JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 491 of 2198

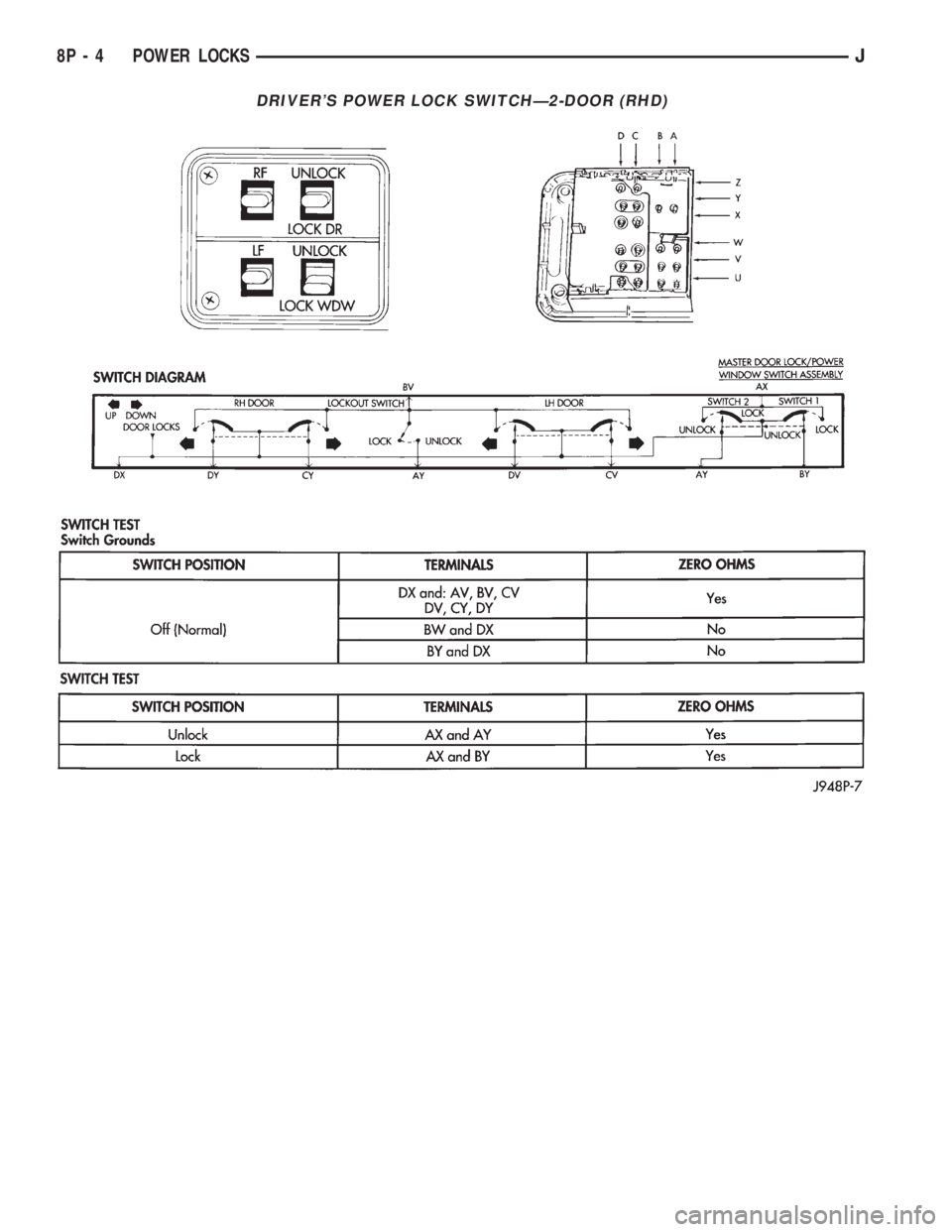

DRIVER'S POWER LOCK SWITCHÐ2-DOOR (RHD)

