JEEP CHEROKEE 2018 Owner handbook (in English)

Manufacturer: JEEP, Model Year: 2018, Model line: CHEROKEE, Model: JEEP CHEROKEE 2018Pages: 312, PDF Size: 4.91 MB

Page 171 of 312

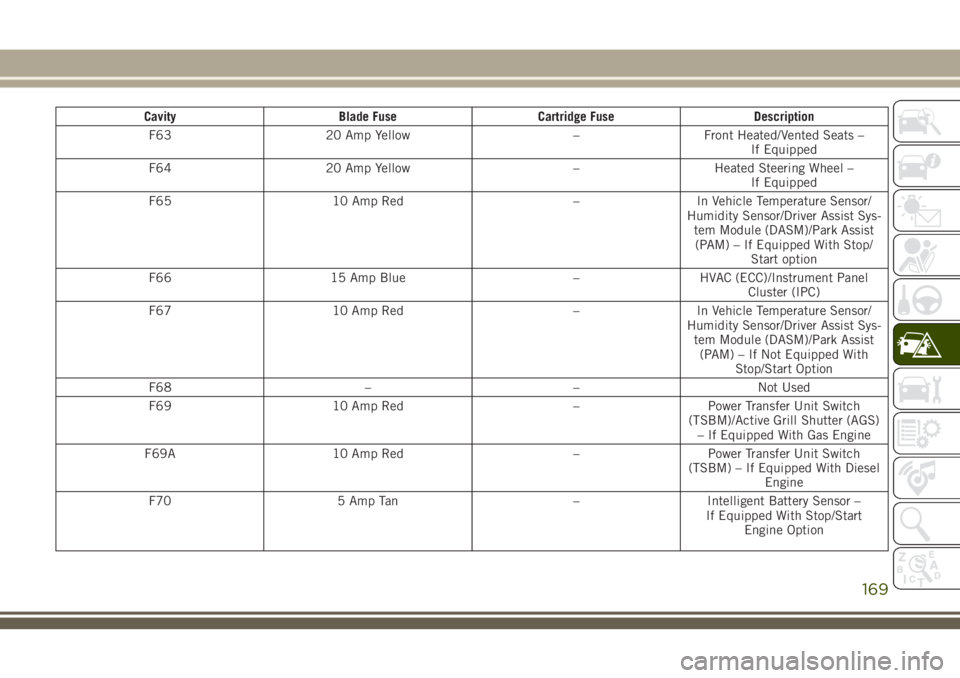

CavityBlade Fuse Cartridge Fuse Description

F63 20 Amp Yellow –Front Heated/Vented Seats –

If Equipped

F64 20 Amp Yellow –Heated Steering Wheel –

If Equipped

F65 10 Amp Red –In Vehicle Temperature Sensor/

Humidity Sensor/Driver Assist Sys- tem Module (DASM)/Park Assist(PAM) – If Equipped With Stop/ Start option

F66 15 Amp Blue –HVAC (ECC)/Instrument Panel

Cluster (IPC)

F67 10 Amp Red –In Vehicle Temperature Sensor/

Humidity Sensor/Driver Assist Sys- tem Module (DASM)/Park Assist(PAM) – If Not Equipped With Stop/Start Option

