button JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 74 of 2198

(5) Lubricate all differential components with hy-

poid gear lubricant.

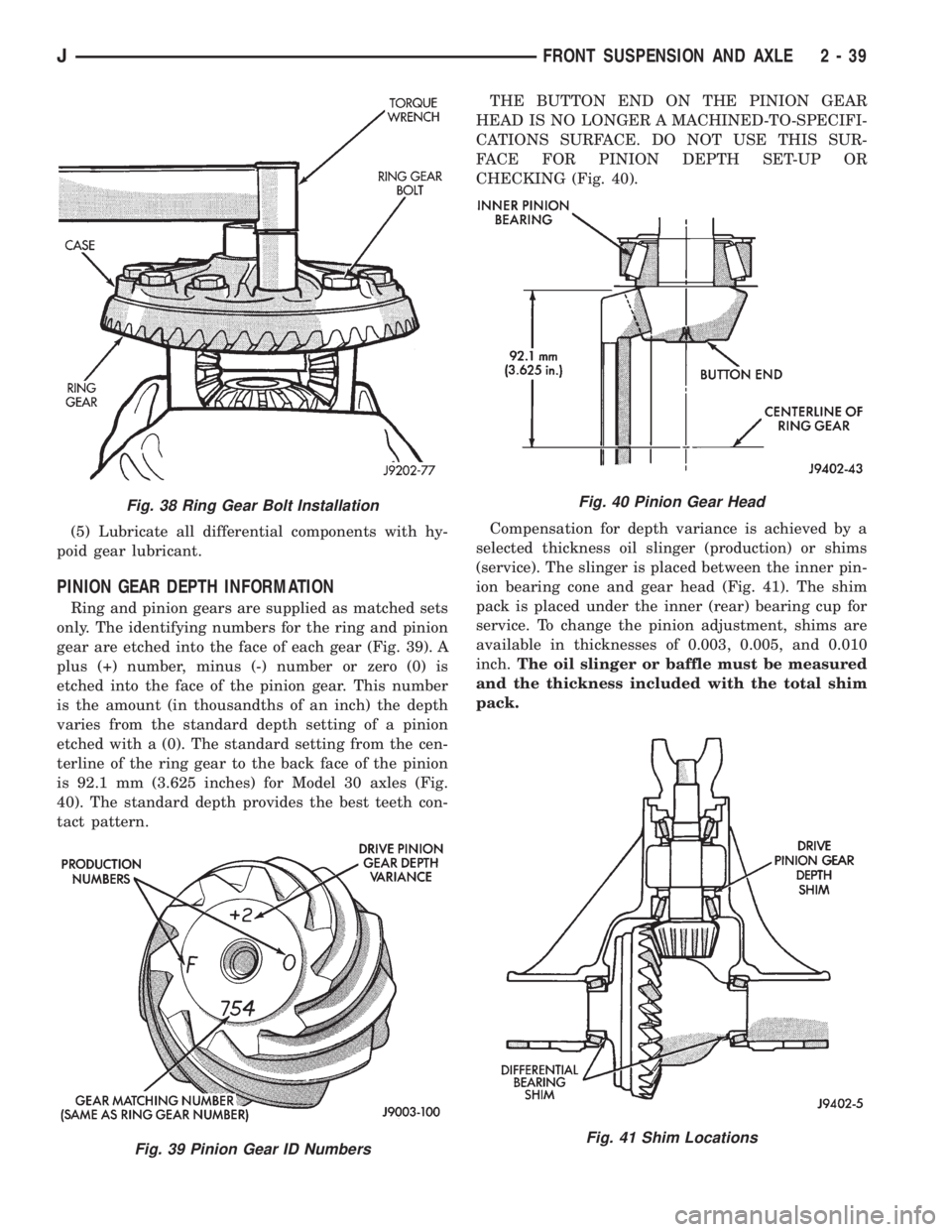

PINION GEAR DEPTH INFORMATION

Ring and pinion gears are supplied as matched sets

only. The identifying numbers for the ring and pinion

gear are etched into the face of each gear (Fig. 39). A

plus (+) number, minus (-) number or zero (0) is

etched into the face of the pinion gear. This number

is the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

etched with a (0). The standard setting from the cen-

terline of the ring gear to the back face of the pinion

is 92.1 mm (3.625 inches) for Model 30 axles (Fig.

40). The standard depth provides the best teeth con-

tact pattern.THE BUTTON END ON THE PINION GEAR

HEAD IS NO LONGER A MACHINED-TO-SPECIFI-

CATIONS SURFACE. DO NOT USE THIS SUR-

FACE FOR PINION DEPTH SET-UP OR

CHECKING (Fig. 40).

Compensation for depth variance is achieved by a

selected thickness oil slinger (production) or shims

(service). The slinger is placed between the inner pin-

ion bearing cone and gear head (Fig. 41). The shim

pack is placed under the inner (rear) bearing cup for

service. To change the pinion adjustment, shims are

available in thicknesses of 0.003, 0.005, and 0.010

inch.The oil slinger or baffle must be measured

and the thickness included with the total shim

pack.

Fig. 38 Ring Gear Bolt Installation

Fig. 39 Pinion Gear ID Numbers

Fig. 40 Pinion Gear Head

Fig. 41 Shim Locations

JFRONT SUSPENSION AND AXLE 2 - 39

Page 106 of 2198

²Smooth appearance with no broken/dented sur-

faces on the bearing rollers or the roller contact sur-

faces

²Bearing cups must not be distorted or cracked

²Machined surfaces should be smooth and without

any raised edges

²Raised metal on shoulders of cup bores should be

removed with a hand stone

²Wear and damage to pinion gear mate shaft, pin-

ion gears, side gears and thrust washers. Replace as

a matched set only.

²Ring and pinion gear for worn and chipped teeth

²Ring gear for damaged bolt threads. Replaced as a

matched set only.

²Pinion yoke for cracks, worn splines, pitted areas,

and a rough/corroded seal contact surface. Repair or

replace as necessary.

²Preload shims for damage and distortion. Install

new shims if necessary.

DIFFERENTIAL ASSEMBLY

(1) Install the following components in the differ-

ential case.

²Differential side gears and thrust washers

²Pinion gears and thrust washers

²Pinion gear mate shaft (align holes in shaft and

case)

(2) Lubricate all differential components with hy-

poid gear lubricant.