8P - 4 POWER LOCKSJ

Page 492 of 2198

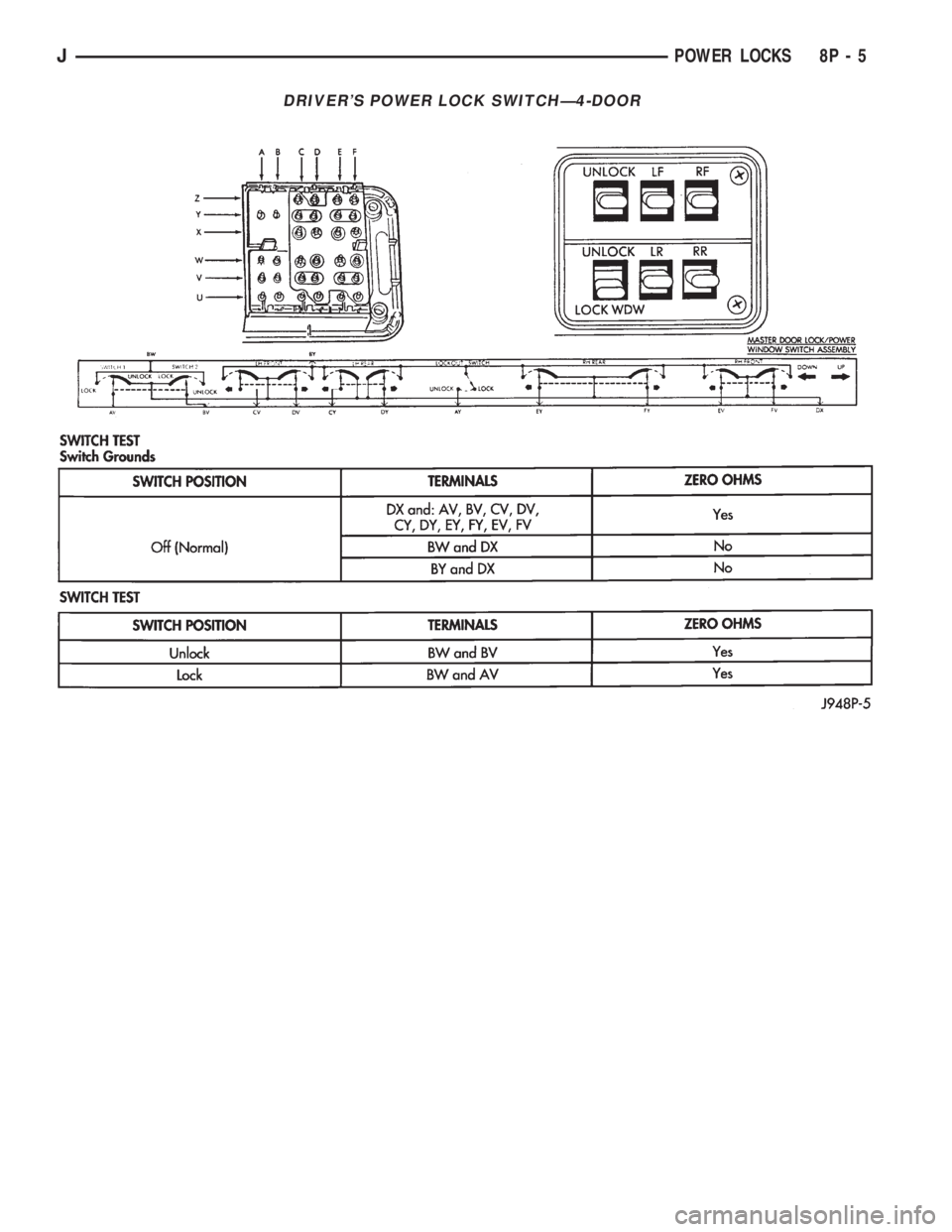

DRIVER'S POWER LOCK SWITCHÐ4-DOOR

JPOWER LOCKS 8P - 5

Page 493 of 2198

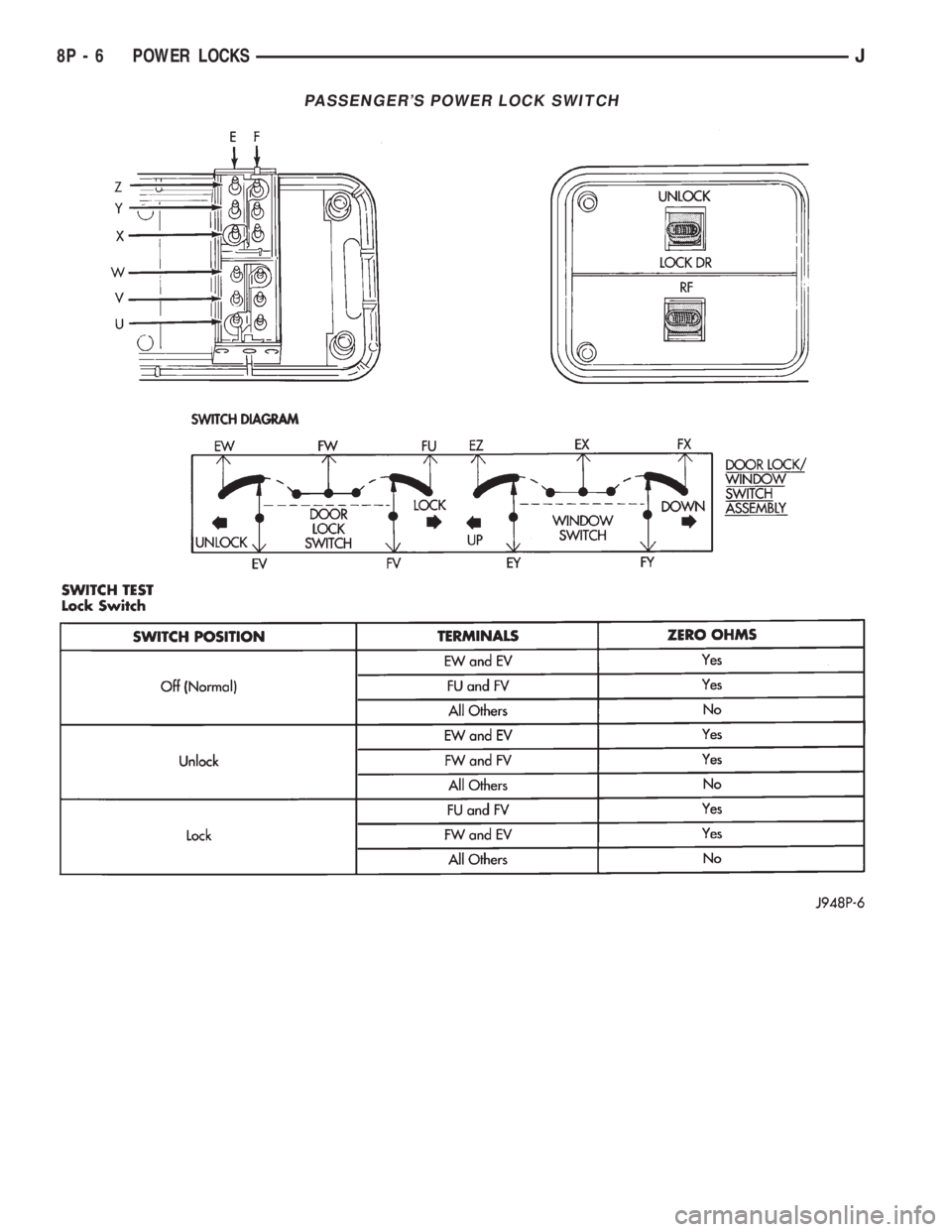

PASSENGER'S POWER LOCK SWITCH

8P - 6 POWER LOCKSJ

Page 494 of 2198

POWER LOCK MOTOR

(1) Once it is determined which lock motor is inop-

erative, that motor can be tested. Disconnect the wire

connector at the motor. Apply 12 volts to the motor

terminals to check its operation in one direction. Re-

verse the polarity to check the operation in the other

direction. If OK, repair circuits to power lock/unlock

relays as required. If not OK, replace the motor.