F68 ––Not Used

F69 10 Amp Red –Power Transfer Unit Switch

(TSBM)/Active Grill Shutter (AGS) – If Equipped With Gas Engine

F69A 10 Amp Red –Power Transfer Unit Switch

(TSBM) – If Equipped With Diesel Engine

F70 5 Amp Tan –Intelligent Battery Sensor –

If Equipped With Stop/Start Engine Option

169

Page 172 of 312

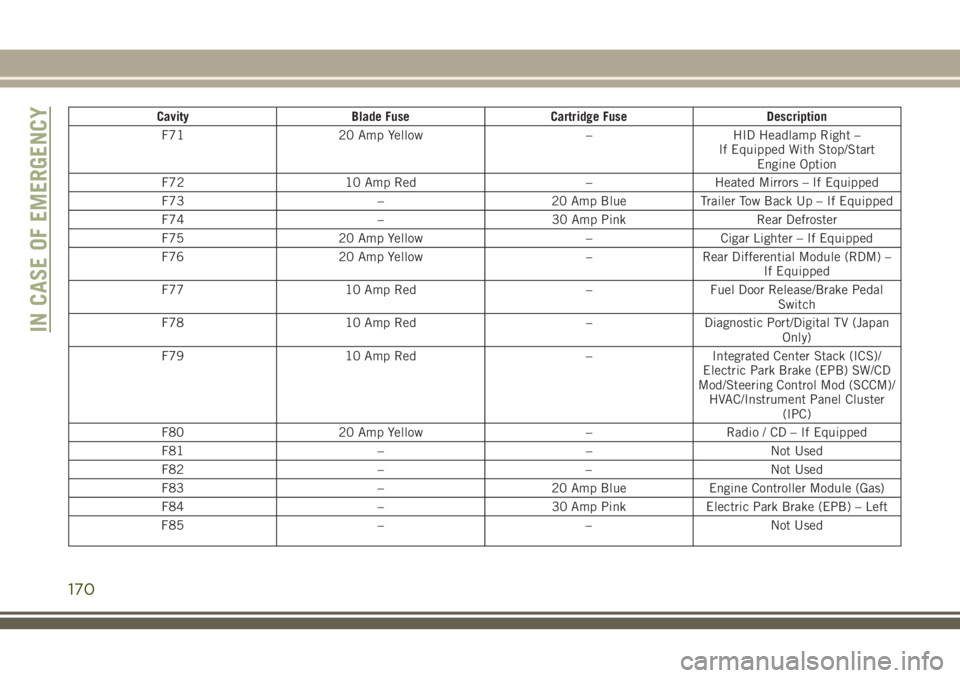

CavityBlade Fuse Cartridge Fuse Description

F71 20 Amp Yellow –HID Headlamp Right –

If Equipped With Stop/Start Engine Option

F72 10 Amp Red –Heated Mirrors – If Equipped

F73 –20 Amp BlueTrailer Tow Back Up – If Equipped

F74 –30 Amp Pink Rear Defroster

F75 20 Amp Yellow –Cigar Lighter – If Equipped

F76 20 Amp Yellow –Rear Differential Module (RDM) –

If Equipped

F77 10 Amp Red –Fuel Door Release/Brake Pedal

Switch

F78 10 Amp Red –Diagnostic Port/Digital TV (Japan

Only)

F79 10 Amp Red –Integrated Center Stack (ICS)/

Electric Park Brake (EPB) SW/CD

Mod/Steering Control Mod (SCCM)/ HVAC/Instrument Panel Cluster (IPC)

F80 20 Amp Yellow –Radio / CD – If Equipped

F81 ––Not Used

F82 ––Not Used

F83 –20 Amp BlueEngine Controller Module (Gas)

