dash panel JEEP CHEROKEE 1995 Service Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1842 of 2198

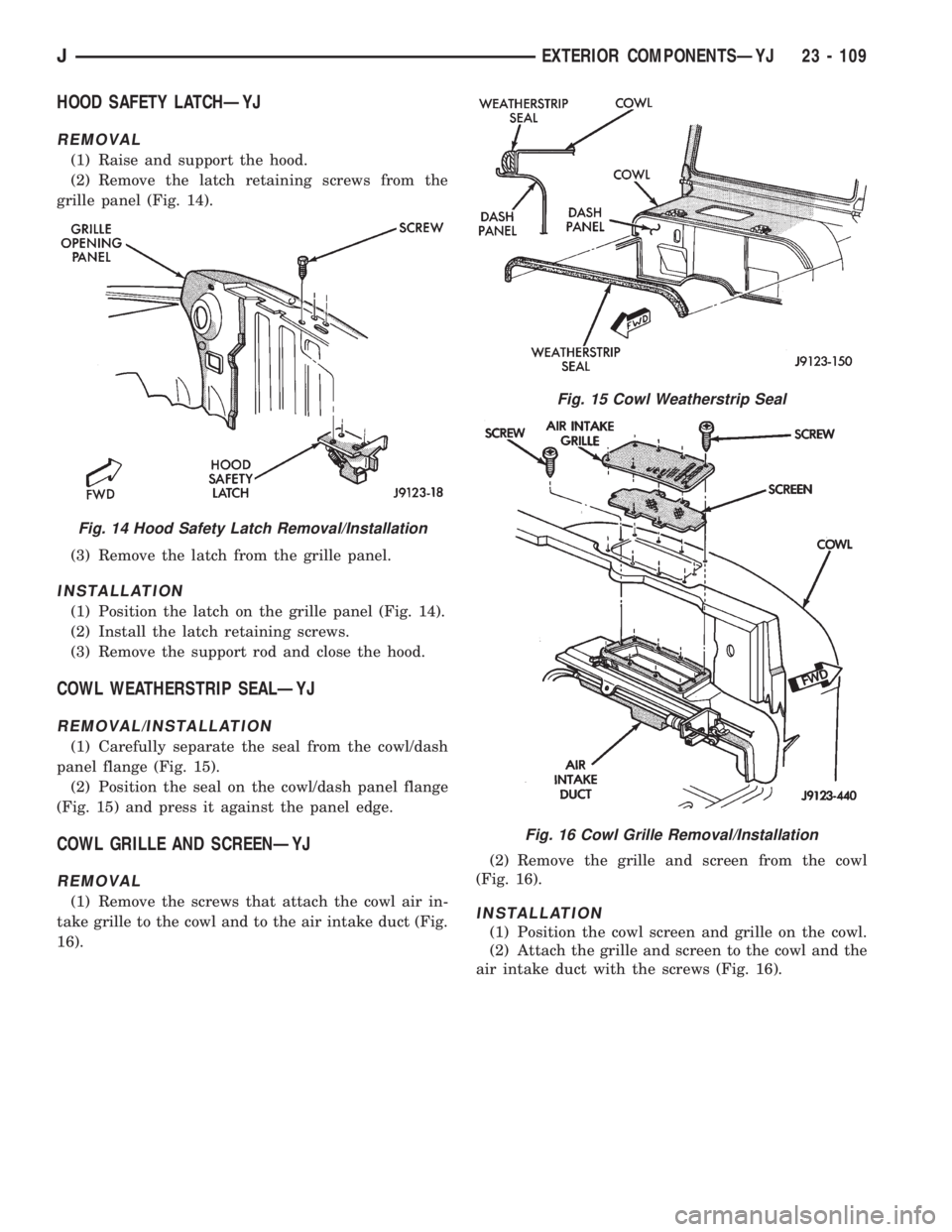

HOOD SAFETY LATCHÐYJ

REMOVAL

(1) Raise and support the hood.

(2) Remove the latch retaining screws from the

grille panel (Fig. 14).

(3) Remove the latch from the grille panel.

INSTALLATION

(1) Position the latch on the grille panel (Fig. 14).

(2) Install the latch retaining screws.

(3) Remove the support rod and close the hood.

COWL WEATHERSTRIP SEALÐYJ

REMOVAL/INSTALLATION

(1) Carefully separate the seal from the cowl/dash

panel flange (Fig. 15).

(2) Position the seal on the cowl/dash panel flange

(Fig. 15) and press it against the panel edge.

COWL GRILLE AND SCREENÐYJ

REMOVAL

(1) Remove the screws that attach the cowl air in-

take grille to the cowl and to the air intake duct (Fig.

16).(2) Remove the grille and screen from the cowl

(Fig. 16).INSTALLATION

(1) Position the cowl screen and grille on the cowl.

(2) Attach the grille and screen to the cowl and the

air intake duct with the screws (Fig. 16).

Fig. 14 Hood Safety Latch Removal/Installation

Fig. 15 Cowl Weatherstrip Seal

Fig. 16 Cowl Grille Removal/Installation

JEXTERIOR COMPONENTSÐYJ 23 - 109

Page 1891 of 2198

PAINT

INTRODUCTION

Exterior vehicle body colors are identified on the

Vehicle Code plate. The plate is located on the left

side of the dash panel in the engine compartment.

The color code location is described in the Introduc-

tion of this manual. The color names provided in the

Paint and Trim Code Description chart are the color

names used on most repair product containers. The

color names in the new vehicle ordering guides may

vary depending on vehicle line but use the same color

code.

BASE COAT/CLEAR COAT FINISH

On most vehicles a two part paint application (base

coat/clear coat) is used. Color paint that is applied to

primer is called base coat. The clear coat protects the

base coat from ultra violet light and provides a dura-

ble high gloss finish.

WET SANDING,BUFFING AND POLISHING

Minor acid etching, orange peel or smudging in

clear coat can be reduced with light wet sanding,

hand buffing and polishing. If the finish has been

wet sanded in the past, it can not be repeated. Wet

sanding operation should be performed by a trained

automotive painter.

CAUTION: Do not remove clear coat finish, if

equipped. Base coat paint must retain clear coat to

shine.

PAINTED SURFACE TOUCH-UP

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-ble to avoid corrosion. For best results, use Mopar

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

TOUCH-UP PROCEDURE

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with Mopar Tar/Road Oil

Remover and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle fill the defect without running. Do

not stroke brush applicator on body surface. Allow

the filler/ primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clear coat, the touch-up

color can be lightly (600 grit) wet sanded and pol-

ished with rubbing compound.

(6) On vehicles with clear coat, Apply clear top

coat to touch-up paint with the same technique as

described in step 4. Allow clear top coat to dry hard.

If desired, step 5 can be performed on clear top coat.

