lock JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1521 of 2198

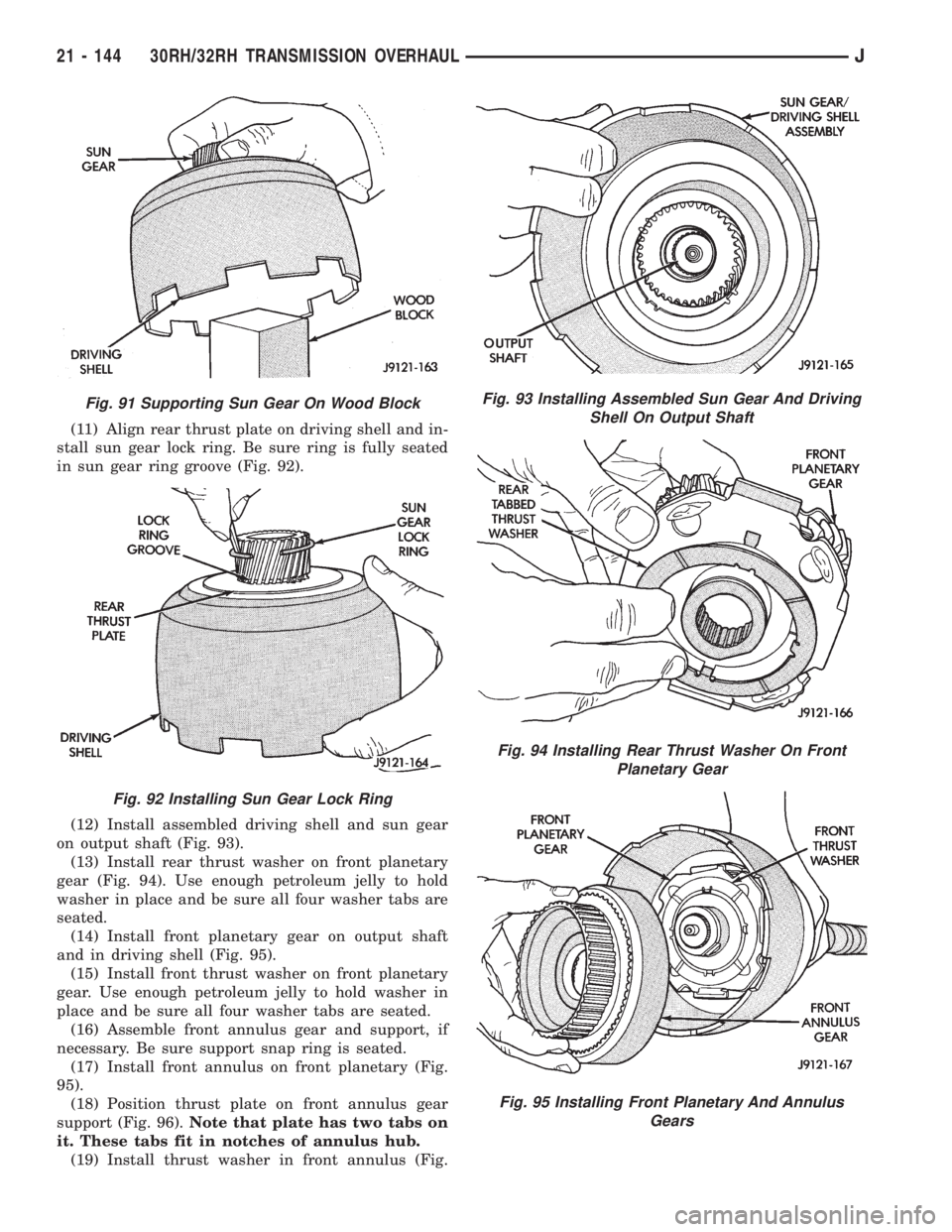

(11) Align rear thrust plate on driving shell and in-

stall sun gear lock ring. Be sure ring is fully seated

in sun gear ring groove (Fig. 92).

(12) Install assembled driving shell and sun gear

on output shaft (Fig. 93).

(13) Install rear thrust washer on front planetary

gear (Fig. 94). Use enough petroleum jelly to hold

washer in place and be sure all four washer tabs are

seated.

(14) Install front planetary gear on output shaft

and in driving shell (Fig. 95).

(15) Install front thrust washer on front planetary

gear. Use enough petroleum jelly to hold washer in

place and be sure all four washer tabs are seated.

(16) Assemble front annulus gear and support, if

necessary. Be sure support snap ring is seated.

(17) Install front annulus on front planetary (Fig.

95).