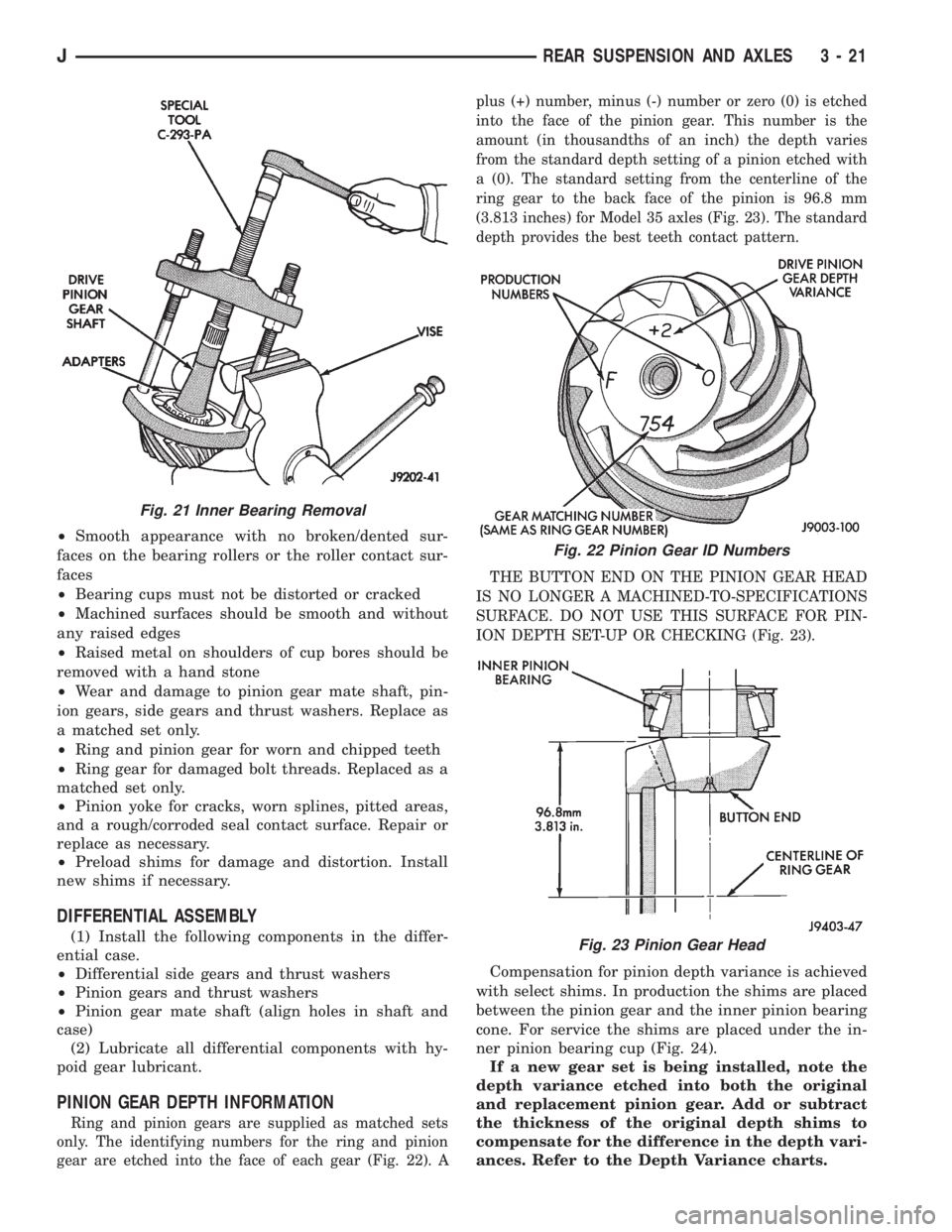

PINION GEAR DEPTH INFORMATION

Ring and pinion gears are supplied as matched sets

only. The identifying numbers for the ring and pinion

gear are etched into the face of each gear (Fig. 22). Aplus (+) number, minus (-) number or zero (0) is etched

into the face of the pinion gear. This number is the

amount (in thousandths of an inch) the depth varies

from the standard depth setting of a pinion etched with

a (0). The standard setting from the centerline of the

ring gear to the back face of the pinion is 96.8 mm

(3.813 inches) for Model 35 axles (Fig. 23). The standard

depth provides the best teeth contact pattern.

THE BUTTON END ON THE PINION GEAR HEAD

IS NO LONGER A MACHINED-TO-SPECIFICATIONS

SURFACE. DO NOT USE THIS SURFACE FOR PIN-

ION DEPTH SET-UP OR CHECKING (Fig. 23).

Compensation for pinion depth variance is achieved

with select shims. In production the shims are placed

between the pinion gear and the inner pinion bearing

cone. For service the shims are placed under the in-

ner pinion bearing cup (Fig. 24).

If a new gear set is being installed, note the

depth variance etched into both the original

and replacement pinion gear. Add or subtract

the thickness of the original depth shims to

compensate for the difference in the depth vari-

ances. Refer to the Depth Variance charts.