23 - 158 PAINTÐXJÐYJJ

Page 1924 of 2198

(1) Install the filter drier.

(2) Install and tighten the nut attaching the filter

drier to the side sill weld stud.

(3) Plug the harness to the low pressure switch.

(4) Remove the plugs the openings. Connect the

A/C hoses to the receiver dryer.

(5) Evacuate and charge the A/C system.

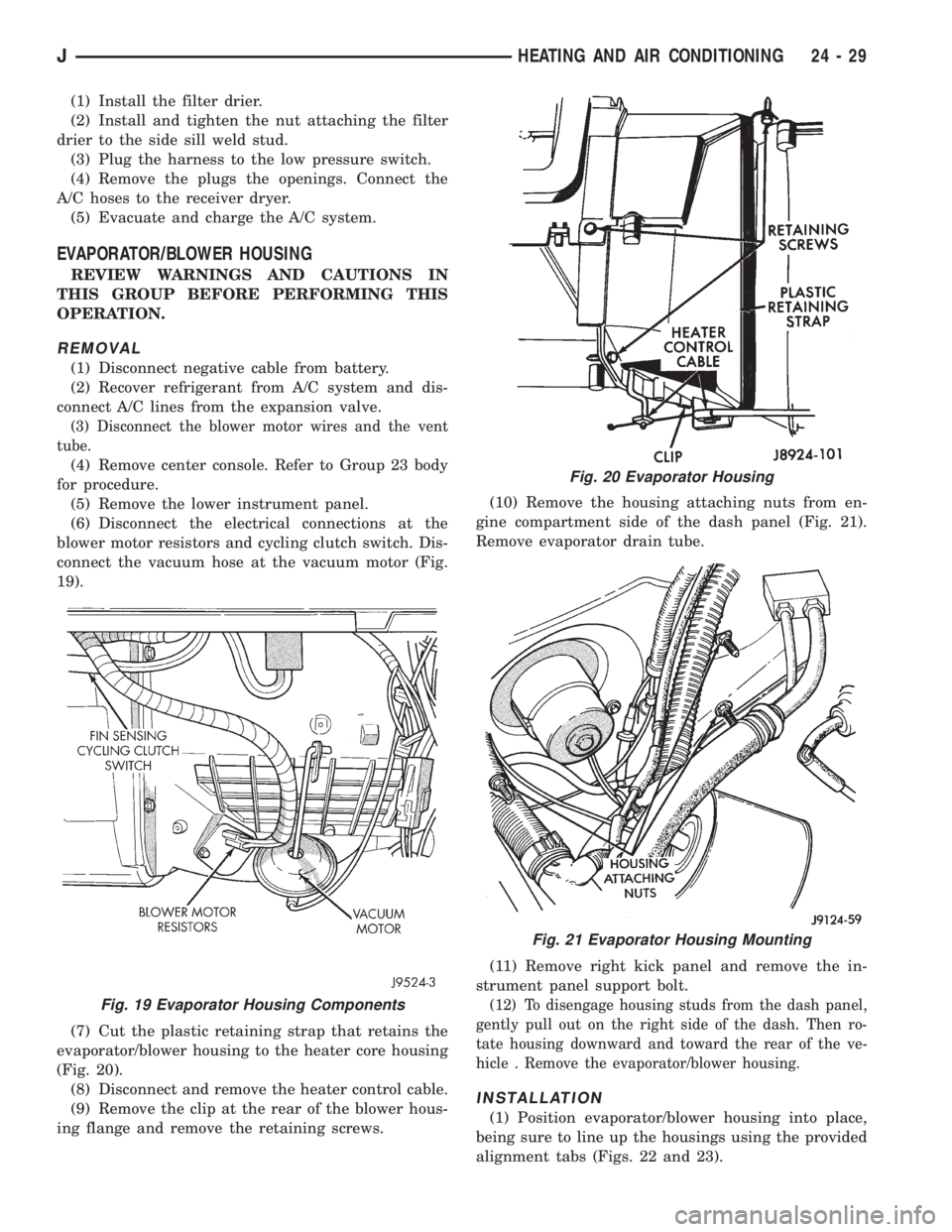

EVAPORATOR/BLOWER HOUSING

REVIEW WARNINGS AND CAUTIONS IN

THIS GROUP BEFORE PERFORMING THIS

OPERATION.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Recover refrigerant from A/C system and dis-

connect A/C lines from the expansion valve.

(3) Disconnect the blower motor wires and the vent

tube.

(4) Remove center console. Refer to Group 23 body

for procedure.

(5) Remove the lower instrument panel.

(6) Disconnect the electrical connections at the

blower motor resistors and cycling clutch switch. Dis-

connect the vacuum hose at the vacuum motor (Fig.

19).

(7) Cut the plastic retaining strap that retains the

evaporator/blower housing to the heater core housing

(Fig. 20).

(8) Disconnect and remove the heater control cable.

(9) Remove the clip at the rear of the blower hous-

ing flange and remove the retaining screws.(10) Remove the housing attaching nuts from en-

gine compartment side of the dash panel (Fig. 21).

Remove evaporator drain tube.

(11) Remove right kick panel and remove the in-

strument panel support bolt.

(12) To disengage housing studs from the dash panel,

gently pull out on the right side of the dash. Then ro-

tate housing downward and toward the rear of the ve-

hicle . Remove the evaporator/blower housing.

