ECU JEEP CHEROKEE 1995 Service Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 184 of 2198

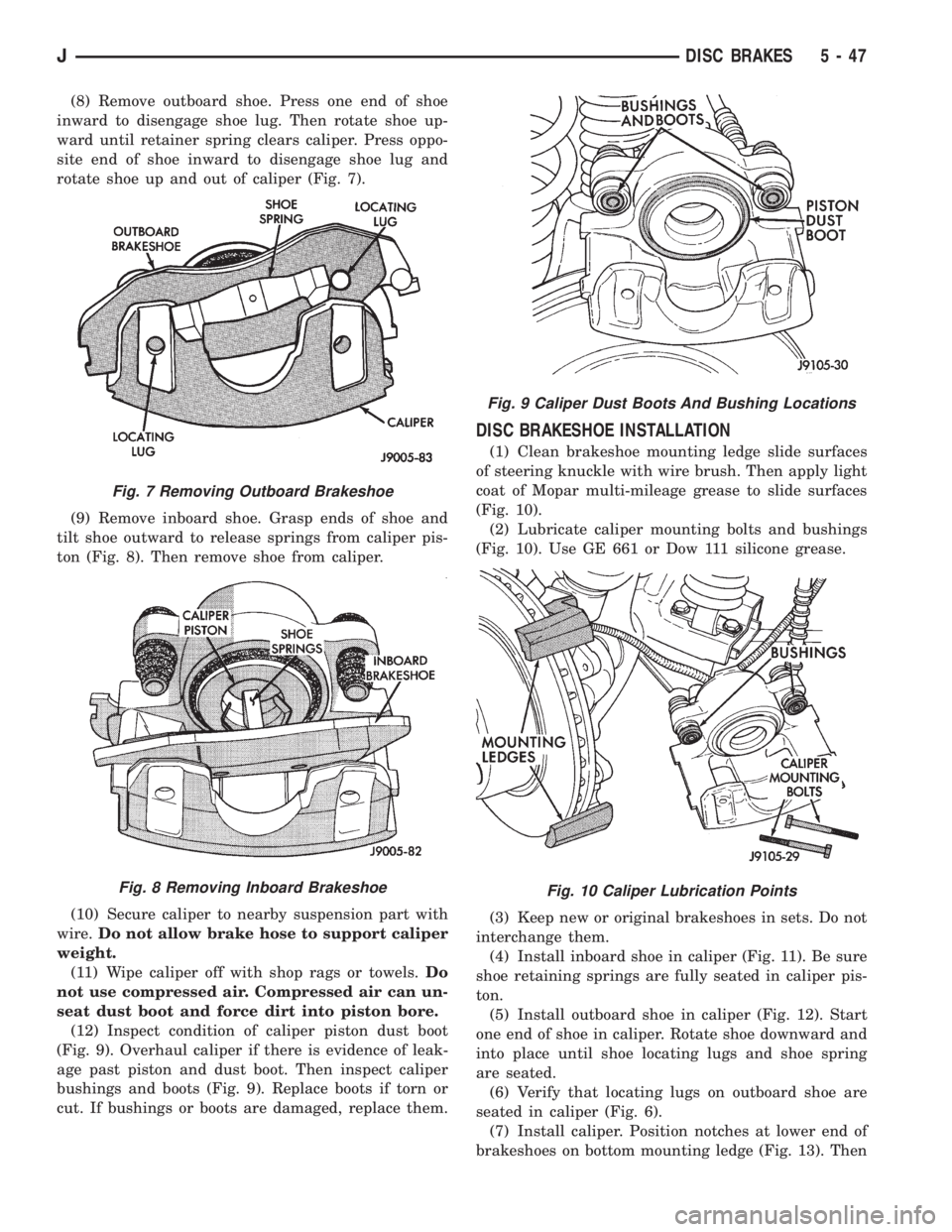

(8) Remove outboard shoe. Press one end of shoe

inward to disengage shoe lug. Then rotate shoe up-

ward until retainer spring clears caliper. Press oppo-

site end of shoe inward to disengage shoe lug and

rotate shoe up and out of caliper (Fig. 7).

(9) Remove inboard shoe. Grasp ends of shoe and

tilt shoe outward to release springs from caliper pis-

ton (Fig. 8). Then remove shoe from caliper.

(10) Secure caliper to nearby suspension part with

wire.Do not allow brake hose to support caliper

weight.

(11) Wipe caliper off with shop rags or towels.Do

not use compressed air. Compressed air can un-

seat dust boot and force dirt into piston bore.

(12) Inspect condition of caliper piston dust boot

(Fig. 9). Overhaul caliper if there is evidence of leak-

age past piston and dust boot. Then inspect caliper

bushings and boots (Fig. 9). Replace boots if torn or

cut. If bushings or boots are damaged, replace them.

DISC BRAKESHOE INSTALLATION

(1) Clean brakeshoe mounting ledge slide surfaces

of steering knuckle with wire brush. Then apply light

coat of Mopar multi-mileage grease to slide surfaces

(Fig. 10).

(2) Lubricate caliper mounting bolts and bushings

(Fig. 10). Use GE 661 or Dow 111 silicone grease.

(3) Keep new or original brakeshoes in sets. Do not

interchange them.

(4) Install inboard shoe in caliper (Fig. 11). Be sure

shoe retaining springs are fully seated in caliper pis-

ton.

(5) Install outboard shoe in caliper (Fig. 12). Start

one end of shoe in caliper. Rotate shoe downward and

into place until shoe locating lugs and shoe spring

are seated.

(6) Verify that locating lugs on outboard shoe are

seated in caliper (Fig. 6).

