dash panel JEEP CHEROKEE 1995 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 221 of 2198

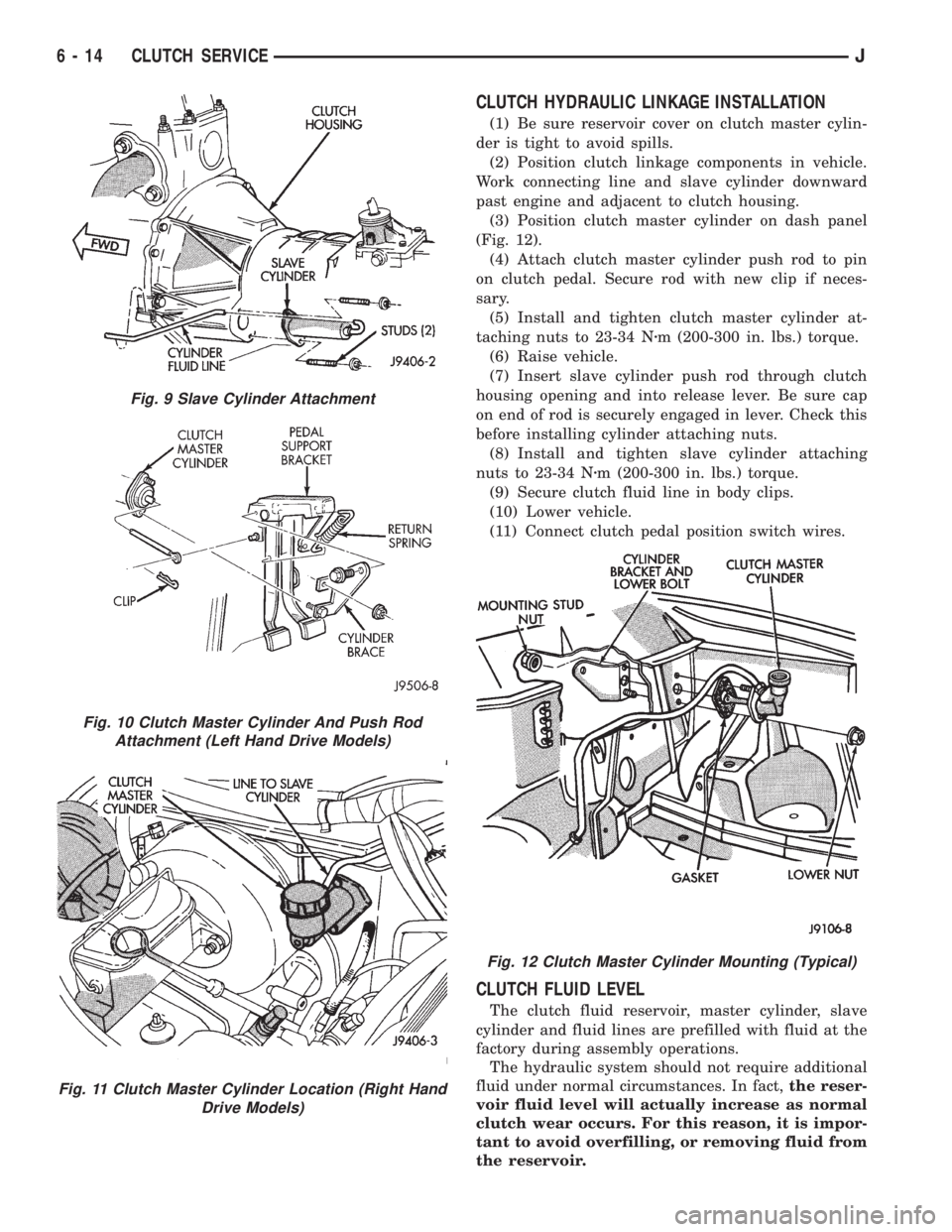

CLUTCH HYDRAULIC LINKAGE INSTALLATION

(1) Be sure reservoir cover on clutch master cylin-

der is tight to avoid spills.

(2) Position clutch linkage components in vehicle.

Work connecting line and slave cylinder downward

past engine and adjacent to clutch housing.

(3) Position clutch master cylinder on dash panel

(Fig. 12).

(4) Attach clutch master cylinder push rod to pin

on clutch pedal. Secure rod with new clip if neces-

sary.

(5) Install and tighten clutch master cylinder at-

taching nuts to 23-34 Nzm (200-300 in. lbs.) torque.

(6) Raise vehicle.

(7) Insert slave cylinder push rod through clutch

housing opening and into release lever. Be sure cap

on end of rod is securely engaged in lever. Check this

before installing cylinder attaching nuts.

(8) Install and tighten slave cylinder attaching

nuts to 23-34 Nzm (200-300 in. lbs.) torque.

(9) Secure clutch fluid line in body clips.

(10) Lower vehicle.

(11) Connect clutch pedal position switch wires.

CLUTCH FLUID LEVEL

The clutch fluid reservoir, master cylinder, slave

cylinder and fluid lines are prefilled with fluid at the

factory during assembly operations.

The hydraulic system should not require additional

fluid under normal circumstances. In fact,the reser-

voir fluid level will actually increase as normal

clutch wear occurs. For this reason, it is impor-

tant to avoid overfilling, or removing fluid from

the reservoir.

Fig. 9 Slave Cylinder Attachment

Fig. 10 Clutch Master Cylinder And Push Rod

Attachment (Left Hand Drive Models)

Fig. 11 Clutch Master Cylinder Location (Right Hand

Drive Models)

Fig. 12 Clutch Master Cylinder Mounting (Typical)

6 - 14 CLUTCH SERVICEJ

Page 358 of 2198

ignition switch to ON. Lamp should light. If OK, go

to next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug cluster connector B. Check for

continuity between cavity 2 (cavity 15 - RHD) of clus-

ter connector B and a good ground. There should be

no continuity. If OK, go to next step. If not OK, re-

pair short circuit to PCM as required.

(4) Check continuity between cavity 2 (cavity 15 -

RHD) of cluster connector B and cavity 32 of PCM

connector. There should be continuity. If not OK, re-

pair open circuit to PCM as required.

