JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 481 of 2198

the airbag cushion so it can discharge the gas it pro-

duces directly into the cushion. The protective cover

is fitted to the front of the airbag module and forms

a decorative cover in the center of the steering wheel.

Upon airbag deployment, this cover will split hori-

zontally.

STORAGE

The airbag module must be stored in its original,

special container until used for service. Also, it must

be stored in a clean, dry environment; away from

sources of extreme heat, sparks, and high electrical

energy. Always place or store the module on a surface

with the trim cover facing up to minimize movement

in case of accidental deployment.

IMPACT SENSOR/INFLATOR ASSEMBLY

The impact sensor/inflator assembly is mounted to

the back of the airbag module. It seals the hole in

the steering wheel side of the airbag cushion so that

gas produced in the inflator can be discharged di-

rectly into the cushion.

The impact sensor provides verification of the di-

rection and severity of the impact. A spherical sens-

ing mass housed in a cylinder will move forward and

rotate a D-shaft when the vehicle is subjected to a

frontal impact of sufficient severity. Airbag inflation

is designed to occur at a precisely calibrated vehicle

deceleration force, and is not linked to vehicle road

speed.The D-shaft retains two spring-loaded firing pins.

When a firing pin is released by the D-shaft, it

strikes and ignites a primer. The primer then reacts

with the pelletized, solid generant contained in the

inflator to produce the nitrogen gas that inflates the

airbag cushion.

ARMING/DISARMING MECHANISM

The steering wheel hub incorporates an airbag

arming/disarming mechanism and a specially de-

signed nut-blocker. The nut-blocker serves as a safety

to prevent removal of the airbag module until the

unit has been disarmed. A removable plastic cover

plug on the top, outer hub of the steering wheel al-

lows access to the arming screw.

When the airbag module is disarmed, the arming

screw extends upward from the steering wheel hub.

This will prevent installation of the plastic cover

plug. Also, the nut-blocker is retracted to allow ac-

cess to the two upper airbag module mounting nuts.

When the airbag module is armed, the plastic cover

plug will install flush with the outer surface of the

steering wheel hub. In addition, the nut-blocker will

prevent access to the two upper airbag module

mounting nuts.

DIAGNOSIS

This mechanical airbag system can not be diag-

nosed or repaired. The only serviced component is

the airbag module assembly. If the airbag module isdamaged in any way or deployed, it must be re-

placed.

SERVICE PROCEDURES

AIRBAG SYSTEM SERVICE (DEPLOYED)

Any vehicle which is to be returned to use after an

airbag deployment, must have the airbag module re-

placed. This is a one-time component and cannot be

reused.

AIRBAG MODULE HANDLING

UNDEPLOYED

At no time should any source of electricity be per-

mitted near the inflator on the back of the module.

When carrying an undeployed module, the trim cover

should be pointed away from the body to minimizeinjury in the event of accidental deployment. If the

module is placed on a bench or other surface, the

plastic trim cover should be face up to minimize

movement in case of accidental deployment.

In addition, the airbag module should be disarmed

whenever the steering wheel or steering column re-

quires service or removal. Failure to observe this

warning could result in accidental airbag deployment

and possible personal injury. Refer to Group 19 -

Steering for more service procedures on steering

wheel and steering column.

8M - 2 RESTRAINT SYSTEMSJ

Page 482 of 2198

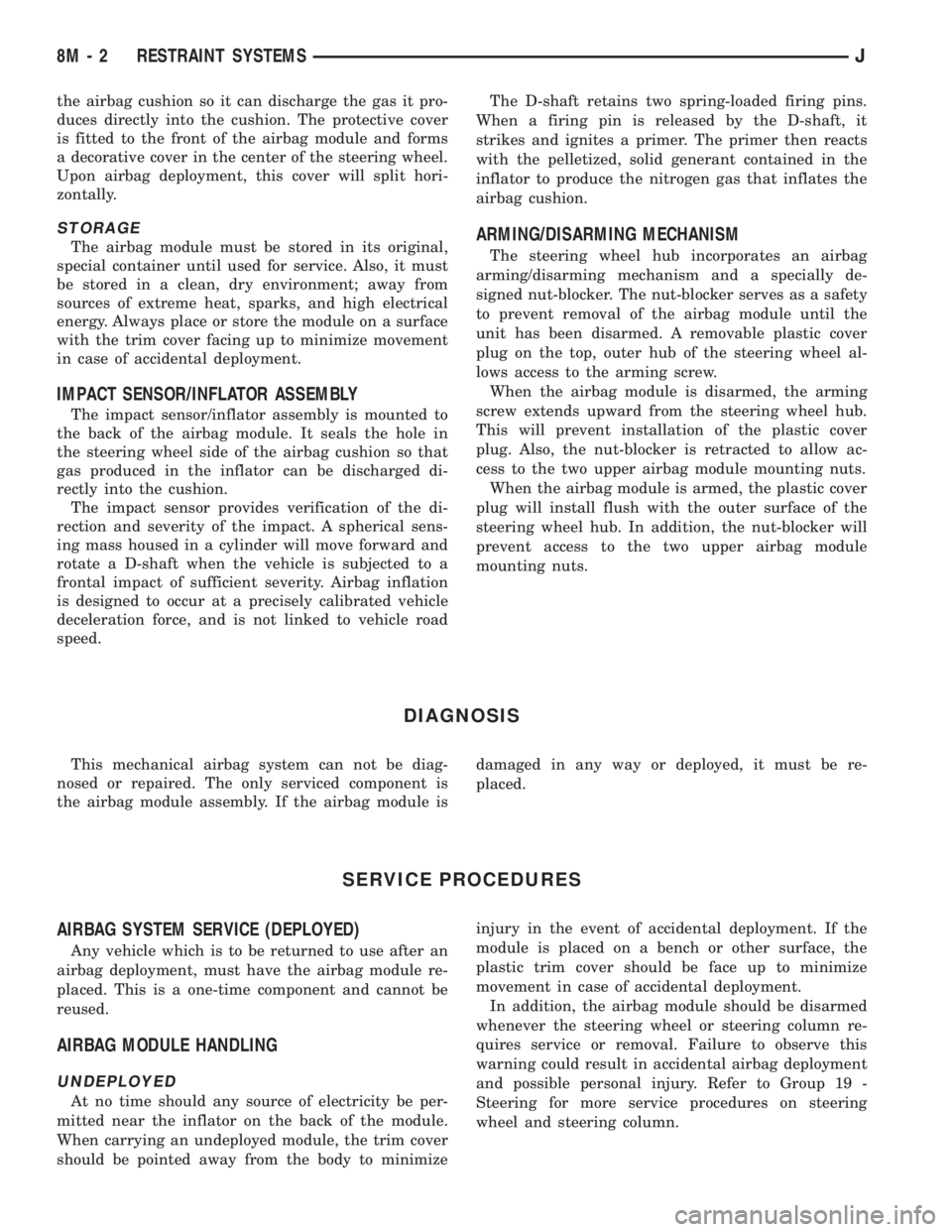

DEPLOYED

Following an airbag deployment, the vehicle inte-

rior will contain a powdery residue. This residue is

primarily sodium bicarbonate (baking soda), used as

an airbag cushion lubricant. However, there will also

be traces of sodium hydroxide powder, a chemical

byproduct of the generant used for airbag deploy-

ment. Since this powder can irritate the skin, eyes,

nose or throat, be sure to wear safety glasses, rubber

gloves and a long-sleeved shirt during cleanup (Fig.