Fig. 21 Inner Bearing Removal

Fig. 22 Pinion Gear ID Numbers

Fig. 23 Pinion Gear Head

JREAR SUSPENSION AND AXLES 3 - 21

Page 198 of 2198

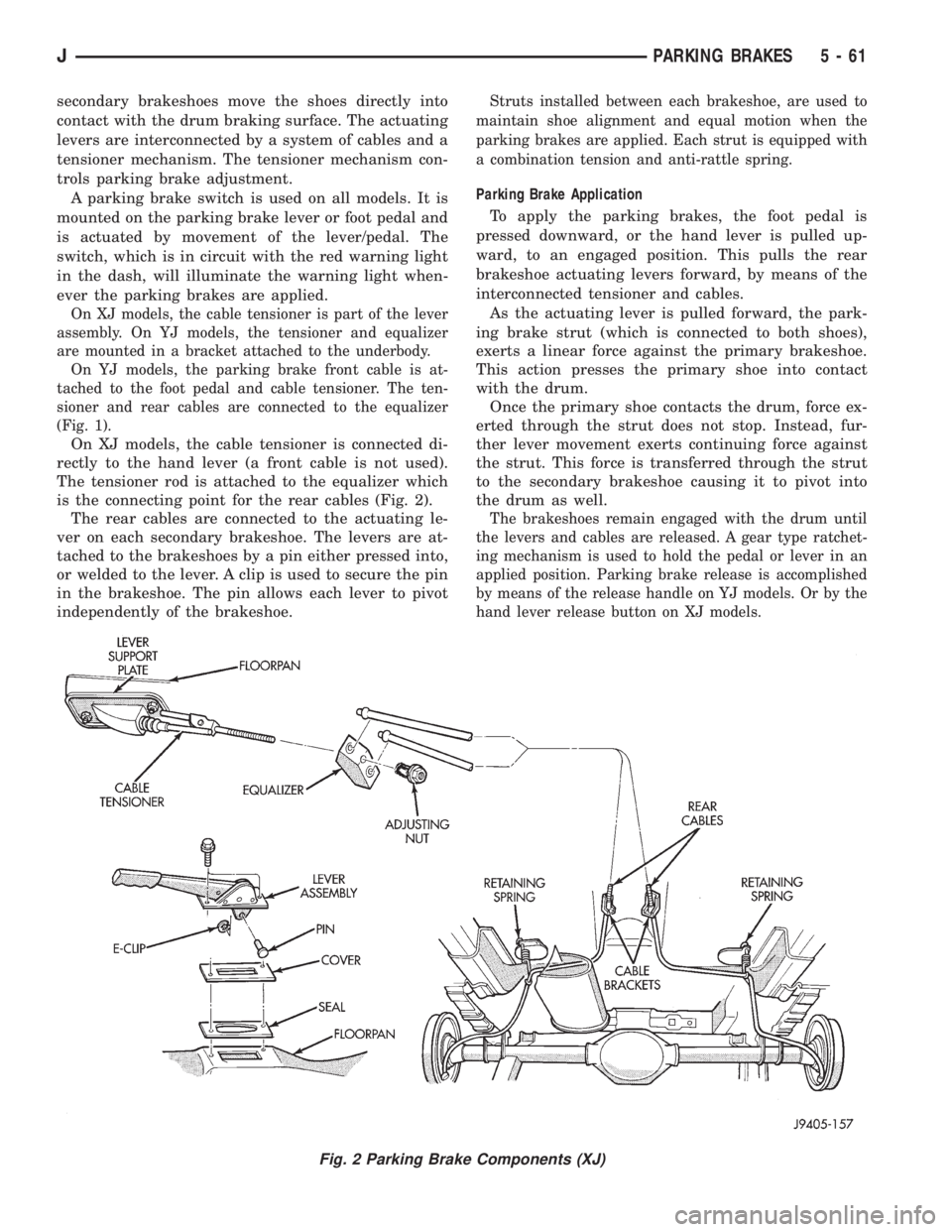

secondary brakeshoes move the shoes directly into

contact with the drum braking surface. The actuating

levers are interconnected by a system of cables and a

tensioner mechanism. The tensioner mechanism con-

trols parking brake adjustment.

A parking brake switch is used on all models. It is

mounted on the parking brake lever or foot pedal and

is actuated by movement of the lever/pedal. The

switch, which is in circuit with the red warning light

in the dash, will illuminate the warning light when-

ever the parking brakes are applied.

On XJ models, the cable tensioner is part of the lever

assembly. On YJ models, the tensioner and equalizer

are mounted in a bracket attached to the underbody.

On YJ models, the parking brake front cable is at-

tached to the foot pedal and cable tensioner. The ten-

sioner and rear cables are connected to the equalizer

(Fig. 1).

On XJ models, the cable tensioner is connected di-

rectly to the hand lever (a front cable is not used).

The tensioner rod is attached to the equalizer which

is the connecting point for the rear cables (Fig. 2).

The rear cables are connected to the actuating le-

ver on each secondary brakeshoe. The levers are at-

tached to the brakeshoes by a pin either pressed into,

or welded to the lever. A clip is used to secure the pin

in the brakeshoe. The pin allows each lever to pivot

independently of the brakeshoe.

Struts installed between each brakeshoe, are used to

maintain shoe alignment and equal motion when the

parking brakes are applied. Each strut is equipped with

a combination tension and anti-rattle spring.

Parking Brake Application

To apply the parking brakes, the foot pedal is

pressed downward, or the hand lever is pulled up-

ward, to an engaged position. This pulls the rear

brakeshoe actuating levers forward, by means of the

interconnected tensioner and cables.

As the actuating lever is pulled forward, the park-

ing brake strut (which is connected to both shoes),

exerts a linear force against the primary brakeshoe.

This action presses the primary shoe into contact

with the drum.

Once the primary shoe contacts the drum, force ex-

erted through the strut does not stop. Instead, fur-

ther lever movement exerts continuing force against

the strut. This force is transferred through the strut

to the secondary brakeshoe causing it to pivot into

the drum as well.

The brakeshoes remain engaged with the drum until

the levers and cables are released. A gear type ratchet-

ing mechanism is used to hold the pedal or lever in an

applied position. Parking brake release is accomplished

by means of the release handle on YJ models. Or by the

hand lever release button on XJ models.

Fig. 2 Parking Brake Components (XJ)

JPARKING BRAKES 5 - 61

Page 304 of 2198

OVERHEAD CONSOLE

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 5

GENERAL INFORMATION

An overhead console featuring an electronic com-

pass and thermometer is an available option for XJ

(Cherokee) models. Following are general descrip-

tions of major components used in the overhead con-

sole. Refer to Group 8W - Wiring Diagrams for

complete circuit descriptions and diagrams.

COMPASS

The compass will display the direction in which the

vehicle is pointed using the eight major compass

headings (Examples: north is N, northeast is NE). It

does not display the headings in actual degrees. The

display is turned on or off using the COMP/TEMP

button to the left of the display.

The self-calibrating compass unit requires no ad-

justing in normal use. The only calibration that may

prove necessary is to drive the vehicle in 3 complete

circles, on level ground, in not less than 48 seconds.

This will reorient the unit to its vehicle.

The unit also will compensate for magnetism the

body of the vehicle may acquire during normal use.

However, avoid placing anything magnetic directly on

the roof of the vehicle. Magnetic mounts for an an-

tenna, a repair order hat or a funeral procession flag

can exceed the compensating ability of the compass

unit if placed on the roof panel. Magnetic bit drivers

used on the fasteners that hold the assembly to the

roof header can also affect compass operation.

If the vehicle roof should become magnetized, the

demagnetizing and calibration procedures may be re-

quired to restore proper operation.

THERMOMETER

The thermometer displays the outside ambient

temperature. The temperature displayed can be

changed from Fahrenheit to Celsius using the US/

METRIC button. The displayed temperature is not

an instant reading of conditions, but an average tem-

perature. It may take the unit several minutes to re-

act to a major temperature change such as driving

out of a heated garage into winter temperatures.

When the ignition switch is turned OFF, the lastdisplayed temperature reading stays in memory.

When the ignition switch is turned ON again, the

thermometer will display the memory temperature

for one minute; then update the display to the cur-

rent average temperature reading within five min-

utes.