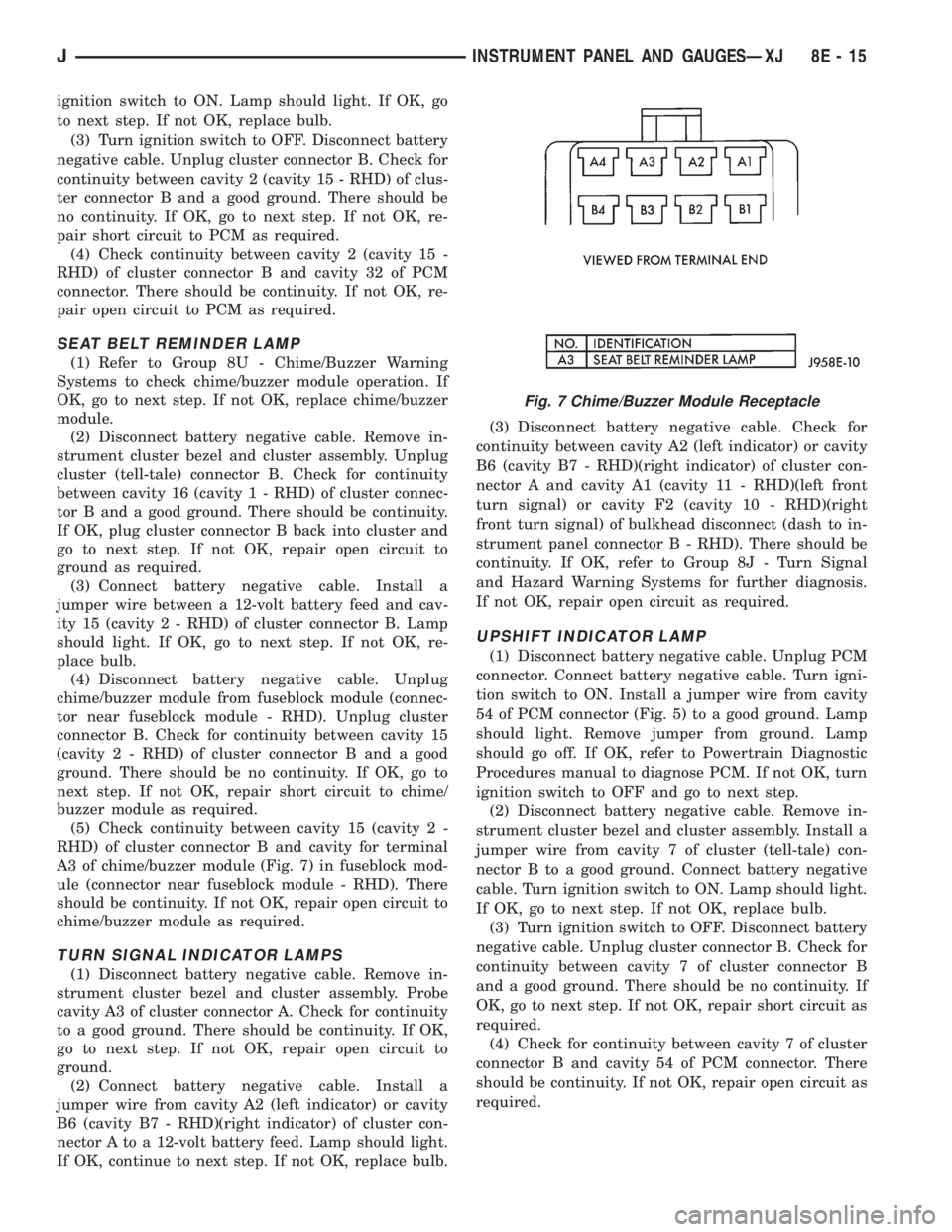

SEAT BELT REMINDER LAMP

(1) Refer to Group 8U - Chime/Buzzer Warning

Systems to check chime/buzzer module operation. If

OK, go to next step. If not OK, replace chime/buzzer

module.

(2) Disconnect battery negative cable. Remove in-

strument cluster bezel and cluster assembly. Unplug

cluster (tell-tale) connector B. Check for continuity

between cavity 16 (cavity 1 - RHD) of cluster connec-

tor B and a good ground. There should be continuity.

If OK, plug cluster connector B back into cluster and

go to next step. If not OK, repair open circuit to

ground as required.

(3) Connect battery negative cable. Install a

jumper wire between a 12-volt battery feed and cav-

ity 15 (cavity 2 - RHD) of cluster connector B. Lamp

should light. If OK, go to next step. If not OK, re-

place bulb.

(4) Disconnect battery negative cable. Unplug

chime/buzzer module from fuseblock module (connec-

tor near fuseblock module - RHD). Unplug cluster

connector B. Check for continuity between cavity 15

(cavity 2 - RHD) of cluster connector B and a good

ground. There should be no continuity. If OK, go to

next step. If not OK, repair short circuit to chime/

buzzer module as required.

(5) Check continuity between cavity 15 (cavity 2 -

RHD) of cluster connector B and cavity for terminal

A3 of chime/buzzer module (Fig. 7) in fuseblock mod-

ule (connector near fuseblock module - RHD). There

should be continuity. If not OK, repair open circuit to

chime/buzzer module as required.

TURN SIGNAL INDICATOR LAMPS

(1) Disconnect battery negative cable. Remove in-

strument cluster bezel and cluster assembly. Probe

cavity A3 of cluster connector A. Check for continuity

to a good ground. There should be continuity. If OK,

go to next step. If not OK, repair open circuit to

ground.

(2) Connect battery negative cable. Install a

jumper wire from cavity A2 (left indicator) or cavity

B6 (cavity B7 - RHD)(right indicator) of cluster con-

nector A to a 12-volt battery feed. Lamp should light.

If OK, continue to next step. If not OK, replace bulb.(3) Disconnect battery negative cable. Check for

continuity between cavity A2 (left indicator) or cavity

B6 (cavity B7 - RHD)(right indicator) of cluster con-

nector A and cavity A1 (cavity 11 - RHD)(left front

turn signal) or cavity F2 (cavity 10 - RHD)(right

front turn signal) of bulkhead disconnect (dash to in-

strument panel connector B - RHD). There should be

continuity. If OK, refer to Group 8J - Turn Signal

and Hazard Warning Systems for further diagnosis.

If not OK, repair open circuit as required.

UPSHIFT INDICATOR LAMP

(1) Disconnect battery negative cable. Unplug PCM

connector. Connect battery negative cable. Turn igni-

tion switch to ON. Install a jumper wire from cavity

54 of PCM connector (Fig. 5) to a good ground. Lamp

should light. Remove jumper from ground. Lamp

should go off. If OK, refer to Powertrain Diagnostic

Procedures manual to diagnose PCM. If not OK, turn

ignition switch to OFF and go to next step.

(2) Disconnect battery negative cable. Remove in-

strument cluster bezel and cluster assembly. Install a

jumper wire from cavity 7 of cluster (tell-tale) con-

nector B to a good ground. Connect battery negative

cable. Turn ignition switch to ON. Lamp should light.

If OK, go to next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug cluster connector B. Check for

continuity between cavity 7 of cluster connector B

and a good ground. There should be no continuity. If

OK, go to next step. If not OK, repair short circuit as

required.

(4) Check for continuity between cavity 7 of cluster

connector B and cavity 54 of PCM connector. There

should be continuity. If not OK, repair open circuit as

required.

Fig. 7 Chime/Buzzer Module Receptacle

JINSTRUMENT PANEL AND GAUGESÐXJ 8E - 15

Page 396 of 2198

(9) Apply a rubberized undercoating material to

the splash panel screws.

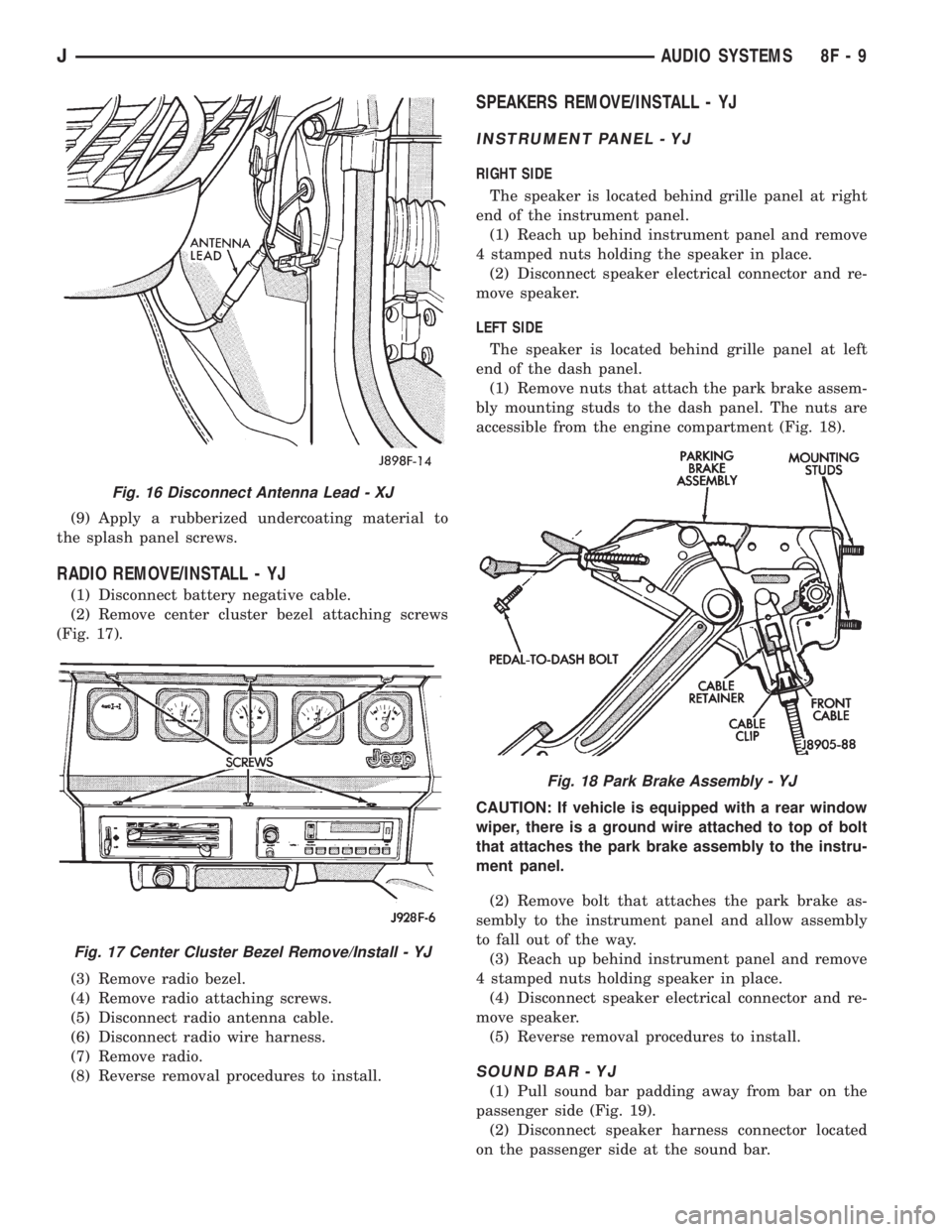

RADIO REMOVE/INSTALL - YJ

(1) Disconnect battery negative cable.