F84 –30 Amp PinkElectric Park Brake (EPB) – Left

F85 ––Not Used

IN CASE OF EMERGENCY

170

Page 173 of 312

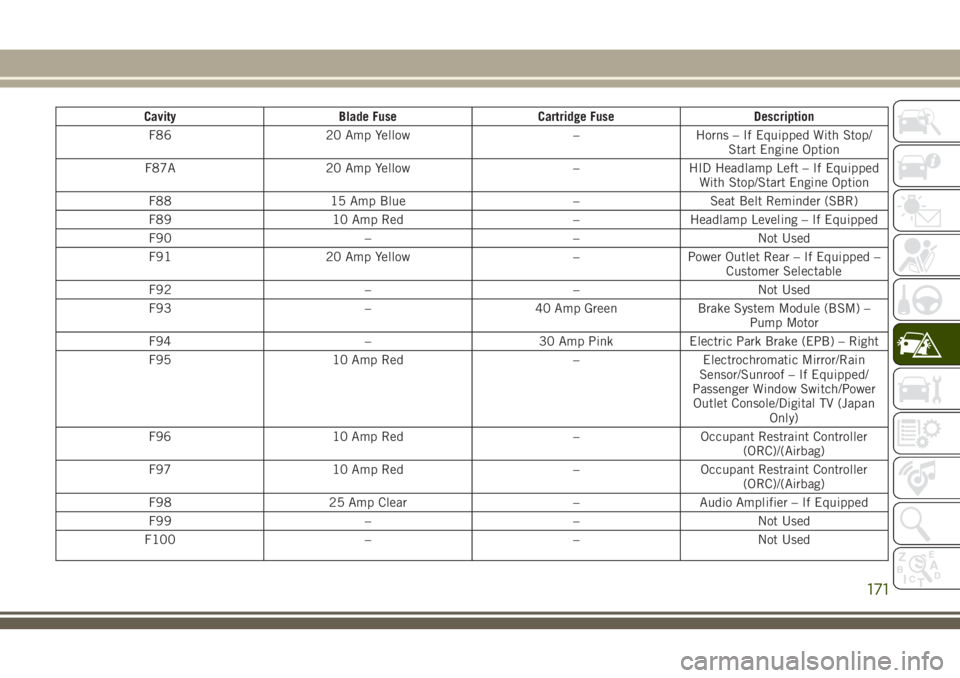

CavityBlade Fuse Cartridge Fuse Description

F86 20 Amp Yellow –Horns – If Equipped With Stop/

Start Engine Option

F87A 20 Amp Yellow –HID Headlamp Left – If Equipped

With Stop/Start Engine Option

F88 15 Amp Blue –Seat Belt Reminder (SBR)

F89 10 Amp Red –Headlamp Leveling – If Equipped

F90 ––Not Used

F91 20 Amp Yellow –Power Outlet Rear – If Equipped –

Customer Selectable

F92 ––Not Used

F93 –40 Amp GreenBrake System Module (BSM) –

Pump Motor

F94 –30 Amp PinkElectric Park Brake (EPB) – Right

F95 10 Amp Red –Electrochromatic Mirror/Rain

Sensor/Sunroof – If Equipped/

Passenger Window Switch/Power Outlet Console/Digital TV (Japan Only)

F96 10 Amp Red –Occupant Restraint Controller

(ORC)/(Airbag)

F97 10 Amp Red –Occupant Restraint Controller

(ORC)/(Airbag)