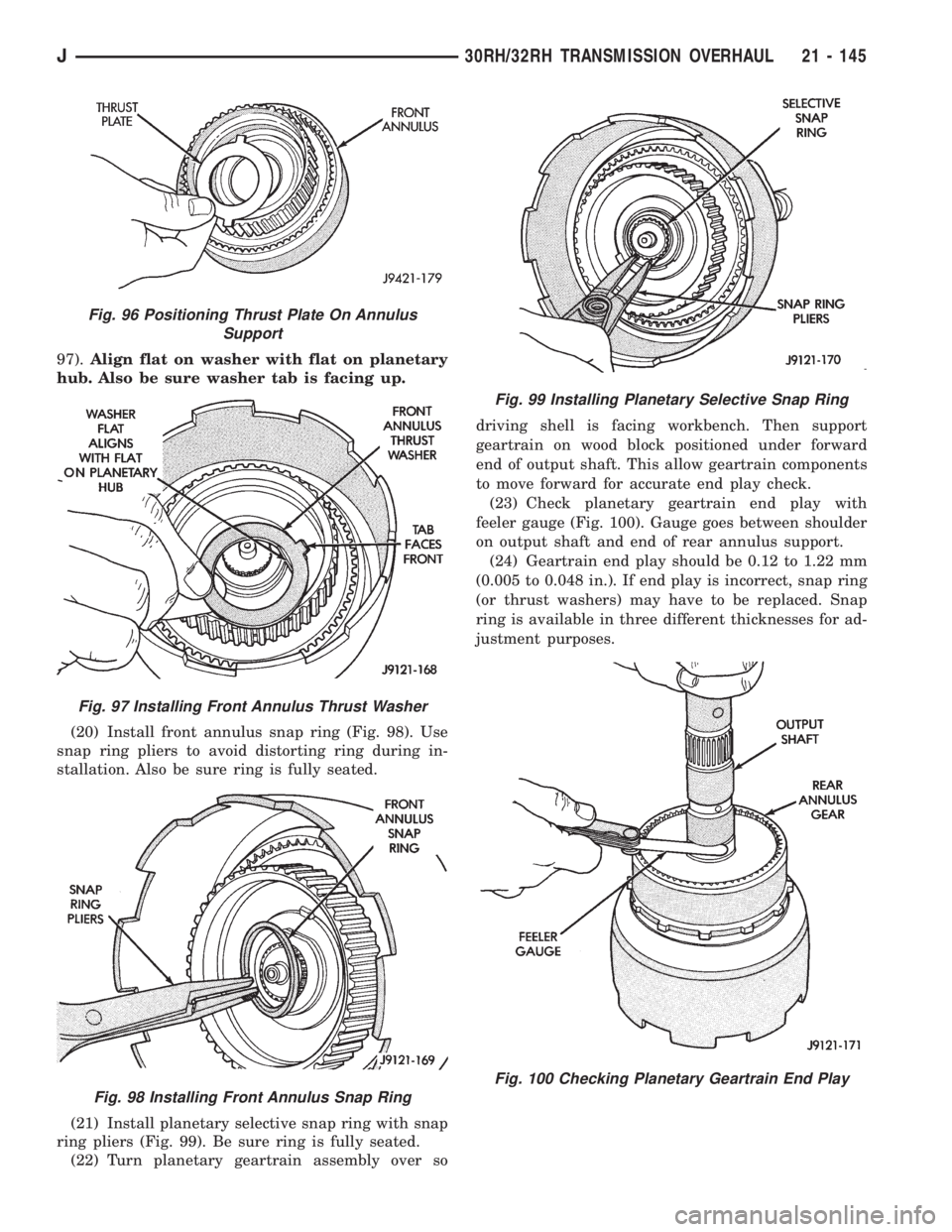

(18) Position thrust plate on front annulus gear

support (Fig. 96).Note that plate has two tabs on

it. These tabs fit in notches of annulus hub.

(19) Install thrust washer in front annulus (Fig.

Fig. 91 Supporting Sun Gear On Wood Block

Fig. 92 Installing Sun Gear Lock Ring

Fig. 93 Installing Assembled Sun Gear And Driving

Shell On Output Shaft

Fig. 94 Installing Rear Thrust Washer On Front

Planetary Gear

Fig. 95 Installing Front Planetary And Annulus

Gears

21 - 144 30RH/32RH TRANSMISSION OVERHAULJ

Page 1522 of 2198

97).Align flat on washer with flat on planetary

hub. Also be sure washer tab is facing up.

(20) Install front annulus snap ring (Fig. 98). Use

snap ring pliers to avoid distorting ring during in-

stallation. Also be sure ring is fully seated.

(21) Install planetary selective snap ring with snap

ring pliers (Fig. 99). Be sure ring is fully seated.

(22) Turn planetary geartrain assembly over sodriving shell is facing workbench. Then support

geartrain on wood block positioned under forward

end of output shaft. This allow geartrain components

to move forward for accurate end play check.

(23) Check planetary geartrain end play with

feeler gauge (Fig. 100). Gauge goes between shoulder

on output shaft and end of rear annulus support.

(24) Geartrain end play should be 0.12 to 1.22 mm

(0.005 to 0.048 in.). If end play is incorrect, snap ring

(or thrust washers) may have to be replaced. Snap

ring is available in three different thicknesses for ad-

justment purposes.

Fig. 96 Positioning Thrust Plate On Annulus

Support

Fig. 97 Installing Front Annulus Thrust Washer

Fig. 98 Installing Front Annulus Snap Ring

Fig. 99 Installing Planetary Selective Snap Ring

Fig. 100 Checking Planetary Geartrain End Play

J30RH/32RH TRANSMISSION OVERHAUL 21 - 145

Page 1523 of 2198

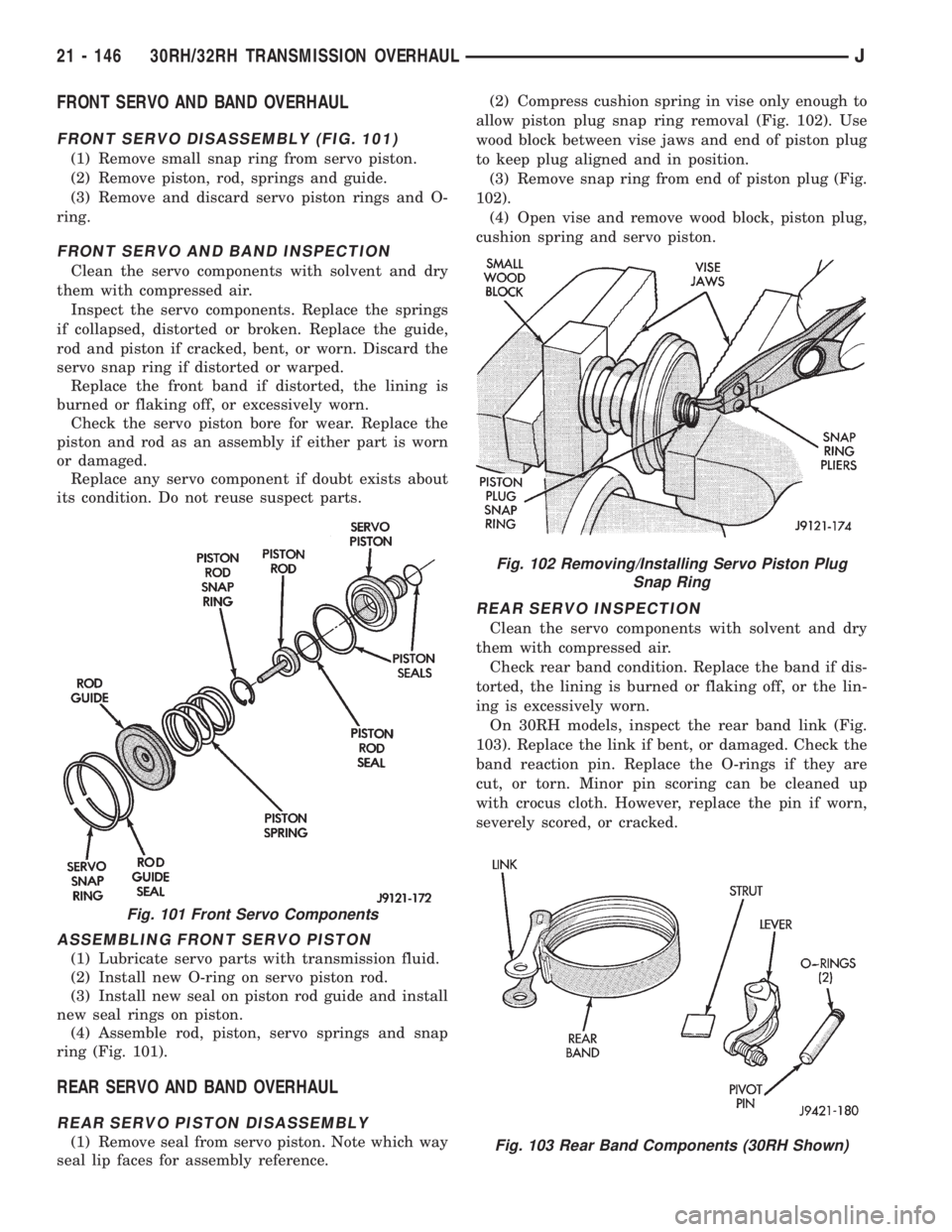

FRONT SERVO AND BAND OVERHAUL

FRONT SERVO DISASSEMBLY (FIG. 101)

(1) Remove small snap ring from servo piston.