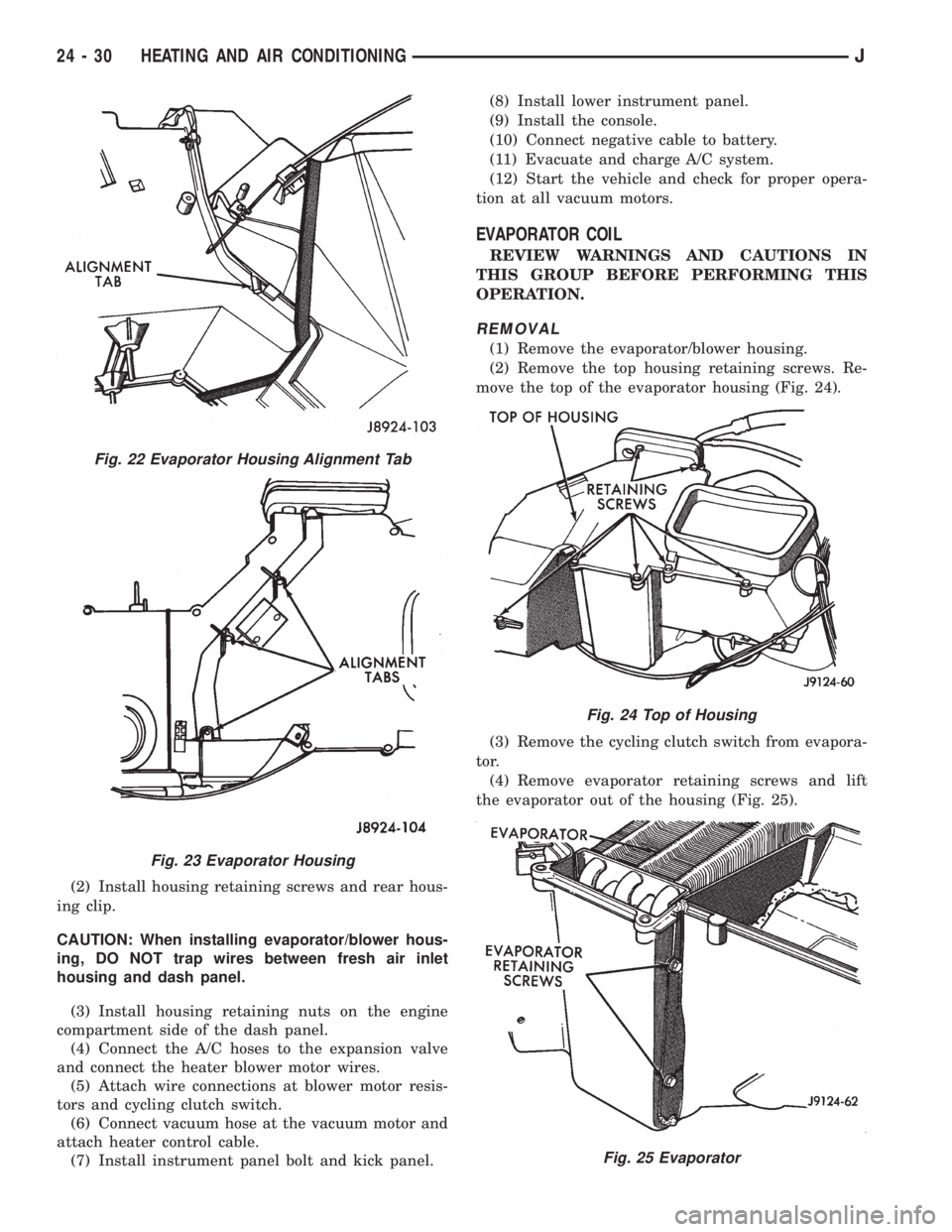

INSTALLATION

(1) Position evaporator/blower housing into place,

being sure to line up the housings using the provided

alignment tabs (Figs. 22 and 23).

Fig. 19 Evaporator Housing Components

Fig. 20 Evaporator Housing

Fig. 21 Evaporator Housing Mounting

JHEATING AND AIR CONDITIONING 24 - 29

Page 1925 of 2198

(2) Install housing retaining screws and rear hous-

ing clip.

CAUTION: When installing evaporator/blower hous-

ing, DO NOT trap wires between fresh air inlet

housing and dash panel.

(3) Install housing retaining nuts on the engine

compartment side of the dash panel.

(4) Connect the A/C hoses to the expansion valve

and connect the heater blower motor wires.

(5) Attach wire connections at blower motor resis-

tors and cycling clutch switch.

(6) Connect vacuum hose at the vacuum motor and

attach heater control cable.

(7) Install instrument panel bolt and kick panel.(8) Install lower instrument panel.

(9) Install the console.

(10) Connect negative cable to battery.

(11) Evacuate and charge A/C system.

(12) Start the vehicle and check for proper opera-

tion at all vacuum motors.

EVAPORATOR COIL

REVIEW WARNINGS AND CAUTIONS IN

THIS GROUP BEFORE PERFORMING THIS

OPERATION.

REMOVAL

(1) Remove the evaporator/blower housing.

(2) Remove the top housing retaining screws. Re-

move the top of the evaporator housing (Fig. 24).

(3) Remove the cycling clutch switch from evapora-

tor.

(4) Remove evaporator retaining screws and lift

the evaporator out of the housing (Fig. 25).

Fig. 22 Evaporator Housing Alignment Tab

Fig. 23 Evaporator Housing

Fig. 24 Top of Housing

Fig. 25 Evaporator

24 - 30 HEATING AND AIR CONDITIONINGJ

Page 1927 of 2198

COMPONENT SERVICEÐYJ VEHICLES

INDEX

page page

A/C Blower Motor......................... 35

A/C Condenser........................... 34

Blower Motor (Heating)..................... 33

Blower Motor/Air Door Motor Switch Replacement . 32

Defroster Nozzle and Duct.................. 33

Description.............................. 32

Evaporator and Housing.................... 35

Expansion Valve.......................... 35Fresh Air Door Vacuum Motor................ 34

Fresh Air Intake Duct...................... 34

Heater Control Replacement................. 32

Heater Core and Housing................... 33

Receiver-Drier Replacement................. 35

Temperature Control Thermostat.............. 34

Vent Door Control Cables................... 32

DESCRIPTION

The air conditioning evaporator housing is

mounted to the bottom of instrument panel. The

evaporator, blower motor, thermostat, and expansion

valve are located in the evaporator housing. The com-

pressor, condenser, receiver-dryer and refrigerant

lines are located in the engine compartment.

The heater housing is mounted to the dash panel

behind the instrument panel.