(2) Remove center cluster bezel attaching screws

(Fig. 17).

(3) Remove radio bezel.

(4) Remove radio attaching screws.

(5) Disconnect radio antenna cable.

(6) Disconnect radio wire harness.

(7) Remove radio.

(8) Reverse removal procedures to install.

SPEAKERS REMOVE/INSTALL - YJ

INSTRUMENT PANEL - YJ

RIGHT SIDE

The speaker is located behind grille panel at right

end of the instrument panel.

(1) Reach up behind instrument panel and remove

4 stamped nuts holding the speaker in place.

(2) Disconnect speaker electrical connector and re-

move speaker.

LEFT SIDE

The speaker is located behind grille panel at left

end of the dash panel.

(1) Remove nuts that attach the park brake assem-

bly mounting studs to the dash panel. The nuts are

accessible from the engine compartment (Fig. 18).

CAUTION: If vehicle is equipped with a rear window

wiper, there is a ground wire attached to top of bolt

that attaches the park brake assembly to the instru-

ment panel.

(2) Remove bolt that attaches the park brake as-

sembly to the instrument panel and allow assembly

to fall out of the way.

(3) Reach up behind instrument panel and remove

4 stamped nuts holding speaker in place.

(4) Disconnect speaker electrical connector and re-

move speaker.

(5) Reverse removal procedures to install.

SOUND BAR - YJ

(1) Pull sound bar padding away from bar on the

passenger side (Fig. 19).

(2) Disconnect speaker harness connector located

on the passenger side at the sound bar.

Fig. 16 Disconnect Antenna Lead - XJ

Fig. 17 Center Cluster Bezel Remove/Install - YJ

Fig. 18 Park Brake Assembly - YJ

JAUDIO SYSTEMS 8F - 9

Page 410 of 2198

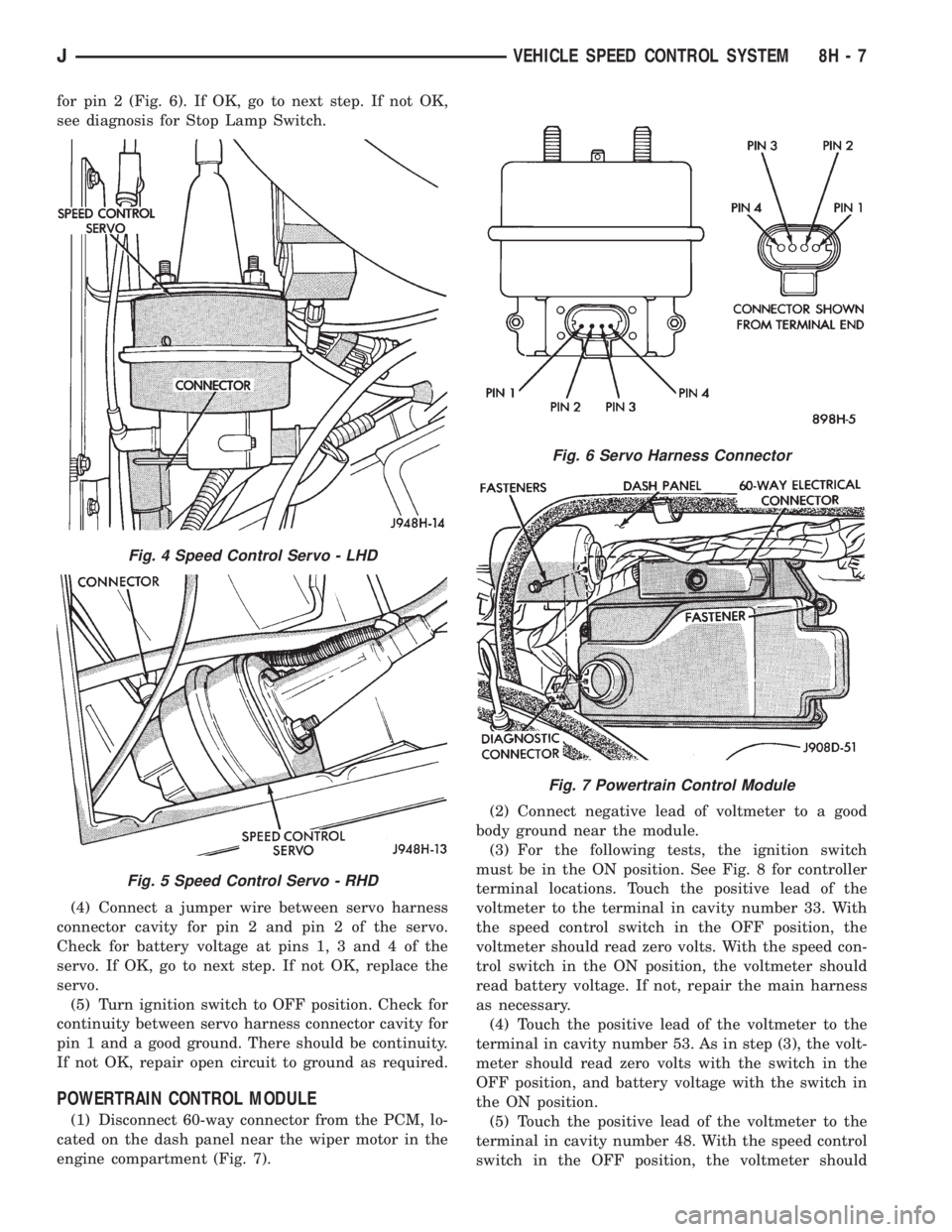

for pin 2 (Fig. 6). If OK, go to next step. If not OK,

see diagnosis for Stop Lamp Switch.

(4) Connect a jumper wire between servo harness

connector cavity for pin 2 and pin 2 of the servo.

Check for battery voltage at pins 1, 3 and 4 of the

servo. If OK, go to next step. If not OK, replace the

servo.

(5) Turn ignition switch to OFF position. Check for

continuity between servo harness connector cavity for

pin 1 and a good ground. There should be continuity.

If not OK, repair open circuit to ground as required.

POWERTRAIN CONTROL MODULE

(1) Disconnect 60-way connector from the PCM, lo-

cated on the dash panel near the wiper motor in the

engine compartment (Fig. 7).(2) Connect negative lead of voltmeter to a good

body ground near the module.

(3) For the following tests, the ignition switch

must be in the ON position. See Fig. 8 for controller

terminal locations. Touch the positive lead of the

voltmeter to the terminal in cavity number 33. With

the speed control switch in the OFF position, the

voltmeter should read zero volts. With the speed con-

trol switch in the ON position, the voltmeter should

read battery voltage. If not, repair the main harness

as necessary.

(4) Touch the positive lead of the voltmeter to the

terminal in cavity number 53. As in step (3), the volt-

meter should read zero volts with the switch in the

OFF position, and battery voltage with the switch in

the ON position.