(2) Remove piston, rod, springs and guide.

(3) Remove and discard servo piston rings and O-

ring.

FRONT SERVO AND BAND INSPECTION

Clean the servo components with solvent and dry

them with compressed air.

Inspect the servo components. Replace the springs

if collapsed, distorted or broken. Replace the guide,

rod and piston if cracked, bent, or worn. Discard the

servo snap ring if distorted or warped.

Replace the front band if distorted, the lining is

burned or flaking off, or excessively worn.

Check the servo piston bore for wear. Replace the

piston and rod as an assembly if either part is worn

or damaged.

Replace any servo component if doubt exists about

its condition. Do not reuse suspect parts.

ASSEMBLING FRONT SERVO PISTON

(1) Lubricate servo parts with transmission fluid.

(2) Install new O-ring on servo piston rod.

(3) Install new seal on piston rod guide and install

new seal rings on piston.

(4) Assemble rod, piston, servo springs and snap

ring (Fig. 101).

REAR SERVO AND BAND OVERHAUL

REAR SERVO PISTON DISASSEMBLY

(1) Remove seal from servo piston. Note which way

seal lip faces for assembly reference.(2) Compress cushion spring in vise only enough to

allow piston plug snap ring removal (Fig. 102). Use

wood block between vise jaws and end of piston plug

to keep plug aligned and in position.

(3) Remove snap ring from end of piston plug (Fig.

102).

(4) Open vise and remove wood block, piston plug,

cushion spring and servo piston.

REAR SERVO INSPECTION

Clean the servo components with solvent and dry

them with compressed air.

Check rear band condition. Replace the band if dis-

torted, the lining is burned or flaking off, or the lin-

ing is excessively worn.

On 30RH models, inspect the rear band link (Fig.

103). Replace the link if bent, or damaged. Check the

band reaction pin. Replace the O-rings if they are

cut, or torn. Minor pin scoring can be cleaned up

with crocus cloth. However, replace the pin if worn,

severely scored, or cracked.

Fig. 101 Front Servo Components

Fig. 102 Removing/Installing Servo Piston Plug

Snap Ring

Fig. 103 Rear Band Components (30RH Shown)

21 - 146 30RH/32RH TRANSMISSION OVERHAULJ

Page 1526 of 2198

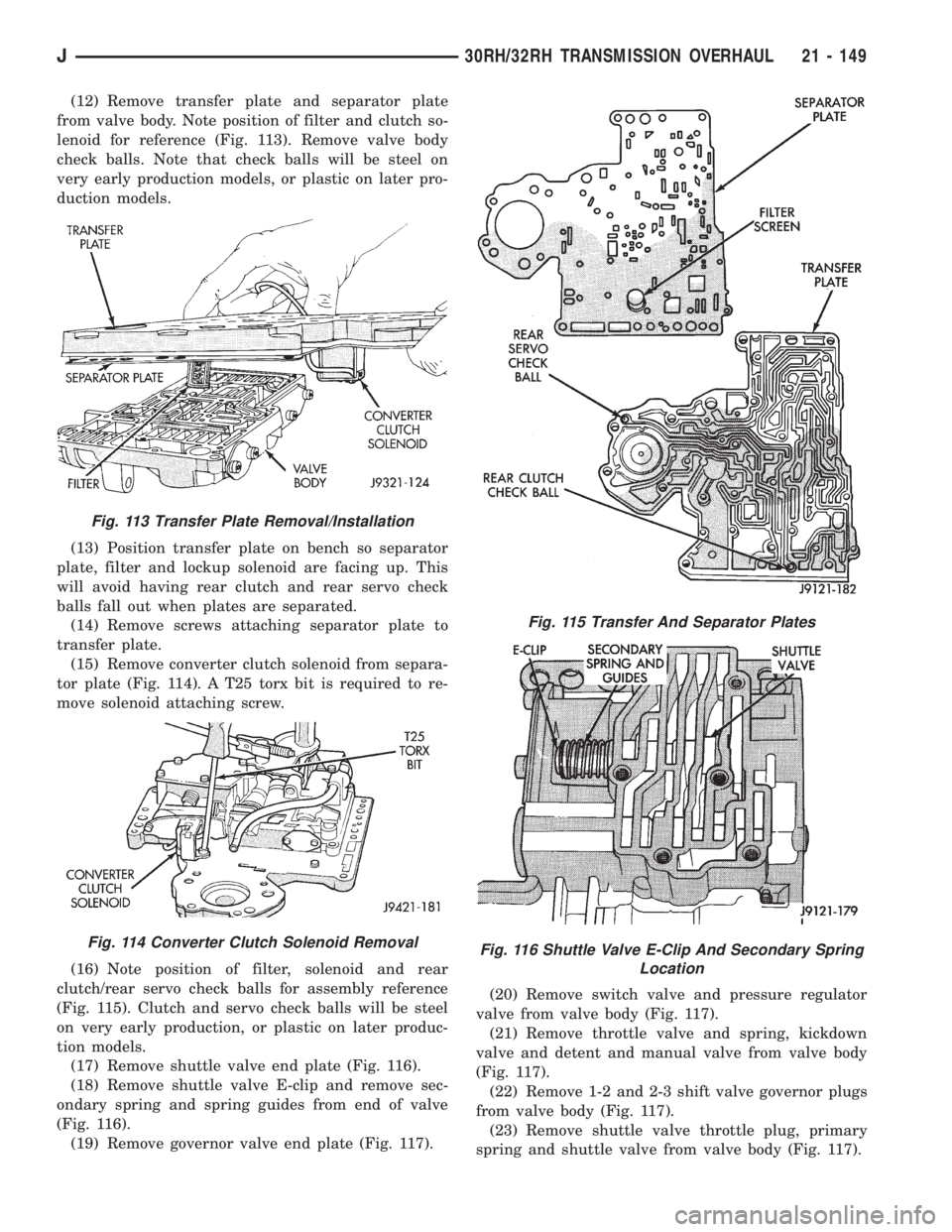

(12) Remove transfer plate and separator plate

from valve body. Note position of filter and clutch so-

lenoid for reference (Fig. 113). Remove valve body

check balls. Note that check balls will be steel on

very early production models, or plastic on later pro-

duction models.

(13) Position transfer plate on bench so separator

plate, filter and lockup solenoid are facing up. This

will avoid having rear clutch and rear servo check

balls fall out when plates are separated.

(14) Remove screws attaching separator plate to

transfer plate.

(15) Remove converter clutch solenoid from separa-

tor plate (Fig. 114). A T25 torx bit is required to re-

move solenoid attaching screw.

(16) Note position of filter, solenoid and rear

clutch/rear servo check balls for assembly reference

(Fig. 115). Clutch and servo check balls will be steel

on very early production, or plastic on later produc-

tion models.

(17) Remove shuttle valve end plate (Fig. 116).

(18) Remove shuttle valve E-clip and remove sec-

ondary spring and spring guides from end of valve

(Fig. 116).