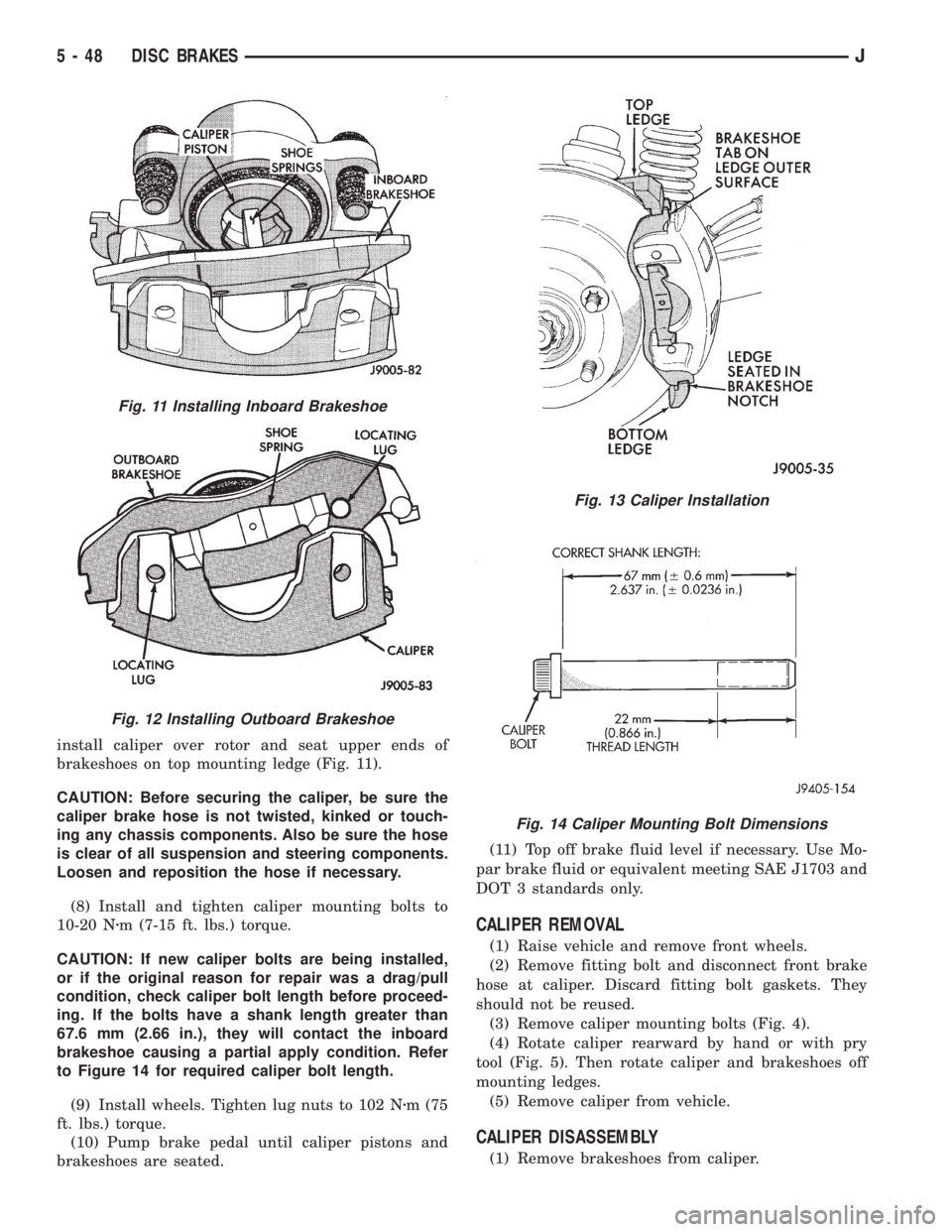

(7) Install caliper. Position notches at lower end of

brakeshoes on bottom mounting ledge (Fig. 13). Then

Fig. 7 Removing Outboard Brakeshoe

Fig. 8 Removing Inboard Brakeshoe

Fig. 9 Caliper Dust Boots And Bushing Locations

Fig. 10 Caliper Lubrication Points

JDISC BRAKES 5 - 47

Page 185 of 2198

install caliper over rotor and seat upper ends of

brakeshoes on top mounting ledge (Fig. 11).

CAUTION: Before securing the caliper, be sure the

caliper brake hose is not twisted, kinked or touch-

ing any chassis components. Also be sure the hose

is clear of all suspension and steering components.

Loosen and reposition the hose if necessary.

(8) Install and tighten caliper mounting bolts to

10-20 Nzm (7-15 ft. lbs.) torque.

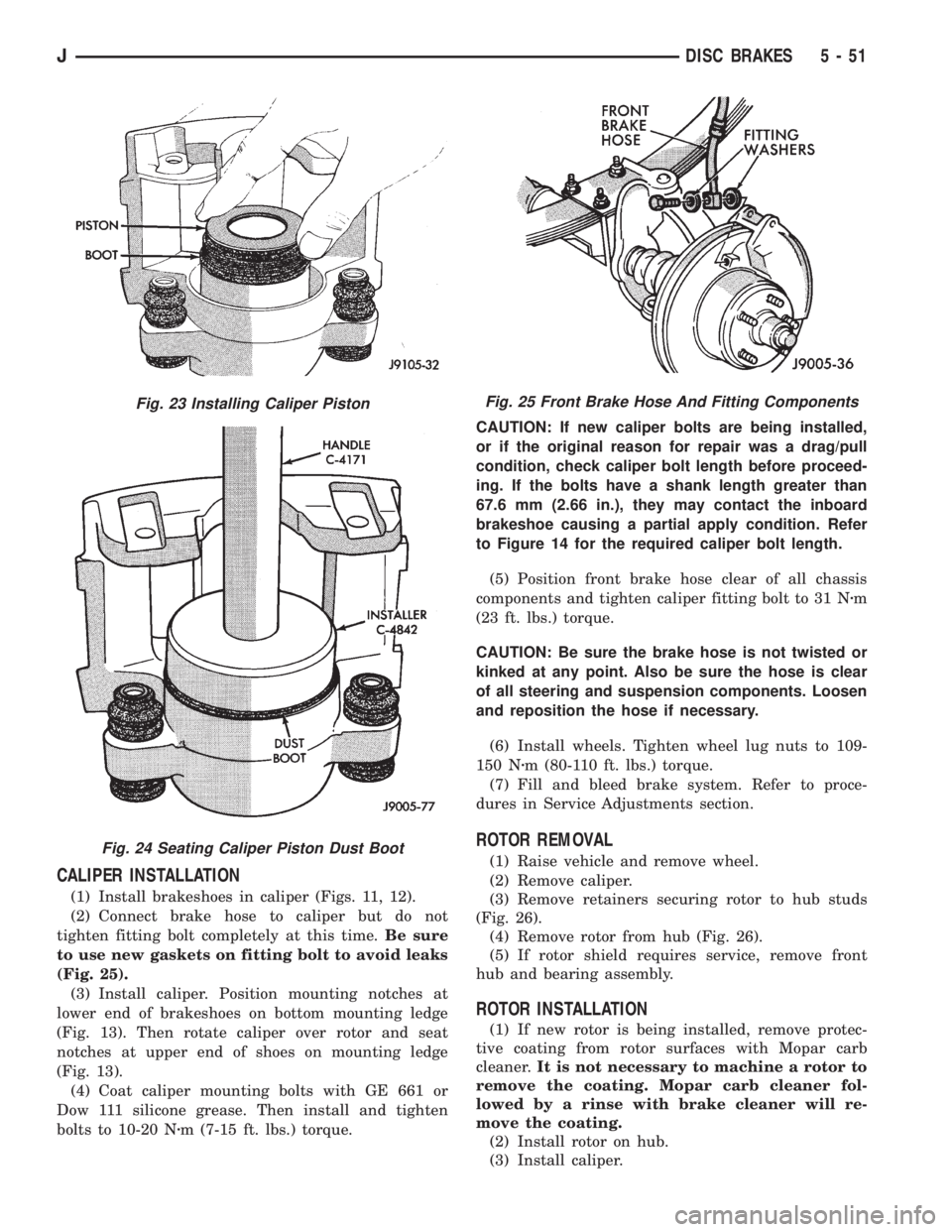

CAUTION: If new caliper bolts are being installed,

or if the original reason for repair was a drag/pull

condition, check caliper bolt length before proceed-

ing. If the bolts have a shank length greater than

67.6 mm (2.66 in.), they will contact the inboard

brakeshoe causing a partial apply condition. Refer

to Figure 14 for required caliper bolt length.