F98 25 Amp Clear –Audio Amplifier – If Equipped

F99 ––Not Used

F100 ––Not Used

171

Page 174 of 312

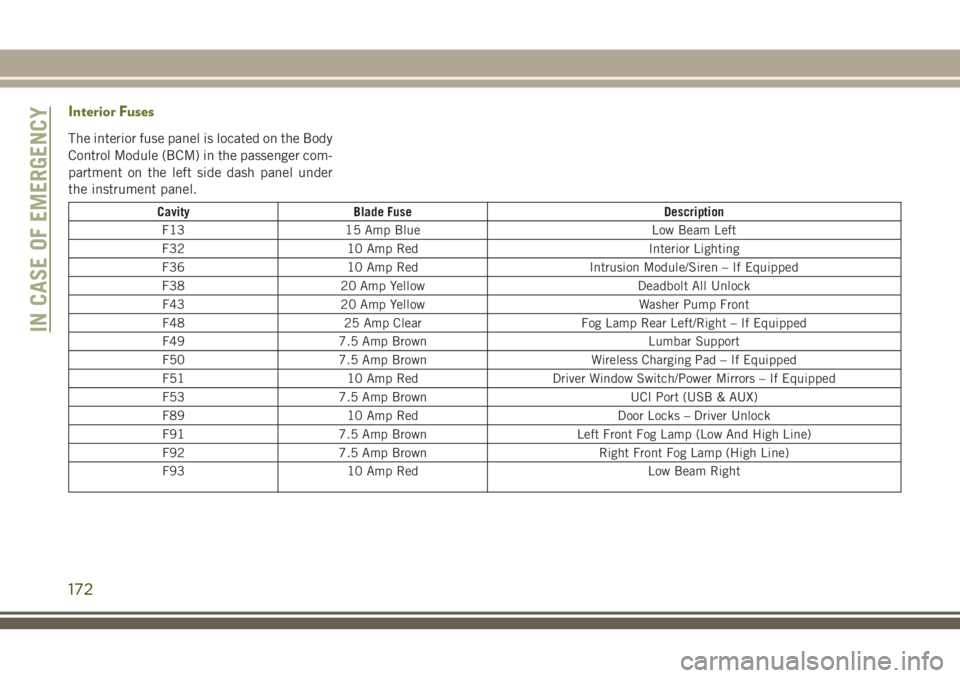

Interior Fuses

The interior fuse panel is located on the Body

Control Module (BCM) in the passenger com-

partment on the left side dash panel under

the instrument panel.

CavityBlade Fuse Description

F13 15 Amp Blue Low Beam Left

F32 10 Amp Red Interior Lighting

F36 10 Amp Red Intrusion Module/Siren – If Equipped

F38 20 Amp Yellow Deadbolt All Unlock

F43 20 Amp Yellow Washer Pump Front

F48 25 Amp Clear Fog Lamp Rear Left/Right – If Equipped

F49 7.5 Amp Brown Lumbar Support

F50 7.5 Amp Brown Wireless Charging Pad – If Equipped

F51 10 Amp Red Driver Window Switch/Power Mirrors – If Equipped

F53 7.5 Amp Brown UCI Port (USB & AUX)

F89 10 Amp Red Door Locks – Driver Unlock

F91 7.5 Amp Brown Left Front Fog Lamp (Low And High Line)

F92 7.5 Amp Brown Right Front Fog Lamp (High Line)

F93 10 Amp Red Low Beam Right

IN CASE OF EMERGENCY

172

Page 175 of 312

JACKING AND TIRE

CHANGING

WARNING!

• Do not attempt to change a tire on theside of the vehicle close to moving traf-

fic. Pull far enough off the road to avoid

the danger of being hit when operating

the jack or changing the wheel.