READING AND COURTESY LAMPS

All reading and courtesy lamps in the overhead

console are activated by the door jamb switches.

When all doors and the liftgate are closed, the lamps

can be individually activated by depressing the corre-

sponding lens. When a door and/or the liftgate is

open, depressing the lamp lens switches will not turn

the lamps off. Refer to Group 8L - Lamps, for diag-

nosis and service of these lamps.

KEYLESS ENTRY RECEIVER

The overhead console houses the keyless entry re-

ceiver. Refer to Group 8P - Power Locks, for diagno-

sis and service of this component.

REMOTE GARAGE DOOR OPENER STORAGE

A compartment in the overhead console is designed

to hold most remote garage door opener transmitters.

The transmitter is mounted within the compartment

with an adhesive-backed hook and loop fastener

patch. Then one to three pegs are selected and

mounted on a post on the inside of the storage com-

partment door. The pegs may be stacked, if neces-

sary. The peg(s) selected must be long enough to

activate the button of the transmitter each time the

storage compartment door is depressed.

SUNGLASSES STORAGE

A flocked storage compartment for sunglasses is in-

cluded in the overhead console. This compartment

features a push/push-type latch and a viscous damp-

ening system for a fluid opening motion.

JOVERHEAD CONSOLE 8C - 1

Page 305 of 2198

DIAGNOSIS

COMPASS/DISPLAY SELF-DIAGNOSTIC TEST

This self-diagnostic test is used to determine that

the compass and all of its display segments are oper-

ating properly electrically. Initiate the self-diagnostic

test as follows:

(1) With the ignition switch in the OFF position,

simultaneously press and hold the COMP/TEMP but-

ton and the US/METRIC button.

(2) Turn ignition switch to the ON position.

(3) Continue to hold both buttons until the display

performs a walking segment test. In this test all of

the compass points are displayed, along with various

number combinations. These combinations verify that

all display segments are functional. If any segment

should fail to light during the test, the unit is faulty

and requires replacement. To repeat the test, momen-

tarily depress and release the COMP/TEMP button

one time.

(4) Momentarily depress and release the US/MET-

RIC button one time and all segments will light si-

multaneously for about 2 seconds. If any segment

should fail to light during the test, the unit is faulty

and requires replacement. To repeat the test, momen-

tarily depress and release the COMP/TEMP button

one time.

(5) Momentarily depress and release the US/MET-

RIC button one time or turn the ignition switch to

OFF to exit the self-diagnostic mode and return to

normal operation.

If the compass functions, but accuracy is sus-

pect, it may be necessary to perform a variation

adjustment. This procedure allows the unit to

accommodate variations in the earth's mag-

netic field strength based on geographic loca-

tion. See Compass Variation Adjustment, in this

group.

If the compass display has blanked out and

only CAL appears, demagnetizing may be nec-

essary to remove excessive residual magnetic

fields from the vehicle. See Compass Demagne-

tizing, in this group.

THERMOMETER DIAGNOSIS

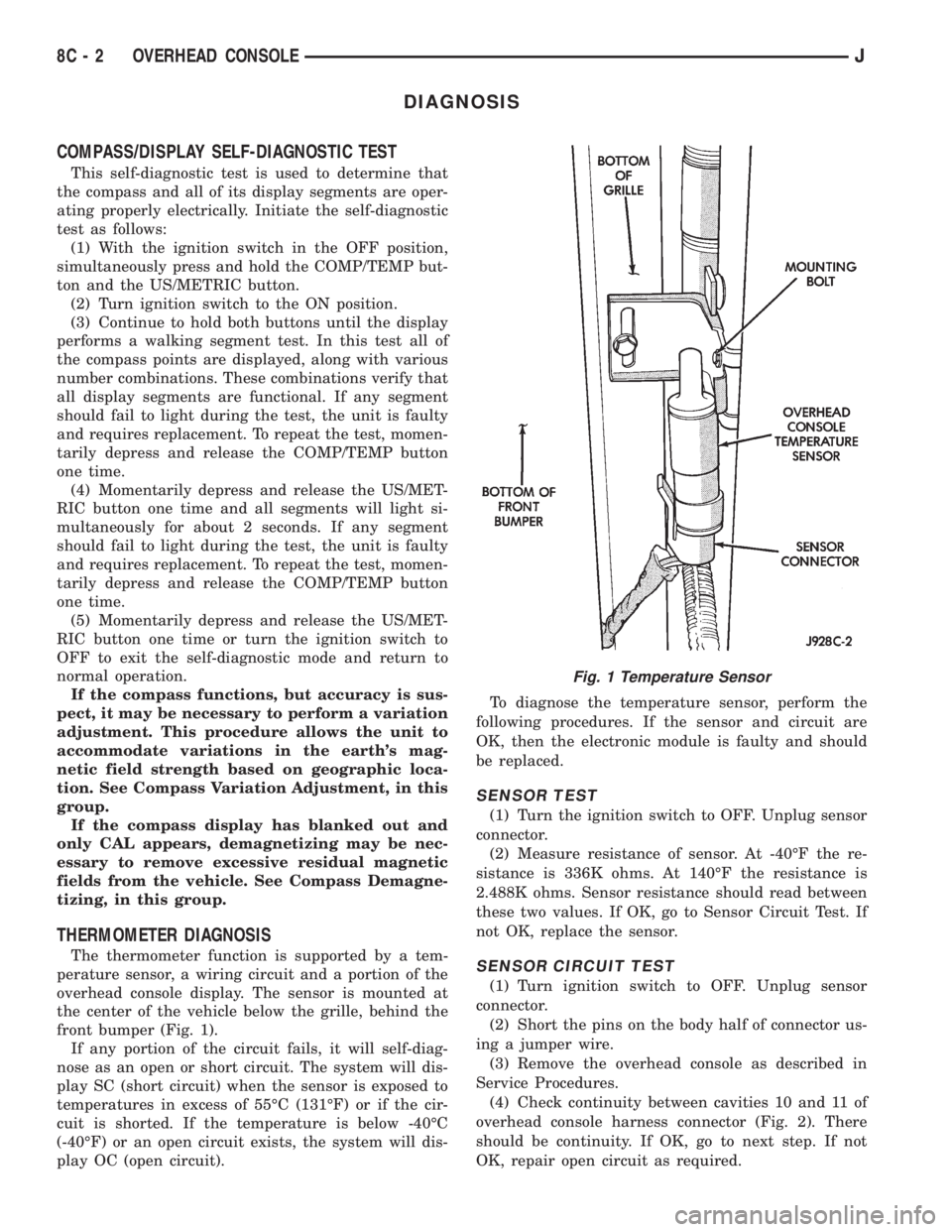

The thermometer function is supported by a tem-

perature sensor, a wiring circuit and a portion of the

overhead console display. The sensor is mounted at

the center of the vehicle below the grille, behind the

front bumper (Fig. 1).