(9) Install wheels. Tighten lug nuts to 102 Nzm (75

ft. lbs.) torque.

(10) Pump brake pedal until caliper pistons and

brakeshoes are seated.(11) Top off brake fluid level if necessary. Use Mo-

par brake fluid or equivalent meeting SAE J1703 and

DOT 3 standards only.

CALIPER REMOVAL

(1) Raise vehicle and remove front wheels.

(2) Remove fitting bolt and disconnect front brake

hose at caliper. Discard fitting bolt gaskets. They

should not be reused.

(3) Remove caliper mounting bolts (Fig. 4).

(4) Rotate caliper rearward by hand or with pry

tool (Fig. 5). Then rotate caliper and brakeshoes off

mounting ledges.

(5) Remove caliper from vehicle.

CALIPER DISASSEMBLY

(1) Remove brakeshoes from caliper.

Fig. 11 Installing Inboard Brakeshoe

Fig. 12 Installing Outboard Brakeshoe

Fig. 13 Caliper Installation

Fig. 14 Caliper Mounting Bolt Dimensions

5 - 48 DISC BRAKESJ

Page 188 of 2198

CALIPER INSTALLATION

(1) Install brakeshoes in caliper (Figs. 11, 12).

(2) Connect brake hose to caliper but do not

tighten fitting bolt completely at this time.Be sure

to use new gaskets on fitting bolt to avoid leaks

(Fig. 25).

(3) Install caliper. Position mounting notches at

lower end of brakeshoes on bottom mounting ledge

(Fig. 13). Then rotate caliper over rotor and seat

notches at upper end of shoes on mounting ledge

(Fig. 13).

(4) Coat caliper mounting bolts with GE 661 or

Dow 111 silicone grease. Then install and tighten

bolts to 10-20 Nzm (7-15 ft. lbs.) torque.CAUTION: If new caliper bolts are being installed,

or if the original reason for repair was a drag/pull

condition, check caliper bolt length before proceed-

ing. If the bolts have a shank length greater than

67.6 mm (2.66 in.), they may contact the inboard

brakeshoe causing a partial apply condition. Refer

to Figure 14 for the required caliper bolt length.

(5) Position front brake hose clear of all chassis

components and tighten caliper fitting bolt to 31 Nzm

(23 ft. lbs.) torque.

CAUTION: Be sure the brake hose is not twisted or

kinked at any point. Also be sure the hose is clear

of all steering and suspension components. Loosen

and reposition the hose if necessary.

(6) Install wheels. Tighten wheel lug nuts to 109-

150 Nzm (80-110 ft. lbs.) torque.

(7) Fill and bleed brake system. Refer to proce-

dures in Service Adjustments section.

ROTOR REMOVAL

(1) Raise vehicle and remove wheel.

(2) Remove caliper.

(3) Remove retainers securing rotor to hub studs

(Fig. 26).

(4) Remove rotor from hub (Fig. 26).

(5) If rotor shield requires service, remove front

hub and bearing assembly.

ROTOR INSTALLATION

(1) If new rotor is being installed, remove protec-

tive coating from rotor surfaces with Mopar carb

cleaner.It is not necessary to machine a rotor to

remove the coating. Mopar carb cleaner fol-

lowed by a rinse with brake cleaner will re-

move the coating.

(2) Install rotor on hub.

(3) Install caliper.

Fig. 23 Installing Caliper Piston

Fig. 24 Seating Caliper Piston Dust Boot

Fig. 25 Front Brake Hose And Fitting Components

JDISC BRAKES 5 - 51

Page 189 of 2198

(4) Install new spring nuts on wheel studs.

(5) Install wheel and lower vehicle.

DISC BRAKE ROTOR THICKNESS

Rotor minimum usable thickness is 22.7 mm (0.89

in.). This dimension is either cast, or stamped on the

rotor hub, or outer edge.

Measure rotor thickness at the center of the brake-

shoe contact surface.

Replace the rotor if worn below minimum thick-

ness. Also replace the rotor if refinishing would re-

duce thickness below the allowable minimum.