1).

If you experience skin irritation during

cleanup, run cool water over the affected area.

Also, if you experience irritation of the nose or

throat, exit the vehicle for fresh air until the ir-

ritation ceases. If irritation continues, see a

physician.

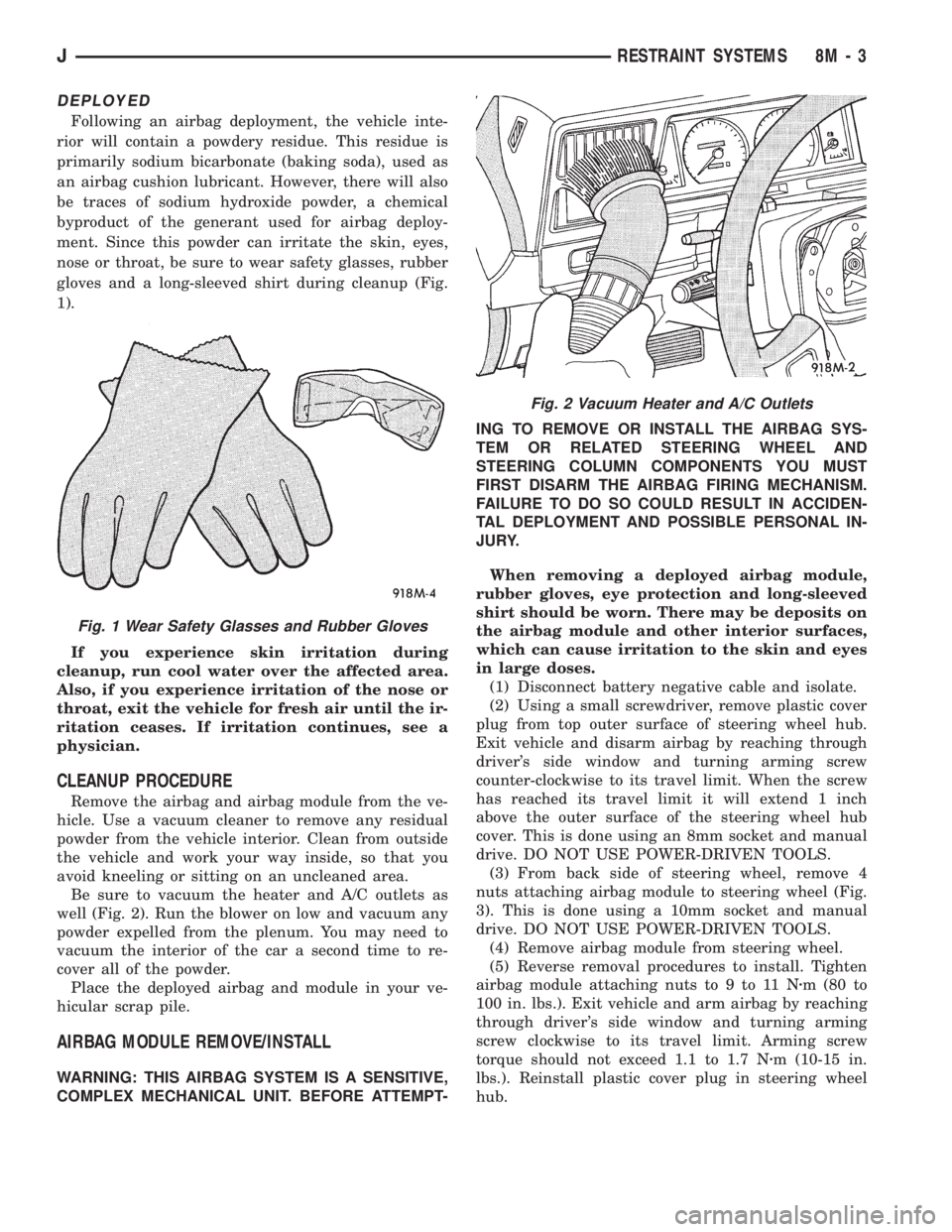

CLEANUP PROCEDURE

Remove the airbag and airbag module from the ve-

hicle. Use a vacuum cleaner to remove any residual

powder from the vehicle interior. Clean from outside

the vehicle and work your way inside, so that you

avoid kneeling or sitting on an uncleaned area.

Be sure to vacuum the heater and A/C outlets as

well (Fig. 2). Run the blower on low and vacuum any

powder expelled from the plenum. You may need to

vacuum the interior of the car a second time to re-

cover all of the powder.

Place the deployed airbag and module in your ve-

hicular scrap pile.

