phone JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1130 of 2198

OIL PUMP

The positive-displacement gear-type oil pump is

driven by the distributor shaft, which is driven by a

gear on the camshaft. Oil is siphoned into the pump

through an inlet tube and strainer assembly that is

pressed into the pump body.

The pump incorporates a nonadjustable pressure

relief valve to limit maximum pressure to 517 kPa

(75 psi). In the relief position, the valve permits oil to

bypass through a passage in the pump body to the

inlet side of the pump.

Oil pump removal or replacement will not affect

the distributor timing because the distributor drive

gear remains in mesh with the camshaft gear.

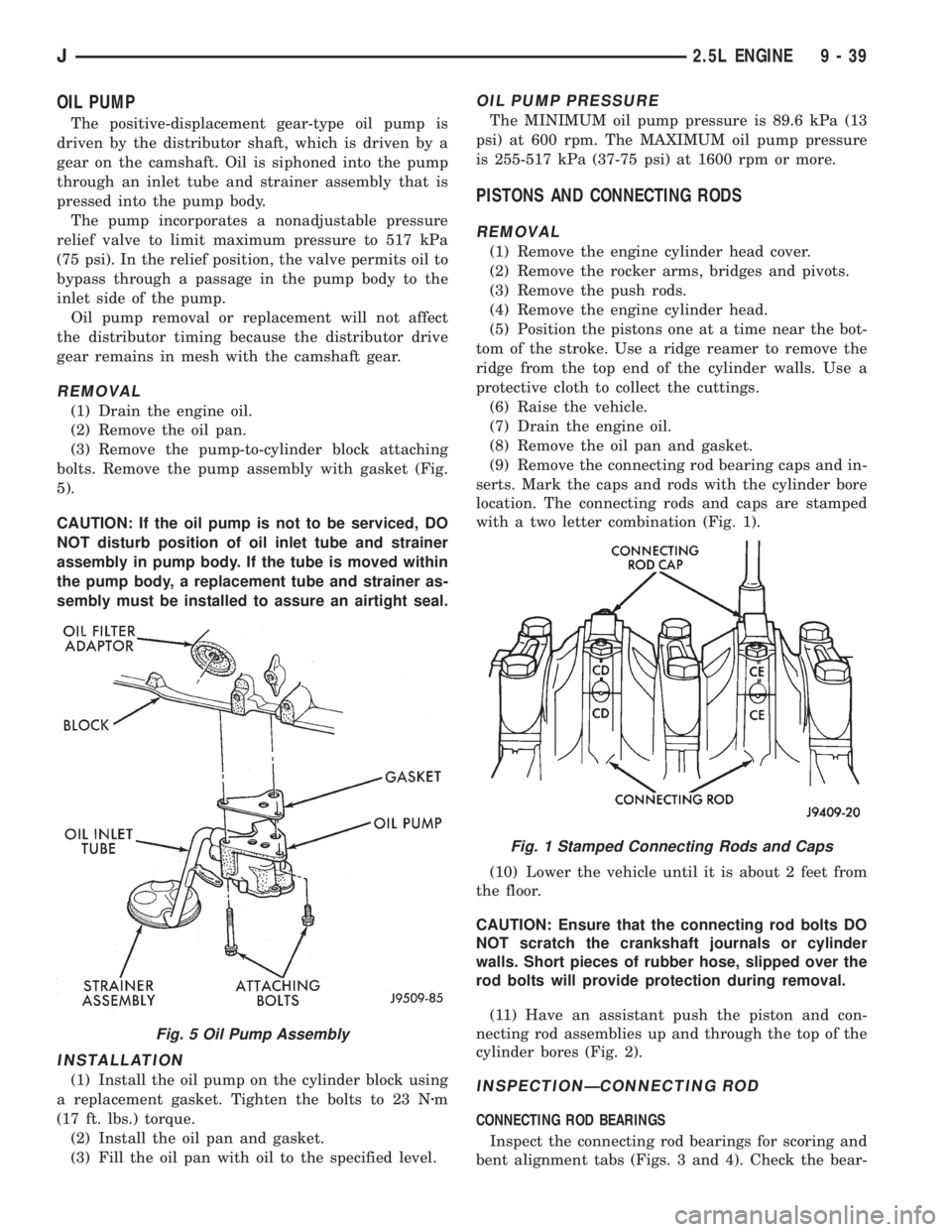

REMOVAL

(1) Drain the engine oil.

(2) Remove the oil pan.

(3) Remove the pump-to-cylinder block attaching

bolts. Remove the pump assembly with gasket (Fig.

5).