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

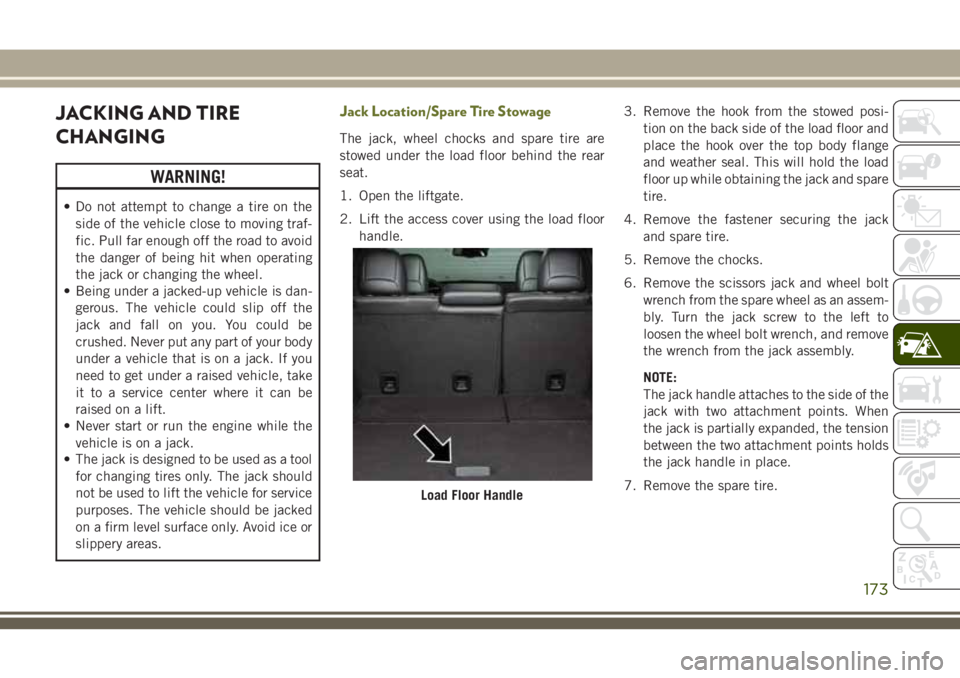

Jack Location/Spare Tire Stowage

The jack, wheel chocks and spare tire are

stowed under the load floor behind the rear

seat.

1. Open the liftgate.

2. Lift the access cover using the load floor handle. 3. Remove the hook from the stowed posi-

tion on the back side of the load floor and

place the hook over the top body flange

and weather seal. This will hold the load

floor up while obtaining the jack and spare

tire.

4. Remove the fastener securing the jack and spare tire.

5. Remove the chocks.

6. Remove the scissors jack and wheel bolt wrench from the spare wheel as an assem-

bly. Turn the jack screw to the left to

loosen the wheel bolt wrench, and remove

the wrench from the jack assembly.

NOTE:

The jack handle attaches to the side of the

jack with two attachment points. When

the jack is partially expanded, the tension

between the two attachment points holds

the jack handle in place.

7. Remove the spare tire.

Load Floor Handle

173

Page 176 of 312

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

Preparations For Jacking

1. Park the vehicle on a firm level surface asfar from the edge of the roadway as pos-

sible. Avoid icy or slippery areas.

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic. Pull

far enough off the road to avoid being hit

when operating the jack or changing the

wheel.

2. Turn on the Hazard Warning flasher.

3. Apply the parking brake.

4. Place the gear selector into PARK (auto- matic transmission) or REVERSE (manual

transmission). 5. Turn the ignition off to the LOCK position.