(5) Touch the positive lead of the voltmeter to the

terminal in cavity number 48. With the speed control

switch in the OFF position, the voltmeter should

Fig. 4 Speed Control Servo - LHD

Fig. 5 Speed Control Servo - RHD

Fig. 6 Servo Harness Connector

Fig. 7 Powertrain Control Module

JVEHICLE SPEED CONTROL SYSTEM 8H - 7

Page 462 of 2198

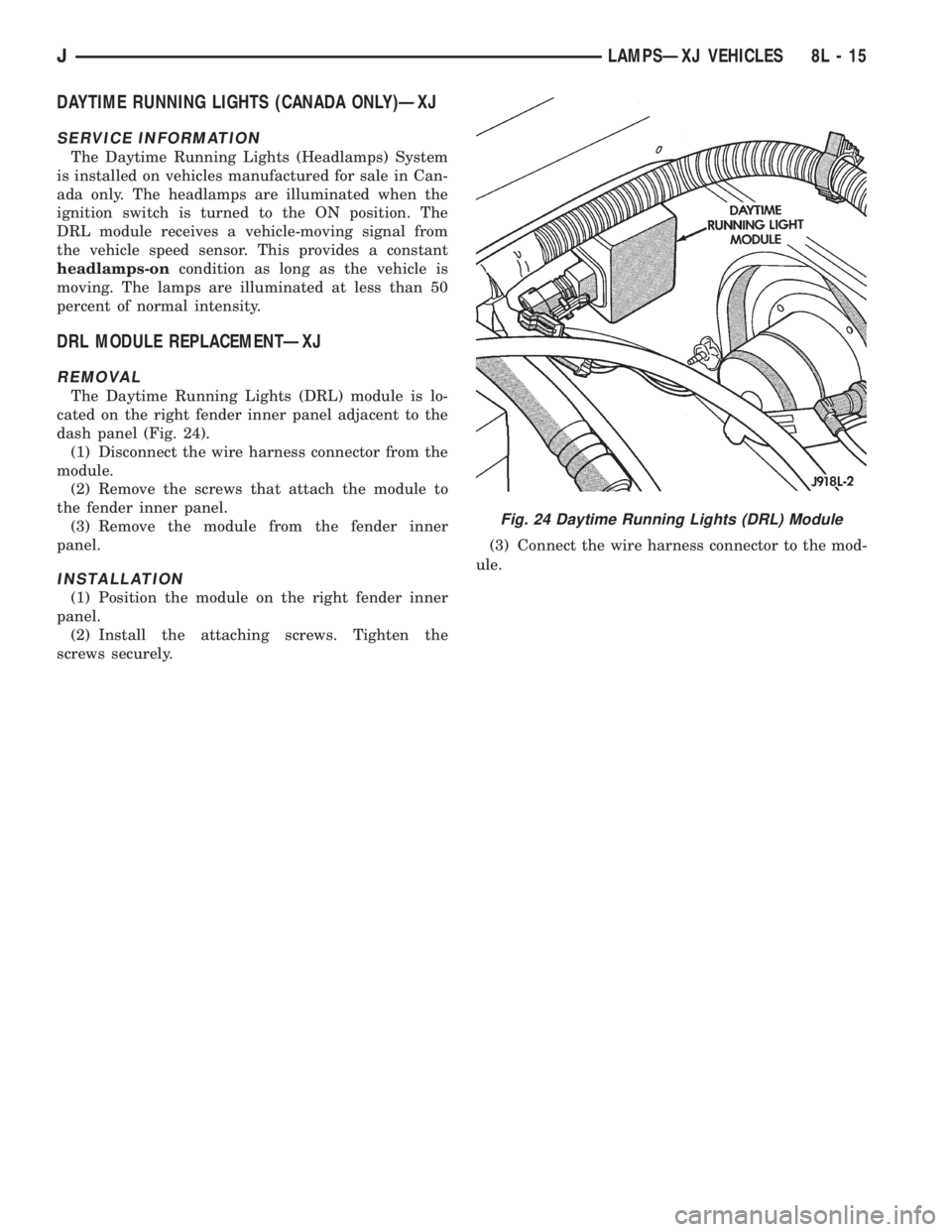

DAYTIME RUNNING LIGHTS (CANADA ONLY)ÐXJ

SERVICE INFORMATION

The Daytime Running Lights (Headlamps) System

is installed on vehicles manufactured for sale in Can-

ada only. The headlamps are illuminated when the

ignition switch is turned to the ON position. The

DRL module receives a vehicle-moving signal from

the vehicle speed sensor. This provides a constant

headlamps-oncondition as long as the vehicle is

moving. The lamps are illuminated at less than 50

percent of normal intensity.

DRL MODULE REPLACEMENTÐXJ

REMOVAL

The Daytime Running Lights (DRL) module is lo-

cated on the right fender inner panel adjacent to the

dash panel (Fig. 24).

(1) Disconnect the wire harness connector from the

module.

(2) Remove the screws that attach the module to

the fender inner panel.

(3) Remove the module from the fender inner

panel.

INSTALLATION

(1) Position the module on the right fender inner

panel.

(2) Install the attaching screws. Tighten the

screws securely.(3) Connect the wire harness connector to the mod-

ule.

Fig. 24 Daytime Running Lights (DRL) Module

JLAMPSÐXJ VEHICLES 8L - 15

Page 780 of 2198

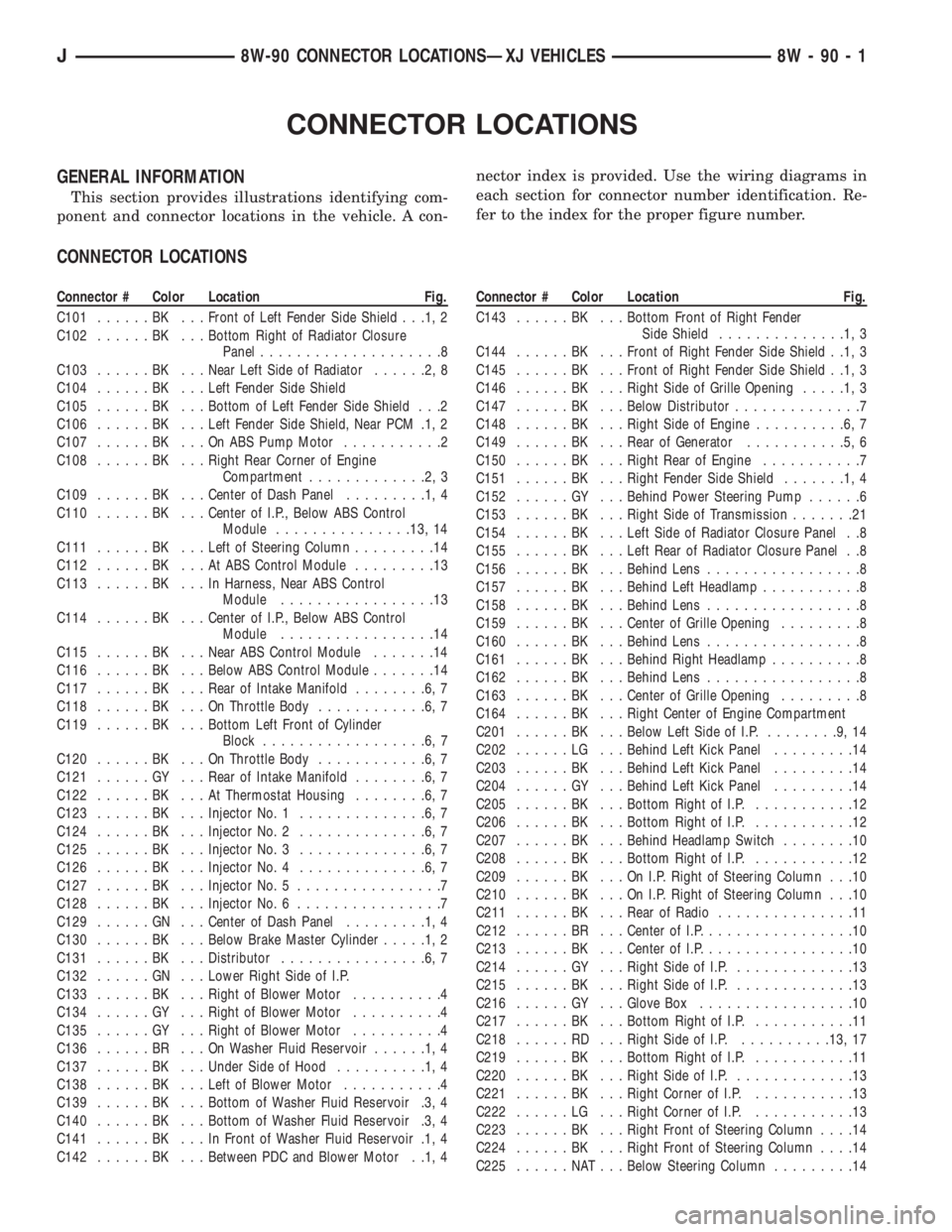

CONNECTOR LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying com-

ponent and connector locations in the vehicle. A con-nector index is provided. Use the wiring diagrams in

each section for connector number identification. Re-

fer to the index for the proper figure number.

CONNECTOR LOCATIONS

Connector # Color Location Fig.