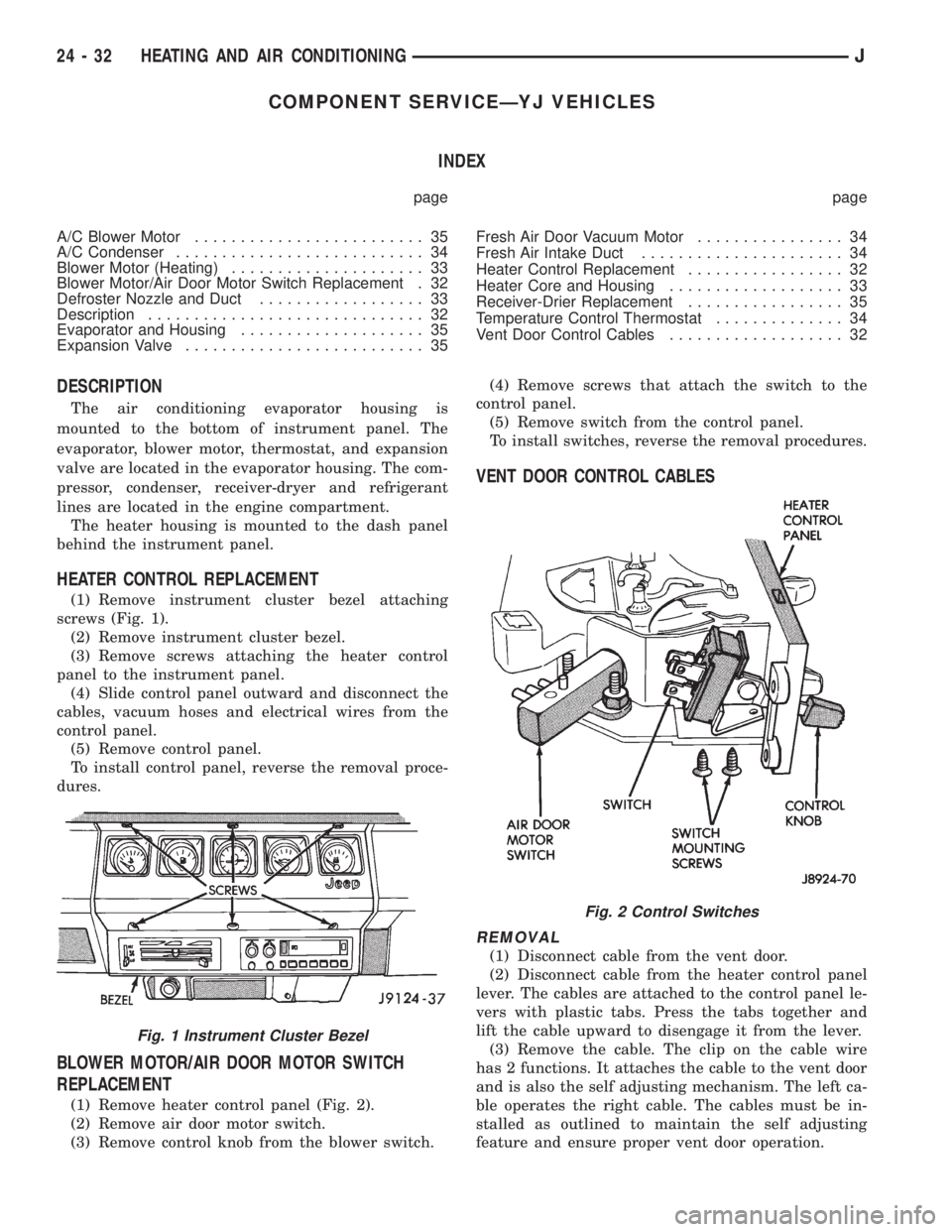

HEATER CONTROL REPLACEMENT

(1) Remove instrument cluster bezel attaching

screws (Fig. 1).

(2) Remove instrument cluster bezel.

(3) Remove screws attaching the heater control

panel to the instrument panel.

(4) Slide control panel outward and disconnect the

cables, vacuum hoses and electrical wires from the

control panel.

(5) Remove control panel.

To install control panel, reverse the removal proce-

dures.

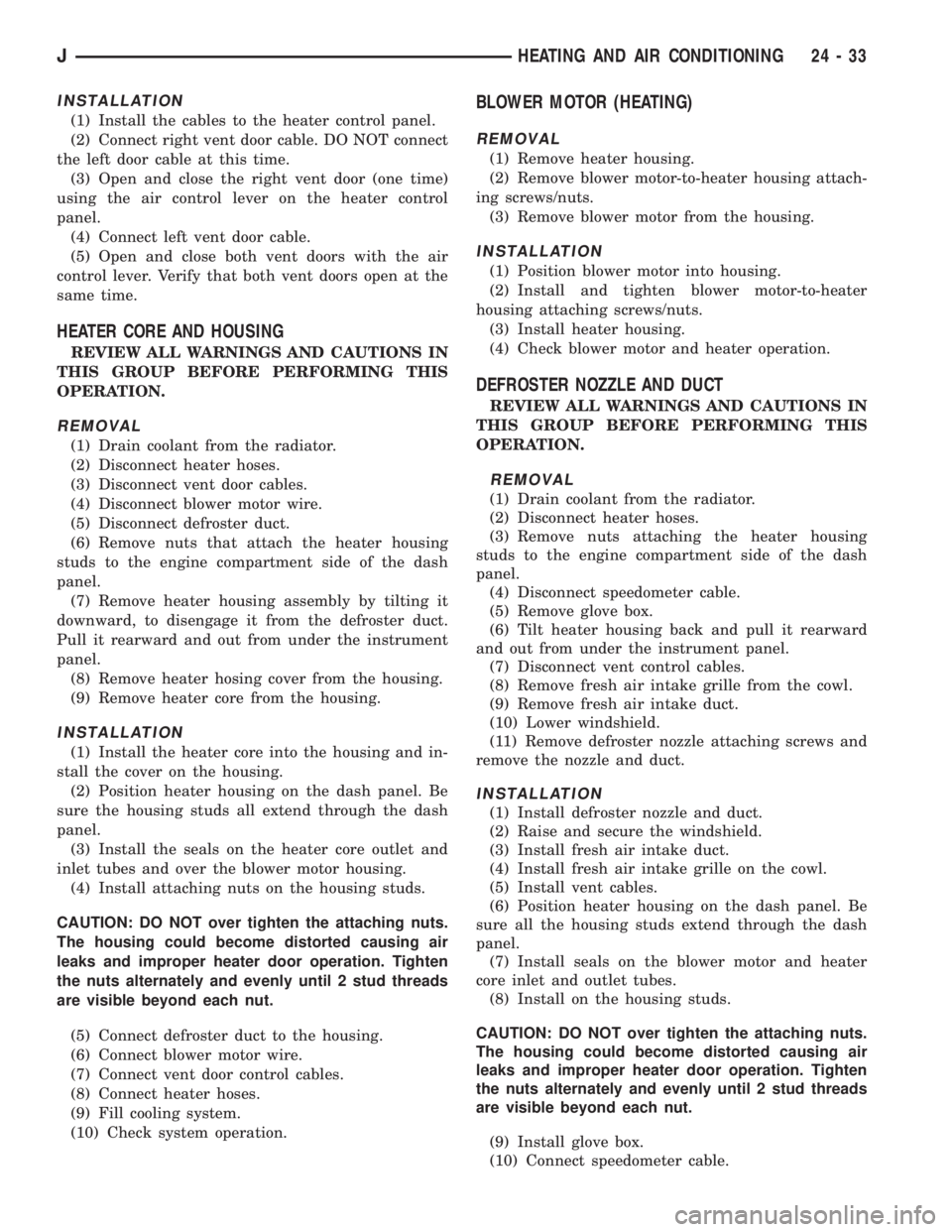

BLOWER MOTOR/AIR DOOR MOTOR SWITCH

REPLACEMENT

(1) Remove heater control panel (Fig. 2).

(2) Remove air door motor switch.

(3) Remove control knob from the blower switch.(4) Remove screws that attach the switch to the

control panel.

(5) Remove switch from the control panel.

To install switches, reverse the removal procedures.

VENT DOOR CONTROL CABLES

REMOVAL

(1) Disconnect cable from the vent door.

(2) Disconnect cable from the heater control panel

lever. The cables are attached to the control panel le-

vers with plastic tabs. Press the tabs together and

lift the cable upward to disengage it from the lever.

