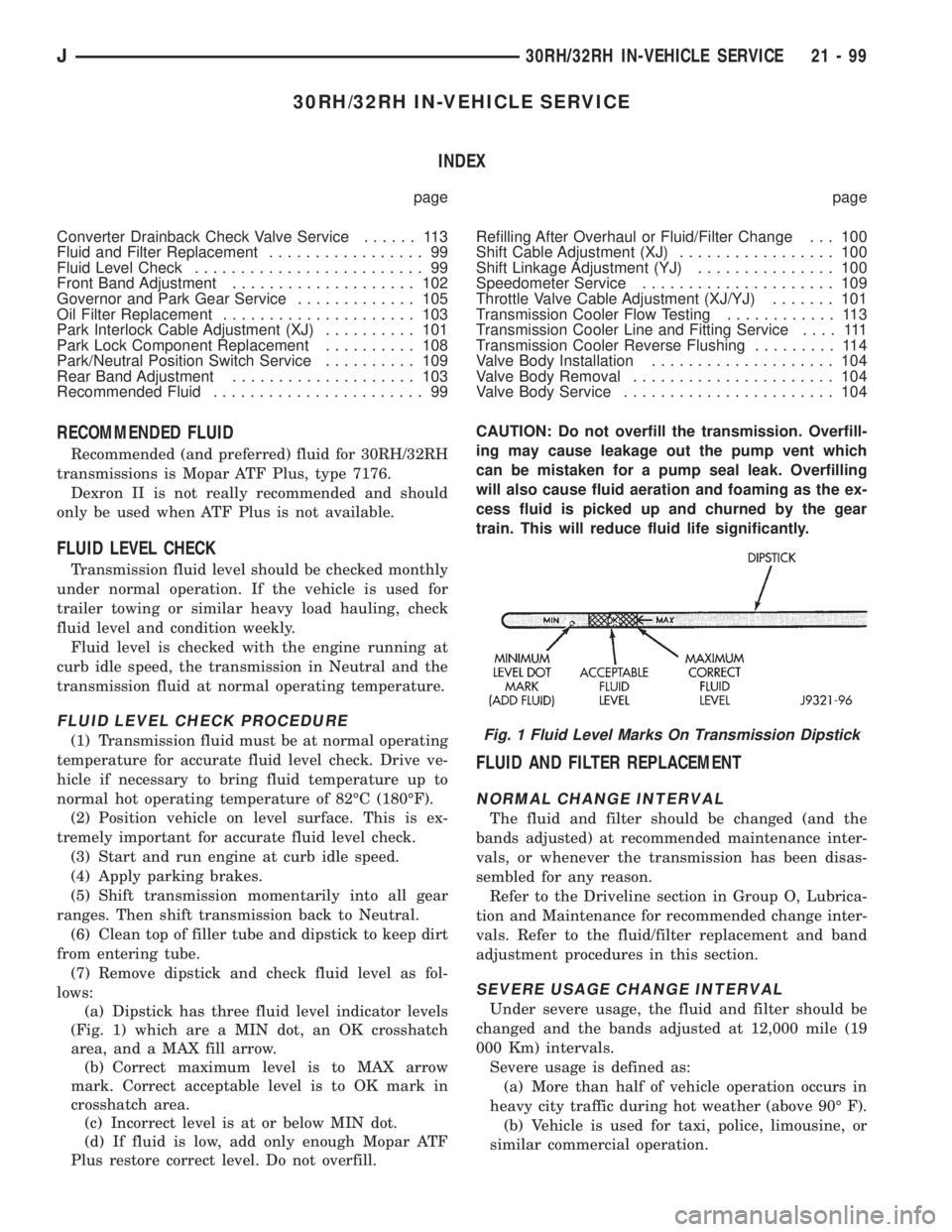

(a) Dipstick has three fluid level indicator levels

(Fig. 1) which are a MIN dot, an OK crosshatch

area, and a MAX fill arrow.

(b) Correct maximum level is to MAX arrow

mark. Correct acceptable level is to OK mark in

crosshatch area.

(c) Incorrect level is at or below MIN dot.

(d) If fluid is low, add only enough Mopar ATF

Plus restore correct level. Do not overfill.CAUTION: Do not overfill the transmission. Overfill-

ing may cause leakage out the pump vent which

can be mistaken for a pump seal leak. Overfilling

will also cause fluid aeration and foaming as the ex-

cess fluid is picked up and churned by the gear

train. This will reduce fluid life significantly.