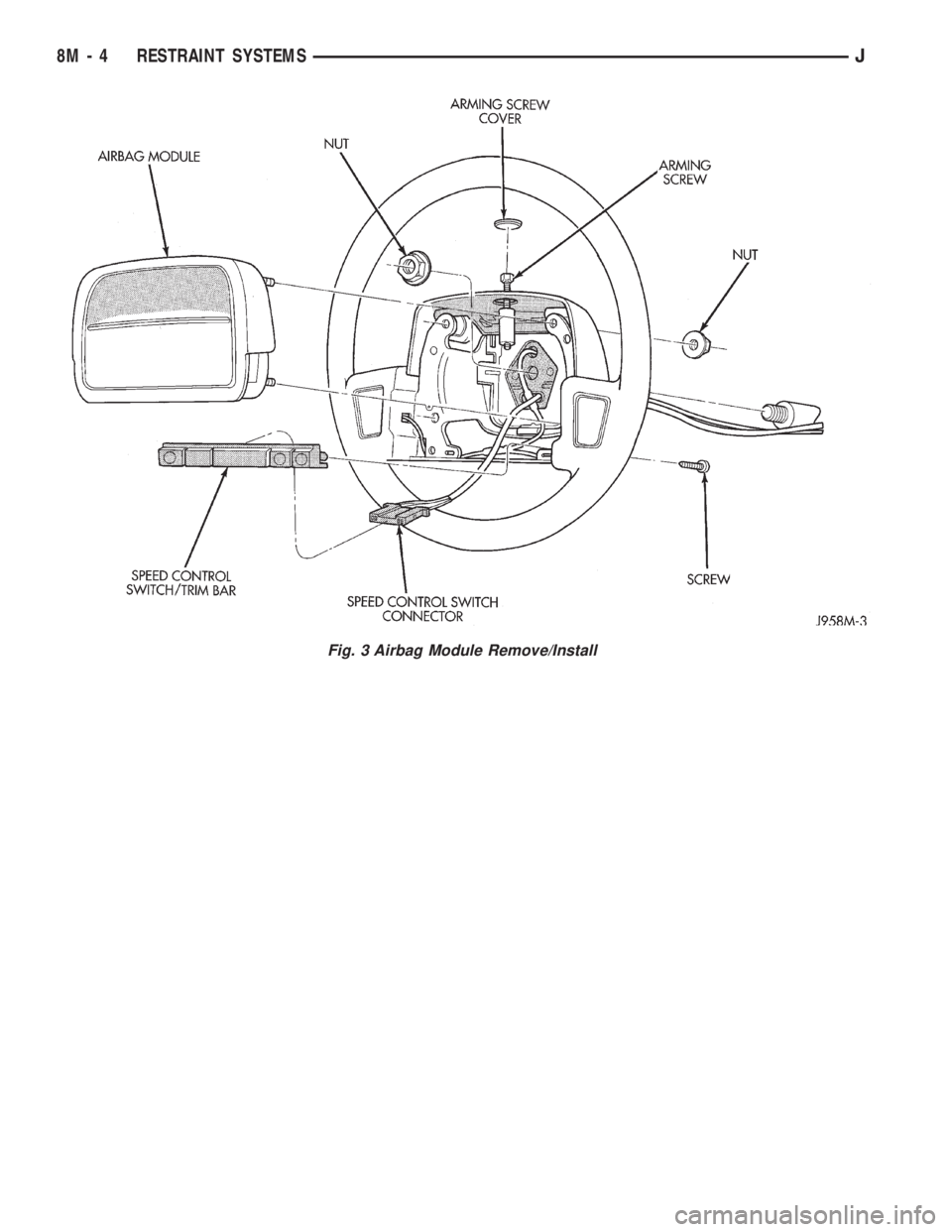

AIRBAG MODULE REMOVE/INSTALL

WARNING: THIS AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX MECHANICAL UNIT. BEFORE ATTEMPT-ING TO REMOVE OR INSTALL THE AIRBAG SYS-

TEM OR RELATED STEERING WHEEL AND

STEERING COLUMN COMPONENTS YOU MUST

FIRST DISARM THE AIRBAG FIRING MECHANISM.

FAILURE TO DO SO COULD RESULT IN ACCIDEN-

TAL DEPLOYMENT AND POSSIBLE PERSONAL IN-

JURY.

When removing a deployed airbag module,

rubber gloves, eye protection and long-sleeved

shirt should be worn. There may be deposits on

the airbag module and other interior surfaces,

which can cause irritation to the skin and eyes

in large doses.

(1) Disconnect battery negative cable and isolate.

(2) Using a small screwdriver, remove plastic cover

plug from top outer surface of steering wheel hub.

Exit vehicle and disarm airbag by reaching through

driver's side window and turning arming screw

counter-clockwise to its travel limit. When the screw

has reached its travel limit it will extend 1 inch

above the outer surface of the steering wheel hub

cover. This is done using an 8mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

(3) From back side of steering wheel, remove 4

nuts attaching airbag module to steering wheel (Fig.

3). This is done using a 10mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

(4) Remove airbag module from steering wheel.

(5) Reverse removal procedures to install. Tighten

airbag module attaching nuts to 9 to 11 Nzm (80 to

100 in. lbs.). Exit vehicle and arm airbag by reaching

through driver's side window and turning arming

screw clockwise to its travel limit. Arming screw

torque should not exceed 1.1 to 1.7 Nzm (10-15 in.

lbs.). Reinstall plastic cover plug in steering wheel

hub.

Fig. 1 Wear Safety Glasses and Rubber Gloves

Fig. 2 Vacuum Heater and A/C Outlets

JRESTRAINT SYSTEMS 8M - 3

Page 483 of 2198

Fig. 3 Airbag Module Remove/Install

8M - 4 RESTRAINT SYSTEMSJ

Page 484 of 2198

REAR WINDOW DEFOGGER

CONTENTS

page page

DIAGNOSIS............................. 1

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 3

GENERAL INFORMATION

The electrically-heated rear window defogger is an

available option on XJ (Cherokee), and YJ (Wrangler)

models equipped with the hardtop roof option. Fol-

lowing are general descriptions of the major compo-

nents in the rear window defogger system. Refer to

Group 8W - Wiring Diagrams for complete circuit de-

scriptions and diagrams.

REAR WINDOW GLASS GRID

The heated rear window glass has two electrically-

conductive vertical bus bars and a series of horizon-

tal grid lines made of a silver-ceramic material,

which is baked on and bonded to the inside surface of

the glass. The grid lines and bus bars comprise a

parallel electrical circuit.

When the rear window defogger switch is placed in

the ON position, current is directed to the rear win-

dow grid lines through the bus bars. The grid lines

heat the rear window to clear the surface of fog or

snow. Circuit protection for the heated grid circuit is

provided by fuse 18 (XJ) or fuse 6 (YJ) in the fuse-

block module.

The grid lines and bus bars are highly resistant to

abrasion. However, it is possible for an open to occur

in an individual grid line resulting in no current flow

through the line. The grid lines can be damaged or

scraped off with sharp instruments. Care should be

taken in cleaning the glass or removing foreign ma-

terials, decals or stickers. Normal glass cleaning sol-

vents or hot water used with rags or toweling is

recommended.A repair kit is available to repair the grid lines and

bus bars, or to reinstall the heated glass pigtail

wires.

DEFOGGER SWITCH

The rear window defogger switch is mounted in the

instrument panel left of the steering column for XJ,

or right of the steering column for YJ. The switch cir-

cuit is protected by fuse 8 (XJ) or fuse 9 (YJ) in the

fuseblock module. Actuating the switch energizes the

relay and electronic timer. A light-emitting diode

(LED) in the switch (XJ), or a indicator lamp in the

switch (YJ), illuminates to indicate when the system

is turned on. The defogger switch can not be re-

paired. If faulty, the switch must be replaced.

DEFOGGER RELAY/TIMER

The defogger relay/timer is located in the relay cen-

ter on XJ models, or taped to the instrument panel

wiring harness behind the parking brake pedal in the

left cowl side area on YJ models. When the rear de-

fogger switch is actuated, the rear defogger relay is

energized. This causes current to flow through the

grid circuit for approximately 10 minutes, or until

the rear window defogger switch or ignition switch

are turned off.

DIAGNOSIS

SYSTEM TESTS

Electrically-heated rear window defogger operation

can be confirmed in the following manner:

(1) Turn the ignition switch to the ON position.

(2) Turn rear window defogger control switch ON.

(3) Monitor vehicle voltmeter. With the control

switch ON, a distinct needle deflection should be

noted.(4) The rear window defogger operation can be

checked by feeling the glass. A distinct difference in

temperature between the grid lines and adjacent

clear glass can be detected within 3 to 4 minutes of

operation.