(3) Remove the cable. The clip on the cable wire

has 2 functions. It attaches the cable to the vent door

and is also the self adjusting mechanism. The left ca-

ble operates the right cable. The cables must be in-

stalled as outlined to maintain the self adjusting

feature and ensure proper vent door operation.

Fig. 1 Instrument Cluster Bezel

Fig. 2 Control Switches

24 - 32 HEATING AND AIR CONDITIONINGJ

Page 1928 of 2198

INSTALLATION

(1) Install the cables to the heater control panel.

(2) Connect right vent door cable. DO NOT connect

the left door cable at this time.

(3) Open and close the right vent door (one time)

using the air control lever on the heater control

panel.

(4) Connect left vent door cable.

(5) Open and close both vent doors with the air

control lever. Verify that both vent doors open at the

same time.

HEATER CORE AND HOUSING

REVIEW ALL WARNINGS AND CAUTIONS IN

THIS GROUP BEFORE PERFORMING THIS

OPERATION.

REMOVAL

(1) Drain coolant from the radiator.

(2) Disconnect heater hoses.

(3) Disconnect vent door cables.

(4) Disconnect blower motor wire.

(5) Disconnect defroster duct.

(6) Remove nuts that attach the heater housing

studs to the engine compartment side of the dash

panel.

(7) Remove heater housing assembly by tilting it

downward, to disengage it from the defroster duct.

Pull it rearward and out from under the instrument

panel.

(8) Remove heater hosing cover from the housing.

(9) Remove heater core from the housing.

INSTALLATION

(1) Install the heater core into the housing and in-

stall the cover on the housing.

(2) Position heater housing on the dash panel. Be

sure the housing studs all extend through the dash

panel.

(3) Install the seals on the heater core outlet and

inlet tubes and over the blower motor housing.

(4) Install attaching nuts on the housing studs.

CAUTION: DO NOT over tighten the attaching nuts.

The housing could become distorted causing air

leaks and improper heater door operation. Tighten

the nuts alternately and evenly until 2 stud threads

are visible beyond each nut.

(5) Connect defroster duct to the housing.

(6) Connect blower motor wire.

(7) Connect vent door control cables.

(8) Connect heater hoses.

(9) Fill cooling system.

(10) Check system operation.

BLOWER MOTOR (HEATING)

REMOVAL

(1) Remove heater housing.

(2) Remove blower motor-to-heater housing attach-

ing screws/nuts.

(3) Remove blower motor from the housing.

INSTALLATION

(1) Position blower motor into housing.

(2) Install and tighten blower motor-to-heater

housing attaching screws/nuts.

(3) Install heater housing.

(4) Check blower motor and heater operation.

DEFROSTER NOZZLE AND DUCT

REVIEW ALL WARNINGS AND CAUTIONS IN

THIS GROUP BEFORE PERFORMING THIS

OPERATION.

REMOVAL

(1) Drain coolant from the radiator.

(2) Disconnect heater hoses.

(3) Remove nuts attaching the heater housing

studs to the engine compartment side of the dash

panel.

(4) Disconnect speedometer cable.

(5) Remove glove box.

(6) Tilt heater housing back and pull it rearward

and out from under the instrument panel.

(7) Disconnect vent control cables.

(8) Remove fresh air intake grille from the cowl.

(9) Remove fresh air intake duct.

(10) Lower windshield.

(11) Remove defroster nozzle attaching screws and

remove the nozzle and duct.

INSTALLATION

(1) Install defroster nozzle and duct.

(2) Raise and secure the windshield.

(3) Install fresh air intake duct.

(4) Install fresh air intake grille on the cowl.

(5) Install vent cables.

(6) Position heater housing on the dash panel. Be

sure all the housing studs extend through the dash

panel.

(7) Install seals on the blower motor and heater

core inlet and outlet tubes.

(8) Install on the housing studs.

CAUTION: DO NOT over tighten the attaching nuts.

The housing could become distorted causing air

leaks and improper heater door operation. Tighten

the nuts alternately and evenly until 2 stud threads

are visible beyond each nut.

(9) Install glove box.

(10) Connect speedometer cable.

JHEATING AND AIR CONDITIONING 24 - 33

Page 1929 of 2198

(11) Connect the heater hoses.

(12) Fill cooling system.

FRESH AIR DOOR VACUUM MOTOR

REMOVAL

(1) Remove glove box and assist handle.

(2) Disconnect vacuum hose from the motor.

(3) Remove motor lever retaining clip.

(4) Remove motor attaching nuts and remove the

motor from the fresh air duct.

INSTALLATION

(1) Position motor on fresh air duct and install the

motor attaching nuts.

(2) Align motor lever with the air door lever and

install the lever retaining clip.

(3) Connect vacuum hose to the motor.

(4) Install glove box and assist handle.

FRESH AIR INTAKE DUCT

REVIEW WARNINGS AND CAUTIONS IN

THIS GROUP BEFORE PERFORMING THIS

OPERATION.

REMOVAL

(1) Drain coolant from the radiator.

(2) Disconnect heater hoses.

(3) Remove nuts attaching the heater housing

studs to the dash panel from inside the engine com-

partment.

(4) Disconnect speedometer cable.

(5) Remove glove box and assist handle.

(6) Tilt heater housing back and pull it rearward

and out from under the instrument panel.

(7) Disconnect vent cables.

(8) Remove windshield bracket bolts and lower

windshield.

(9) Remove fresh air intake grille from the cowl.

(10) Remove fresh air intake duct.

INSTALLATION

(1) Install fresh air intake duct.

(2) Install defroster nozzle and duct.

(3) Raise and secure the windshield.

(4) Install fresh air grille on the cowl.

(5) Install vent cables.

(6) Position heater housing on the dash panel. Be

sure all the housing studs extend through the dash

panel.

(7) Install seals on the blower motor and heater

core inlet and outlet tubes.

(8) Install nuts on the heater housing studs.

CAUTION: DO NOT over tighten the attaching nuts.

The housing could become distorted causing air

leaks and improper heater door operation. Tightenthe nuts alternately and evenly until 2 stud threads

are visible beyond each nut.

(9) Install glove box and assist handle.

(10) Connect speedometer cable.

(11) Connect heater hoses.

(12) Fill cooling system.

TEMPERATURE CONTROL THERMOSTAT

REMOVAL

(1) Remove mounting bolts and lower the evapora-

tor housing.

(2) Remove the attaching screws holding the top

and bottom housings together.

(3) Separate the housings.

(4) Remove the thermostat.

INSTALLATION

(1) Install temperature control thermostat. Insert

thermostat capillary tube into the evaporator coil a

minimum of 50 mm (2 inch).

CAUTION: Handle the tube with care to avoid bends

or kinks that could cause the thermostat to mal-

function.