If any portion of the circuit fails, it will self-diag-

nose as an open or short circuit. The system will dis-

play SC (short circuit) when the sensor is exposed to

temperatures in excess of 55ÉC (131ÉF) or if the cir-

cuit is shorted. If the temperature is below -40ÉC

(-40ÉF) or an open circuit exists, the system will dis-

play OC (open circuit).To diagnose the temperature sensor, perform the

following procedures. If the sensor and circuit are

OK, then the electronic module is faulty and should

be replaced.

SENSOR TEST

(1) Turn the ignition switch to OFF. Unplug sensor

connector.

(2) Measure resistance of sensor. At -40ÉF the re-

sistance is 336K ohms. At 140ÉF the resistance is

2.488K ohms. Sensor resistance should read between

these two values. If OK, go to Sensor Circuit Test. If

not OK, replace the sensor.

SENSOR CIRCUIT TEST

(1) Turn ignition switch to OFF. Unplug sensor

connector.

(2) Short the pins on the body half of connector us-

ing a jumper wire.

(3) Remove the overhead console as described in

Service Procedures.

(4) Check continuity between cavities 10 and 11 of

overhead console harness connector (Fig. 2). There

should be continuity. If OK, go to next step. If not

OK, repair open circuit as required.

Fig. 1 Temperature Sensor

8C - 2 OVERHEAD CONSOLEJ

Page 308 of 2198

SERVICE PROCEDURES

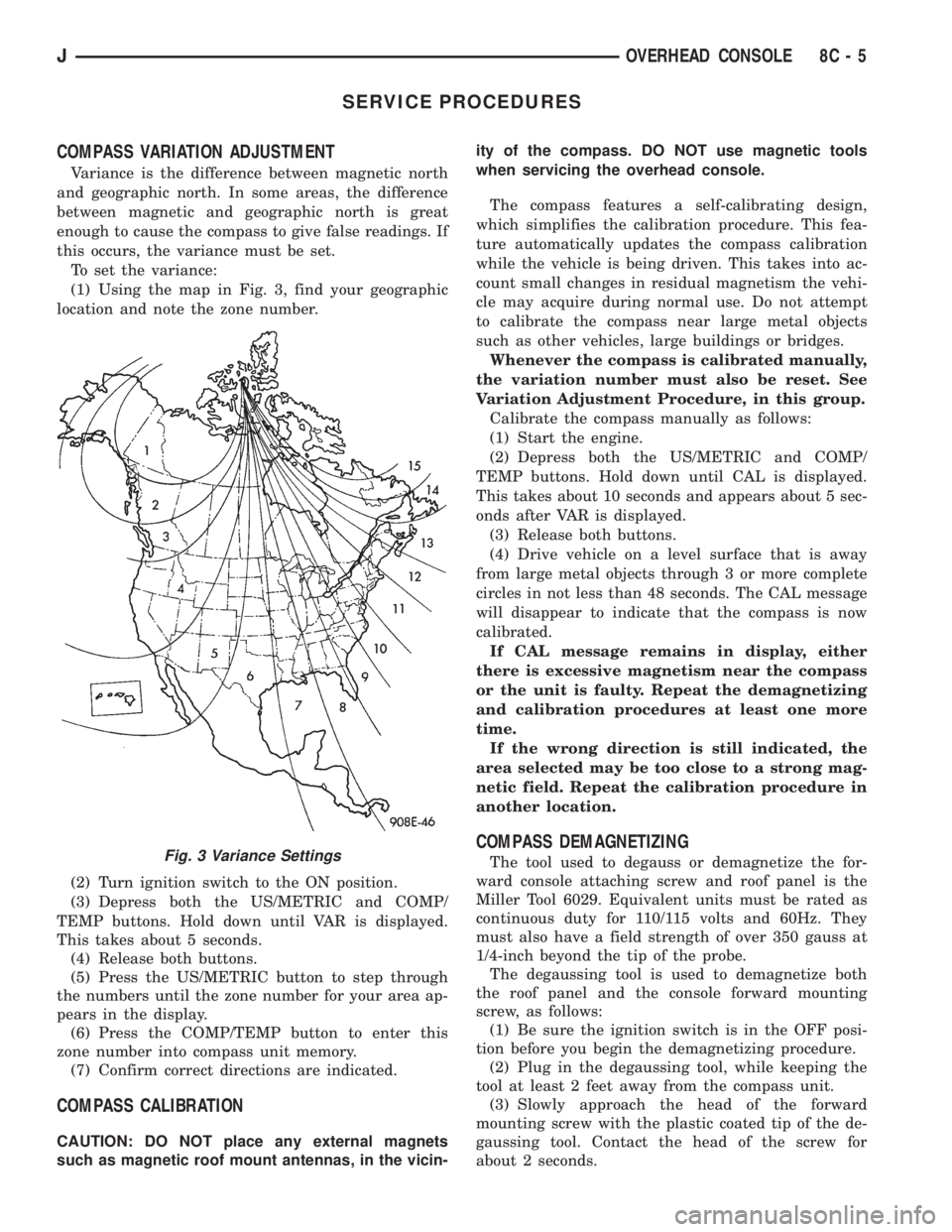

COMPASS VARIATION ADJUSTMENT

Variance is the difference between magnetic north

and geographic north. In some areas, the difference

between magnetic and geographic north is great

enough to cause the compass to give false readings. If

this occurs, the variance must be set.

To set the variance:

(1) Using the map in Fig. 3, find your geographic

location and note the zone number.

(2) Turn ignition switch to the ON position.

(3) Depress both the US/METRIC and COMP/

TEMP buttons. Hold down until VAR is displayed.

This takes about 5 seconds.

(4) Release both buttons.

(5) Press the US/METRIC button to step through

the numbers until the zone number for your area ap-

pears in the display.

(6) Press the COMP/TEMP button to enter this

zone number into compass unit memory.

(7) Confirm correct directions are indicated.

COMPASS CALIBRATION

CAUTION: DO NOT place any external magnets

such as magnetic roof mount antennas, in the vicin-ity of the compass. DO NOT use magnetic tools

when servicing the overhead console.