(2) If all lock motors are inoperative, the problem

may be caused by one shorted motor. Disconnecting a

shorted motor will allow the good motors to operate.

Disconnect each motor connector, one at a time, and

re-check both lock and unlock functions while operat-

ing the door lock switch. If disconnecting one motor

causes the other motors to become functional, go

back to step 1 to test the disconnected motor.

KEYLESS ENTRY TRANSMITTER

(1) Depress either transmitter button and note

whether red Light-Emitting Diode (LED) on trans-

mitter case lights. If OK, go to next step. If not OK,

replace batteries as described under Keyless Entry

Transmitter in Service Procedures. Test transmitter

operation. If OK, discard faulty batteries. If not OK,

go to next step.

(2) Perform transmitter program procedure with

suspect transmitter and another known good trans-

mitter, as described in Service Procedures. Test oper-

ation with both transmitters. If both transmitters fail

to operate power locks, see Keyless Entry Module di-

agnosis. If known good transmitter operates power

locks and suspect transmitter does not, replace faulty

transmitter. Be certain to perform transmitter pro-

gram procedure again when replacing faulty trans-

mitter and to erase test transmitter access code from

keyless entry module.

KEYLESS ENTRY MODULE

(1) Check fuse 9 in fuseblock module. If OK, go to

next step. If not OK, replace fuse.

(2) Check for battery voltage at fuse 9. If OK, go to

next step. If not OK, repair circuit from power distri-

bution center.

(3) Access keyless entry module connectors as de-

scribed in Keyless Entry Module Remove/Install.

(4) Unplug module connector from module. Check

connector and receptacle in module for loose, cor-

roded, or damaged terminals and pins. If OK, go to

next step. If not OK, repair as required.

(5) Probe connector cavity for module terminal 1

and check for battery voltage. If OK, go to next step.

If not OK, repair circuit to fuse 9 as required.

(6) Install a jumper wire from connector cavity for

module terminal 1 to connector cavity for module ter-

minal 3. Doors should lock. If OK, go to step 8. If not

OK, go to next step.

(7) Check for continuity between connector cavity

for module terminal 3 and lock relay terminal 3 (86).

There should be continuity. If OK, replace lock relay.

If not OK, repair circuit as required.

(8) Install a jumper wire from connector cavity for

module terminal 1 to connector cavity for module ter-

minal 4. Doors should unlock. If OK, replace module.

If not OK, go to next step.

(9) Check for continuity between connector cavity

for module terminal 4 and unlock relay terminal 3

(86). There should be continuity. If OK, replace un-

lock relay. If not OK, repair circuit as required.