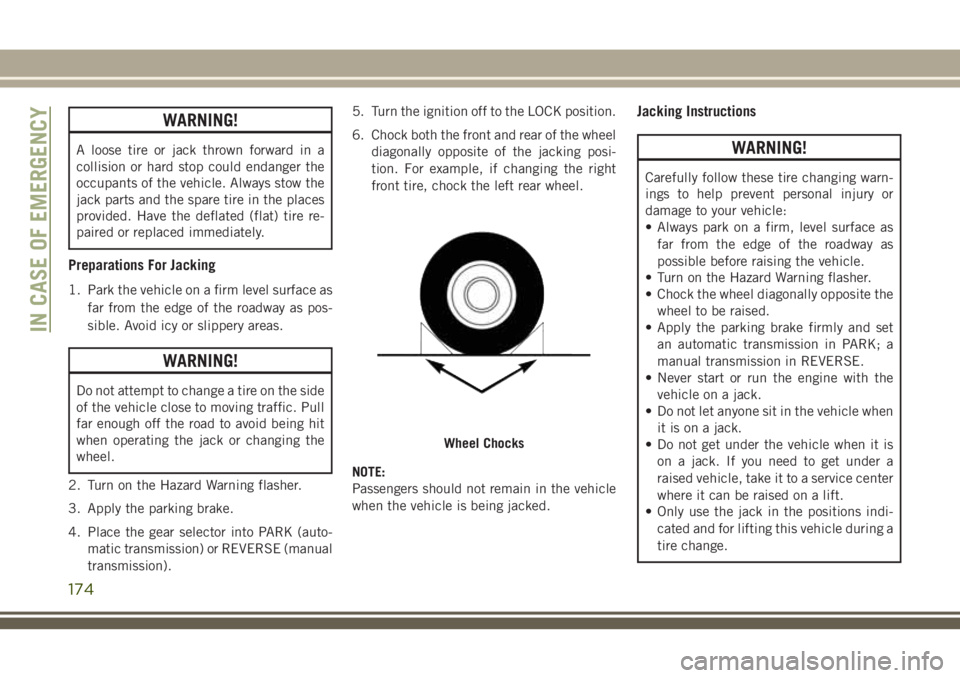

6. Chock both the front and rear of the wheel

diagonally opposite of the jacking posi-

tion. For example, if changing the right

front tire, chock the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Jacking Instructions

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Chock the wheel diagonally opposite the

wheel to be raised.

• Apply the parking brake firmly and set

an automatic transmission in PARK; a

manual transmission in REVERSE.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

• Only use the jack in the positions indi-

cated and for lifting this vehicle during a

tire change.

Wheel Chocks

IN CASE OF EMERGENCY

174

Page 177 of 312

WARNING!

• If working on or near a roadway, beextremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

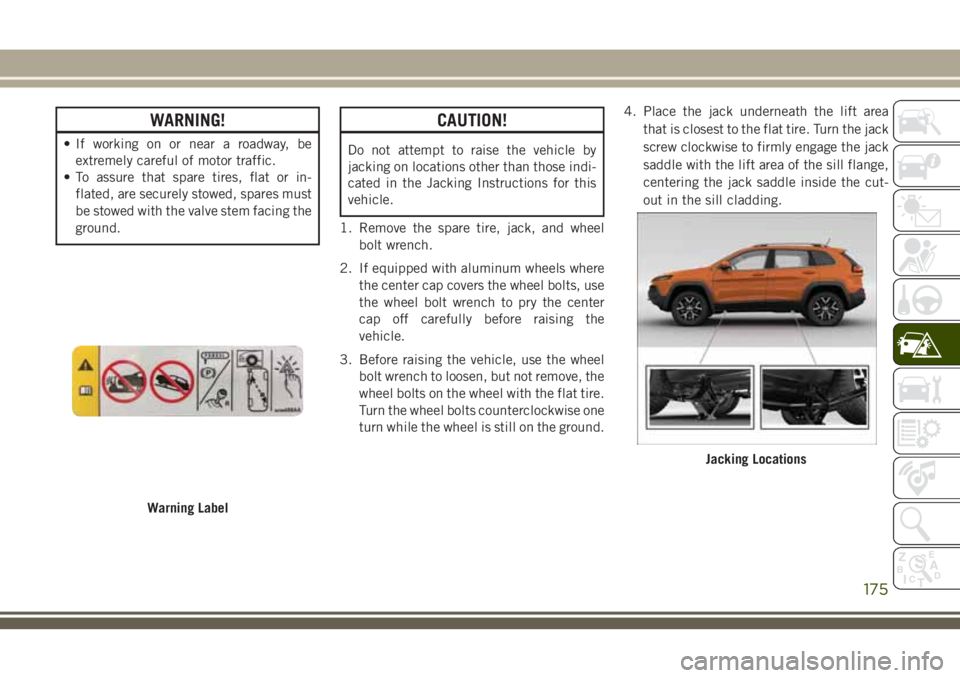

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

1. Remove the spare tire, jack, and wheel bolt wrench.

2. If equipped with aluminum wheels where the center cap covers the wheel bolts, use

the wheel bolt wrench to pry the center

cap off carefully before raising the

vehicle.

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove, the

wheel bolts on the wheel with the flat tire.

Turn the wheel bolts counterclockwise one

turn while the wheel is still on the ground. 4. Place the jack underneath the lift area

that is closest to the flat tire. Turn the jack

screw clockwise to firmly engage the jack

saddle with the lift area of the sill flange,

centering the jack saddle inside the cut-

out in the sill cladding.