FLUID AND FILTER REPLACEMENT

NORMAL CHANGE INTERVAL

The fluid and filter should be changed (and the

bands adjusted) at recommended maintenance inter-

vals, or whenever the transmission has been disas-

sembled for any reason.

Refer to the Driveline section in Group O, Lubrica-

tion and Maintenance for recommended change inter-

vals. Refer to the fluid/filter replacement and band

adjustment procedures in this section.

SEVERE USAGE CHANGE INTERVAL

Under severe usage, the fluid and filter should be

changed and the bands adjusted at 12,000 mile (19

000 Km) intervals.

Severe usage is defined as:

(a) More than half of vehicle operation occurs in

heavy city traffic during hot weather (above 90É F).

(b) Vehicle is used for taxi, police, limousine, or

similar commercial operation.

Fig. 1 Fluid Level Marks On Transmission Dipstick

J30RH/32RH IN-VEHICLE SERVICE 21 - 99

Page 1477 of 2198

(c) Vehicle is used for trailer towing or heavy

load hauling.

FLUID/FILTER REPLACEMENT PROCEDURE

(1) Raise vehicle.

(2) Remove oil pan and drain fluid.

(3) Clean oil pan and pan magnet. Then clean re-

maining gasket material from gasket surface of

transmission case.

(4) Remove fluid filter screws and remove filter.

(5) Position new filter on valve body and install fil-

ter screws. Tighten screws to 4 Nzm (35 in. lbs.)

torque.

(6) Adjust rear band at this time if required.

(7) Position new gasket on oil pan and install pan

on transmission. Tighten pan bolts to 150 in. lbs. (17

Nzm) torque.

(8) Adjust front band at this time if required.

(9) Lower vehicle and refill transmission with Mo-

par ATF Plus, type 7176 fluid.

REFILLING AFTER OVERHAUL OR FLUID/FILTER

CHANGE

The most effective way to avoid overfilling after a

fluid change or overhaul is as follows:

(1) Remove dipstick and insert clean funnel in

transmission fill tube.

(2) Add following initial quantity of Mopar ATF

Plus to transmission:

(a) If only fluid and filter were changed, add3

pints (1-1/2 quarts)of ATF Plus to transmission.

(b) If transmission was completely overhauled

and torque converter was replaced or drained, add

10 pints (5 quarts)of ATF Plus to transmission.

(3) Apply parking brakes.

(4) Start and run engine at normal curb idle speed.

(5) Apply service brakes, shift transmission

through all gear ranges then back to Neutral, and

leave engine running at curb idle speed.

(6) Remove funnel, insert dipstick and check fluid

level. Add only enough fluid to bring level toMIN

dot mark on dipstick.

(7) Drive vehicle until transmission fluid is at nor-

mal operating temperature. Then recheck fluid level

as described in next step.

(8) Leave engine running at curb idle speed, shift

into Neutral, and check fluid level again. This time,

add just enough fluid to bring level up toMAX ar-

row mark but do not overfill.

(9) When fluid level is correct, shut engine off, re-

lease park brake, remove funnel, and reseat dipstick

in fill tube.