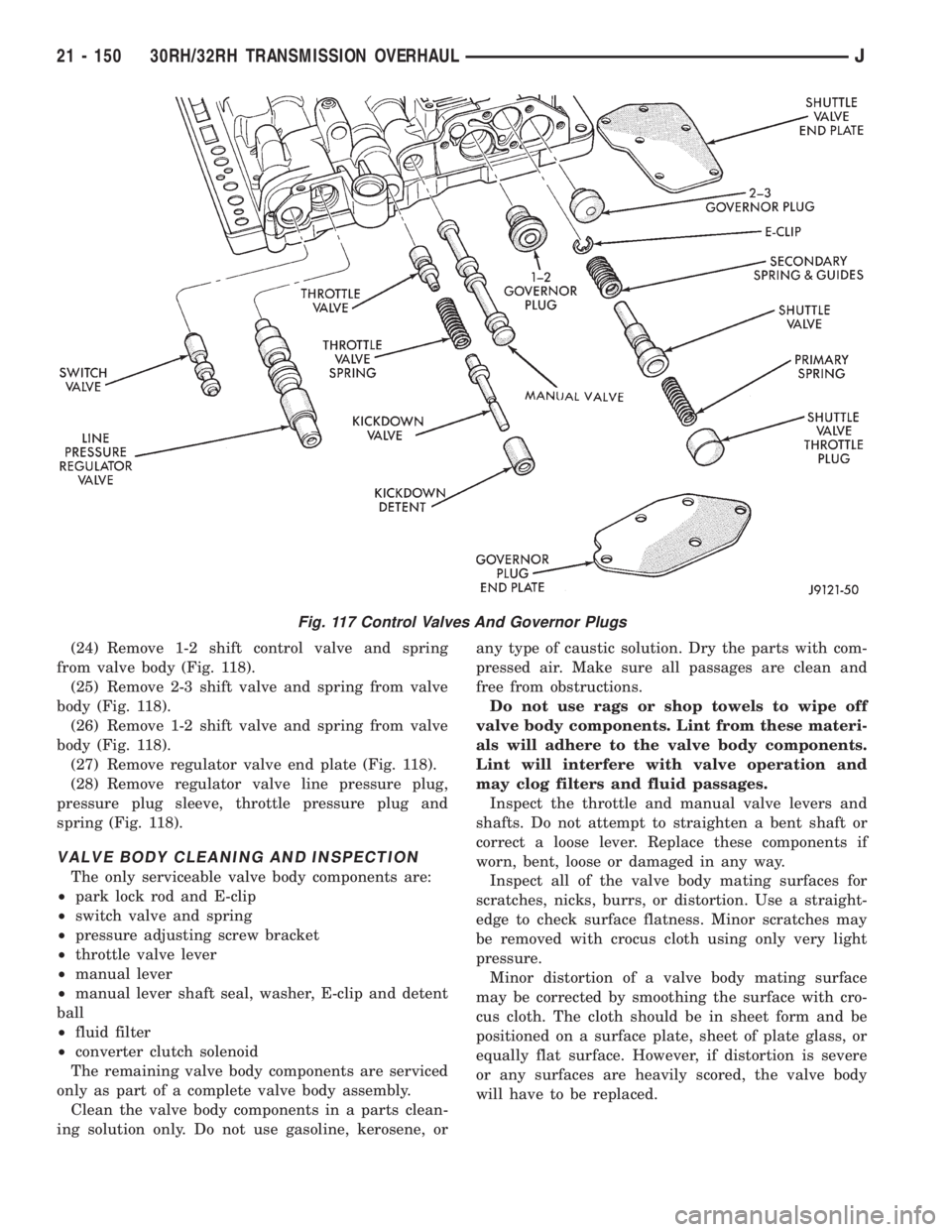

(19) Remove governor valve end plate (Fig. 117).(20) Remove switch valve and pressure regulator

valve from valve body (Fig. 117).

(21) Remove throttle valve and spring, kickdown

valve and detent and manual valve from valve body

(Fig. 117).

(22) Remove 1-2 and 2-3 shift valve governor plugs

from valve body (Fig. 117).

(23) Remove shuttle valve throttle plug, primary

spring and shuttle valve from valve body (Fig. 117).

Fig. 113 Transfer Plate Removal/Installation

Fig. 114 Converter Clutch Solenoid Removal

Fig. 115 Transfer And Separator Plates

Fig. 116 Shuttle Valve E-Clip And Secondary Spring

Location

J30RH/32RH TRANSMISSION OVERHAUL 21 - 149

Page 1527 of 2198

(24) Remove 1-2 shift control valve and spring

from valve body (Fig. 118).

(25) Remove 2-3 shift valve and spring from valve

body (Fig. 118).

(26) Remove 1-2 shift valve and spring from valve

body (Fig. 118).

(27) Remove regulator valve end plate (Fig. 118).

(28) Remove regulator valve line pressure plug,

pressure plug sleeve, throttle pressure plug and

spring (Fig. 118).

VALVE BODY CLEANING AND INSPECTION

The only serviceable valve body components are:

²park lock rod and E-clip

²switch valve and spring

²pressure adjusting screw bracket

²throttle valve lever

²manual lever

²manual lever shaft seal, washer, E-clip and detent

ball

²fluid filter

²converter clutch solenoid

The remaining valve body components are serviced

only as part of a complete valve body assembly.

Clean the valve body components in a parts clean-

ing solution only. Do not use gasoline, kerosene, orany type of caustic solution. Dry the parts with com-

pressed air. Make sure all passages are clean and

free from obstructions.

Do not use rags or shop towels to wipe off

valve body components. Lint from these materi-

als will adhere to the valve body components.

Lint will interfere with valve operation and

may clog filters and fluid passages.

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with cro-

cus cloth. The cloth should be in sheet form and be

positioned on a surface plate, sheet of plate glass, or

equally flat surface. However, if distortion is severe

or any surfaces are heavily scored, the valve body

will have to be replaced.

Fig. 117 Control Valves And Governor Plugs

21 - 150 30RH/32RH TRANSMISSION OVERHAULJ

Page 1530 of 2198

VALVE BODY ASSEMBLY AND ADJUSTMENT

CAUTION: Do not force valves or plugs into place

during reassembly. If the valve body bores, valves

and plugs are free of distortion or burrs, the valve

body components should all slide into place easily.

In addition, do not overtighten the transfer plate

and valve body screws during reassembly. Over-

tightening can distort the valve body resulting in

valve sticking, cross leakage and unsatisfactory op-

eration. Tighten valve body screws to recom-

mended torque only.

(1) Lubricate valve body bores, valves and plugs

with Mopar ATF Plus transmission fluid.