Warning Label

Jacking Locations

175

Page 178 of 312

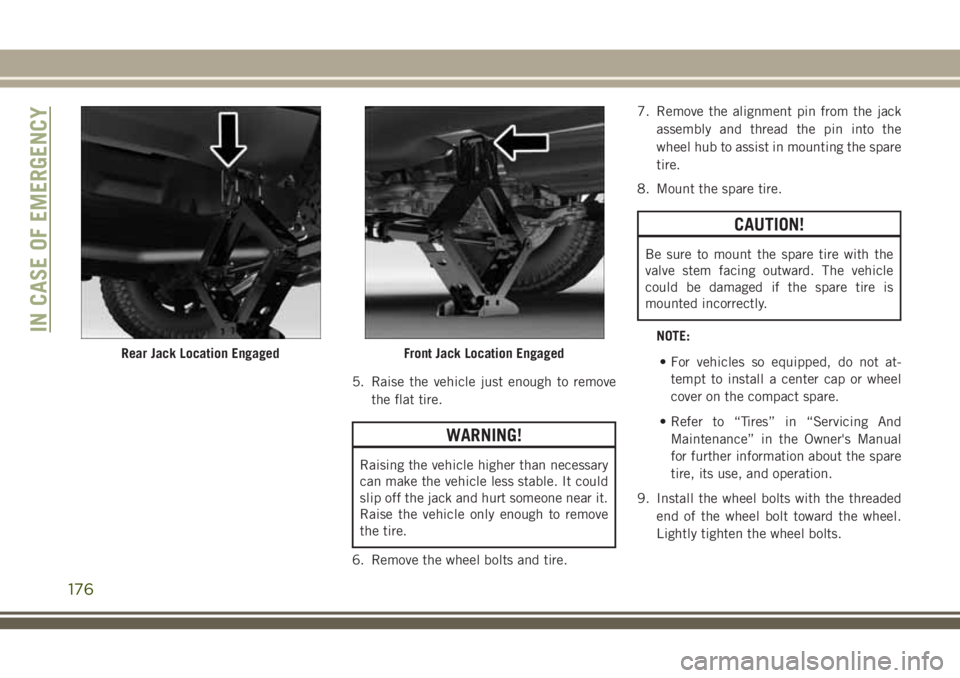

5. Raise the vehicle just enough to removethe flat tire.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

6. Remove the wheel bolts and tire. 7. Remove the alignment pin from the jack

assembly and thread the pin into the

wheel hub to assist in mounting the spare

tire.

8. Mount the spare tire.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.

NOTE:• For vehicles so equipped, do not at- tempt to install a center cap or wheel

cover on the compact spare.

• Refer to “Tires” in “Servicing And Maintenance” in the Owner's Manual

for further information about the spare

tire, its use, and operation.

9. Install the wheel bolts with the threaded end of the wheel bolt toward the wheel.

Lightly tighten the wheel bolts.

Rear Jack Location EngagedFront Jack Location Engaged

IN CASE OF EMERGENCY

176

Page 179 of 312

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

10. Lower the vehicle to the ground by turn- ing the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of

the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened

twice. Refer to “Torque Specifications”

in “Technical Specifications” for the

proper lug bolt torque. If in doubt about

the correct tightness, have them

checked with a torque wrench by your

authorized dealer or at a service station.

12. Securely stow the jack, tools, chocks, and flat tire.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

Changing Procedure

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with thethreaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury. 3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of

the handle for increased leverage. Tighten

the wheel bolts in a star pattern until each

wheel bolt has been tightened twice. Re-

fer to “Torque Specifications” in “Techni-

cal Specifications” for the proper lug bolt

torque. If in doubt about the correct tight-

ness, have them checked with a torque

wrench by your authorized dealer or ser-

vice station.