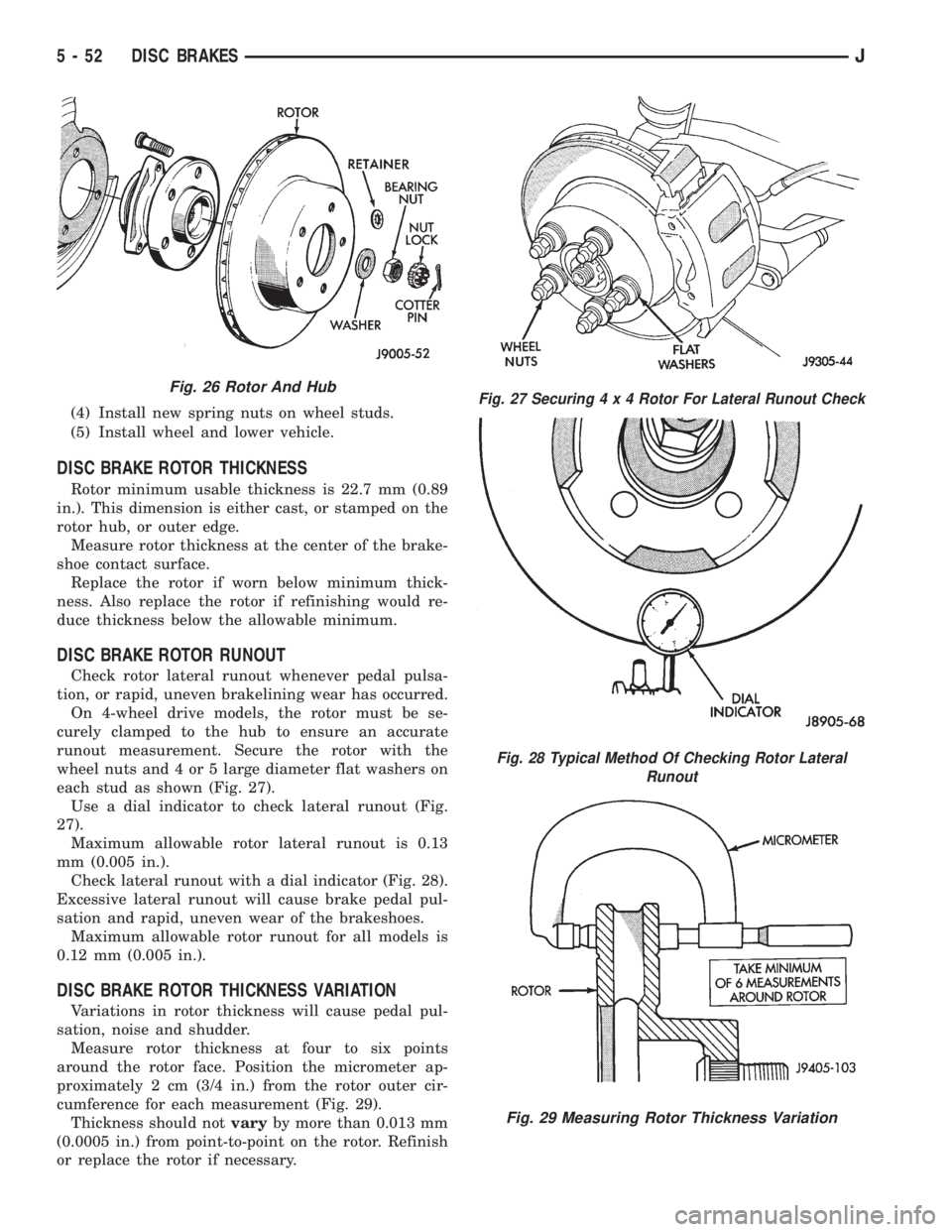

DISC BRAKE ROTOR RUNOUT

Check rotor lateral runout whenever pedal pulsa-

tion, or rapid, uneven brakelining wear has occurred.

On 4-wheel drive models, the rotor must be se-

curely clamped to the hub to ensure an accurate

runout measurement. Secure the rotor with the

wheel nuts and 4 or 5 large diameter flat washers on

each stud as shown (Fig. 27).

Use a dial indicator to check lateral runout (Fig.

27).

Maximum allowable rotor lateral runout is 0.13

mm (0.005 in.).

Check lateral runout with a dial indicator (Fig. 28).

Excessive lateral runout will cause brake pedal pul-

sation and rapid, uneven wear of the brakeshoes.

Maximum allowable rotor runout for all models is

0.12 mm (0.005 in.).

DISC BRAKE ROTOR THICKNESS VARIATION

Variations in rotor thickness will cause pedal pul-

sation, noise and shudder.

Measure rotor thickness at four to six points

around the rotor face. Position the micrometer ap-

proximately 2 cm (3/4 in.) from the rotor outer cir-

cumference for each measurement (Fig. 29).

Thickness should notvaryby more than 0.013 mm

(0.0005 in.) from point-to-point on the rotor. Refinish

or replace the rotor if necessary.

Fig. 26 Rotor And HubFig. 27 Securing4x4Rotor For Lateral Runout Check

Fig. 28 Typical Method Of Checking Rotor Lateral

Runout

Fig. 29 Measuring Rotor Thickness Variation

5 - 52 DISC BRAKESJ

Page 192 of 2198

DRUM BRAKES

INDEX

page page

Brake Drum Refinishing.................... 58

Drum Brake Adjustment.................... 57

Drum Brakeshoe Installation................. 55

Drum Brakeshoe Removal................... 55

Support Plate Replacement.................. 58Wheel Cylinder Installation.................. 58

Wheel Cylinder Overhaul.................... 57

Wheel Cylinder Removal.................... 57

Wheel Nut Tightening...................... 59

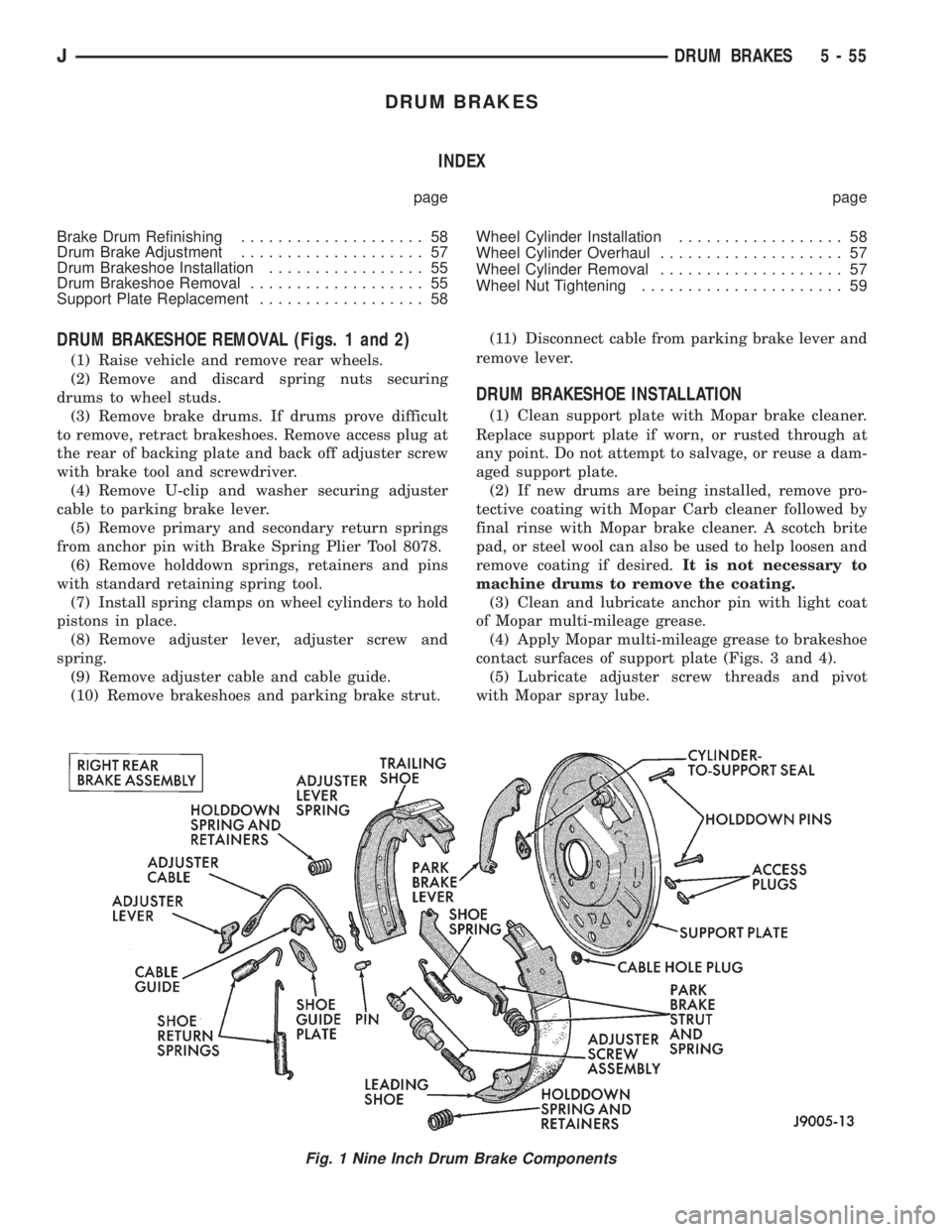

DRUM BRAKESHOE REMOVAL (Figs. 1 and 2)

(1) Raise vehicle and remove rear wheels.

(2) Remove and discard spring nuts securing

drums to wheel studs.

(3) Remove brake drums. If drums prove difficult

to remove, retract brakeshoes. Remove access plug at

the rear of backing plate and back off adjuster screw

with brake tool and screwdriver.