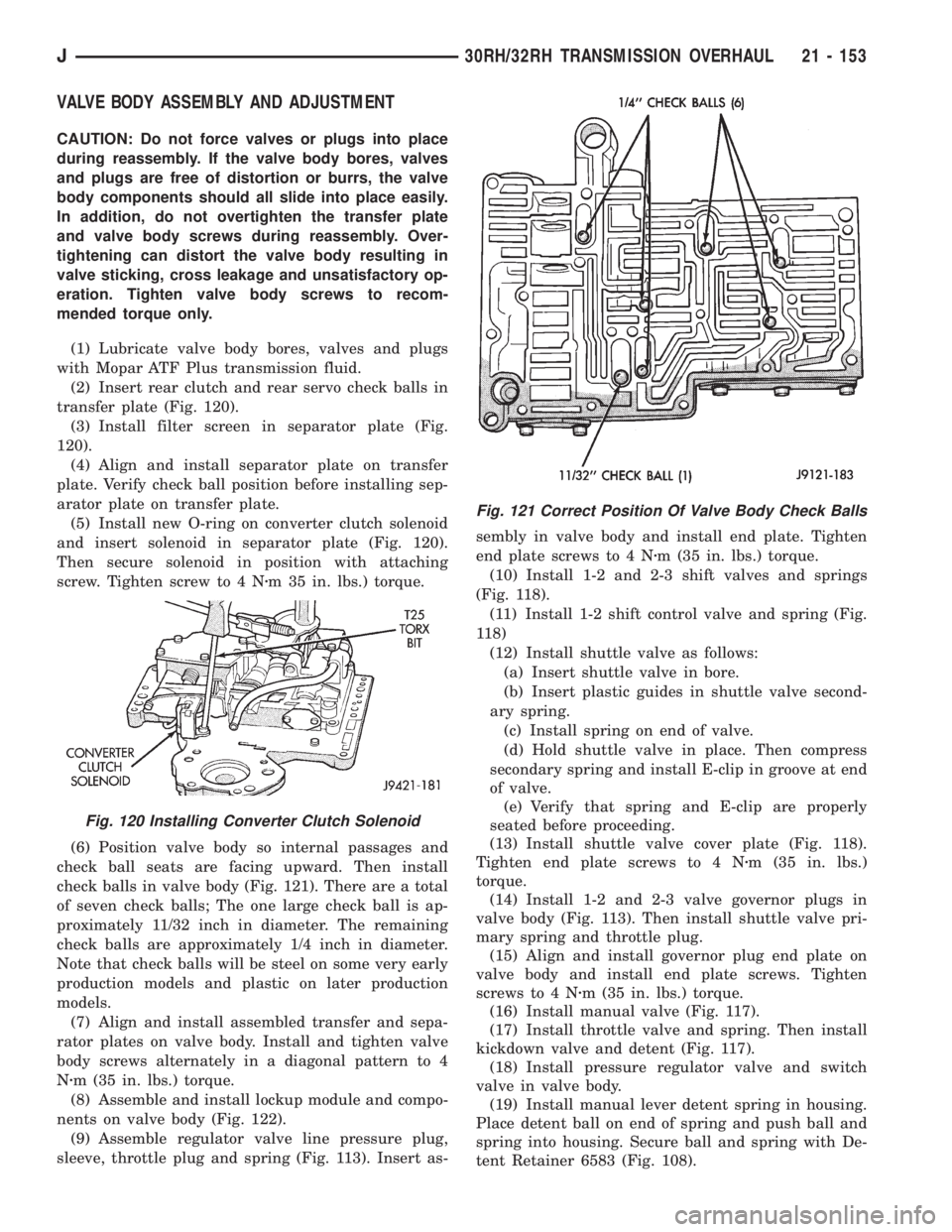

(2) Insert rear clutch and rear servo check balls in

transfer plate (Fig. 120).

(3) Install filter screen in separator plate (Fig.

120).

(4) Align and install separator plate on transfer

plate. Verify check ball position before installing sep-

arator plate on transfer plate.

(5) Install new O-ring on converter clutch solenoid

and insert solenoid in separator plate (Fig. 120).

Then secure solenoid in position with attaching

screw. Tighten screw to 4 Nzm 35 in. lbs.) torque.

(6) Position valve body so internal passages and

check ball seats are facing upward. Then install

check balls in valve body (Fig. 121). There are a total

of seven check balls; The one large check ball is ap-

proximately 11/32 inch in diameter. The remaining

check balls are approximately 1/4 inch in diameter.

Note that check balls will be steel on some very early

production models and plastic on later production

models.

(7) Align and install assembled transfer and sepa-

rator plates on valve body. Install and tighten valve

body screws alternately in a diagonal pattern to 4

Nzm (35 in. lbs.) torque.

(8) Assemble and install lockup module and compo-

nents on valve body (Fig. 122).

(9) Assemble regulator valve line pressure plug,

sleeve, throttle plug and spring (Fig. 113). Insert as-sembly in valve body and install end plate. Tighten

end plate screws to 4 Nzm (35 in. lbs.) torque.

(10) Install 1-2 and 2-3 shift valves and springs

(Fig. 118).

(11) Install 1-2 shift control valve and spring (Fig.

118)

(12) Install shuttle valve as follows:

(a) Insert shuttle valve in bore.

(b) Insert plastic guides in shuttle valve second-

ary spring.

(c) Install spring on end of valve.

(d) Hold shuttle valve in place. Then compress

secondary spring and install E-clip in groove at end

of valve.

(e) Verify that spring and E-clip are properly

seated before proceeding.

(13) Install shuttle valve cover plate (Fig. 118).

Tighten end plate screws to 4 Nzm (35 in. lbs.)

torque.

(14) Install 1-2 and 2-3 valve governor plugs in

valve body (Fig. 113). Then install shuttle valve pri-

mary spring and throttle plug.

(15) Align and install governor plug end plate on

valve body and install end plate screws. Tighten

screws to 4 Nzm (35 in. lbs.) torque.

(16) Install manual valve (Fig. 117).

(17) Install throttle valve and spring. Then install

kickdown valve and detent (Fig. 117).

(18) Install pressure regulator valve and switch

valve in valve body.

(19) Install manual lever detent spring in housing.

Place detent ball on end of spring and push ball and

spring into housing. Secure ball and spring with De-

tent Retainer 6583 (Fig. 108).