(2) Assemble the housing and install the attaching

screws. DO NOT over tighten the attaching screws.

(3) Install the evaporator housing.

A/C CONDENSER

REVIEW WARNINGS AND CAUTIONS IN

THIS GROUP BEFORE PERFORMING THIS

OPERATION.

REMOVAL

(1) Recover refrigerant from A/C system.

(2) Drain the radiator.

(3) Remove fan shroud and radiator.

(4) Disconnect A/C line from the condenser.

(5) Remove condenser attaching screws and tilt the

bottom of the condenser toward the engine.Plug all

the condenser openings to prevent entry of dirt

or moisture.

(6) Working from under the vehicle, disconnect the

receiver-drier to-evaporator hose fitting from the re-

ceiver-drier.

(7) Remove condenser and receiver-drier as an as-

sembly.

(8) Remove receiver-drier from the condenser, if

necessary.

INSTALLATION

Add 30 ml (1 fluid oz.) of refrigerant oil to the A/C

system if the condenser is replaced.

(1) Attach receiver-drier to the condenser.

(2) Install condenser and connect A/C line to the

receiver-drier.

24 - 34 HEATING AND AIR CONDITIONINGJ

Page 1930 of 2198

(3) Install condenser attaching screws.

(4) Connect condenser A/C line.

(5) Install radiator and fan shroud.

(6) Fill coolant system (Refer to cooling for proper

procedure).

(7) Evacuate, charge and leak test the air condi-

tioning system.

RECEIVER-DRIER REPLACEMENT

REVIEW ALL WARNINGS AND CAUTIONS IN

THIS GROUP BEFORE PERFORMING THIS

OPERATION.

REMOVAL

(1) Recover refrigerant from A/C system.

(2) Disconnect A/C lines from the receiver-drier.

(3) Remove receiver-drier attaching screws and re-

move receiver-drier.

INSTALLATION

(1) Position receiver-drier in place and install re-

ceiver-drier attaching screws.

(2) Connect A/C lines to receiver-drier.

(3) Evacuate, charge and leak test the air condi-

tioning system.

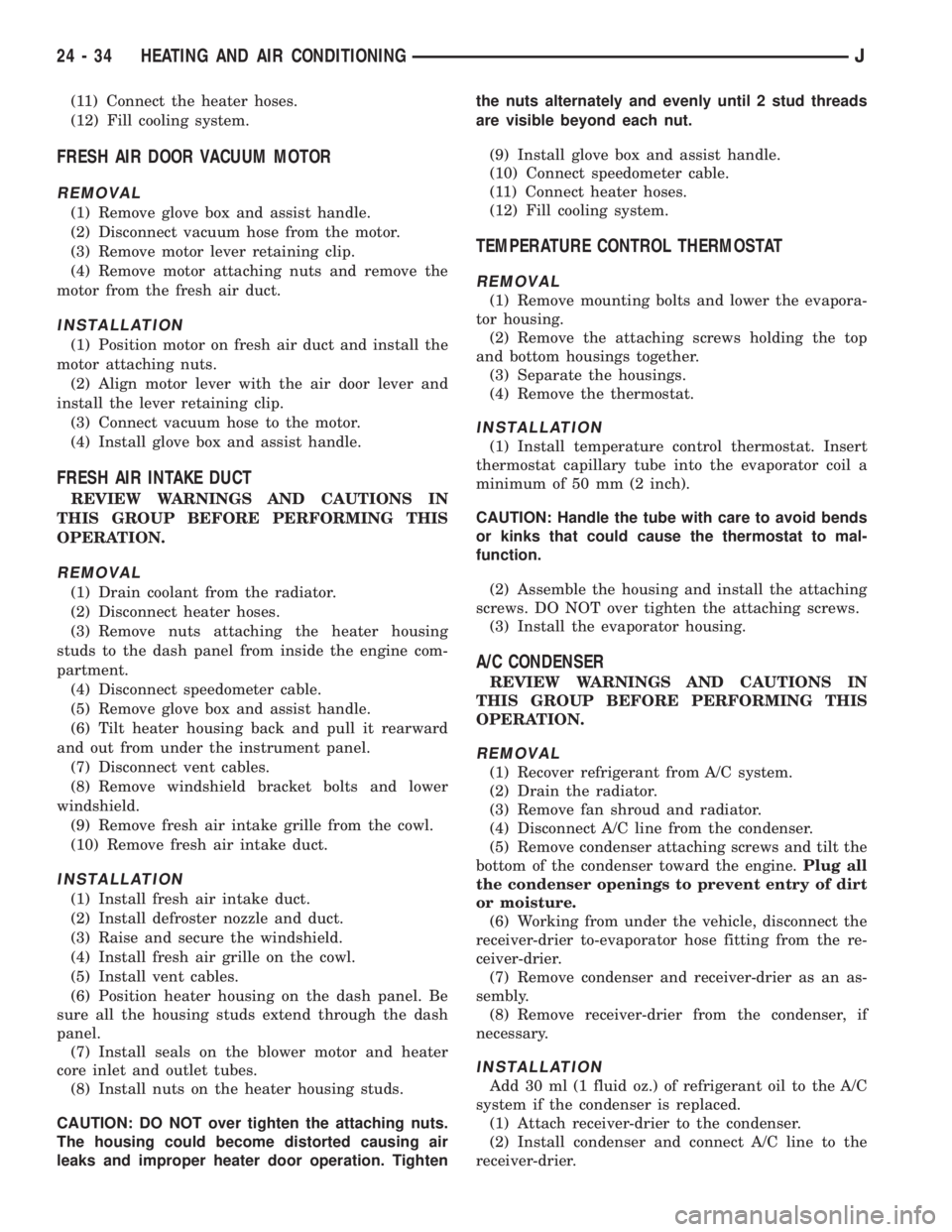

EVAPORATOR AND HOUSING

REVIEW ALL WARNINGS AND CAUTIONS IN

THIS GROUP BEFORE PERFORMING THIS

OPERATION.

REMOVAL

(1) Recover refrigerant from A/C system.

(2) Disconnect A/C lines.

(3) Remove hose clamps and dash grommet retain-

ing screws.

(4) Remove the evaporator housing-to-instrument

panel attaching screws and the housing mounting

bracket screw (Fig. 3).

(5) Lower the evaporator housing and pull the

hoses and hose grommet through the dash opening.(6) Remove upper housing and remove evaporator.

The evaporator core, control switches, expansion

valve, blower motor and housing can be serviced af-

ter removing evaporator housing (Fig. 4).

INSTALLATION

Add 30 ml (1 fluid oz.) of refrigerant oil to the A/C

system if the evaporator is replaced.

(1) Install evaporator into housing and install up-

per housing.

(2) Push A/C hoses through the grommet openings

and install the hose grommet by pushing it toward

the engine compartment.

(3) Install hose grommet attaching screws.