JPOWER LOCKS 8P - 7

Page 495 of 2198

SERVICE PROCEDURES

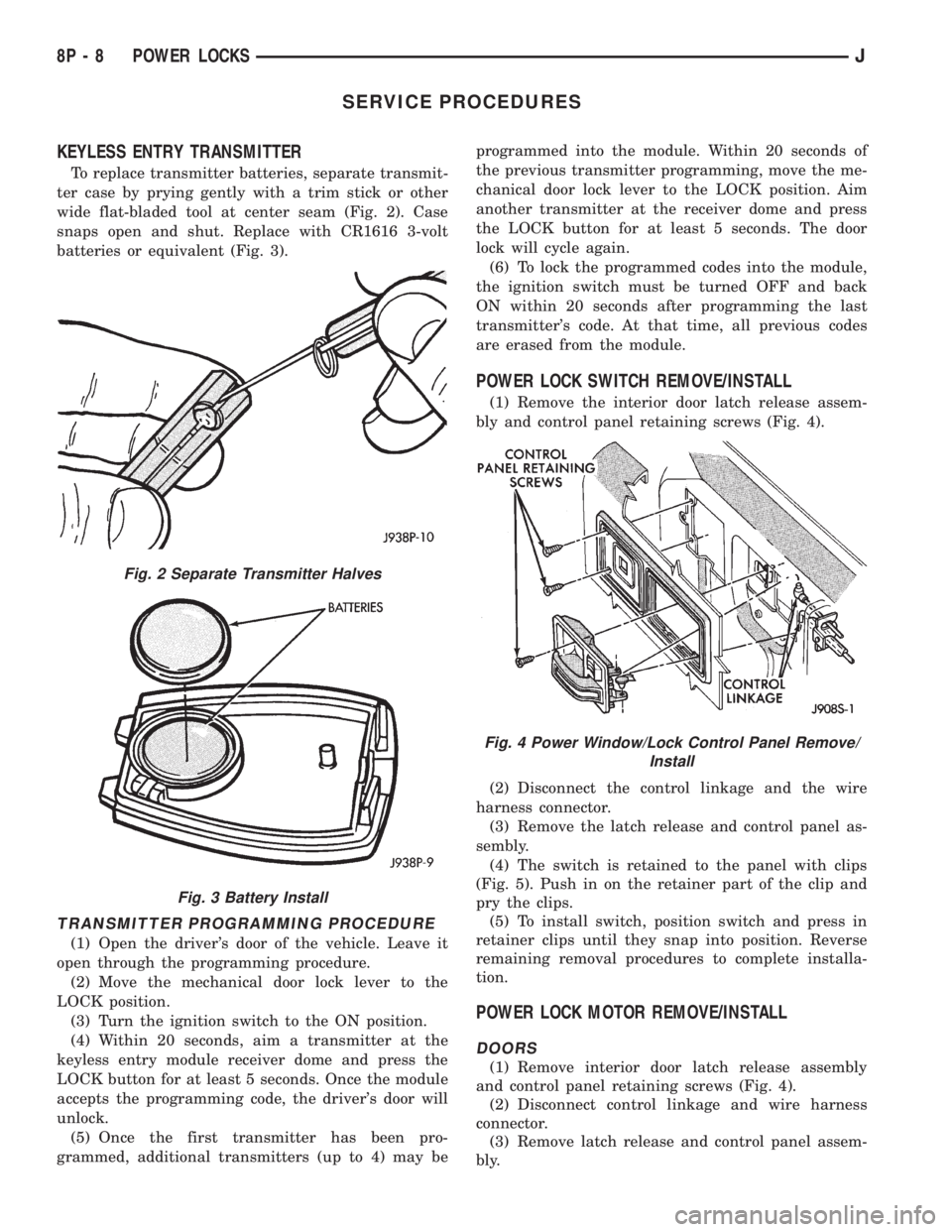

KEYLESS ENTRY TRANSMITTER

To replace transmitter batteries, separate transmit-

ter case by prying gently with a trim stick or other

wide flat-bladed tool at center seam (Fig. 2). Case

snaps open and shut. Replace with CR1616 3-volt

batteries or equivalent (Fig. 3).

TRANSMITTER PROGRAMMING PROCEDURE

(1) Open the driver's door of the vehicle. Leave it

open through the programming procedure.

(2) Move the mechanical door lock lever to the

LOCK position.

(3) Turn the ignition switch to the ON position.

(4) Within 20 seconds, aim a transmitter at the

keyless entry module receiver dome and press the

LOCK button for at least 5 seconds. Once the module

accepts the programming code, the driver's door will

unlock.

(5) Once the first transmitter has been pro-

grammed, additional transmitters (up to 4) may beprogrammed into the module. Within 20 seconds of

the previous transmitter programming, move the me-

chanical door lock lever to the LOCK position. Aim

another transmitter at the receiver dome and press

the LOCK button for at least 5 seconds. The door

lock will cycle again.

(6) To lock the programmed codes into the module,

the ignition switch must be turned OFF and back

ON within 20 seconds after programming the last

transmitter's code. At that time, all previous codes

are erased from the module.

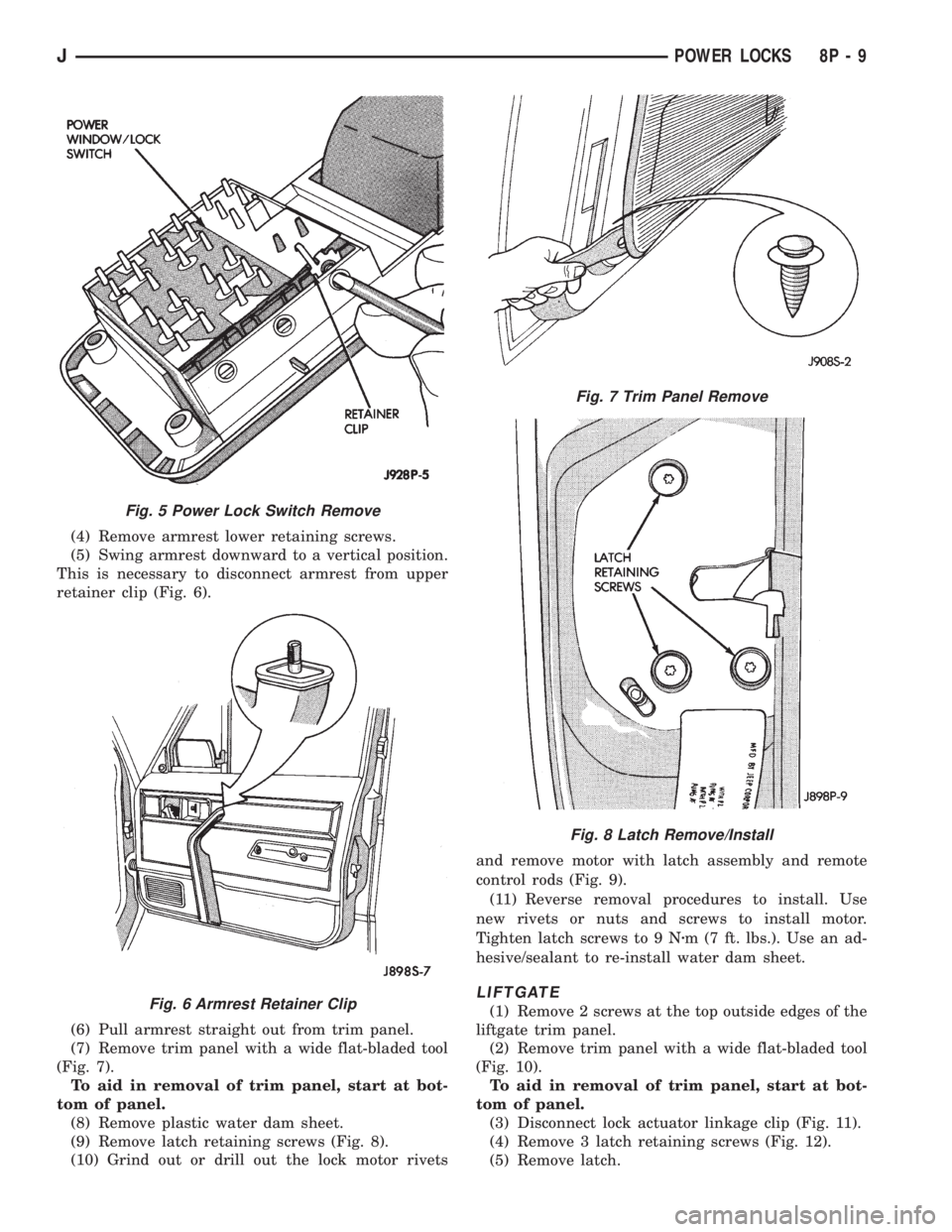

POWER LOCK SWITCH REMOVE/INSTALL

(1) Remove the interior door latch release assem-

bly and control panel retaining screws (Fig. 4).