CAUTION: If the oil pump is not to be serviced, DO

NOT disturb position of oil inlet tube and strainer

assembly in pump body. If the tube is moved within

the pump body, a replacement tube and strainer as-

sembly must be installed to assure an airtight seal.

INSTALLATION

(1) Install the oil pump on the cylinder block using

a replacement gasket. Tighten the bolts to 23 Nzm

(17 ft. lbs.) torque.

(2) Install the oil pan and gasket.

(3) Fill the oil pan with oil to the specified level.

OIL PUMP PRESSURE

The MINIMUM oil pump pressure is 89.6 kPa (13

psi) at 600 rpm. The MAXIMUM oil pump pressure

is 255-517 kPa (37-75 psi) at 1600 rpm or more.

PISTONS AND CONNECTING RODS

REMOVAL

(1) Remove the engine cylinder head cover.

(2) Remove the rocker arms, bridges and pivots.

(3) Remove the push rods.

(4) Remove the engine cylinder head.

(5) Position the pistons one at a time near the bot-

tom of the stroke. Use a ridge reamer to remove the

ridge from the top end of the cylinder walls. Use a

protective cloth to collect the cuttings.

(6) Raise the vehicle.

(7) Drain the engine oil.

(8) Remove the oil pan and gasket.

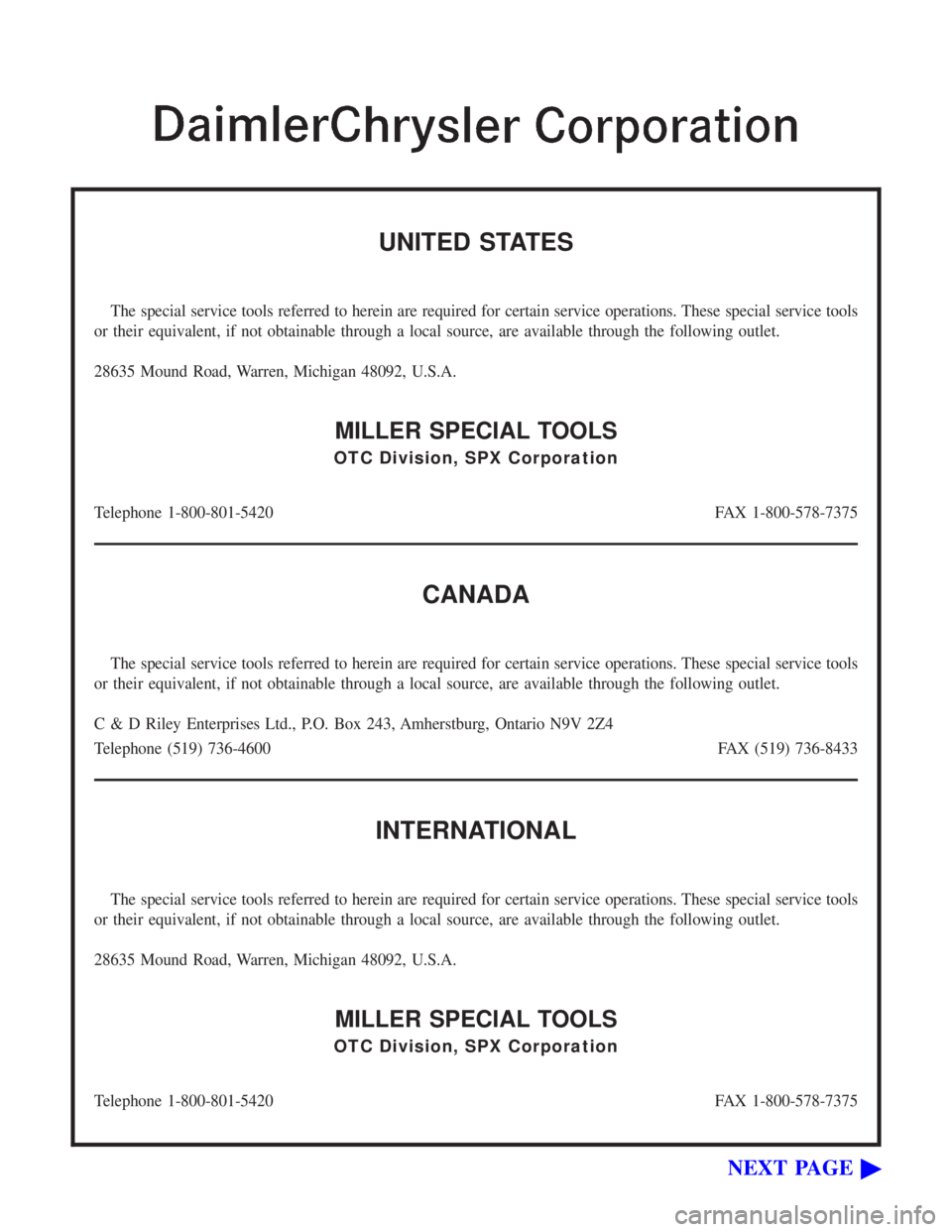

(9) Remove the connecting rod bearing caps and in-

serts. Mark the caps and rods with the cylinder bore

location. The connecting rods and caps are stamped

with a two letter combination (Fig. 1).