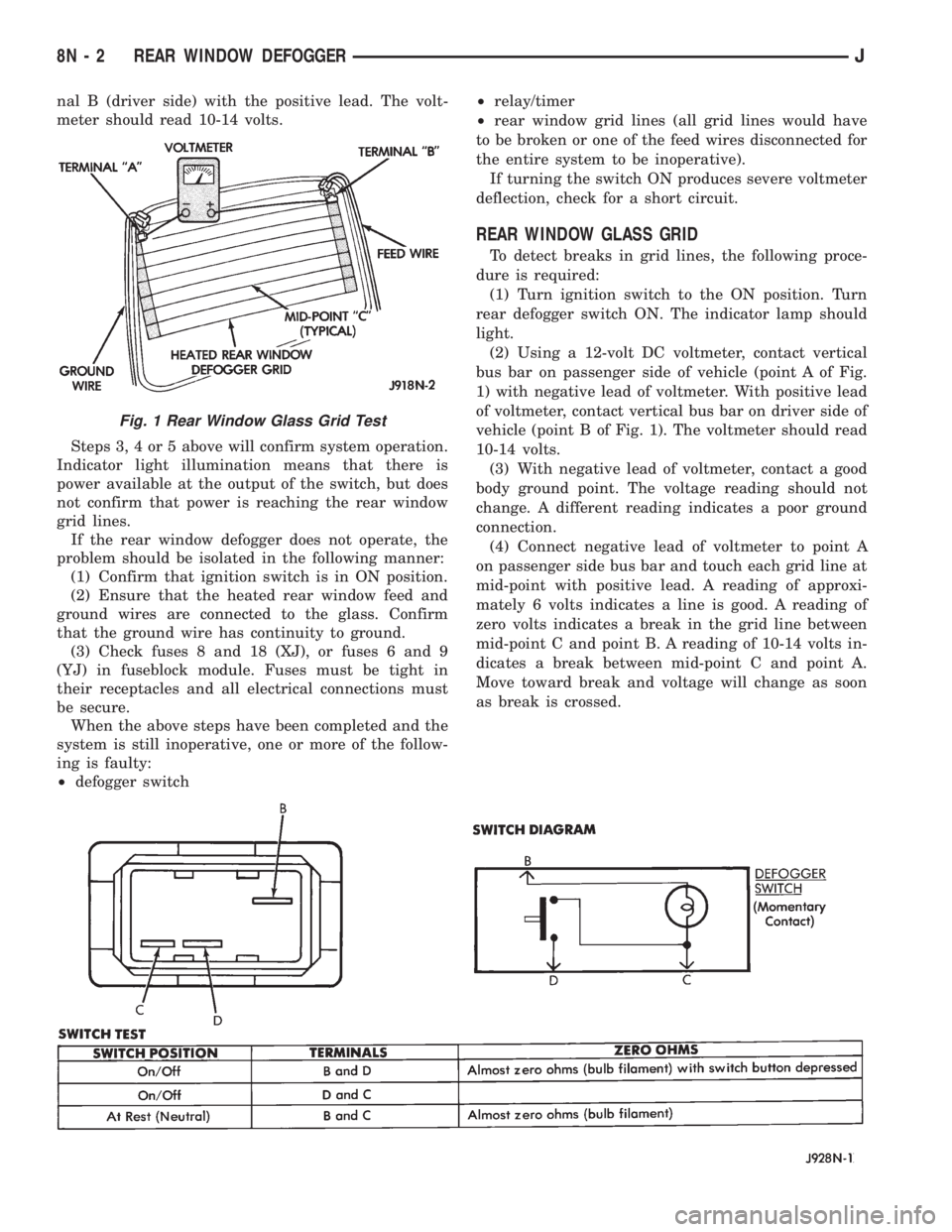

(5) Using a DC voltmeter, contact terminal A (Fig.

1) (passenger side) with the negative lead, and termi-

JREAR WINDOW DEFOGGER 8N - 1

Page 485 of 2198

nal B (driver side) with the positive lead. The volt-

meter should read 10-14 volts.

Steps 3, 4 or 5 above will confirm system operation.

Indicator light illumination means that there is

power available at the output of the switch, but does

not confirm that power is reaching the rear window

grid lines.

If the rear window defogger does not operate, the

problem should be isolated in the following manner:

(1) Confirm that ignition switch is in ON position.

(2) Ensure that the heated rear window feed and

ground wires are connected to the glass. Confirm

that the ground wire has continuity to ground.

(3) Check fuses 8 and 18 (XJ), or fuses 6 and 9

(YJ) in fuseblock module. Fuses must be tight in

their receptacles and all electrical connections must

be secure.

When the above steps have been completed and the

system is still inoperative, one or more of the follow-

ing is faulty:

²defogger switch²relay/timer

²rear window grid lines (all grid lines would have

to be broken or one of the feed wires disconnected for

the entire system to be inoperative).

If turning the switch ON produces severe voltmeter

deflection, check for a short circuit.

REAR WINDOW GLASS GRID

To detect breaks in grid lines, the following proce-

dure is required:

(1) Turn ignition switch to the ON position. Turn

rear defogger switch ON. The indicator lamp should

light.

(2) Using a 12-volt DC voltmeter, contact vertical

bus bar on passenger side of vehicle (point A of Fig.

1) with negative lead of voltmeter. With positive lead

of voltmeter, contact vertical bus bar on driver side of

vehicle (point B of Fig. 1). The voltmeter should read

10-14 volts.

(3) With negative lead of voltmeter, contact a good

body ground point. The voltage reading should not

change. A different reading indicates a poor ground

connection.

(4) Connect negative lead of voltmeter to point A

on passenger side bus bar and touch each grid line at

mid-point with positive lead. A reading of approxi-

mately 6 volts indicates a line is good. A reading of

zero volts indicates a break in the grid line between

mid-point C and point B. A reading of 10-14 volts in-

dicates a break between mid-point C and point A.

Move toward break and voltage will change as soon

as break is crossed.