(4) Remove U-clip and washer securing adjuster

cable to parking brake lever.

(5) Remove primary and secondary return springs

from anchor pin with Brake Spring Plier Tool 8078.

(6) Remove holddown springs, retainers and pins

with standard retaining spring tool.

(7) Install spring clamps on wheel cylinders to hold

pistons in place.

(8) Remove adjuster lever, adjuster screw and

spring.

(9) Remove adjuster cable and cable guide.

(10) Remove brakeshoes and parking brake strut.(11) Disconnect cable from parking brake lever and

remove lever.

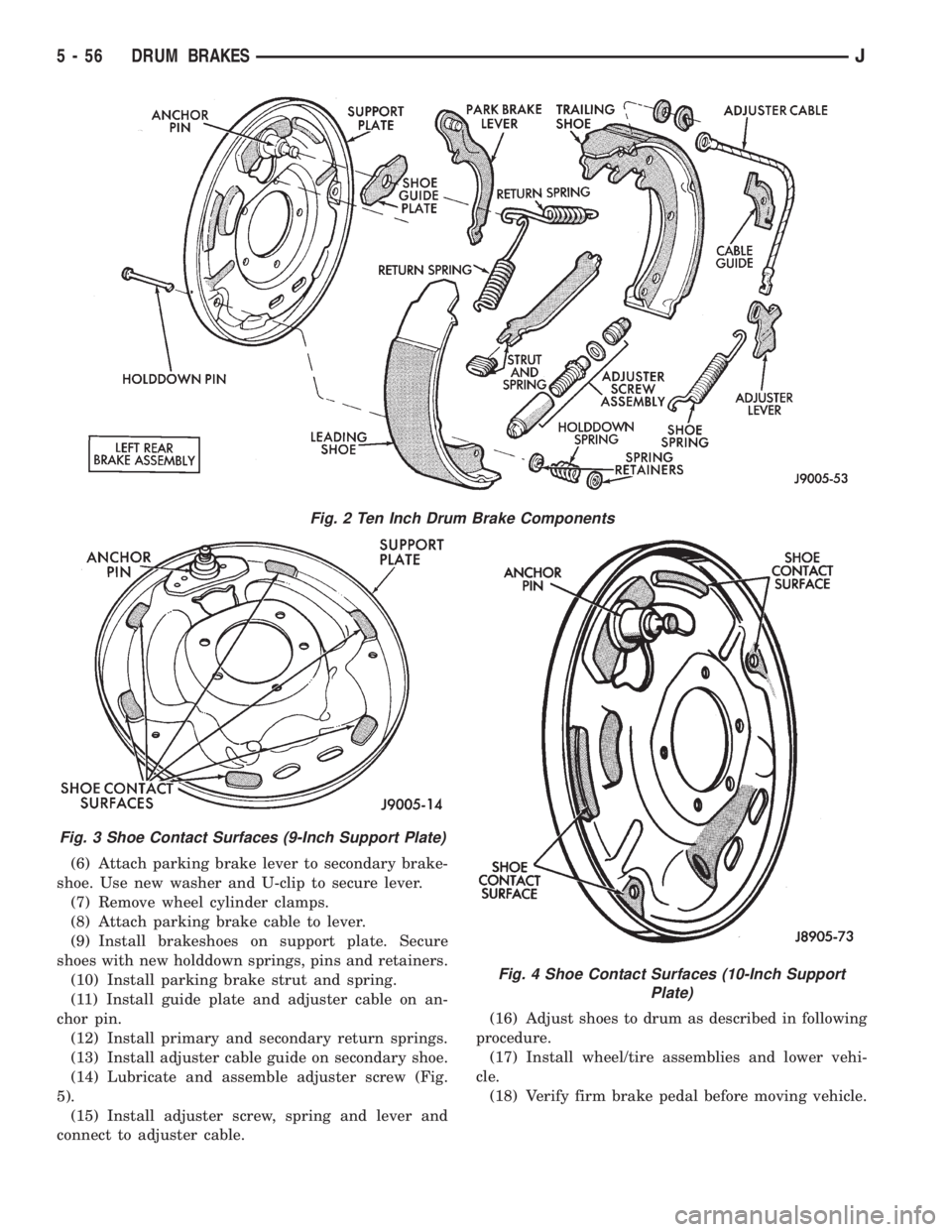

DRUM BRAKESHOE INSTALLATION

(1) Clean support plate with Mopar brake cleaner.

Replace support plate if worn, or rusted through at

any point. Do not attempt to salvage, or reuse a dam-

aged support plate.

(2) If new drums are being installed, remove pro-

tective coating with Mopar Carb cleaner followed by

final rinse with Mopar brake cleaner. A scotch brite

pad, or steel wool can also be used to help loosen and

remove coating if desired.It is not necessary to

machine drums to remove the coating.

(3) Clean and lubricate anchor pin with light coat

of Mopar multi-mileage grease.

(4) Apply Mopar multi-mileage grease to brakeshoe

contact surfaces of support plate (Figs. 3 and 4).

(5) Lubricate adjuster screw threads and pivot

with Mopar spray lube.

Fig. 1 Nine Inch Drum Brake Components

JDRUM BRAKES 5 - 55

Page 193 of 2198

(6) Attach parking brake lever to secondary brake-

shoe. Use new washer and U-clip to secure lever.

(7) Remove wheel cylinder clamps.

(8) Attach parking brake cable to lever.

(9) Install brakeshoes on support plate. Secure

shoes with new holddown springs, pins and retainers.

(10) Install parking brake strut and spring.

(11) Install guide plate and adjuster cable on an-

chor pin.

(12) Install primary and secondary return springs.

(13) Install adjuster cable guide on secondary shoe.

(14) Lubricate and assemble adjuster screw (Fig.

5).

(15) Install adjuster screw, spring and lever and

connect to adjuster cable.(16) Adjust shoes to drum as described in following

procedure.

(17) Install wheel/tire assemblies and lower vehi-

cle.

(18) Verify firm brake pedal before moving vehicle.