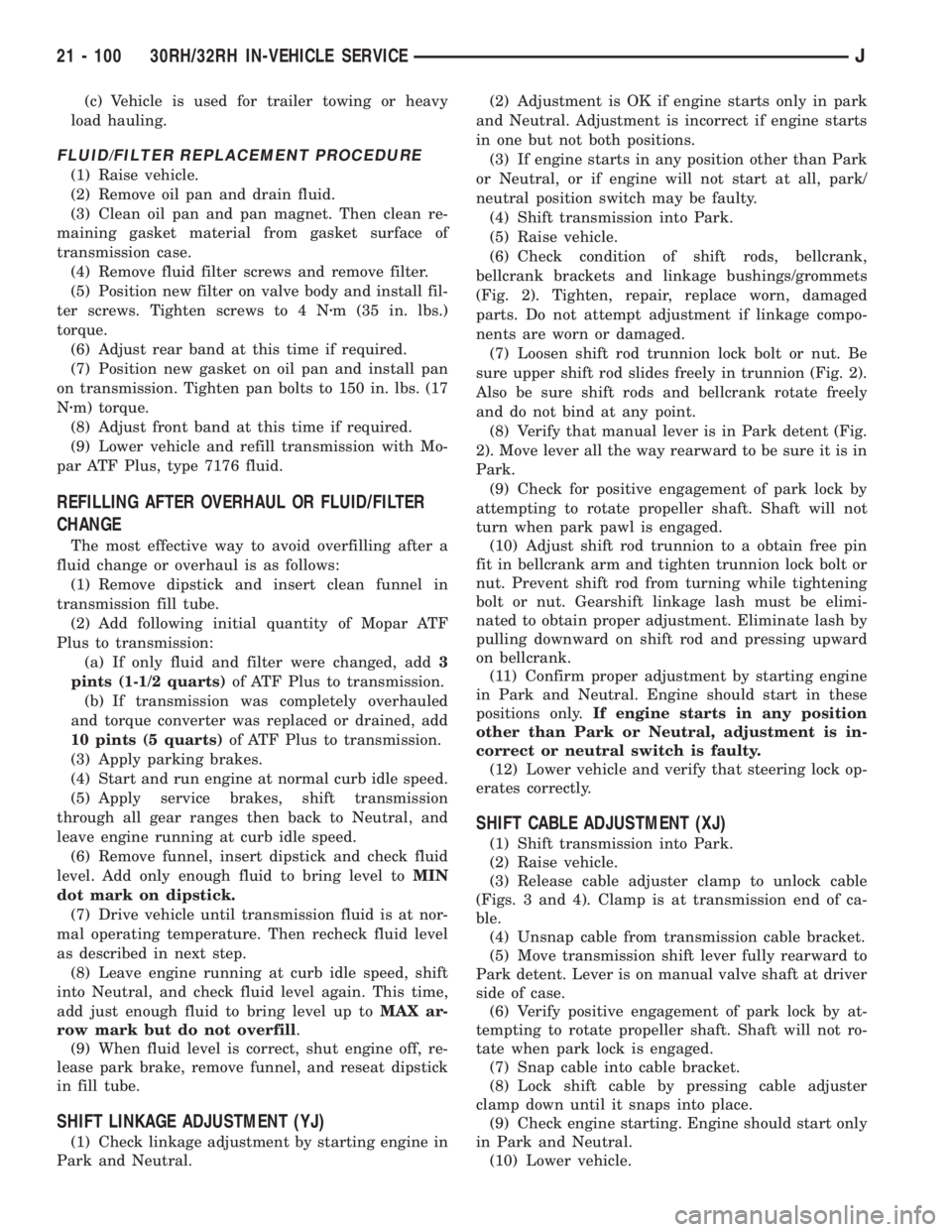

SHIFT LINKAGE ADJUSTMENT (YJ)

(1) Check linkage adjustment by starting engine in

Park and Neutral.(2) Adjustment is OK if engine starts only in park

and Neutral. Adjustment is incorrect if engine starts

in one but not both positions.

(3) If engine starts in any position other than Park

or Neutral, or if engine will not start at all, park/

neutral position switch may be faulty.

(4) Shift transmission into Park.

(5) Raise vehicle.

(6) Check condition of shift rods, bellcrank,

bellcrank brackets and linkage bushings/grommets

(Fig. 2). Tighten, repair, replace worn, damaged

parts. Do not attempt adjustment if linkage compo-

nents are worn or damaged.

(7) Loosen shift rod trunnion lock bolt or nut. Be

sure upper shift rod slides freely in trunnion (Fig. 2).

Also be sure shift rods and bellcrank rotate freely

and do not bind at any point.

(8) Verify that manual lever is in Park detent (Fig.

2). Move lever all the way rearward to be sure it is in

Park.

(9) Check for positive engagement of park lock by

attempting to rotate propeller shaft. Shaft will not

turn when park pawl is engaged.

(10) Adjust shift rod trunnion to a obtain free pin

fit in bellcrank arm and tighten trunnion lock bolt or

nut. Prevent shift rod from turning while tightening

bolt or nut. Gearshift linkage lash must be elimi-

nated to obtain proper adjustment. Eliminate lash by

pulling downward on shift rod and pressing upward

on bellcrank.

(11) Confirm proper adjustment by starting engine

in Park and Neutral. Engine should start in these

positions only.If engine starts in any position

other than Park or Neutral, adjustment is in-

correct or neutral switch is faulty.

(12) Lower vehicle and verify that steering lock op-

erates correctly.