Fig. 120 Installing Converter Clutch Solenoid

Fig. 121 Correct Position Of Valve Body Check Balls

J30RH/32RH TRANSMISSION OVERHAUL 21 - 153

Page 1532 of 2198

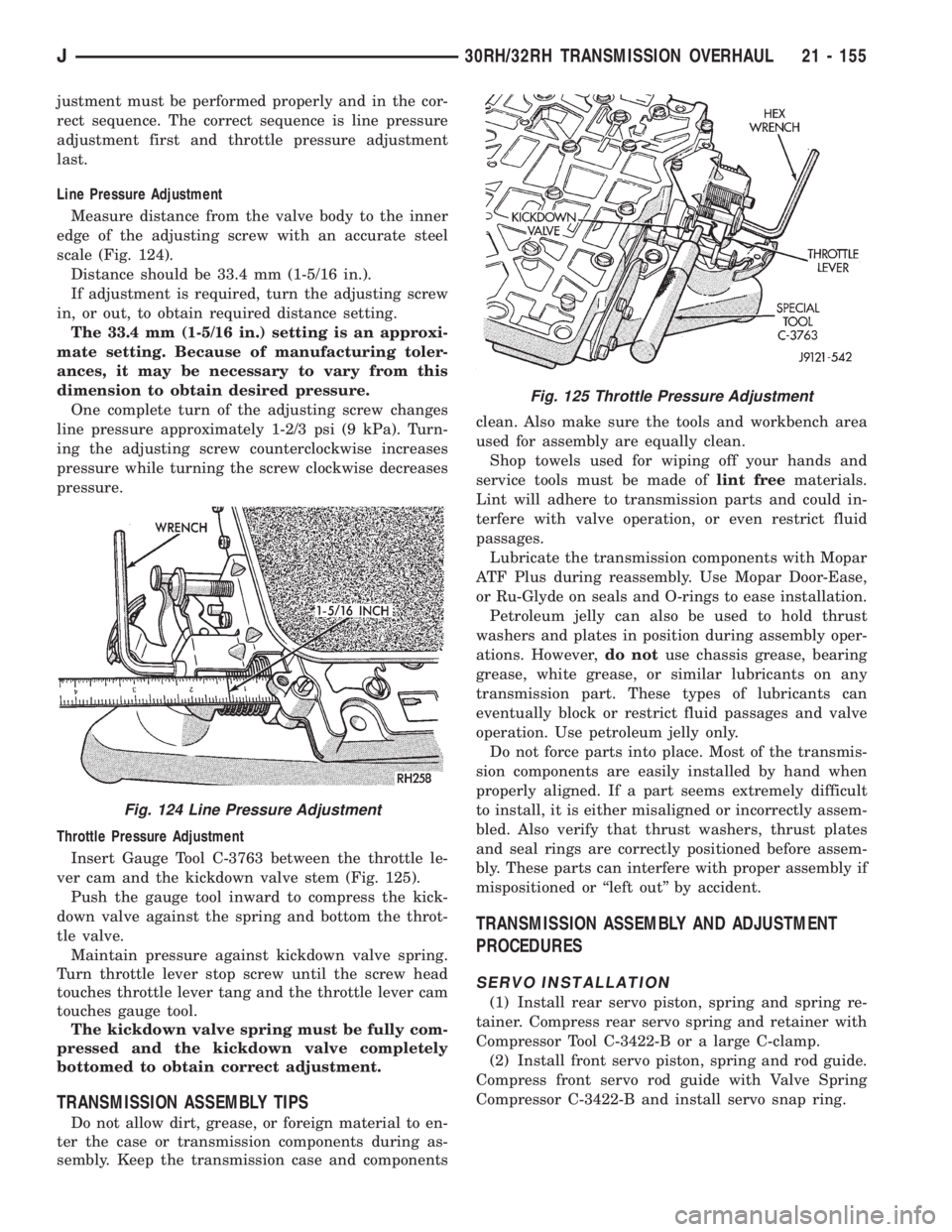

justment must be performed properly and in the cor-

rect sequence. The correct sequence is line pressure

adjustment first and throttle pressure adjustment

last.

Line Pressure Adjustment

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 124).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

The 33.4 mm (1-5/16 in.) setting is an approxi-

mate setting. Because of manufacturing toler-

ances, it may be necessary to vary from this

dimension to obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa). Turn-

ing the adjusting screw counterclockwise increases

pressure while turning the screw clockwise decreases

pressure.

Throttle Pressure Adjustment

Insert Gauge Tool C-3763 between the throttle le-

ver cam and the kickdown valve stem (Fig. 125).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

The kickdown valve spring must be fully com-

pressed and the kickdown valve completely

bottomed to obtain correct adjustment.

TRANSMISSION ASSEMBLY TIPS

Do not allow dirt, grease, or foreign material to en-

ter the case or transmission components during as-

sembly. Keep the transmission case and componentsclean. Also make sure the tools and workbench area

used for assembly are equally clean.

Shop towels used for wiping off your hands and

service tools must be made oflint freematerials.

Lint will adhere to transmission parts and could in-

terfere with valve operation, or even restrict fluid

passages.

Lubricate the transmission components with Mopar

ATF Plus during reassembly. Use Mopar Door-Ease,

or Ru-Glyde on seals and O-rings to ease installation.

Petroleum jelly can also be used to hold thrust

washers and plates in position during assembly oper-

ations. However,do notuse chassis grease, bearing

grease, white grease, or similar lubricants on any

transmission part. These types of lubricants can

eventually block or restrict fluid passages and valve

operation. Use petroleum jelly only.

Do not force parts into place. Most of the transmis-

sion components are easily installed by hand when

properly aligned. If a part seems extremely difficult

to install, it is either misaligned or incorrectly assem-

bled. Also verify that thrust washers, thrust plates

and seal rings are correctly positioned before assem-

bly. These parts can interfere with proper assembly if

mispositioned or ``left out'' by accident.

TRANSMISSION ASSEMBLY AND ADJUSTMENT

PROCEDURES

SERVO INSTALLATION

(1) Install rear servo piston, spring and spring re-

tainer. Compress rear servo spring and retainer with

Compressor Tool C-3422-B or a large C-clamp.

(2) Install front servo piston, spring and rod guide.

Compress front servo rod guide with Valve Spring

Compressor C-3422-B and install servo snap ring.