(2) Disconnect the control linkage and the wire

harness connector.

(3) Remove the latch release and control panel as-

sembly.

(4) The switch is retained to the panel with clips

(Fig. 5). Push in on the retainer part of the clip and

pry the clips.

(5) To install switch, position switch and press in

retainer clips until they snap into position. Reverse

remaining removal procedures to complete installa-

tion.

POWER LOCK MOTOR REMOVE/INSTALL

DOORS

(1) Remove interior door latch release assembly

and control panel retaining screws (Fig. 4).

(2) Disconnect control linkage and wire harness

connector.

(3) Remove latch release and control panel assem-

bly.

Fig. 2 Separate Transmitter Halves

Fig. 3 Battery Install

Fig. 4 Power Window/Lock Control Panel Remove/

Install

8P - 8 POWER LOCKSJ

Page 496 of 2198

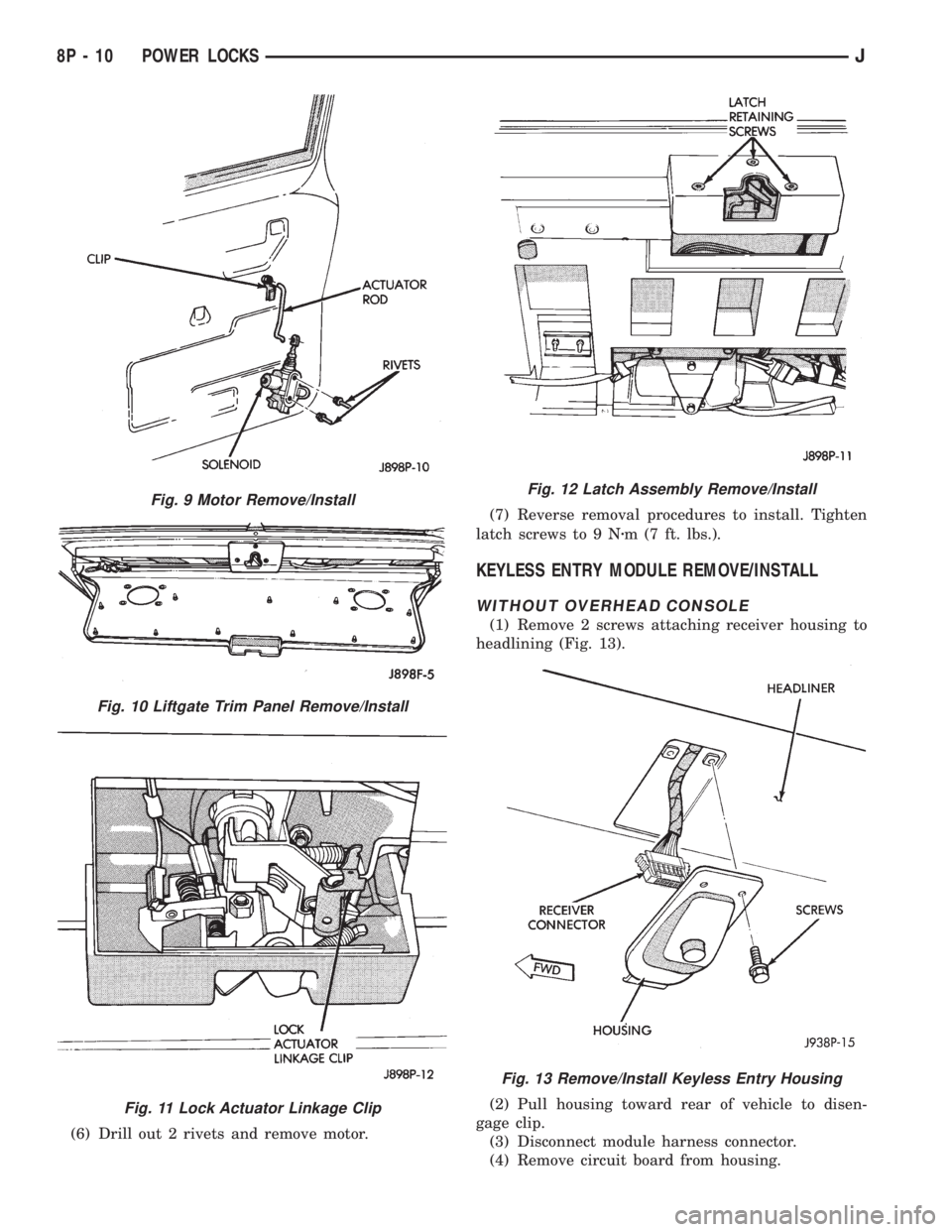

(4) Remove armrest lower retaining screws.

(5) Swing armrest downward to a vertical position.

This is necessary to disconnect armrest from upper

retainer clip (Fig. 6).

(6) Pull armrest straight out from trim panel.

(7) Remove trim panel with a wide flat-bladed tool

(Fig. 7).