C101......BK ...Front of Left Fender Side Shield . . .1, 2

C102......BK ...Bottom Right of Radiator Closure

Panel....................8

C103......BK ...Near Left Side of Radiator......2,8

C104......BK ...Left Fender Side Shield

C105......BK ...Bottom of Left Fender Side Shield . . .2

C106......BK ...Left Fender Side Shield, Near PCM .1, 2

C107......BK ...OnABSPump Motor...........2

C108......BK ...Right Rear Corner of Engine

Compartment.............2,3

C109......BK ...Center of Dash Panel.........1,4

C110......BK ...Center of I.P., Below ABS Control

Module...............13, 14

C111......BK ...Left of Steering Column.........14

C112......BK ...AtABSControl Module.........13

C113......BK ...InHarness, Near ABS Control

Module.................13

C114......BK ...Center of I.P., Below ABS Control

Module.................14

C115......BK ...Near ABS Control Module.......14

C116......BK ...Below ABS Control Module.......14

C117......BK ...Rear of Intake Manifold........6,7

C118......BK ...OnThrottle Body............6,7

C119......BK ...Bottom Left Front of Cylinder

Block..................6,7

C120......BK ...OnThrottle Body............6,7

C121......GY ...Rear of Intake Manifold........6,7

C122......BK ...AtThermostat Housing........6,7

C123......BK ...Injector No. 1..............6,7

C124......BK ...Injector No. 2..............6,7

C125......BK ...Injector No. 3..............6,7

C126......BK ...Injector No. 4..............6,7

C127......BK ...Injector No. 5................7

C128......BK ...Injector No. 6................7

C129......GN ...Center of Dash Panel.........1,4

C130......BK ...Below Brake Master Cylinder.....1,2

C131......BK ...Distributor................6,7

C132......GN ...Lower Right Side of I.P.

C133......BK ...Right of Blower Motor..........4

C134......GY ...Right of Blower Motor..........4

C135......GY ...Right of Blower Motor..........4

C136......BR ...OnWasher Fluid Reservoir......1,4

C137......BK ...Under Side of Hood..........1,4

C138......BK ...Left of Blower Motor...........4

C139......BK ...Bottom of Washer Fluid Reservoir .3, 4

C140......BK ...Bottom of Washer Fluid Reservoir .3, 4

C141......BK ...InFront of Washer Fluid Reservoir .1, 4

C142......BK ...Between PDC and Blower Motor . .1, 4Connector # Color Location Fig.

C143......BK ...Bottom Front of Right Fender

Side Shield..............1,3

C144......BK ...Front of Right Fender Side Shield . .1, 3

C145......BK ...Front of Right Fender Side Shield . .1, 3

C146......BK ...Right Side of Grille Opening.....1,3

C147......BK ...Below Distributor..............7

C148......BK ...Right Side of Engine..........6,7

C149......BK ...Rear of Generator...........5,6

C150......BK ...Right Rear of Engine...........7

C151......BK ...Right Fender Side Shield.......1,4

C152......GY ...Behind Power Steering Pump......6

C153......BK ...Right Side of Transmission.......21

C154......BK ...Left Side of Radiator Closure Panel . .8

C155......BK ...Left Rear of Radiator Closure Panel . .8

C156......BK ...Behind Lens.................8

C157......BK ...Behind Left Headlamp...........8

C158......BK ...Behind Lens.................8

C159......BK ...Center of Grille Opening.........8

C160......BK ...Behind Lens.................8

C161......BK ...Behind Right Headlamp..........8

C162......BK ...Behind Lens.................8

C163......BK ...Center of Grille Opening.........8

C164......BK ...Right Center of Engine Compartment

C201......BK ...Below Left Side of I.P.........9,14

C202......LG ...Behind Left Kick Panel.........14

C203......BK ...Behind Left Kick Panel.........14

C204......GY ...Behind Left Kick Panel.........14

C205......BK ...Bottom Right of I.P............12

C206......BK ...Bottom Right of I.P............12

C207......BK ...Behind Headlamp Switch........10

C208......BK ...Bottom Right of I.P............12

C209......BK ...OnI.P.Right of Steering Column . . .10

C210......BK ...OnI.P.Right of Steering Column . . .10

C211......BK ...Rear of Radio...............11

C212......BR ...Center of I.P.................10

C213......BK ...Center of I.P.................10

C214......GY ...Right Side of I.P..............13

C215......BK ...Right Side of I.P..............13

C216......GY ...Glove Box.................10

C217......BK ...Bottom Right of I.P............11

C218......RD ...Right Side of I.P...........13, 17

C219......BK ...Bottom Right of I.P............11

C220......BK ...Right Side of I.P..............13

C221......BK ...Right Corner of I.P............13

C222......LG ...Right Corner of I.P............13

C223......BK ...Right Front of Steering Column....14

C224......BK ...Right Front of Steering Column....14

C225......NAT...Below Steering Column.........14

J8W-90 CONNECTOR LOCATIONSÐXJ VEHICLES 8W - 90 - 1

Page 804 of 2198

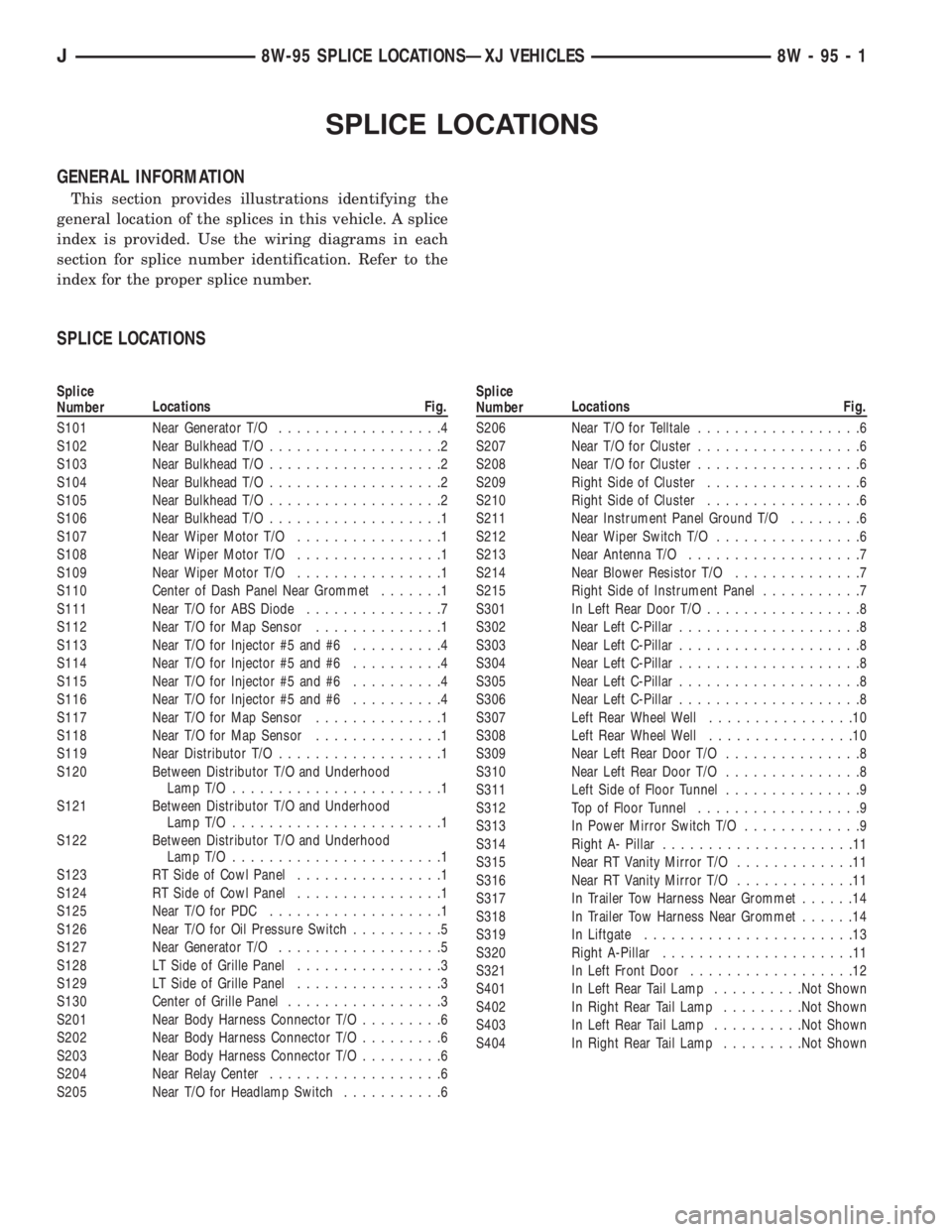

SPLICE LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying the

general location of the splices in this vehicle. A splice

index is provided. Use the wiring diagrams in each

section for splice number identification. Refer to the

index for the proper splice number.

SPLICE LOCATIONS

Splice

NumberLocations Fig.