Fig. 1 Rear Window Glass Grid Test

8N - 2 REAR WINDOW DEFOGGERJ

Page 486 of 2198

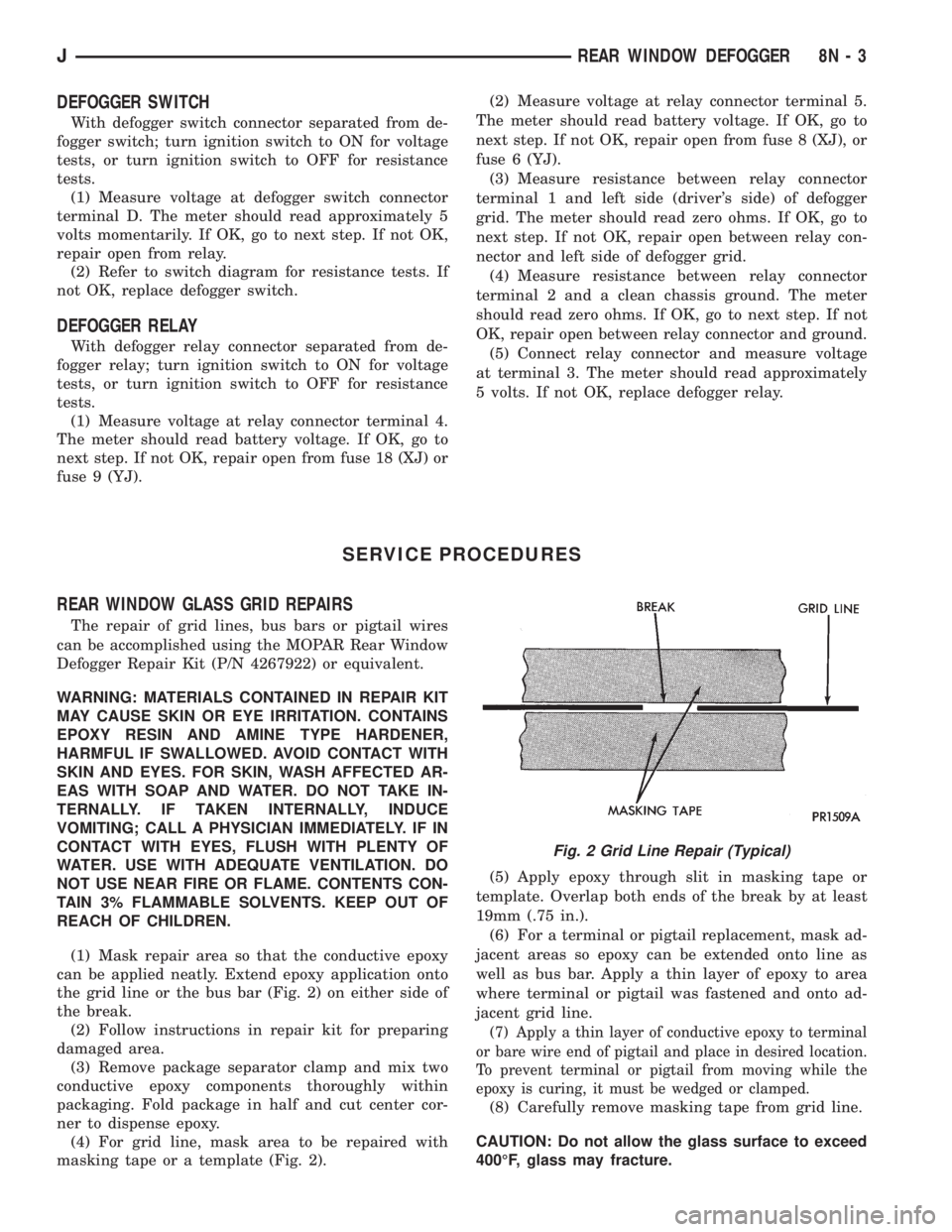

DEFOGGER SWITCH

With defogger switch connector separated from de-

fogger switch; turn ignition switch to ON for voltage

tests, or turn ignition switch to OFF for resistance

tests.

(1) Measure voltage at defogger switch connector

terminal D. The meter should read approximately 5

volts momentarily. If OK, go to next step. If not OK,

repair open from relay.

(2) Refer to switch diagram for resistance tests. If

not OK, replace defogger switch.

DEFOGGER RELAY

With defogger relay connector separated from de-

fogger relay; turn ignition switch to ON for voltage

tests, or turn ignition switch to OFF for resistance

tests.

(1) Measure voltage at relay connector terminal 4.

The meter should read battery voltage. If OK, go to

next step. If not OK, repair open from fuse 18 (XJ) or

fuse 9 (YJ).(2) Measure voltage at relay connector terminal 5.

The meter should read battery voltage. If OK, go to

next step. If not OK, repair open from fuse 8 (XJ), or

fuse 6 (YJ).

(3) Measure resistance between relay connector

terminal 1 and left side (driver's side) of defogger

grid. The meter should read zero ohms. If OK, go to

next step. If not OK, repair open between relay con-

nector and left side of defogger grid.

(4) Measure resistance between relay connector

terminal 2 and a clean chassis ground. The meter

should read zero ohms. If OK, go to next step. If not

OK, repair open between relay connector and ground.

(5) Connect relay connector and measure voltage

at terminal 3. The meter should read approximately

5 volts. If not OK, replace defogger relay.

SERVICE PROCEDURES

REAR WINDOW GLASS GRID REPAIRS

The repair of grid lines, bus bars or pigtail wires

can be accomplished using the MOPAR Rear Window

Defogger Repair Kit (P/N 4267922) or equivalent.

WARNING: MATERIALS CONTAINED IN REPAIR KIT

MAY CAUSE SKIN OR EYE IRRITATION. CONTAINS

EPOXY RESIN AND AMINE TYPE HARDENER,

HARMFUL IF SWALLOWED. AVOID CONTACT WITH

SKIN AND EYES. FOR SKIN, WASH AFFECTED AR-

EAS WITH SOAP AND WATER. DO NOT TAKE IN-

TERNALLY. IF TAKEN INTERNALLY, INDUCE

VOMITING; CALL A PHYSICIAN IMMEDIATELY. IF IN

CONTACT WITH EYES, FLUSH WITH PLENTY OF

WATER. USE WITH ADEQUATE VENTILATION. DO

NOT USE NEAR FIRE OR FLAME. CONTENTS CON-

TAIN 3% FLAMMABLE SOLVENTS. KEEP OUT OF

REACH OF CHILDREN.