5. Lower the jack until it is free. Remove the wheel chocks. Reassemble the lug wrench

to the jack assembly and stow it in the

spare tire area. Secure the assembly using

the means provided. Release the parking

brake before driving the vehicle.

6. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure

that all wheel bolts are properly seated

against the wheel.

177

Page 180 of 312

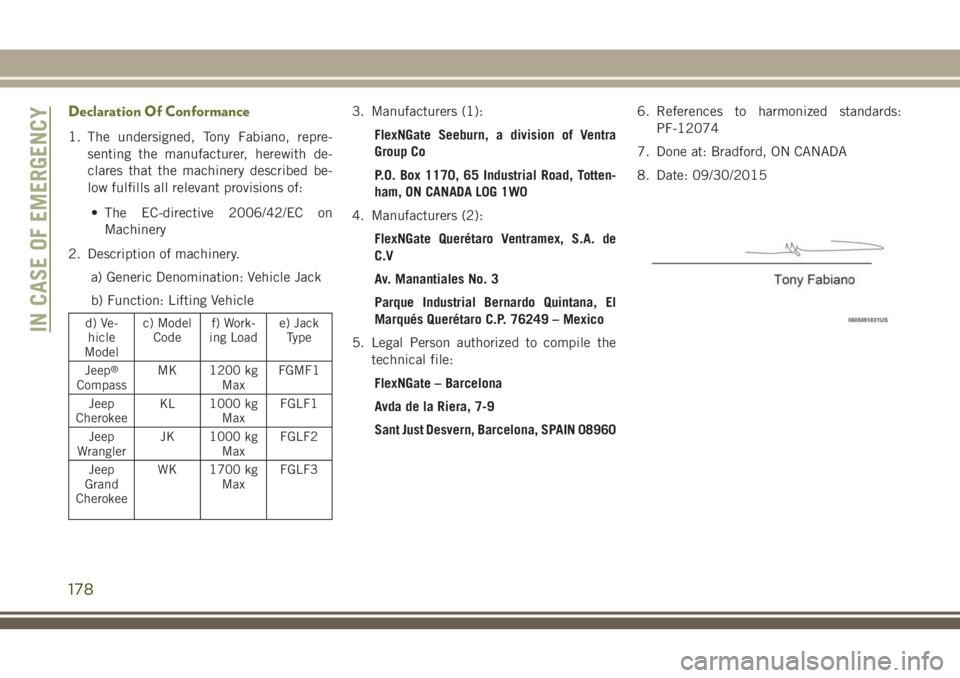

Declaration Of Conformance

1. The undersigned, Tony Fabiano, repre-senting the manufacturer, herewith de-

clares that the machinery described be-

low fulfills all relevant provisions of:

• The EC-directive 2006/42/EC on Machinery

2. Description of machinery. a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d) Ve-hicle

Model c) Model

Code f) Work-

ing Load e) Jack

Type

Jeep

®

Compass MK 1200 kg

MaxFGMF1

Jeep

Cherokee KL 1000 kg

MaxFGLF1

Jeep

Wrangler JK 1000 kg

MaxFGLF2

Jeep

Grand

Cherokee WK 1700 kg

MaxFGLF3

3. Manufacturers (1):

FlexNGate Seeburn, a division of Ventra

Group Co

P.O. Box 1170, 65 Industrial Road, Totten-

ham, ON CANADA L0G 1W0

4. Manufacturers (2): FlexNGate Querétaro Ventramex, S.A. de

C.V

Av. Manantiales No. 3

Parque Industrial Bernardo Quintana, El

Marqués Querétaro C.P. 76249 – Mexico

5. Legal Person authorized to compile the technical file:

FlexNGate – Barcelona

Avda de la Riera, 7-9

Sant Just Desvern, Barcelona, SPAIN 08960 6. References to harmonized standards:

PF-12074

7. Done at: Bradford, ON CANADA

8. Date: 09/30/2015

IN CASE OF EMERGENCY

178