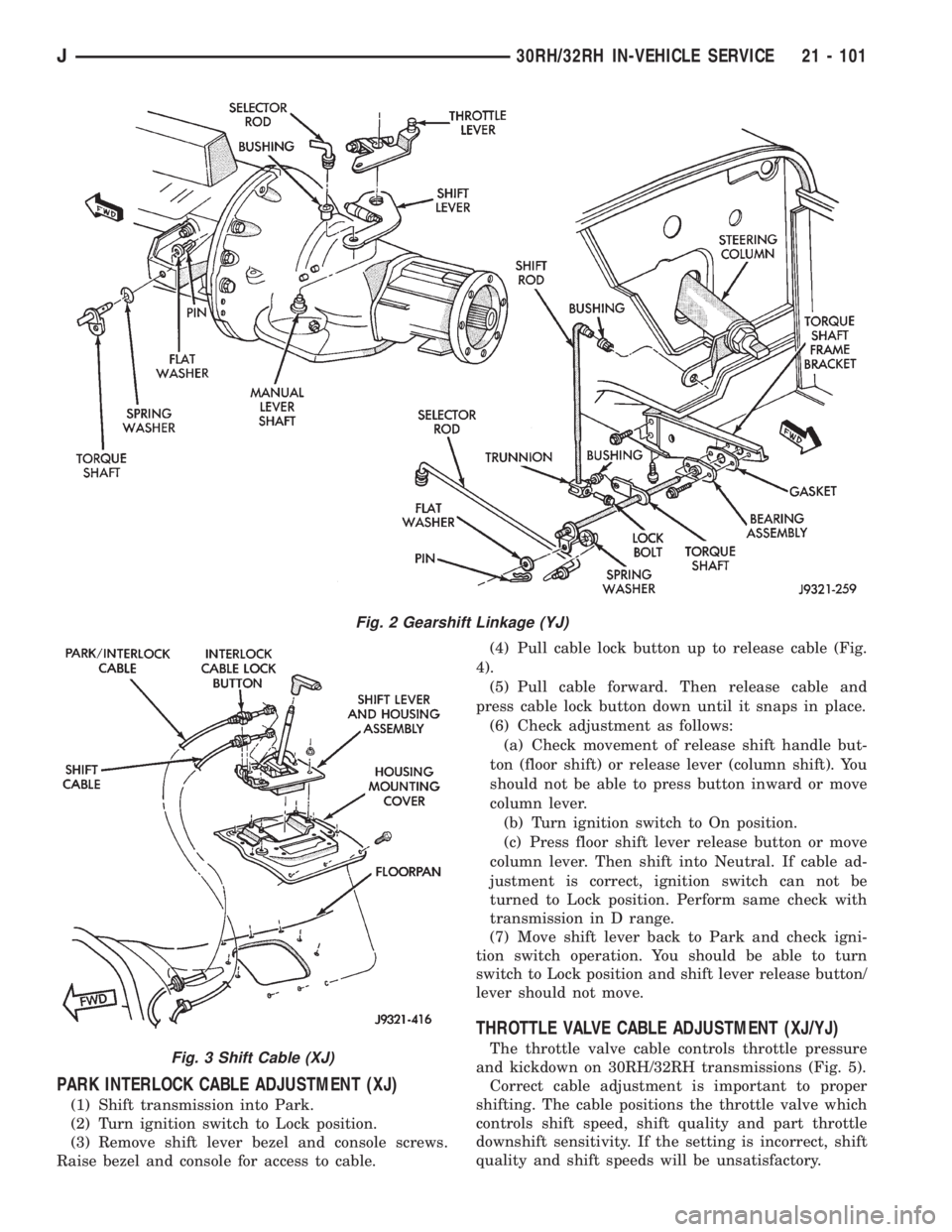

SHIFT CABLE ADJUSTMENT (XJ)

(1) Shift transmission into Park.

(2) Raise vehicle.

(3) Release cable adjuster clamp to unlock cable

(Figs. 3 and 4). Clamp is at transmission end of ca-

ble.

(4) Unsnap cable from transmission cable bracket.

(5) Move transmission shift lever fully rearward to

Park detent. Lever is on manual valve shaft at driver

side of case.

(6) Verify positive engagement of park lock by at-

tempting to rotate propeller shaft. Shaft will not ro-

tate when park lock is engaged.

(7) Snap cable into cable bracket.

(8) Lock shift cable by pressing cable adjuster

clamp down until it snaps into place.

(9) Check engine starting. Engine should start only

in Park and Neutral.

(10) Lower vehicle.

21 - 100 30RH/32RH IN-VEHICLE SERVICEJ

Page 1478 of 2198

PARK INTERLOCK CABLE ADJUSTMENT (XJ)

(1) Shift transmission into Park.

(2) Turn ignition switch to Lock position.

(3) Remove shift lever bezel and console screws.

Raise bezel and console for access to cable.(4) Pull cable lock button up to release cable (Fig.

4).

(5) Pull cable forward. Then release cable and

press cable lock button down until it snaps in place.

(6) Check adjustment as follows:

(a) Check movement of release shift handle but-

ton (floor shift) or release lever (column shift). You

should not be able to press button inward or move

column lever.