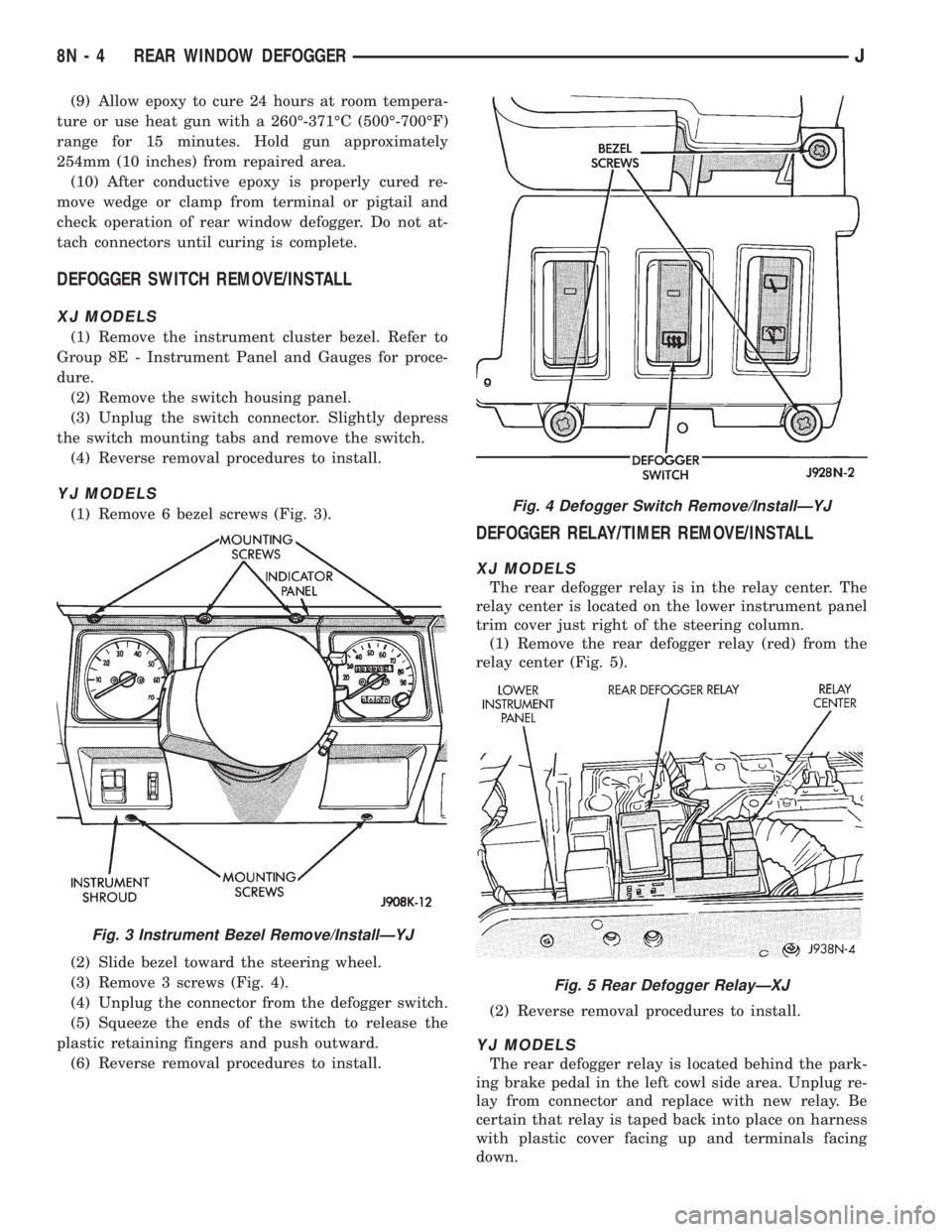

(1) Mask repair area so that the conductive epoxy

can be applied neatly. Extend epoxy application onto

the grid line or the bus bar (Fig. 2) on either side of

the break.

(2) Follow instructions in repair kit for preparing

damaged area.

(3) Remove package separator clamp and mix two

conductive epoxy components thoroughly within

packaging. Fold package in half and cut center cor-

ner to dispense epoxy.

(4) For grid line, mask area to be repaired with

masking tape or a template (Fig. 2).(5) Apply epoxy through slit in masking tape or

template. Overlap both ends of the break by at least

19mm (.75 in.).

(6) For a terminal or pigtail replacement, mask ad-

jacent areas so epoxy can be extended onto line as

well as bus bar. Apply a thin layer of epoxy to area

where terminal or pigtail was fastened and onto ad-

jacent grid line.

(7) Apply a thin layer of conductive epoxy to terminal

or bare wire end of pigtail and place in desired location.

To prevent terminal or pigtail from moving while the

epoxy is curing, it must be wedged or clamped.

(8) Carefully remove masking tape from grid line.

CAUTION: Do not allow the glass surface to exceed

400ÉF, glass may fracture.

Fig. 2 Grid Line Repair (Typical)

JREAR WINDOW DEFOGGER 8N - 3

Page 487 of 2198

(9) Allow epoxy to cure 24 hours at room tempera-

ture or use heat gun with a 260É-371ÉC (500É-700ÉF)

range for 15 minutes. Hold gun approximately

254mm (10 inches) from repaired area.

(10) After conductive epoxy is properly cured re-

move wedge or clamp from terminal or pigtail and

check operation of rear window defogger. Do not at-

tach connectors until curing is complete.

DEFOGGER SWITCH REMOVE/INSTALL

XJ MODELS

(1) Remove the instrument cluster bezel. Refer to

Group 8E - Instrument Panel and Gauges for proce-

dure.

(2) Remove the switch housing panel.

(3) Unplug the switch connector. Slightly depress

the switch mounting tabs and remove the switch.

(4) Reverse removal procedures to install.

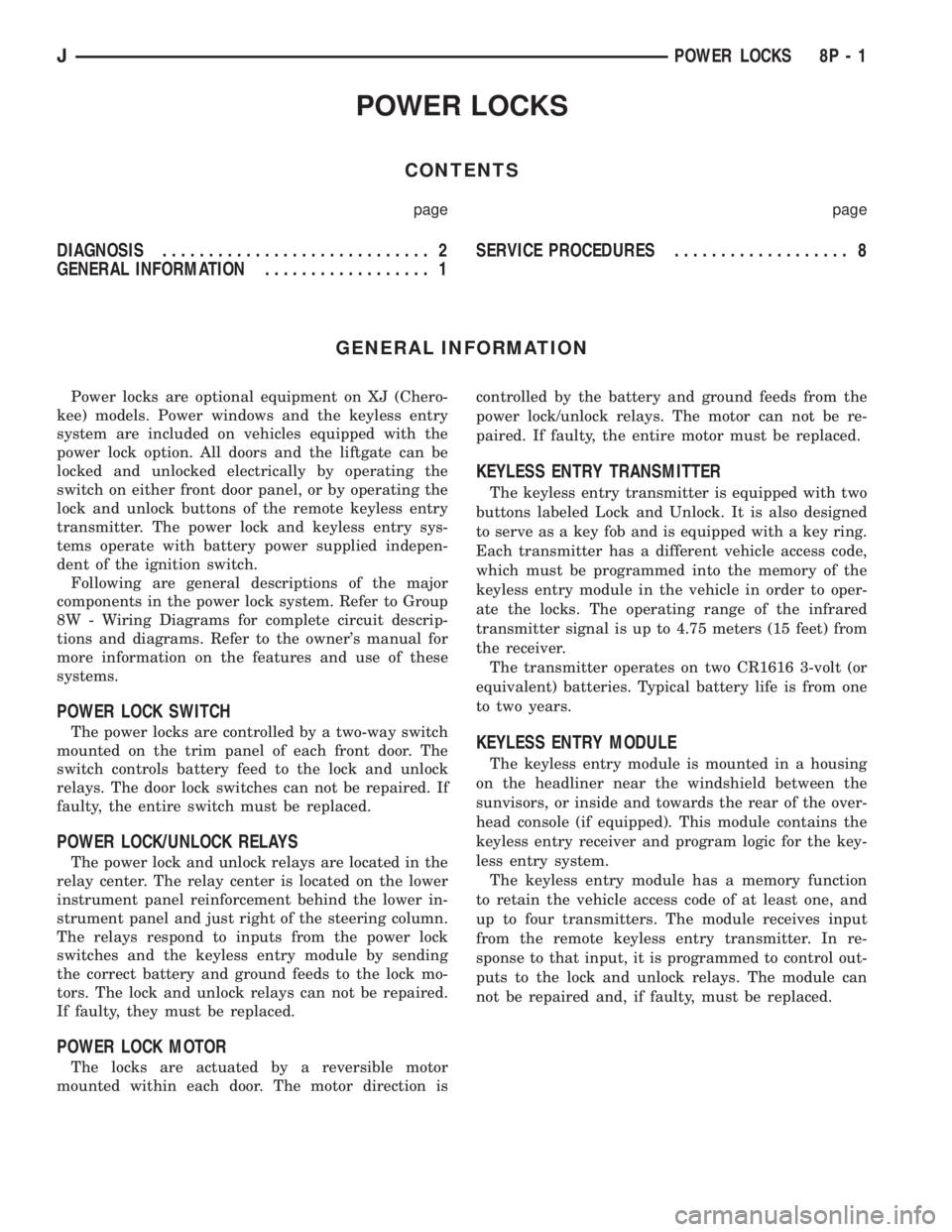

YJ MODELS

(1) Remove 6 bezel screws (Fig. 3).