Fig. 2 Ten Inch Drum Brake Components

Fig. 3 Shoe Contact Surfaces (9-Inch Support Plate)

Fig. 4 Shoe Contact Surfaces (10-Inch Support

Plate)

5 - 56 DRUM BRAKESJ

Page 198 of 2198

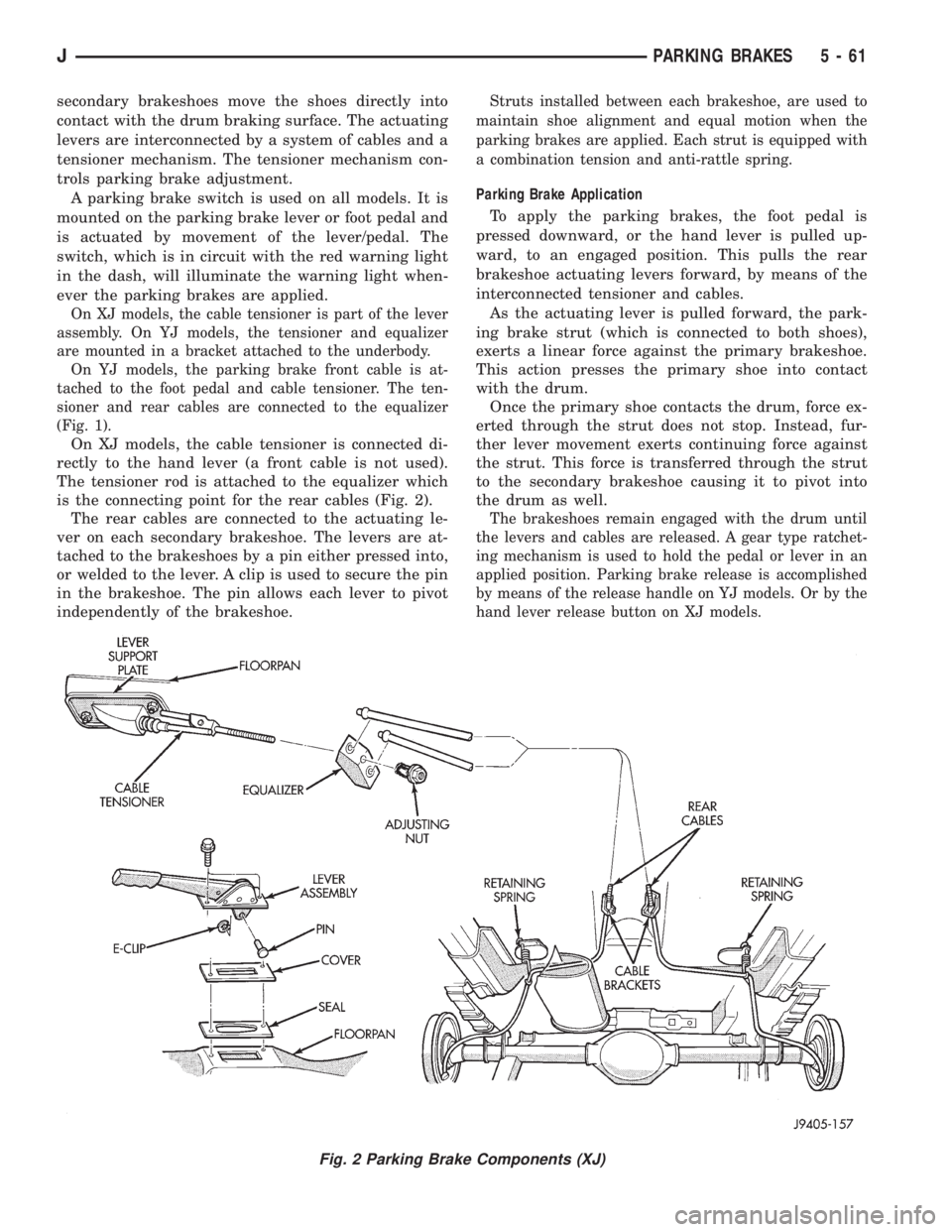

secondary brakeshoes move the shoes directly into

contact with the drum braking surface. The actuating

levers are interconnected by a system of cables and a

tensioner mechanism. The tensioner mechanism con-

trols parking brake adjustment.

A parking brake switch is used on all models. It is

mounted on the parking brake lever or foot pedal and

is actuated by movement of the lever/pedal. The

switch, which is in circuit with the red warning light

in the dash, will illuminate the warning light when-

ever the parking brakes are applied.

On XJ models, the cable tensioner is part of the lever

assembly. On YJ models, the tensioner and equalizer

are mounted in a bracket attached to the underbody.

On YJ models, the parking brake front cable is at-

tached to the foot pedal and cable tensioner. The ten-

sioner and rear cables are connected to the equalizer

(Fig. 1).

On XJ models, the cable tensioner is connected di-

rectly to the hand lever (a front cable is not used).

The tensioner rod is attached to the equalizer which

is the connecting point for the rear cables (Fig. 2).

The rear cables are connected to the actuating le-

ver on each secondary brakeshoe. The levers are at-

tached to the brakeshoes by a pin either pressed into,

or welded to the lever. A clip is used to secure the pin

in the brakeshoe. The pin allows each lever to pivot

independently of the brakeshoe.

Struts installed between each brakeshoe, are used to

maintain shoe alignment and equal motion when the

parking brakes are applied. Each strut is equipped with

a combination tension and anti-rattle spring.

Parking Brake Application

To apply the parking brakes, the foot pedal is

pressed downward, or the hand lever is pulled up-

ward, to an engaged position. This pulls the rear

brakeshoe actuating levers forward, by means of the

interconnected tensioner and cables.

As the actuating lever is pulled forward, the park-

ing brake strut (which is connected to both shoes),

exerts a linear force against the primary brakeshoe.

This action presses the primary shoe into contact

with the drum.

Once the primary shoe contacts the drum, force ex-

erted through the strut does not stop. Instead, fur-

ther lever movement exerts continuing force against

the strut. This force is transferred through the strut

to the secondary brakeshoe causing it to pivot into

the drum as well.

The brakeshoes remain engaged with the drum until

the levers and cables are released. A gear type ratchet-

ing mechanism is used to hold the pedal or lever in an

applied position. Parking brake release is accomplished

by means of the release handle on YJ models. Or by the

hand lever release button on XJ models.

Fig. 2 Parking Brake Components (XJ)