The compass features a self-calibrating design,

which simplifies the calibration procedure. This fea-

ture automatically updates the compass calibration

while the vehicle is being driven. This takes into ac-

count small changes in residual magnetism the vehi-

cle may acquire during normal use. Do not attempt

to calibrate the compass near large metal objects

such as other vehicles, large buildings or bridges.

Whenever the compass is calibrated manually,

the variation number must also be reset. See

Variation Adjustment Procedure, in this group.

Calibrate the compass manually as follows:

(1) Start the engine.

(2) Depress both the US/METRIC and COMP/

TEMP buttons. Hold down until CAL is displayed.

This takes about 10 seconds and appears about 5 sec-

onds after VAR is displayed.

(3) Release both buttons.

(4) Drive vehicle on a level surface that is away

from large metal objects through 3 or more complete

circles in not less than 48 seconds. The CAL message

will disappear to indicate that the compass is now

calibrated.

If CAL message remains in display, either

there is excessive magnetism near the compass

or the unit is faulty. Repeat the demagnetizing

and calibration procedures at least one more

time.

If the wrong direction is still indicated, the

area selected may be too close to a strong mag-

netic field. Repeat the calibration procedure in

another location.

COMPASS DEMAGNETIZING

The tool used to degauss or demagnetize the for-

ward console attaching screw and roof panel is the

Miller Tool 6029. Equivalent units must be rated as

continuous duty for 110/115 volts and 60Hz. They

must also have a field strength of over 350 gauss at

1/4-inch beyond the tip of the probe.

The degaussing tool is used to demagnetize both

the roof panel and the console forward mounting

screw, as follows:

(1) Be sure the ignition switch is in the OFF posi-

tion before you begin the demagnetizing procedure.

(2) Plug in the degaussing tool, while keeping the

tool at least 2 feet away from the compass unit.

(3) Slowly approach the head of the forward

mounting screw with the plastic coated tip of the de-

gaussing tool. Contact the head of the screw for

about 2 seconds.Fig. 3 Variance Settings

JOVERHEAD CONSOLE 8C - 5

Page 318 of 2198

(8) If voltage is not present at supply wire, check

for voltage at pin-7 of powertrain control module

(PCM) 60-way connector. Leave the PCM connector

connected for this test.

(9) If voltage is still not present, perform vehicle

test using the DRB scan tool.

(10) If voltage is present at pin-7, but not at the

supply wire:

(a) Check continuity between the supply wire.

This is checked between the distributor connector

and pin-7 at the PCM. If continuity is not present,

repair the harness as necessary.

(b) Check for continuity between the camshaft

position sensor output wire and pin-44 at the PCM.

If continuity is not present, repair the harness as

necessary.

(c) Check for continuity between the ground cir-

cuit wire at the distributor connector and ground.

If continuity is not present, repair the harness as

necessary.

(11) While observing the voltmeter, crank the en-

gine with ignition switch. The voltmeter needle

should fluctuate between 0 and 5 volts while the en-

gine is cranking. This verifies that the camshaft po-

sition sensor in the distributor is operating properly

and a sync pulse signal is being generated.

If sync pulse signal is not present, replacement of

the camshaft position sensor is necessary.

For removal or installation of ignition system com-

ponents, refer to the Component Removal/Installa-

tion section of this group.

For system operation and component identification,

refer to the Component Identification/System Opera-

tion section of this group.

CRANKSHAFT POSITION SENSOR TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

The sensor is located on the transmission bellhous-

ing at the left/rear side of the engine block (Figs. 2, 3

or 4).

(1) Near the rear of the intake manifold, discon-

nect sensor pigtail harness connector from main wir-

ing harness.

(2) Place an ohmmeter across terminals B and C

(Fig. 5). Ohmmeter should be set to 1K-to-10K scale

for this test. The meter reading should be open (no

resistance). Replace sensor if a low resistance is indi-

cated.

For removal or installation of ignition system com-

ponents, refer to the Component Removal/Installa-

tion section of this group.DISTRIBUTOR CAP

INSPECTION

Remove the distributor cap and wipe it clean with

a dry lint free cloth. Visually inspect the cap for

cracks, carbon paths, broken towers, or damaged ro-

tor button (Figs. 6 and 7). Also check for white depos-

its on the inside (caused by condensation entering

the cap through cracks). Replace any cap that dis-

plays charred or eroded terminals. The inside flat

surface of a terminal end (faces toward rotor) will in-

dicate some evidence of erosion from normal opera-

tion. Examine the terminal ends for evidence of

mechanical interference with the rotor tip.

If replacement of the distributor cap is necessary,

transfer spark plug cables from the original cap to

the new cap. This should be done one cable at a time.

Each cable is installed onto the tower of the new cap

that corresponds to its tower position on the original

Fig. 2 Crankshaft Position SensorÐ2.5L 4-Cyl.

EngineÐTypical

Fig. 3 Crankshaft Position SensorÐ4.0L 6-Cyl.

EngineÐAll Except YJ models With Auto. Trans.

JIGNITION SYSTEMS 8D - 7

Page 326 of 2198

To test ignition coil-to-distributor cap cable, do not

remove the cable from the cap. Connect ohmmeter to

rotor button (center contact) of distributor cap and

terminal at ignition coil end of cable. If resistance is

not within specifications as found in the Spark Plug

Cable Resistance chart, remove the cable from the

distributor cap. Connect the ohmmeter to the termi-

nal ends of the cable. If resistance is not within spec-

ifications as found in the Spark Plug Cable

Resistance chart, replace the cable. Inspect the igni-

tion coil tower for cracks, burns or corrosion.

For removal and installation of spark plug cables,

refer to Spark Plug Secondary Cables in the Compo-

nent Removal/Installation section.