(2) Slide bezel toward the steering wheel.

(3) Remove 3 screws (Fig. 4).

(4) Unplug the connector from the defogger switch.

(5) Squeeze the ends of the switch to release the

plastic retaining fingers and push outward.

(6) Reverse removal procedures to install.

DEFOGGER RELAY/TIMER REMOVE/INSTALL

XJ MODELS

The rear defogger relay is in the relay center. The

relay center is located on the lower instrument panel

trim cover just right of the steering column.

(1) Remove the rear defogger relay (red) from the

relay center (Fig. 5).

(2) Reverse removal procedures to install.

YJ MODELS

The rear defogger relay is located behind the park-

ing brake pedal in the left cowl side area. Unplug re-

lay from connector and replace with new relay. Be

certain that relay is taped back into place on harness

with plastic cover facing up and terminals facing

down.

Fig. 3 Instrument Bezel Remove/InstallÐYJ

Fig. 4 Defogger Switch Remove/InstallÐYJ

Fig. 5 Rear Defogger RelayÐXJ

8N - 4 REAR WINDOW DEFOGGERJ

Page 488 of 2198

POWER LOCKS

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 8

GENERAL INFORMATION

Power locks are optional equipment on XJ (Chero-

kee) models. Power windows and the keyless entry

system are included on vehicles equipped with the

power lock option. All doors and the liftgate can be

locked and unlocked electrically by operating the

switch on either front door panel, or by operating the

lock and unlock buttons of the remote keyless entry

transmitter. The power lock and keyless entry sys-

tems operate with battery power supplied indepen-

dent of the ignition switch.

Following are general descriptions of the major

components in the power lock system. Refer to Group

8W - Wiring Diagrams for complete circuit descrip-

tions and diagrams. Refer to the owner's manual for

more information on the features and use of these

systems.

POWER LOCK SWITCH

The power locks are controlled by a two-way switch

mounted on the trim panel of each front door. The

switch controls battery feed to the lock and unlock

relays. The door lock switches can not be repaired. If

faulty, the entire switch must be replaced.

POWER LOCK/UNLOCK RELAYS

The power lock and unlock relays are located in the

relay center. The relay center is located on the lower

instrument panel reinforcement behind the lower in-

strument panel and just right of the steering column.

The relays respond to inputs from the power lock

switches and the keyless entry module by sending

the correct battery and ground feeds to the lock mo-

tors. The lock and unlock relays can not be repaired.

If faulty, they must be replaced.

POWER LOCK MOTOR

The locks are actuated by a reversible motor

mounted within each door. The motor direction iscontrolled by the battery and ground feeds from the

power lock/unlock relays. The motor can not be re-

paired. If faulty, the entire motor must be replaced.

KEYLESS ENTRY TRANSMITTER

The keyless entry transmitter is equipped with two

buttons labeled Lock and Unlock. It is also designed

to serve as a key fob and is equipped with a key ring.

Each transmitter has a different vehicle access code,

which must be programmed into the memory of the

keyless entry module in the vehicle in order to oper-

ate the locks. The operating range of the infrared

transmitter signal is up to 4.75 meters (15 feet) from

the receiver.

The transmitter operates on two CR1616 3-volt (or

equivalent) batteries. Typical battery life is from one

to two years.

KEYLESS ENTRY MODULE

The keyless entry module is mounted in a housing

on the headliner near the windshield between the

sunvisors, or inside and towards the rear of the over-

head console (if equipped). This module contains the

keyless entry receiver and program logic for the key-

less entry system.

The keyless entry module has a memory function

to retain the vehicle access code of at least one, and

up to four transmitters. The module receives input

from the remote keyless entry transmitter. In re-

sponse to that input, it is programmed to control out-

puts to the lock and unlock relays. The module can

not be repaired and, if faulty, must be replaced.

JPOWER LOCKS 8P - 1

Page 489 of 2198

DIAGNOSIS

As a preliminary system diagnosis, note system op-

eration while you actuate both the Lock and Unlock

functions with the power lock switches and the key-

less entry transmitter. Then, proceed as follows:

²If system fails to function with either the switches

or the transmitter, see Power Lock System diagnosis.

²If system functions with both switches, but not the

transmitter, see Keyless Entry Transmitter diagnosis.

²If system functions with transmitter, but not with

one or both switches, see Power Lock System diagno-

sis.

²If one lock fails to operate with the switches or

transmitter, see Power Lock Motor diagnosis.

POWER LOCK SYSTEM

(1) Inspect fuse 13 in fuseblock module. Replace if

necessary. If OK, measure voltage at battery side of

fuse. There should be 12 volts. If not OK, repair open

from Power Distribution Center.

(2) Remove door switch(es) and measure voltage at

terminal 1. Meter should read battery voltage. If OK,

go to next step. If not OK, repair open to fuse 9 in

fuseblock module.