Fig. 124 Line Pressure Adjustment

Fig. 125 Throttle Pressure Adjustment

J30RH/32RH TRANSMISSION OVERHAUL 21 - 155

Page 1534 of 2198

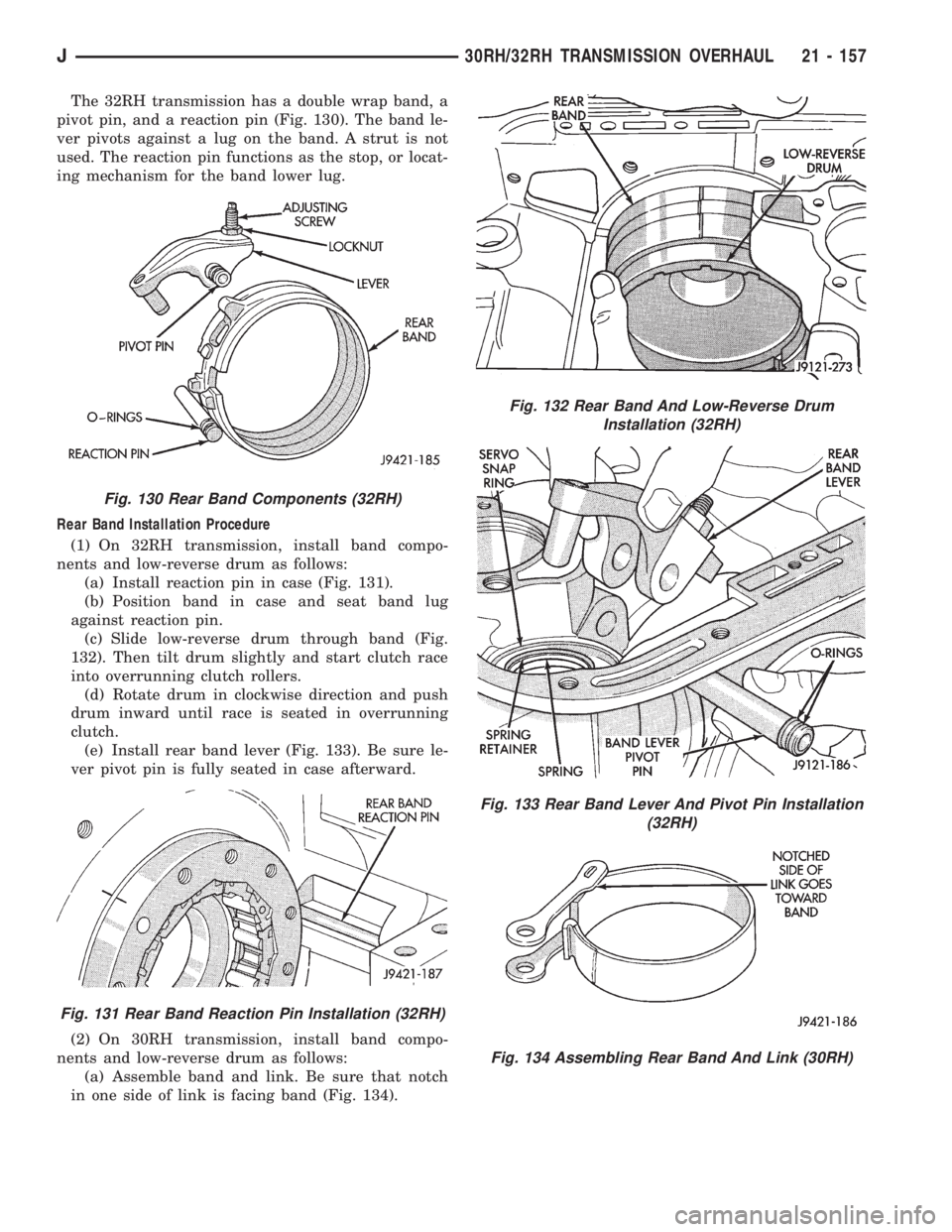

The 32RH transmission has a double wrap band, a

pivot pin, and a reaction pin (Fig. 130). The band le-

ver pivots against a lug on the band. A strut is not

used. The reaction pin functions as the stop, or locat-

ing mechanism for the band lower lug.

Rear Band Installation Procedure

(1) On 32RH transmission, install band compo-

nents and low-reverse drum as follows:

(a) Install reaction pin in case (Fig. 131).

(b) Position band in case and seat band lug

against reaction pin.

(c) Slide low-reverse drum through band (Fig.

132). Then tilt drum slightly and start clutch race

into overrunning clutch rollers.

(d) Rotate drum in clockwise direction and push

drum inward until race is seated in overrunning

clutch.

(e) Install rear band lever (Fig. 133). Be sure le-

ver pivot pin is fully seated in case afterward.

(2) On 30RH transmission, install band compo-

nents and low-reverse drum as follows:

(a) Assemble band and link. Be sure that notch

in one side of link is facing band (Fig. 134).

Fig. 130 Rear Band Components (32RH)

Fig. 131 Rear Band Reaction Pin Installation (32RH)

Fig. 132 Rear Band And Low-Reverse Drum

Installation (32RH)

Fig. 133 Rear Band Lever And Pivot Pin Installation

(32RH)

Fig. 134 Assembling Rear Band And Link (30RH)

J30RH/32RH TRANSMISSION OVERHAUL 21 - 157

Page 1535 of 2198

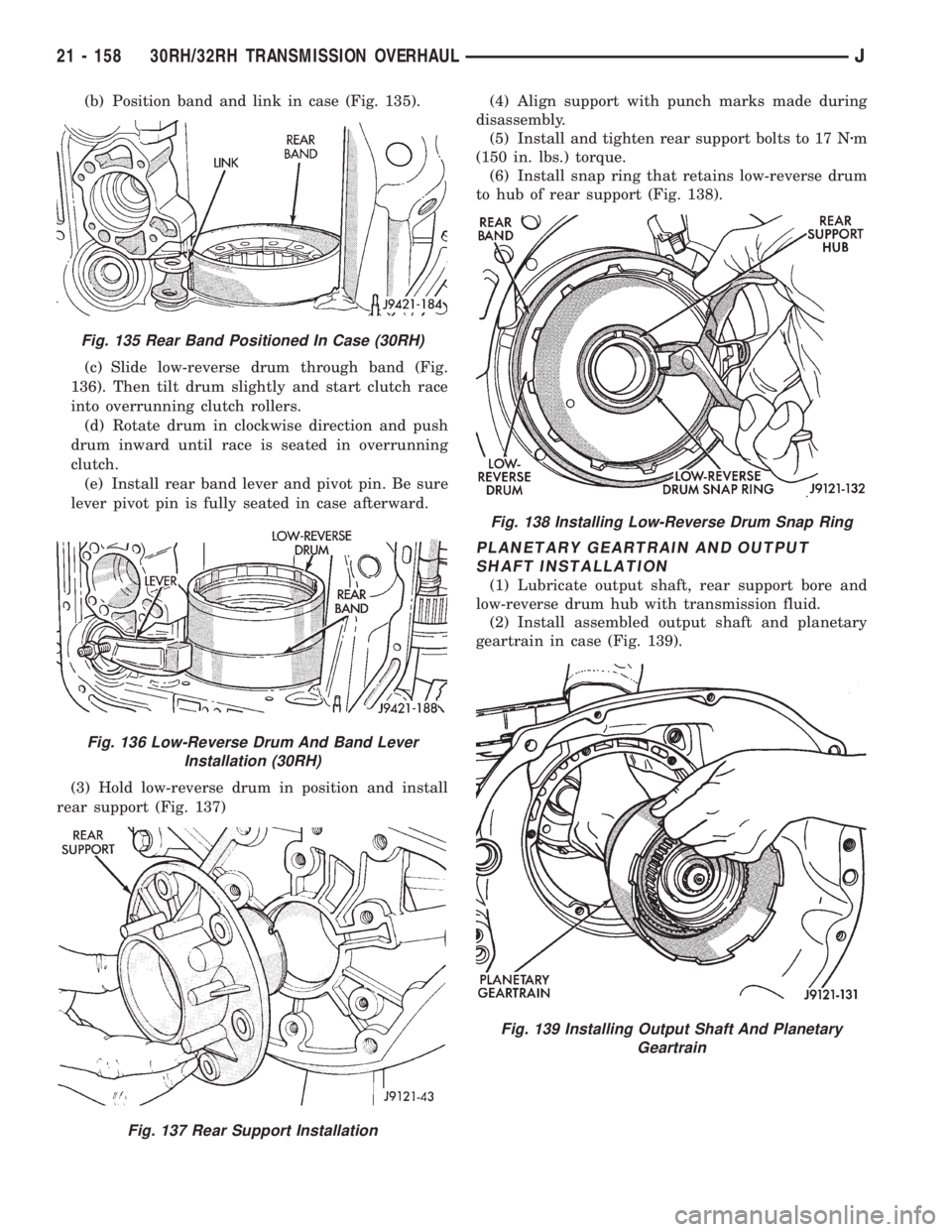

(b) Position band and link in case (Fig. 135).