S101 Near Generator T/O..................4

S102 Near Bulkhead T/O...................2

S103 Near Bulkhead T/O...................2

S104 Near Bulkhead T/O...................2

S105 Near Bulkhead T/O...................2

S106 Near Bulkhead T/O...................1

S107 Near Wiper Motor T/O................1

S108 Near Wiper Motor T/O................1

S109 Near Wiper Motor T/O................1

S110 Center of Dash Panel Near Grommet.......1

S111 Near T/O for ABS Diode...............7

S112 Near T/O for Map Sensor..............1

S113 Near T/O for Injector #5 and #6..........4

S114 Near T/O for Injector #5 and #6..........4

S115 Near T/O for Injector #5 and #6..........4

S116 Near T/O for Injector #5 and #6..........4

S117 Near T/O for Map Sensor..............1

S118 Near T/O for Map Sensor..............1

S119 Near Distributor T/O..................1

S120 Between Distributor T/O and Underhood

Lamp T/O.......................1

S121 Between Distributor T/O and Underhood

Lamp T/O.......................1

S122 Between Distributor T/O and Underhood

Lamp T/O.......................1

S123 RT Side of Cowl Panel................1

S124 RT Side of Cowl Panel................1

S125 Near T/O for PDC...................1

S126 Near T/O for Oil Pressure Switch..........5

S127 Near Generator T/O..................5

S128 LT Side of Grille Panel................3

S129 LT Side of Grille Panel................3

S130 Center of Grille Panel.................3

S201 Near Body Harness Connector T/O.........6

S202 Near Body Harness Connector T/O.........6

S203 Near Body Harness Connector T/O.........6

S204 Near Relay Center...................6

S205 Near T/O for Headlamp Switch...........6Splice

NumberLocations Fig.

S206 Near T/O for Telltale..................6

S207 Near T/O for Cluster..................6

S208 Near T/O for Cluster..................6

S209 Right Side of Cluster.................6

S210 Right Side of Cluster.................6

S211 Near Instrument Panel Ground T/O........6

S212 Near Wiper Switch T/O................6

S213 Near Antenna T/O...................7

S214 Near Blower Resistor T/O..............7

S215 Right Side of Instrument Panel...........7

S301 In Left Rear Door T/O.................8

S302 Near Left C-Pillar....................8

S303 Near Left C-Pillar....................8

S304 Near Left C-Pillar....................8

S305 Near Left C-Pillar....................8

S306 Near Left C-Pillar....................8

S307 Left Rear Wheel Well................10

S308 Left Rear Wheel Well................10

S309 Near Left Rear Door T/O...............8

S310 Near Left Rear Door T/O...............8

S311 Left Side of Floor Tunnel...............9

S312 Top of Floor Tunnel..................9

S313 In Power Mirror Switch T/O.............9

S314 Right A- Pillar.....................11

S315 Near RT Vanity Mirror T/O.............11

S316 Near RT Vanity Mirror T/O.............11

S317 In Trailer Tow Harness Near Grommet......14

S318 In Trailer Tow Harness Near Grommet......14

S319 In Liftgate.......................13

S320 Right A-Pillar.....................11

S321 In Left Front Door..................12

S401 In Left Rear Tail Lamp..........Not Shown

S402 In Right Rear Tail Lamp.........Not Shown

S403 In Left Rear Tail Lamp..........Not Shown

S404 In Right Rear Tail Lamp.........Not Shown

J8W-95 SPLICE LOCATIONSÐXJ VEHICLES 8W - 95 - 1

Page 1064 of 2198

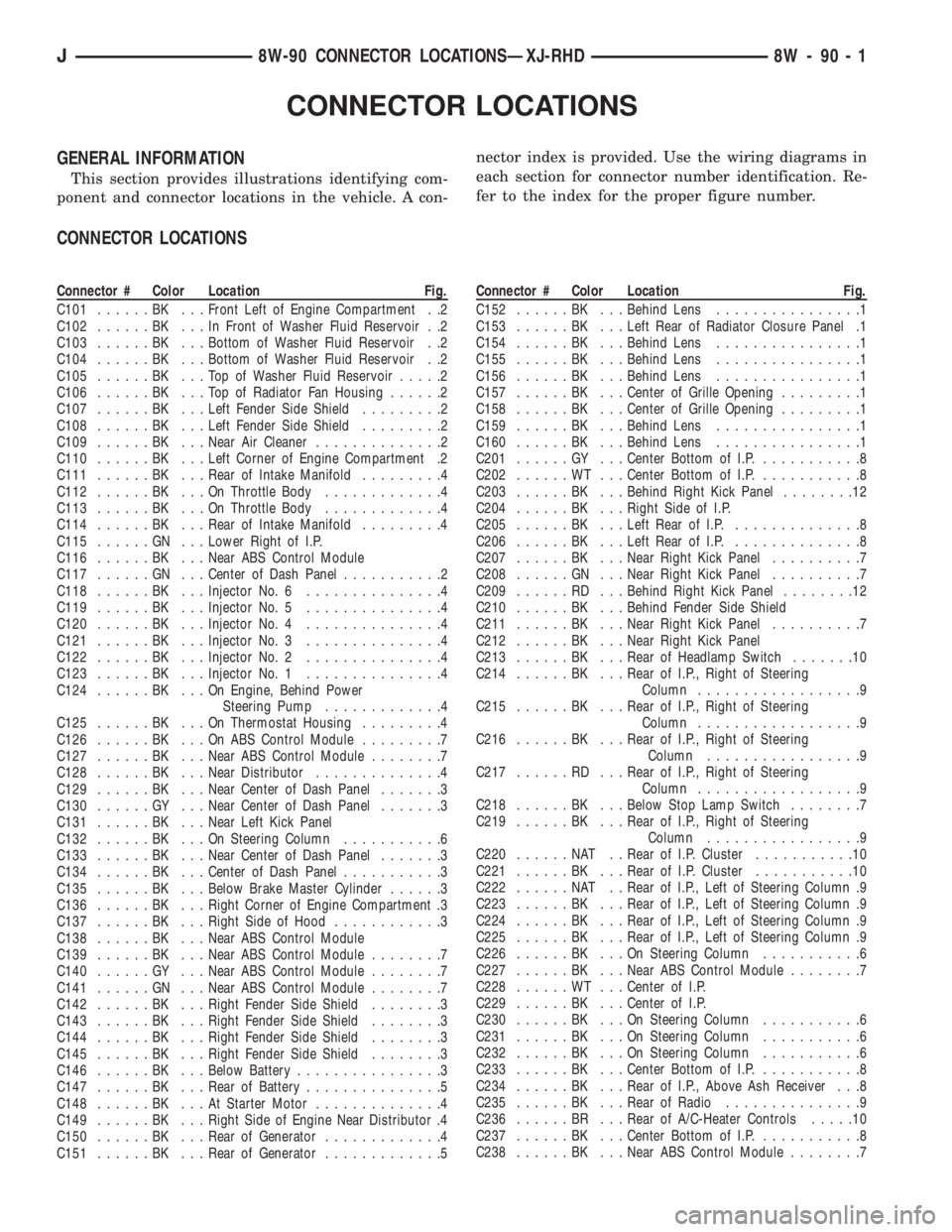

CONNECTOR LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying com-

ponent and connector locations in the vehicle. A con-nector index is provided. Use the wiring diagrams in

each section for connector number identification. Re-

fer to the index for the proper figure number.

CONNECTOR LOCATIONS

Connector # Color Location Fig.

C101......BK ...Front Left of Engine Compartment . .2

C102......BK ...InFront of Washer Fluid Reservoir . .2

C103......BK ...Bottom of Washer Fluid Reservoir . .2

C104......BK ...Bottom of Washer Fluid Reservoir . .2

C105......BK ...TopofWasher Fluid Reservoir.....2

C106......BK ...TopofRadiator Fan Housing......2

C107......BK ...Left Fender Side Shield.........2

C108......BK ...Left Fender Side Shield.........2

C109......BK ...Near Air Cleaner..............2

C110......BK ...Left Corner of Engine Compartment .2

C111......BK ...Rear of Intake Manifold.........4

C112......BK ...OnThrottle Body.............4

C113......BK ...OnThrottle Body.............4

C114......BK ...Rear of Intake Manifold.........4

C115......GN ...Lower Right of I.P.