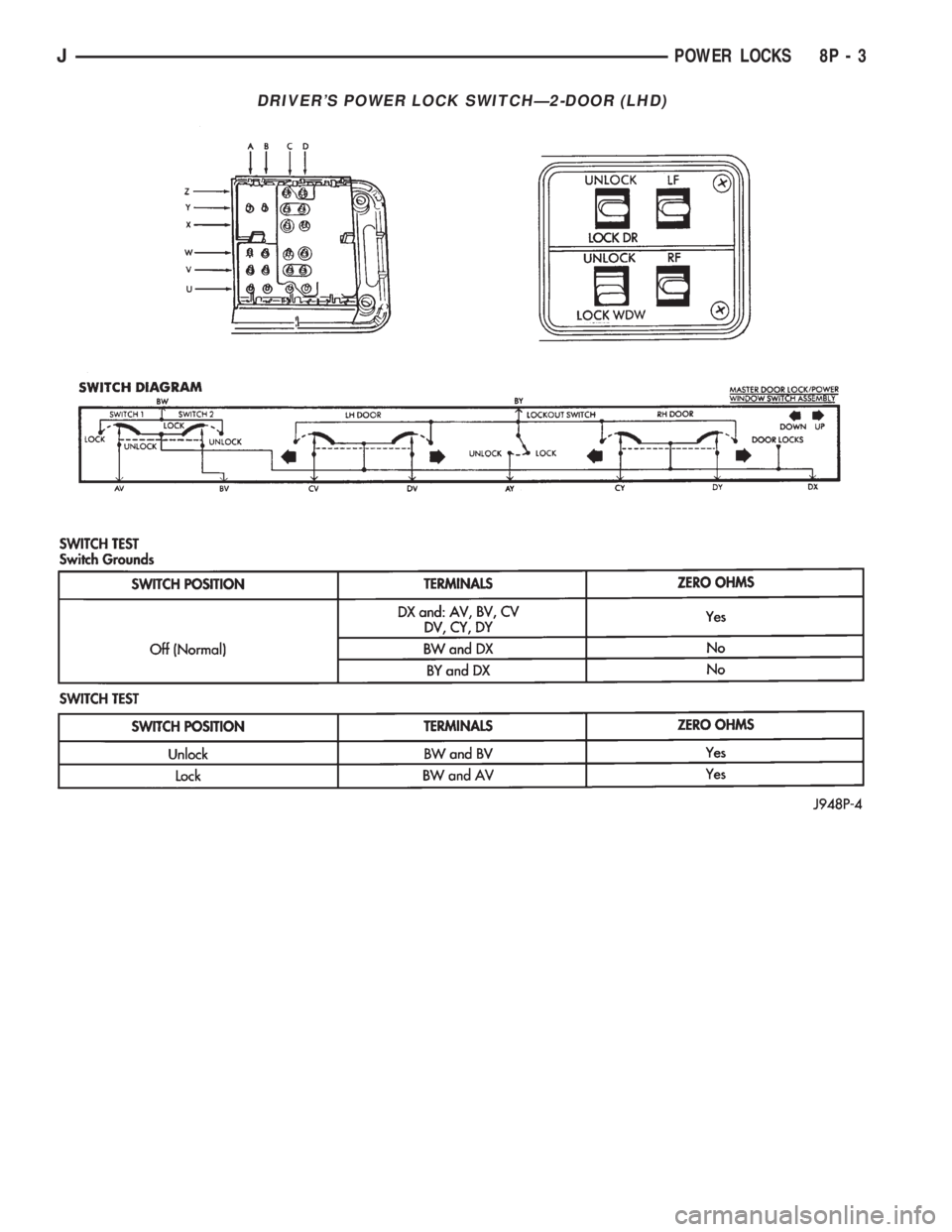

(3) Check door switch continuity as shown in the

applicable charts on the following pages. If OK, go to

next step. If not OK, replace switch.

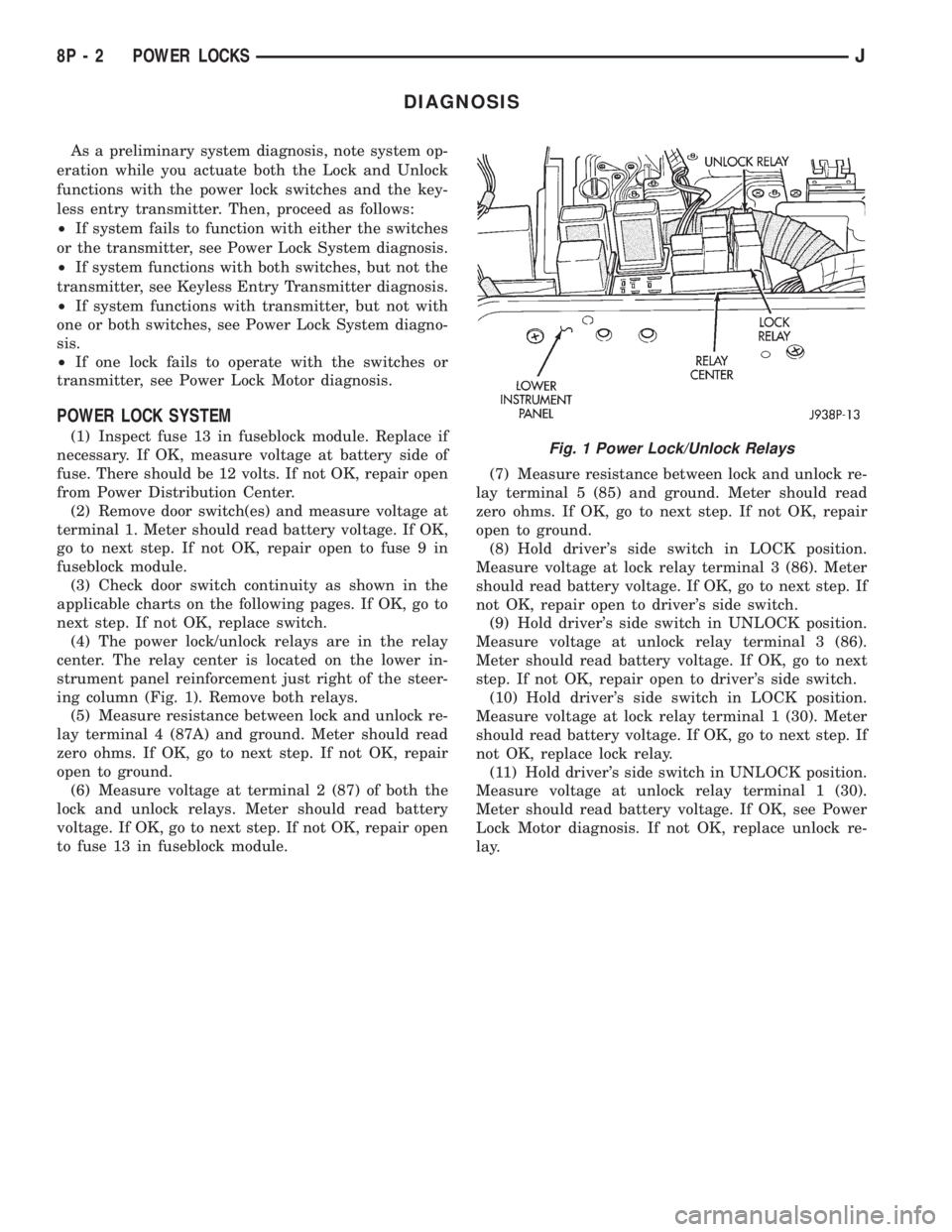

(4) The power lock/unlock relays are in the relay

center. The relay center is located on the lower in-

strument panel reinforcement just right of the steer-

ing column (Fig. 1). Remove both relays.

(5) Measure resistance between lock and unlock re-

lay terminal 4 (87A) and ground. Meter should read

zero ohms. If OK, go to next step. If not OK, repair

open to ground.

(6) Measure voltage at terminal 2 (87) of both the

lock and unlock relays. Meter should read battery

voltage. If OK, go to next step. If not OK, repair open

to fuse 13 in fuseblock module.(7) Measure resistance between lock and unlock re-

lay terminal 5 (85) and ground. Meter should read

zero ohms. If OK, go to next step. If not OK, repair

open to ground.

(8) Hold driver's side switch in LOCK position.

Measure voltage at lock relay terminal 3 (86). Meter

should read battery voltage. If OK, go to next step. If

not OK, repair open to driver's side switch.

(9) Hold driver's side switch in UNLOCK position.

Measure voltage at unlock relay terminal 3 (86).

Meter should read battery voltage. If OK, go to next

step. If not OK, repair open to driver's side switch.

(10) Hold driver's side switch in LOCK position.

Measure voltage at lock relay terminal 1 (30). Meter

should read battery voltage. If OK, go to next step. If

not OK, replace lock relay.

(11) Hold driver's side switch in UNLOCK position.

Measure voltage at unlock relay terminal 1 (30).

Meter should read battery voltage. If OK, see Power

Lock Motor diagnosis. If not OK, replace unlock re-

lay.Fig. 1 Power Lock/Unlock Relays

8P - 2 POWER LOCKSJ

Page 490 of 2198

DRIVER'S POWER LOCK SWITCHÐ2-DOOR (LHD)

JPOWER LOCKS 8P - 3