(c) Slide low-reverse drum through band (Fig.

136). Then tilt drum slightly and start clutch race

into overrunning clutch rollers.

(d) Rotate drum in clockwise direction and push

drum inward until race is seated in overrunning

clutch.

(e) Install rear band lever and pivot pin. Be sure

lever pivot pin is fully seated in case afterward.

(3) Hold low-reverse drum in position and install

rear support (Fig. 137)(4) Align support with punch marks made during

disassembly.

(5) Install and tighten rear support bolts to 17 Nzm

(150 in. lbs.) torque.

(6) Install snap ring that retains low-reverse drum

to hub of rear support (Fig. 138).

PLANETARY GEARTRAIN AND OUTPUT

SHAFT INSTALLATION

(1) Lubricate output shaft, rear support bore and

low-reverse drum hub with transmission fluid.

(2) Install assembled output shaft and planetary

geartrain in case (Fig. 139).

Fig. 135 Rear Band Positioned In Case (30RH)

Fig. 136 Low-Reverse Drum And Band Lever

Installation (30RH)

Fig. 137 Rear Support Installation

Fig. 138 Installing Low-Reverse Drum Snap Ring

Fig. 139 Installing Output Shaft And Planetary

Geartrain

21 - 158 30RH/32RH TRANSMISSION OVERHAULJ

Page 1538 of 2198

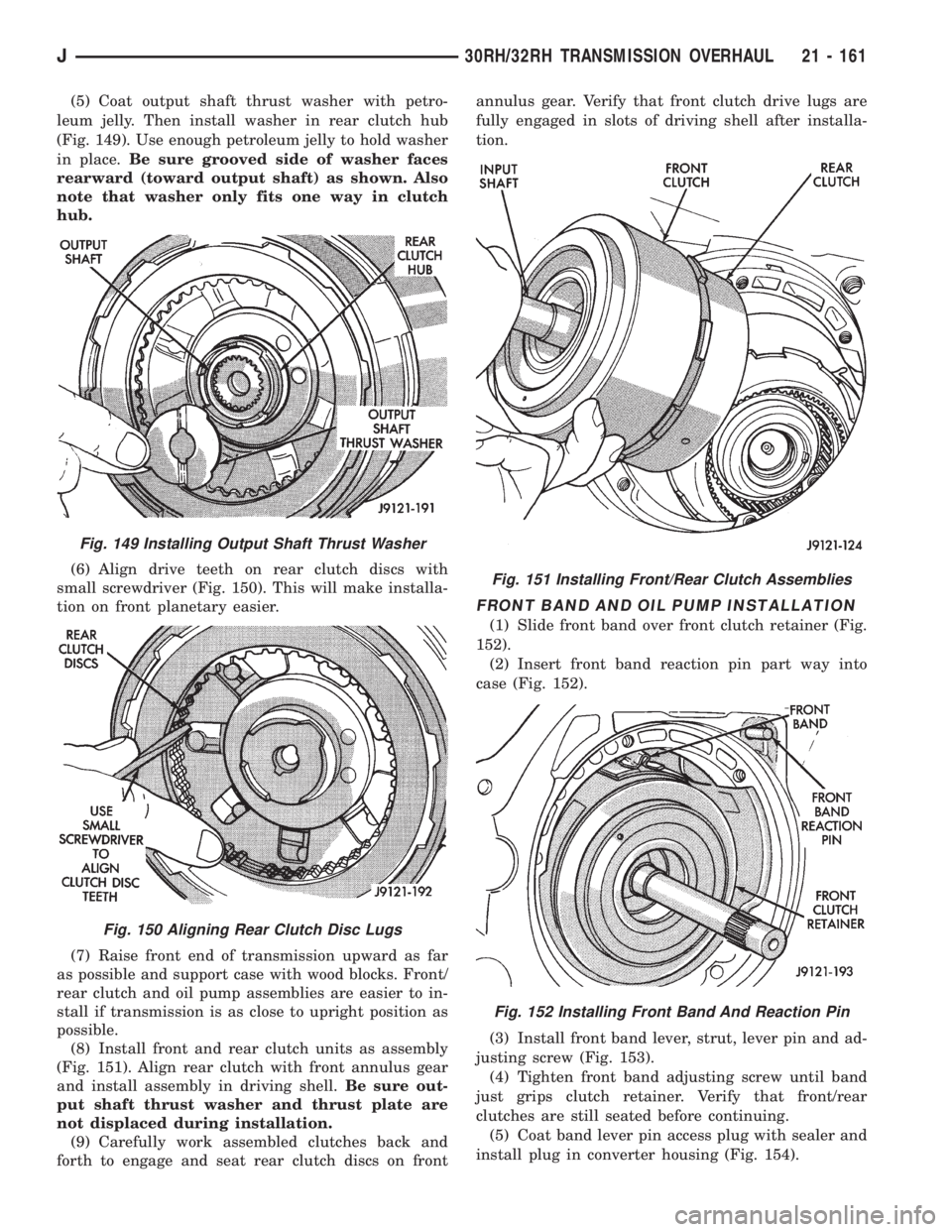

(5) Coat output shaft thrust washer with petro-

leum jelly. Then install washer in rear clutch hub

(Fig. 149). Use enough petroleum jelly to hold washer

in place.Be sure grooved side of washer faces

rearward (toward output shaft) as shown. Also

note that washer only fits one way in clutch

hub.

(6) Align drive teeth on rear clutch discs with

small screwdriver (Fig. 150). This will make installa-

tion on front planetary easier.

(7) Raise front end of transmission upward as far

as possible and support case with wood blocks. Front/

rear clutch and oil pump assemblies are easier to in-

stall if transmission is as close to upright position as

possible.

(8) Install front and rear clutch units as assembly

(Fig. 151). Align rear clutch with front annulus gear

and install assembly in driving shell.Be sure out-

put shaft thrust washer and thrust plate are

not displaced during installation.

(9) Carefully work assembled clutches back and

forth to engage and seat rear clutch discs on frontannulus gear. Verify that front clutch drive lugs are

fully engaged in slots of driving shell after installa-

tion.

FRONT BAND AND OIL PUMP INSTALLATION

(1) Slide front band over front clutch retainer (Fig.

152).

(2) Insert front band reaction pin part way into

case (Fig. 152).

(3) Install front band lever, strut, lever pin and ad-

justing screw (Fig. 153).

(4) Tighten front band adjusting screw until band

just grips clutch retainer. Verify that front/rear

clutches are still seated before continuing.

(5) Coat band lever pin access plug with sealer and

install plug in converter housing (Fig. 154).

Fig. 149 Installing Output Shaft Thrust Washer

Fig. 150 Aligning Rear Clutch Disc Lugs

Fig. 151 Installing Front/Rear Clutch Assemblies

Fig. 152 Installing Front Band And Reaction Pin

J30RH/32RH TRANSMISSION OVERHAUL 21 - 161