C116......BK ...Near ABS Control Module

C117......GN ...Center of Dash Panel...........2

C118......BK ...Injector No. 6...............4

C119......BK ...Injector No. 5...............4

C120......BK ...Injector No. 4...............4

C121......BK ...Injector No. 3...............4

C122......BK ...Injector No. 2...............4

C123......BK ...Injector No. 1...............4

C124......BK ...OnEngine, Behind Power

Steering Pump.............4

C125......BK ...OnThermostat Housing.........4

C126......BK ...OnABSControl Module.........7

C127......BK ...Near ABS Control Module........7

C128......BK ...Near Distributor..............4

C129......BK ...Near Center of Dash Panel.......3

C130......GY ...Near Center of Dash Panel.......3

C131......BK ...Near Left Kick Panel

C132......BK ...OnSteering Column...........6

C133......BK ...Near Center of Dash Panel.......3

C134......BK ...Center of Dash Panel...........3

C135......BK ...Below Brake Master Cylinder......3

C136......BK ...Right Corner of Engine Compartment .3

C137......BK ...Right Side of Hood............3

C138......BK ...Near ABS Control Module

C139......BK ...Near ABS Control Module........7

C140......GY ...Near ABS Control Module........7

C141......GN ...Near ABS Control Module........7

C142......BK ...Right Fender Side Shield........3

C143......BK ...Right Fender Side Shield........3

C144......BK ...Right Fender Side Shield........3

C145......BK ...Right Fender Side Shield........3

C146......BK ...Below Battery................3

C147......BK ...Rear of Battery...............5

C148......BK ...AtStarter Motor..............4

C149......BK ...Right Side of Engine Near Distributor .4

C150......BK ...Rear of Generator.............4

C151......BK ...Rear of Generator.............5Connector # Color Location Fig.

C152......BK ...Behind Lens................1

C153......BK ...Left Rear of Radiator Closure Panel .1

C154......BK ...Behind Lens................1

C155......BK ...Behind Lens................1

C156......BK ...Behind Lens................1

C157......BK ...Center of Grille Opening.........1

C158......BK ...Center of Grille Opening.........1

C159......BK ...Behind Lens................1

C160......BK ...Behind Lens................1

C201......GY ...Center Bottom of I.P............8

C202......WT ...Center Bottom of I.P............8

C203......BK ...Behind Right Kick Panel........12

C204......BK ...Right Side of I.P.

C205......BK ...Left Rear of I.P...............8

C206......BK ...Left Rear of I.P...............8

C207......BK ...Near Right Kick Panel..........7

C208......GN ...Near Right Kick Panel..........7

C209......RD ...Behind Right Kick Panel........12

C210......BK ...Behind Fender Side Shield

C211......BK ...Near Right Kick Panel..........7

C212......BK ...Near Right Kick Panel

C213......BK ...Rear of Headlamp Switch.......10

C214......BK ...Rear of I.P., Right of Steering

Column..................9

C215......BK ...Rear of I.P., Right of Steering

Column..................9

C216......BK ...Rear of I.P., Right of Steering

Column.................9

C217......RD ...Rear of I.P., Right of Steering

Column..................9

C218......BK ...Below Stop Lamp Switch........7

C219......BK ...Rear of I.P., Right of Steering

Column.................9

C220......NAT ..Rear of I.P. Cluster...........10

C221......BK ...Rear of I.P. Cluster...........10

C222......NAT ..Rear of I.P., Left of Steering Column .9

C223......BK ...Rear of I.P., Left of Steering Column .9

C224......BK ...Rear of I.P., Left of Steering Column .9

C225......BK ...Rear of I.P., Left of Steering Column .9

C226......BK ...OnSteering Column...........6

C227......BK ...Near ABS Control Module........7

C228......WT ...Center of I.P.

C229......BK ...Center of I.P.

C230......BK ...OnSteering Column...........6

C231......BK ...OnSteering Column...........6

C232......BK ...OnSteering Column...........6

C233......BK ...Center Bottom of I.P............8

C234......BK ...Rear of I.P., Above Ash Receiver . . .8

C235......BK ...Rear of Radio...............9

C236......BR ...Rear of A/C-Heater Controls.....10

C237......BK ...Center Bottom of I.P............8

C238......BK ...Near ABS Control Module........7

J8W-90 CONNECTOR LOCATIONSÐXJ-RHD 8W - 90 - 1

Page 1151 of 2198

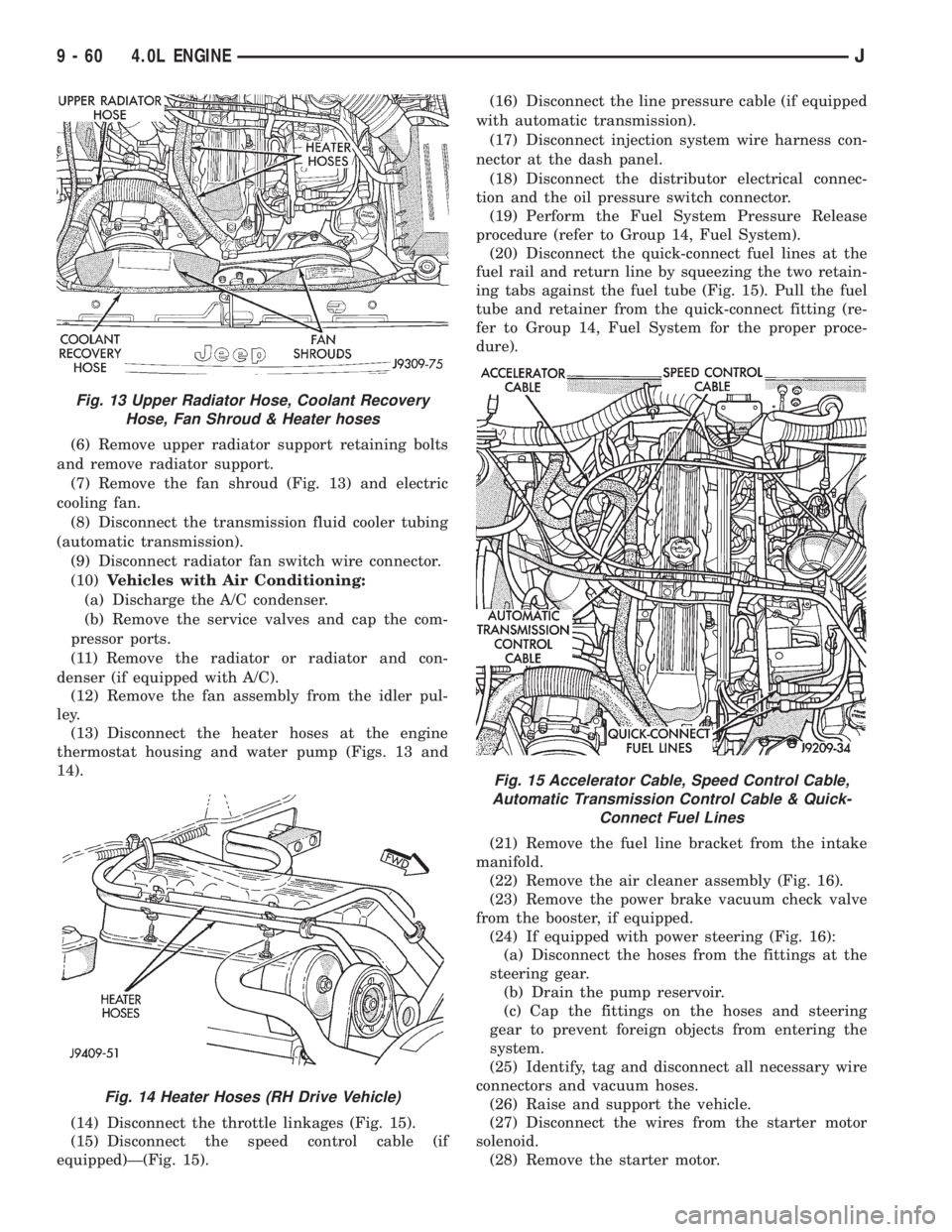

(6) Remove upper radiator support retaining bolts

and remove radiator support.

(7) Remove the fan shroud (Fig. 13) and electric

cooling fan.

(8) Disconnect the transmission fluid cooler tubing

(automatic transmission).

(9) Disconnect radiator fan switch wire connector.

(10)Vehicles with Air Conditioning:

(a) Discharge the A/C condenser.

(b) Remove the service valves and cap the com-

pressor ports.

(11) Remove the radiator or radiator and con-

denser (if equipped with A/C).

(12) Remove the fan assembly from the idler pul-

ley.

(13) Disconnect the heater hoses at the engine

thermostat housing and water pump (Figs. 13 and

14).