(4) Raise evaporator housing and install the evap-

orator housing-to- instrument panel attaching

screws.

(5) Install A/C lines.

(6) Evacuate, charge and leak test the system.

EXPANSION VALVE

REVIEW WARNINGS AND CAUTIONS IN

THIS GROUP BEFORE PERFORMING THIS

OPERATION.

REMOVAL

(1) Recover refrigerant from A/C system.

(2) Remove evaporator housing

(3) Remove the insulation wrapped around the suc-

tion hose fitting, expansion valve and evaporator tub-

ing.

(4) Mark the capillary tube location on the evapo-

rator tubing.

(5) Disconnect inlet and outlet hose fittings, and

remove the capillary tube clamp.

(6) Disconnect and remove the expansion valve.

INSTALLATION

(1) Clean evaporator tubing to provide a positive

contact with the expansion valve capillary tube.

(2) Install expansion valve.

(3) Clamp the capillary tube at the marked loca-

tion on the evaporator tubing.

(4) Connect inlet and outlet hose fittings.The

capillary tube must be securely clamped and

have positive metal-to-metal contact with the

evaporator tubing.

(5) Wrap expansion valve, inlet hose fitting and

capillary tube with insulation.

(6) Install evaporator housing.

(7) Evacuate, charge and leak test the system.

A/C BLOWER MOTOR

It is not necessary to discharge the system to ser-

vice the blower motor. The evaporator housing need

only be lowered for access to the blower motor at-

taching screws.Fig. 3 Evaporator Housing

JHEATING AND AIR CONDITIONING 24 - 35

Page 1937 of 2198

EMISSION CONTROLS

INDEX

page page

Crankcase Ventilation System................. 5

EVAP (Evaporation) Control System............ 4

EVAP Canister............................ 4Fuel Tank Filler Tube Cap.................... 4

Oxygen (O2S) Sensor....................... 6

Pressure Relief/Rollover Valve................. 6

EVAP (EVAPORATION) CONTROL SYSTEM

GENERAL INFORMATION

The function of the EVAP control system is to pre-

vent the emissions of gasoline vapors from the fuel

tank into the atmosphere. When fuel evaporates in

the fuel tank, the vapors pass through vent hoses or

tubes to a carbon filled EVAP canister. They are tem-

porarily held in the canister until they can be drawn

into the intake manifold when the engine is running.

The EVAP canister is a feature on all models for

the storage of fuel vapors from the fuel tank.

The hoses used in this system are specially

manufactured. If replacement becomes neces-

sary, it is important to use only fuel resistant

hose.

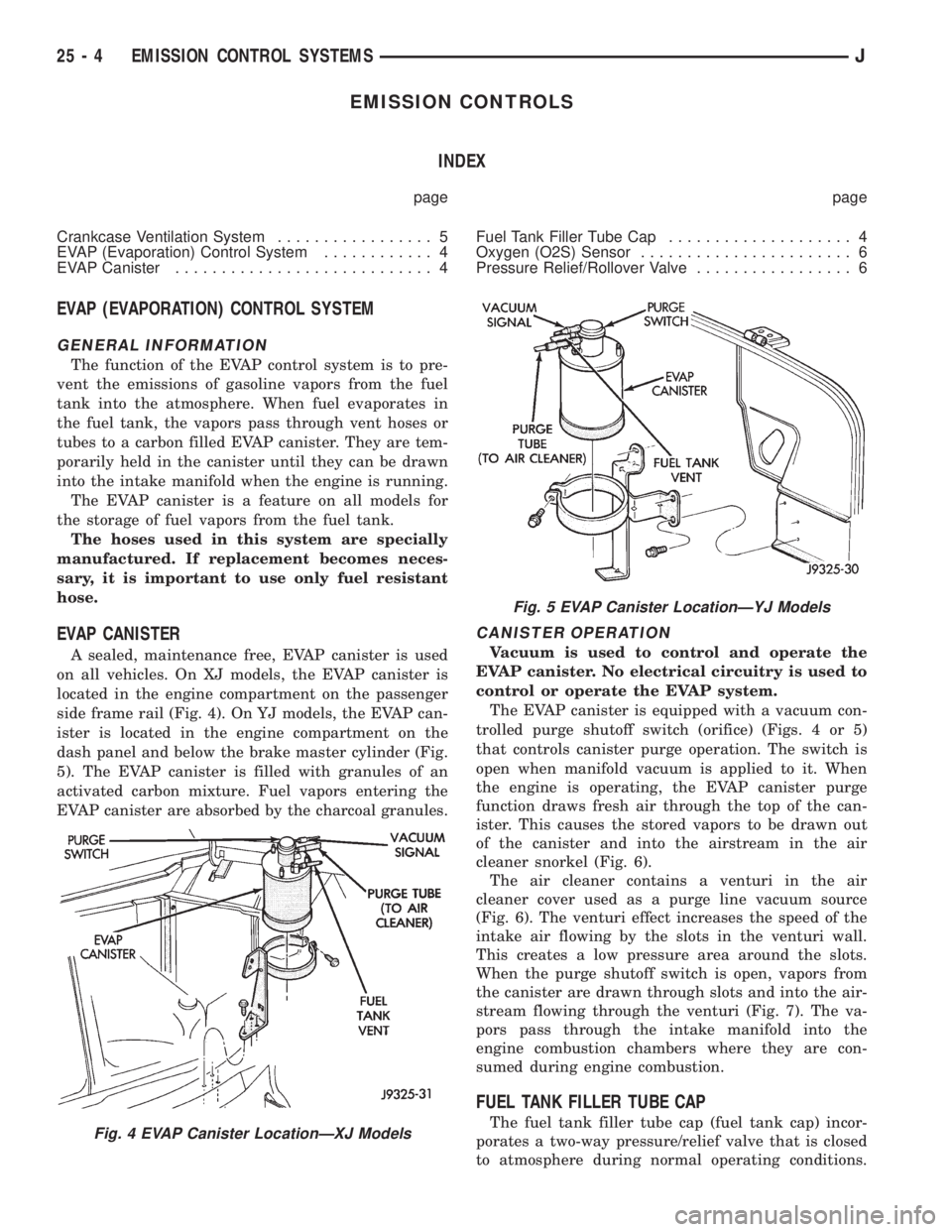

EVAP CANISTER

A sealed, maintenance free, EVAP canister is used

on all vehicles. On XJ models, the EVAP canister is

located in the engine compartment on the passenger

side frame rail (Fig. 4). On YJ models, the EVAP can-

ister is located in the engine compartment on the

dash panel and below the brake master cylinder (Fig.

5). The EVAP canister is filled with granules of an

activated carbon mixture. Fuel vapors entering the

EVAP canister are absorbed by the charcoal granules.

CANISTER OPERATION

Vacuum is used to control and operate the

EVAP canister. No electrical circuitry is used to

control or operate the EVAP system.