(b) Turn ignition switch to On position.

(c) Press floor shift lever release button or move

column lever. Then shift into Neutral. If cable ad-

justment is correct, ignition switch can not be

turned to Lock position. Perform same check with

transmission in D range.

(7) Move shift lever back to Park and check igni-

tion switch operation. You should be able to turn

switch to Lock position and shift lever release button/

lever should not move.

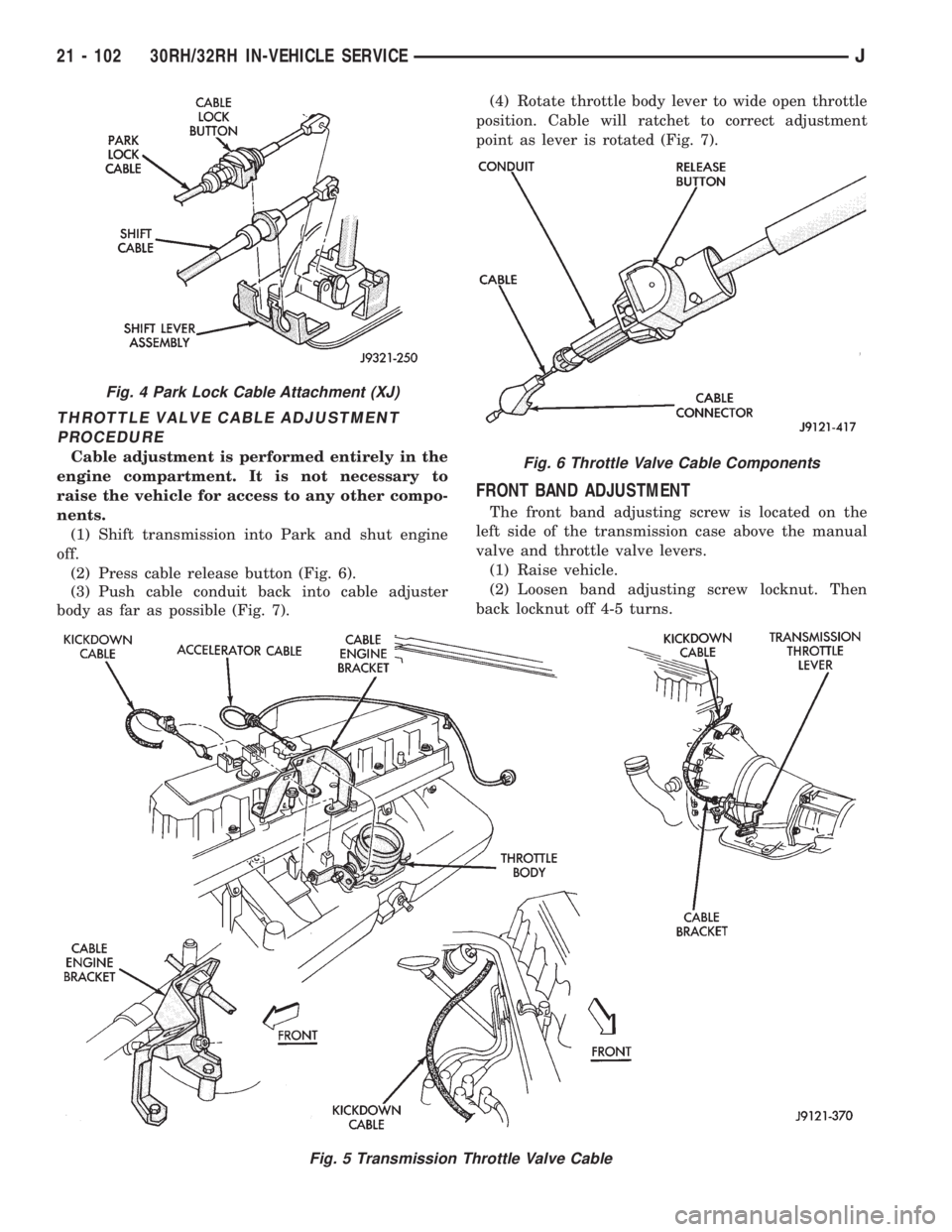

THROTTLE VALVE CABLE ADJUSTMENT (XJ/YJ)

The throttle valve cable controls throttle pressure

and kickdown on 30RH/32RH transmissions (Fig. 5).

Correct cable adjustment is important to proper

shifting. The cable positions the throttle valve which

controls shift speed, shift quality and part throttle

downshift sensitivity. If the setting is incorrect, shift

quality and shift speeds will be unsatisfactory.