To aid in removal of trim panel, start at bot-

tom of panel.

(8) Remove plastic water dam sheet.

(9) Remove latch retaining screws (Fig. 8).

(10) Grind out or drill out the lock motor rivetsand remove motor with latch assembly and remote

control rods (Fig. 9).

(11) Reverse removal procedures to install. Use

new rivets or nuts and screws to install motor.

Tighten latch screws to 9 Nzm (7 ft. lbs.). Use an ad-

hesive/sealant to re-install water dam sheet.

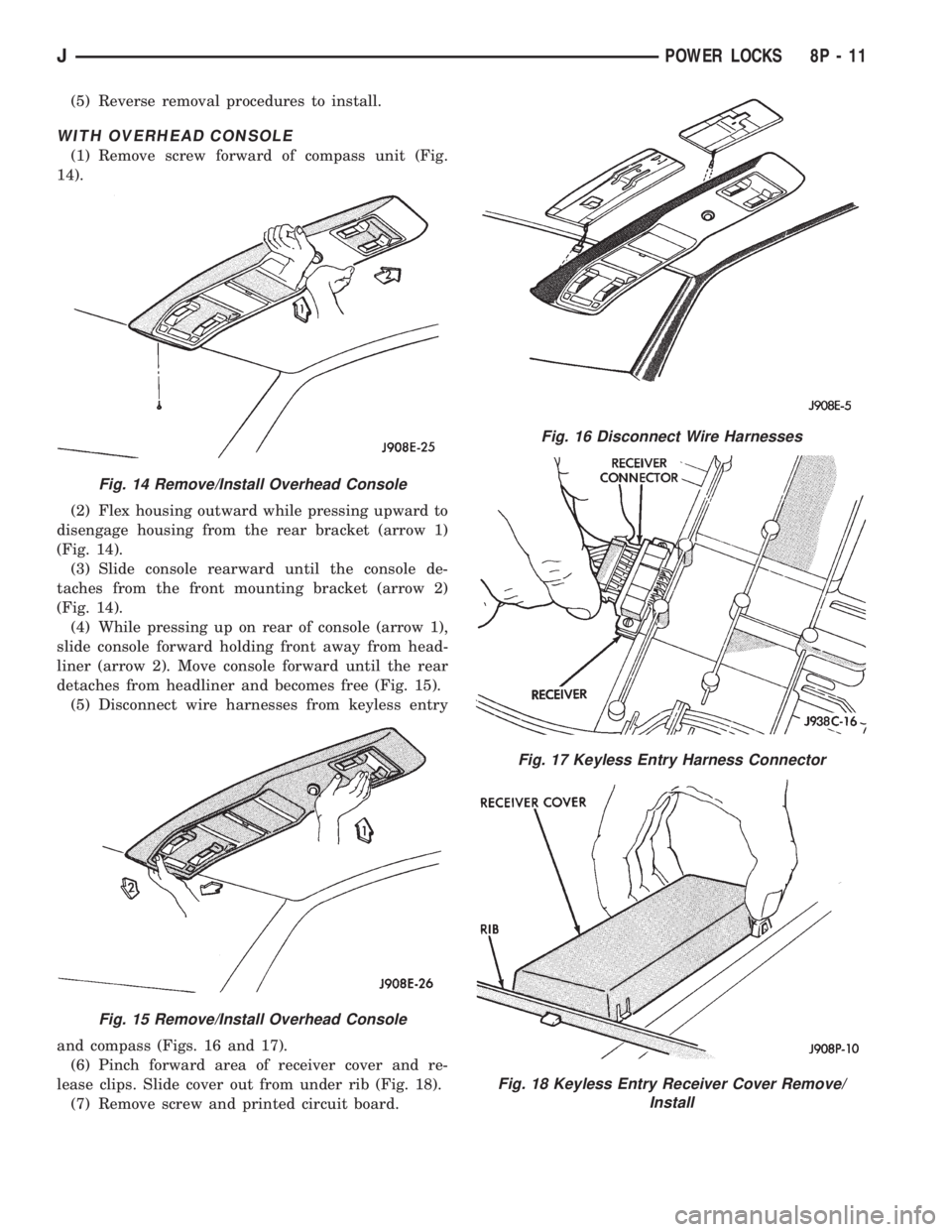

LIFTGATE

(1) Remove 2 screws at the top outside edges of the

liftgate trim panel.

(2) Remove trim panel with a wide flat-bladed tool

(Fig. 10).

To aid in removal of trim panel, start at bot-

tom of panel.

(3) Disconnect lock actuator linkage clip (Fig. 11).

(4) Remove 3 latch retaining screws (Fig. 12).

(5) Remove latch.

Fig. 5 Power Lock Switch Remove

Fig. 6 Armrest Retainer Clip

Fig. 7 Trim Panel Remove

Fig. 8 Latch Remove/Install

JPOWER LOCKS 8P - 9

Page 497 of 2198

(6) Drill out 2 rivets and remove motor.(7) Reverse removal procedures to install. Tighten

latch screws to 9 Nzm (7 ft. lbs.).

KEYLESS ENTRY MODULE REMOVE/INSTALL

WITHOUT OVERHEAD CONSOLE

(1) Remove 2 screws attaching receiver housing to

headlining (Fig. 13).

(2) Pull housing toward rear of vehicle to disen-

gage clip.

(3) Disconnect module harness connector.

(4) Remove circuit board from housing.

Fig. 9 Motor Remove/Install

Fig. 10 Liftgate Trim Panel Remove/Install

Fig. 11 Lock Actuator Linkage Clip

Fig. 12 Latch Assembly Remove/Install

Fig. 13 Remove/Install Keyless Entry Housing

8P - 10 POWER LOCKSJ

Page 498 of 2198

(5) Reverse removal procedures to install.