JPARKING BRAKES 5 - 61

Page 199 of 2198

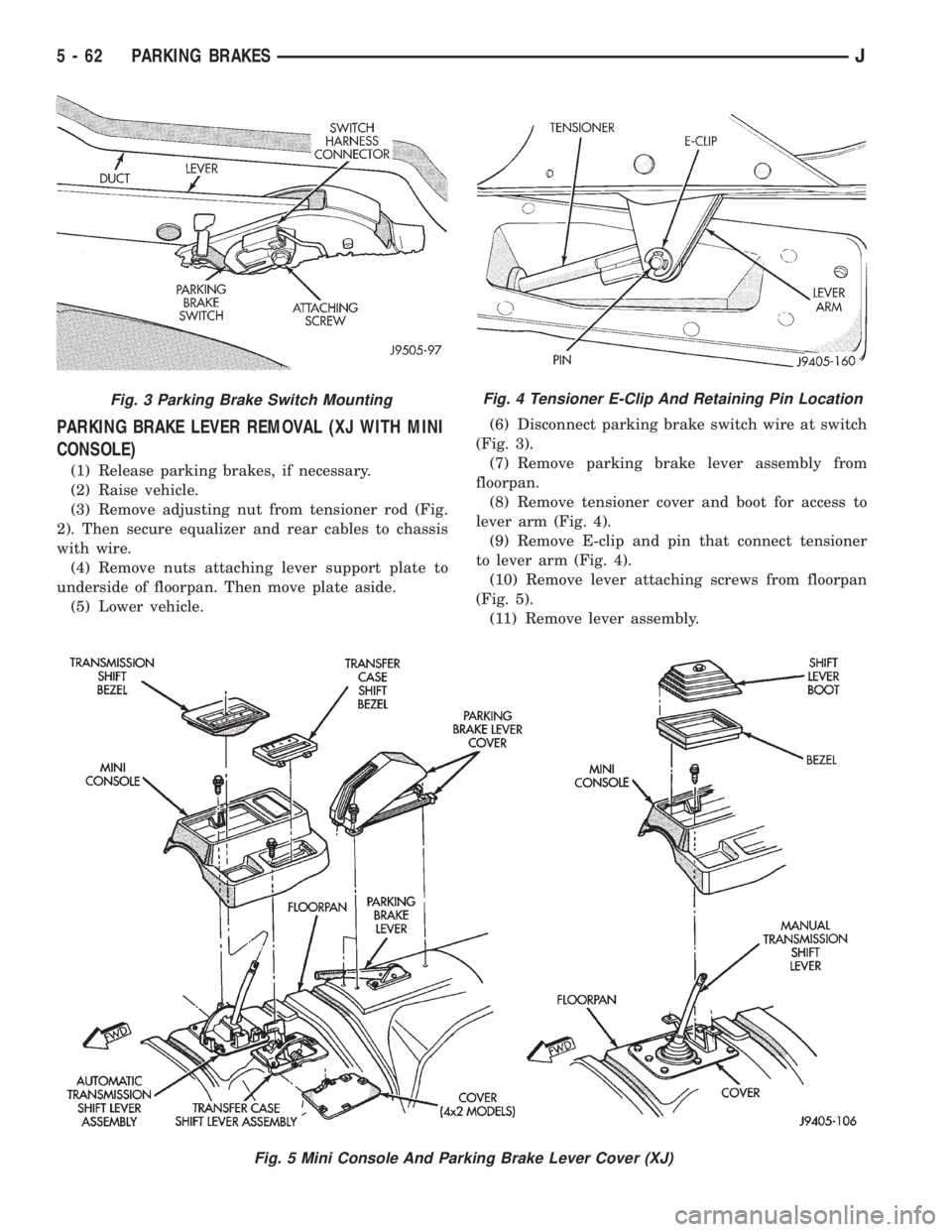

PARKING BRAKE LEVER REMOVAL (XJ WITH MINI

CONSOLE)

(1) Release parking brakes, if necessary.

(2) Raise vehicle.

(3) Remove adjusting nut from tensioner rod (Fig.

2). Then secure equalizer and rear cables to chassis

with wire.

(4) Remove nuts attaching lever support plate to

underside of floorpan. Then move plate aside.

(5) Lower vehicle.(6) Disconnect parking brake switch wire at switch

(Fig. 3).

(7) Remove parking brake lever assembly from

floorpan.

(8) Remove tensioner cover and boot for access to

lever arm (Fig. 4).

(9) Remove E-clip and pin that connect tensioner

to lever arm (Fig. 4).

(10) Remove lever attaching screws from floorpan

(Fig. 5).

(11) Remove lever assembly.

Fig. 3 Parking Brake Switch MountingFig. 4 Tensioner E-Clip And Retaining Pin Location

Fig. 5 Mini Console And Parking Brake Lever Cover (XJ)

5 - 62 PARKING BRAKESJ

Page 200 of 2198

(12) Parking brake switch can be serviced at this

time, if necessary.

PARKING BRAKE LEVER INSTALLATION (XJ WITH

MINI CONSOLE)

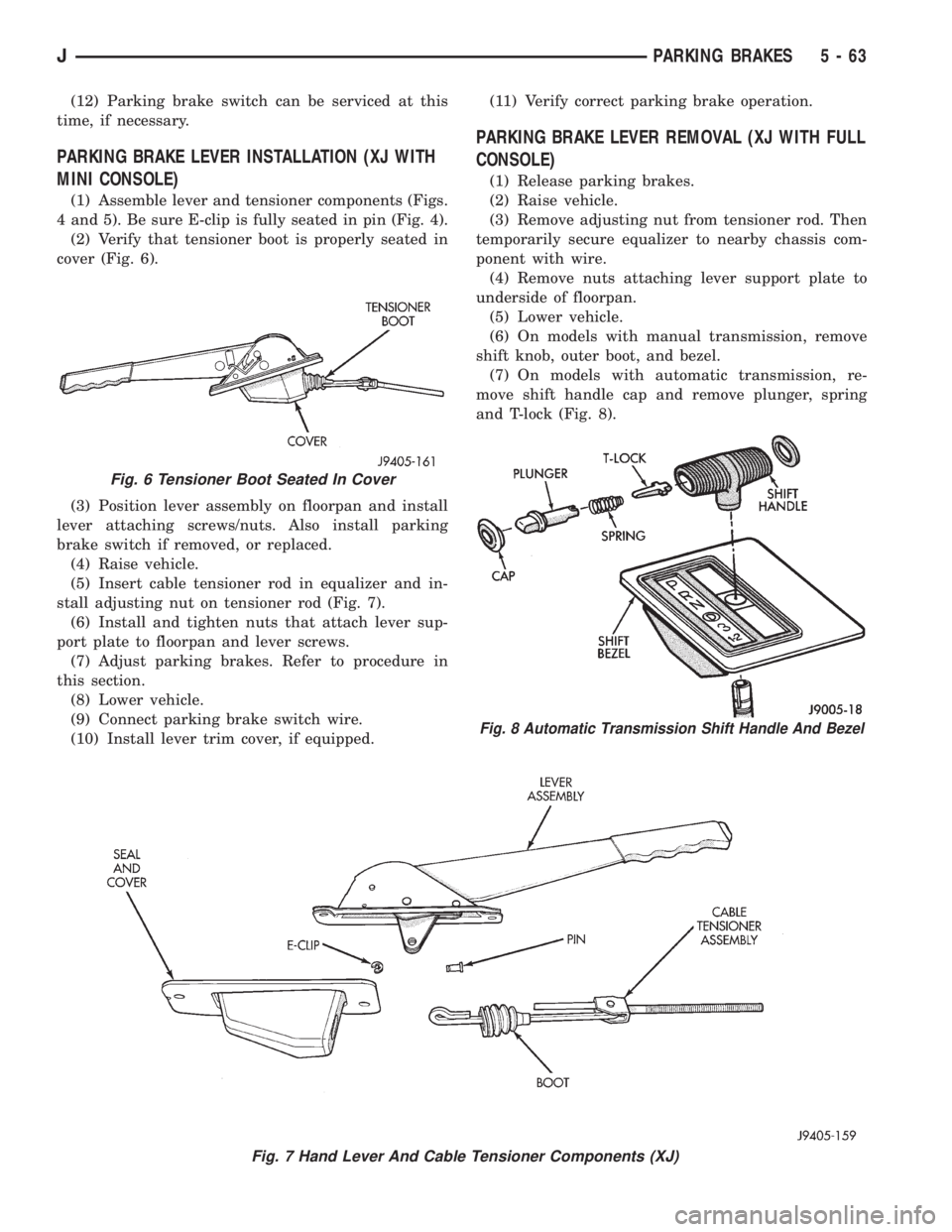

(1) Assemble lever and tensioner components (Figs.