Fig. 2 Gearshift Linkage (YJ)

Fig. 3 Shift Cable (XJ)

J30RH/32RH IN-VEHICLE SERVICE 21 - 101

Page 1479 of 2198

THROTTLE VALVE CABLE ADJUSTMENT

PROCEDURE

Cable adjustment is performed entirely in the

engine compartment. It is not necessary to

raise the vehicle for access to any other compo-

nents.

(1) Shift transmission into Park and shut engine

off.

(2) Press cable release button (Fig. 6).

(3) Push cable conduit back into cable adjuster

body as far as possible (Fig. 7).(4) Rotate throttle body lever to wide open throttle

position. Cable will ratchet to correct adjustment

point as lever is rotated (Fig. 7).

FRONT BAND ADJUSTMENT

The front band adjusting screw is located on the

left side of the transmission case above the manual

valve and throttle valve levers.

(1) Raise vehicle.

(2) Loosen band adjusting screw locknut. Then

back locknut off 4-5 turns.

Fig. 5 Transmission Throttle Valve Cable

Fig. 4 Park Lock Cable Attachment (XJ)

Fig. 6 Throttle Valve Cable Components

21 - 102 30RH/32RH IN-VEHICLE SERVICEJ

Page 1480 of 2198

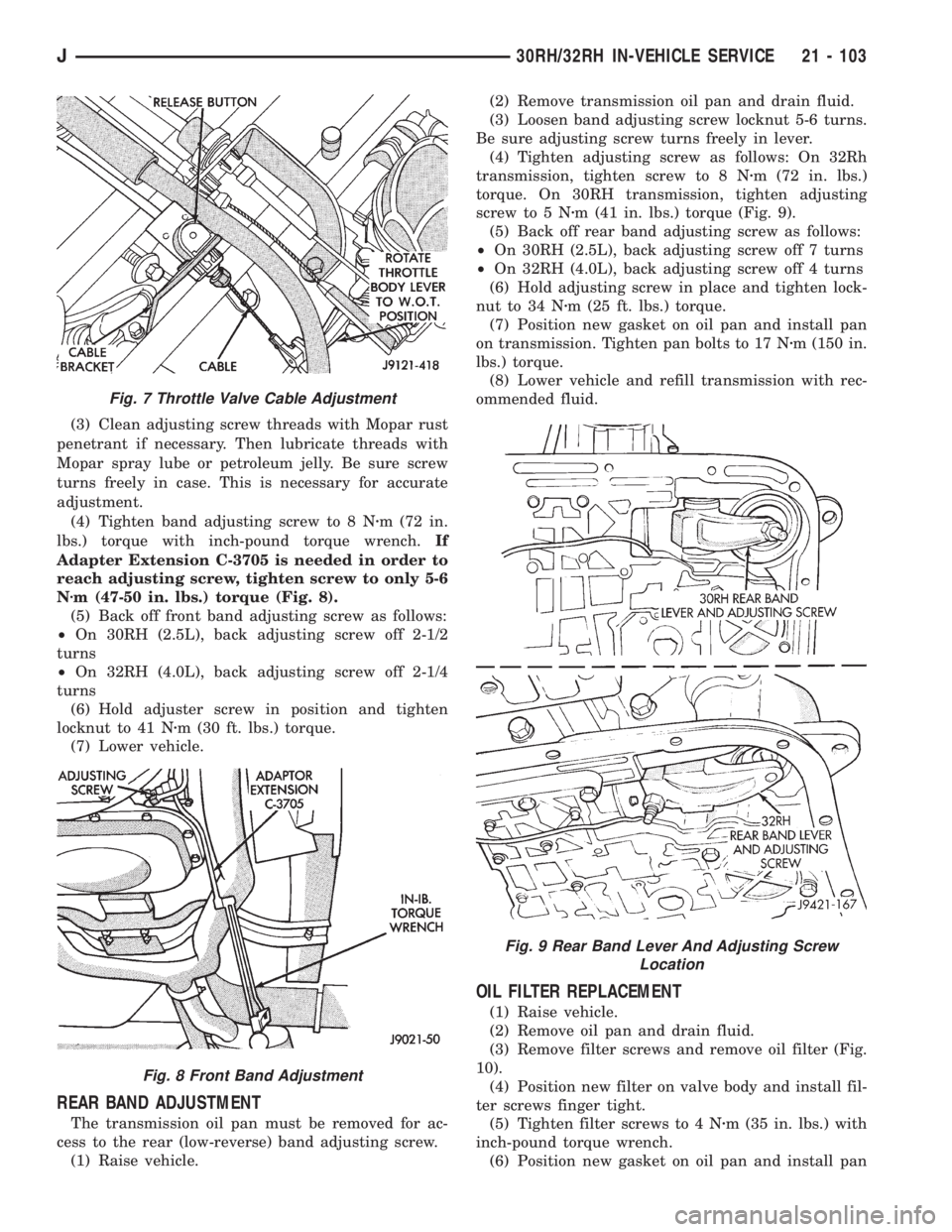

(3) Clean adjusting screw threads with Mopar rust

penetrant if necessary. Then lubricate threads with

Mopar spray lube or petroleum jelly. Be sure screw

turns freely in case. This is necessary for accurate

adjustment.

(4) Tighten band adjusting screw to 8 Nzm (72 in.

lbs.) torque with inch-pound torque wrench.If

Adapter Extension C-3705 is needed in order to

reach adjusting screw, tighten screw to only 5-6

Nzm (47-50 in. lbs.) torque (Fig. 8).

(5) Back off front band adjusting screw as follows:

²On 30RH (2.5L), back adjusting screw off 2-1/2

turns

²On 32RH (4.0L), back adjusting screw off 2-1/4

turns

(6) Hold adjuster screw in position and tighten

locknut to 41 Nzm (30 ft. lbs.) torque.

(7) Lower vehicle.