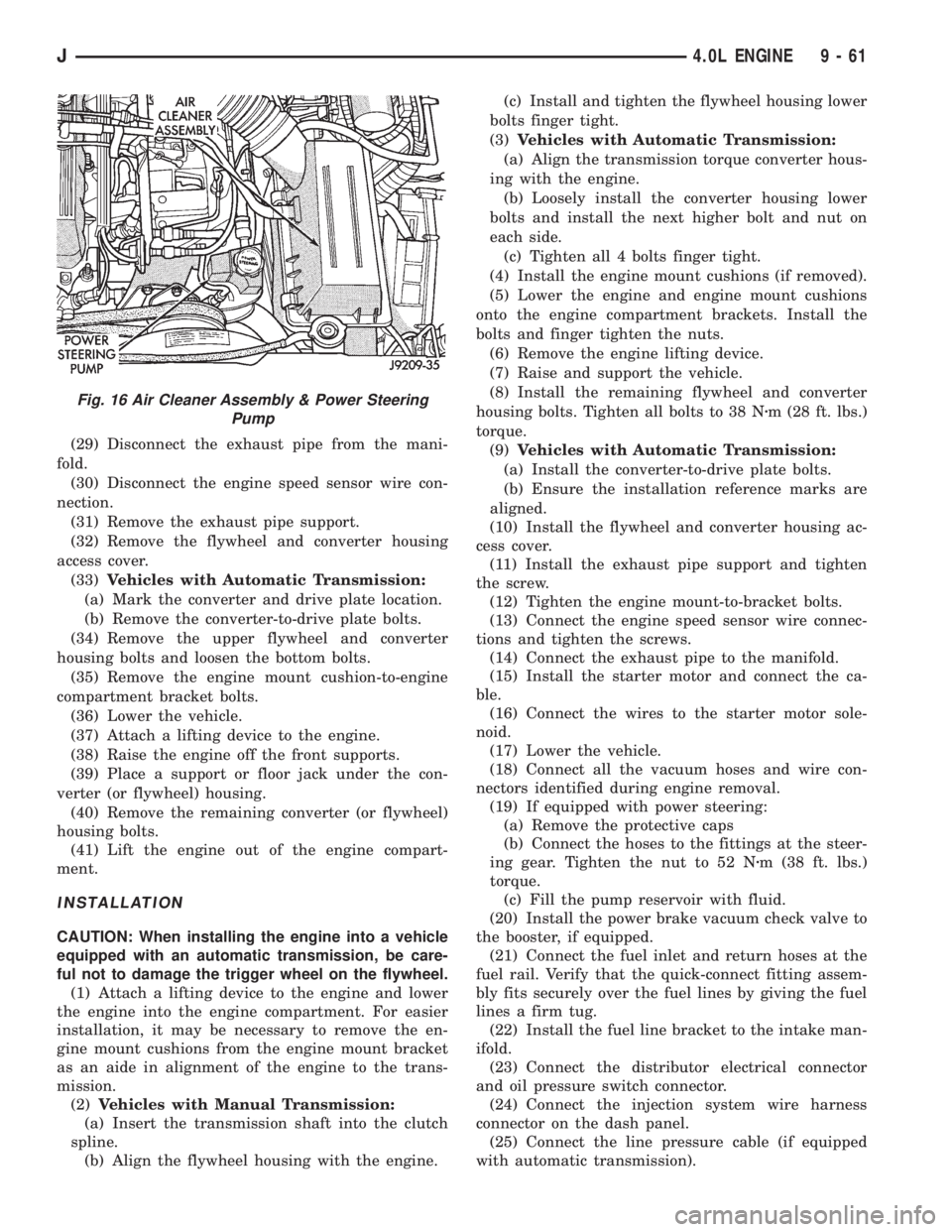

(14) Disconnect the throttle linkages (Fig. 15).

(15) Disconnect the speed control cable (if

equipped)Ð(Fig. 15).(16) Disconnect the line pressure cable (if equipped

with automatic transmission).

(17) Disconnect injection system wire harness con-

nector at the dash panel.

(18) Disconnect the distributor electrical connec-

tion and the oil pressure switch connector.

(19) Perform the Fuel System Pressure Release

procedure (refer to Group 14, Fuel System).

(20) Disconnect the quick-connect fuel lines at the

fuel rail and return line by squeezing the two retain-

ing tabs against the fuel tube (Fig. 15). Pull the fuel

tube and retainer from the quick-connect fitting (re-

fer to Group 14, Fuel System for the proper proce-

dure).

(21) Remove the fuel line bracket from the intake

manifold.

(22) Remove the air cleaner assembly (Fig. 16).

(23) Remove the power brake vacuum check valve

from the booster, if equipped.

(24) If equipped with power steering (Fig. 16):

(a) Disconnect the hoses from the fittings at the

steering gear.

(b) Drain the pump reservoir.

(c) Cap the fittings on the hoses and steering

gear to prevent foreign objects from entering the

system.

(25) Identify, tag and disconnect all necessary wire

connectors and vacuum hoses.

(26) Raise and support the vehicle.

(27) Disconnect the wires from the starter motor

solenoid.

(28) Remove the starter motor.

Fig. 13 Upper Radiator Hose, Coolant Recovery

Hose, Fan Shroud & Heater hoses

Fig. 14 Heater Hoses (RH Drive Vehicle)

Fig. 15 Accelerator Cable, Speed Control Cable,

Automatic Transmission Control Cable & Quick-

Connect Fuel Lines

9 - 60 4.0L ENGINEJ

Page 1152 of 2198

(29) Disconnect the exhaust pipe from the mani-

fold.

(30) Disconnect the engine speed sensor wire con-

nection.

(31) Remove the exhaust pipe support.

(32) Remove the flywheel and converter housing

access cover.

(33)Vehicles with Automatic Transmission:

(a) Mark the converter and drive plate location.

(b) Remove the converter-to-drive plate bolts.

(34) Remove the upper flywheel and converter

housing bolts and loosen the bottom bolts.

(35) Remove the engine mount cushion-to-engine

compartment bracket bolts.

(36) Lower the vehicle.

(37) Attach a lifting device to the engine.

(38) Raise the engine off the front supports.

(39) Place a support or floor jack under the con-

verter (or flywheel) housing.

(40) Remove the remaining converter (or flywheel)

housing bolts.

(41) Lift the engine out of the engine compart-

ment.

INSTALLATION

CAUTION: When installing the engine into a vehicle

equipped with an automatic transmission, be care-

ful not to damage the trigger wheel on the flywheel.

(1) Attach a lifting device to the engine and lower

the engine into the engine compartment. For easier

installation, it may be necessary to remove the en-

gine mount cushions from the engine mount bracket

as an aide in alignment of the engine to the trans-

mission.

(2)Vehicles with Manual Transmission:

(a) Insert the transmission shaft into the clutch

spline.

(b) Align the flywheel housing with the engine.(c) Install and tighten the flywheel housing lower

bolts finger tight.

(3)Vehicles with Automatic Transmission:

(a) Align the transmission torque converter hous-

ing with the engine.

(b) Loosely install the converter housing lower

bolts and install the next higher bolt and nut on

each side.

(c) Tighten all 4 bolts finger tight.

(4) Install the engine mount cushions (if removed).

(5) Lower the engine and engine mount cushions

onto the engine compartment brackets. Install the

bolts and finger tighten the nuts.

(6) Remove the engine lifting device.

(7) Raise and support the vehicle.

(8) Install the remaining flywheel and converter

housing bolts. Tighten all bolts to 38 Nzm (28 ft. lbs.)

torque.

(9)Vehicles with Automatic Transmission:

(a) Install the converter-to-drive plate bolts.

(b) Ensure the installation reference marks are

aligned.

(10) Install the flywheel and converter housing ac-

cess cover.

(11) Install the exhaust pipe support and tighten

the screw.

(12) Tighten the engine mount-to-bracket bolts.

(13) Connect the engine speed sensor wire connec-

tions and tighten the screws.

(14) Connect the exhaust pipe to the manifold.

(15) Install the starter motor and connect the ca-

ble.

(16) Connect the wires to the starter motor sole-

noid.

(17) Lower the vehicle.

(18) Connect all the vacuum hoses and wire con-

nectors identified during engine removal.

(19) If equipped with power steering:

(a) Remove the protective caps

(b) Connect the hoses to the fittings at the steer-

ing gear. Tighten the nut to 52 Nzm (38 ft. lbs.)

torque.

(c) Fill the pump reservoir with fluid.

(20) Install the power brake vacuum check valve to

the booster, if equipped.

(21) Connect the fuel inlet and return hoses at the

fuel rail. Verify that the quick-connect fitting assem-

bly fits securely over the fuel lines by giving the fuel

lines a firm tug.

(22) Install the fuel line bracket to the intake man-

ifold.

(23) Connect the distributor electrical connector

and oil pressure switch connector.

(24) Connect the injection system wire harness

connector on the dash panel.

(25) Connect the line pressure cable (if equipped

with automatic transmission).

Fig. 16 Air Cleaner Assembly & Power Steering

Pump

J4.0L ENGINE 9 - 61