WITH OVERHEAD CONSOLE

(1) Remove screw forward of compass unit (Fig.

14).

(2) Flex housing outward while pressing upward to

disengage housing from the rear bracket (arrow 1)

(Fig. 14).

(3) Slide console rearward until the console de-

taches from the front mounting bracket (arrow 2)

(Fig. 14).

(4) While pressing up on rear of console (arrow 1),

slide console forward holding front away from head-

liner (arrow 2). Move console forward until the rear

detaches from headliner and becomes free (Fig. 15).

(5) Disconnect wire harnesses from keyless entry

and compass (Figs. 16 and 17).

(6) Pinch forward area of receiver cover and re-

lease clips. Slide cover out from under rib (Fig. 18).

(7) Remove screw and printed circuit board.

Fig. 14 Remove/Install Overhead Console

Fig. 15 Remove/Install Overhead Console

Fig. 16 Disconnect Wire Harnesses

Fig. 17 Keyless Entry Harness Connector

Fig. 18 Keyless Entry Receiver Cover Remove/

Install

JPOWER LOCKS 8P - 11

Page 499 of 2198

(8) Reverse removal procedures to install. Be sure

to flex housing outward near the keyless entry mod-

ule until the console snaps onto the rear mounting

bracket.

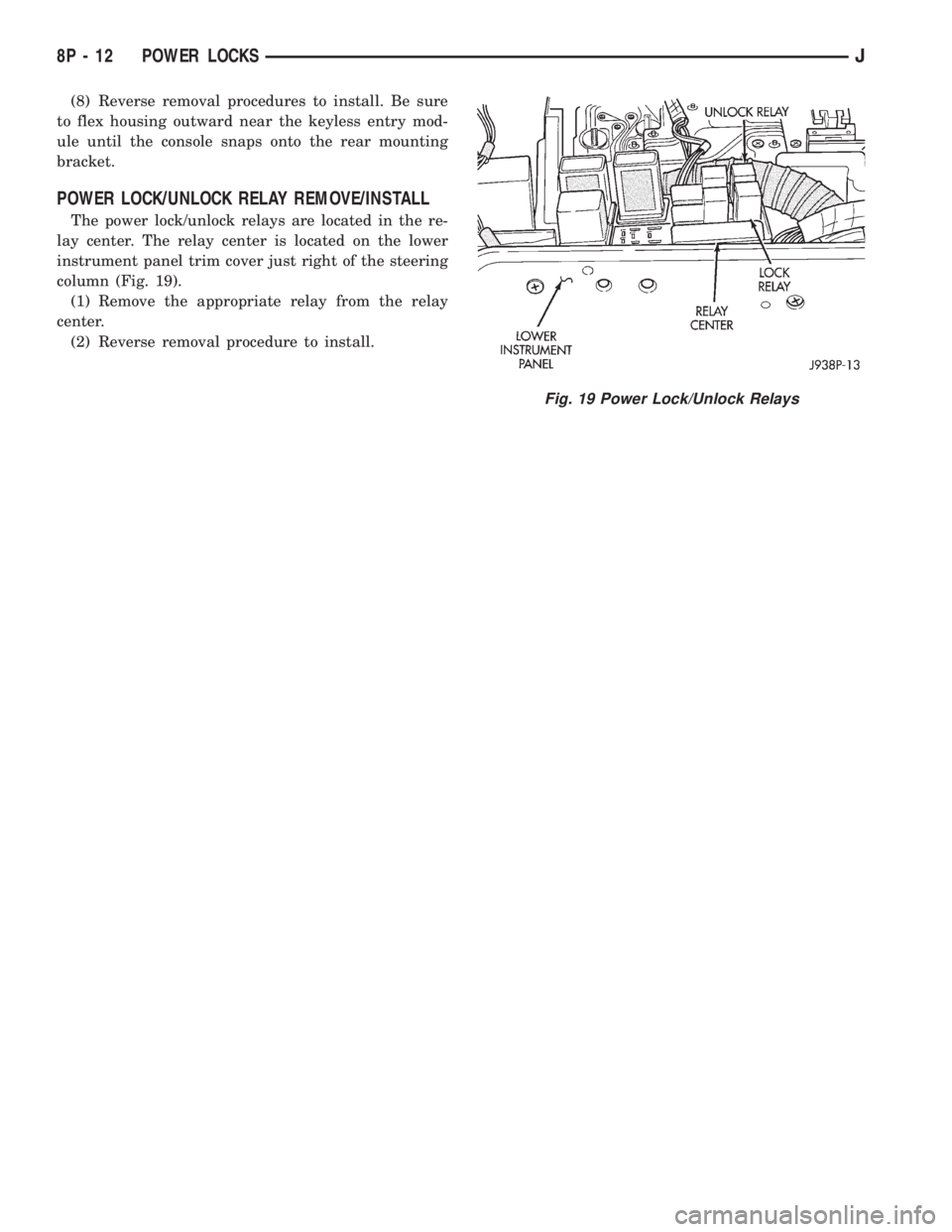

POWER LOCK/UNLOCK RELAY REMOVE/INSTALL

The power lock/unlock relays are located in the re-

lay center. The relay center is located on the lower

instrument panel trim cover just right of the steering

column (Fig. 19).

(1) Remove the appropriate relay from the relay

center.

(2) Reverse removal procedure to install.

Fig. 19 Power Lock/Unlock Relays

8P - 12 POWER LOCKSJ

Page 500 of 2198

POWER SEATS

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 3

GENERAL INFORMATION

A six-way driver's side power seat is an available

option on XJ (Cherokee) models. The power seat sys-

tem receives battery feed through fuse 6 in the power

distribution center and circuit breaker 16 in the fuse-

block module at all times.