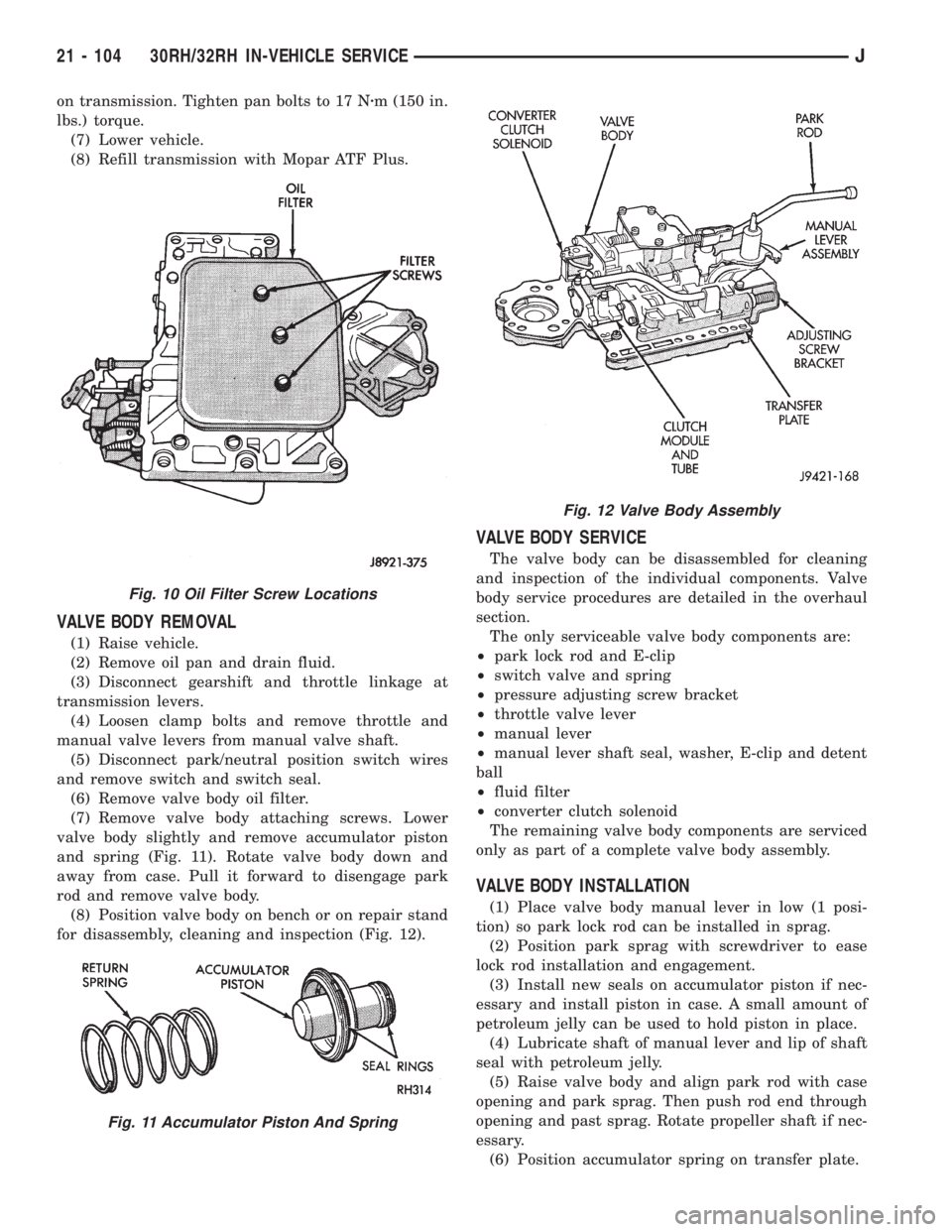

REAR BAND ADJUSTMENT

The transmission oil pan must be removed for ac-

cess to the rear (low-reverse) band adjusting screw.

(1) Raise vehicle.(2) Remove transmission oil pan and drain fluid.

(3) Loosen band adjusting screw locknut 5-6 turns.

Be sure adjusting screw turns freely in lever.

(4) Tighten adjusting screw as follows: On 32Rh

transmission, tighten screw to 8 Nzm (72 in. lbs.)

torque. On 30RH transmission, tighten adjusting

screw to 5 Nzm (41 in. lbs.) torque (Fig. 9).

(5) Back off rear band adjusting screw as follows:

²On 30RH (2.5L), back adjusting screw off 7 turns

²On 32RH (4.0L), back adjusting screw off 4 turns

(6) Hold adjusting screw in place and tighten lock-

nut to 34 Nzm (25 ft. lbs.) torque.

(7) Position new gasket on oil pan and install pan

on transmission. Tighten pan bolts to 17 Nzm (150 in.

lbs.) torque.

(8) Lower vehicle and refill transmission with rec-

ommended fluid.

OIL FILTER REPLACEMENT

(1) Raise vehicle.

(2) Remove oil pan and drain fluid.

(3) Remove filter screws and remove oil filter (Fig.

10).

(4) Position new filter on valve body and install fil-

ter screws finger tight.

(5) Tighten filter screws to 4 Nzm (35 in. lbs.) with

inch-pound torque wrench.

(6) Position new gasket on oil pan and install pan

Fig. 7 Throttle Valve Cable Adjustment

Fig. 8 Front Band Adjustment

Fig. 9 Rear Band Lever And Adjusting Screw

Location

J30RH/32RH IN-VEHICLE SERVICE 21 - 103

Page 1481 of 2198

on transmission. Tighten pan bolts to 17 Nzm (150 in.

lbs.) torque.

(7) Lower vehicle.

(8) Refill transmission with Mopar ATF Plus.

VALVE BODY REMOVAL

(1) Raise vehicle.

(2) Remove oil pan and drain fluid.

(3) Disconnect gearshift and throttle linkage at

transmission levers.

(4) Loosen clamp bolts and remove throttle and