(10) Lower the vehicle until it is about 2 feet from

the floor.

CAUTION: Ensure that the connecting rod bolts DO

NOT scratch the crankshaft journals or cylinder

walls. Short pieces of rubber hose, slipped over the

rod bolts will provide protection during removal.

(11) Have an assistant push the piston and con-

necting rod assemblies up and through the top of the

cylinder bores (Fig. 2).

INSPECTIONÐCONNECTING ROD

CONNECTING ROD BEARINGS

Inspect the connecting rod bearings for scoring and

bent alignment tabs (Figs. 3 and 4). Check the bear-

Fig. 5 Oil Pump Assembly

Fig. 1 Stamped Connecting Rods and Caps

J2.5L ENGINE 9 - 39

Page 2186 of 2198

UNITED STATES

The special service tools referred to herein are required for certain service operations. These special service tools

or their equivalent, if not obtainable through a local source, are available through the following outlet.

28635 Mound Road, Warren, Michigan 48092, U.S.A.

MILLER SPECIAL TOOLS

OTC Division, SPX Corporation

Telephone 1-800-801-5420 FAX 1-800-578-7375

CANADA

The special service tools referred to herein are required for certain service operations. These special service tools

or their equivalent, if not obtainable through a local source, are available through the following outlet.

C & D Riley Enterprises Ltd., P.O. Box 243, Amherstburg, Ontario N9V 2Z4

Telephone (519) 736-4600 FAX (519) 736-8433

INTERNATIONAL

The special service tools referred to herein are required for certain service operations. These special service tools

or their equivalent, if not obtainable through a local source, are available through the following outlet.

28635 Mound Road, Warren, Michigan 48092, U.S.A.

MILLER SPECIAL TOOLS

OTC Division, SPX Corporation

Telephone 1-800-801-5420 FAX 1-800-578-7375

NEXT PAGE©

Page 2187 of 2198

CAUTION

ALL SERVICE AND REBUILDING INSTRUCTIONS CONTAINED HEREIN

ARE APPLICABLE TO, AND FOR THE CONVENIENCE OF, THE AUTOMOTIVE

TRADE ONLY. All test and repair procedures on components or assemblies in

non-automotive applications should be repaired in accordance with instructions

supplied by the manufacturer of the total product.

Proper service and repair is important to the safe, reliable, operation of all motor

vehicles. The service procedures recommended and described in this publication were

developed for professional service personnel and are effective methods for performing

vehicle repair. Following these procedures will help assure efficient economical vehicle

performance and service reliability. Some of these service procedures require the use

of special tools designed for specific procedures. These special tools should be used

when recommended throughout this publication.

Special attention should be exercised when working with spring or tension loaded

fasteners and devices such as E-Clips, Circlips, Snap rings, etc., as careless removal

may cause personal injury. Always wear safety goggles whenever working on vehicles

or vehicle components.

It is important to note that this publication contains variousCautionsandWarnings.

These should be carefully read in order to minimize the risk of personal injury, or the

possibility that improper service methods may damage the vehicle or render it unsafe.

It is important to note that theseCautionsandWarningscover only the situations

and procedures DaimlerChrysler Corporation has encountered and recommended.

DaimlerChrysler Corporation could not possibly know, evaluate, and advise the

service trade of all conceivable ways that service may be performed, or of the possible

hazards of each. Consequently, DaimlerChrysler Corporation has not undertaken any

such broad service review. Accordingly, anyone who uses a service procedure, or tool,

that is not recommended in this publication must assure oneself thoroughly that

neither personal safety, nor vehicle safety, be jeopardized by the service methods they

select.

SERVICE AND OWNER MANUALS

Available for Chrysler, Plymouth, Dodge,

Dodge Truck, and Jeep

Tvehicles.

Telephone orders may be placed at the number below.

Credit cards are accepted (no CODs). Please have your

order information available at time of call.

CALL: (800) 890-4038 OR FAX: (440) 572-0815

FOR A FREE CATALOG OR TO PLACE AN ORDER.

NEXT PAGE©

llllllllllll