The EVAP canister is equipped with a vacuum con-

trolled purge shutoff switch (orifice) (Figs. 4 or 5)

that controls canister purge operation. The switch is

open when manifold vacuum is applied to it. When

the engine is operating, the EVAP canister purge

function draws fresh air through the top of the can-

ister. This causes the stored vapors to be drawn out

of the canister and into the airstream in the air

cleaner snorkel (Fig. 6).

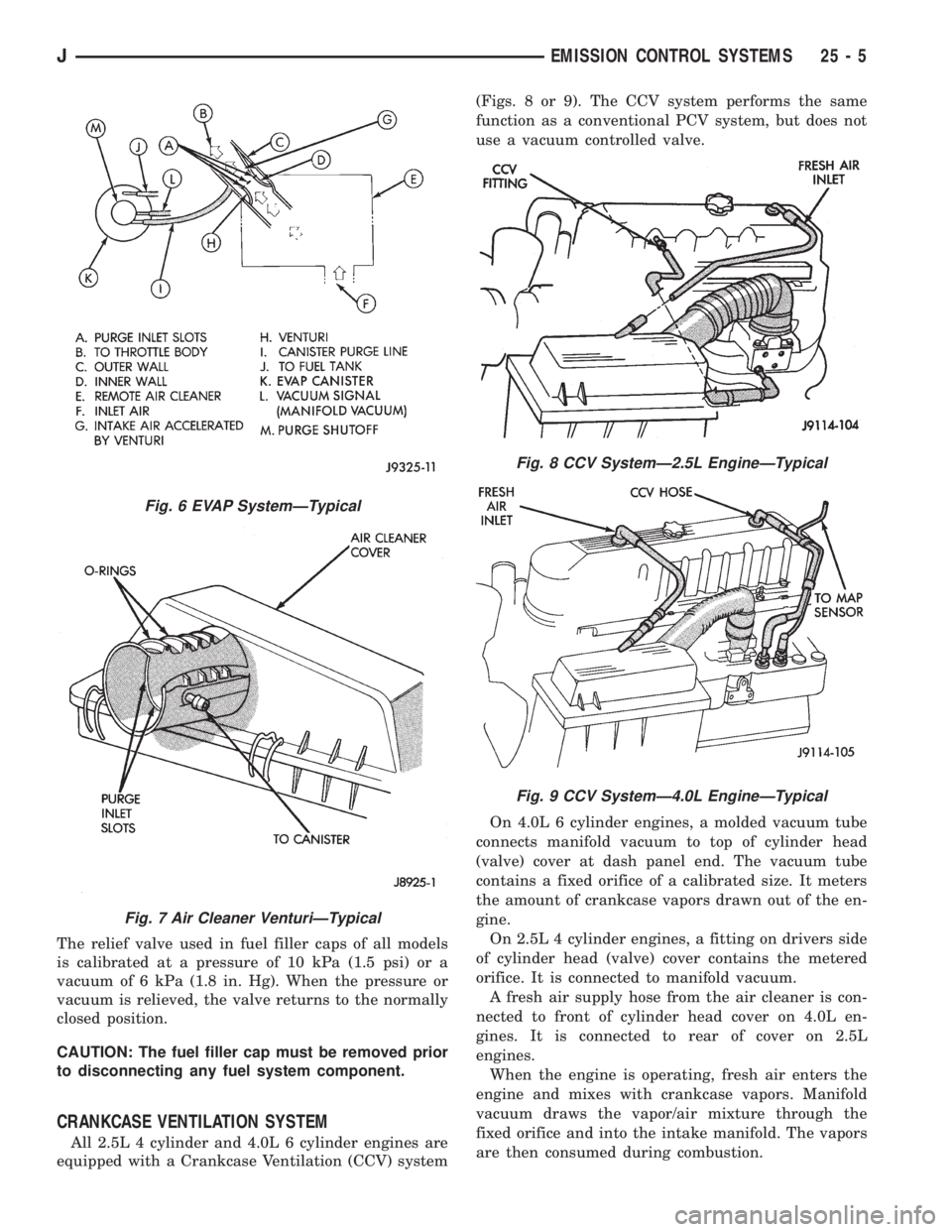

The air cleaner contains a venturi in the air

cleaner cover used as a purge line vacuum source

(Fig. 6). The venturi effect increases the speed of the

intake air flowing by the slots in the venturi wall.

This creates a low pressure area around the slots.

When the purge shutoff switch is open, vapors from

the canister are drawn through slots and into the air-

stream flowing through the venturi (Fig. 7). The va-

pors pass through the intake manifold into the

engine combustion chambers where they are con-

sumed during engine combustion.

FUEL TANK FILLER TUBE CAP

The fuel tank filler tube cap (fuel tank cap) incor-

porates a two-way pressure/relief valve that is closed

to atmosphere during normal operating conditions.Fig. 4 EVAP Canister LocationÐXJ Models

Fig. 5 EVAP Canister LocationÐYJ Models

25 - 4 EMISSION CONTROL SYSTEMSJ

Page 1938 of 2198

The relief valve used in fuel filler caps of all models

is calibrated at a pressure of 10 kPa (1.5 psi) or a

vacuum of 6 kPa (1.8 in. Hg). When the pressure or

vacuum is relieved, the valve returns to the normally

closed position.

CAUTION: The fuel filler cap must be removed prior

to disconnecting any fuel system component.

CRANKCASE VENTILATION SYSTEM

All 2.5L 4 cylinder and 4.0L 6 cylinder engines are

equipped with a Crankcase Ventilation (CCV) system(Figs. 8 or 9). The CCV system performs the same

function as a conventional PCV system, but does not

use a vacuum controlled valve.

On 4.0L 6 cylinder engines, a molded vacuum tube

connects manifold vacuum to top of cylinder head

(valve) cover at dash panel end. The vacuum tube

contains a fixed orifice of a calibrated size. It meters

the amount of crankcase vapors drawn out of the en-

gine.

On 2.5L 4 cylinder engines, a fitting on drivers side

of cylinder head (valve) cover contains the metered

orifice. It is connected to manifold vacuum.

A fresh air supply hose from the air cleaner is con-

nected to front of cylinder head cover on 4.0L en-

gines. It is connected to rear of cover on 2.5L

engines.

When the engine is operating, fresh air enters the

engine and mixes with crankcase vapors. Manifold

vacuum draws the vapor/air mixture through the

fixed orifice and into the intake manifold. The vapors

are then consumed during combustion.

Fig. 6 EVAP SystemÐTypical

Fig. 7 Air Cleaner VenturiÐTypical

Fig. 8 CCV SystemÐ2.5L EngineÐTypical

Fig. 9 CCV SystemÐ4.0L EngineÐTypical

JEMISSION CONTROL SYSTEMS 25 - 5