THROTTLE POSITION SENSOR TEST

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

OXYGEN (O2S) SENSOR TESTS

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

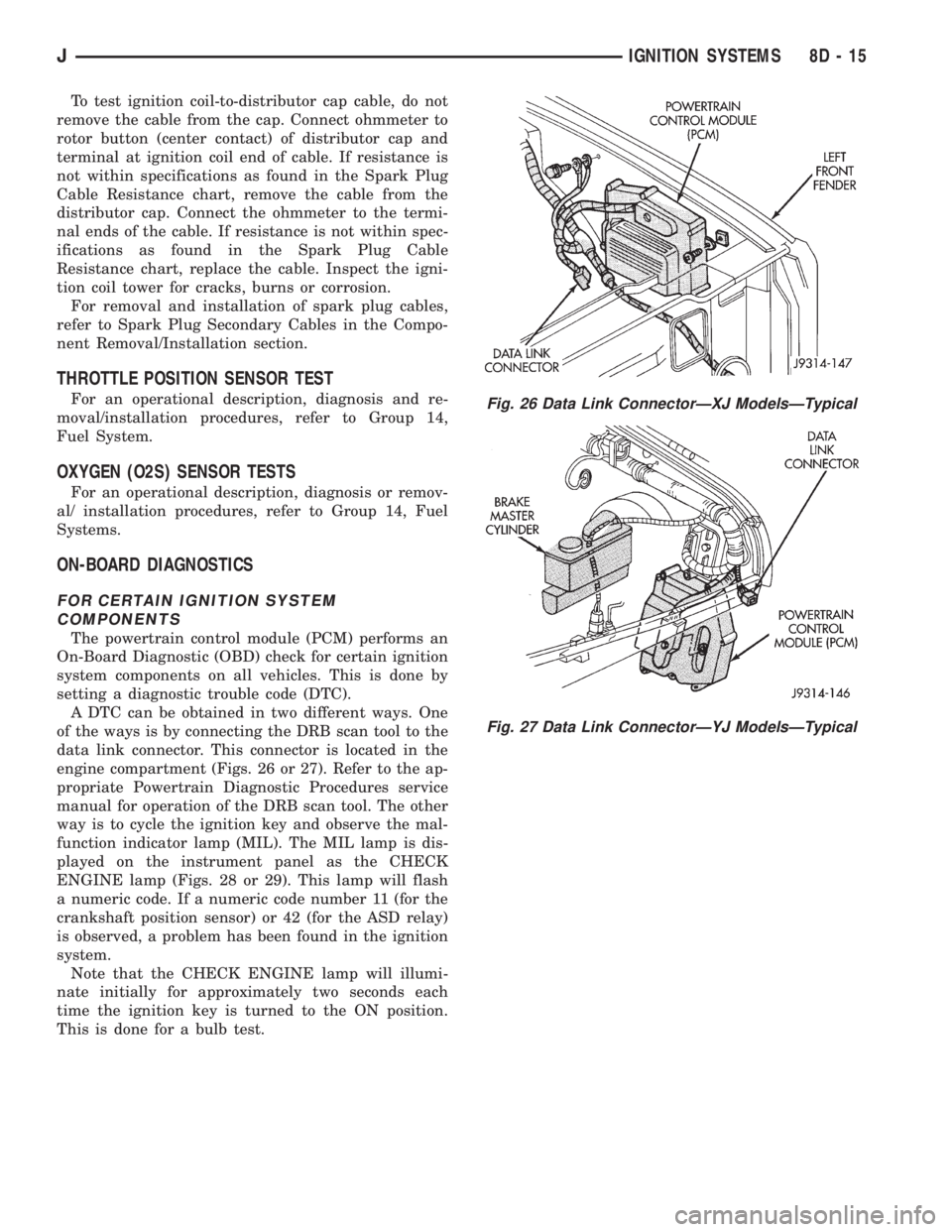

ON-BOARD DIAGNOSTICS

FOR CERTAIN IGNITION SYSTEM

COMPONENTS

The powertrain control module (PCM) performs an

On-Board Diagnostic (OBD) check for certain ignition

system components on all vehicles. This is done by

setting a diagnostic trouble code (DTC).

A DTC can be obtained in two different ways. One

of the ways is by connecting the DRB scan tool to the

data link connector. This connector is located in the

engine compartment (Figs. 26 or 27). Refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual for operation of the DRB scan tool. The other

way is to cycle the ignition key and observe the mal-

function indicator lamp (MIL). The MIL lamp is dis-

played on the instrument panel as the CHECK

ENGINE lamp (Figs. 28 or 29). This lamp will flash

a numeric code. If a numeric code number 11 (for the

crankshaft position sensor) or 42 (for the ASD relay)

is observed, a problem has been found in the ignition

system.

Note that the CHECK ENGINE lamp will illumi-

nate initially for approximately two seconds each

time the ignition key is turned to the ON position.

This is done for a bulb test.