Following are general descriptions of the major

components in the power seat system. Refer to Group

8W - Wiring Diagrams for complete circuit descrip-

tions and diagrams.

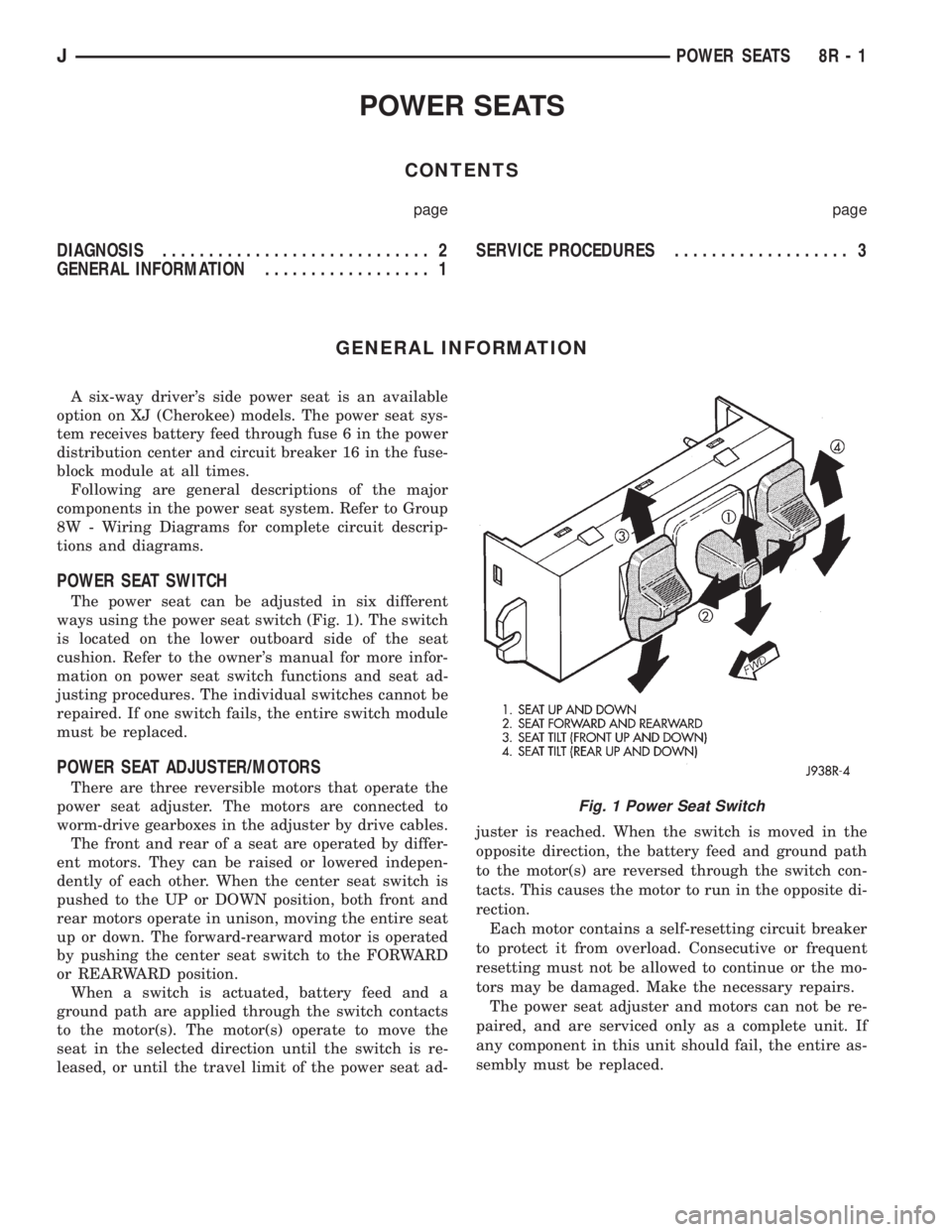

POWER SEAT SWITCH

The power seat can be adjusted in six different

ways using the power seat switch (Fig. 1). The switch

is located on the lower outboard side of the seat

cushion. Refer to the owner's manual for more infor-

mation on power seat switch functions and seat ad-

justing procedures. The individual switches cannot be

repaired. If one switch fails, the entire switch module

must be replaced.

POWER SEAT ADJUSTER/MOTORS

There are three reversible motors that operate the

power seat adjuster. The motors are connected to

worm-drive gearboxes in the adjuster by drive cables.

The front and rear of a seat are operated by differ-

ent motors. They can be raised or lowered indepen-

dently of each other. When the center seat switch is

pushed to the UP or DOWN position, both front and

rear motors operate in unison, moving the entire seat

up or down. The forward-rearward motor is operated

by pushing the center seat switch to the FORWARD

or REARWARD position.

When a switch is actuated, battery feed and a

ground path are applied through the switch contacts

to the motor(s). The motor(s) operate to move the

seat in the selected direction until the switch is re-

leased, or until the travel limit of the power seat ad-juster is reached. When the switch is moved in the

opposite direction, the battery feed and ground path

to the motor(s) are reversed through the switch con-

tacts. This causes the motor to run in the opposite di-

rection.

Each motor contains a self-resetting circuit breaker

to protect it from overload. Consecutive or frequent

resetting must not be allowed to continue or the mo-

tors may be damaged. Make the necessary repairs.

The power seat adjuster and motors can not be re-

paired, and are serviced only as a complete unit. If

any component in this unit should fail, the entire as-

sembly must be replaced.

Fig. 1 Power Seat Switch

JPOWER SEATS 8R - 1