4 and 5). Be sure E-clip is fully seated in pin (Fig. 4).

(2) Verify that tensioner boot is properly seated in

cover (Fig. 6).

(3) Position lever assembly on floorpan and install

lever attaching screws/nuts. Also install parking

brake switch if removed, or replaced.

(4) Raise vehicle.

(5) Insert cable tensioner rod in equalizer and in-

stall adjusting nut on tensioner rod (Fig. 7).

(6) Install and tighten nuts that attach lever sup-

port plate to floorpan and lever screws.

(7) Adjust parking brakes. Refer to procedure in

this section.

(8) Lower vehicle.

(9) Connect parking brake switch wire.

(10) Install lever trim cover, if equipped.(11) Verify correct parking brake operation.

PARKING BRAKE LEVER REMOVAL (XJ WITH FULL

CONSOLE)

(1) Release parking brakes.

(2) Raise vehicle.

(3) Remove adjusting nut from tensioner rod. Then

temporarily secure equalizer to nearby chassis com-

ponent with wire.

(4) Remove nuts attaching lever support plate to

underside of floorpan.

(5) Lower vehicle.

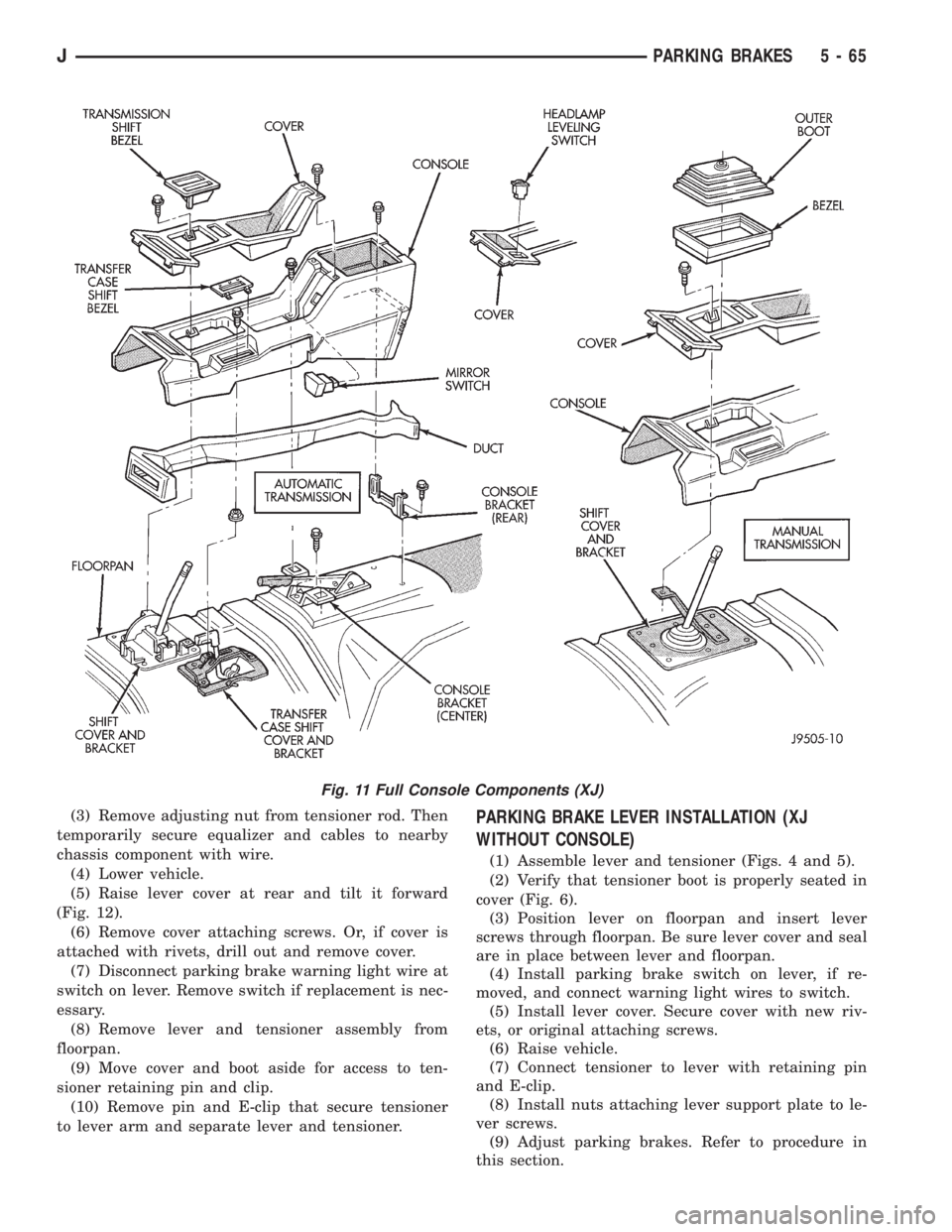

(6) On models with manual transmission, remove

shift knob, outer boot, and bezel.

(7) On models with automatic transmission, re-

move shift handle cap and remove plunger, spring

and T-lock (Fig. 8).

Fig. 7 Hand Lever And Cable Tensioner Components (XJ)

Fig. 6 Tensioner Boot Seated In Cover

Fig. 8 Automatic Transmission Shift Handle And Bezel

JPARKING BRAKES 5 - 63

Page 202 of 2198

(3) Remove adjusting nut from tensioner rod. Then

temporarily secure equalizer and cables to nearby

chassis component with wire.

(4) Lower vehicle.

(5) Raise lever cover at rear and tilt it forward

(Fig. 12).

(6) Remove cover attaching screws. Or, if cover is

attached with rivets, drill out and remove cover.

(7) Disconnect parking brake warning light wire at

switch on lever. Remove switch if replacement is nec-

essary.

(8) Remove lever and tensioner assembly from

floorpan.

(9) Move cover and boot aside for access to ten-

sioner retaining pin and clip.

(10) Remove pin and E-clip that secure tensioner

to lever arm and separate lever and tensioner.PARKING BRAKE LEVER INSTALLATION (XJ

WITHOUT CONSOLE)

(1) Assemble lever and tensioner (Figs. 4 and 5).

(2) Verify that tensioner boot is properly seated in

cover (Fig. 6).

(3) Position lever on floorpan and insert lever

screws through floorpan. Be sure lever cover and seal

are in place between lever and floorpan.

(4) Install parking brake switch on lever, if re-

moved, and connect warning light wires to switch.

(5) Install lever cover. Secure cover with new riv-

ets, or original attaching screws.

(6) Raise vehicle.

(7) Connect tensioner to lever with retaining pin

and E-clip.

(8) Install nuts attaching lever support plate to le-

ver screws.

(9) Adjust parking brakes. Refer to procedure in

this section.

Fig. 11 Full Console Components (XJ)

JPARKING BRAKES 5 - 65