Fig. 26 Data Link ConnectorÐXJ ModelsÐTypical

Fig. 27 Data Link ConnectorÐYJ ModelsÐTypical

JIGNITION SYSTEMS 8D - 15

Page 363 of 2198

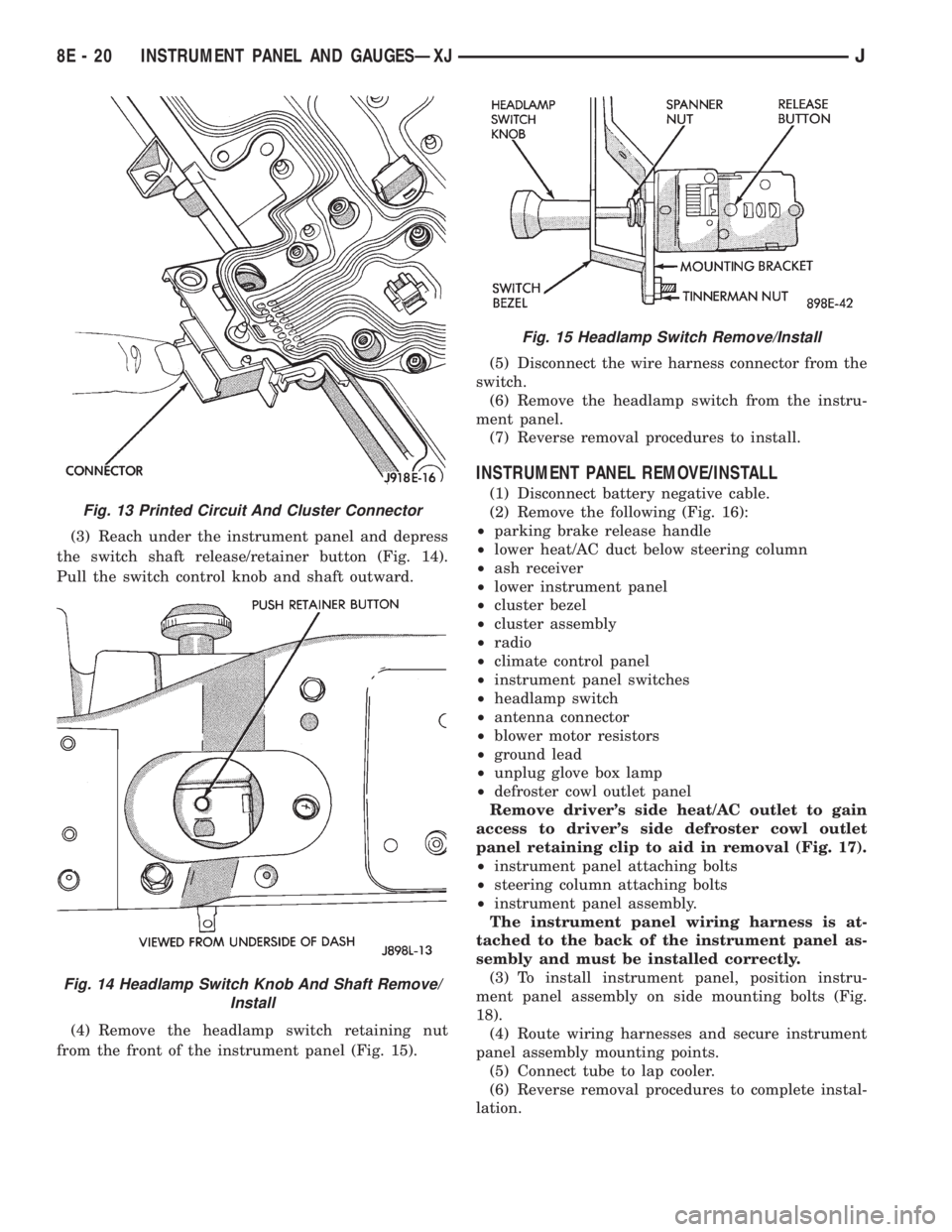

(3) Reach under the instrument panel and depress

the switch shaft release/retainer button (Fig. 14).

Pull the switch control knob and shaft outward.

(4) Remove the headlamp switch retaining nut

from the front of the instrument panel (Fig. 15).(5) Disconnect the wire harness connector from the

switch.

(6) Remove the headlamp switch from the instru-

ment panel.

(7) Reverse removal procedures to install.

INSTRUMENT PANEL REMOVE/INSTALL

(1) Disconnect battery negative cable.

(2) Remove the following (Fig. 16):

²parking brake release handle

²lower heat/AC duct below steering column

²ash receiver

²lower instrument panel

²cluster bezel

²cluster assembly

²radio

²climate control panel

²instrument panel switches

²headlamp switch

²antenna connector

²blower motor resistors

²ground lead

²unplug glove box lamp

²defroster cowl outlet panel

Remove driver's side heat/AC outlet to gain

access to driver's side defroster cowl outlet

panel retaining clip to aid in removal (Fig. 17).

²instrument panel attaching bolts

²steering column attaching bolts

²instrument panel assembly.

The instrument panel wiring harness is at-

tached to the back of the instrument panel as-

sembly and must be installed correctly.

(3) To install instrument panel, position instru-

ment panel assembly on side mounting bolts (Fig.

18).

(4) Route wiring harnesses and secure instrument

panel assembly mounting points.

(5) Connect tube to lap cooler.

(6) Reverse removal procedures to complete instal-

lation.

Fig. 13 Printed Circuit And Cluster Connector

Fig. 14 Headlamp Switch Knob And Shaft Remove/

Install

Fig. 15 Headlamp Switch Remove/Install

8E - 20 INSTRUMENT PANEL AND GAUGESÐXJJ

Page 369 of 2198

voltage is supplied to one side of the indicator bulb. A

ground path for the bulb is provided by 3 switches.

The bulb will light when:

²the brake warning switch is closed (indicating un-

equal brake system hydraulic pressures possibly due

to brake fluid leakage)

²the ignition switch is in the START position (bulb

test)

²the parking brake switch is closed (parking brake

is applied).

Refer to Group 5 - Brakes for more information.

FOUR-WHEEL DRIVE INDICATOR LAMP

This lamp lights when the transfer case is engaged

in the 4H or 4L position. Voltage is supplied to one

side of the indicator bulb. A switch on the front axle

disconnect housing is connected to the other side of

the indicator bulb. When the switch is closed, a path

to ground is provided and the indicator bulb lights.

HEADLAMP HIGH BEAM INDICATOR LAMP

The high beam indicator lamp is controlled by the

headlamp dimmer switch. One side of the indicator

bulb is grounded at all times. The other side of the

bulb receives battery feed through the contacts of the

dimmer switch when the turn signal switch lever is

actuated to turn the headlamp high beams on. Refer

to Group 8L - Lamps for more information.

MALFUNCTION INDICATOR LAMP

The CHECK ENGINE or Malfunction Indicator

Lamp (MIL) lights each time the ignition switch is

turned ON, and stays on for 3 seconds as a bulb test.

If the Powertrain Control Module (PCM) receives an

incorrect signal or no signal from certain fuel or

emission system related circuits or components, the

lamp is turned on. This will indicate that the PCM

has recorded a Diagnostic Trouble Code (DTC) in

electronic memory for a circuit or component mal-

function. Refer to Group 14 - Fuel System for more

information.

SEAT BELT REMINDER LAMP

The seat belt reminder lamp lights for 4 to 8 sec-

onds after the ignition switch is turned to the ON po-sition. A timer in the chime/buzzer module controls

ignition-switched battery feed to the lamp. Refer to

Group 8U - Chime/Buzzer Warning Systems for more

information.

TURN SIGNAL INDICATOR LAMPS

The left and right turn signal indicator lamps are

controlled by the turn signal and hazard warning

switches. One side of the bulb for each lamp is

grounded at all times. The other side of the bulb re-

ceives battery feed through the contacts of the turn

signal switch, when the turn signal lever or hazard

warning button are actuated. Refer to Group 8J -

Turn Signal and Hazard Warning Systems for more

information.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have

an optional upshift indicator lamp. Ground feed for

the lamp is switched by the Powertrain Control Mod-

ule (PCM). The lamp lights to indicate when the

driver should shift to the next highest gear for best

fuel economy. The PCM will turn the lamp off after 3

to 5 seconds if the upshift is not performed. The lamp

will remain off until the vehicle stops accelerating

and is brought back to the range of lamp operation,

or until the transmission is shifted into another gear.

The indicator lamp is normally on when the igni-

tion switch is turned ON and is turned off when the

engine is started. The lamp will be turned on during

vehicle operation according to engine speed and load.

CLUSTER ILLUMINATION LAMPS

All cluster illumination lamps receive battery feed

from the instrument lamps fuse in the fuseblock

module through the panel dimmer switch. When the

park or headlamps are on, the cluster illumination

lamps light. Illumination brightness can be adjusted

by rotating the panel dimmer thumb-wheel, which is

next to the headlamp switch.

8E - 26 INSTRUMENT PANEL AND GAUGESÐYJJ