manual valve levers from manual valve shaft.

(5) Disconnect park/neutral position switch wires

and remove switch and switch seal.

(6) Remove valve body oil filter.

(7) Remove valve body attaching screws. Lower

valve body slightly and remove accumulator piston

and spring (Fig. 11). Rotate valve body down and

away from case. Pull it forward to disengage park

rod and remove valve body.

(8) Position valve body on bench or on repair stand

for disassembly, cleaning and inspection (Fig. 12).

VALVE BODY SERVICE

The valve body can be disassembled for cleaning

and inspection of the individual components. Valve

body service procedures are detailed in the overhaul

section.

The only serviceable valve body components are:

²park lock rod and E-clip

²switch valve and spring

²pressure adjusting screw bracket

²throttle valve lever

²manual lever

²manual lever shaft seal, washer, E-clip and detent

ball

²fluid filter

²converter clutch solenoid

The remaining valve body components are serviced

only as part of a complete valve body assembly.

VALVE BODY INSTALLATION

(1) Place valve body manual lever in low (1 posi-

tion) so park lock rod can be installed in sprag.

(2) Position park sprag with screwdriver to ease

lock rod installation and engagement.

(3) Install new seals on accumulator piston if nec-

essary and install piston in case. A small amount of

petroleum jelly can be used to hold piston in place.

(4) Lubricate shaft of manual lever and lip of shaft

seal with petroleum jelly.

(5) Raise valve body and align park rod with case

opening and park sprag. Then push rod end through

opening and past sprag. Rotate propeller shaft if nec-

essary.

(6) Position accumulator spring on transfer plate.

Fig. 10 Oil Filter Screw Locations

Fig. 11 Accumulator Piston And Spring

Fig. 12 Valve Body Assembly

21 - 104 30RH/32RH IN-VEHICLE SERVICEJ